Engine torque spec DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1494 of 2627

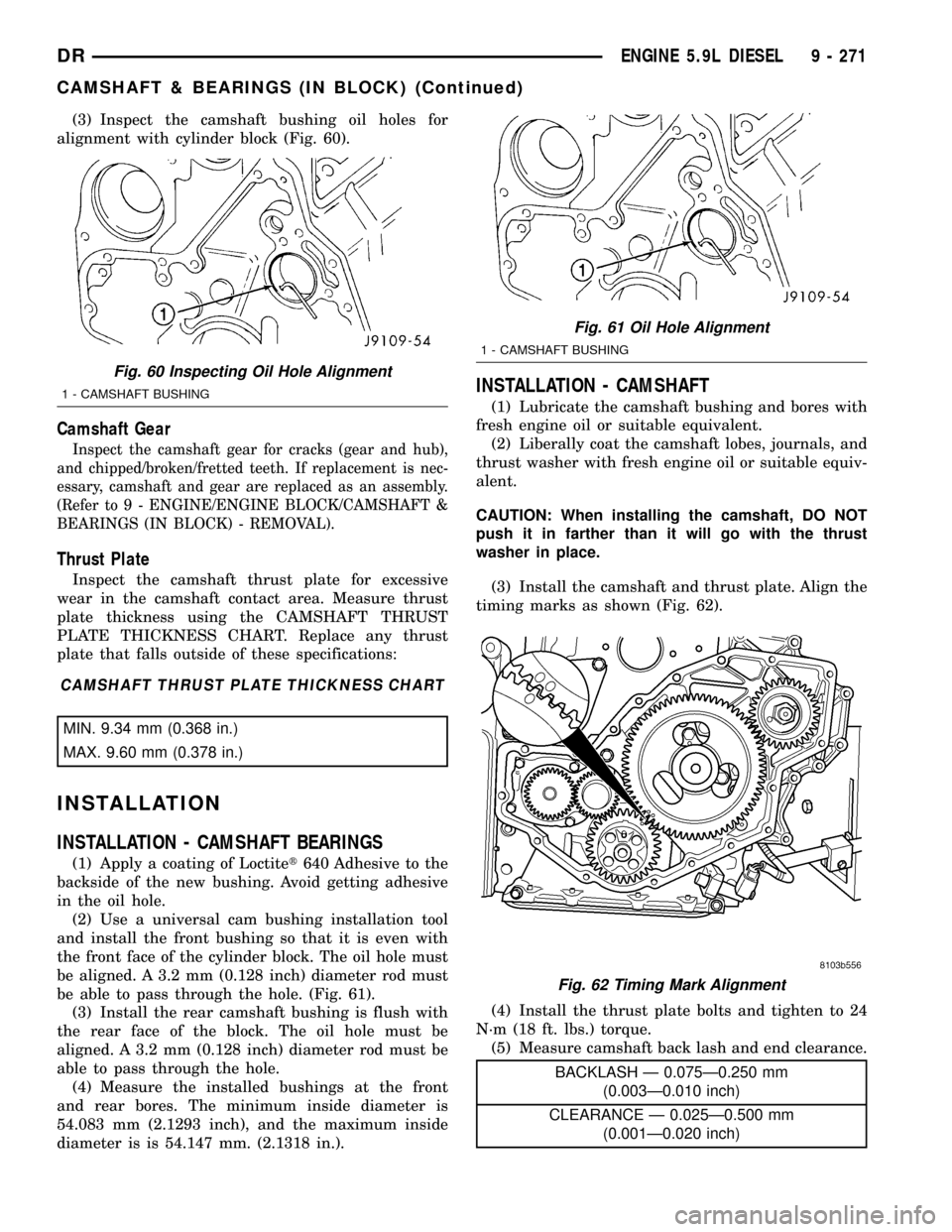

(3) Inspect the camshaft bushing oil holes for

alignment with cylinder block (Fig. 60).

Camshaft Gear

Inspect the camshaft gear for cracks (gear and hub),

and chipped/broken/fretted teeth. If replacement is nec-

essary, camshaft and gear are replaced as an assembly.

(Refer to 9 - ENGINE/ENGINE BLOCK/CAMSHAFT &

BEARINGS (IN BLOCK) - REMOVAL).

Thrust Plate

Inspect the camshaft thrust plate for excessive

wear in the camshaft contact area. Measure thrust

plate thickness using the CAMSHAFT THRUST

PLATE THICKNESS CHART. Replace any thrust

plate that falls outside of these specifications:

CAMSHAFT THRUST PLATE THICKNESS CHART

MIN. 9.34 mm (0.368 in.)

MAX. 9.60 mm (0.378 in.)

INSTALLATION

INSTALLATION - CAMSHAFT BEARINGS

(1) Apply a coating of Loctitet640 Adhesive to the

backside of the new bushing. Avoid getting adhesive

in the oil hole.

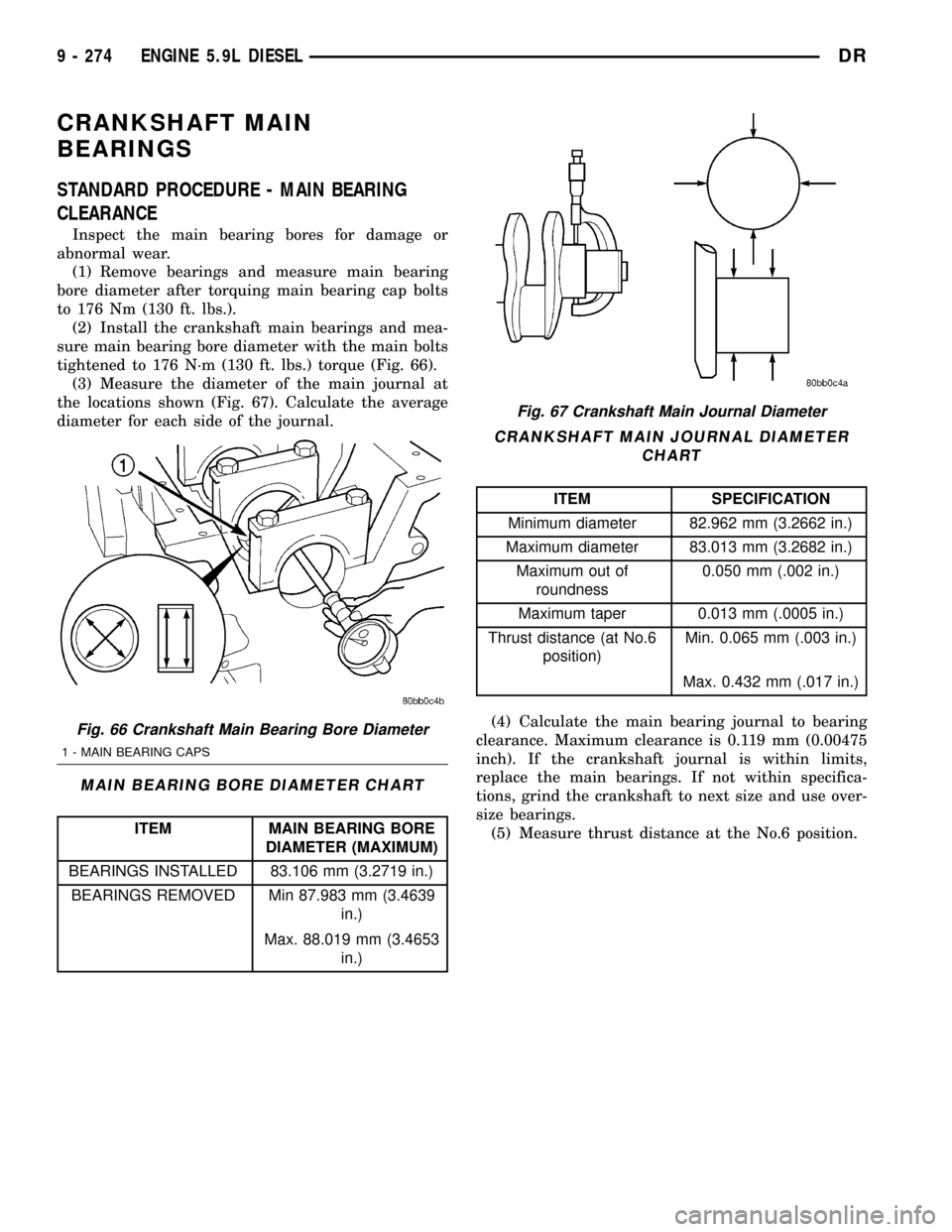

(2) Use a universal cam bushing installation tool

and install the front bushing so that it is even with

the front face of the cylinder block. The oil hole must

be aligned. A 3.2 mm (0.128 inch) diameter rod must

be able to pass through the hole. (Fig. 61).

(3) Install the rear camshaft bushing is flush with

the rear face of the block. The oil hole must be

aligned. A 3.2 mm (0.128 inch) diameter rod must be

able to pass through the hole.

(4) Measure the installed bushings at the front

and rear bores. The minimum inside diameter is

54.083 mm (2.1293 inch), and the maximum inside

diameter is is 54.147 mm. (2.1318 in.).

INSTALLATION - CAMSHAFT

(1) Lubricate the camshaft bushing and bores with

fresh engine oil or suitable equivalent.

(2) Liberally coat the camshaft lobes, journals, and

thrust washer with fresh engine oil or suitable equiv-

alent.

CAUTION: When installing the camshaft, DO NOT

push it in farther than it will go with the thrust

washer in place.

(3) Install the camshaft and thrust plate. Align the

timing marks as shown (Fig. 62).

(4) Install the thrust plate bolts and tighten to 24

N´m (18 ft. lbs.) torque.

(5) Measure camshaft back lash and end clearance.

BACKLASH Ð 0.075Ð0.250 mm

(0.003Ð0.010 inch)

CLEARANCE Ð 0.025Ð0.500 mm

(0.001Ð0.020 inch)

Fig. 60 Inspecting Oil Hole Alignment

1 - CAMSHAFT BUSHING

Fig. 61 Oil Hole Alignment

1 - CAMSHAFT BUSHING

Fig. 62 Timing Mark Alignment

DRENGINE 5.9L DIESEL 9 - 271

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1497 of 2627

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE - MAIN BEARING

CLEARANCE

Inspect the main bearing bores for damage or

abnormal wear.

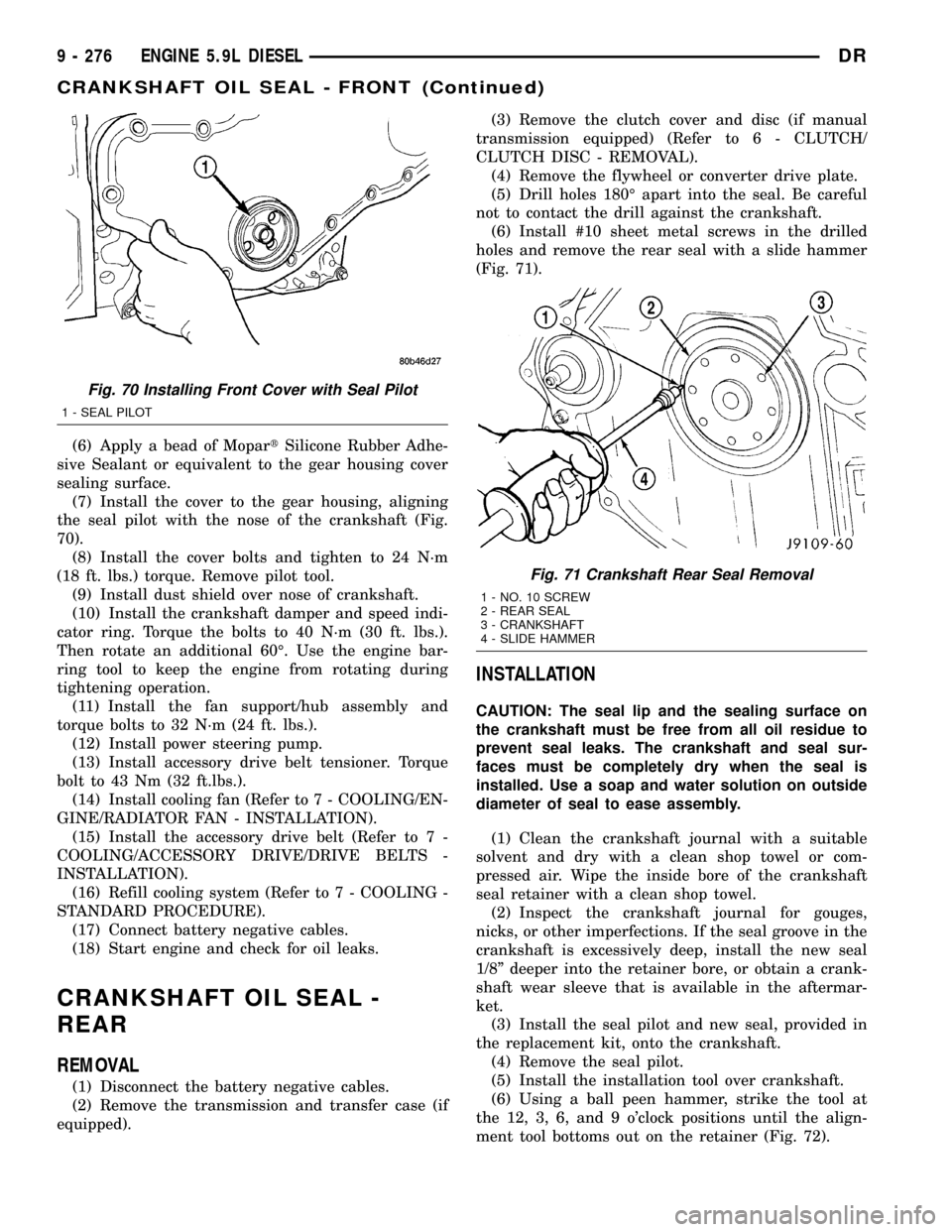

(1) Remove bearings and measure main bearing

bore diameter after torquing main bearing cap bolts

to 176 Nm (130 ft. lbs.).

(2) Install the crankshaft main bearings and mea-

sure main bearing bore diameter with the main bolts

tightened to 176 N´m (130 ft. lbs.) torque (Fig. 66).

(3) Measure the diameter of the main journal at

the locations shown (Fig. 67). Calculate the average

diameter for each side of the journal.

MAIN BEARING BORE DIAMETER CHART

ITEM MAIN BEARING BORE

DIAMETER (MAXIMUM)

BEARINGS INSTALLED 83.106 mm (3.2719 in.)

BEARINGS REMOVED Min 87.983 mm (3.4639

in.)

Max. 88.019 mm (3.4653

in.)

CRANKSHAFT MAIN JOURNAL DIAMETER

CHART

ITEM SPECIFICATION

Minimum diameter 82.962 mm (3.2662 in.)

Maximum diameter 83.013 mm (3.2682 in.)

Maximum out of

roundness0.050 mm (.002 in.)

Maximum taper 0.013 mm (.0005 in.)

Thrust distance (at No.6

position)Min. 0.065 mm (.003 in.)

Max. 0.432 mm (.017 in.)

(4) Calculate the main bearing journal to bearing

clearance. Maximum clearance is 0.119 mm (0.00475

inch). If the crankshaft journal is within limits,

replace the main bearings. If not within specifica-

tions, grind the crankshaft to next size and use over-

size bearings.

(5) Measure thrust distance at the No.6 position.

Fig. 66 Crankshaft Main Bearing Bore Diameter

1 - MAIN BEARING CAPS

Fig. 67 Crankshaft Main Journal Diameter

9 - 274 ENGINE 5.9L DIESELDR

Page 1499 of 2627

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the cover to the gear housing, aligning

the seal pilot with the nose of the crankshaft (Fig.

70).

(8) Install the cover bolts and tighten to 24 N´m

(18 ft. lbs.) torque. Remove pilot tool.

(9) Install dust shield over nose of crankshaft.

(10) Install the crankshaft damper and speed indi-

cator ring. Torque the bolts to 40 N´m (30 ft. lbs.).

Then rotate an additional 60É. Use the engine bar-

ring tool to keep the engine from rotating during

tightening operation.

(11) Install the fan support/hub assembly and

torque bolts to 32 N´m (24 ft. lbs.).

(12) Install power steering pump.

(13) Install accessory drive belt tensioner. Torque

bolt to 43 Nm (32 ft.lbs.).

(14) Install cooling fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(15) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(16) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(17) Connect battery negative cables.

(18) Start engine and check for oil leaks.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the transmission and transfer case (if

equipped).(3) Remove the clutch cover and disc (if manual

transmission equipped) (Refer to 6 - CLUTCH/

CLUTCH DISC - REMOVAL).

(4) Remove the flywheel or converter drive plate.

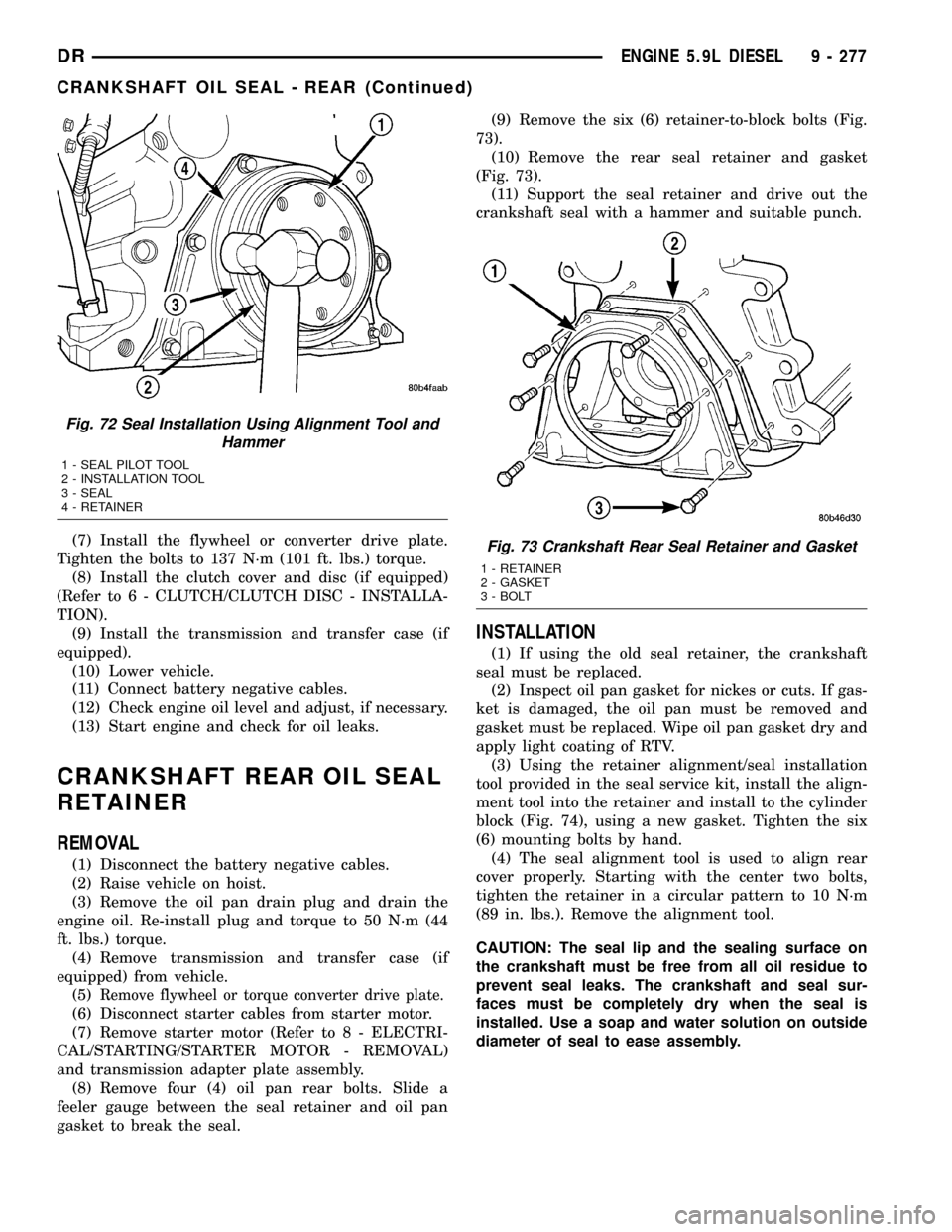

(5) Drill holes 180É apart into the seal. Be careful

not to contact the drill against the crankshaft.

(6) Install #10 sheet metal screws in the drilled

holes and remove the rear seal with a slide hammer

(Fig. 71).

INSTALLATION

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(1) Clean the crankshaft journal with a suitable

solvent and dry with a clean shop towel or com-

pressed air. Wipe the inside bore of the crankshaft

seal retainer with a clean shop towel.

(2) Inspect the crankshaft journal for gouges,

nicks, or other imperfections. If the seal groove in the

crankshaft is excessively deep, install the new seal

1/8º deeper into the retainer bore, or obtain a crank-

shaft wear sleeve that is available in the aftermar-

ket.

(3) Install the seal pilot and new seal, provided in

the replacement kit, onto the crankshaft.

(4) Remove the seal pilot.

(5) Install the installation tool over crankshaft.

(6) Using a ball peen hammer, strike the tool at

the 12, 3, 6, and 9 o'clock positions until the align-

ment tool bottoms out on the retainer (Fig. 72).

Fig. 70 Installing Front Cover with Seal Pilot

1 - SEAL PILOT

Fig. 71 Crankshaft Rear Seal Removal

1 - NO. 10 SCREW

2 - REAR SEAL

3 - CRANKSHAFT

4 - SLIDE HAMMER

9 - 276 ENGINE 5.9L DIESELDR

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1500 of 2627

(7) Install the flywheel or converter drive plate.

Tighten the bolts to 137 N´m (101 ft. lbs.) torque.

(8) Install the clutch cover and disc (if equipped)

(Refer to 6 - CLUTCH/CLUTCH DISC - INSTALLA-

TION).

(9) Install the transmission and transfer case (if

equipped).

(10) Lower vehicle.

(11) Connect battery negative cables.

(12) Check engine oil level and adjust, if necessary.

(13) Start engine and check for oil leaks.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Remove the oil pan drain plug and drain the

engine oil. Re-install plug and torque to 50 N´m (44

ft. lbs.) torque.

(4) Remove transmission and transfer case (if

equipped) from vehicle.

(5)

Remove flywheel or torque converter drive plate.

(6) Disconnect starter cables from starter motor.

(7) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(8) Remove four (4) oil pan rear bolts. Slide a

feeler gauge between the seal retainer and oil pan

gasket to break the seal.(9) Remove the six (6) retainer-to-block bolts (Fig.

73).

(10) Remove the rear seal retainer and gasket

(Fig. 73).

(11) Support the seal retainer and drive out the

crankshaft seal with a hammer and suitable punch.

INSTALLATION

(1) If using the old seal retainer, the crankshaft

seal must be replaced.

(2) Inspect oil pan gasket for nickes or cuts. If gas-

ket is damaged, the oil pan must be removed and

gasket must be replaced. Wipe oil pan gasket dry and

apply light coating of RTV.

(3) Using the retainer alignment/seal installation

tool provided in the seal service kit, install the align-

ment tool into the retainer and install to the cylinder

block (Fig. 74), using a new gasket. Tighten the six

(6) mounting bolts by hand.

(4) The seal alignment tool is used to align rear

cover properly. Starting with the center two bolts,

tighten the retainer in a circular pattern to 10 N´m

(89 in. lbs.). Remove the alignment tool.

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

Fig. 72 Seal Installation Using Alignment Tool and

Hammer

1 - SEAL PILOT TOOL

2 - INSTALLATION TOOL

3 - SEAL

4 - RETAINER

Fig. 73 Crankshaft Rear Seal Retainer and Gasket

1 - RETAINER

2 - GASKET

3 - BOLT

DRENGINE 5.9L DIESEL 9 - 277

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1509 of 2627

INSTALLATION

(1) Install speed indicator ring.

NOTE: The speed indicator ring is located over a

dowel pin.

(2) Install the crankshaft damper and bolts.

Tighten bolts to 40 N´m (30 ft. lbs.) torque, plus an

additional 60É.

NOTE: The damper must be installed so the hole is

located over the dowel pin.

(3) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

FRONT MOUNT

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the viscous fan/drive assembly (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(3) Raise vehicle on hoist.

(4) Install engine support fixture tool# 8534 and

steel bracket tool # 8534A

(5) Loosen the thru-bolt and nut.

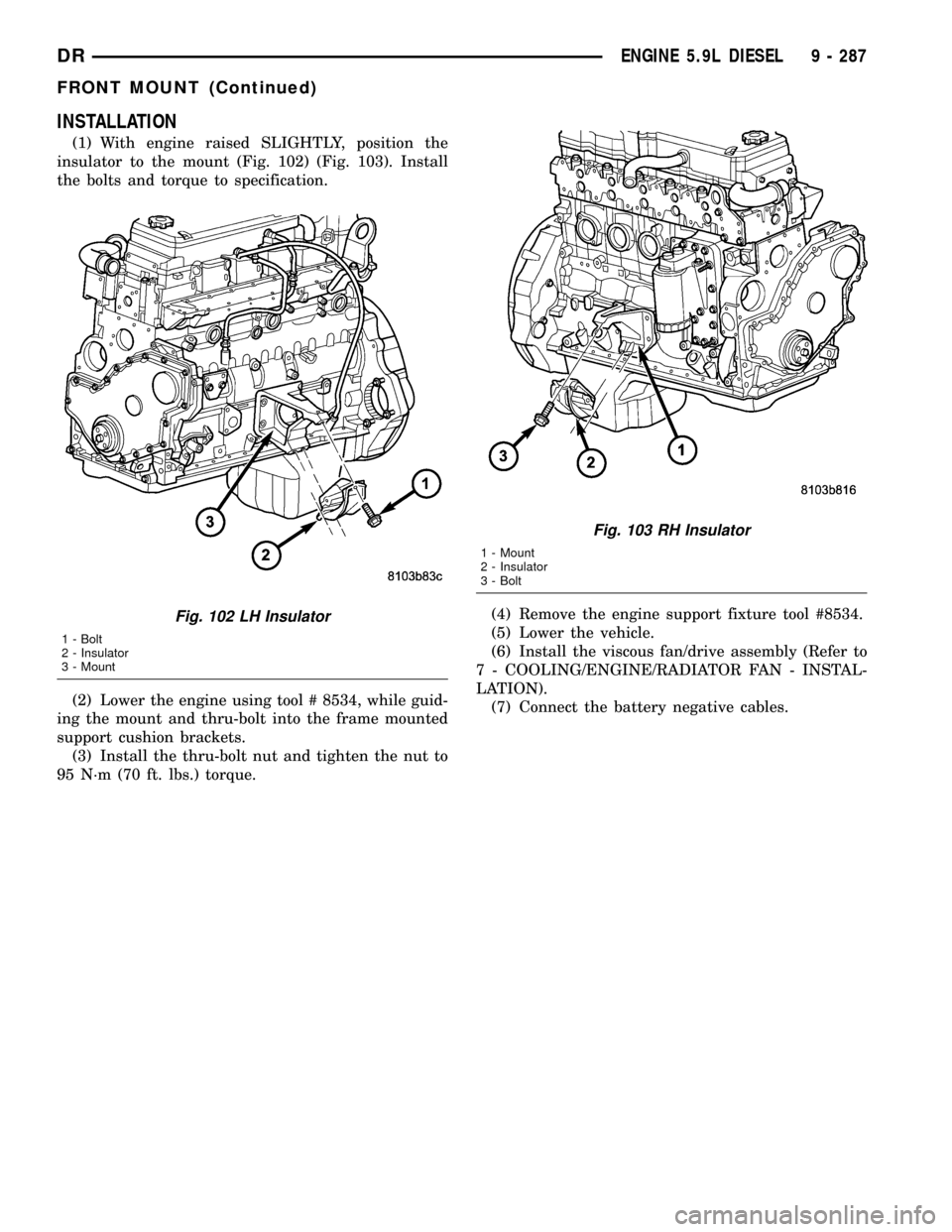

(6) Lift the engine SLIGHTLY and remove the

insulator to block bolts (Fig. 101) (Fig. 100).

(7) Remove the insulator from the vehicle.

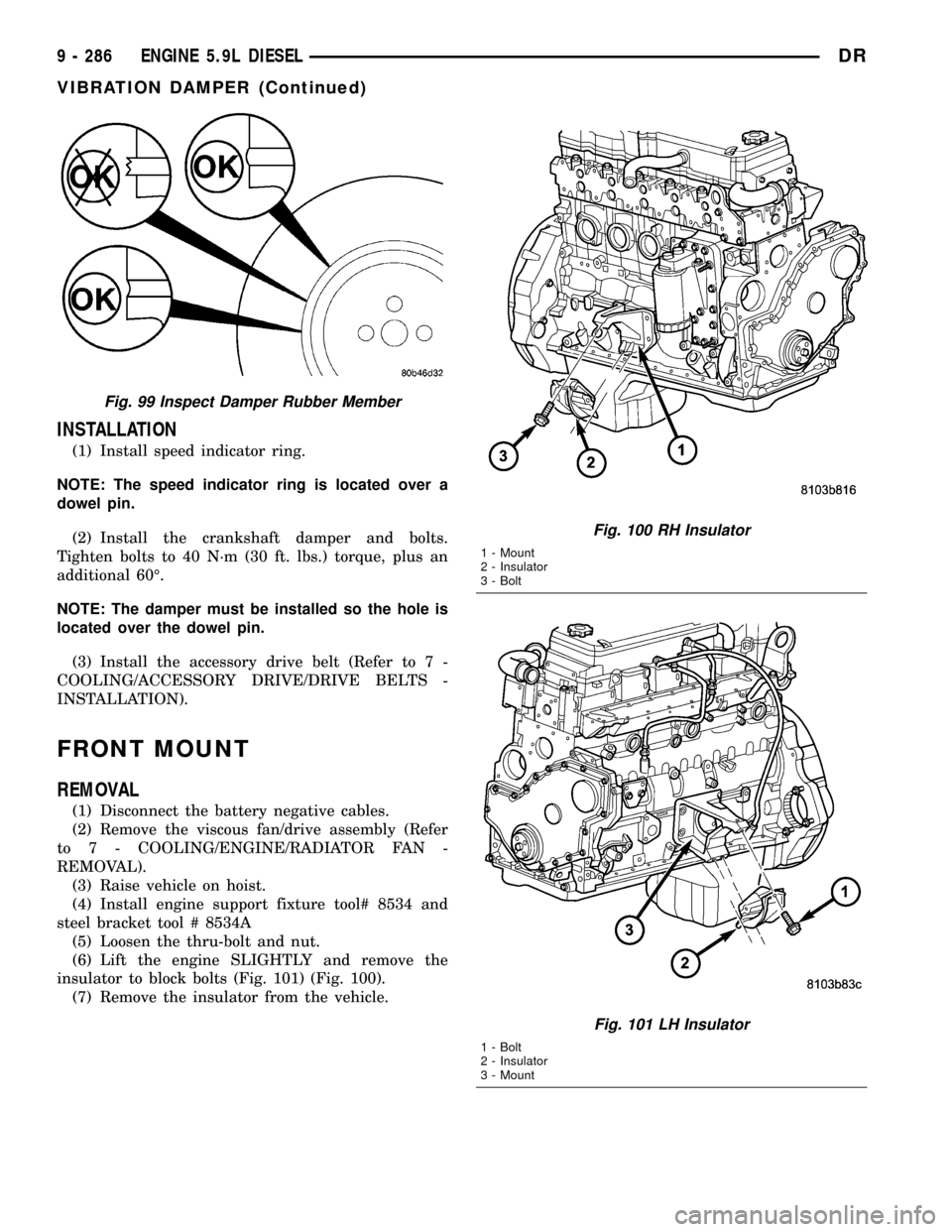

Fig. 99 Inspect Damper Rubber Member

Fig. 100 RH Insulator

1 - Mount

2 - Insulator

3 - Bolt

Fig. 101 LH Insulator

1 - Bolt

2 - Insulator

3 - Mount

9 - 286 ENGINE 5.9L DIESELDR

VIBRATION DAMPER (Continued)

Page 1510 of 2627

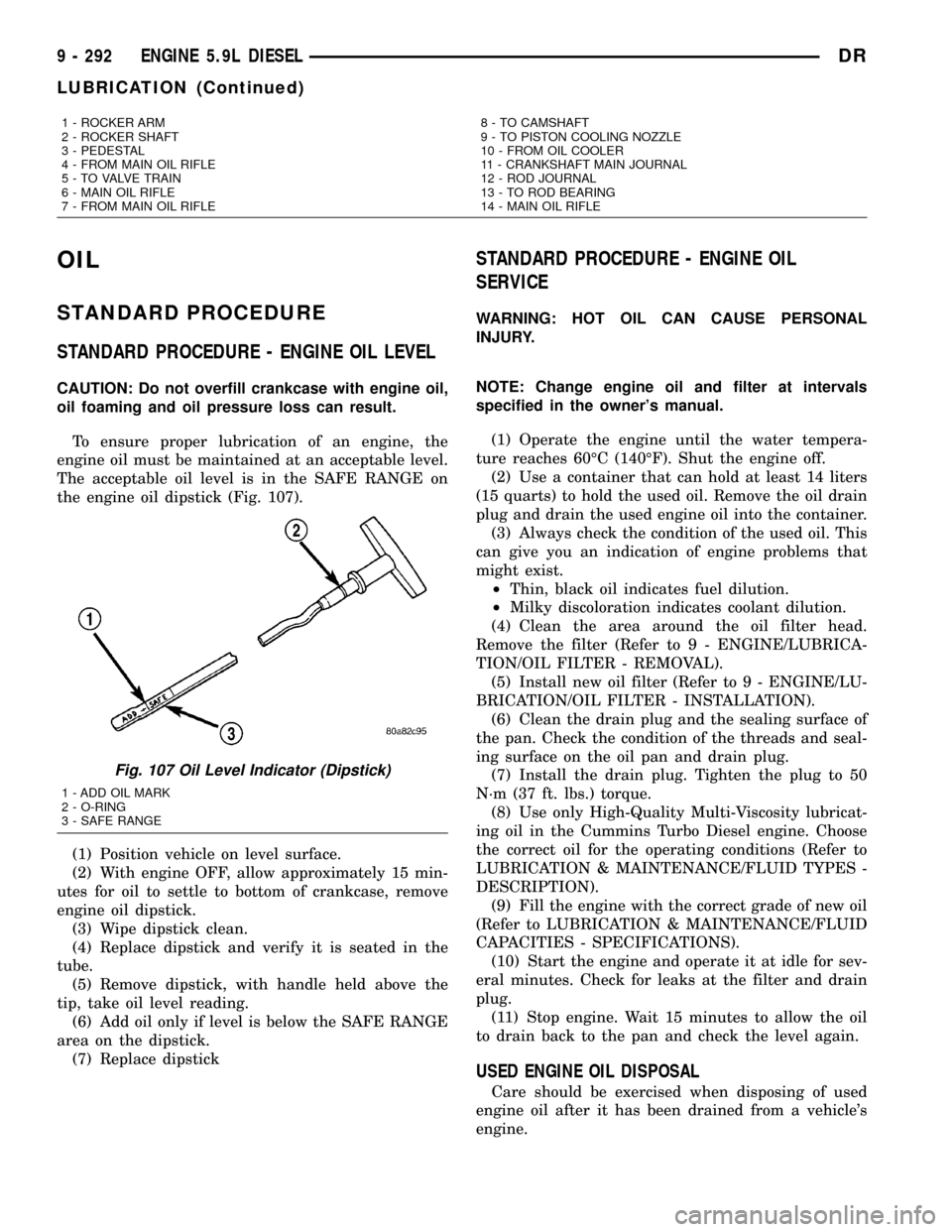

INSTALLATION

(1) With engine raised SLIGHTLY, position the

insulator to the mount (Fig. 102) (Fig. 103). Install

the bolts and torque to specification.

(2) Lower the engine using tool # 8534, while guid-

ing the mount and thru-bolt into the frame mounted

support cushion brackets.

(3) Install the thru-bolt nut and tighten the nut to

95 N´m (70 ft. lbs.) torque.(4) Remove the engine support fixture tool #8534.

(5) Lower the vehicle.

(6) Install the viscous fan/drive assembly (Refer to

7 - COOLING/ENGINE/RADIATOR FAN - INSTAL-

LATION).

(7) Connect the battery negative cables.

Fig. 102 LH Insulator

1 - Bolt

2 - Insulator

3 - Mount

Fig. 103 RH Insulator

1 - Mount

2 - Insulator

3 - Bolt

DRENGINE 5.9L DIESEL 9 - 287

FRONT MOUNT (Continued)

Page 1515 of 2627

OIL

STANDARD PROCEDURE

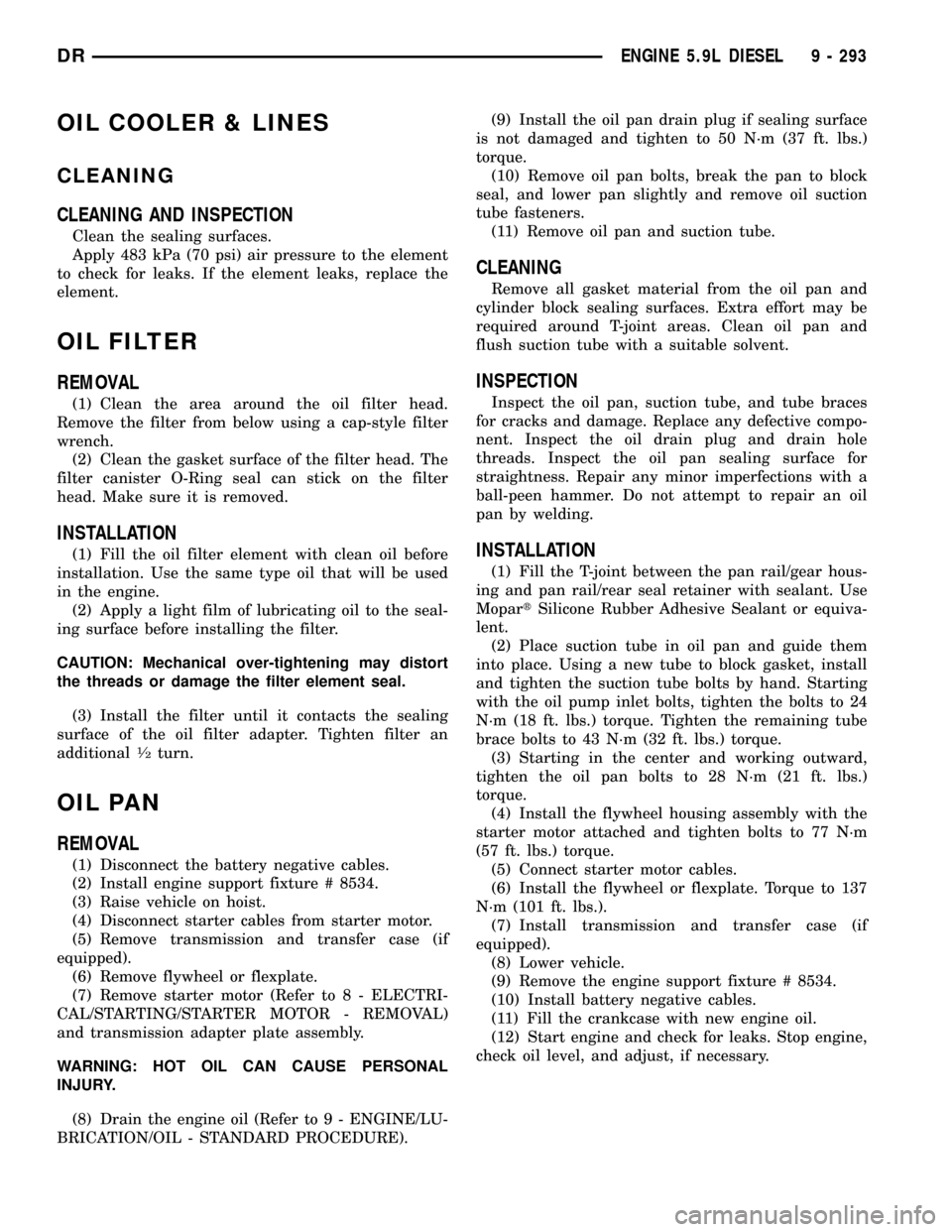

STANDARD PROCEDURE - ENGINE OIL LEVEL

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable oil level is in the SAFE RANGE on

the engine oil dipstick (Fig. 107).

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately 15 min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Replace dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the SAFE RANGE

area on the dipstick.

(7) Replace dipstick

STANDARD PROCEDURE - ENGINE OIL

SERVICE

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

NOTE: Change engine oil and filter at intervals

specified in the owner's manual.

(1) Operate the engine until the water tempera-

ture reaches 60ÉC (140ÉF). Shut the engine off.

(2) Use a container that can hold at least 14 liters

(15 quarts) to hold the used oil. Remove the oil drain

plug and drain the used engine oil into the container.

(3) Always check the condition of the used oil. This

can give you an indication of engine problems that

might exist.

²Thin, black oil indicates fuel dilution.

²Milky discoloration indicates coolant dilution.

(4) Clean the area around the oil filter head.

Remove the filter (Refer to 9 - ENGINE/LUBRICA-

TION/OIL FILTER - REMOVAL).

(5) Install new oil filter (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION).

(6) Clean the drain plug and the sealing surface of

the pan. Check the condition of the threads and seal-

ing surface on the oil pan and drain plug.

(7) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(8) Use only High-Quality Multi-Viscosity lubricat-

ing oil in the Cummins Turbo Diesel engine. Choose

the correct oil for the operating conditions (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

(9) Fill the engine with the correct grade of new oil

(Refer to LUBRICATION & MAINTENANCE/FLUID

CAPACITIES - SPECIFICATIONS).

(10) Start the engine and operate it at idle for sev-

eral minutes. Check for leaks at the filter and drain

plug.

(11) Stop engine. Wait 15 minutes to allow the oil

to drain back to the pan and check the level again.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing of used

engine oil after it has been drained from a vehicle's

engine.

1 - ROCKER ARM

2 - ROCKER SHAFT

3 - PEDESTAL

4 - FROM MAIN OIL RIFLE

5 - TO VALVE TRAIN

6 - MAIN OIL RIFLE

7 - FROM MAIN OIL RIFLE8 - TO CAMSHAFT

9 - TO PISTON COOLING NOZZLE

10 - FROM OIL COOLER

11 - CRANKSHAFT MAIN JOURNAL

12 - ROD JOURNAL

13 - TO ROD BEARING

14 - MAIN OIL RIFLE

Fig. 107 Oil Level Indicator (Dipstick)

1 - ADD OIL MARK

2 - O-RING

3 - SAFE RANGE

9 - 292 ENGINE 5.9L DIESELDR

LUBRICATION (Continued)

Page 1516 of 2627

OIL COOLER & LINES

CLEANING

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter from below using a cap-style filter

wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional

1¤2turn.

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Install engine support fixture # 8534.

(3) Raise vehicle on hoist.

(4) Disconnect starter cables from starter motor.

(5) Remove transmission and transfer case (if

equipped).

(6) Remove flywheel or flexplate.

(7) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(8) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).(9) Install the oil pan drain plug if sealing surface

is not damaged and tighten to 50 N´m (37 ft. lbs.)

torque.

(10) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(11) Remove oil pan and suction tube.

CLEANING

Remove all gasket material from the oil pan and

cylinder block sealing surfaces. Extra effort may be

required around T-joint areas. Clean oil pan and

flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces

for cracks and damage. Replace any defective compo-

nent. Inspect the oil drain plug and drain hole

threads. Inspect the oil pan sealing surface for

straightness. Repair any minor imperfections with a

ball-peen hammer. Do not attempt to repair an oil

pan by welding.

INSTALLATION

(1) Fill the T-joint between the pan rail/gear hous-

ing and pan rail/rear seal retainer with sealant. Use

MopartSilicone Rubber Adhesive Sealant or equiva-

lent.

(2) Place suction tube in oil pan and guide them

into place. Using a new tube to block gasket, install

and tighten the suction tube bolts by hand. Starting

with the oil pump inlet bolts, tighten the bolts to 24

N´m (18 ft. lbs.) torque. Tighten the remaining tube

brace bolts to 43 N´m (32 ft. lbs.) torque.

(3) Starting in the center and working outward,

tighten the oil pan bolts to 28 N´m (21 ft. lbs.)

torque.

(4) Install the flywheel housing assembly with the

starter motor attached and tighten bolts to 77 N´m

(57 ft. lbs.) torque.

(5) Connect starter motor cables.

(6) Install the flywheel or flexplate. Torque to 137

N´m (101 ft. lbs.).

(7) Install transmission and transfer case (if

equipped).

(8) Lower vehicle.

(9) Remove the engine support fixture # 8534.

(10) Install battery negative cables.

(11) Fill the crankcase with new engine oil.

(12) Start engine and check for leaks. Stop engine,

check oil level, and adjust, if necessary.

DRENGINE 5.9L DIESEL 9 - 293

Page 1517 of 2627

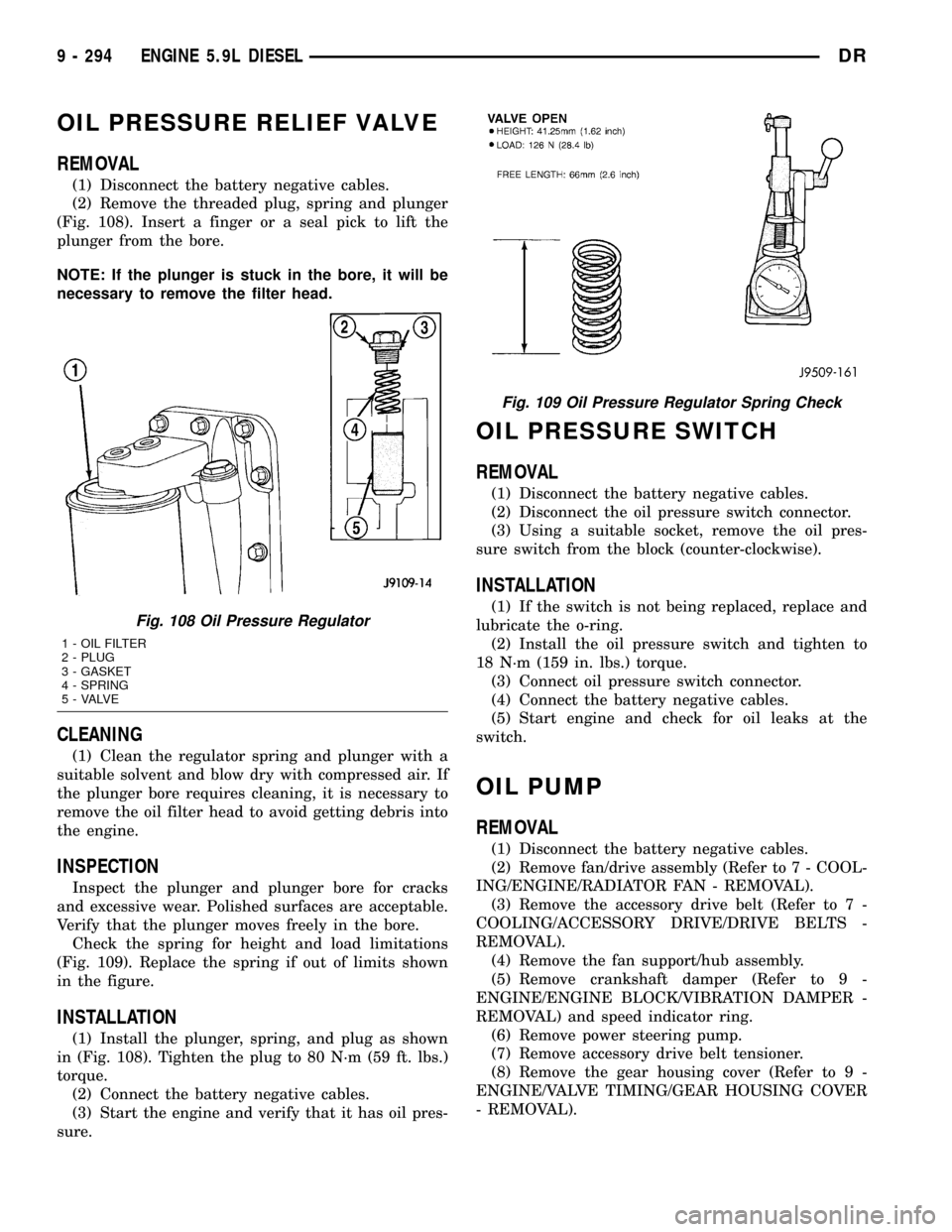

OIL PRESSURE RELIEF VALVE

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the threaded plug, spring and plunger

(Fig. 108). Insert a finger or a seal pick to lift the

plunger from the bore.

NOTE: If the plunger is stuck in the bore, it will be

necessary to remove the filter head.

CLEANING

(1) Clean the regulator spring and plunger with a

suitable solvent and blow dry with compressed air. If

the plunger bore requires cleaning, it is necessary to

remove the oil filter head to avoid getting debris into

the engine.

INSPECTION

Inspect the plunger and plunger bore for cracks

and excessive wear. Polished surfaces are acceptable.

Verify that the plunger moves freely in the bore.

Check the spring for height and load limitations

(Fig. 109). Replace the spring if out of limits shown

in the figure.

INSTALLATION

(1) Install the plunger, spring, and plug as shown

in (Fig. 108). Tighten the plug to 80 N´m (59 ft. lbs.)

torque.

(2) Connect the battery negative cables.

(3) Start the engine and verify that it has oil pres-

sure.

OIL PRESSURE SWITCH

REMOVAL

(1) Disconnect the battery negative cables.

(2) Disconnect the oil pressure switch connector.

(3) Using a suitable socket, remove the oil pres-

sure switch from the block (counter-clockwise).

INSTALLATION

(1) If the switch is not being replaced, replace and

lubricate the o-ring.

(2) Install the oil pressure switch and tighten to

18 N´m (159 in. lbs.) torque.

(3) Connect oil pressure switch connector.

(4) Connect the battery negative cables.

(5) Start engine and check for oil leaks at the

switch.

OIL PUMP

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove fan/drive assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove the fan support/hub assembly.

(5) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(6) Remove power steering pump.

(7) Remove accessory drive belt tensioner.

(8) Remove the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- REMOVAL).

Fig. 108 Oil Pressure Regulator

1 - OIL FILTER

2 - PLUG

3 - GASKET

4 - SPRING

5 - VALVE

Fig. 109 Oil Pressure Regulator Spring Check

9 - 294 ENGINE 5.9L DIESELDR

Page 1521 of 2627

INSTALLATION

(1) Using a new gasket, install the intake manifold

cover.

(2) Install the cover-to-cylinder head bolts that do

not hold down the fuel rail. Tighten the bolts to 24

N´m (18 ft. lbs.) torque.

(3) Install the high pressure rail and fuel lines

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL LINES - INSTALLATION).

(4) Using two (2) new gaskets, install the intake

air grid heater and air inlet housing. Position the

ground cable and install and tighten the bolts to 24

N´m (18 ft. lbs.) torque.

(5) Connect the manifold air temperature/pressure

sensor connector.

(6) Install and tighten the air intake heater power

supply nuts to 14 N´m (120 in. lbs.) torque.

(7) Install the APPS bracket. Torque fasteners to

43 N´m (32ft lbs.) torque.

(8) Install oil dipstick tube support at fuel filter

housing.

(9) Install the engine oil dipstick tube and mount-

ing bolt.

(10) Position the charge air cooler outlet tube onto

the air inlet housing. Tighten the clamps to 11 N´m

(100 in. lbs.) torque.

(11) Attach the engine wire harness to the air inlet

housing at two locations.

(12) Prime the fuel system. Refer to the fuel prim-

ing procedure in Group 14, Fuel System.

(13) Connect the battery negative cables.

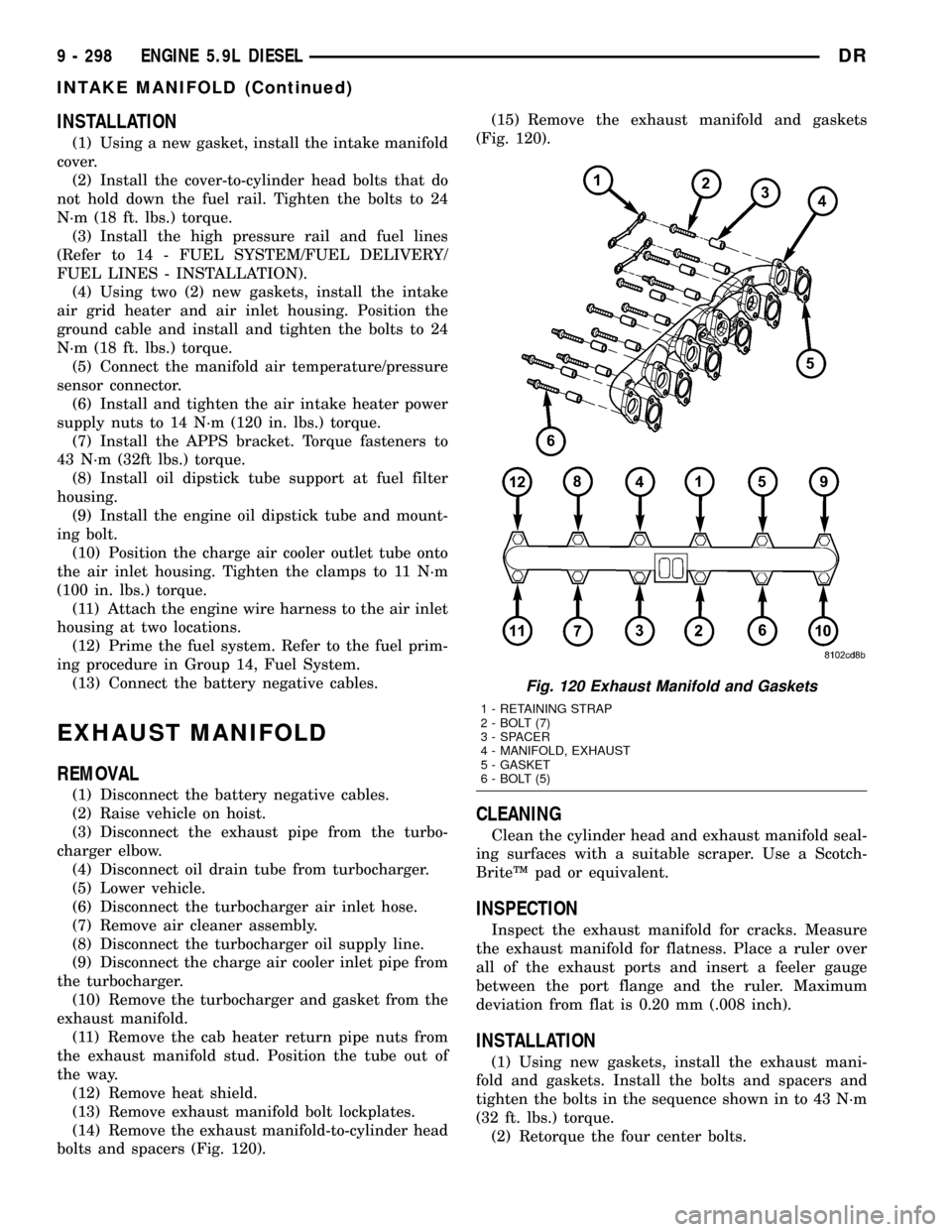

EXHAUST MANIFOLD

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Disconnect the exhaust pipe from the turbo-

charger elbow.

(4) Disconnect oil drain tube from turbocharger.

(5) Lower vehicle.

(6) Disconnect the turbocharger air inlet hose.

(7) Remove air cleaner assembly.

(8) Disconnect the turbocharger oil supply line.

(9) Disconnect the charge air cooler inlet pipe from

the turbocharger.

(10) Remove the turbocharger and gasket from the

exhaust manifold.

(11) Remove the cab heater return pipe nuts from

the exhaust manifold stud. Position the tube out of

the way.

(12) Remove heat shield.

(13) Remove exhaust manifold bolt lockplates.

(14) Remove the exhaust manifold-to-cylinder head

bolts and spacers (Fig. 120).(15) Remove the exhaust manifold and gaskets

(Fig. 120).

CLEANING

Clean the cylinder head and exhaust manifold seal-

ing surfaces with a suitable scraper. Use a Scotch-

BriteŸ pad or equivalent.

INSPECTION

Inspect the exhaust manifold for cracks. Measure

the exhaust manifold for flatness. Place a ruler over

all of the exhaust ports and insert a feeler gauge

between the port flange and the ruler. Maximum

deviation from flat is 0.20 mm (.008 inch).

INSTALLATION

(1) Using new gaskets, install the exhaust mani-

fold and gaskets. Install the bolts and spacers and

tighten the bolts in the sequence shown in to 43 N´m

(32 ft. lbs.) torque.

(2) Retorque the four center bolts.

Fig. 120 Exhaust Manifold and Gaskets

1 - RETAINING STRAP

2 - BOLT (7)

3 - SPACER

4 - MANIFOLD, EXHAUST

5 - GASKET

6 - BOLT (5)

9 - 298 ENGINE 5.9L DIESELDR

INTAKE MANIFOLD (Continued)