air condition DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 694 of 2627

SKIM cannot be repaired and, if faulty or damaged,

the unit must be replaced.

DIAGNOSIS AND TESTING

VEHICLE THEFT SECURITY SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINT SYSTEMS BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: The most reliable, efficient, and accurate

means to diagnose the Vehicle Theft Security Sys-

tem (VTSS) and Sentry Key Immobilizer System

(SKIS) involves the use of a DRBlllTscan tool and

the proper Powertrain Diagnostic Procedures man-

ual.

The Vehicle Theft Security System (VTSS), Sentry

Key Immobilizer System (SKIS) and the Programma-

ble Communication Interface (PCI) bus network

should be diagnosed using a DRBIIItscan tool. The

DRBIIItwill allow confirmation that the PCI bus is

functional, that the Sentry Key Immobilizer Module

(SKIM) is placing the proper messages on the PCI

bus, and that the Powertrain Control Module (PCM)

and the Instrument Cluster are receiving the PCI

bus messages. Refer to the proper Powertrain or

Body Diagnostic Procedures manual.

Visually inspect the related wiring harness connec-

tors. Look for broken, bent, pushed out or corroded

terminals. If any of the conditions are present, repair

as necessary. Refer to Wiring Diagrams for complete

circuit descriptions and diagrams. Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/SEN-

TRY KEY IMMOBILIZER MODULE - REMOVAL for

SKIM replacement.

STANDARD PROCEDURE

CONFIGURING A NEW MODULE / SWITCH

OPERATING MODES

To configure a new module or to switch operating

modes, a DRBIIItscan tool must be used.

(1) Hook up the DRBIIItscan tool to the Data

Link Connector (DLC).

(2) With the key in the ignition, turn the key to

the RUN position.(3) After the DRBIIItscan tool initialization, per-

form the following:

(a) Select ªTheft Alarm.º

(b) Select ªVTSS.º

(c) Select ªMiscellaneous.º

(4) Once in the ªMiscellaneousº screen:

(a) If you wish to configure a new module, select

ªConfigure Module.º

(b) If you wish to put the module into customer

usage mode, select ªEnable VTSS.º

(c) If you wish to put the module into dealer lot

mode, select ªDealer Lot.º

SENTRY KEY IMMOBILIZER SYSTEM

INITIALIZATION

The Sentry Key Immobilizer System (SKIS) initial-

ization should be performed following a Sentry Key

Immobilizer Module (SKIM) replacement.

It can be summarized by the following:

(1) Obtain the vehicles unique PIN number

assigned to it's original SKIM from the vehicle

owner, the vehicle's invoice or from Chrysler's Cus-

tomer Center.

(2) With the DRBIIItscan tool, select ªTheft

Alarm,º ªSKIM,º Miscellaneous.º Select ªSKIM Mod-

ule Replacedº function and the DRBIIItwill prompt

you through the following steps.

(3) Enter secured access mode using the unique

four digit PIN number.

(4) Program the vehicle's VIN number into the

SKIM's memory.

(5) Program the country code into the SKIM's

memory (U.S.).

(6) Transfer the vehicle's unique Secret Key data

from the PCM. This process will require the SKIM to

be insecured access mode. The PIN number must

be entered into the DRBIIItbefore the SKIM will

entersecured access mode. Oncesecured access

modeis active, the SKIM will remain in that mode

for 60 seconds.

(7) Program all customer keys into the SKIM's

memory. This required that the SKIM be insecured

access modeThe SKIM will immediately exit

secured access modeafter each key is pro-

grammed.

NOTE: If a PCM is replaced, the unique ªSecret

Keyº data must be transferred from the SKIM to the

PCM. This procedure requires the SKIM to be

placed in SECURED ACCESS MODE using the four

digit PIN code.

DRVEHICLE THEFT SECURITY 8Q - 3

VEHICLE THEFT SECURITY (Continued)

Page 705 of 2627

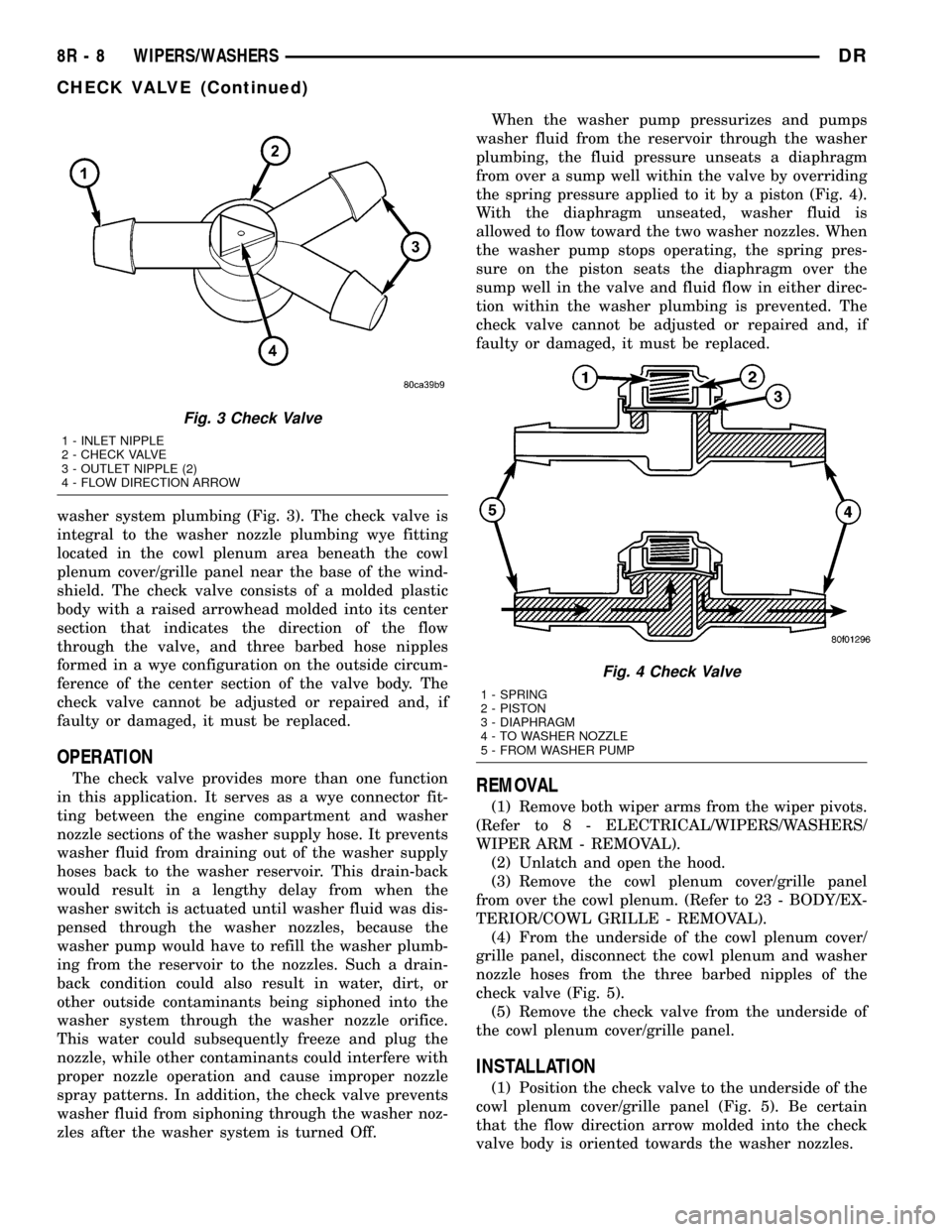

washer system plumbing (Fig. 3). The check valve is

integral to the washer nozzle plumbing wye fitting

located in the cowl plenum area beneath the cowl

plenum cover/grille panel near the base of the wind-

shield. The check valve consists of a molded plastic

body with a raised arrowhead molded into its center

section that indicates the direction of the flow

through the valve, and three barbed hose nipples

formed in a wye configuration on the outside circum-

ference of the center section of the valve body. The

check valve cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.

OPERATION

The check valve provides more than one function

in this application. It serves as a wye connector fit-

ting between the engine compartment and washer

nozzle sections of the washer supply hose. It prevents

washer fluid from draining out of the washer supply

hoses back to the washer reservoir. This drain-back

would result in a lengthy delay from when the

washer switch is actuated until washer fluid was dis-

pensed through the washer nozzles, because the

washer pump would have to refill the washer plumb-

ing from the reservoir to the nozzles. Such a drain-

back condition could also result in water, dirt, or

other outside contaminants being siphoned into the

washer system through the washer nozzle orifice.

This water could subsequently freeze and plug the

nozzle, while other contaminants could interfere with

proper nozzle operation and cause improper nozzle

spray patterns. In addition, the check valve prevents

washer fluid from siphoning through the washer noz-

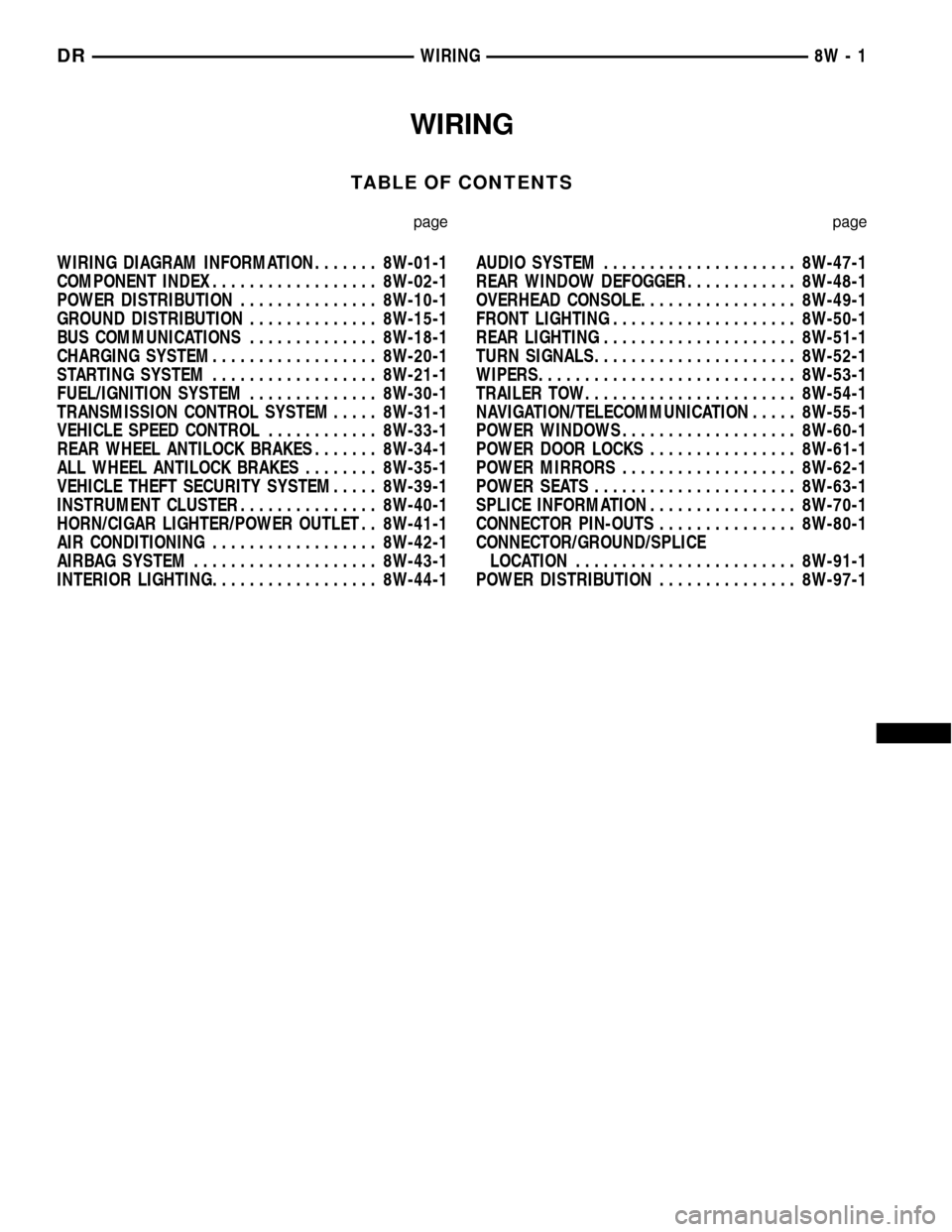

zles after the washer system is turned Off.When the washer pump pressurizes and pumps

washer fluid from the reservoir through the washer

plumbing, the fluid pressure unseats a diaphragm

from over a sump well within the valve by overriding

the spring pressure applied to it by a piston (Fig. 4).

With the diaphragm unseated, washer fluid is

allowed to flow toward the two washer nozzles. When

the washer pump stops operating, the spring pres-

sure on the piston seats the diaphragm over the

sump well in the valve and fluid flow in either direc-

tion within the washer plumbing is prevented. The

check valve cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.REMOVAL

(1) Remove both wiper arms from the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - REMOVAL).

(2) Unlatch and open the hood.

(3) Remove the cowl plenum cover/grille panel

from over the cowl plenum. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - REMOVAL).

(4) From the underside of the cowl plenum cover/

grille panel, disconnect the cowl plenum and washer

nozzle hoses from the three barbed nipples of the

check valve (Fig. 5).

(5) Remove the check valve from the underside of

the cowl plenum cover/grille panel.

INSTALLATION

(1) Position the check valve to the underside of the

cowl plenum cover/grille panel (Fig. 5). Be certain

that the flow direction arrow molded into the check

valve body is oriented towards the washer nozzles.

Fig. 3 Check Valve

1 - INLET NIPPLE

2 - CHECK VALVE

3 - OUTLET NIPPLE (2)

4 - FLOW DIRECTION ARROW

Fig. 4 Check Valve

1 - SPRING

2 - PISTON

3 - DIAPHRAGM

4 - TO WASHER NOZZLE

5 - FROM WASHER PUMP

8R - 8 WIPERS/WASHERSDR

CHECK VALVE (Continued)

Page 726 of 2627

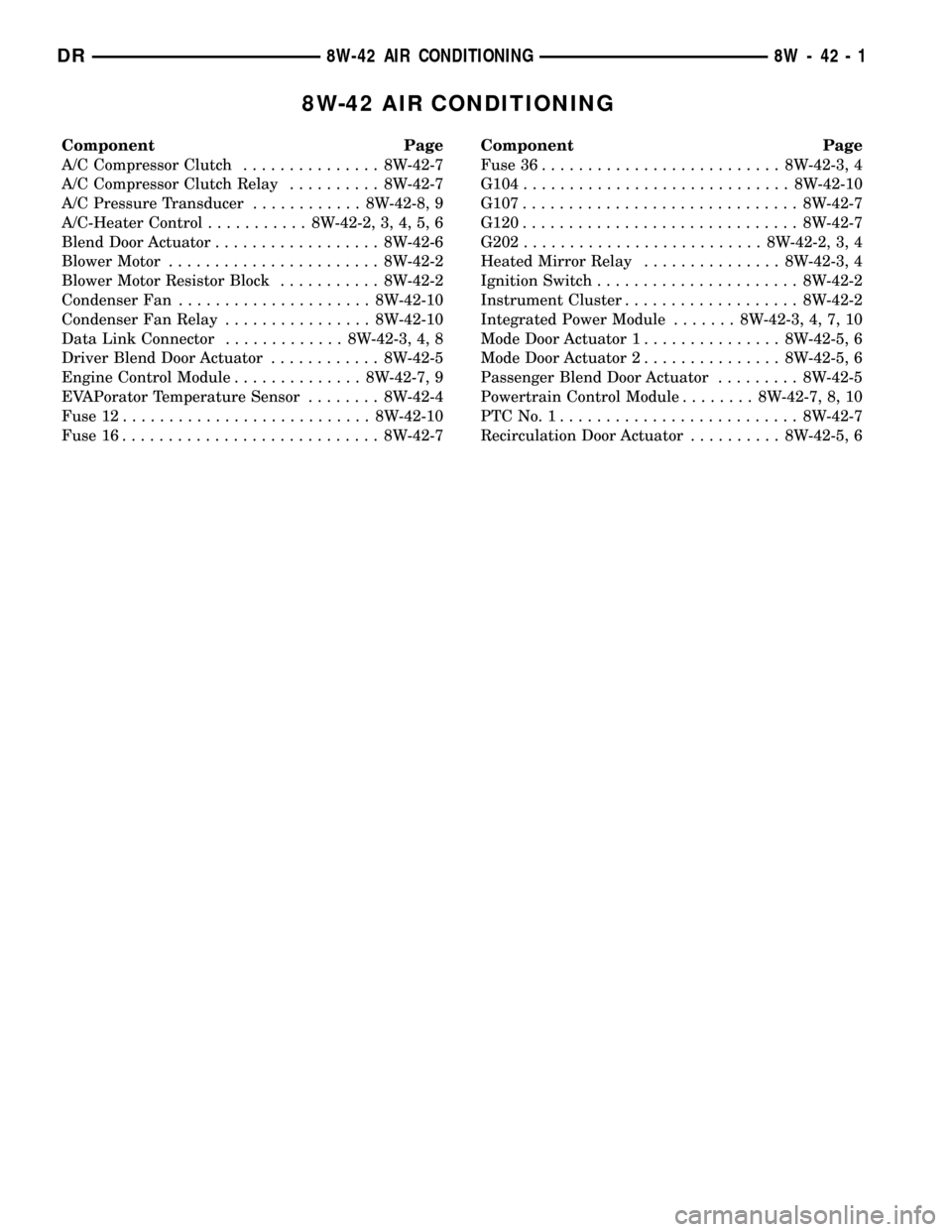

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

REAR WHEEL ANTILOCK BRAKES....... 8W-34-1

ALL WHEEL ANTILOCK BRAKES........ 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING.................. 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATION..... 8W-55-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 DRWIRING 8W - 1

Page 954 of 2627

8W-42 AIR CONDITIONING

Component Page

A/C Compressor Clutch............... 8W-42-7

A/C Compressor Clutch Relay.......... 8W-42-7

A/C Pressure Transducer............ 8W-42-8, 9

A/C-Heater Control........... 8W-42-2, 3, 4, 5, 6

Blend Door Actuator.................. 8W-42-6

Blower Motor....................... 8W-42-2

Blower Motor Resistor Block........... 8W-42-2

Condenser Fan..................... 8W-42-10

Condenser Fan Relay................ 8W-42-10

Data Link Connector............. 8W-42-3, 4, 8

Driver Blend Door Actuator............ 8W-42-5

Engine Control Module.............. 8W-42-7, 9

EVAPorator Temperature Sensor........ 8W-42-4

Fuse 12........................... 8W-42-10

Fuse 16............................ 8W-42-7Component Page

Fuse 36.......................... 8W-42-3, 4

G104............................. 8W-42-10

G107.............................. 8W-42-7

G120.............................. 8W-42-7

G202.......................... 8W-42-2, 3, 4

Heated Mirror Relay............... 8W-42-3, 4

Ignition Switch...................... 8W-42-2

Instrument Cluster................... 8W-42-2

Integrated Power Module....... 8W-42-3, 4, 7, 10

Mode Door Actuator 1............... 8W-42-5, 6

Mode Door Actuator 2............... 8W-42-5, 6

Passenger Blend Door Actuator......... 8W-42-5

Powertrain Control Module........ 8W-42-7, 8, 10

PTCNo.1.......................... 8W-42-7

Recirculation Door Actuator.......... 8W-42-5, 6

DR8W-42 AIR CONDITIONING 8W - 42 - 1

Page 1222 of 2627

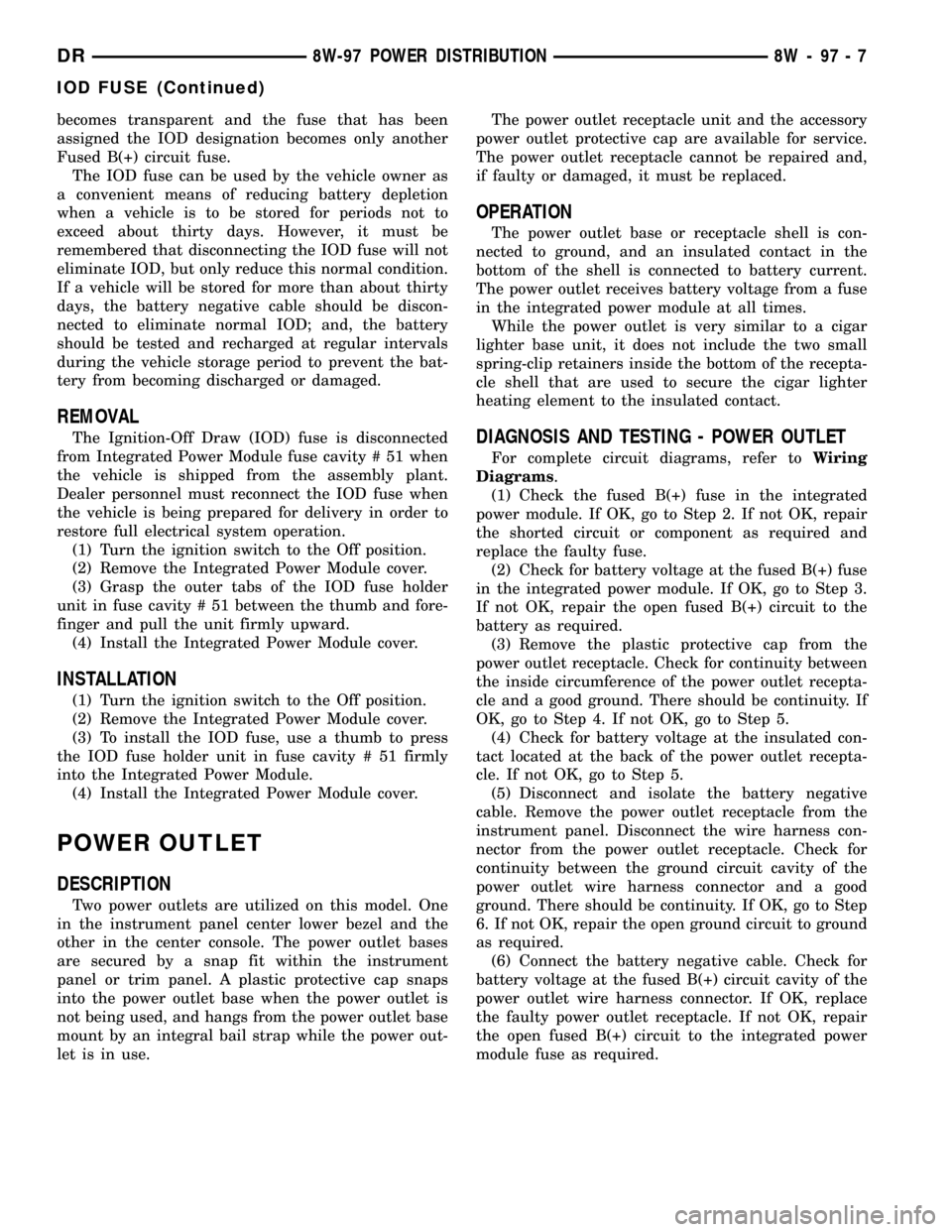

becomes transparent and the fuse that has been

assigned the IOD designation becomes only another

Fused B(+) circuit fuse.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that disconnecting the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged.

REMOVAL

The Ignition-Off Draw (IOD) fuse is disconnected

from Integrated Power Module fuse cavity # 51 when

the vehicle is shipped from the assembly plant.

Dealer personnel must reconnect the IOD fuse when

the vehicle is being prepared for delivery in order to

restore full electrical system operation.

(1) Turn the ignition switch to the Off position.

(2) Remove the Integrated Power Module cover.

(3) Grasp the outer tabs of the IOD fuse holder

unit in fuse cavity # 51 between the thumb and fore-

finger and pull the unit firmly upward.

(4) Install the Integrated Power Module cover.

INSTALLATION

(1) Turn the ignition switch to the Off position.

(2) Remove the Integrated Power Module cover.

(3) To install the IOD fuse, use a thumb to press

the IOD fuse holder unit in fuse cavity # 51 firmly

into the Integrated Power Module.

(4) Install the Integrated Power Module cover.

POWER OUTLET

DESCRIPTION

Two power outlets are utilized on this model. One

in the instrument panel center lower bezel and the

other in the center console. The power outlet bases

are secured by a snap fit within the instrument

panel or trim panel. A plastic protective cap snaps

into the power outlet base when the power outlet is

not being used, and hangs from the power outlet base

mount by an integral bail strap while the power out-

let is in use.The power outlet receptacle unit and the accessory

power outlet protective cap are available for service.

The power outlet receptacle cannot be repaired and,

if faulty or damaged, it must be replaced.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet receives battery voltage from a fuse

in the integrated power module at all times.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the recepta-

cle shell that are used to secure the cigar lighter

heating element to the insulated contact.

DIAGNOSIS AND TESTING - POWER OUTLET

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Check the fused B(+) fuse in the integrated

power module. If OK, go to Step 2. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the integrated power module. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit to the

battery as required.

(3) Remove the plastic protective cap from the

power outlet receptacle. Check for continuity between

the inside circumference of the power outlet recepta-

cle and a good ground. There should be continuity. If

OK, go to Step 4. If not OK, go to Step 5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the power outlet receptacle from the

instrument panel. Disconnect the wire harness con-

nector from the power outlet receptacle. Check for

continuity between the ground circuit cavity of the

power outlet wire harness connector and a good

ground. There should be continuity. If OK, go to Step

6. If not OK, repair the open ground circuit to ground

as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the integrated power

module fuse as required.

DR8W-97 POWER DISTRIBUTION 8W - 97 - 7

IOD FUSE (Continued)

Page 1227 of 2627

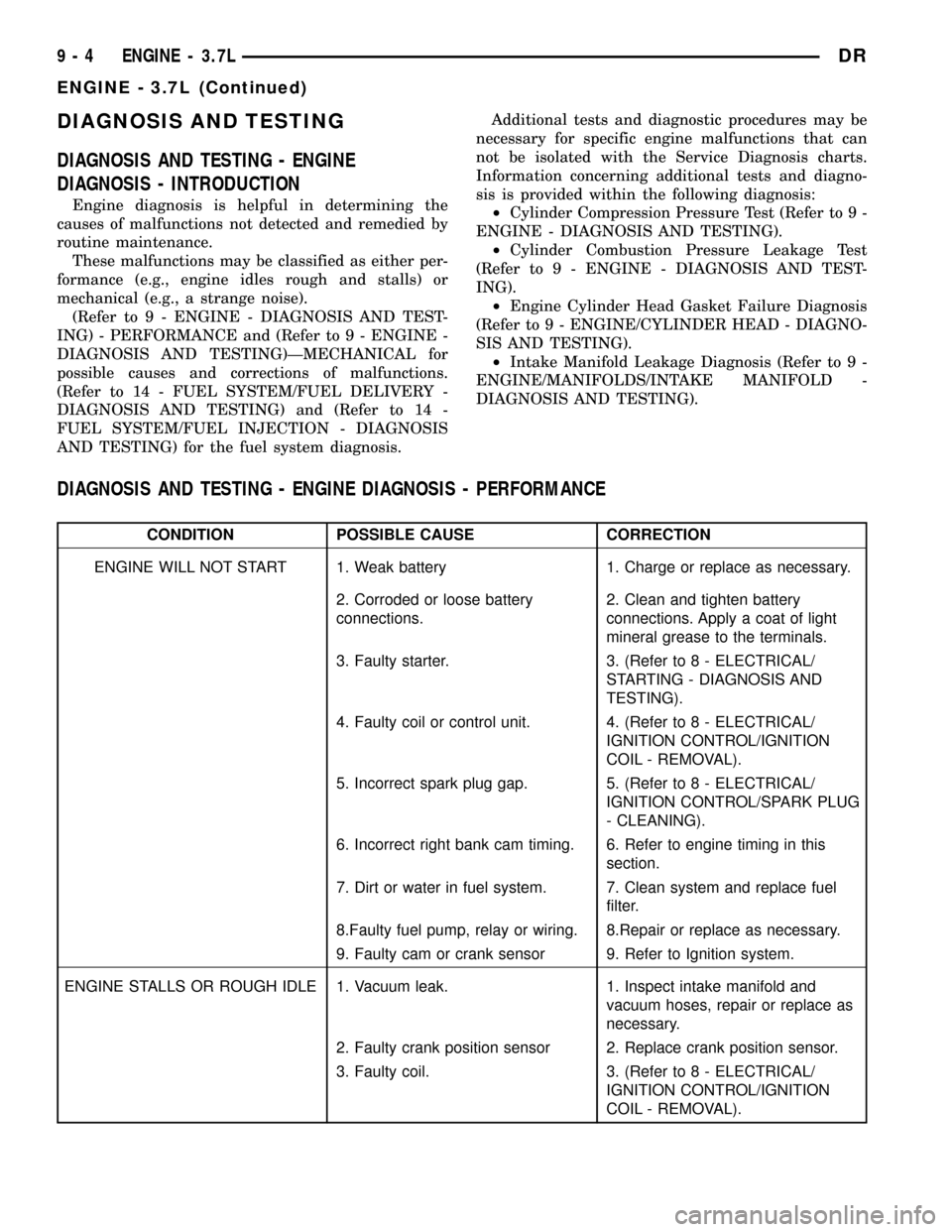

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either per-

formance (e.g., engine idles rough and stalls) or

mechanical (e.g., a strange noise).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING) - PERFORMANCE and (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)ÐMECHANICAL for

possible causes and corrections of malfunctions.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

DIAGNOSIS AND TESTING) and (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION - DIAGNOSIS

AND TESTING) for the fuel system diagnosis.Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following diagnosis:

²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING).

²Engine Cylinder Head Gasket Failure Diagnosis

(Refer to 9 - ENGINE/CYLINDER HEAD - DIAGNO-

SIS AND TESTING).

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING).

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND

TESTING).

4. Faulty coil or control unit. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect spark plug gap. 5. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

6. Incorrect right bank cam timing. 6. Refer to engine timing in this

section.

7. Dirt or water in fuel system. 7. Clean system and replace fuel

filter.

8.Faulty fuel pump, relay or wiring. 8.Repair or replace as necessary.

9. Faulty cam or crank sensor 9. Refer to Ignition system.

ENGINE STALLS OR ROUGH IDLE 1. Vacuum leak. 1. Inspect intake manifold and

vacuum hoses, repair or replace as

necessary.

2. Faulty crank position sensor 2. Replace crank position sensor.

3. Faulty coil. 3. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

9 - 4 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1228 of 2627

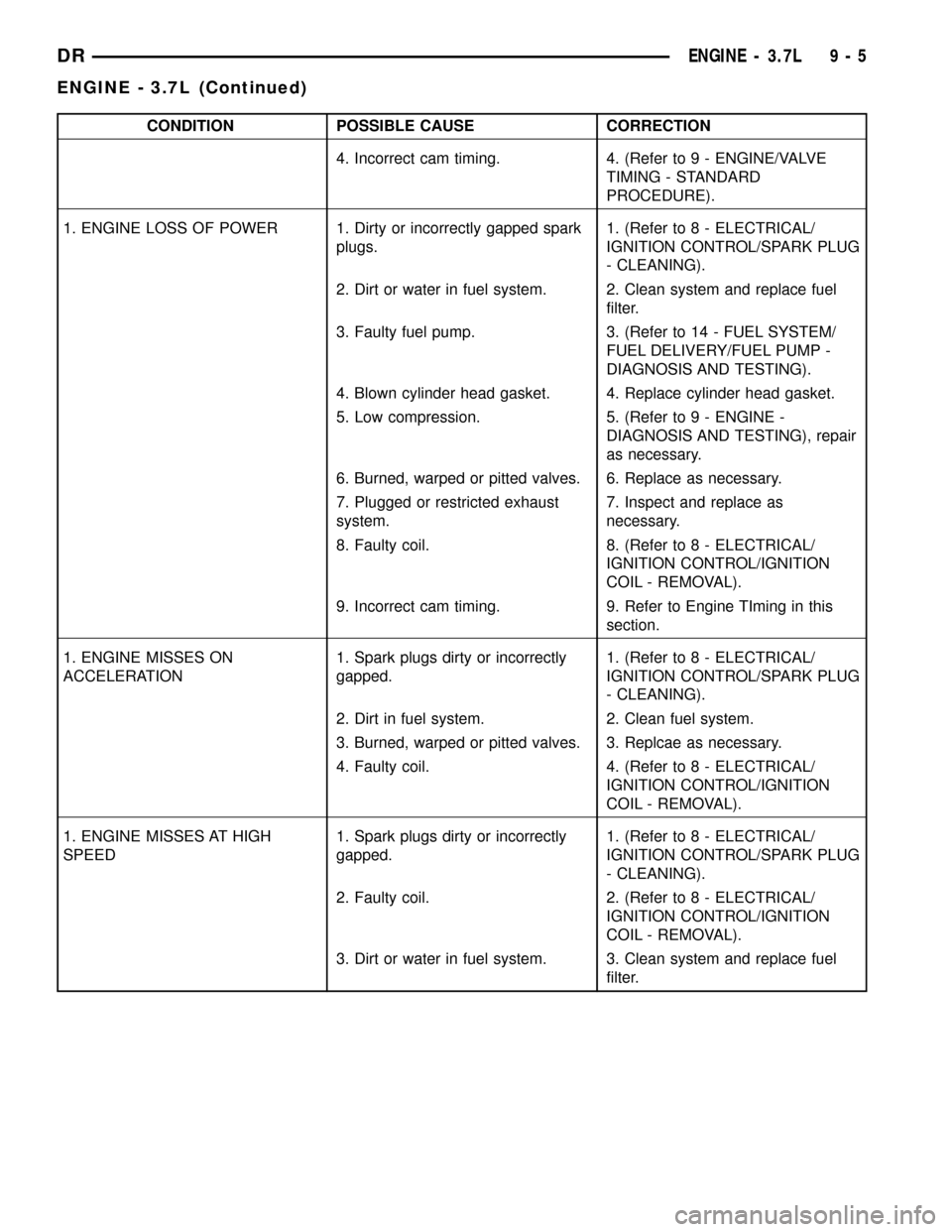

CONDITION POSSIBLE CAUSE CORRECTION

4. Incorrect cam timing. 4. (Refer to 9 - ENGINE/VALVE

TIMING - STANDARD

PROCEDURE).

1. ENGINE LOSS OF POWER 1. Dirty or incorrectly gapped spark

plugs.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

2. Dirt or water in fuel system. 2. Clean system and replace fuel

filter.

3. Faulty fuel pump. 3. (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING).

4. Blown cylinder head gasket. 4. Replace cylinder head gasket.

5. Low compression. 5. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING), repair

as necessary.

6. Burned, warped or pitted valves. 6. Replace as necessary.

7. Plugged or restricted exhaust

system.7. Inspect and replace as

necessary.

8. Faulty coil. 8. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

9. Incorrect cam timing. 9. Refer to Engine TIming in this

section.

1. ENGINE MISSES ON

ACCELERATION1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

2. Dirt in fuel system. 2. Clean fuel system.

3. Burned, warped or pitted valves. 3. Replcae as necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

1. ENGINE MISSES AT HIGH

SPEED1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

2. Faulty coil. 2. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

3. Dirt or water in fuel system. 3. Clean system and replace fuel

filter.

DRENGINE - 3.7L 9 - 5

ENGINE - 3.7L (Continued)

Page 1230 of 2627

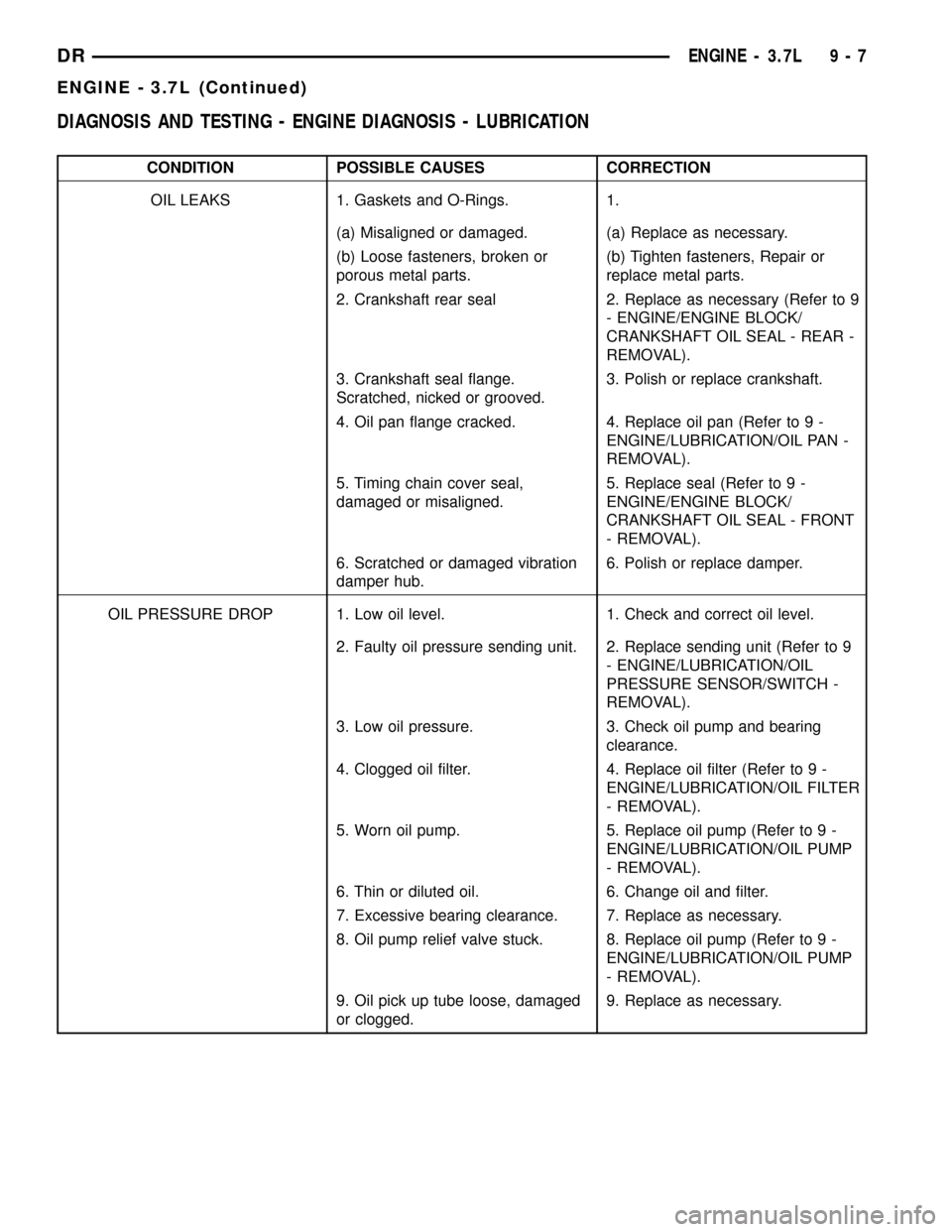

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - LUBRICATION

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS 1. Gaskets and O-Rings. 1.

(a) Misaligned or damaged. (a) Replace as necessary.

(b) Loose fasteners, broken or

porous metal parts.(b) Tighten fasteners, Repair or

replace metal parts.

2. Crankshaft rear seal 2. Replace as necessary (Refer to 9

- ENGINE/ENGINE BLOCK/

CRANKSHAFT OIL SEAL - REAR -

REMOVAL).

3. Crankshaft seal flange.

Scratched, nicked or grooved.3. Polish or replace crankshaft.

4. Oil pan flange cracked. 4. Replace oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

5. Timing chain cover seal,

damaged or misaligned.5. Replace seal (Refer to 9 -

ENGINE/ENGINE BLOCK/

CRANKSHAFT OIL SEAL - FRONT

- REMOVAL).

6. Scratched or damaged vibration

damper hub.6. Polish or replace damper.

OIL PRESSURE DROP 1. Low oil level. 1. Check and correct oil level.

2. Faulty oil pressure sending unit. 2. Replace sending unit (Refer to 9

- ENGINE/LUBRICATION/OIL

PRESSURE SENSOR/SWITCH -

REMOVAL).

3. Low oil pressure. 3. Check oil pump and bearing

clearance.

4. Clogged oil filter. 4. Replace oil filter (Refer to 9 -

ENGINE/LUBRICATION/OIL FILTER

- REMOVAL).

5. Worn oil pump. 5. Replace oil pump (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP

- REMOVAL).

6. Thin or diluted oil. 6. Change oil and filter.

7. Excessive bearing clearance. 7. Replace as necessary.

8. Oil pump relief valve stuck. 8. Replace oil pump (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP

- REMOVAL).

9. Oil pick up tube loose, damaged

or clogged.9. Replace as necessary.

DRENGINE - 3.7L 9 - 7

ENGINE - 3.7L (Continued)

Page 1231 of 2627

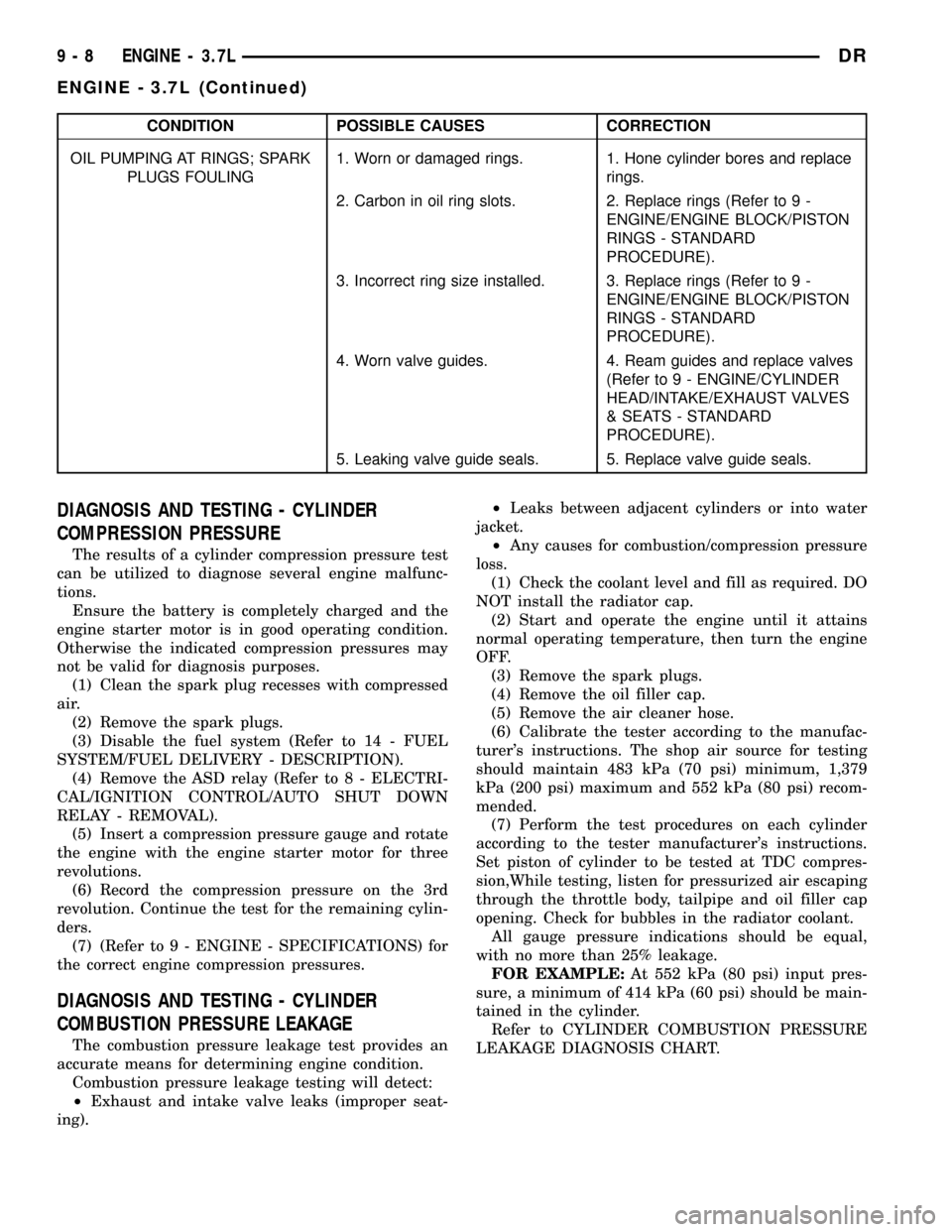

CONDITION POSSIBLE CAUSES CORRECTION

OIL PUMPING AT RINGS; SPARK

PLUGS FOULING1. Worn or damaged rings. 1. Hone cylinder bores and replace

rings.

2. Carbon in oil ring slots. 2. Replace rings (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON

RINGS - STANDARD

PROCEDURE).

3. Incorrect ring size installed. 3. Replace rings (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON

RINGS - STANDARD

PROCEDURE).

4. Worn valve guides. 4. Ream guides and replace valves

(Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES

& SEATS - STANDARD

PROCEDURE).

5. Leaking valve guide seals. 5. Replace valve guide seals.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs.

(3) Disable the fuel system (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DESCRIPTION).

(4) Remove the ASD relay (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/AUTO SHUT DOWN

RELAY - REMOVAL).

(5) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(6) Record the compression pressure on the 3rd

revolution. Continue the test for the remaining cylin-

ders.

(7) (Refer to 9 - ENGINE - SPECIFICATIONS) for

the correct engine compression pressures.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

(1) Check the coolant level and fill as required. DO

NOT install the radiator cap.

(2) Start and operate the engine until it attains

normal operating temperature, then turn the engine

OFF.

(3) Remove the spark plugs.

(4) Remove the oil filler cap.

(5) Remove the air cleaner hose.

(6) Calibrate the tester according to the manufac-

turer's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

(7) Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

Set piston of cylinder to be tested at TDC compres-

sion,While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to CYLINDER COMBUSTION PRESSURE

LEAKAGE DIAGNOSIS CHART.

9 - 8 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1232 of 2627

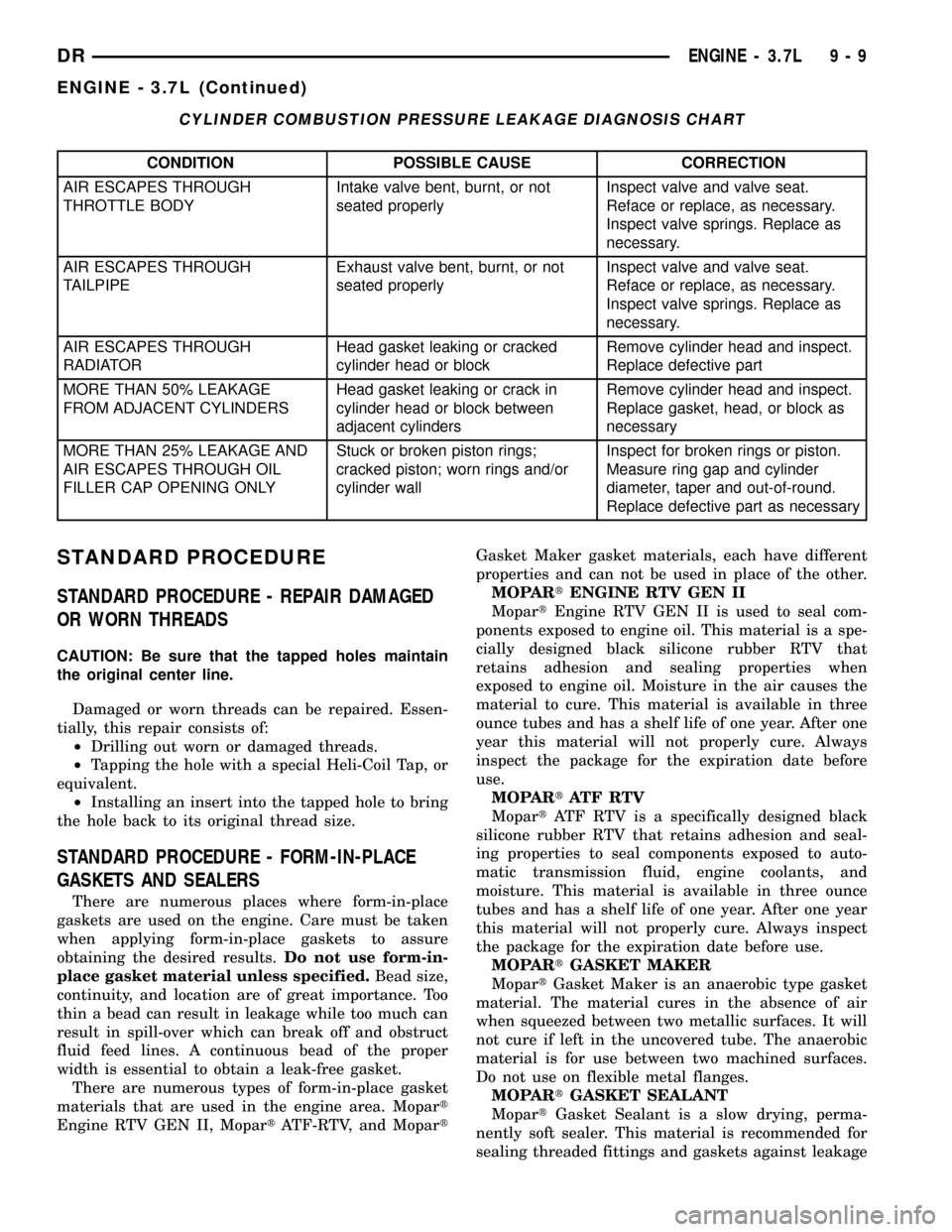

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and MopartGasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

DRENGINE - 3.7L 9 - 9

ENGINE - 3.7L (Continued)