Connector location DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1215 of 2627

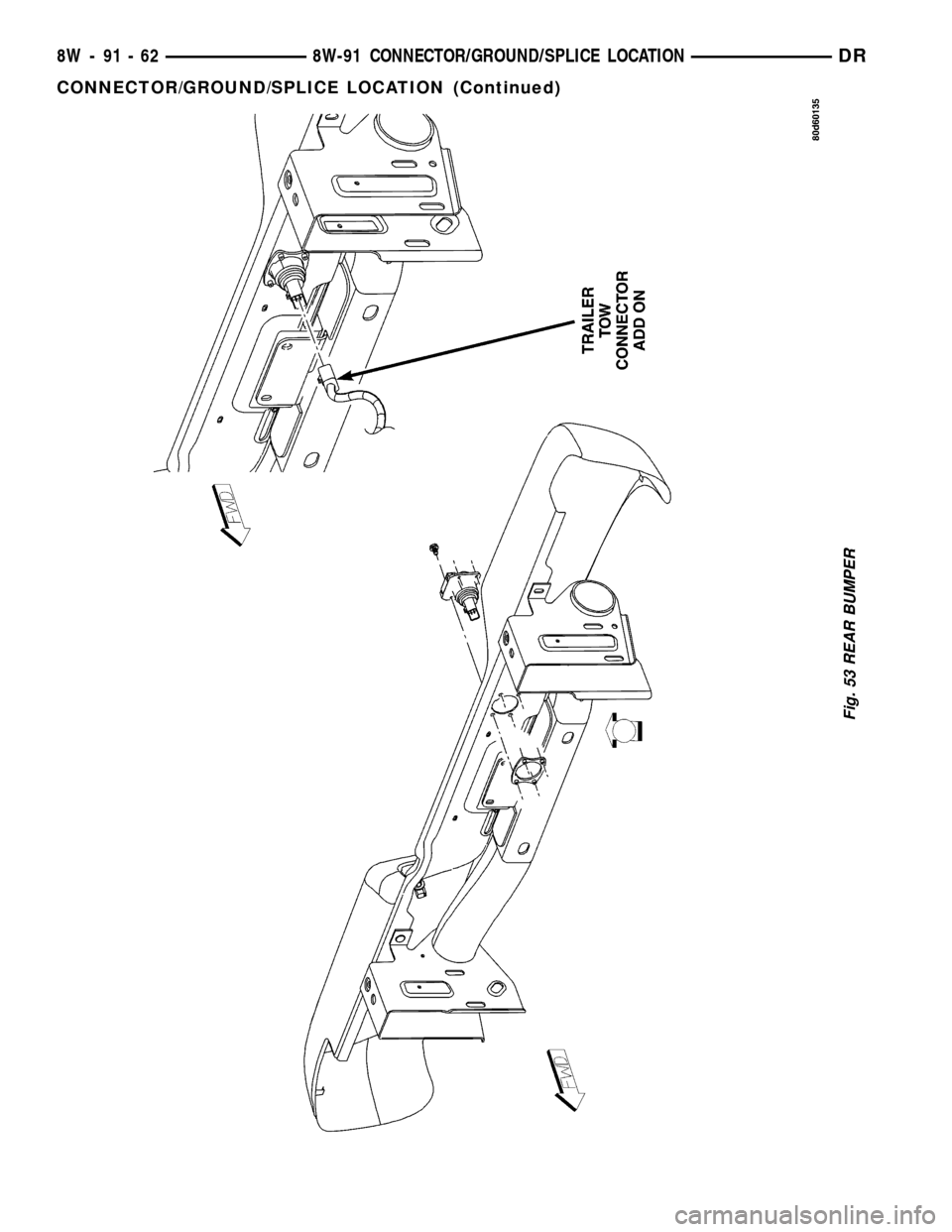

Fig. 53 REAR BUMPER

8W - 91 - 62 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1219 of 2627

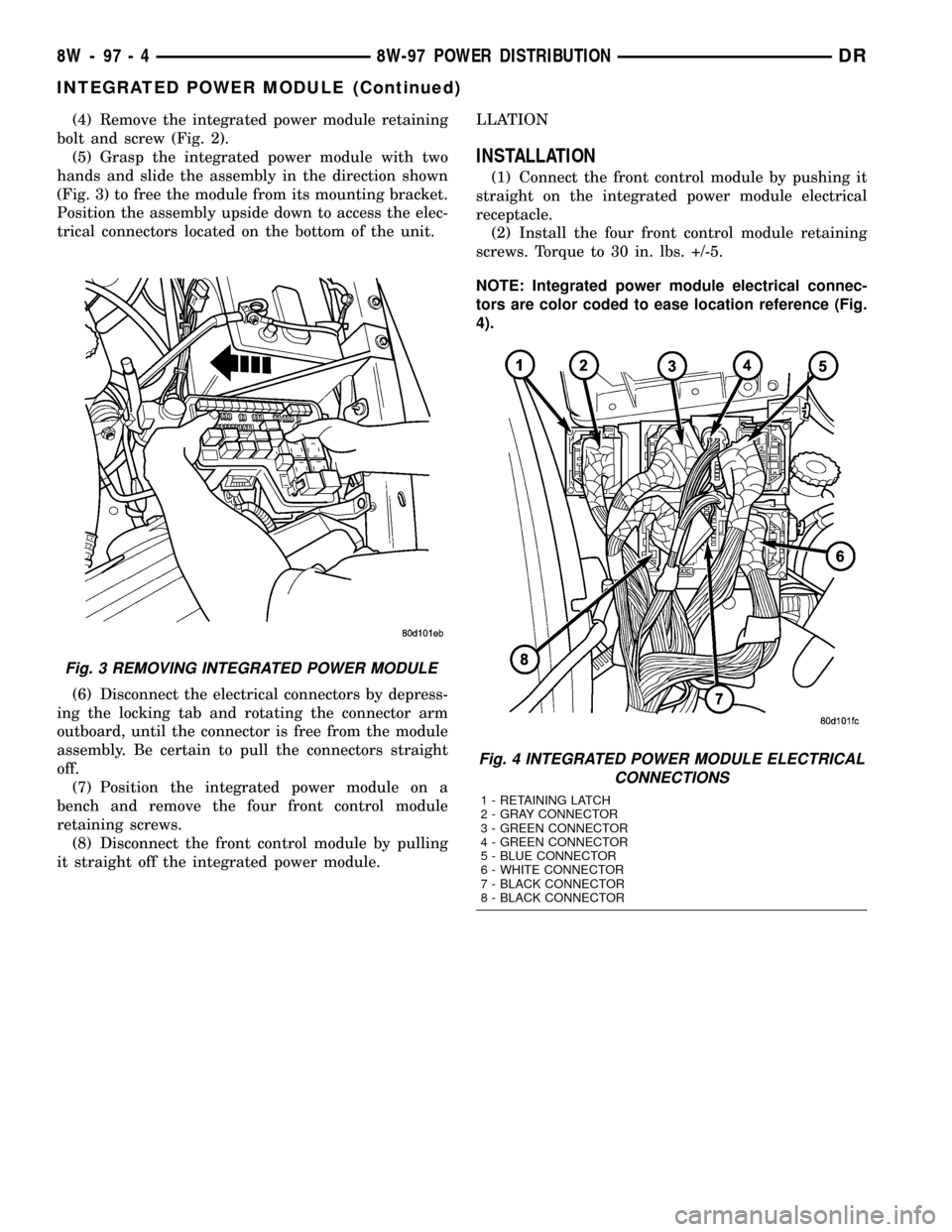

(4) Remove the integrated power module retaining

bolt and screw (Fig. 2).

(5) Grasp the integrated power module with two

hands and slide the assembly in the direction shown

(Fig. 3) to free the module from its mounting bracket.

Position the assembly upside down to access the elec-

trical connectors located on the bottom of the unit.

(6) Disconnect the electrical connectors by depress-

ing the locking tab and rotating the connector arm

outboard, until the connector is free from the module

assembly. Be certain to pull the connectors straight

off.

(7) Position the integrated power module on a

bench and remove the four front control module

retaining screws.

(8) Disconnect the front control module by pulling

it straight off the integrated power module.LLATION

INSTALLATION

(1) Connect the front control module by pushing it

straight on the integrated power module electrical

receptacle.

(2) Install the four front control module retaining

screws. Torque to 30 in. lbs. +/-5.

NOTE: Integrated power module electrical connec-

tors are color coded to ease location reference (Fig.

4).

Fig. 3 REMOVING INTEGRATED POWER MODULE

Fig. 4 INTEGRATED POWER MODULE ELECTRICAL

CONNECTIONS

1 - RETAINING LATCH

2 - GRAY CONNECTOR

3 - GREEN CONNECTOR

4 - GREEN CONNECTOR

5 - BLUE CONNECTOR

6 - WHITE CONNECTOR

7 - BLACK CONNECTOR

8 - BLACK CONNECTOR

8W - 97 - 4 8W-97 POWER DISTRIBUTIONDR

INTEGRATED POWER MODULE (Continued)

Page 1221 of 2627

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRI-

CAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3) Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straightfrom the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the inte-

grated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - INSTALLATION).

(4) Connect the positive and negative battery

cables.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is disconnected within the Inte-

grated Power Module when the vehicle is shipped

from the factory. Dealer personnel are to reconnect

the IOD fuse in the Integrated Power Module as part

of the preparation procedures performed just prior to

new vehicle delivery.

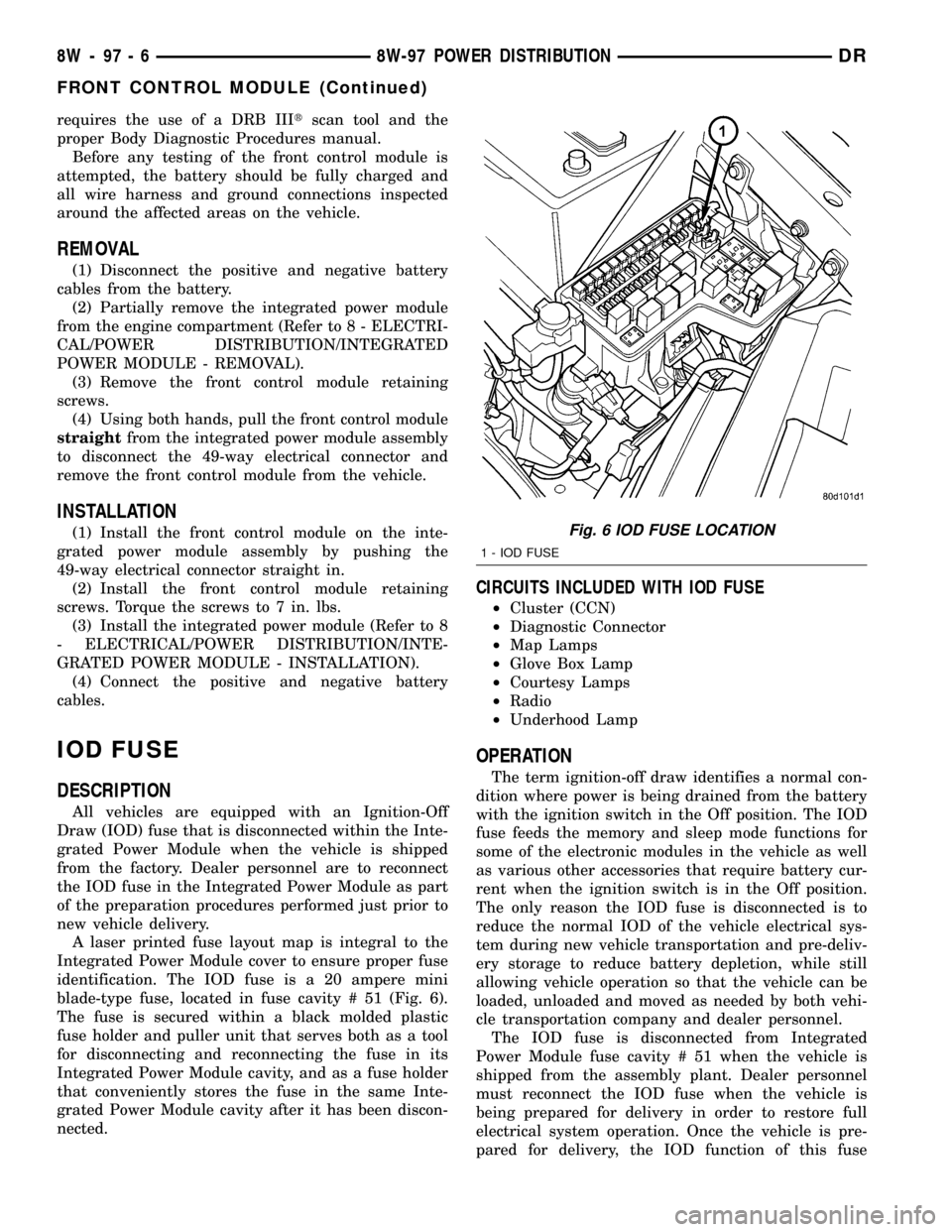

A laser printed fuse layout map is integral to the

Integrated Power Module cover to ensure proper fuse

identification. The IOD fuse is a 20 ampere mini

blade-type fuse, located in fuse cavity # 51 (Fig. 6).

The fuse is secured within a black molded plastic

fuse holder and puller unit that serves both as a tool

for disconnecting and reconnecting the fuse in its

Integrated Power Module cavity, and as a fuse holder

that conveniently stores the fuse in the same Inte-

grated Power Module cavity after it has been discon-

nected.

CIRCUITS INCLUDED WITH IOD FUSE

²Cluster (CCN)

²Diagnostic Connector

²Map Lamps

²Glove Box Lamp

²Courtesy Lamps

²Radio

²Underhood Lamp

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position.

The only reason the IOD fuse is disconnected is to

reduce the normal IOD of the vehicle electrical sys-

tem during new vehicle transportation and pre-deliv-

ery storage to reduce battery depletion, while still

allowing vehicle operation so that the vehicle can be

loaded, unloaded and moved as needed by both vehi-

cle transportation company and dealer personnel.

The IOD fuse is disconnected from Integrated

Power Module fuse cavity # 51 when the vehicle is

shipped from the assembly plant. Dealer personnel

must reconnect the IOD fuse when the vehicle is

being prepared for delivery in order to restore full

electrical system operation. Once the vehicle is pre-

pared for delivery, the IOD function of this fuse

Fig. 6 IOD FUSE LOCATION

1 - IOD FUSE

8W - 97 - 6 8W-97 POWER DISTRIBUTIONDR

FRONT CONTROL MODULE (Continued)

Page 1296 of 2627

(1) Start the engine.

(2) Spray a small stream of water (spray bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components: Refer to FUEL SYSTEM for compo-

nent locations.

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect vapor purge hose, brake booster

hose, speed control servo hose, positive crankcase

ventilation (PCV) hose.

(6) Disconnect generator electrical connections.

(7) Disconnect air conditioning compressor electri-

cal connections.

(8) Disconnect left and right radio suppressor

straps.

(9) Disconnect and remove ignition coil towers.

(10) Remove top oil dipstick tube retaining bolt

and ground strap.

(11) Bleed fuel system (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY - STANDARD PROCE-

DURE).

(12) Remove fuel rail.

(13) Remove throttle body assembly and mounting

bracket.

(14) Drain cooling system below coolant tempera-

ture level (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(15) Remove the heater hoses from the engine

front cover and the heater core.

(16) Unclip and remove heater hoses and tubes

from intake manifold.

(17) Remove coolant temperature sensor (Refer to

7 - COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - REMOVAL).

(18) Remove intake manifold retaining fasteners in

reverse order of tightening sequence.

(19) Remove intake manifold.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

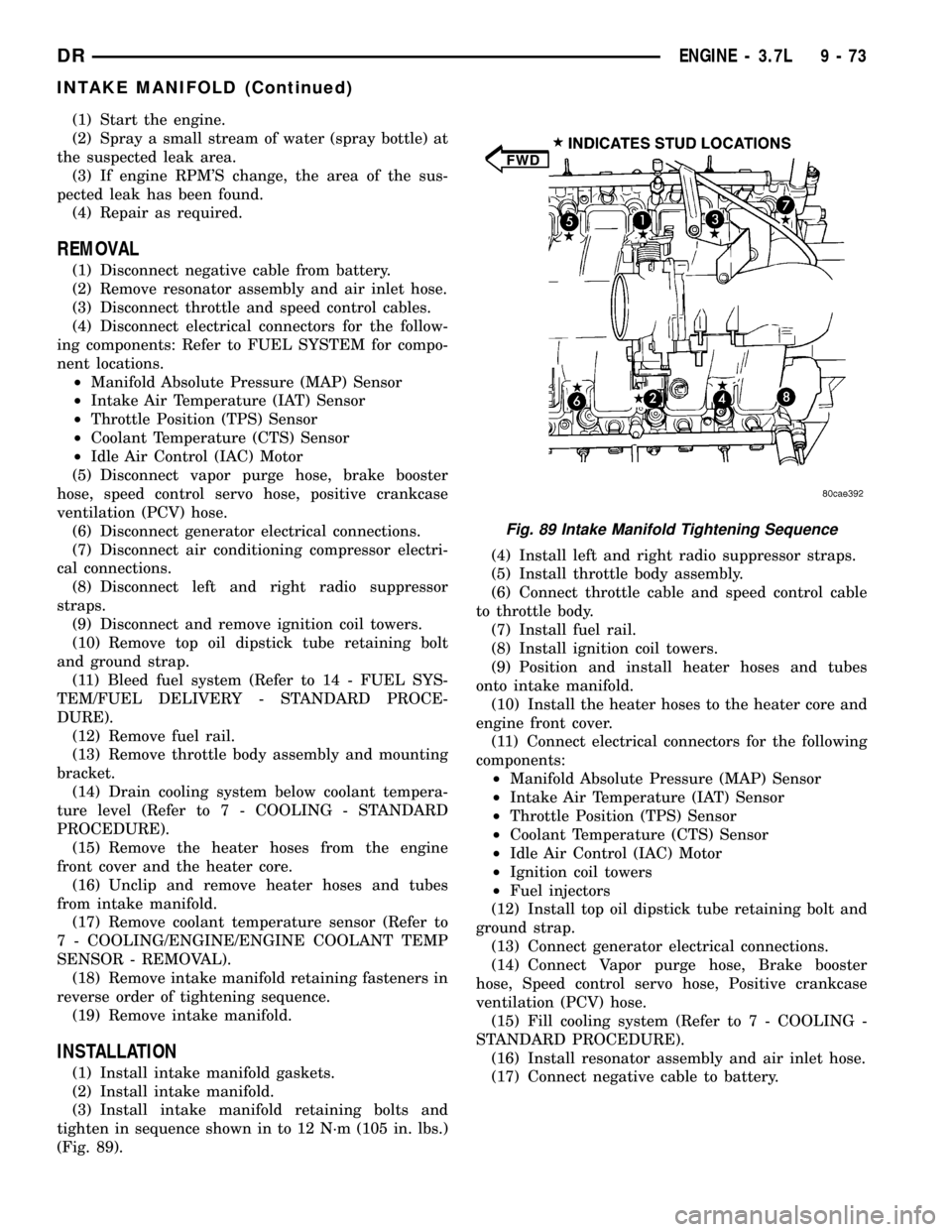

(3) Install intake manifold retaining bolts and

tighten in sequence shown in to 12 N´m (105 in. lbs.)

(Fig. 89).(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Connect throttle cable and speed control cable

to throttle body.

(7) Install fuel rail.

(8) Install ignition coil towers.

(9) Position and install heater hoses and tubes

onto intake manifold.

(10) Install the heater hoses to the heater core and

engine front cover.

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Connect generator electrical connections.

(14) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(15) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(16) Install resonator assembly and air inlet hose.

(17) Connect negative cable to battery.

Fig. 89 Intake Manifold Tightening Sequence

DRENGINE - 3.7L 9 - 73

INTAKE MANIFOLD (Continued)

Page 1346 of 2627

(7) Remove cylinder head cover and gasket.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

CLEANING

Clean cylinder head cover gasket surface.

Clean head rail, if necessary.

INSTALLATION

INSTALLATION - RIGHT SIDE

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

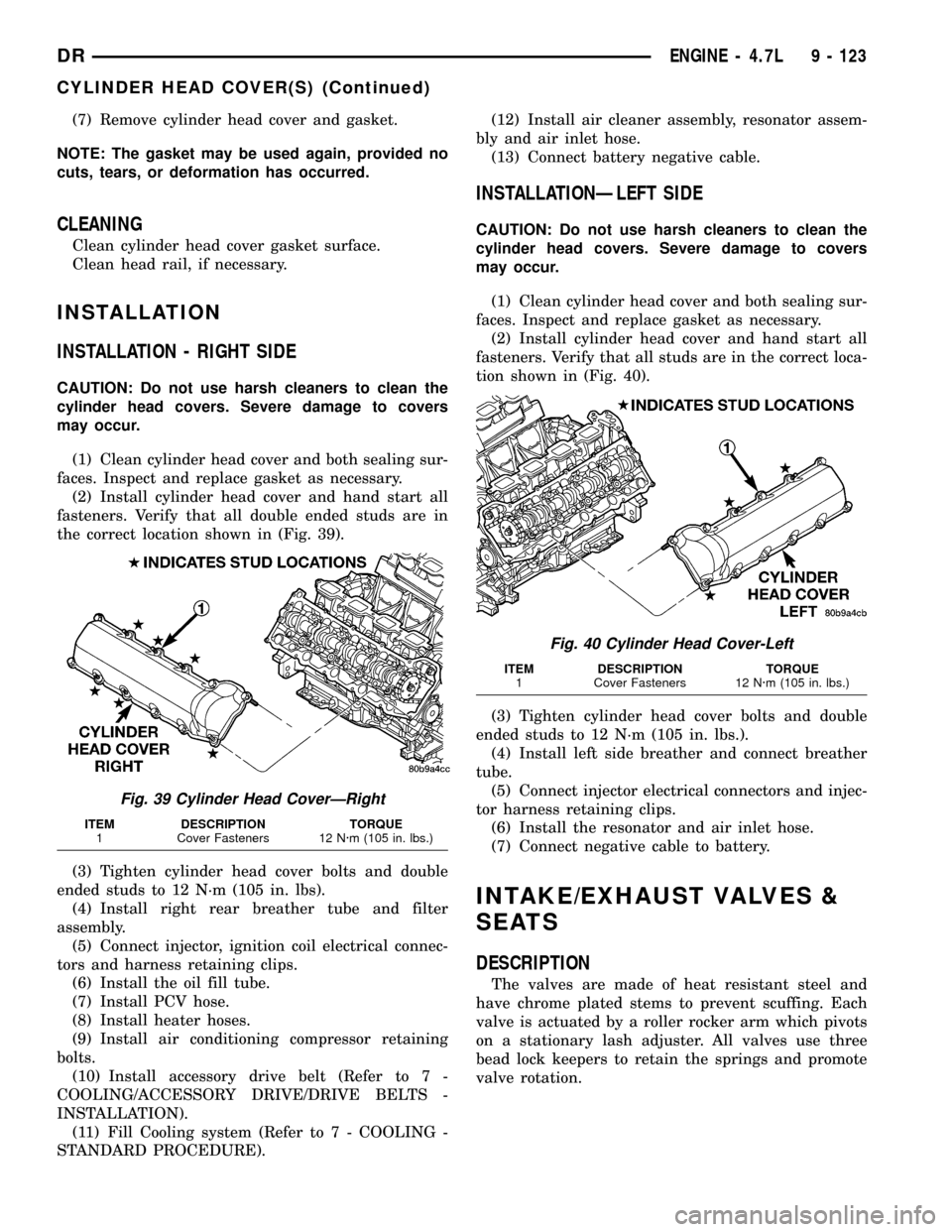

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Install cylinder head cover and hand start all

fasteners. Verify that all double ended studs are in

the correct location shown in (Fig. 39).

(3) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs).

(4) Install right rear breather tube and filter

assembly.

(5) Connect injector, ignition coil electrical connec-

tors and harness retaining clips.

(6) Install the oil fill tube.

(7) Install PCV hose.

(8) Install heater hoses.

(9) Install air conditioning compressor retaining

bolts.

(10) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(11) Fill Cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).(12) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(13) Connect battery negative cable.

INSTALLATIONÐLEFT SIDE

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Install cylinder head cover and hand start all

fasteners. Verify that all studs are in the correct loca-

tion shown in (Fig. 40).

(3) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs.).

(4) Install left side breather and connect breather

tube.

(5) Connect injector electrical connectors and injec-

tor harness retaining clips.

(6) Install the resonator and air inlet hose.

(7) Connect negative cable to battery.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. Each

valve is actuated by a roller rocker arm which pivots

on a stationary lash adjuster. All valves use three

bead lock keepers to retain the springs and promote

valve rotation.

Fig. 39 Cylinder Head CoverÐRight

ITEM DESCRIPTION TORQUE

1 Cover Fasteners 12 N´m (105 in. lbs.)

Fig. 40 Cylinder Head Cover-Left

ITEM DESCRIPTION TORQUE

1 Cover Fasteners 12 N´m (105 in. lbs.)

DRENGINE - 4.7L 9 - 123

CYLINDER HEAD COVER(S) (Continued)

Page 1424 of 2627

CAUTION: The head gaskets are marked ªTOPº to

indicate which side goes up.

(4) Position cylinder heads onto head gaskets and

cylinder block.

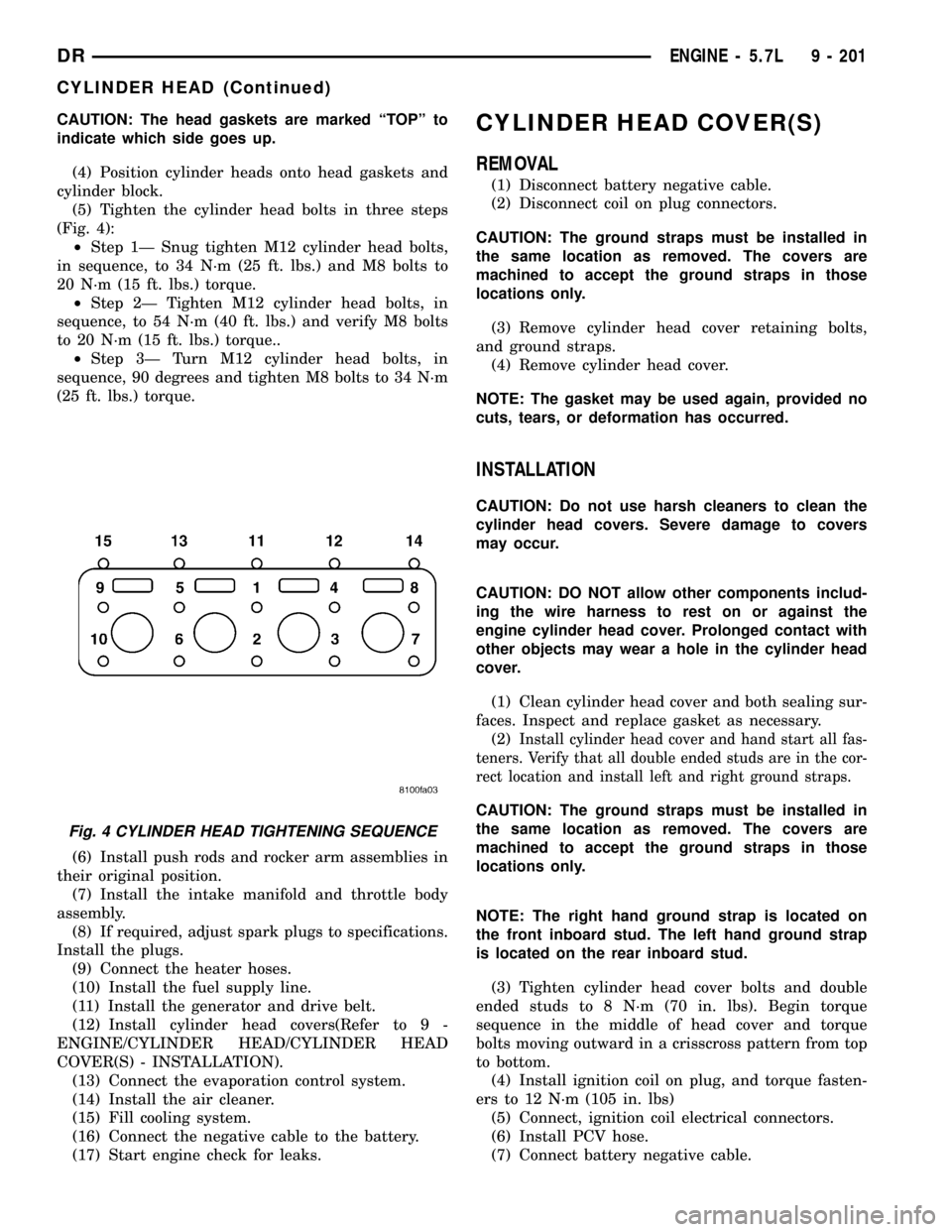

(5) Tighten the cylinder head bolts in three steps

(Fig. 4):

²Step 1Ð Snug tighten M12 cylinder head bolts,

in sequence, to 34 N´m (25 ft. lbs.) and M8 bolts to

20 N´m (15 ft. lbs.) torque.

²Step 2Ð Tighten M12 cylinder head bolts, in

sequence, to 54 N´m (40 ft. lbs.) and verify M8 bolts

to 20 N´m (15 ft. lbs.) torque..

²Step 3Ð Turn M12 cylinder head bolts, in

sequence, 90 degrees and tighten M8 bolts to 34 N´m

(25 ft. lbs.) torque.

(6) Install push rods and rocker arm assemblies in

their original position.

(7) Install the intake manifold and throttle body

assembly.

(8) If required, adjust spark plugs to specifications.

Install the plugs.

(9) Connect the heater hoses.

(10) Install the fuel supply line.

(11) Install the generator and drive belt.

(12) Install cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(13) Connect the evaporation control system.

(14) Install the air cleaner.

(15) Fill cooling system.

(16) Connect the negative cable to the battery.

(17) Start engine check for leaks.CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect coil on plug connectors.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

(3) Remove cylinder head cover retaining bolts,

and ground straps.

(4) Remove cylinder head cover.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the

engine cylinder head cover. Prolonged contact with

other objects may wear a hole in the cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2)

Install cylinder head cover and hand start all fas-

teners. Verify that all double ended studs are in the cor-

rect location and install left and right ground straps.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

NOTE: The right hand ground strap is located on

the front inboard stud. The left hand ground strap

is located on the rear inboard stud.

(3) Tighten cylinder head cover bolts and double

ended studs to 8 N´m (70 in. lbs). Begin torque

sequence in the middle of head cover and torque

bolts moving outward in a crisscross pattern from top

to bottom.

(4) Install ignition coil on plug, and torque fasten-

ers to 12 N´m (105 in. lbs)

(5) Connect, ignition coil electrical connectors.

(6) Install PCV hose.

(7) Connect battery negative cable.

Fig. 4 CYLINDER HEAD TIGHTENING SEQUENCE

DRENGINE - 5.7L 9 - 201

CYLINDER HEAD (Continued)

Page 1462 of 2627

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION/LEAKAGE TESTS

CYLINDER COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure batteries are completely charged and the

engine starter motor is in good operating condition.

Otherwise, the indicated compression pressures may

not be valid for diagnostic purposes.

(1) Disconnect the fuel inlet line to the fuel trans-

fer pump. Plug the fuel line from the fuel tank.

(2) Start the engine and idle until the engine stalls

(runs out of fuel).

(3) Disconnect all three injector wire harness con-

nectors at the rocker housing.

(4) Remove the breather cover and cylinder head

cover.

(5) Remove the high pressure fuel line between the

cylinder head and fuel rail for the cylinder to be

tested. Use tool# 9011 to cap this fuel rail on the cyl-

inder being tested.

(6) Remove the exhaust rocker lever.

(7) Use Tool 9010 to remove the injector and cop-

per sealing washer.

(8) Install the exhaust rocker lever and torque to

36 N´m (27 ft. lbs.).

(9) Cover the remaining rocker levers with clean

shop towels to prevent any oil splatter under the

hood.

(10) Place a rag over the compression test tool fit-

ting. Crank the engine for 2±3 seconds to purge any

fuel that may have drained into the cylinder when

the injector was removed.

(11) Connect the compression test gauge.

(12) Crank the engine for 5 seconds and record the

pressure reading. Repeat this step three times and

calculate the average of the three readings.

NOTE: The minimum cylinder pressure is 350 psi.

Cylinder pressure should be within 20% from cylin-

der to cylinder.

(13) Combustion pressure leakage can be checked

if cylinder pressure is below the specification. Per-

form the leakage test procedure on each cylinder

according to the tester manufacturer instructions.

(14) Upon completion of the test check an erase

any engine related fault codes.

CYLINDER COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss

(1) Start and operate the engine until it attains

normal operating temperature.

(2) Remove the breather cover and cylinder head

cover.

(3) Disconnect all three injector wire harness con-

nectors at the rocker housing.

(4) Bring the cylinder to be tested to TDC.

(5) Remove the high pressure fuel line between the

cylinder head and the fuel rail for the cylinder to be

tested.

(6) Install capping Tool 9011 onto the rail.

(7) Remove the high pressure connector nut and

high pressure connector with Tool 9015.

(8) Remove the exhaust and intake rocker lever.

(9) Use Tool 9010 to remove the injector and cop-

per sealing washer.

(10) Install compression test Tool 9007 into the

injector bore.

(11) Connect the leakage tester and perform the

leakage test procedure on each cylinder according to

the tester manufacturer's instructions.

(12) Upon completion of the test check and erase

any engine related fault codes.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

DRENGINE 5.9L DIESEL 9 - 239

ENGINE 5.9L DIESEL (Continued)

Page 1464 of 2627

(10) Drain engine oil. Remove and discard the oil

filter (Refer to 9 - ENGINE/LUBRICATION/OIL FIL-

TER - REMOVAL).

(11) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(12) Install a new oil filter (Refer to 9 - ENGINE/

LUBRICATION/OIL FILTER - INSTALLATION).

(13) Fill engine crankcase with the specified

amount and grade of oil (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES - SPECIFICA-

TIONS).

(14) Connect the negative cable(s) to the battery.

(15) Start the engine and check for any leaks.

REMOVAL

REMOVAL - ENGINE

(1) Disconnect both battery negative cables.

(2) Disconnect engine grid heater harness at grid

heater relays.

(3) Disconnect electrical connections from rear of

alternator.

(4) Recover A/C refrigerant. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

(5) Raise vehicle on a hoist.

(6) Drain engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Remove engine oil drain plug and drain engine

oil.

(8) Reinstall drain plug. Tighten to 50N´m (37 ft.

lbs.) torque.

(9) Lower the vehicle.

(10) Remove fan/drive assembly. Refer to Section 7

± Fan/Drive Removal

(11) Remove radiator upper hose.

(12) Remove upper fan shroud mounting bolts.

(13) Disconnect the coolant recovery bottle hose

from the radiator fill neck and remove bottle.

(14) Using a 36mm wrench, remove viscous fan/

drive assembly. (Refer to 7 - COOLING/ENGINE/RA-

DIATOR FAN - REMOVAL).

(15) Remove cooling fan and shroud together.

(16) Disconnect heater core supply and return

hoses from the cylinder head fitting and coolant pipe.

(17) Raise vehicle on a hoist.

(18) Remove transmission and transfer case (if

equipped).

(19) Disconnect exhaust pipe from turbocharger

extension pipe.

(20) Disconnect engine harness to vehicle harness

connectors.

(21) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).(22) Remove flywheel/flexplate.

(23) Remove transmission adapter

(24) Disconnect A/C suction/discharge hose from

the rear of the A/C compressor.

(25) Lower vehicle.

(26) Disconnect lower radiator hose from radiator

outlet.

(27) Automatic transmission models:

(28) Disconnect transmission oil cooler lines from

in front of radiator using special tool #6931

(29) Remove radiator. (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(30) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(31) Disconnect charge air cooler piping.

(32) Remove charge air cooler mounting bolts.

(33) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(34) Remove damper and speed indicator ring from

front of engine.

(35) Disconnect engine block heater connector.

(36) Disconnect A/C compressor and pressure sen-

sor electrical connectors.

(37) Remove the passenger battery ground cable

from the engine block. Remove the driver side bat-

tery ground cable from the engine block.

(38) Remove power steering pump from engine by

removing 3 bolts.

(39) Remove accelerator linkage cover.

(40) Disconnect cables from on-engine APPS.

(41) Disconnect the ECM power connector.

(42) Disconnect the ECM ground wire from the

hydroform screw.

(43) Disconnect the fuel supply and return hoses.

(44) Remove the cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(45) Disconnect the 3 injector harness connectors

at the rocker housing. Disconnect the wire harnesses

from the injectors.

(46) Remove the rear engine lift bracket.

(47) Remove cylinder #4, #5, and #6 intake and

exhaust rocker arms, pedestals, and push tubes. Note

the original location for re-assembly.

(48) Loosen #6 fuel line shield bolts and rotate

shield out of the way.

(49) Remove cylinder #5 and #6 high pressure fuel

lines. Remove the fuel connector tube nut and fuel

connector tube. Remove cylinder #5 and #6 fuel injec-

tor.

(50) Remove rocker housing.

DRENGINE 5.9L DIESEL 9 - 241

ENGINE 5.9L DIESEL (Continued)

Page 1477 of 2627

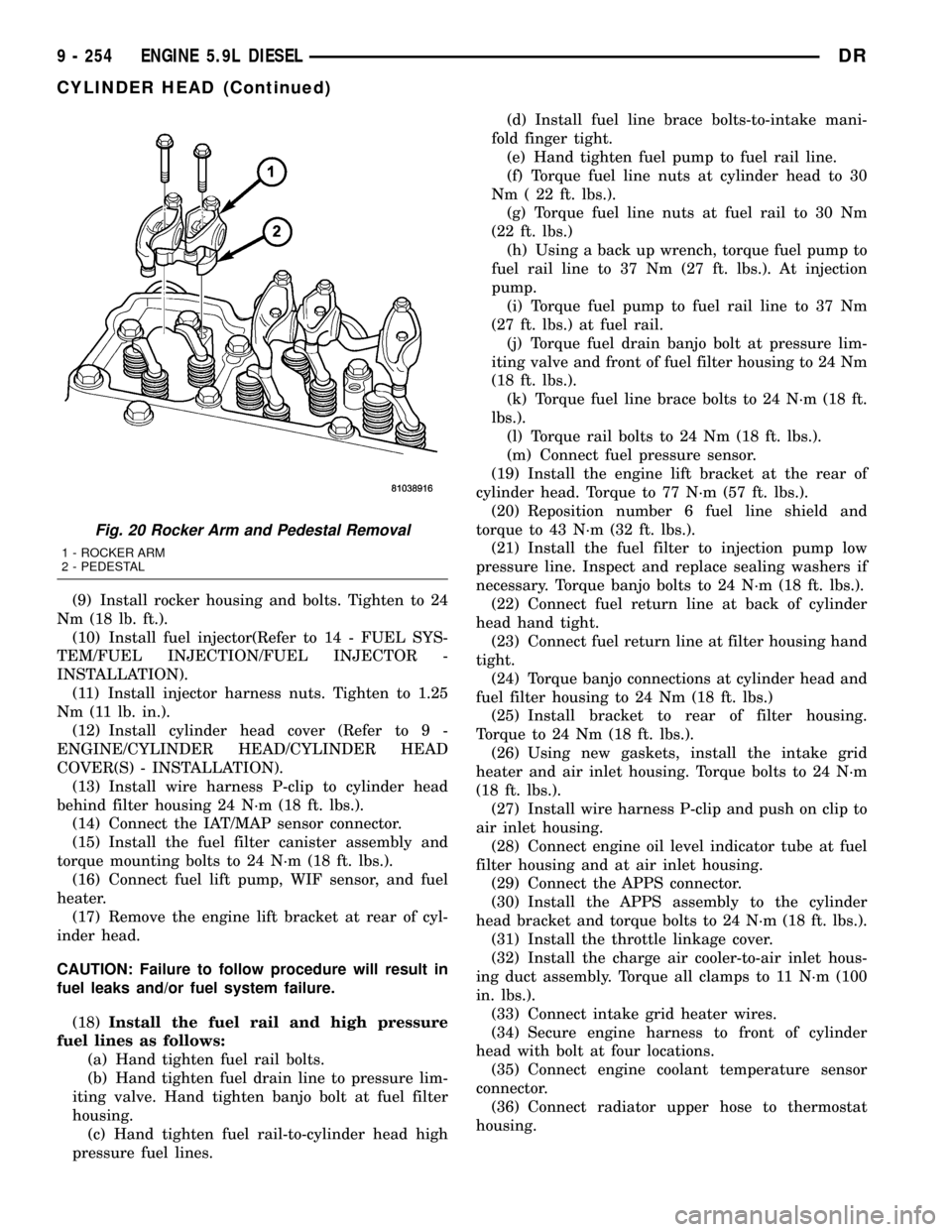

(9) Install rocker housing and bolts. Tighten to 24

Nm (18 lb. ft.).

(10) Install fuel injector(Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(11) Install injector harness nuts. Tighten to 1.25

Nm (11 lb. in.).

(12) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(13) Install wire harness P-clip to cylinder head

behind filter housing 24 N´m (18 ft. lbs.).

(14) Connect the IAT/MAP sensor connector.

(15) Install the fuel filter canister assembly and

torque mounting bolts to 24 N´m (18 ft. lbs.).

(16) Connect fuel lift pump, WIF sensor, and fuel

heater.

(17) Remove the engine lift bracket at rear of cyl-

inder head.

CAUTION: Failure to follow procedure will result in

fuel leaks and/or fuel system failure.

(18)Install the fuel rail and high pressure

fuel lines as follows:

(a) Hand tighten fuel rail bolts.

(b) Hand tighten fuel drain line to pressure lim-

iting valve. Hand tighten banjo bolt at fuel filter

housing.

(c) Hand tighten fuel rail-to-cylinder head high

pressure fuel lines.(d) Install fuel line brace bolts-to-intake mani-

fold finger tight.

(e) Hand tighten fuel pump to fuel rail line.

(f) Torque fuel line nuts at cylinder head to 30

Nm ( 22 ft. lbs.).

(g) Torque fuel line nuts at fuel rail to 30 Nm

(22 ft. lbs.)

(h) Using a back up wrench, torque fuel pump to

fuel rail line to 37 Nm (27 ft. lbs.). At injection

pump.

(i) Torque fuel pump to fuel rail line to 37 Nm

(27 ft. lbs.) at fuel rail.

(j) Torque fuel drain banjo bolt at pressure lim-

iting valve and front of fuel filter housing to 24 Nm

(18 ft. lbs.).

(k) Torque fuel line brace bolts to 24 N´m (18 ft.

lbs.).

(l) Torque rail bolts to 24 Nm (18 ft. lbs.).

(m) Connect fuel pressure sensor.

(19) Install the engine lift bracket at the rear of

cylinder head. Torque to 77 N´m (57 ft. lbs.).

(20) Reposition number 6 fuel line shield and

torque to 43 N´m (32 ft. lbs.).

(21) Install the fuel filter to injection pump low

pressure line. Inspect and replace sealing washers if

necessary. Torque banjo bolts to 24 N´m (18 ft. lbs.).

(22) Connect fuel return line at back of cylinder

head hand tight.

(23) Connect fuel return line at filter housing hand

tight.

(24) Torque banjo connections at cylinder head and

fuel filter housing to 24 Nm (18 ft. lbs.)

(25) Install bracket to rear of filter housing.

Torque to 24 Nm (18 ft. lbs.).

(26) Using new gaskets, install the intake grid

heater and air inlet housing. Torque bolts to 24 N´m

(18 ft. lbs.).

(27) Install wire harness P-clip and push on clip to

air inlet housing.

(28) Connect engine oil level indicator tube at fuel

filter housing and at air inlet housing.

(29) Connect the APPS connector.

(30) Install the APPS assembly to the cylinder

head bracket and torque bolts to 24 N´m (18 ft. lbs.).

(31) Install the throttle linkage cover.

(32) Install the charge air cooler-to-air inlet hous-

ing duct assembly. Torque all clamps to 11 N´m (100

in. lbs.).

(33) Connect intake grid heater wires.

(34) Secure engine harness to front of cylinder

head with bolt at four locations.

(35) Connect engine coolant temperature sensor

connector.

(36) Connect radiator upper hose to thermostat

housing.

Fig. 20 Rocker Arm and Pedestal Removal

1 - ROCKER ARM

2 - PEDESTAL

9 - 254 ENGINE 5.9L DIESELDR

CYLINDER HEAD (Continued)

Page 1483 of 2627

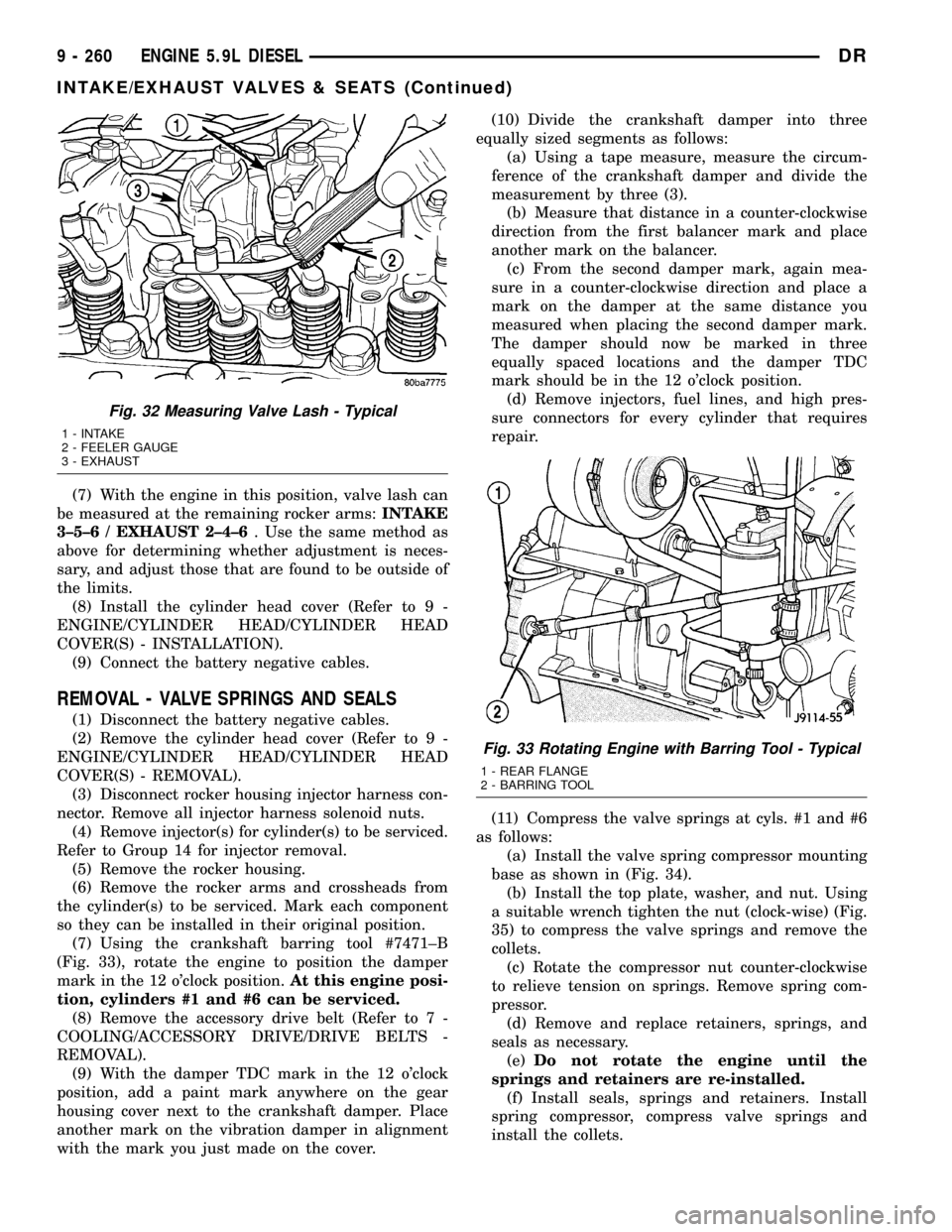

(7) With the engine in this position, valve lash can

be measured at the remaining rocker arms:INTAKE

3±5±6 / EXHAUST 2±4±6. Use the same method as

above for determining whether adjustment is neces-

sary, and adjust those that are found to be outside of

the limits.

(8) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(9) Connect the battery negative cables.

REMOVAL - VALVE SPRINGS AND SEALS

(1) Disconnect the battery negative cables.

(2) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(3) Disconnect rocker housing injector harness con-

nector. Remove all injector harness solenoid nuts.

(4) Remove injector(s) for cylinder(s) to be serviced.

Refer to Group 14 for injector removal.

(5) Remove the rocker housing.

(6) Remove the rocker arms and crossheads from

the cylinder(s) to be serviced. Mark each component

so they can be installed in their original position.

(7) Using the crankshaft barring tool #7471±B

(Fig. 33), rotate the engine to position the damper

mark in the 12 o'clock position.At this engine posi-

tion, cylinders #1 and #6 can be serviced.

(8) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(9) With the damper TDC mark in the 12 o'clock

position, add a paint mark anywhere on the gear

housing cover next to the crankshaft damper. Place

another mark on the vibration damper in alignment

with the mark you just made on the cover.(10) Divide the crankshaft damper into three

equally sized segments as follows:

(a) Using a tape measure, measure the circum-

ference of the crankshaft damper and divide the

measurement by three (3).

(b) Measure that distance in a counter-clockwise

direction from the first balancer mark and place

another mark on the balancer.

(c) From the second damper mark, again mea-

sure in a counter-clockwise direction and place a

mark on the damper at the same distance you

measured when placing the second damper mark.

The damper should now be marked in three

equally spaced locations and the damper TDC

mark should be in the 12 o'clock position.

(d) Remove injectors, fuel lines, and high pres-

sure connectors for every cylinder that requires

repair.

(11) Compress the valve springs at cyls. #1 and #6

as follows:

(a) Install the valve spring compressor mounting

base as shown in (Fig. 34).

(b) Install the top plate, washer, and nut. Using

a suitable wrench tighten the nut (clock-wise) (Fig.

35) to compress the valve springs and remove the

collets.

(c) Rotate the compressor nut counter-clockwise

to relieve tension on springs. Remove spring com-

pressor.

(d) Remove and replace retainers, springs, and

seals as necessary.

(e)Do not rotate the engine until the

springs and retainers are re-installed.

(f) Install seals, springs and retainers. Install

spring compressor, compress valve springs and

install the collets.

Fig. 32 Measuring Valve Lash - Typical

1 - INTAKE

2 - FEELER GAUGE

3 - EXHAUST

Fig. 33 Rotating Engine with Barring Tool - Typical

1 - REAR FLANGE

2 - BARRING TOOL

9 - 260 ENGINE 5.9L DIESELDR

INTAKE/EXHAUST VALVES & SEATS (Continued)