Connectors DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2352 of 2627

(2) Position the switch bezel and seat the attach-

ment clips fully.

(3) Seat the clips on the steering column opening

cover and the lower drivers side bezel fully.

INSTRUMENT PANEL CENTER

BEZEL

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CAUTION: When removing and installing the center

bezel, use tape or other suitable material to protect

the cupholder and ash receiver from damage.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL)

(3) Open the ashtray and cup holder.

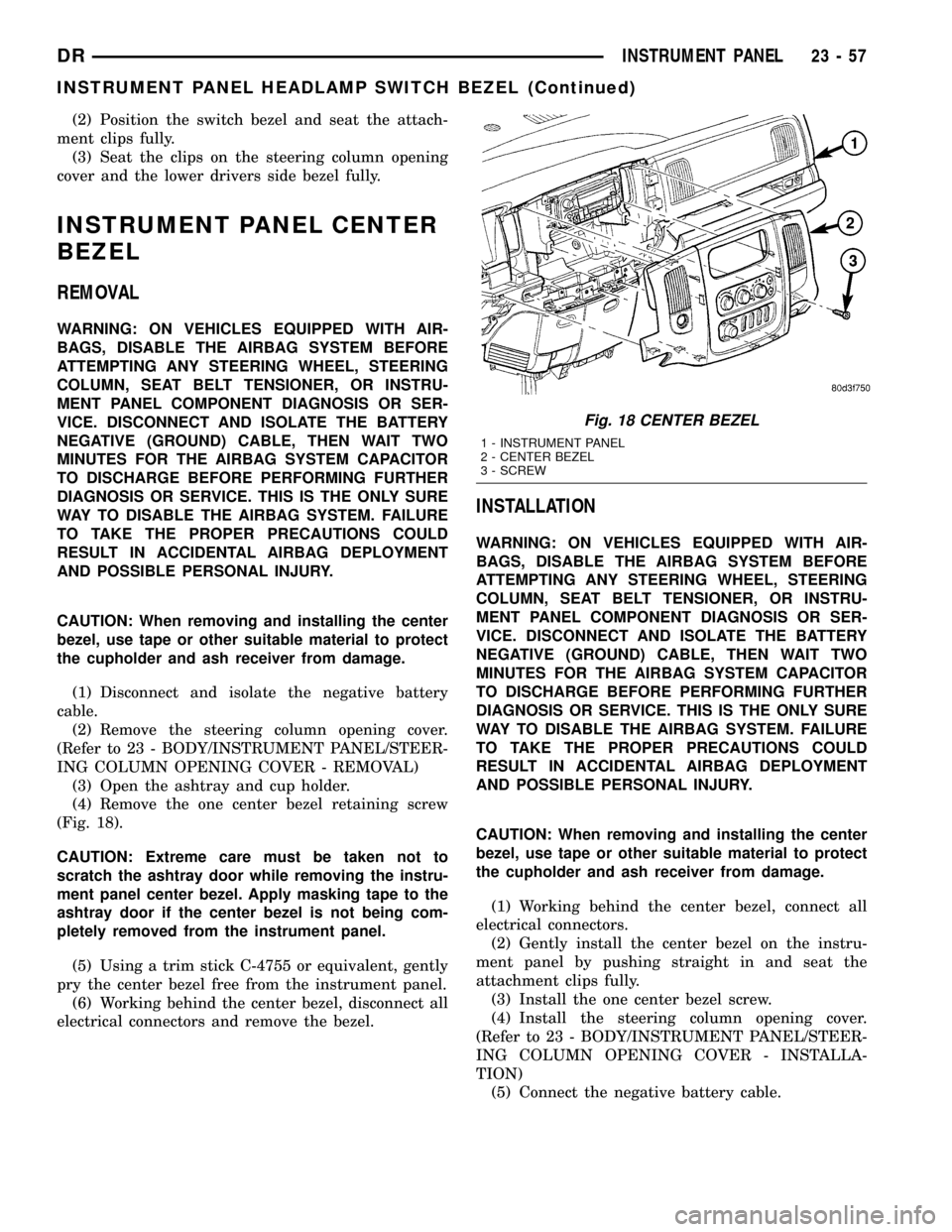

(4) Remove the one center bezel retaining screw

(Fig. 18).

CAUTION: Extreme care must be taken not to

scratch the ashtray door while removing the instru-

ment panel center bezel. Apply masking tape to the

ashtray door if the center bezel is not being com-

pletely removed from the instrument panel.

(5) Using a trim stick C-4755 or equivalent, gently

pry the center bezel free from the instrument panel.

(6) Working behind the center bezel, disconnect all

electrical connectors and remove the bezel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CAUTION: When removing and installing the center

bezel, use tape or other suitable material to protect

the cupholder and ash receiver from damage.

(1) Working behind the center bezel, connect all

electrical connectors.

(2) Gently install the center bezel on the instru-

ment panel by pushing straight in and seat the

attachment clips fully.

(3) Install the one center bezel screw.

(4) Install the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION)

(5) Connect the negative battery cable.

Fig. 18 CENTER BEZEL

1 - INSTRUMENT PANEL

2 - CENTER BEZEL

3 - SCREW

DRINSTRUMENT PANEL 23 - 57

INSTRUMENT PANEL HEADLAMP SWITCH BEZEL (Continued)

Page 2378 of 2627

SEAT CUSHION / COVER -

FRONT

REMOVAL

(1) Remove the front seat. (Refer to 23 - BODY/

SEATS/SEAT - FRONT - REMOVAL)

(2) Remove the screw and remove the recliner han-

dle.

(3) Remove the two screws and remove the power

seat controls, if equipped, and disconnect the electri-

cal connector.

(4) Remove the seat track. (Refer to 23 - BODY/

SEATS/SEAT TRACK - REMOVAL)

(5) Disconnect the j-straps and remove the seat

cushion and cover.

INSTALLATION

(1) Position the seat cushion and cover onto the

frame assembly and connect the j-straps.

(2) Install the seat track. (Refer to 23 - BODY/

SEATS/SEAT TRACK - INSTALLATION)

(3) Connect the power seat control switch electrical

connector, if equipped.

(4) Install the power seat control switch and

install the two screws, if equipped.

(5) Install the recliner handle and install the

screw.

(6) Install the front seat. (Refer to 23 - BODY/

SEATS/SEAT - FRONT - INSTALLATION)

SEAT TRACK

REMOVAL

(1) Remove the front seat. (Refer to 23 - BODY/

SEATS/SEAT - FRONT - REMOVAL)

(2) Disconnect the heated seat electrical connec-

tors, if equipped.

(3) Remove the four nuts attaching the seat track

to the seat and remove the track.

INSTALLATION

(1) Position the seat track onto the seat and install

the four nuts.

(2) Tighten the four nuts to 25 N´m (18 ft. lbs.).

(3) Connect the heated seat electrical connectors, if

equipped.

(4) Install the seat. (Refer to 23 - BODY/SEATS/

SEAT - FRONT - INSTALLATION)

SEAT - REAR

REMOVAL

(1) Remove the load floor. (Refer to 23 - BODY/IN-

TERIOR/LOAD FLOOR - REMOVAL)

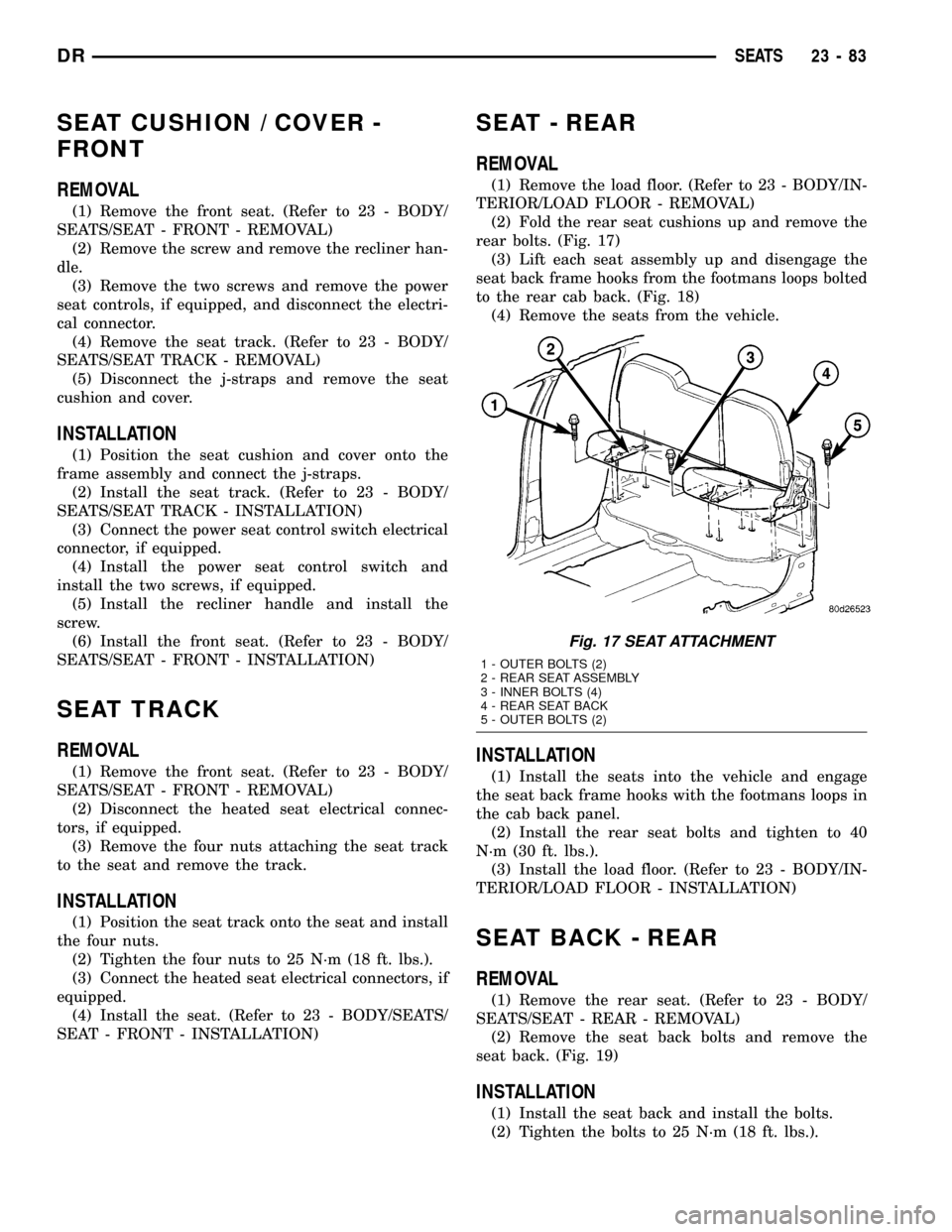

(2) Fold the rear seat cushions up and remove the

rear bolts. (Fig. 17)

(3) Lift each seat assembly up and disengage the

seat back frame hooks from the footmans loops bolted

to the rear cab back. (Fig. 18)

(4) Remove the seats from the vehicle.

INSTALLATION

(1) Install the seats into the vehicle and engage

the seat back frame hooks with the footmans loops in

the cab back panel.

(2) Install the rear seat bolts and tighten to 40

N´m (30 ft. lbs.).

(3) Install the load floor. (Refer to 23 - BODY/IN-

TERIOR/LOAD FLOOR - INSTALLATION)

SEAT BACK - REAR

REMOVAL

(1) Remove the rear seat. (Refer to 23 - BODY/

SEATS/SEAT - REAR - REMOVAL)

(2) Remove the seat back bolts and remove the

seat back. (Fig. 19)

INSTALLATION

(1) Install the seat back and install the bolts.

(2) Tighten the bolts to 25 N´m (18 ft. lbs.).

Fig. 17 SEAT ATTACHMENT

1 - OUTER BOLTS (2)

2 - REAR SEAT ASSEMBLY

3 - INNER BOLTS (4)

4 - REAR SEAT BACK

5 - OUTER BOLTS (2)

DRSEATS 23 - 83

Page 2494 of 2627

²Faulty A/C-heater control.

²Faulty related wiring harness or connectors.

²Improper engine coolant temperature.

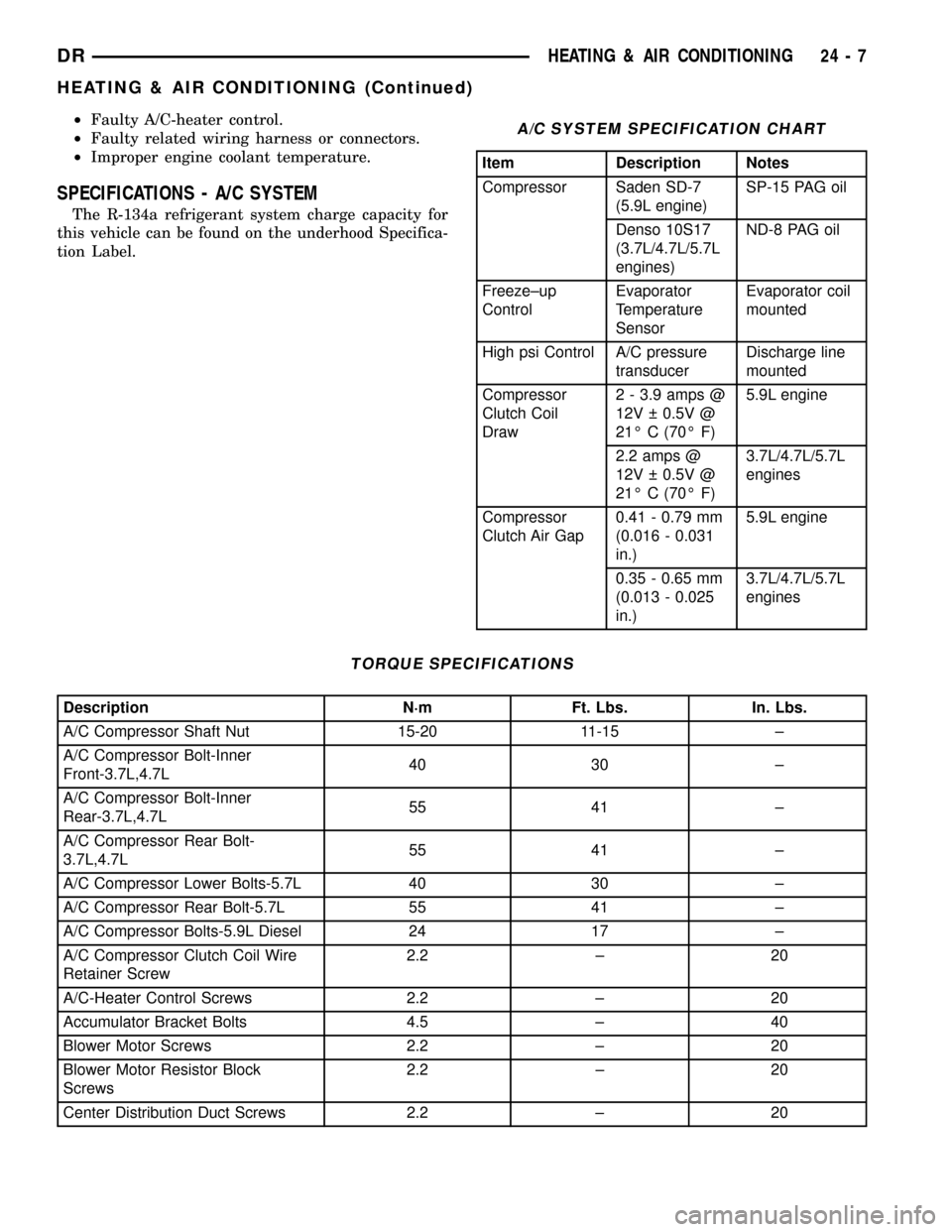

SPECIFICATIONS - A/C SYSTEM

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood Specifica-

tion Label.

A/C SYSTEM SPECIFICATION CHART

Item Description Notes

Compressor Saden SD-7

(5.9L engine)SP-15 PAG oil

Denso 10S17

(3.7L/4.7L/5.7L

engines)ND-8 PAG oil

Freeze±up

ControlEvaporator

Temperature

SensorEvaporator coil

mounted

High psi Control A/C pressure

transducerDischarge line

mounted

Compressor

Clutch Coil

Draw2 - 3.9 amps @

12V 0.5V @

21É C (70É F)5.9L engine

2.2 amps @

12V 0.5V @

21É C (70É F)3.7L/4.7L/5.7L

engines

Compressor

Clutch Air Gap0.41 - 0.79 mm

(0.016 - 0.031

in.)5.9L engine

0.35 - 0.65 mm

(0.013 - 0.025

in.)3.7L/4.7L/5.7L

engines

TORQUE SPECIFICATIONS

Description N´m Ft. Lbs. In. Lbs.

A/C Compressor Shaft Nut 15-20 11-15 ±

A/C Compressor Bolt-Inner

Front-3.7L,4.7L40 30 ±

A/C Compressor Bolt-Inner

Rear-3.7L,4.7L55 41 ±

A/C Compressor Rear Bolt-

3.7L,4.7L55 41 ±

A/C Compressor Lower Bolts-5.7L 40 30 ±

A/C Compressor Rear Bolt-5.7L 55 41 ±

A/C Compressor Bolts-5.9L Diesel 24 17 ±

A/C Compressor Clutch Coil Wire

Retainer Screw2.2 ± 20

A/C-Heater Control Screws 2.2 ± 20

Accumulator Bracket Bolts 4.5 ± 40

Blower Motor Screws 2.2 ± 20

Blower Motor Resistor Block

Screws2.2 ± 20

Center Distribution Duct Screws 2.2 ± 20

DRHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 2522 of 2627

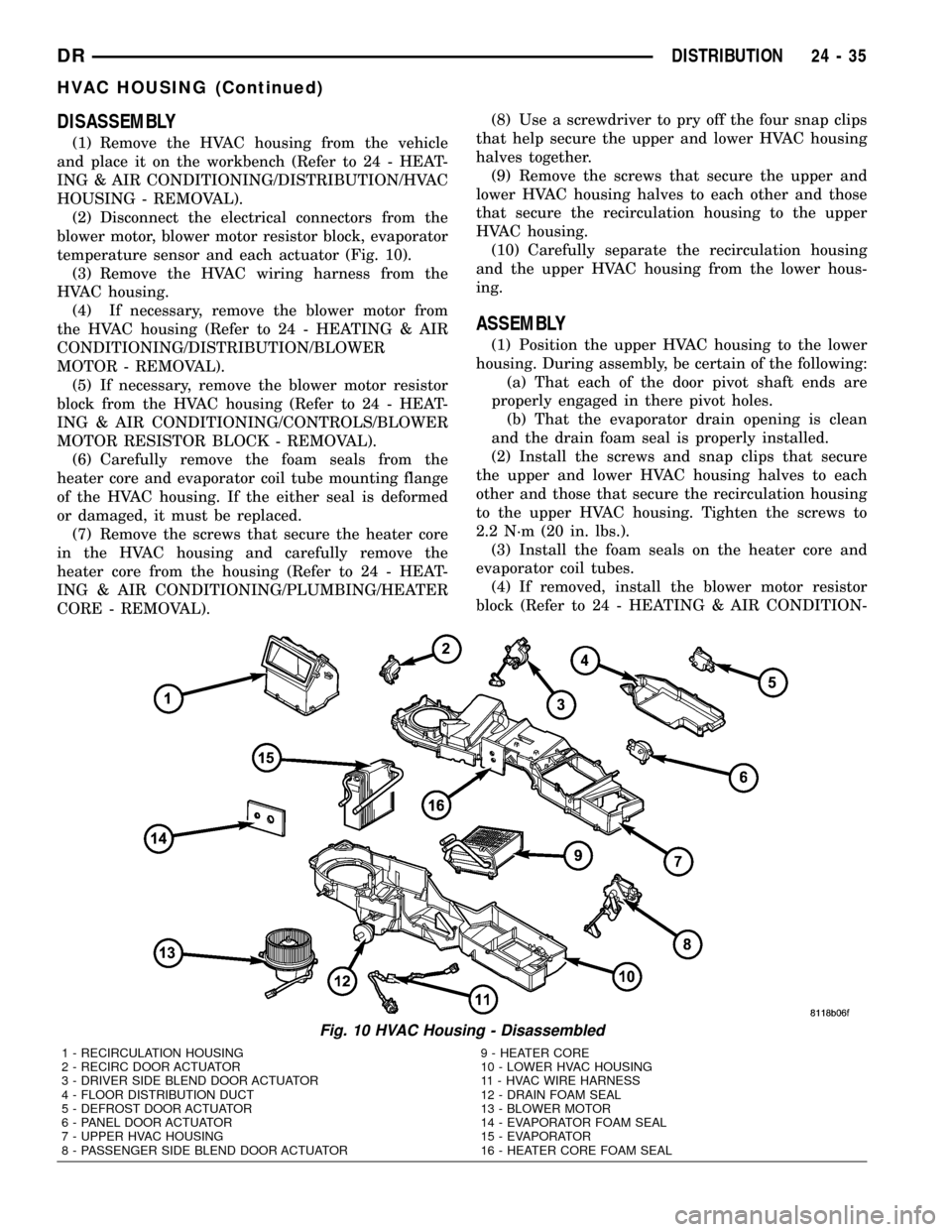

DISASSEMBLY

(1) Remove the HVAC housing from the vehicle

and place it on the workbench (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - REMOVAL).

(2) Disconnect the electrical connectors from the

blower motor, blower motor resistor block, evaporator

temperature sensor and each actuator (Fig. 10).

(3) Remove the HVAC wiring harness from the

HVAC housing.

(4) If necessary, remove the blower motor from

the HVAC housing (Refer to 24 - HEATING & AIR

CONDITIONING/DISTRIBUTION/BLOWER

MOTOR - REMOVAL).

(5) If necessary, remove the blower motor resistor

block from the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RESISTOR BLOCK - REMOVAL).

(6) Carefully remove the foam seals from the

heater core and evaporator coil tube mounting flange

of the HVAC housing. If the either seal is deformed

or damaged, it must be replaced.

(7) Remove the screws that secure the heater core

in the HVAC housing and carefully remove the

heater core from the housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/HEATER

CORE - REMOVAL).(8) Use a screwdriver to pry off the four snap clips

that help secure the upper and lower HVAC housing

halves together.

(9) Remove the screws that secure the upper and

lower HVAC housing halves to each other and those

that secure the recirculation housing to the upper

HVAC housing.

(10) Carefully separate the recirculation housing

and the upper HVAC housing from the lower hous-

ing.

ASSEMBLY

(1) Position the upper HVAC housing to the lower

housing. During assembly, be certain of the following:

(a) That each of the door pivot shaft ends are

properly engaged in there pivot holes.

(b) That the evaporator drain opening is clean

and the drain foam seal is properly installed.

(2) Install the screws and snap clips that secure

the upper and lower HVAC housing halves to each

other and those that secure the recirculation housing

to the upper HVAC housing. Tighten the screws to

2.2 N´m (20 in. lbs.).

(3) Install the foam seals on the heater core and

evaporator coil tubes.

(4) If removed, install the blower motor resistor

block (Refer to 24 - HEATING & AIR CONDITION-

Fig. 10 HVAC Housing - Disassembled

1 - RECIRCULATION HOUSING

2 - RECIRC DOOR ACTUATOR

3 - DRIVER SIDE BLEND DOOR ACTUATOR

4 - FLOOR DISTRIBUTION DUCT

5 - DEFROST DOOR ACTUATOR

6 - PANEL DOOR ACTUATOR

7 - UPPER HVAC HOUSING

8 - PASSENGER SIDE BLEND DOOR ACTUATOR9 - HEATER CORE

10 - LOWER HVAC HOUSING

11 - HVAC WIRE HARNESS

12 - DRAIN FOAM SEAL

13 - BLOWER MOTOR

14 - EVAPORATOR FOAM SEAL

15 - EVAPORATOR

16 - HEATER CORE FOAM SEAL

DRDISTRIBUTION 24 - 35

HVAC HOUSING (Continued)

Page 2551 of 2627

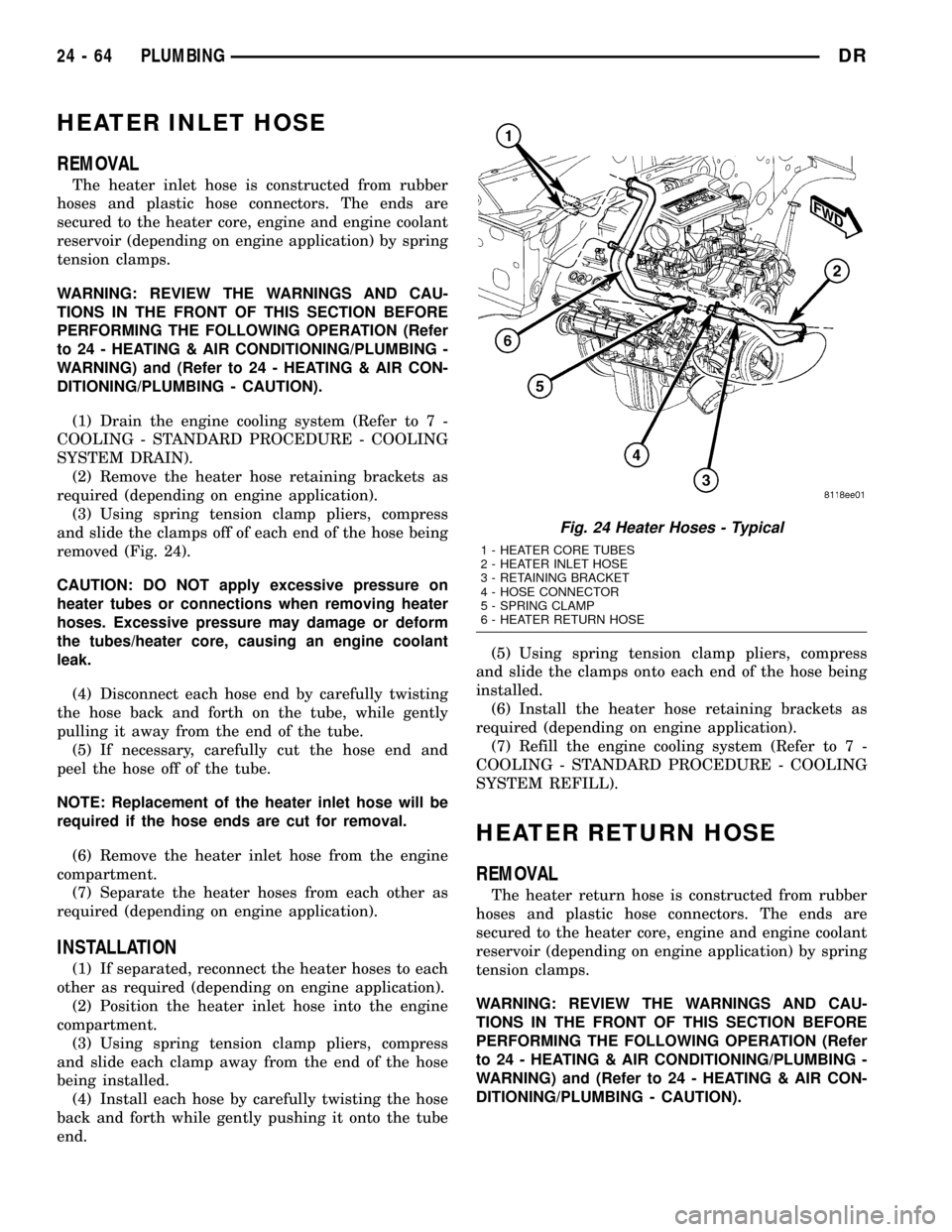

HEATER INLET HOSE

REMOVAL

The heater inlet hose is constructed from rubber

hoses and plastic hose connectors. The ends are

secured to the heater core, engine and engine coolant

reservoir (depending on engine application) by spring

tension clamps.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Remove the heater hose retaining brackets as

required (depending on engine application).

(3) Using spring tension clamp pliers, compress

and slide the clamps off of each end of the hose being

removed (Fig. 24).

CAUTION: DO NOT apply excessive pressure on

heater tubes or connections when removing heater

hoses. Excessive pressure may damage or deform

the tubes/heater core, causing an engine coolant

leak.

(4) Disconnect each hose end by carefully twisting

the hose back and forth on the tube, while gently

pulling it away from the end of the tube.

(5) If necessary, carefully cut the hose end and

peel the hose off of the tube.

NOTE: Replacement of the heater inlet hose will be

required if the hose ends are cut for removal.

(6) Remove the heater inlet hose from the engine

compartment.

(7) Separate the heater hoses from each other as

required (depending on engine application).

INSTALLATION

(1) If separated, reconnect the heater hoses to each

other as required (depending on engine application).

(2) Position the heater inlet hose into the engine

compartment.

(3) Using spring tension clamp pliers, compress

and slide each clamp away from the end of the hose

being installed.

(4) Install each hose by carefully twisting the hose

back and forth while gently pushing it onto the tube

end.(5) Using spring tension clamp pliers, compress

and slide the clamps onto each end of the hose being

installed.

(6) Install the heater hose retaining brackets as

required (depending on engine application).

(7) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

HEATER RETURN HOSE

REMOVAL

The heater return hose is constructed from rubber

hoses and plastic hose connectors. The ends are

secured to the heater core, engine and engine coolant

reservoir (depending on engine application) by spring

tension clamps.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

Fig. 24 Heater Hoses - Typical

1 - HEATER CORE TUBES

2 - HEATER INLET HOSE

3 - RETAINING BRACKET

4 - HOSE CONNECTOR

5 - SPRING CLAMP

6 - HEATER RETURN HOSE

24 - 64 PLUMBINGDR