Valve cover DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1519 of 2627

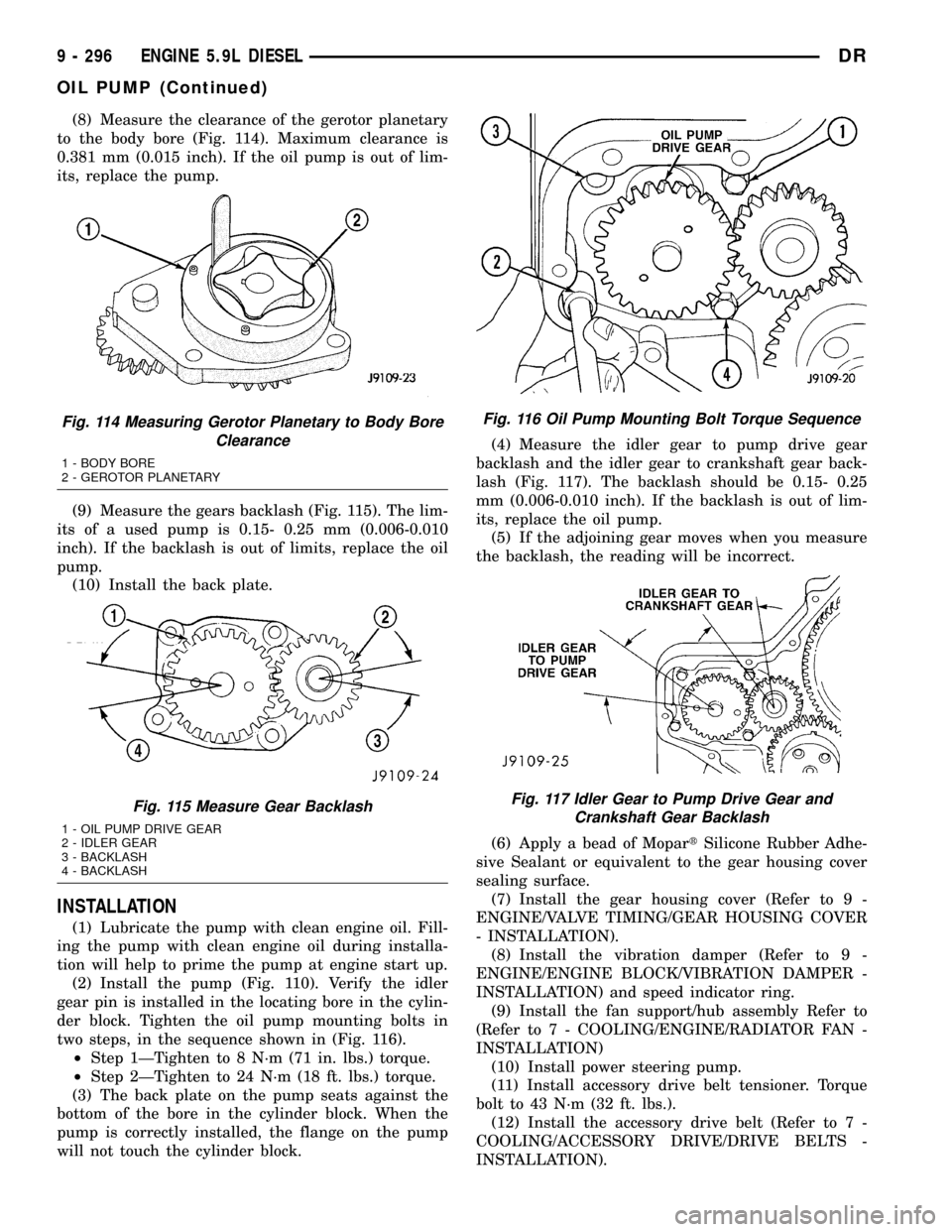

(8) Measure the clearance of the gerotor planetary

to the body bore (Fig. 114). Maximum clearance is

0.381 mm (0.015 inch). If the oil pump is out of lim-

its, replace the pump.

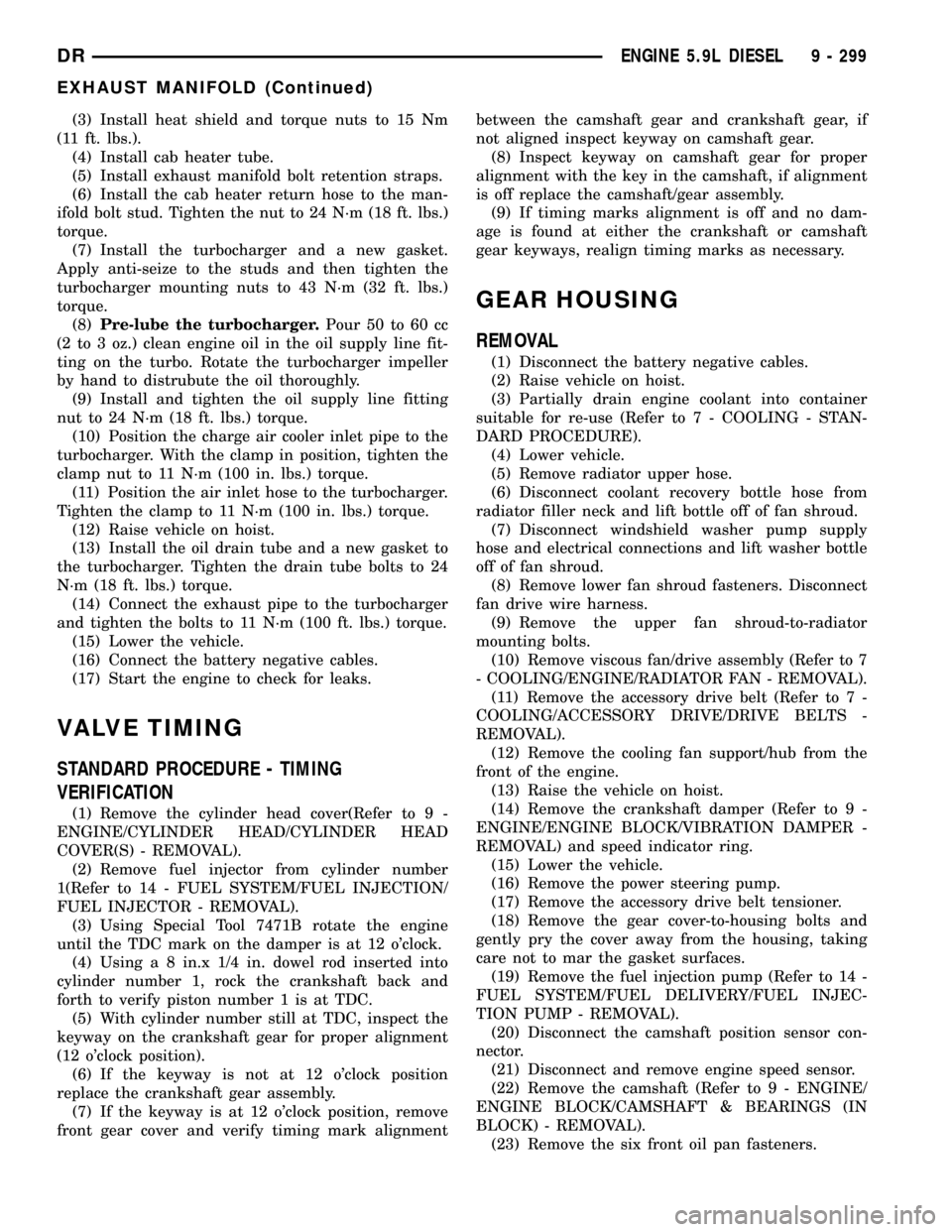

(9) Measure the gears backlash (Fig. 115). The lim-

its of a used pump is 0.15- 0.25 mm (0.006-0.010

inch). If the backlash is out of limits, replace the oil

pump.

(10) Install the back plate.

INSTALLATION

(1) Lubricate the pump with clean engine oil. Fill-

ing the pump with clean engine oil during installa-

tion will help to prime the pump at engine start up.

(2) Install the pump (Fig. 110). Verify the idler

gear pin is installed in the locating bore in the cylin-

der block. Tighten the oil pump mounting bolts in

two steps, in the sequence shown in (Fig. 116).

²Step 1ÐTighten to 8 N´m (71 in. lbs.) torque.

²Step 2ÐTighten to 24 N´m (18 ft. lbs.) torque.

(3) The back plate on the pump seats against the

bottom of the bore in the cylinder block. When the

pump is correctly installed, the flange on the pump

will not touch the cylinder block.(4) Measure the idler gear to pump drive gear

backlash and the idler gear to crankshaft gear back-

lash (Fig. 117). The backlash should be 0.15- 0.25

mm (0.006-0.010 inch). If the backlash is out of lim-

its, replace the oil pump.

(5) If the adjoining gear moves when you measure

the backlash, the reading will be incorrect.

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- INSTALLATION).

(8) Install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION) and speed indicator ring.

(9) Install the fan support/hub assembly Refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION)

(10) Install power steering pump.

(11) Install accessory drive belt tensioner. Torque

bolt to 43 N´m (32 ft. lbs.).

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Fig. 114 Measuring Gerotor Planetary to Body Bore

Clearance

1 - BODY BORE

2 - GEROTOR PLANETARY

Fig. 115 Measure Gear Backlash

1 - OIL PUMP DRIVE GEAR

2 - IDLER GEAR

3 - BACKLASH

4 - BACKLASH

Fig. 116 Oil Pump Mounting Bolt Torque Sequence

Fig. 117 Idler Gear to Pump Drive Gear and

Crankshaft Gear Backlash

9 - 296 ENGINE 5.9L DIESELDR

OIL PUMP (Continued)

Page 1522 of 2627

(3) Install heat shield and torque nuts to 15 Nm

(11 ft. lbs.).

(4) Install cab heater tube.

(5) Install exhaust manifold bolt retention straps.

(6) Install the cab heater return hose to the man-

ifold bolt stud. Tighten the nut to 24 N´m (18 ft. lbs.)

torque.

(7) Install the turbocharger and a new gasket.

Apply anti-seize to the studs and then tighten the

turbocharger mounting nuts to 43 N´m (32 ft. lbs.)

torque.

(8)Pre-lube the turbocharger.Pour 50 to 60 cc

(2 to 3 oz.) clean engine oil in the oil supply line fit-

ting on the turbo. Rotate the turbocharger impeller

by hand to distrubute the oil thoroughly.

(9) Install and tighten the oil supply line fitting

nut to 24 N´m (18 ft. lbs.) torque.

(10) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 11 N´m (100 in. lbs.) torque.

(11) Position the air inlet hose to the turbocharger.

Tighten the clamp to 11 N´m (100 in. lbs.) torque.

(12) Raise vehicle on hoist.

(13) Install the oil drain tube and a new gasket to

the turbocharger. Tighten the drain tube bolts to 24

N´m (18 ft. lbs.) torque.

(14) Connect the exhaust pipe to the turbocharger

and tighten the bolts to 11 N´m (100 ft. lbs.) torque.

(15) Lower the vehicle.

(16) Connect the battery negative cables.

(17) Start the engine to check for leaks.

VALVE TIMING

STANDARD PROCEDURE - TIMING

VERIFICATION

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Remove fuel injector from cylinder number

1(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

FUEL INJECTOR - REMOVAL).

(3) Using Special Tool 7471B rotate the engine

until the TDC mark on the damper is at 12 o'clock.

(4) Using a 8 in.x 1/4 in. dowel rod inserted into

cylinder number 1, rock the crankshaft back and

forth to verify piston number 1 is at TDC.

(5) With cylinder number still at TDC, inspect the

keyway on the crankshaft gear for proper alignment

(12 o'clock position).

(6) If the keyway is not at 12 o'clock position

replace the crankshaft gear assembly.

(7) If the keyway is at 12 o'clock position, remove

front gear cover and verify timing mark alignmentbetween the camshaft gear and crankshaft gear, if

not aligned inspect keyway on camshaft gear.

(8) Inspect keyway on camshaft gear for proper

alignment with the key in the camshaft, if alignment

is off replace the camshaft/gear assembly.

(9) If timing marks alignment is off and no dam-

age is found at either the crankshaft or camshaft

gear keyways, realign timing marks as necessary.

GEAR HOUSING

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove lower fan shroud fasteners. Disconnect

fan drive wire harness.

(9) Remove the upper fan shroud-to-radiator

mounting bolts.

(10) Remove viscous fan/drive assembly (Refer to 7

- COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(11) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(12) Remove the cooling fan support/hub from the

front of the engine.

(13) Raise the vehicle on hoist.

(14) Remove the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(15) Lower the vehicle.

(16) Remove the power steering pump.

(17) Remove the accessory drive belt tensioner.

(18) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

(19) Remove the fuel injection pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(20) Disconnect the camshaft position sensor con-

nector.

(21) Disconnect and remove engine speed sensor.

(22) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(23) Remove the six front oil pan fasteners.

DRENGINE 5.9L DIESEL 9 - 299

EXHAUST MANIFOLD (Continued)

Page 1586 of 2627

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

5.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in intake manifold.

(5) Guide each injector into intake manifold. Be

careful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on shoulders. Pushleftfuel

rail down until injectors have bottomed on shoulders.

(7) Install 4 fuel rail holdown clamps and 4 mount-

ing bolts. Refer to Torque Specifications.

(8) Position spark plug cable tray and cable assem-

bly to intake manifold. Snap 4 cable tray retaining

clips into intake manifold.

(9) Install all cables to spark plugs and ignition

coils.

(10) Connect electrical connector to throttle body.

(11) Install electrical connectors to all 8 ignition

coils. Refer to Ignition Coil Removal/Installation.

(12) Connect electrical connector to throttle body.

(13) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(14) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(15) Install air resonator to throttle body (2 bolts).

(16) Install flexible air duct to air box.

(17) Connect battery cable to battery.

(18) Start engine and check for leaks.

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for place-

ment of the fuel pump module, and (if equipped) cer-

tain ORVR components.

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.Two check (control) valves are mounted into the

top of the fuel tank. Refer to Fuel Tank Check Valve

for additional information.

An evaporation control system is connected to the

fuel tank to reduce emissions of fuel vapors into the

atmosphere. When fuel evaporates from the fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP) and/or an On-Board Refueling

Vapor Recovery (ORVR) system. Refer to Emission

Control System for additional information.

REMOVAL- EXCEPT DIESEL

Fuel Tank Draining

WARNING: THE FUEL SYSTEM MAY BE UNDER

CONSTANT FUEL PRESSURE EVEN WITH THE

ENGINE OFF. THIS PRESSURE MUST BE

RELEASED BEFORE SERVICING FUEL TANK.

Two different procedures may be used to drain fuel

tank: through the fuel fill fitting on tank, or using

the DRBtscan tool. Due to a one-way check valve

installed into the fuel fill opening fitting at the tank,

the tank cannot be drained conventionally at the fill

cap.

The quickest draining procedure involves removing

the rubber fuel fill hose.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRB scan tool for fuel pump

activation procedures. Before disconnecting fuel line

at fuel rail, release fuel pressure. Refer to the Fuel

System Pressure Release Procedure for procedures.

Attach end of special test hose tool number 6541,

6539, 6631 or 6923 at fuel rail disconnection (tool

number will depend on model and/or engine applica-

tion). Position opposite end of this hose tool to an

approved gasoline draining station. Activate fuel

pump and drain tank until empty.

If electric fuel pump is not operating, fuel must be

drained through fuel fill fitting at tank. Refer to fol-

lowing procedures.

(1) Release fuel system pressure.

(2) Raise vehicle.

(3) Thoroughly clean area around fuel fill fitting

and rubber fuel fill hose at tank.

(4) If vehicle is equipped with 4 doors and a 6 foot

(short) box, remove left-rear tire/wheel.

(5) Loosen clamp (Fig. 23) and disconnect rubber

fuel fill hose at tank fitting. Using an approved gas

holding tank, drain fuel tank through this fitting.

DRFUEL DELIVERY - GAS 14 - 17

FUEL RAIL (Continued)

Page 1596 of 2627

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just

above the intake valve ports of the cylinder head.

The engine wiring harness connector for each fuel

injector is equipped with an attached numerical tag

(INJ 1, INJ 2 etc.). This is used to identify each fuel

injector.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width)

based on various inputs.

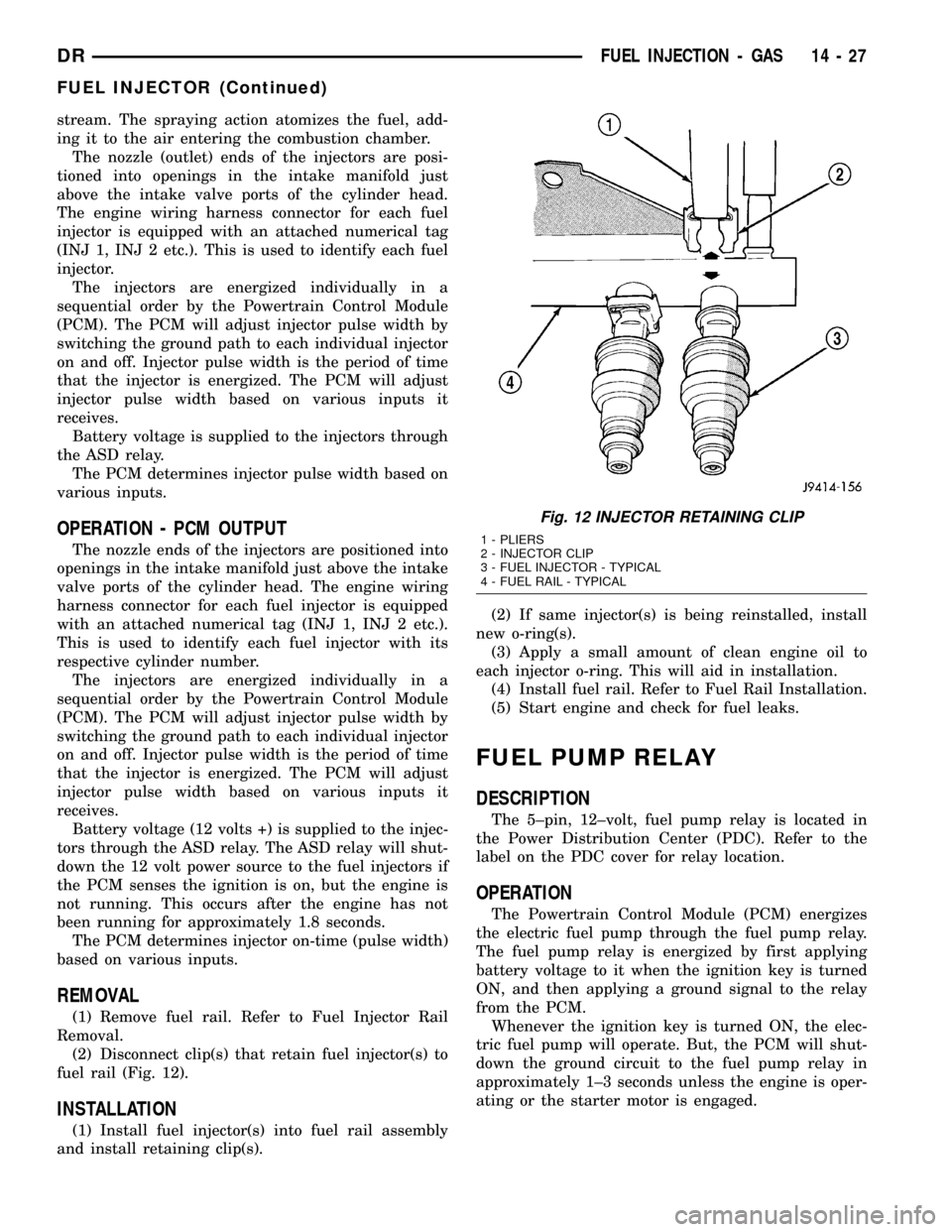

REMOVAL

(1) Remove fuel rail. Refer to Fuel Injector Rail

Removal.

(2) Disconnect clip(s) that retain fuel injector(s) to

fuel rail (Fig. 12).

INSTALLATION

(1) Install fuel injector(s) into fuel rail assembly

and install retaining clip(s).(2) If same injector(s) is being reinstalled, install

new o-ring(s).

(3) Apply a small amount of clean engine oil to

each injector o-ring. This will aid in installation.

(4) Install fuel rail. Refer to Fuel Rail Installation.

(5) Start engine and check for fuel leaks.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

Fig. 12 INJECTOR RETAINING CLIP

1 - PLIERS

2 - INJECTOR CLIP

3 - FUEL INJECTOR - TYPICAL

4 - FUEL RAIL - TYPICAL

DRFUEL INJECTION - GAS 14 - 27

FUEL INJECTOR (Continued)

Page 1620 of 2627

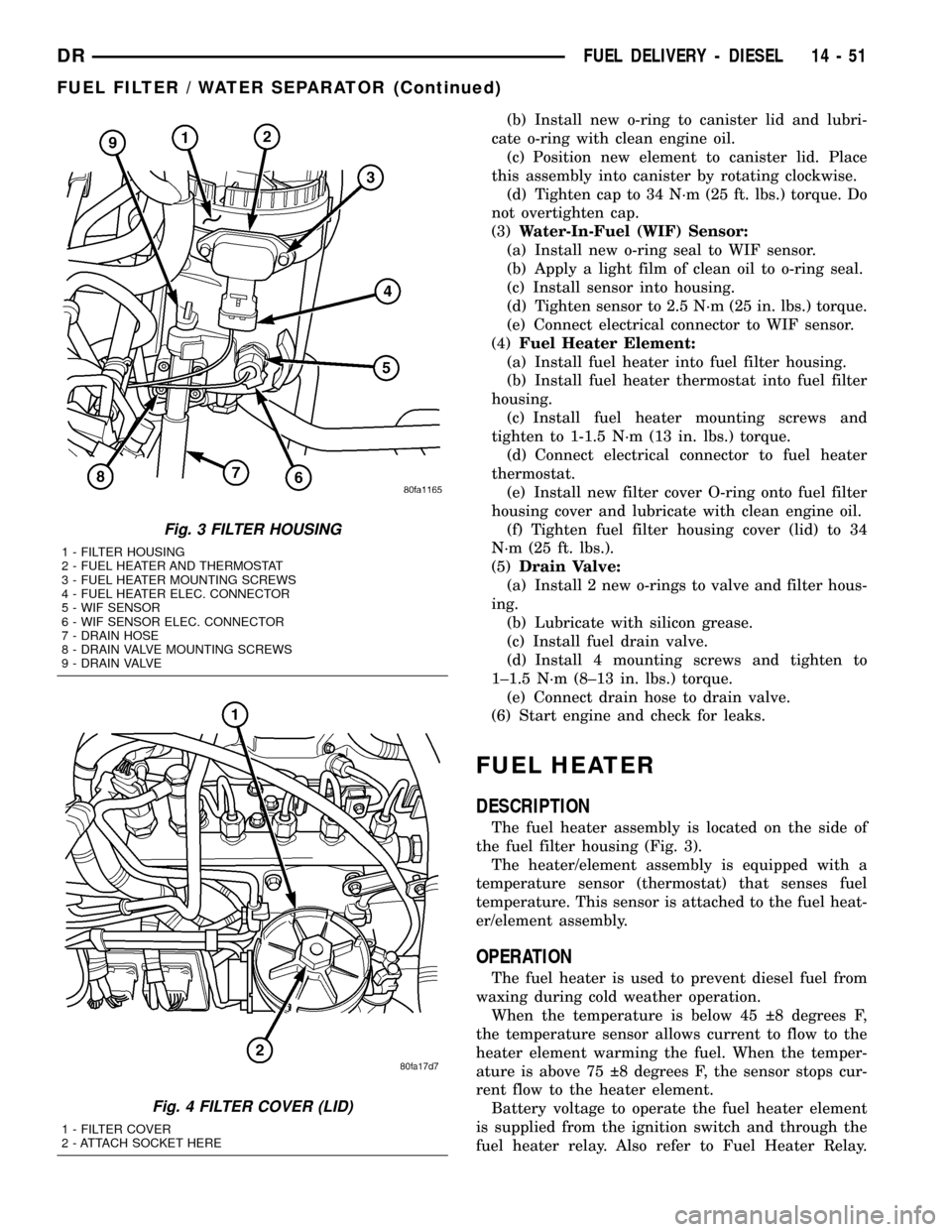

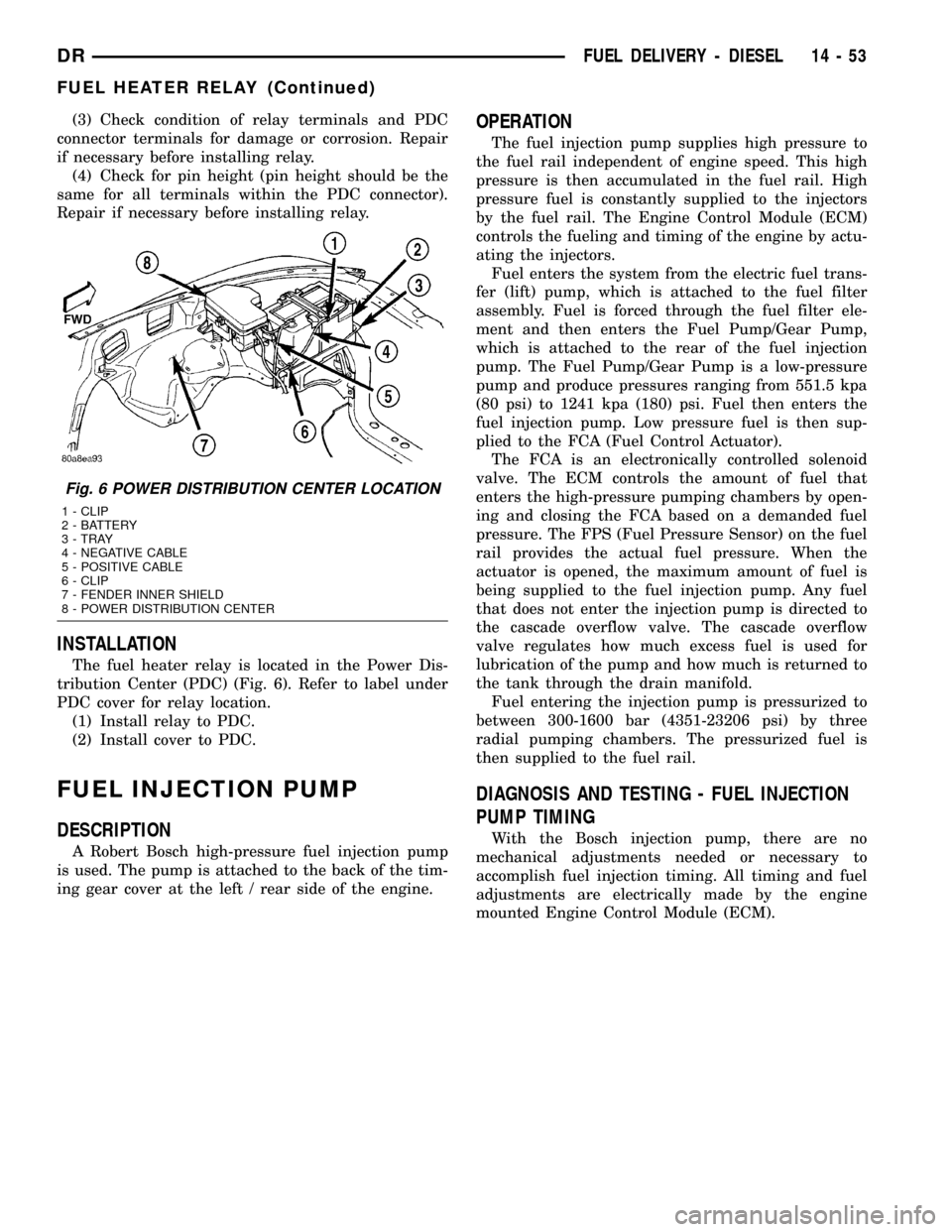

(b) Install new o-ring to canister lid and lubri-

cate o-ring with clean engine oil.

(c) Position new element to canister lid. Place

this assembly into canister by rotating clockwise.

(d) Tighten cap to 34 N´m (25 ft. lbs.) torque. Do

not overtighten cap.

(3)Water-In-Fuel (WIF) Sensor:

(a) Install new o-ring seal to WIF sensor.

(b) Apply a light film of clean oil to o-ring seal.

(c) Install sensor into housing.

(d) Tighten sensor to 2.5 N´m (25 in. lbs.) torque.

(e) Connect electrical connector to WIF sensor.

(4)Fuel Heater Element:

(a) Install fuel heater into fuel filter housing.

(b) Install fuel heater thermostat into fuel filter

housing.

(c) Install fuel heater mounting screws and

tighten to 1-1.5 N´m (13 in. lbs.) torque.

(d) Connect electrical connector to fuel heater

thermostat.

(e) Install new filter cover O-ring onto fuel filter

housing cover and lubricate with clean engine oil.

(f) Tighten fuel filter housing cover (lid) to 34

N´m (25 ft. lbs.).

(5)Drain Valve:

(a) Install 2 new o-rings to valve and filter hous-

ing.

(b) Lubricate with silicon grease.

(c) Install fuel drain valve.

(d) Install 4 mounting screws and tighten to

1±1.5 N´m (8±13 in. lbs.) torque.

(e) Connect drain hose to drain valve.

(6) Start engine and check for leaks.

FUEL HEATER

DESCRIPTION

The fuel heater assembly is located on the side of

the fuel filter housing (Fig. 3).

The heater/element assembly is equipped with a

temperature sensor (thermostat) that senses fuel

temperature. This sensor is attached to the fuel heat-

er/element assembly.

OPERATION

The fuel heater is used to prevent diesel fuel from

waxing during cold weather operation.

When the temperature is below 45 8 degrees F,

the temperature sensor allows current to flow to the

heater element warming the fuel. When the temper-

ature is above 75 8 degrees F, the sensor stops cur-

rent flow to the heater element.

Battery voltage to operate the fuel heater element

is supplied from the ignition switch and through the

fuel heater relay. Also refer to Fuel Heater Relay.

Fig. 3 FILTER HOUSING

1 - FILTER HOUSING

2 - FUEL HEATER AND THERMOSTAT

3 - FUEL HEATER MOUNTING SCREWS

4 - FUEL HEATER ELEC. CONNECTOR

5 - WIF SENSOR

6 - WIF SENSOR ELEC. CONNECTOR

7 - DRAIN HOSE

8 - DRAIN VALVE MOUNTING SCREWS

9 - DRAIN VALVE

Fig. 4 FILTER COVER (LID)

1 - FILTER COVER

2 - ATTACH SOCKET HERE

DRFUEL DELIVERY - DIESEL 14 - 51

FUEL FILTER / WATER SEPARATOR (Continued)

Page 1622 of 2627

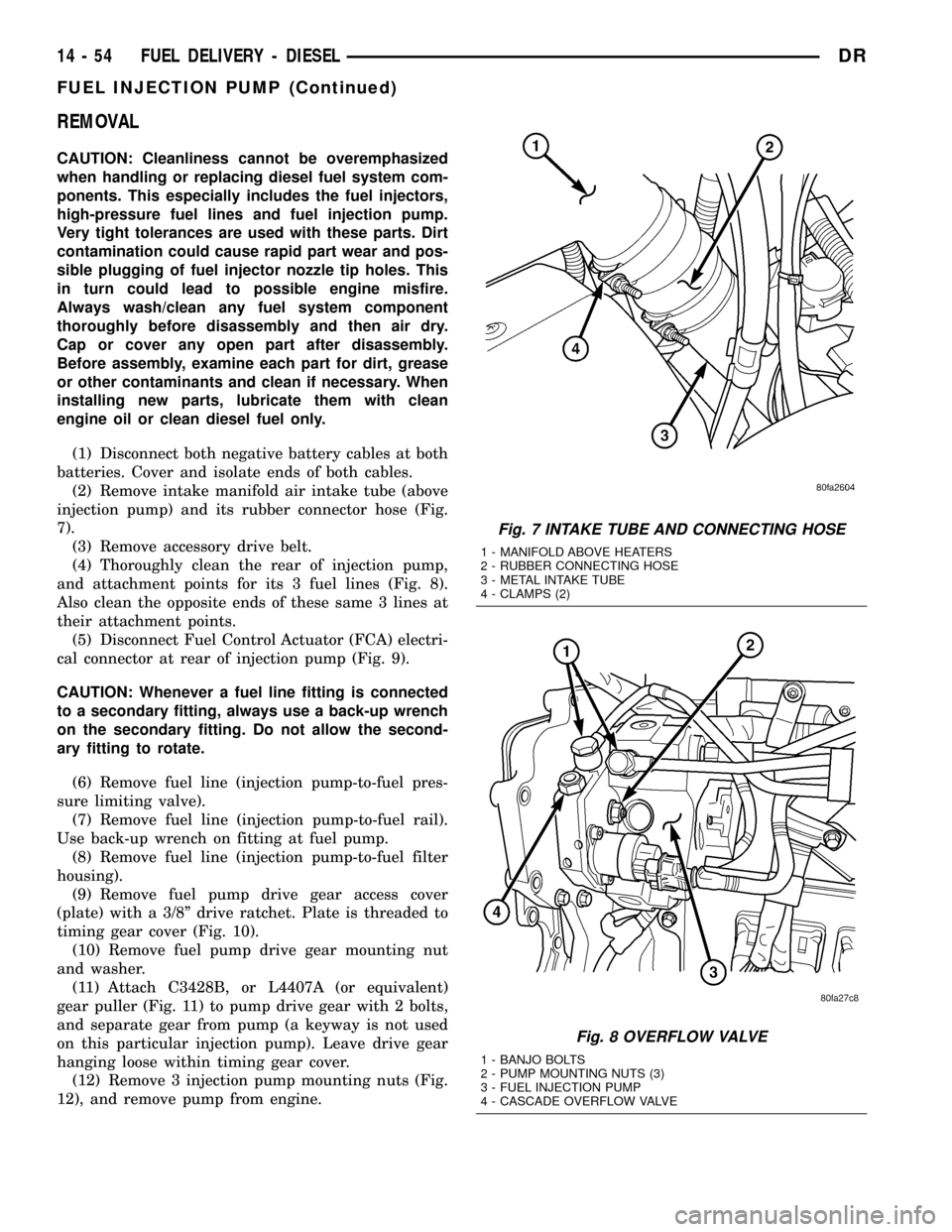

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 6). Refer to label under

PDC cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

FUEL INJECTION PUMP

DESCRIPTION

A Robert Bosch high-pressure fuel injection pump

is used. The pump is attached to the back of the tim-

ing gear cover at the left / rear side of the engine.

OPERATION

The fuel injection pump supplies high pressure to

the fuel rail independent of engine speed. This high

pressure is then accumulated in the fuel rail. High

pressure fuel is constantly supplied to the injectors

by the fuel rail. The Engine Control Module (ECM)

controls the fueling and timing of the engine by actu-

ating the injectors.

Fuel enters the system from the electric fuel trans-

fer (lift) pump, which is attached to the fuel filter

assembly. Fuel is forced through the fuel filter ele-

ment and then enters the Fuel Pump/Gear Pump,

which is attached to the rear of the fuel injection

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FCA based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail provides the actual fuel pressure. When the

actuator is opened, the maximum amount of fuel is

being supplied to the fuel injection pump. Any fuel

that does not enter the injection pump is directed to

the cascade overflow valve. The cascade overflow

valve regulates how much excess fuel is used for

lubrication of the pump and how much is returned to

the tank through the drain manifold.

Fuel entering the injection pump is pressurized to

between 300-1600 bar (4351-23206 psi) by three

radial pumping chambers. The pressurized fuel is

then supplied to the fuel rail.

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING

With the Bosch injection pump, there are no

mechanical adjustments needed or necessary to

accomplish fuel injection timing. All timing and fuel

adjustments are electrically made by the engine

mounted Engine Control Module (ECM).

Fig. 6 POWER DISTRIBUTION CENTER LOCATION

1 - CLIP

2 - BATTERY

3 - TRAY

4 - NEGATIVE CABLE

5 - POSITIVE CABLE

6 - CLIP

7 - FENDER INNER SHIELD

8 - POWER DISTRIBUTION CENTER

DRFUEL DELIVERY - DIESEL 14 - 53

FUEL HEATER RELAY (Continued)

Page 1623 of 2627

REMOVAL

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Disconnect both negative battery cables at both

batteries. Cover and isolate ends of both cables.

(2) Remove intake manifold air intake tube (above

injection pump) and its rubber connector hose (Fig.

7).

(3) Remove accessory drive belt.

(4) Thoroughly clean the rear of injection pump,

and attachment points for its 3 fuel lines (Fig. 8).

Also clean the opposite ends of these same 3 lines at

their attachment points.

(5) Disconnect Fuel Control Actuator (FCA) electri-

cal connector at rear of injection pump (Fig. 9).

CAUTION: Whenever a fuel line fitting is connected

to a secondary fitting, always use a back-up wrench

on the secondary fitting. Do not allow the second-

ary fitting to rotate.

(6) Remove fuel line (injection pump-to-fuel pres-

sure limiting valve).

(7) Remove fuel line (injection pump-to-fuel rail).

Use back-up wrench on fitting at fuel pump.

(8) Remove fuel line (injection pump-to-fuel filter

housing).

(9) Remove fuel pump drive gear access cover

(plate) with a 3/8º drive ratchet. Plate is threaded to

timing gear cover (Fig. 10).

(10) Remove fuel pump drive gear mounting nut

and washer.

(11) Attach C3428B, or L4407A (or equivalent)

gear puller (Fig. 11) to pump drive gear with 2 bolts,

and separate gear from pump (a keyway is not used

on this particular injection pump). Leave drive gear

hanging loose within timing gear cover.

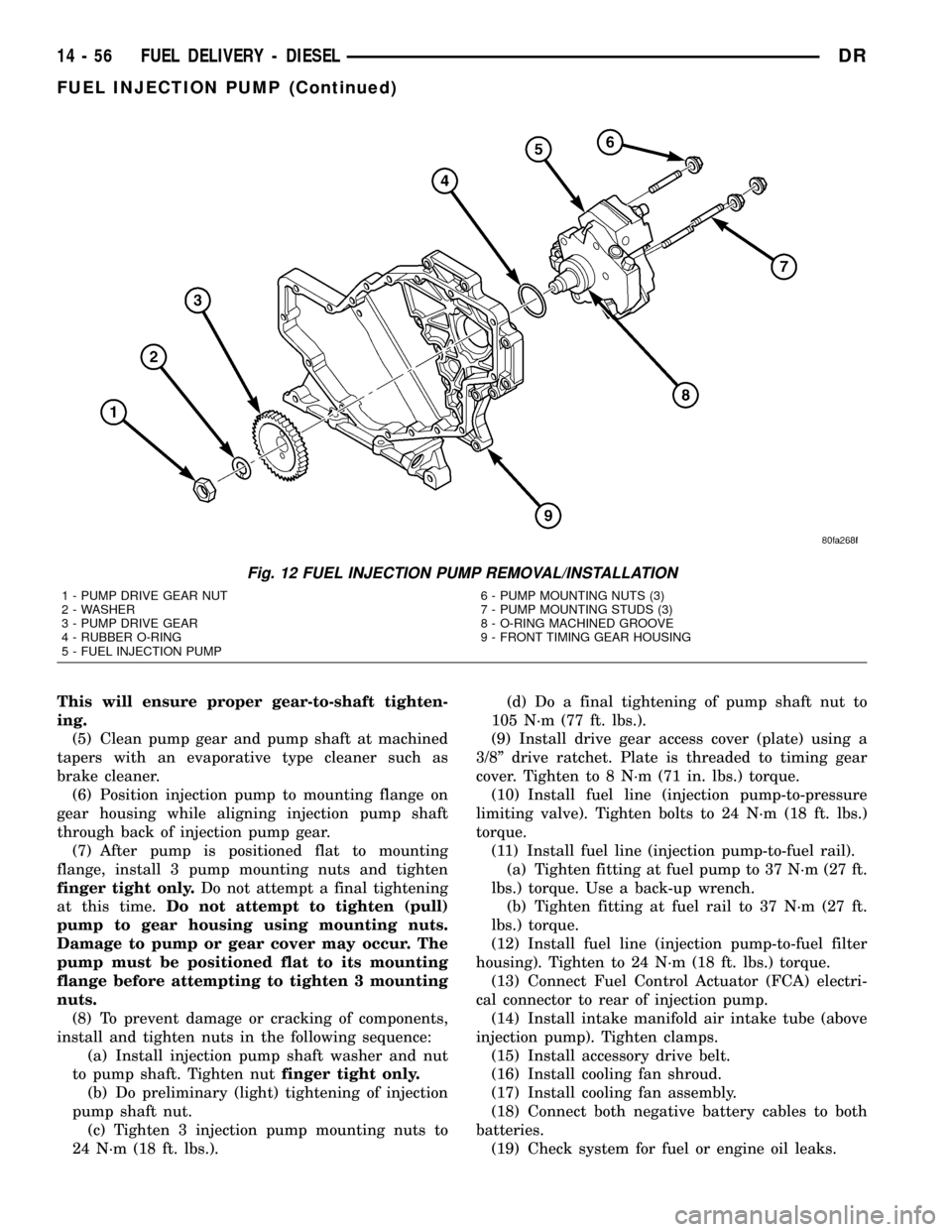

(12) Remove 3 injection pump mounting nuts (Fig.

12), and remove pump from engine.

Fig. 7 INTAKE TUBE AND CONNECTING HOSE

1 - MANIFOLD ABOVE HEATERS

2 - RUBBER CONNECTING HOSE

3 - METAL INTAKE TUBE

4 - CLAMPS (2)

Fig. 8 OVERFLOW VALVE

1 - BANJO BOLTS

2 - PUMP MOUNTING NUTS (3)

3 - FUEL INJECTION PUMP

4 - CASCADE OVERFLOW VALVE

14 - 54 FUEL DELIVERY - DIESELDR

FUEL INJECTION PUMP (Continued)

Page 1625 of 2627

This will ensure proper gear-to-shaft tighten-

ing.

(5) Clean pump gear and pump shaft at machined

tapers with an evaporative type cleaner such as

brake cleaner.

(6) Position injection pump to mounting flange on

gear housing while aligning injection pump shaft

through back of injection pump gear.

(7) After pump is positioned flat to mounting

flange, install 3 pump mounting nuts and tighten

finger tight only.Do not attempt a final tightening

at this time.Do not attempt to tighten (pull)

pump to gear housing using mounting nuts.

Damage to pump or gear cover may occur. The

pump must be positioned flat to its mounting

flange before attempting to tighten 3 mounting

nuts.

(8) To prevent damage or cracking of components,

install and tighten nuts in the following sequence:

(a) Install injection pump shaft washer and nut

to pump shaft. Tighten nutfinger tight only.

(b) Do preliminary (light) tightening of injection

pump shaft nut.

(c) Tighten 3 injection pump mounting nuts to

24 N´m (18 ft. lbs.).(d) Do a final tightening of pump shaft nut to

105 N´m (77 ft. lbs.).

(9) Install drive gear access cover (plate) using a

3/8º drive ratchet. Plate is threaded to timing gear

cover. Tighten to 8 N´m (71 in. lbs.) torque.

(10) Install fuel line (injection pump-to-pressure

limiting valve). Tighten bolts to 24 N´m (18 ft. lbs.)

torque.

(11) Install fuel line (injection pump-to-fuel rail).

(a) Tighten fitting at fuel pump to 37 N´m (27 ft.

lbs.) torque. Use a back-up wrench.

(b) Tighten fitting at fuel rail to 37 N´m (27 ft.

lbs.) torque.

(12) Install fuel line (injection pump-to-fuel filter

housing). Tighten to 24 N´m (18 ft. lbs.) torque.

(13) Connect Fuel Control Actuator (FCA) electri-

cal connector to rear of injection pump.

(14) Install intake manifold air intake tube (above

injection pump). Tighten clamps.

(15) Install accessory drive belt.

(16) Install cooling fan shroud.

(17) Install cooling fan assembly.

(18) Connect both negative battery cables to both

batteries.

(19) Check system for fuel or engine oil leaks.

Fig. 12 FUEL INJECTION PUMP REMOVAL/INSTALLATION

1 - PUMP DRIVE GEAR NUT

2 - WASHER

3 - PUMP DRIVE GEAR

4 - RUBBER O-RING

5 - FUEL INJECTION PUMP6 - PUMP MOUNTING NUTS (3)

7 - PUMP MOUNTING STUDS (3)

8 - O-RING MACHINED GROOVE

9 - FRONT TIMING GEAR HOUSING

14 - 56 FUEL DELIVERY - DIESELDR

FUEL INJECTION PUMP (Continued)

Page 1630 of 2627

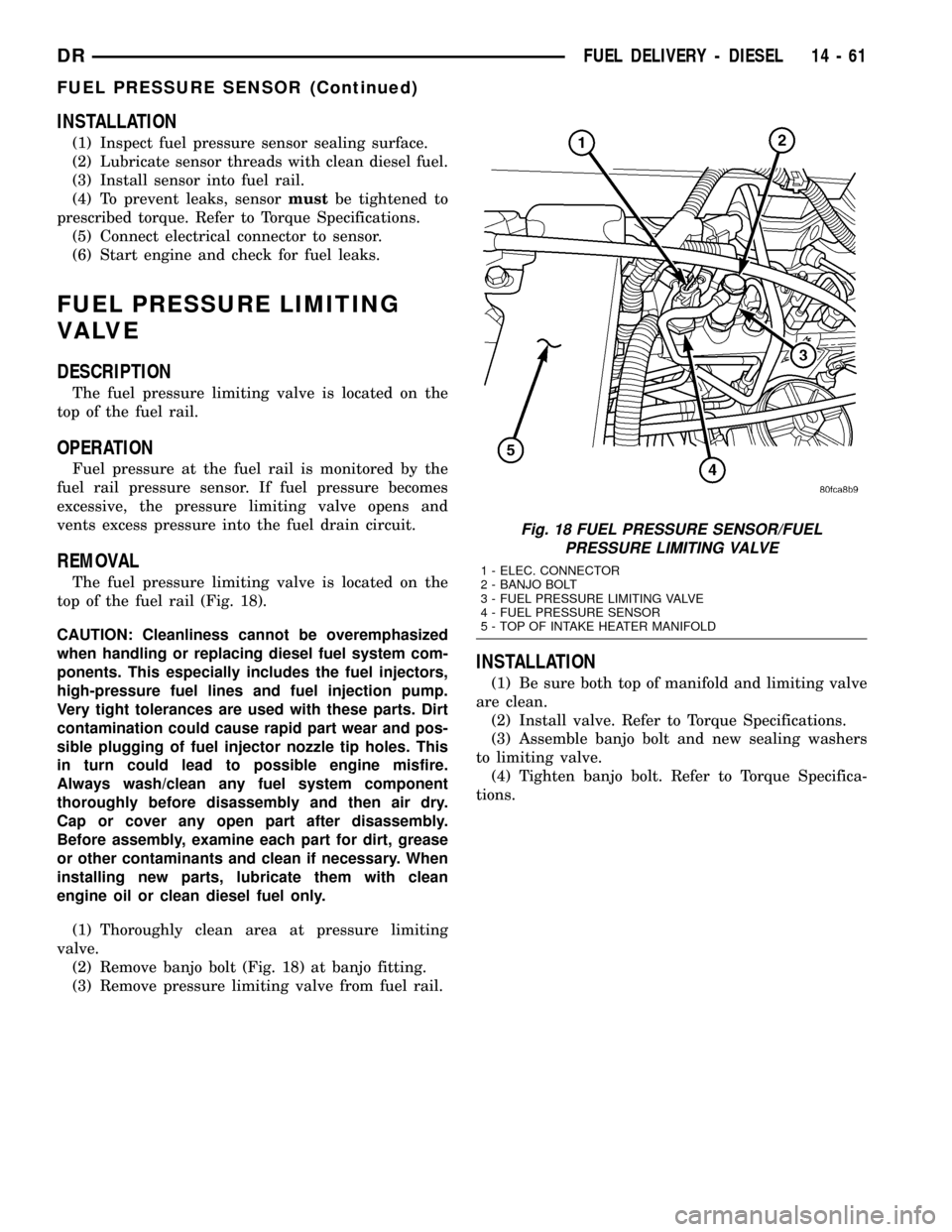

INSTALLATION

(1) Inspect fuel pressure sensor sealing surface.

(2) Lubricate sensor threads with clean diesel fuel.

(3) Install sensor into fuel rail.

(4) To prevent leaks, sensormustbe tightened to

prescribed torque. Refer to Torque Specifications.

(5) Connect electrical connector to sensor.

(6) Start engine and check for fuel leaks.

FUEL PRESSURE LIMITING

VA LV E

DESCRIPTION

The fuel pressure limiting valve is located on the

top of the fuel rail.

OPERATION

Fuel pressure at the fuel rail is monitored by the

fuel rail pressure sensor. If fuel pressure becomes

excessive, the pressure limiting valve opens and

vents excess pressure into the fuel drain circuit.

REMOVAL

The fuel pressure limiting valve is located on the

top of the fuel rail (Fig. 18).

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Thoroughly clean area at pressure limiting

valve.

(2) Remove banjo bolt (Fig. 18) at banjo fitting.

(3) Remove pressure limiting valve from fuel rail.

INSTALLATION

(1) Be sure both top of manifold and limiting valve

are clean.

(2) Install valve. Refer to Torque Specifications.

(3) Assemble banjo bolt and new sealing washers

to limiting valve.

(4) Tighten banjo bolt. Refer to Torque Specifica-

tions.

Fig. 18 FUEL PRESSURE SENSOR/FUEL

PRESSURE LIMITING VALVE

1 - ELEC. CONNECTOR

2 - BANJO BOLT

3 - FUEL PRESSURE LIMITING VALVE

4 - FUEL PRESSURE SENSOR

5 - TOP OF INTAKE HEATER MANIFOLD

DRFUEL DELIVERY - DIESEL 14 - 61

FUEL PRESSURE SENSOR (Continued)

Page 1644 of 2627

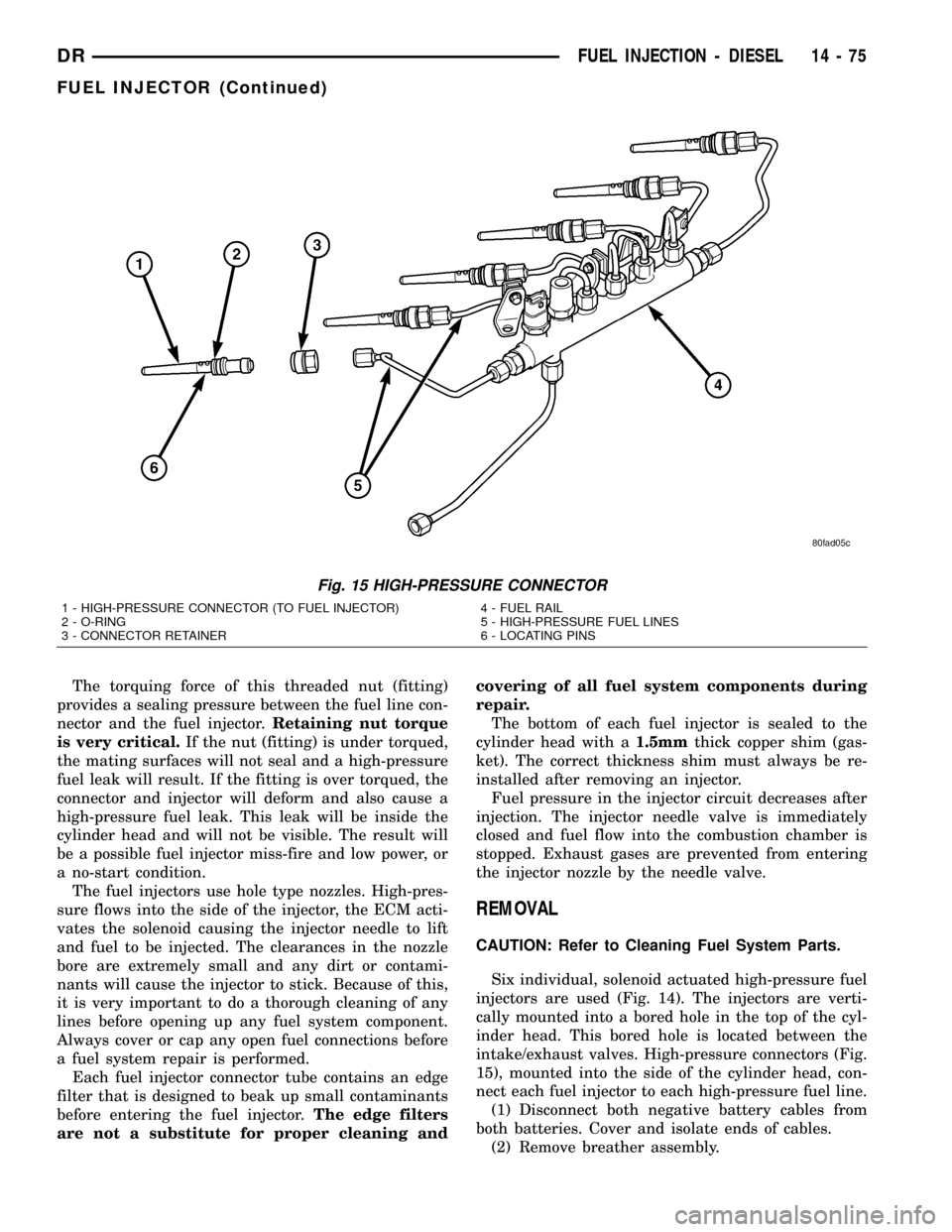

The torquing force of this threaded nut (fitting)

provides a sealing pressure between the fuel line con-

nector and the fuel injector.Retaining nut torque

is very critical.If the nut (fitting) is under torqued,

the mating surfaces will not seal and a high-pressure

fuel leak will result. If the fitting is over torqued, the

connector and injector will deform and also cause a

high-pressure fuel leak. This leak will be inside the

cylinder head and will not be visible. The result will

be a possible fuel injector miss-fire and low power, or

a no-start condition.

The fuel injectors use hole type nozzles. High-pres-

sure flows into the side of the injector, the ECM acti-

vates the solenoid causing the injector needle to lift

and fuel to be injected. The clearances in the nozzle

bore are extremely small and any dirt or contami-

nants will cause the injector to stick. Because of this,

it is very important to do a thorough cleaning of any

lines before opening up any fuel system component.

Always cover or cap any open fuel connections before

a fuel system repair is performed.

Each fuel injector connector tube contains an edge

filter that is designed to beak up small contaminants

before entering the fuel injector.The edge filters

are not a substitute for proper cleaning andcovering of all fuel system components during

repair.

The bottom of each fuel injector is sealed to the

cylinder head with a1.5mmthick copper shim (gas-

ket). The correct thickness shim must always be re-

installed after removing an injector.

Fuel pressure in the injector circuit decreases after

injection. The injector needle valve is immediately

closed and fuel flow into the combustion chamber is

stopped. Exhaust gases are prevented from entering

the injector nozzle by the needle valve.

REMOVAL

CAUTION: Refer to Cleaning Fuel System Parts.

Six individual, solenoid actuated high-pressure fuel

injectors are used (Fig. 14). The injectors are verti-

cally mounted into a bored hole in the top of the cyl-

inder head. This bored hole is located between the

intake/exhaust valves. High-pressure connectors (Fig.

15), mounted into the side of the cylinder head, con-

nect each fuel injector to each high-pressure fuel line.

(1) Disconnect both negative battery cables from

both batteries. Cover and isolate ends of cables.

(2) Remove breather assembly.

Fig. 15 HIGH-PRESSURE CONNECTOR

1 - HIGH-PRESSURE CONNECTOR (TO FUEL INJECTOR)

2 - O-RING

3 - CONNECTOR RETAINER4 - FUEL RAIL

5 - HIGH-PRESSURE FUEL LINES

6 - LOCATING PINS

DRFUEL INJECTION - DIESEL 14 - 75

FUEL INJECTOR (Continued)