steering DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 641 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

NOTE: Before starting this procedure, be certain

that the front wheels are still in the straight-ahead

position.

(1) While holding the centered clockspring rotor

and case stationary in relation to each other, care-

fully slide the clockspring down over the steering col-

umn upper shaft.

(2) Align and seat the hole in the locating tab at

the eleven o'clock position on the clockspring case

over the locating pin on the multi-function switch

mounting housing (Fig. 20).

(3) Install and tighten the two screws that secure

the clockspring to the multi-function switch mount-

ing housing. Tighten the screws to 2 N´m (20 in.

lbs.).

(4) Reconnect the two instrument panel wire har-

ness connectors for the clockspring to the two connec-

tor receptacles below the steering column on the back

of the clockspring housing.

(5) Position the lower shroud onto the steering col-

umn.

(6) From below the steering column, install and

tighten the one center screw that secures the lower

shroud to the steering column lock housing. Tighten

the screw to 2 N´m (20 in. lbs.).(7) Position the upper shroud onto the steering col-

umn. If the vehicle is equipped with an automatic

transmission, be certain to engage the gearshift lever

gap hider into the openings in the right side of the

upper and lower shrouds.

(8) Align the snap features on the upper shroud

with the receptacles on the lower shroud and apply

hand pressure to snap them together.

(9) From below the steering column, install and

tighten the two screws that secure the upper shroud

to the lower shroud. Tighten the screws to 2 N´m (20

in. lbs.).

(10) If the vehicle is equipped with the optional tilt

steering column, align the steering column tilt knob

with the tilt adjuster mechanism lever located on the

left side of the column just below the multi-function

switch control stalk and, using hand pressure, push

the knob firmly onto the lever.

(11) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(12) If a new clockspring has been installed,

remove the plastic locking pin that is securing the

clockspring rotor to the clockspring case to maintain

clockspring centering.

NOTE: When reinstalling the steering wheel, be cer-

tain to index the yellow rubber booted engagement

dowel on the upper surface of the clockspring rotor

between the two fins cast into the lower surface of

the steering wheel armature hub.

(13) Reinstall the steering wheel onto the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - INSTALLATION).

(14) Reconnect the steering wheel wire harness

connectors to the upper clockspring connector recep-

tacles. Be certain that the steering wheel wire har-

ness is routed between the steering wheel back trim

cover and the steering wheel armature.

(15) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

8O - 22 RESTRAINTSDR

CLOCKSPRING (Continued)

Page 642 of 2627

DRIVER AIRBAG

DESCRIPTION

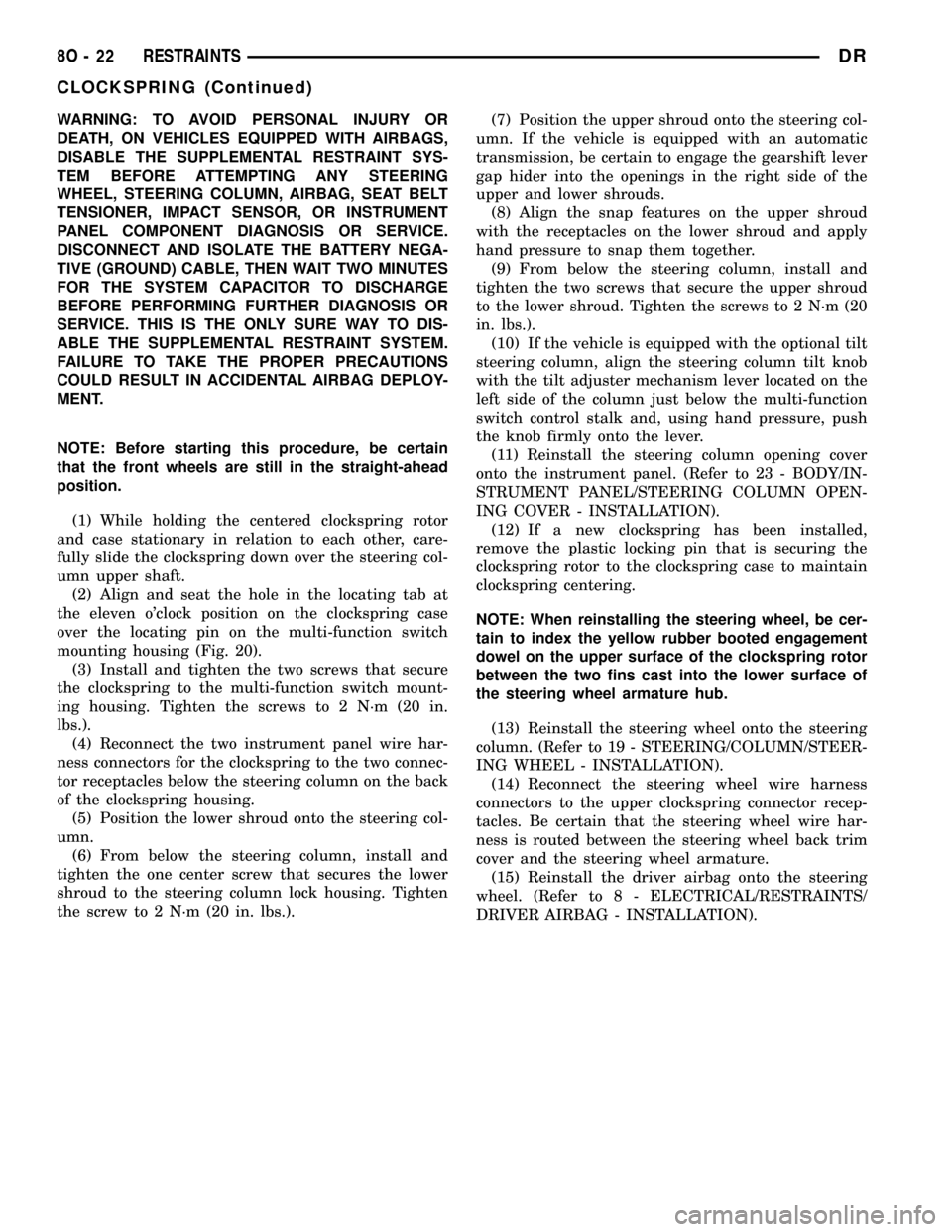

The color-keyed, injection molded, thermoplastic

driver airbag protective trim cover is the most visible

part of the driver airbag (Fig. 21). The driver airbag

is located in the center of the steering wheel, where

it is secured with two screws to the armature of the

four-spoke steering wheel. All models have a chrome

Dodge Ram emblem in the center of the trim cover.

Concealed beneath the driver airbag trim cover are

the horn switch, the folded airbag cushion, the airbag

cushion retainer, the airbag housing, the airbag infla-

tor, and the retainers that secure the inflator to the

airbag housing.

The airbag cushion, housing, and inflator are

secured within an integral receptacle molded into the

back of the trim cover. The four vertical walls of this

receptacle have a total of twelve small windows with

blocking tabs that are engaged by twelve hook forma-

tions around the perimeter of the airbag housing.

Each hook is inserted through one of the windows

and the blocking tab in each window keeps the hook

properly engaged with the trim cover, locking the

trim cover securely into place on the airbag housing.

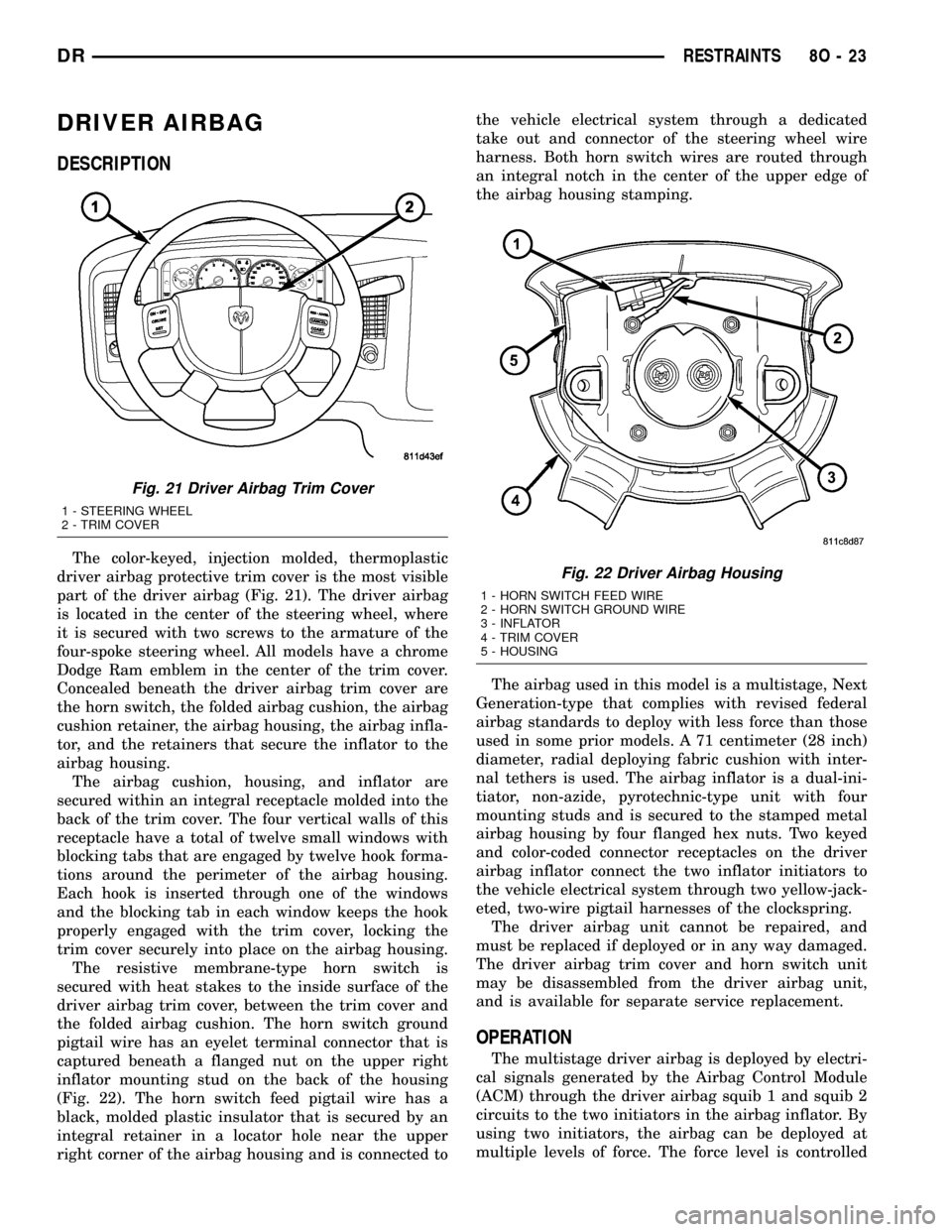

The resistive membrane-type horn switch is

secured with heat stakes to the inside surface of the

driver airbag trim cover, between the trim cover and

the folded airbag cushion. The horn switch ground

pigtail wire has an eyelet terminal connector that is

captured beneath a flanged nut on the upper right

inflator mounting stud on the back of the housing

(Fig. 22). The horn switch feed pigtail wire has a

black, molded plastic insulator that is secured by an

integral retainer in a locator hole near the upper

right corner of the airbag housing and is connected tothe vehicle electrical system through a dedicated

take out and connector of the steering wheel wire

harness. Both horn switch wires are routed through

an integral notch in the center of the upper edge of

the airbag housing stamping.

The airbag used in this model is a multistage, Next

Generation-type that complies with revised federal

airbag standards to deploy with less force than those

used in some prior models. A 71 centimeter (28 inch)

diameter, radial deploying fabric cushion with inter-

nal tethers is used. The airbag inflator is a dual-ini-

tiator, non-azide, pyrotechnic-type unit with four

mounting studs and is secured to the stamped metal

airbag housing by four flanged hex nuts. Two keyed

and color-coded connector receptacles on the driver

airbag inflator connect the two inflator initiators to

the vehicle electrical system through two yellow-jack-

eted, two-wire pigtail harnesses of the clockspring.

The driver airbag unit cannot be repaired, and

must be replaced if deployed or in any way damaged.

The driver airbag trim cover and horn switch unit

may be disassembled from the driver airbag unit,

and is available for separate service replacement.

OPERATION

The multistage driver airbag is deployed by electri-

cal signals generated by the Airbag Control Module

(ACM) through the driver airbag squib 1 and squib 2

circuits to the two initiators in the airbag inflator. By

using two initiators, the airbag can be deployed at

multiple levels of force. The force level is controlled

Fig. 21 Driver Airbag Trim Cover

1 - STEERING WHEEL

2 - TRIM COVER

Fig. 22 Driver Airbag Housing

1 - HORN SWITCH FEED WIRE

2 - HORN SWITCH GROUND WIRE

3 - INFLATOR

4 - TRIM COVER

5 - HOUSING

DRRESTRAINTS 8O - 23

Page 643 of 2627

by the ACM to suit the monitored impact conditions

by providing one of three delay intervals between the

electrical signals provided to the two initiators. The

longer the delay between these signals, the less force-

fully the airbag will deploy.

When the ACM sends the proper electrical signals

to each initiator, the electrical energy generates

enough heat to initiate a small pyrotechnic charge

which, in turn ignites chemical pellets within the

inflator. Once ignited, these chemical pellets burn

rapidly and produce a large quantity of inert gas.

The inflator is sealed to the back of the airbag hous-

ing and a diffuser in the inflator directs all of the

inert gas into the airbag cushion, causing the cushion

to inflate. As the cushion inflates, the driver airbag

trim cover will split at predetermined breakout lines,

then fold back out of the way along with the horn

switch unit. Following an airbag deployment, the air-

bag cushion quickly deflates by venting the inert gas

towards the instrument panel through vent holes

within the fabric used to construct the back (steering

wheel side) panel of the airbag cushion.

Some of the chemicals used to create the inert gas

may be considered hazardous while in their solid

state before they are burned, but they are securely

sealed within the airbag inflator. Typically, both ini-

tiators are used and all potentially hazardous chem-

icals are burned during an airbag deployment event.

However, it is possible for only one initiator to be

used during a deployment due to an airbag system

fault; therefore, it is necessary to always confirm

that both initiators have been used in order to avoid

the improper disposal of potentially live pyrotechnic

or hazardous materials. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - SER-

VICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT).

The inert gas that is produced when the chemicals

are burned is harmless. However, a small amount of

residue from the burned chemicals may cause some

temporary discomfort if it contacts the skin, eyes, or

breathing passages. If skin or eye irritation is noted,

rinse the affected area with plenty of cool, clean

water. If breathing passages are irritated, move to

another area where there is plenty of clean, fresh air

to breath. If the irritation is not alleviated by these

actions, contact a physician.

REMOVAL

The following procedure is for replacement of a

faulty or damaged driver airbag. If the airbag is

faulty or damaged, but not deployed, review the rec-

ommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTALRESTRAINTS). If the driver airbag has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, WHEN REMOVING A DEPLOYED AIRBAG,

RUBBER GLOVES, EYE PROTECTION, AND A

LONG-SLEEVED SHIRT SHOULD BE WORN. THERE

MAY BE DEPOSITS ON THE AIRBAG CUSHION AND

OTHER INTERIOR SURFACES. IN LARGE DOSES,

THESE DEPOSITS MAY CAUSE IRRITATION TO THE

SKIN AND EYES.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

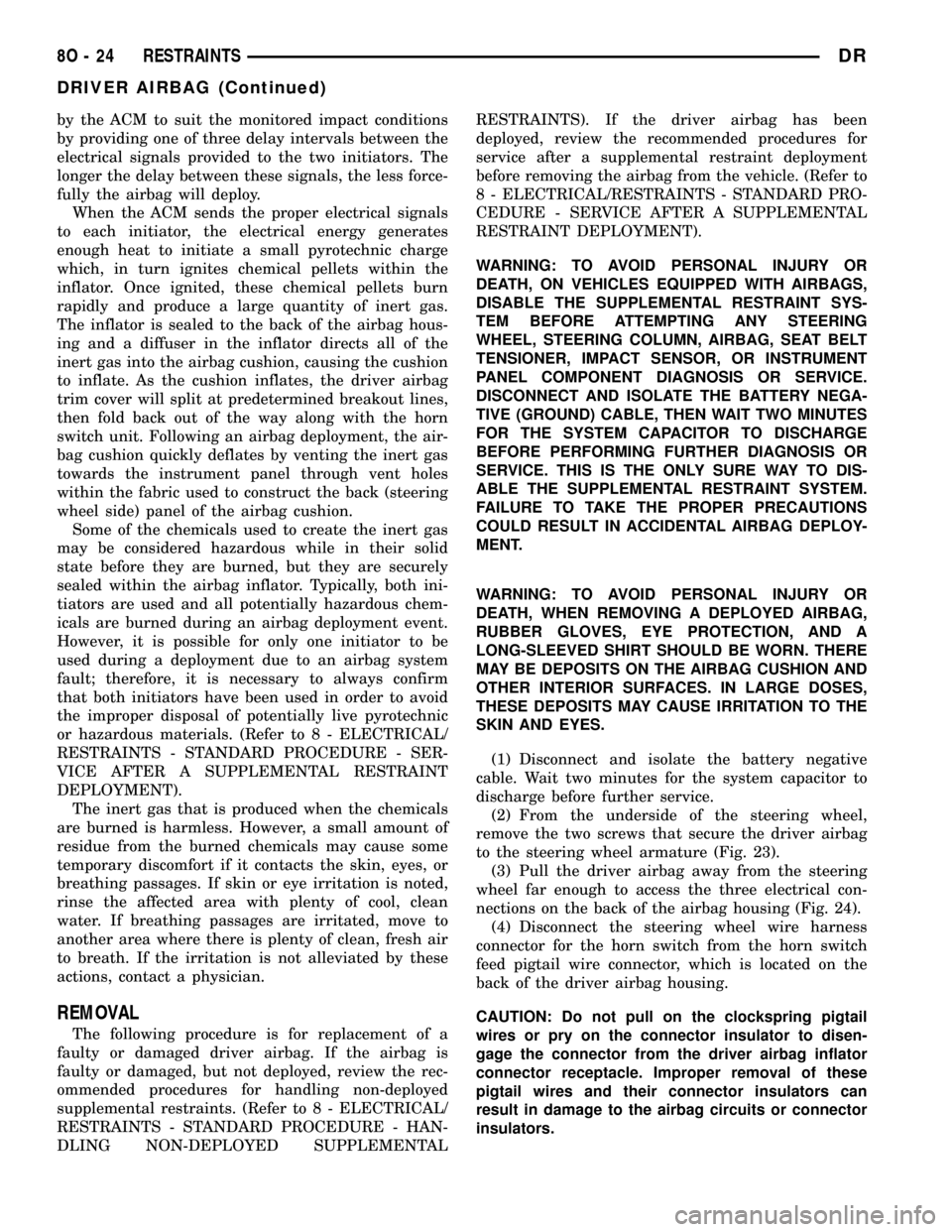

(2) From the underside of the steering wheel,

remove the two screws that secure the driver airbag

to the steering wheel armature (Fig. 23).

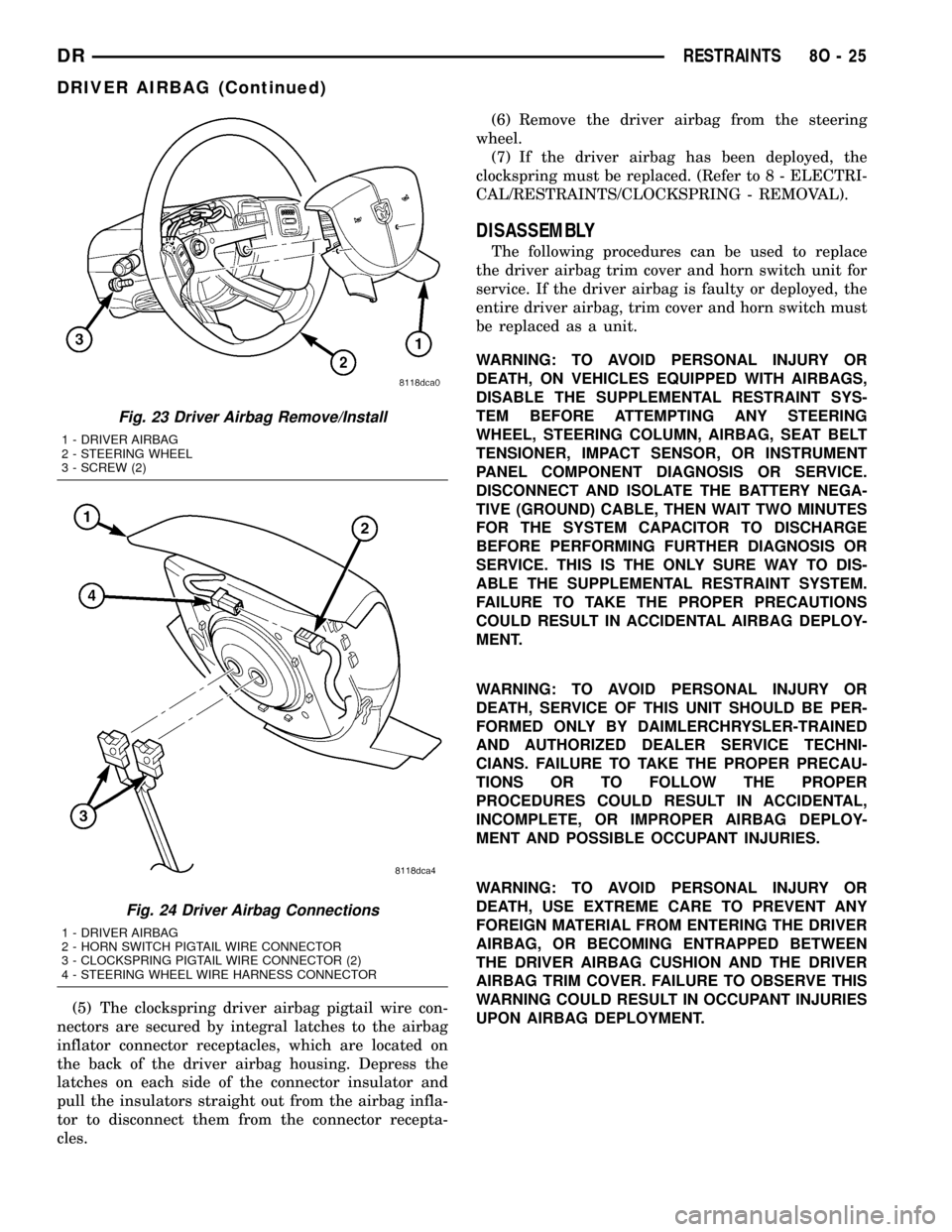

(3) Pull the driver airbag away from the steering

wheel far enough to access the three electrical con-

nections on the back of the airbag housing (Fig. 24).

(4) Disconnect the steering wheel wire harness

connector for the horn switch from the horn switch

feed pigtail wire connector, which is located on the

back of the driver airbag housing.

CAUTION: Do not pull on the clockspring pigtail

wires or pry on the connector insulator to disen-

gage the connector from the driver airbag inflator

connector receptacle. Improper removal of these

pigtail wires and their connector insulators can

result in damage to the airbag circuits or connector

insulators.

8O - 24 RESTRAINTSDR

DRIVER AIRBAG (Continued)

Page 644 of 2627

(5) The clockspring driver airbag pigtail wire con-

nectors are secured by integral latches to the airbag

inflator connector receptacles, which are located on

the back of the driver airbag housing. Depress the

latches on each side of the connector insulator and

pull the insulators straight out from the airbag infla-

tor to disconnect them from the connector recepta-

cles.(6) Remove the driver airbag from the steering

wheel.

(7) If the driver airbag has been deployed, the

clockspring must be replaced. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - REMOVAL).

DISASSEMBLY

The following procedures can be used to replace

the driver airbag trim cover and horn switch unit for

service. If the driver airbag is faulty or deployed, the

entire driver airbag, trim cover and horn switch must

be replaced as a unit.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, SERVICE OF THIS UNIT SHOULD BE PER-

FORMED ONLY BY DAIMLERCHRYSLER-TRAINED

AND AUTHORIZED DEALER SERVICE TECHNI-

CIANS. FAILURE TO TAKE THE PROPER PRECAU-

TIONS OR TO FOLLOW THE PROPER

PROCEDURES COULD RESULT IN ACCIDENTAL,

INCOMPLETE, OR IMPROPER AIRBAG DEPLOY-

MENT AND POSSIBLE OCCUPANT INJURIES.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE DRIVER

AIRBAG, OR BECOMING ENTRAPPED BETWEEN

THE DRIVER AIRBAG CUSHION AND THE DRIVER

AIRBAG TRIM COVER. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN OCCUPANT INJURIES

UPON AIRBAG DEPLOYMENT.

Fig. 23 Driver Airbag Remove/Install

1 - DRIVER AIRBAG

2 - STEERING WHEEL

3 - SCREW (2)

Fig. 24 Driver Airbag Connections

1 - DRIVER AIRBAG

2 - HORN SWITCH PIGTAIL WIRE CONNECTOR

3 - CLOCKSPRING PIGTAIL WIRE CONNECTOR (2)

4 - STEERING WHEEL WIRE HARNESS CONNECTOR

DRRESTRAINTS 8O - 25

DRIVER AIRBAG (Continued)

Page 645 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, THE DRIVER AIRBAG TRIM COVER MUST

NEVER BE PAINTED. REPLACEMENT TRIM COV-

ERS ARE SERVICED IN THE ORIGINAL COLORS.

PAINT MAY CHANGE THE WAY IN WHICH THE

MATERIAL OF THE TRIM COVER RESPONDS TO AN

AIRBAG DEPLOYMENT. FAILURE TO OBSERVE

THIS WARNING COULD RESULT IN OCCUPANT

INJURIES UPON AIRBAG DEPLOYMENT.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Remove the driver airbag from the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) Place the driver airbag on a suitable clean and

dry work surface with the trim cover facing down. If

the trim cover will be reused, be certain to take the

proper precautions to prevent the trim cover from

receiving cosmetic damage during the following pro-

cedures.

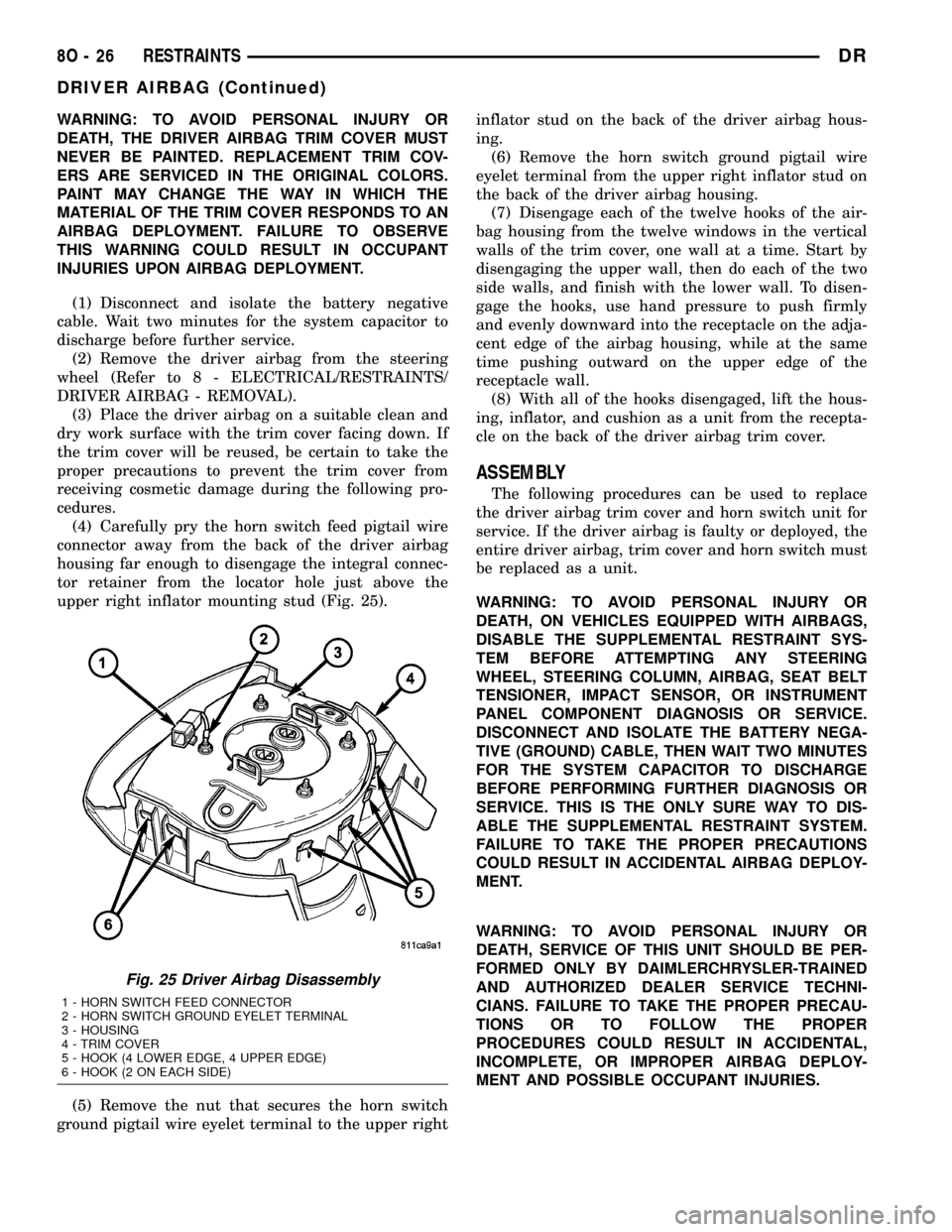

(4) Carefully pry the horn switch feed pigtail wire

connector away from the back of the driver airbag

housing far enough to disengage the integral connec-

tor retainer from the locator hole just above the

upper right inflator mounting stud (Fig. 25).

(5) Remove the nut that secures the horn switch

ground pigtail wire eyelet terminal to the upper rightinflator stud on the back of the driver airbag hous-

ing.

(6) Remove the horn switch ground pigtail wire

eyelet terminal from the upper right inflator stud on

the back of the driver airbag housing.

(7) Disengage each of the twelve hooks of the air-

bag housing from the twelve windows in the vertical

walls of the trim cover, one wall at a time. Start by

disengaging the upper wall, then do each of the two

side walls, and finish with the lower wall. To disen-

gage the hooks, use hand pressure to push firmly

and evenly downward into the receptacle on the adja-

cent edge of the airbag housing, while at the same

time pushing outward on the upper edge of the

receptacle wall.

(8) With all of the hooks disengaged, lift the hous-

ing, inflator, and cushion as a unit from the recepta-

cle on the back of the driver airbag trim cover.

ASSEMBLY

The following procedures can be used to replace

the driver airbag trim cover and horn switch unit for

service. If the driver airbag is faulty or deployed, the

entire driver airbag, trim cover and horn switch must

be replaced as a unit.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, SERVICE OF THIS UNIT SHOULD BE PER-

FORMED ONLY BY DAIMLERCHRYSLER-TRAINED

AND AUTHORIZED DEALER SERVICE TECHNI-

CIANS. FAILURE TO TAKE THE PROPER PRECAU-

TIONS OR TO FOLLOW THE PROPER

PROCEDURES COULD RESULT IN ACCIDENTAL,

INCOMPLETE, OR IMPROPER AIRBAG DEPLOY-

MENT AND POSSIBLE OCCUPANT INJURIES.

Fig. 25 Driver Airbag Disassembly

1 - HORN SWITCH FEED CONNECTOR

2 - HORN SWITCH GROUND EYELET TERMINAL

3 - HOUSING

4 - TRIM COVER

5 - HOOK (4 LOWER EDGE, 4 UPPER EDGE)

6 - HOOK (2 ON EACH SIDE)

8O - 26 RESTRAINTSDR

DRIVER AIRBAG (Continued)

Page 647 of 2627

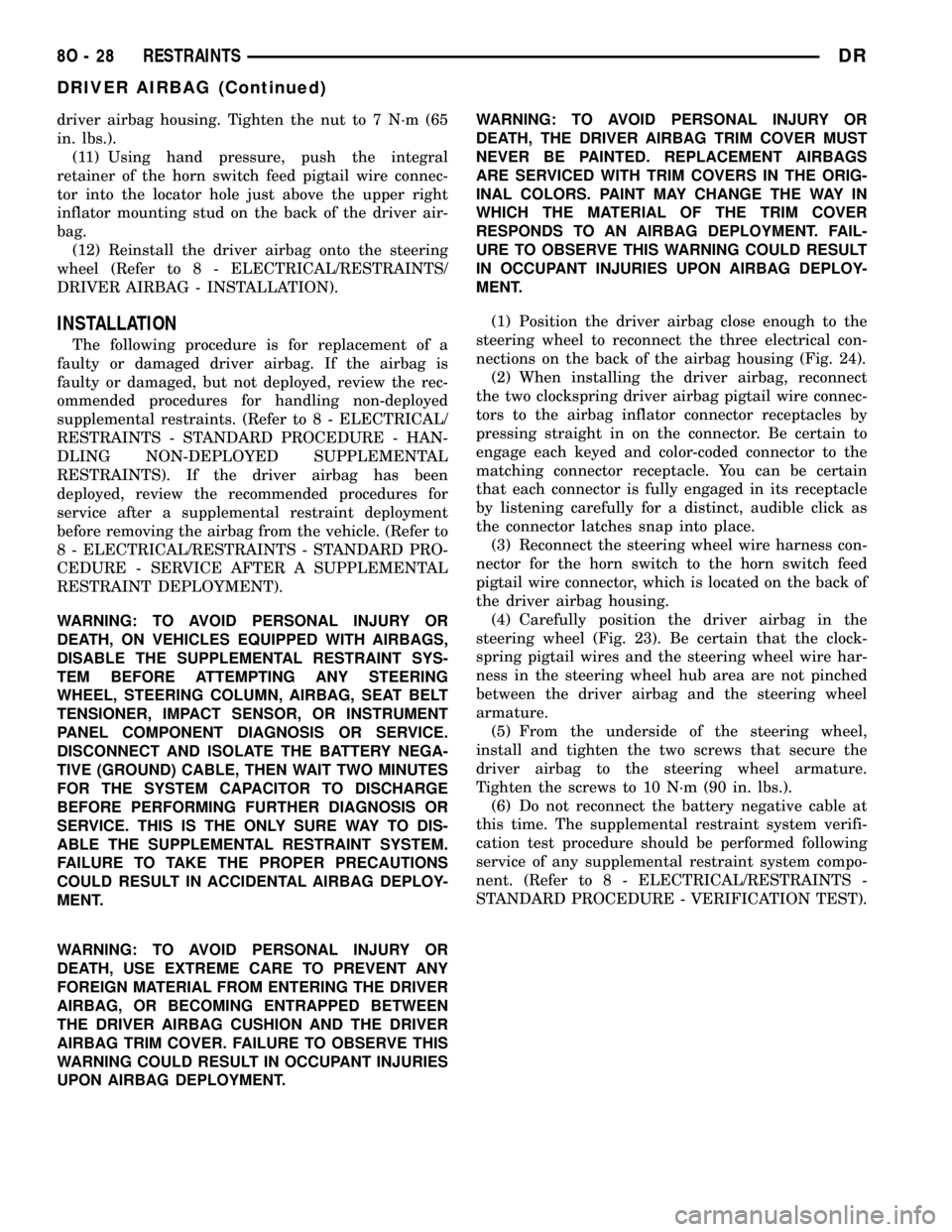

driver airbag housing. Tighten the nut to 7 N´m (65

in. lbs.).

(11) Using hand pressure, push the integral

retainer of the horn switch feed pigtail wire connec-

tor into the locator hole just above the upper right

inflator mounting stud on the back of the driver air-

bag.

(12) Reinstall the driver airbag onto the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

INSTALLATION

The following procedure is for replacement of a

faulty or damaged driver airbag. If the airbag is

faulty or damaged, but not deployed, review the rec-

ommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the driver airbag has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE DRIVER

AIRBAG, OR BECOMING ENTRAPPED BETWEEN

THE DRIVER AIRBAG CUSHION AND THE DRIVER

AIRBAG TRIM COVER. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN OCCUPANT INJURIES

UPON AIRBAG DEPLOYMENT.WARNING: TO AVOID PERSONAL INJURY OR

DEATH, THE DRIVER AIRBAG TRIM COVER MUST

NEVER BE PAINTED. REPLACEMENT AIRBAGS

ARE SERVICED WITH TRIM COVERS IN THE ORIG-

INAL COLORS. PAINT MAY CHANGE THE WAY IN

WHICH THE MATERIAL OF THE TRIM COVER

RESPONDS TO AN AIRBAG DEPLOYMENT. FAIL-

URE TO OBSERVE THIS WARNING COULD RESULT

IN OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Position the driver airbag close enough to the

steering wheel to reconnect the three electrical con-

nections on the back of the airbag housing (Fig. 24).

(2) When installing the driver airbag, reconnect

the two clockspring driver airbag pigtail wire connec-

tors to the airbag inflator connector receptacles by

pressing straight in on the connector. Be certain to

engage each keyed and color-coded connector to the

matching connector receptacle. You can be certain

that each connector is fully engaged in its receptacle

by listening carefully for a distinct, audible click as

the connector latches snap into place.

(3) Reconnect the steering wheel wire harness con-

nector for the horn switch to the horn switch feed

pigtail wire connector, which is located on the back of

the driver airbag housing.

(4) Carefully position the driver airbag in the

steering wheel (Fig. 23). Be certain that the clock-

spring pigtail wires and the steering wheel wire har-

ness in the steering wheel hub area are not pinched

between the driver airbag and the steering wheel

armature.

(5) From the underside of the steering wheel,

install and tighten the two screws that secure the

driver airbag to the steering wheel armature.

Tighten the screws to 10 N´m (90 in. lbs.).

(6) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

8O - 28 RESTRAINTSDR

DRIVER AIRBAG (Continued)

Page 651 of 2627

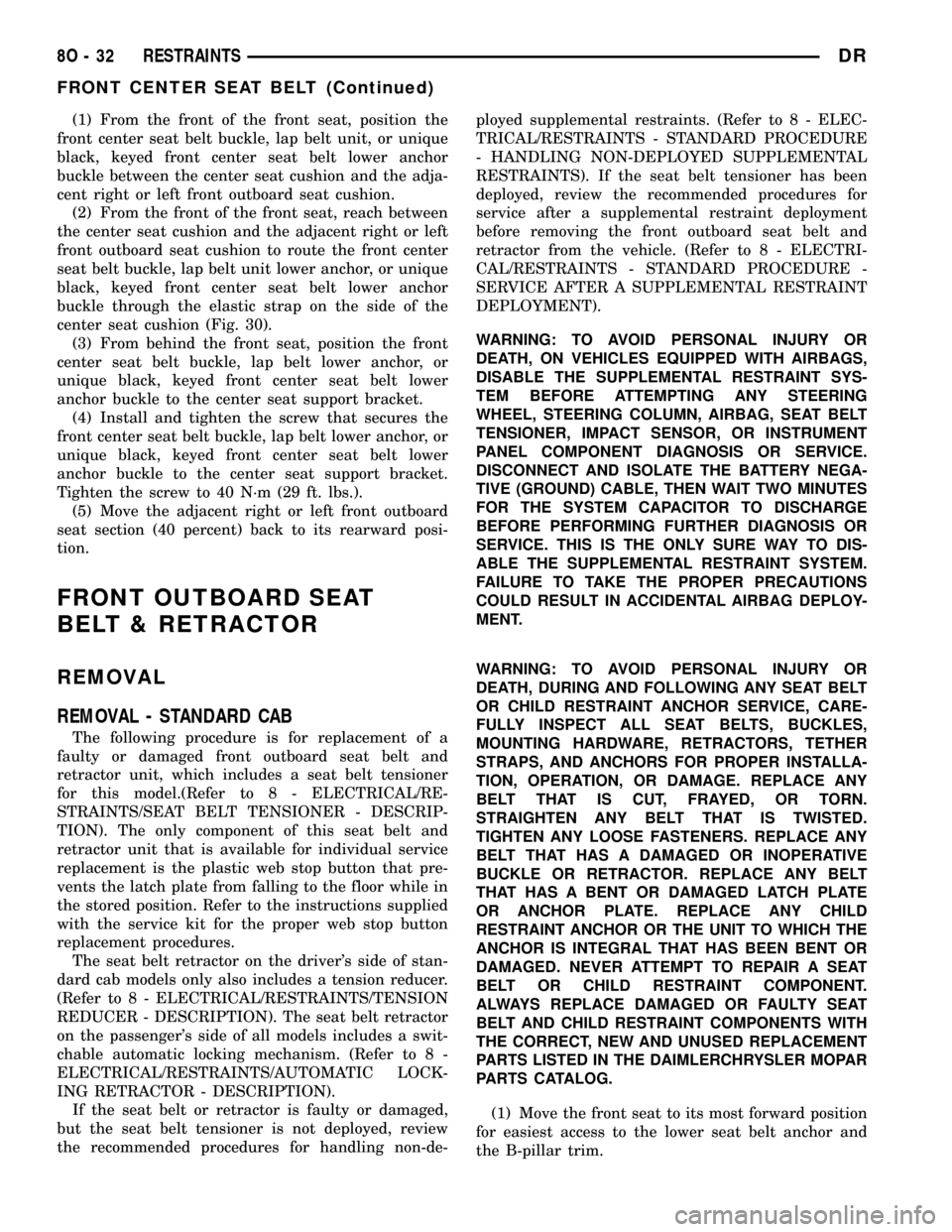

(1) From the front of the front seat, position the

front center seat belt buckle, lap belt unit, or unique

black, keyed front center seat belt lower anchor

buckle between the center seat cushion and the adja-

cent right or left front outboard seat cushion.

(2) From the front of the front seat, reach between

the center seat cushion and the adjacent right or left

front outboard seat cushion to route the front center

seat belt buckle, lap belt unit lower anchor, or unique

black, keyed front center seat belt lower anchor

buckle through the elastic strap on the side of the

center seat cushion (Fig. 30).

(3) From behind the front seat, position the front

center seat belt buckle, lap belt lower anchor, or

unique black, keyed front center seat belt lower

anchor buckle to the center seat support bracket.

(4) Install and tighten the screw that secures the

front center seat belt buckle, lap belt lower anchor, or

unique black, keyed front center seat belt lower

anchor buckle to the center seat support bracket.

Tighten the screw to 40 N´m (29 ft. lbs.).

(5) Move the adjacent right or left front outboard

seat section (40 percent) back to its rearward posi-

tion.

FRONT OUTBOARD SEAT

BELT & RETRACTOR

REMOVAL

REMOVAL - STANDARD CAB

The following procedure is for replacement of a

faulty or damaged front outboard seat belt and

retractor unit, which includes a seat belt tensioner

for this model.(Refer to 8 - ELECTRICAL/RE-

STRAINTS/SEAT BELT TENSIONER - DESCRIP-

TION). The only component of this seat belt and

retractor unit that is available for individual service

replacement is the plastic web stop button that pre-

vents the latch plate from falling to the floor while in

the stored position. Refer to the instructions supplied

with the service kit for the proper web stop button

replacement procedures.

The seat belt retractor on the driver's side of stan-

dard cab models only also includes a tension reducer.

(Refer to 8 - ELECTRICAL/RESTRAINTS/TENSION

REDUCER - DESCRIPTION). The seat belt retractor

on the passenger's side of all models includes a swit-

chable automatic locking mechanism. (Refer to 8 -

ELECTRICAL/RESTRAINTS/AUTOMATIC LOCK-

ING RETRACTOR - DESCRIPTION).

If the seat belt or retractor is faulty or damaged,

but the seat belt tensioner is not deployed, review

the recommended procedures for handling non-de-ployed supplemental restraints. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- HANDLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the seat belt tensioner has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the front outboard seat belt and

retractor from the vehicle. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

SERVICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Move the front seat to its most forward position

for easiest access to the lower seat belt anchor and

the B-pillar trim.

8O - 32 RESTRAINTSDR

FRONT CENTER SEAT BELT (Continued)

Page 653 of 2627

before removing the front outboard seat belt and

retractor from the vehicle. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

SERVICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

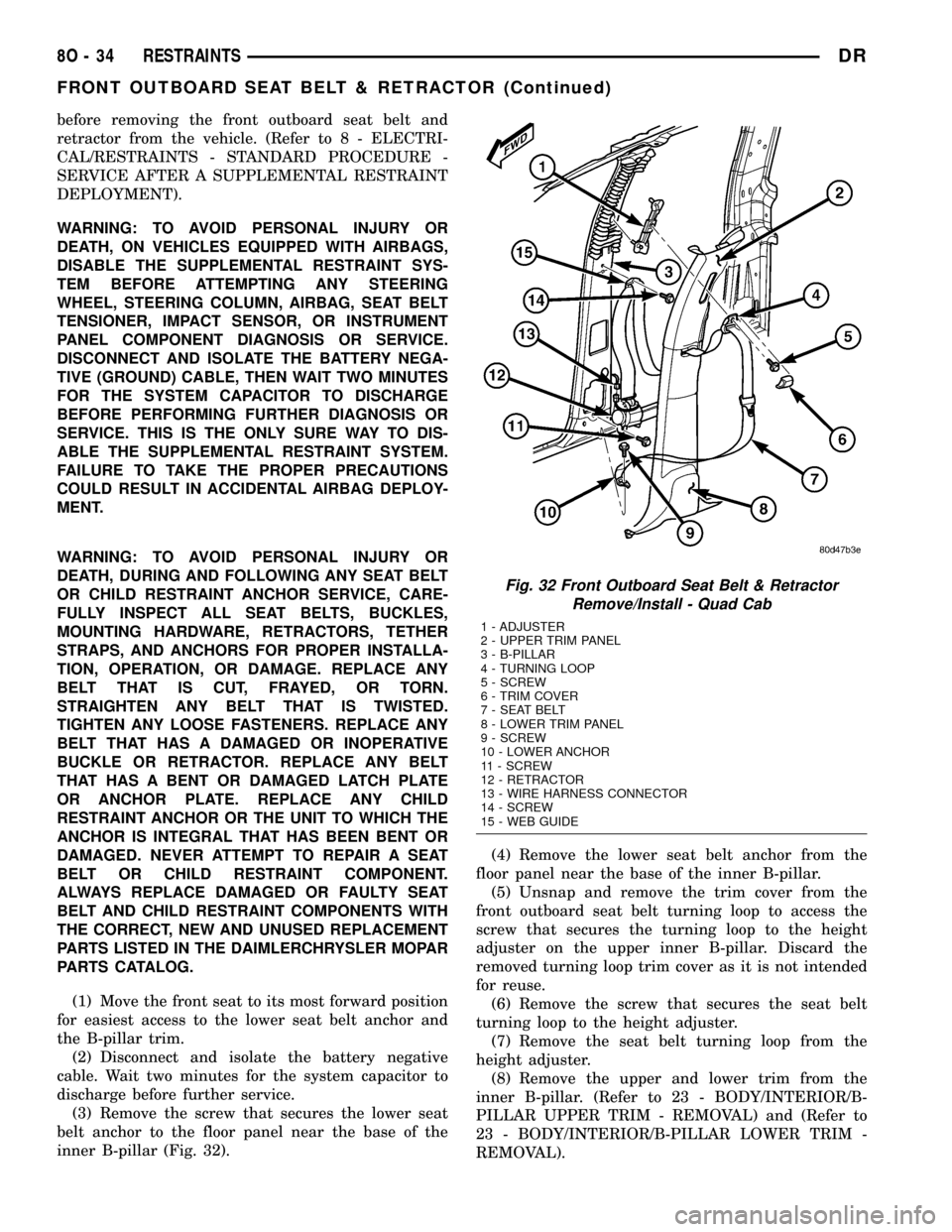

(1) Move the front seat to its most forward position

for easiest access to the lower seat belt anchor and

the B-pillar trim.

(2) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(3) Remove the screw that secures the lower seat

belt anchor to the floor panel near the base of the

inner B-pillar (Fig. 32).(4) Remove the lower seat belt anchor from the

floor panel near the base of the inner B-pillar.

(5) Unsnap and remove the trim cover from the

front outboard seat belt turning loop to access the

screw that secures the turning loop to the height

adjuster on the upper inner B-pillar. Discard the

removed turning loop trim cover as it is not intended

for reuse.

(6) Remove the screw that secures the seat belt

turning loop to the height adjuster.

(7) Remove the seat belt turning loop from the

height adjuster.

(8) Remove the upper and lower trim from the

inner B-pillar. (Refer to 23 - BODY/INTERIOR/B-

PILLAR UPPER TRIM - REMOVAL) and (Refer to

23 - BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL).

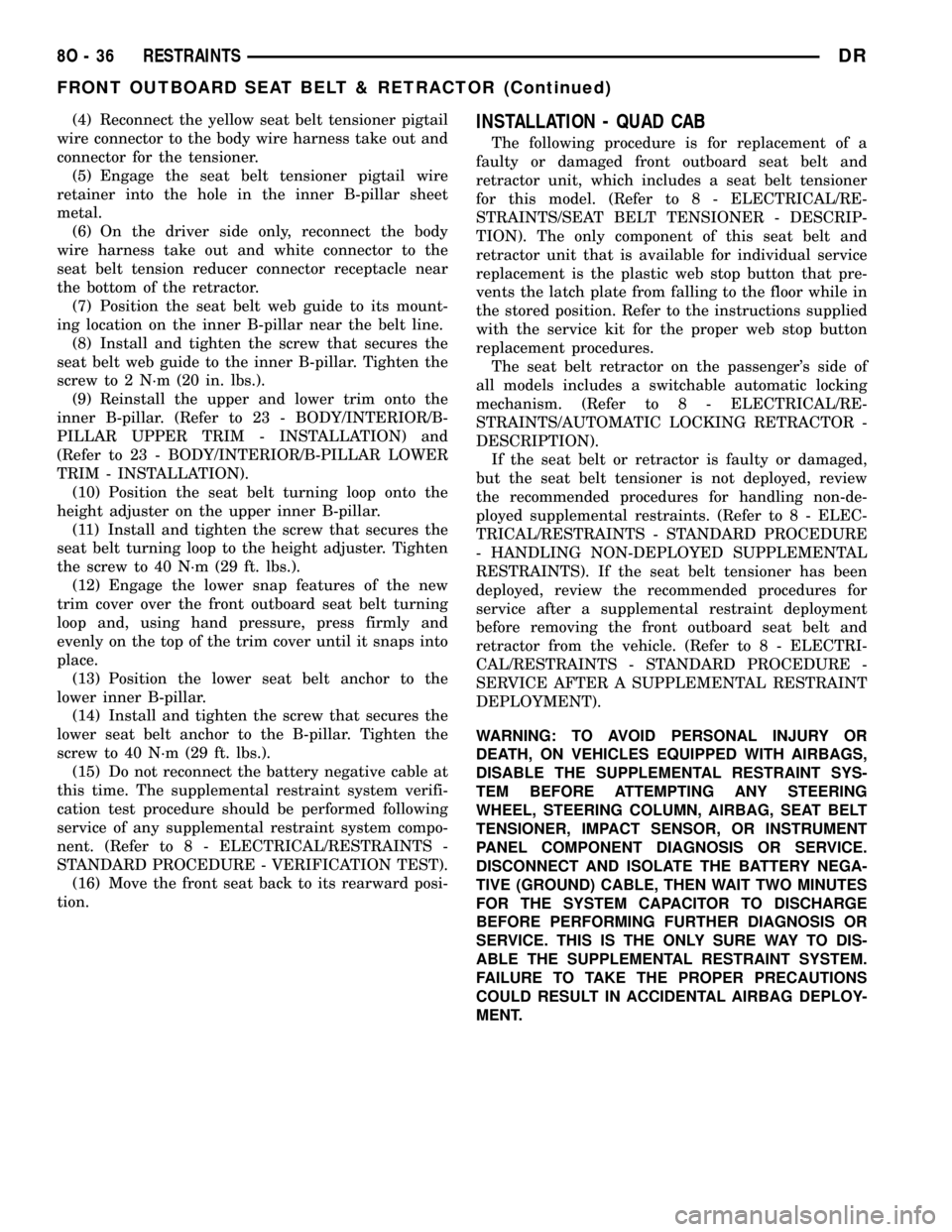

Fig. 32 Front Outboard Seat Belt & Retractor

Remove/Install - Quad Cab

1 - ADJUSTER

2 - UPPER TRIM PANEL

3 - B-PILLAR

4 - TURNING LOOP

5 - SCREW

6 - TRIM COVER

7 - SEAT BELT

8 - LOWER TRIM PANEL

9 - SCREW

10 - LOWER ANCHOR

11 - SCREW

12 - RETRACTOR

13 - WIRE HARNESS CONNECTOR

14 - SCREW

15 - WEB GUIDE

8O - 34 RESTRAINTSDR

FRONT OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 654 of 2627

(9) Remove the screw that secures the seat belt

web guide to the inner B-pillar near the belt line.

(10) Remove the seat belt web guide from the

inner B-pillar.

(11) Disengage the seat belt tensioner pigtail wire

retainer from the hole in the inner B-pillar sheet

metal.

(12) Disconnect the yellow seat belt tensioner pig-

tail wire connector from the body wire harness take

out and connector for the tensioner.

(13) Remove the screw that secures the lower

retractor bracket to the lower inner B-pillar below

the retractor mounting hole.

(14) Disengage the hooks on the upper retractor

bracket from the slots in the lower inner B-pillar

above the retractor mounting hole.

(15) Remove the front outboard seat belt and

retractor from the retractor mounting hole in the

lower inner B-pillar.

INSTALLATION

INSTALLATION - STANDARD CAB

The following procedure is for replacement of a

faulty or damaged front outboard seat belt and

retractor unit, which includes a seat belt tensioner

for this model. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/SEAT BELT TENSIONER - DESCRIP-

TION). The only component of this seat belt and

retractor unit that is available for individual service

replacement is the plastic web stop button that pre-

vents the latch plate from falling to the floor while in

the stored position. Refer to the instructions supplied

with the service kit for the proper web stop button

replacement procedures.

The seat belt retractor on the driver's side of stan-

dard cab models only also includes a tension reducer.

(Refer to 8 - ELECTRICAL/RESTRAINTS/TENSION

REDUCER - DESCRIPTION). The seat belt retractor

on the passenger's side of all models includes a swit-

chable automatic locking mechanism. (Refer to 8 -

ELECTRICAL/RESTRAINTS/AUTOMATIC LOCK-

ING RETRACTOR - DESCRIPTION).

If the seat belt or retractor is faulty or damaged,

but the seat belt tensioner is not deployed, review

the recommended procedures for handling non-de-

ployed supplemental restraints. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- HANDLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the seat belt tensioner has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the front outboard seat belt and

retractor from the vehicle. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -SERVICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Position the front outboard seat belt and

retractor to the retractor mounting hole in the lower

inner B-pillar (Fig. 31).

(2) Engage the hooks on the upper retractor

bracket into the slots in the lower inner B-pillar

above the retractor mounting hole.

(3) Install and tighten the screw that secures the

lower retractor bracket to the lower inner B-pillar

below the retractor mounting hole. Tighten the screw

to 40 N´m (29 ft. lbs.).

DRRESTRAINTS 8O - 35

FRONT OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 655 of 2627

(4) Reconnect the yellow seat belt tensioner pigtail

wire connector to the body wire harness take out and

connector for the tensioner.

(5) Engage the seat belt tensioner pigtail wire

retainer into the hole in the inner B-pillar sheet

metal.

(6) On the driver side only, reconnect the body

wire harness take out and white connector to the

seat belt tension reducer connector receptacle near

the bottom of the retractor.

(7) Position the seat belt web guide to its mount-

ing location on the inner B-pillar near the belt line.

(8) Install and tighten the screw that secures the

seat belt web guide to the inner B-pillar. Tighten the

screw to 2 N´m (20 in. lbs.).

(9) Reinstall the upper and lower trim onto the

inner B-pillar. (Refer to 23 - BODY/INTERIOR/B-

PILLAR UPPER TRIM - INSTALLATION) and

(Refer to 23 - BODY/INTERIOR/B-PILLAR LOWER

TRIM - INSTALLATION).

(10) Position the seat belt turning loop onto the

height adjuster on the upper inner B-pillar.

(11) Install and tighten the screw that secures the

seat belt turning loop to the height adjuster. Tighten

the screw to 40 N´m (29 ft. lbs.).

(12) Engage the lower snap features of the new

trim cover over the front outboard seat belt turning

loop and, using hand pressure, press firmly and

evenly on the top of the trim cover until it snaps into

place.

(13) Position the lower seat belt anchor to the

lower inner B-pillar.

(14) Install and tighten the screw that secures the

lower seat belt anchor to the B-pillar. Tighten the

screw to 40 N´m (29 ft. lbs.).

(15) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

(16) Move the front seat back to its rearward posi-

tion.INSTALLATION - QUAD CAB

The following procedure is for replacement of a

faulty or damaged front outboard seat belt and

retractor unit, which includes a seat belt tensioner

for this model. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/SEAT BELT TENSIONER - DESCRIP-

TION). The only component of this seat belt and

retractor unit that is available for individual service

replacement is the plastic web stop button that pre-

vents the latch plate from falling to the floor while in

the stored position. Refer to the instructions supplied

with the service kit for the proper web stop button

replacement procedures.

The seat belt retractor on the passenger's side of

all models includes a switchable automatic locking

mechanism. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/AUTOMATIC LOCKING RETRACTOR -

DESCRIPTION).

If the seat belt or retractor is faulty or damaged,

but the seat belt tensioner is not deployed, review

the recommended procedures for handling non-de-

ployed supplemental restraints. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- HANDLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the seat belt tensioner has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the front outboard seat belt and

retractor from the vehicle. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

SERVICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

8O - 36 RESTRAINTSDR

FRONT OUTBOARD SEAT BELT & RETRACTOR (Continued)