Body DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 734 of 2627

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

DR8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 735 of 2627

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

resistance in these circuits use a meter with a 10 -

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle's

electrical system can cause damage to the equip-

ment and provide false readings.

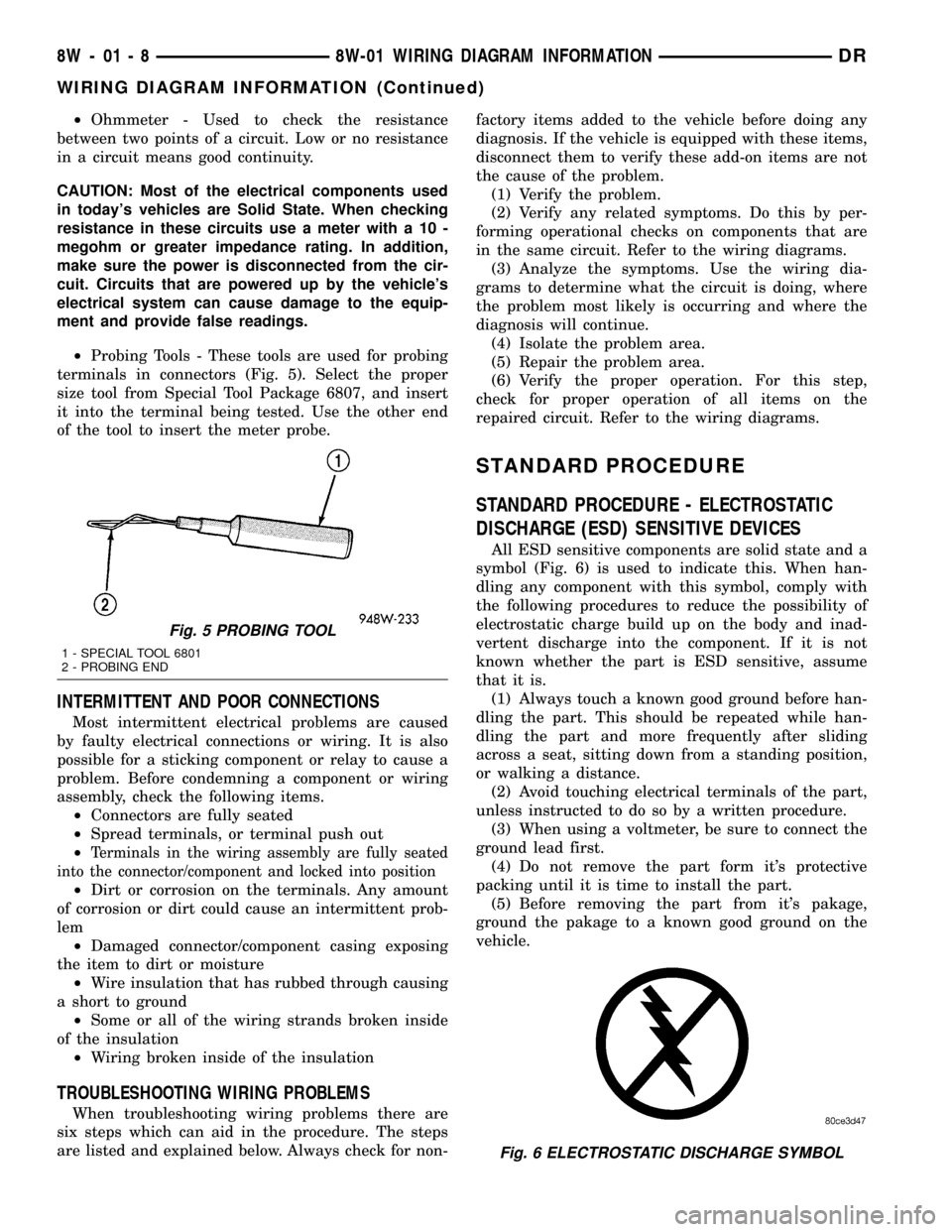

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 5). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly, check the following items.

²Connectors are fully seated

²Spread terminals, or terminal push out

²

Terminals in the wiring assembly are fully seated

into the connector/component and locked into position

²Dirt or corrosion on the terminals. Any amount

of corrosion or dirt could cause an intermittent prob-

lem

²Damaged connector/component casing exposing

the item to dirt or moisture

²Wire insulation that has rubbed through causing

a short to ground

²Some or all of the wiring strands broken inside

of the insulation

²Wiring broken inside of the insulation

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,

disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem area.

(6) Verify the proper operation. For this step,

check for proper operation of all items on the

repaired circuit. Refer to the wiring diagrams.

STANDARD PROCEDURE

STANDARD PROCEDURE - ELECTROSTATIC

DISCHARGE (ESD) SENSITIVE DEVICES

All ESD sensitive components are solid state and a

symbol (Fig. 6) is used to indicate this. When han-

dling any component with this symbol, comply with

the following procedures to reduce the possibility of

electrostatic charge build up on the body and inad-

vertent discharge into the component. If it is not

known whether the part is ESD sensitive, assume

that it is.

(1) Always touch a known good ground before han-

dling the part. This should be repeated while han-

dling the part and more frequently after sliding

across a seat, sitting down from a standing position,

or walking a distance.

(2) Avoid touching electrical terminals of the part,

unless instructed to do so by a written procedure.

(3) When using a voltmeter, be sure to connect the

ground lead first.

(4) Do not remove the part form it's protective

packing until it is time to install the part.

(5) Before removing the part from it's pakage,

ground the pakage to a known good ground on the

vehicle.

Fig. 5 PROBING TOOL

1 - SPECIAL TOOL 6801

2 - PROBING END

Fig. 6 ELECTROSTATIC DISCHARGE SYMBOL

8W - 01 - 8 8W-01 WIRING DIAGRAM INFORMATIONDR

WIRING DIAGRAM INFORMATION (Continued)

Page 1075 of 2627

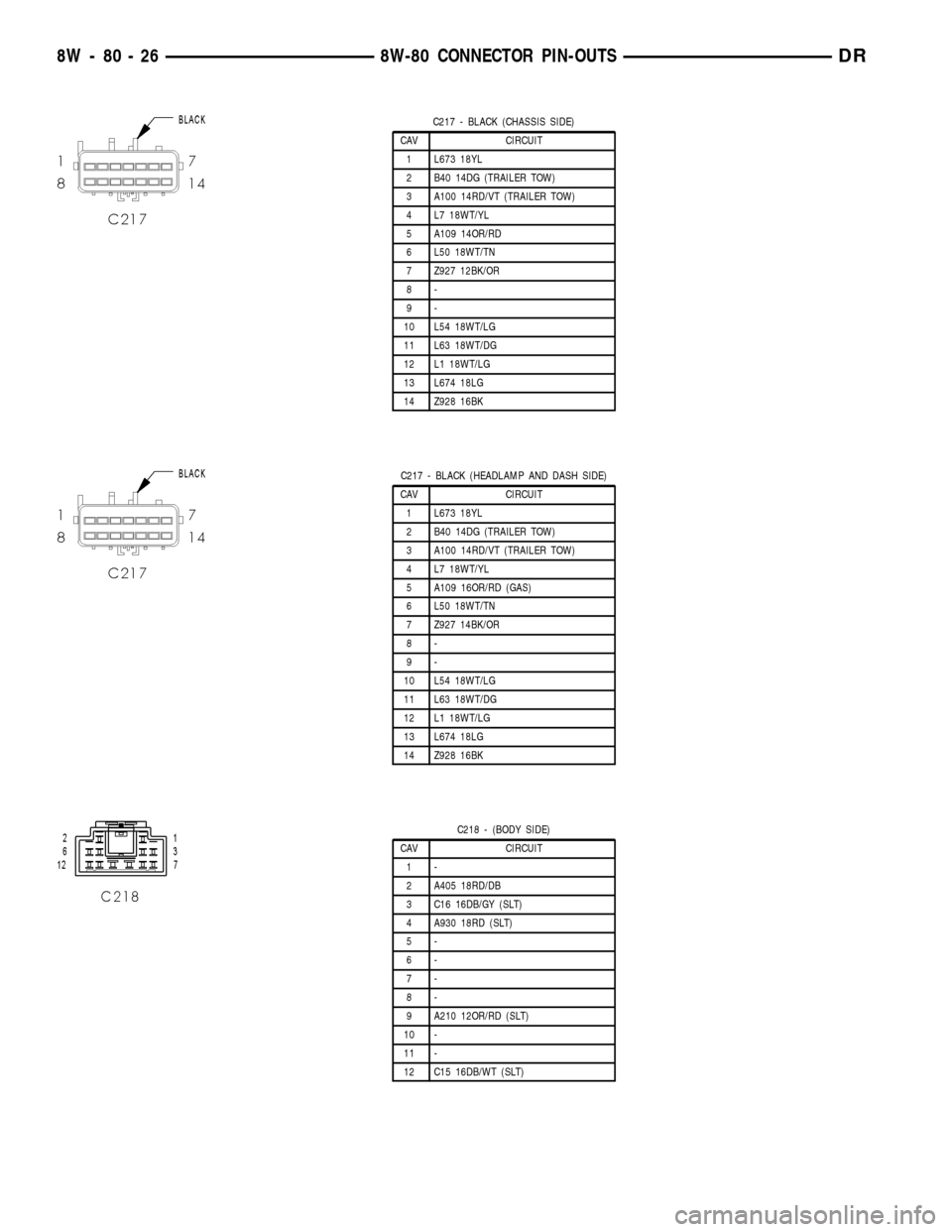

C217 - BLACK (CHASSIS SIDE)

CAV CIRCUIT

1 L673 18YL

2 B40 14DG (TRAILER TOW)

3 A100 14RD/VT (TRAILER TOW)

4 L7 18WT/YL

5 A109 14OR/RD

6 L50 18WT/TN

7 Z927 12BK/OR

8-

9-

10 L54 18WT/LG

11 L63 18WT/DG

12 L1 18WT/LG

13 L674 18LG

14 Z928 16BK

C217 - BLACK (HEADLAMP AND DASH SIDE)

CAV CIRCUIT

1 L673 18YL

2 B40 14DG (TRAILER TOW)

3 A100 14RD/VT (TRAILER TOW)

4 L7 18WT/YL

5 A109 16OR/RD (GAS)

6 L50 18WT/TN

7 Z927 14BK/OR

8-

9-

10 L54 18WT/LG

11 L63 18WT/DG

12 L1 18WT/LG

13 L674 18LG

14 Z928 16BK

C218 - (BODY SIDE)

CAV CIRCUIT

1-

2 A405 18RD/DB

3 C16 16DB/GY (SLT)

4 A930 18RD (SLT)

5-

6-

7-

8-

9 A210 12OR/RD (SLT)

10 -

11 -

12 C15 16DB/WT (SLT)

8W - 80 - 26 8W-80 CONNECTOR PIN-OUTSDR

Page 1080 of 2627

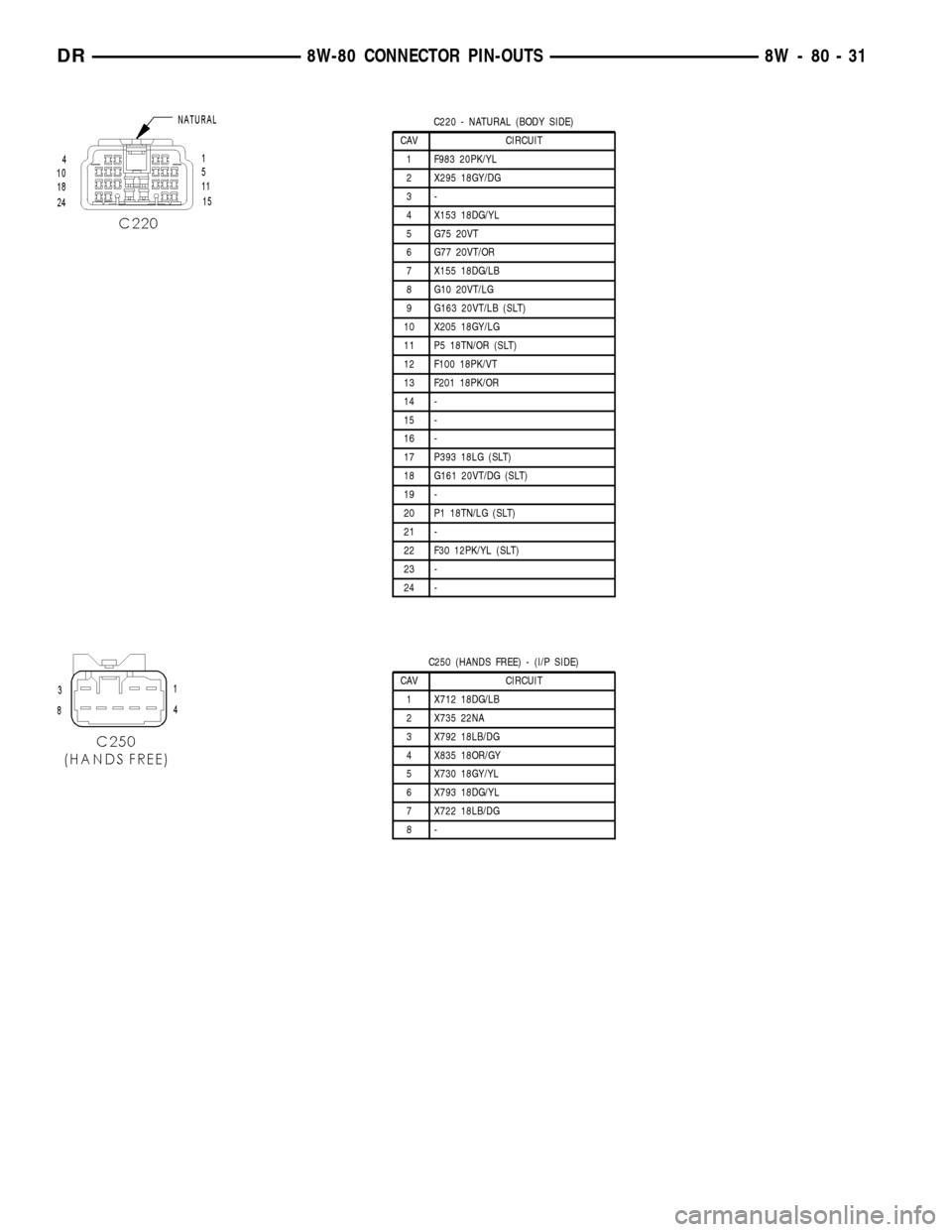

C220 - NATURAL (BODY SIDE)

CAV CIRCUIT

1 F983 20PK/YL

2 X295 18GY/DG

3-

4 X153 18DG/YL

5 G75 20VT

6 G77 20VT/OR

7 X155 18DG/LB

8 G10 20VT/LG

9 G163 20VT/LB (SLT)

10 X205 18GY/LG

11 P5 18TN/OR (SLT)

12 F100 18PK/VT

13 F201 18PK/OR

14 -

15 -

16 -

17 P393 18LG (SLT)

18 G161 20VT/DG (SLT)

19 -

20 P1 18TN/LG (SLT)

21 -

22 F30 12PK/YL (SLT)

23 -

24 -

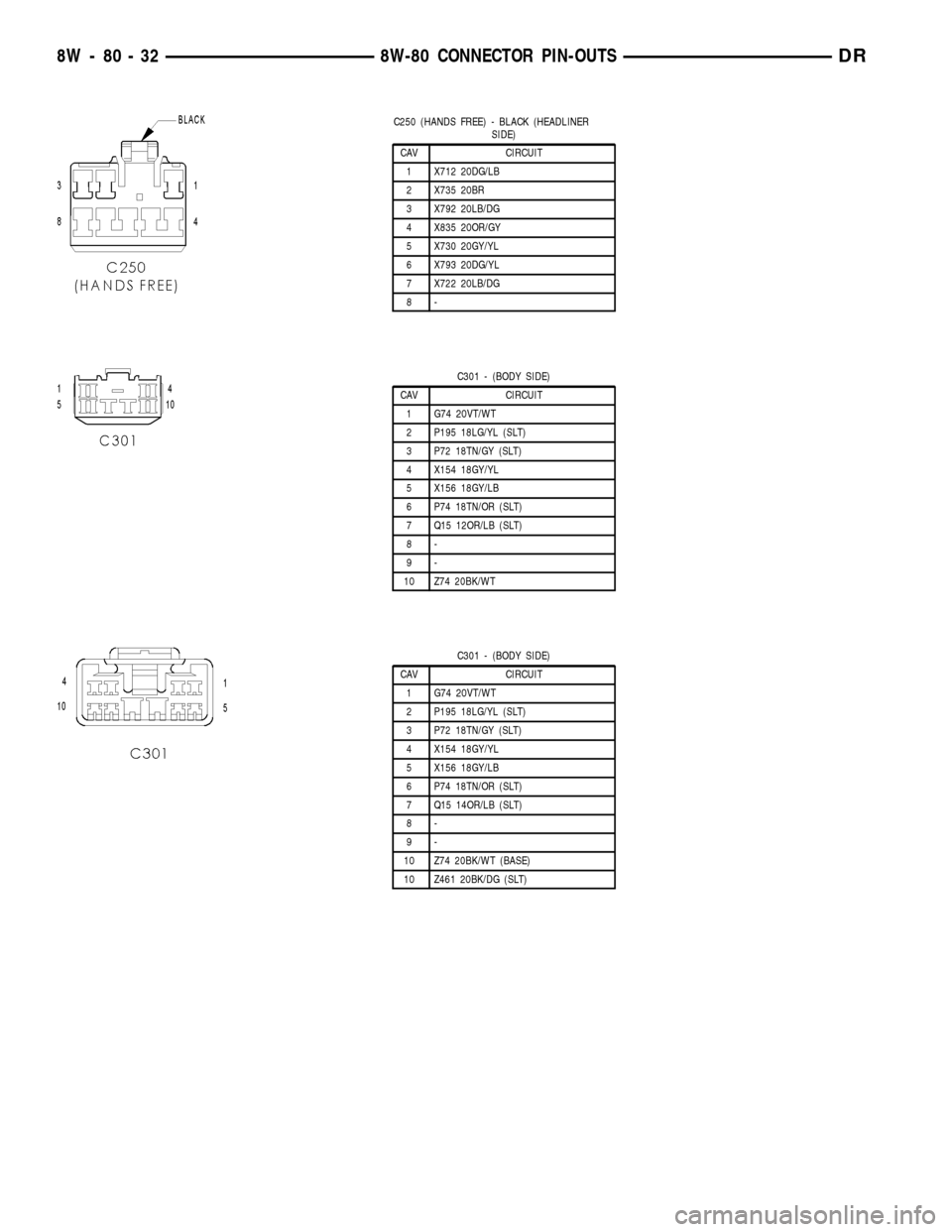

C250 (HANDS FREE) - (I/P SIDE)

CAV CIRCUIT

1 X712 18DG/LB

2 X735 22NA

3 X792 18LB/DG

4 X835 18OR/GY

5 X730 18GY/YL

6 X793 18DG/YL

7 X722 18LB/DG

8-

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 31

Page 1081 of 2627

C250 (HANDS FREE) - BLACK (HEADLINER

SIDE)

CAV CIRCUIT

1 X712 20DG/LB

2 X735 20BR

3 X792 20LB/DG

4 X835 20OR/GY

5 X730 20GY/YL

6 X793 20DG/YL

7 X722 20LB/DG

8-

C301 - (BODY SIDE)

CAV CIRCUIT

1 G74 20VT/WT

2 P195 18LG/YL (SLT)

3 P72 18TN/GY (SLT)

4 X154 18GY/YL

5 X156 18GY/LB

6 P74 18TN/OR (SLT)

7 Q15 12OR/LB (SLT)

8-

9-

10 Z74 20BK/WT

C301 - (BODY SIDE)

CAV CIRCUIT

1 G74 20VT/WT

2 P195 18LG/YL (SLT)

3 P72 18TN/GY (SLT)

4 X154 18GY/YL

5 X156 18GY/LB

6 P74 18TN/OR (SLT)

7 Q15 14OR/LB (SLT)

8-

9-

10 Z74 20BK/WT (BASE)

10 Z461 20BK/DG (SLT)

8W - 80 - 32 8W-80 CONNECTOR PIN-OUTSDR

Page 1082 of 2627

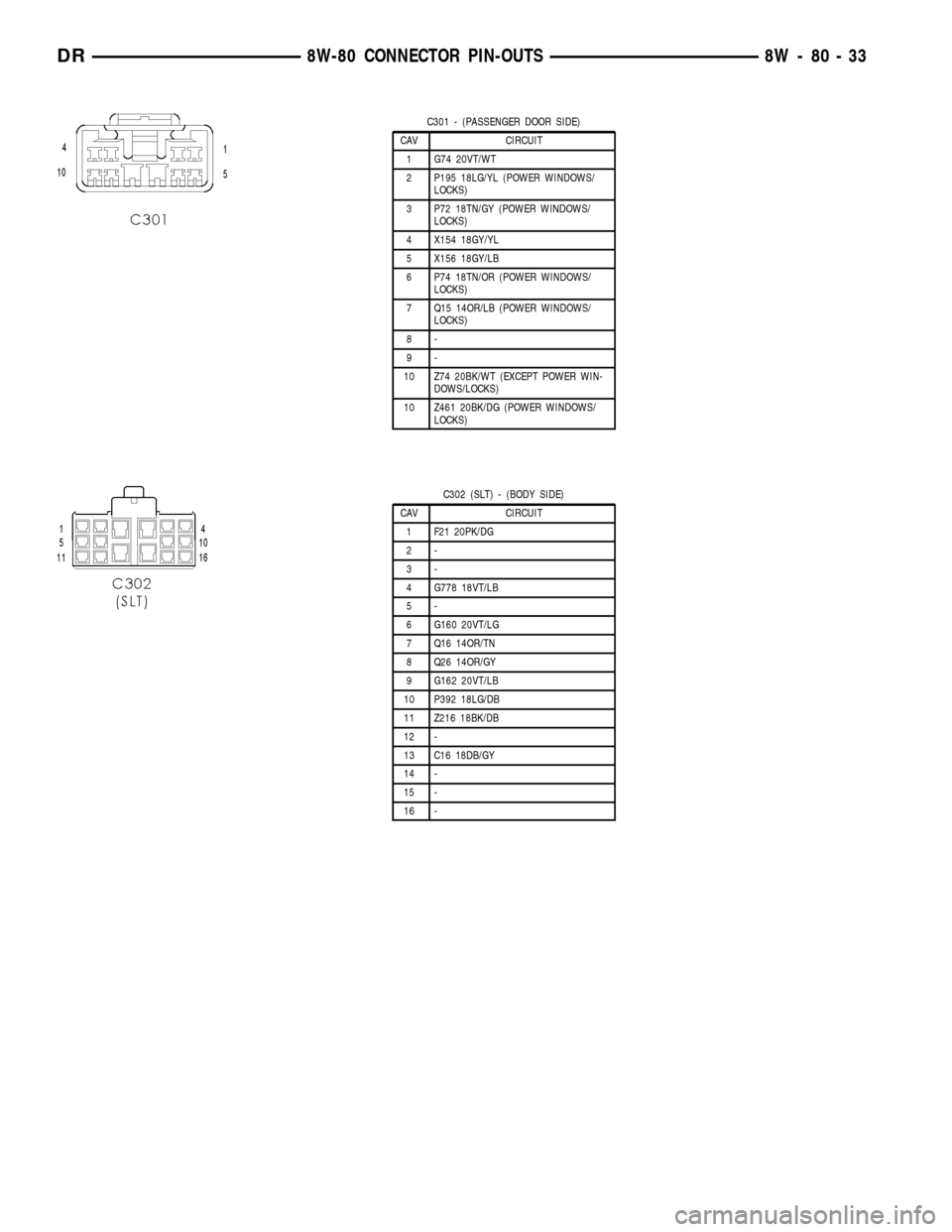

C301 - (PASSENGER DOOR SIDE)

CAV CIRCUIT

1 G74 20VT/WT

2 P195 18LG/YL (POWER WINDOWS/

LOCKS)

3 P72 18TN/GY (POWER WINDOWS/

LOCKS)

4 X154 18GY/YL

5 X156 18GY/LB

6 P74 18TN/OR (POWER WINDOWS/

LOCKS)

7 Q15 14OR/LB (POWER WINDOWS/

LOCKS)

8-

9-

10 Z74 20BK/WT (EXCEPT POWER WIN-

DOWS/LOCKS)

10 Z461 20BK/DG (POWER WINDOWS/

LOCKS)

C302 (SLT) - (BODY SIDE)

CAV CIRCUIT

1 F21 20PK/DG

2-

3-

4 G778 18VT/LB

5-

6 G160 20VT/LG

7 Q16 14OR/TN

8 Q26 14OR/GY

9 G162 20VT/LB

10 P392 18LG/DB

11 Z216 18BK/DB

12 -

13 C16 18DB/GY

14 -

15 -

16 -

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 33

Page 1083 of 2627

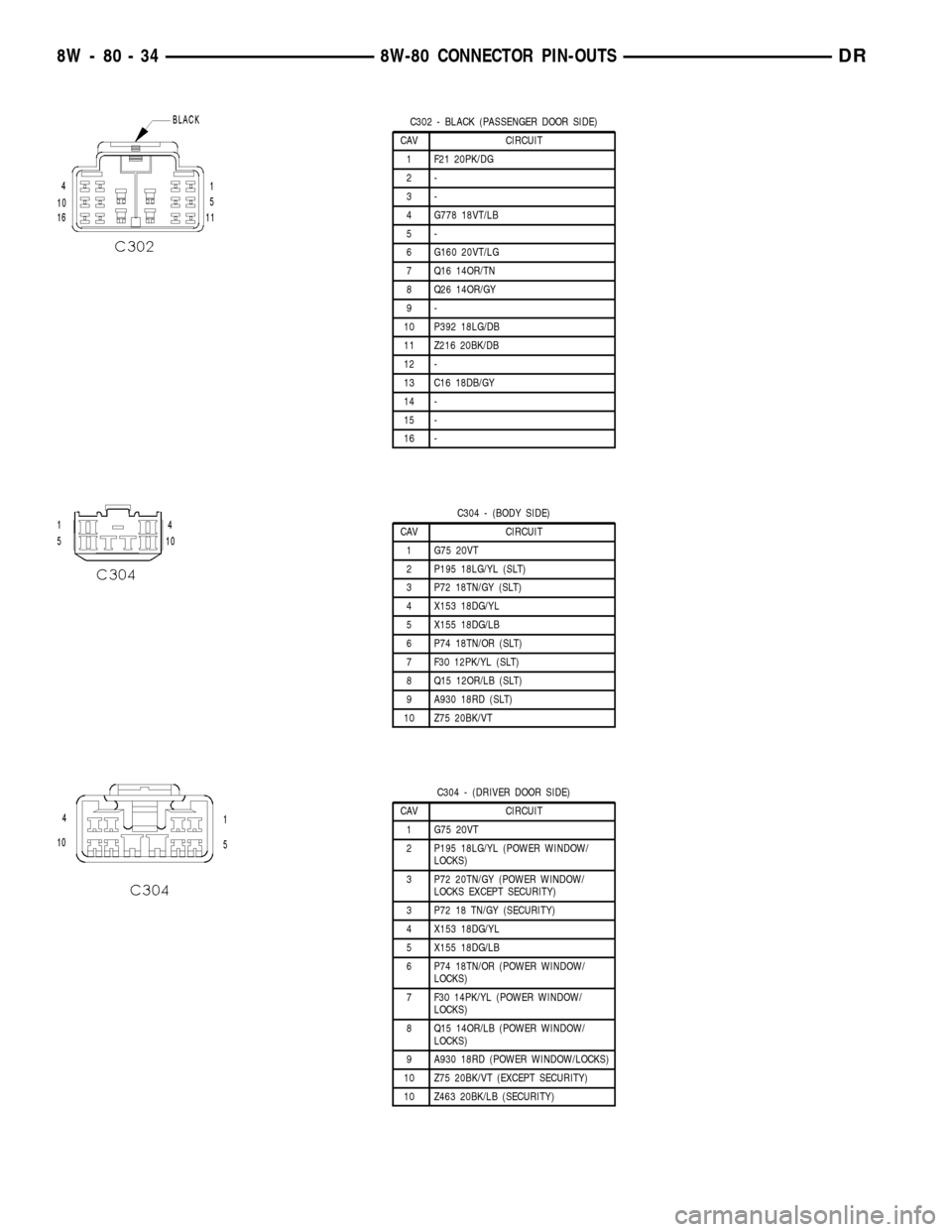

C302 - BLACK (PASSENGER DOOR SIDE)

CAV CIRCUIT

1 F21 20PK/DG

2-

3-

4 G778 18VT/LB

5-

6 G160 20VT/LG

7 Q16 14OR/TN

8 Q26 14OR/GY

9-

10 P392 18LG/DB

11 Z216 20BK/DB

12 -

13 C16 18DB/GY

14 -

15 -

16 -

C304 - (BODY SIDE)

CAV CIRCUIT

1 G75 20VT

2 P195 18LG/YL (SLT)

3 P72 18TN/GY (SLT)

4 X153 18DG/YL

5 X155 18DG/LB

6 P74 18TN/OR (SLT)

7 F30 12PK/YL (SLT)

8 Q15 12OR/LB (SLT)

9 A930 18RD (SLT)

10 Z75 20BK/VT

C304 - (DRIVER DOOR SIDE)

CAV CIRCUIT

1 G75 20VT

2 P195 18LG/YL (POWER WINDOW/

LOCKS)

3 P72 20TN/GY (POWER WINDOW/

LOCKS EXCEPT SECURITY)

3 P72 18 TN/GY (SECURITY)

4 X153 18DG/YL

5 X155 18DG/LB

6 P74 18TN/OR (POWER WINDOW/

LOCKS)

7 F30 14PK/YL (POWER WINDOW/

LOCKS)

8 Q15 14OR/LB (POWER WINDOW/

LOCKS)

9 A930 18RD (POWER WINDOW/LOCKS)

10 Z75 20BK/VT (EXCEPT SECURITY)

10 Z463 20BK/LB (SECURITY)

8W - 80 - 34 8W-80 CONNECTOR PIN-OUTSDR

Page 1084 of 2627

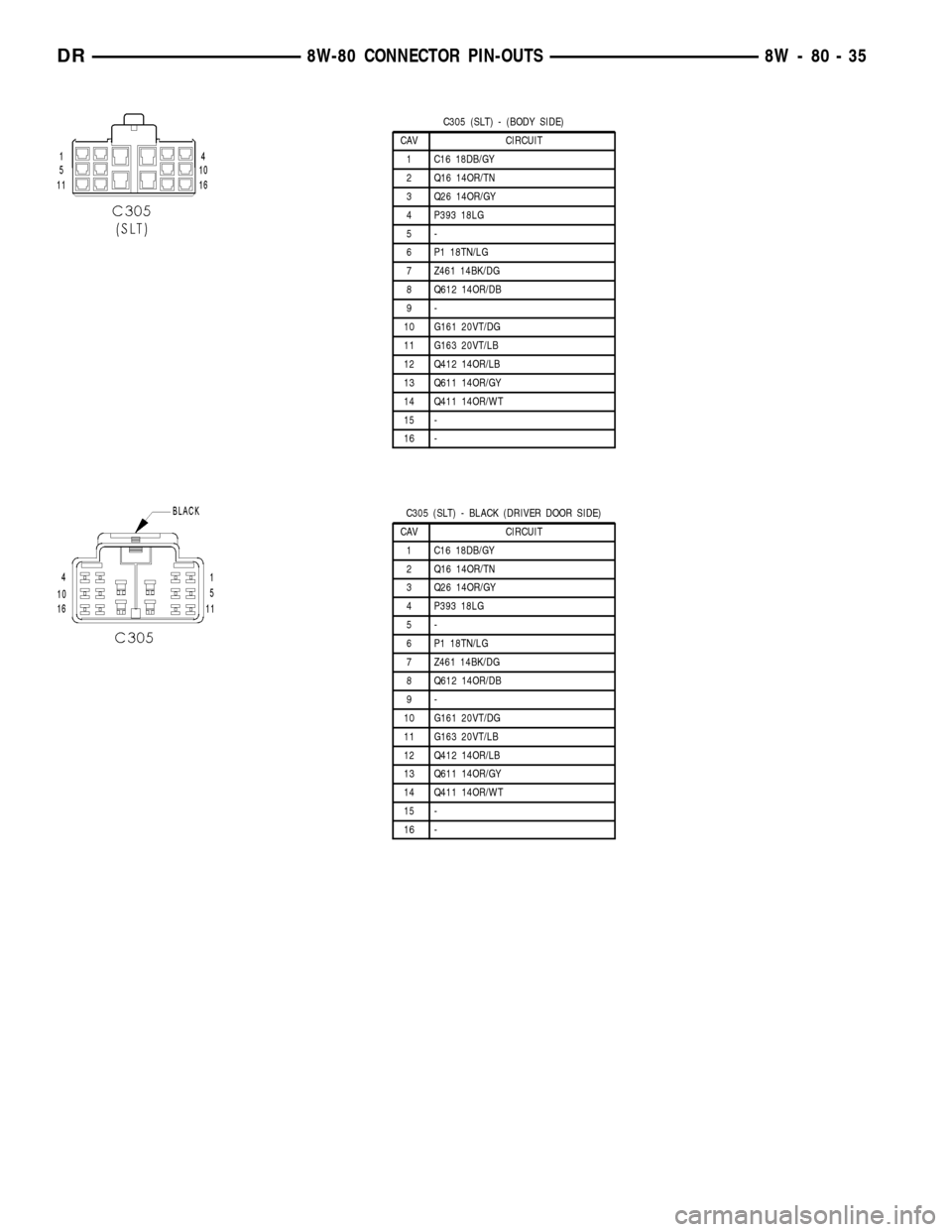

C305 (SLT) - (BODY SIDE)

CAV CIRCUIT

1 C16 18DB/GY

2 Q16 14OR/TN

3 Q26 14OR/GY

4 P393 18LG

5-

6 P1 18TN/LG

7 Z461 14BK/DG

8 Q612 14OR/DB

9-

10 G161 20VT/DG

11 G163 20VT/LB

12 Q412 14OR/LB

13 Q611 14OR/GY

14 Q411 14OR/WT

15 -

16 -

C305 (SLT) - BLACK (DRIVER DOOR SIDE)

CAV CIRCUIT

1 C16 18DB/GY

2 Q16 14OR/TN

3 Q26 14OR/GY

4 P393 18LG

5-

6 P1 18TN/LG

7 Z461 14BK/DG

8 Q612 14OR/DB

9-

10 G161 20VT/DG

11 G163 20VT/LB

12 Q412 14OR/LB

13 Q611 14OR/GY

14 Q411 14OR/WT

15 -

16 -

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 35

Page 1085 of 2627

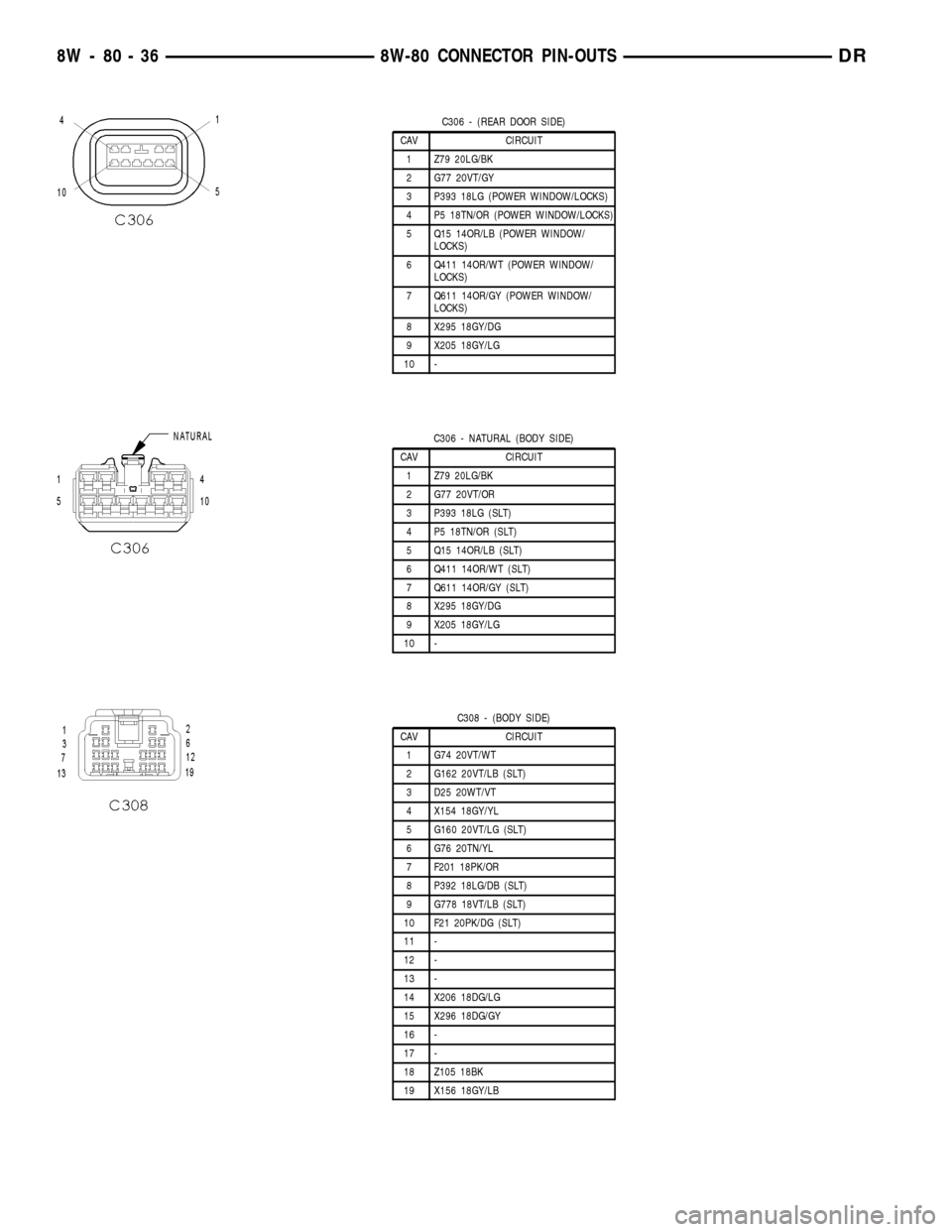

C306 - (REAR DOOR SIDE)

CAV CIRCUIT

1 Z79 20LG/BK

2 G77 20VT/GY

3 P393 18LG (POWER WINDOW/LOCKS)

4 P5 18TN/OR (POWER WINDOW/LOCKS)

5 Q15 14OR/LB (POWER WINDOW/

LOCKS)

6 Q411 14OR/WT (POWER WINDOW/

LOCKS)

7 Q611 14OR/GY (POWER WINDOW/

LOCKS)

8 X295 18GY/DG

9 X205 18GY/LG

10 -

C306 - NATURAL (BODY SIDE)

CAV CIRCUIT

1 Z79 20LG/BK

2 G77 20VT/OR

3 P393 18LG (SLT)

4 P5 18TN/OR (SLT)

5 Q15 14OR/LB (SLT)

6 Q411 14OR/WT (SLT)

7 Q611 14OR/GY (SLT)

8 X295 18GY/DG

9 X205 18GY/LG

10 -

C308 - (BODY SIDE)

CAV CIRCUIT

1 G74 20VT/WT

2 G162 20VT/LB (SLT)

3 D25 20WT/VT

4 X154 18GY/YL

5 G160 20VT/LG (SLT)

6 G76 20TN/YL

7 F201 18PK/OR

8 P392 18LG/DB (SLT)

9 G778 18VT/LB (SLT)

10 F21 20PK/DG (SLT)

11 -

12 -

13 -

14 X206 18DG/LG

15 X296 18DG/GY

16 -

17 -

18 Z105 18BK

19 X156 18GY/LB

8W - 80 - 36 8W-80 CONNECTOR PIN-OUTSDR

Page 1086 of 2627

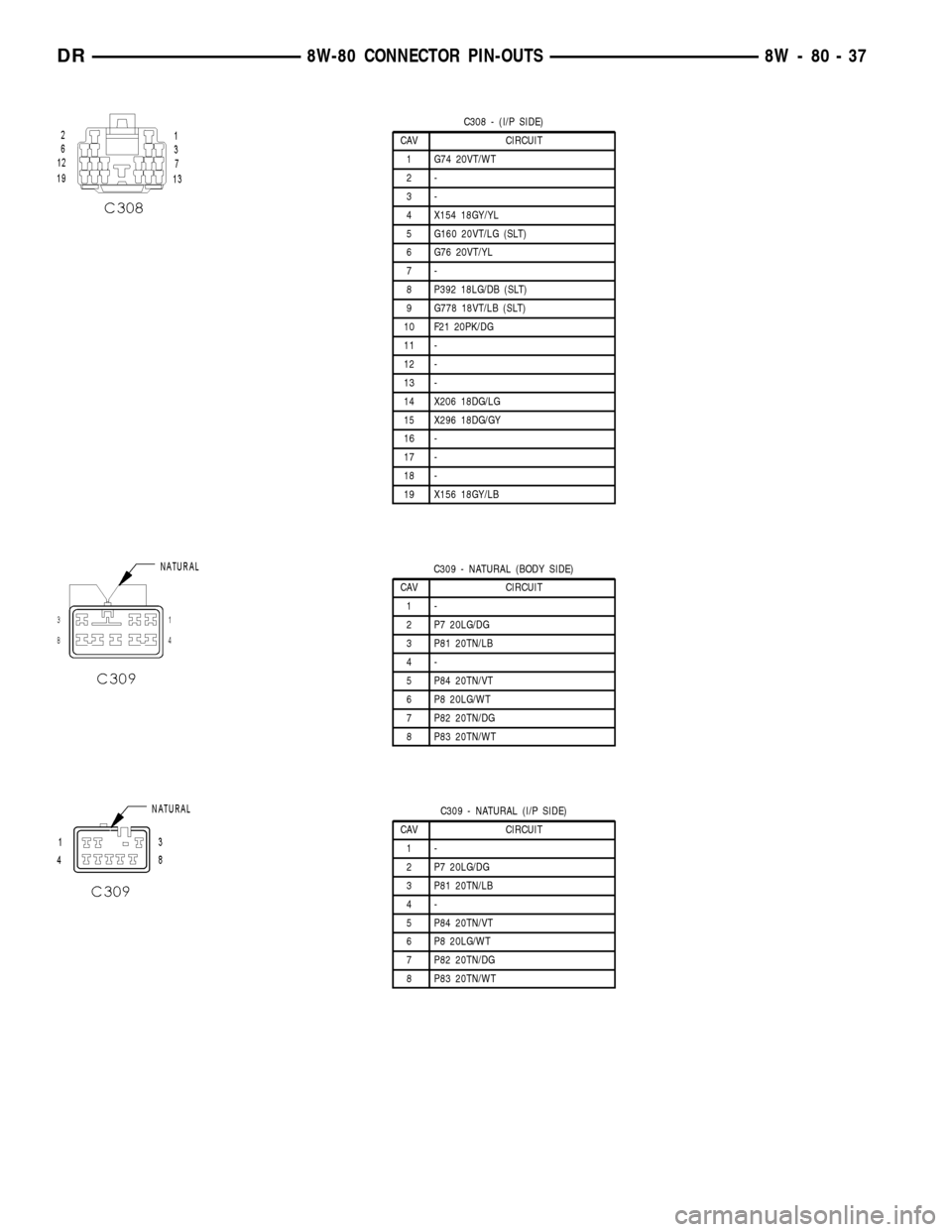

C308 - (I/P SIDE)

CAV CIRCUIT

1 G74 20VT/WT

2-

3-

4 X154 18GY/YL

5 G160 20VT/LG (SLT)

6 G76 20VT/YL

7-

8 P392 18LG/DB (SLT)

9 G778 18VT/LB (SLT)

10 F21 20PK/DG

11 -

12 -

13 -

14 X206 18DG/LG

15 X296 18DG/GY

16 -

17 -

18 -

19 X156 18GY/LB

C309 - NATURAL (BODY SIDE)

CAV CIRCUIT

1-

2 P7 20LG/DG

3 P81 20TN/LB

4-

5 P84 20TN/VT

6 P8 20LG/WT

7 P82 20TN/DG

8 P83 20TN/WT

C309 - NATURAL (I/P SIDE)

CAV CIRCUIT

1-

2 P7 20LG/DG

3 P81 20TN/LB

4-

5 P84 20TN/VT

6 P8 20LG/WT

7 P82 20TN/DG

8 P83 20TN/WT

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 37