DODGE RAM 1500 1998 2.G Workshop Manual

Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1421 of 2627

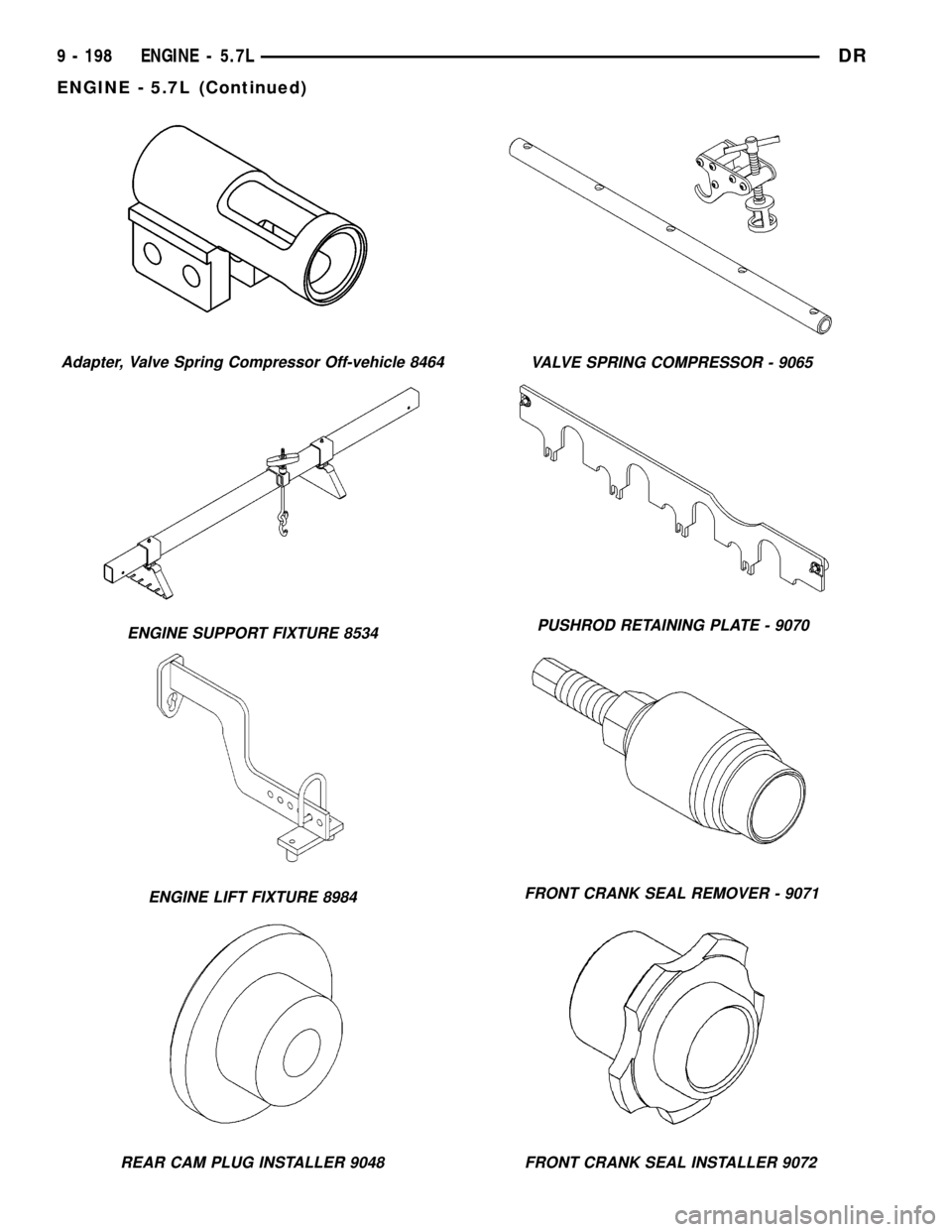

Adapter, Valve Spring Compressor Off-vehicle 8464

ENGINE SUPPORT FIXTURE 8534

ENGINE LIFT FIXTURE 8984

REAR CAM PLUG INSTALLER 9048

VALVE SPRING COMPRESSOR - 9065

PUSHROD RETAINING PLATE - 9070

FRONT CRANK SEAL REMOVER - 9071

FRONT CRANK SEAL INSTALLER 9072

9 - 198 ENGINE - 5.7LDR

ENGINE - 5.7L (Continued)

Page 1422 of 2627

AIR INTAKE SYSTEM

REMOVAL

Filter Element Only

Housing removal is not necessary for element (fil-

ter) replacement.

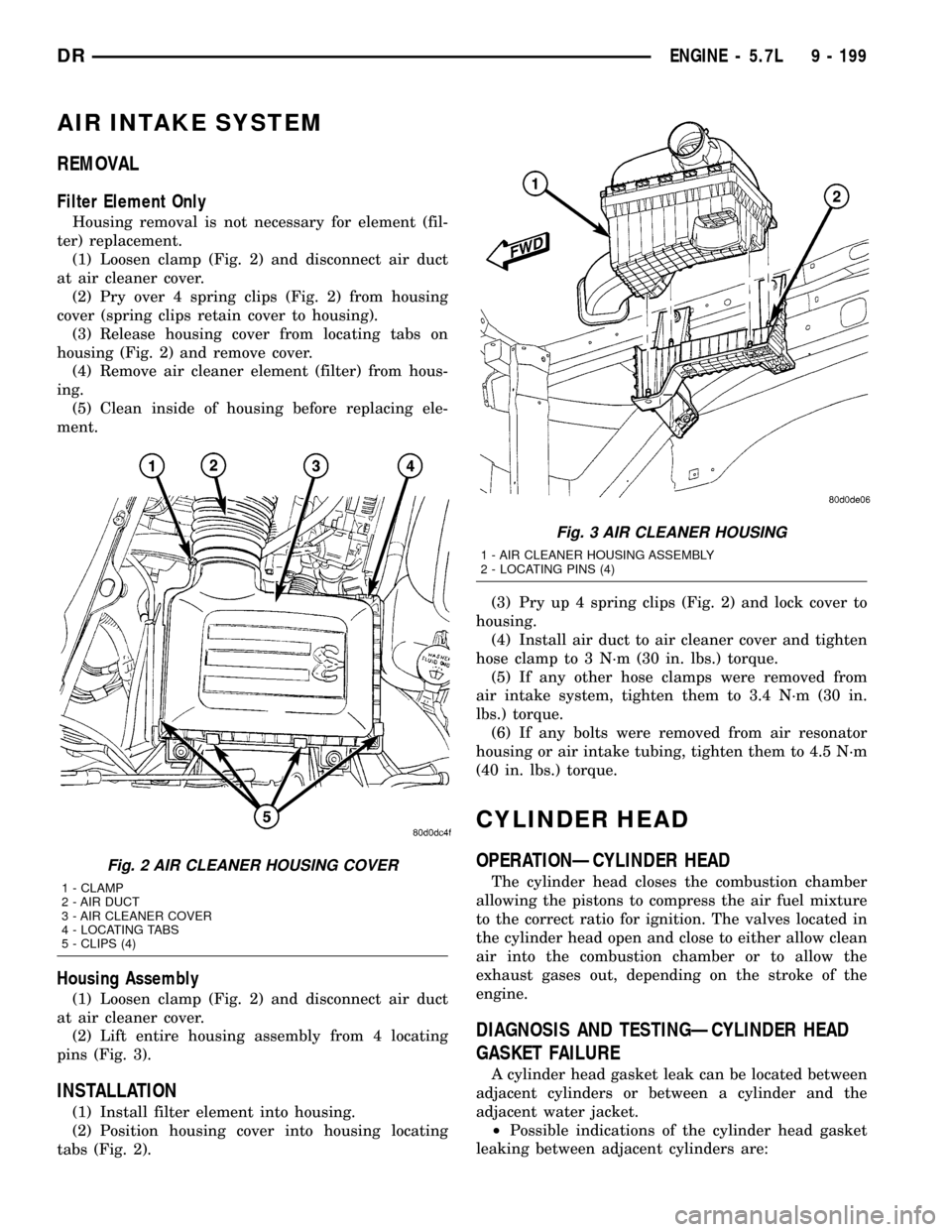

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

(2) Pry over 4 spring clips (Fig. 2) from housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs on

housing (Fig. 2) and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

Housing Assembly

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

(2) Lift entire housing assembly from 4 locating

pins (Fig. 3).

INSTALLATION

(1) Install filter element into housing.

(2) Position housing cover into housing locating

tabs (Fig. 2).(3) Pry up 4 spring clips (Fig. 2) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

CYLINDER HEAD

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture

to the correct ratio for ignition. The valves located in

the cylinder head open and close to either allow clean

air into the combustion chamber or to allow the

exhaust gases out, depending on the stroke of the

engine.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

Fig. 2 AIR CLEANER HOUSING COVER

1 - CLAMP

2 - AIR DUCT

3 - AIR CLEANER COVER

4 - LOCATING TABS

5 - CLIPS (4)

Fig. 3 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

DRENGINE - 5.7L 9 - 199

Page 1423 of 2627

þ Loss of engine power

þ Engine misfiring

þ Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

þ Engine overheating

þ Loss of coolant

þ Excessive steam (white smoke) emitting from

exhaust

þ Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system.

(3) Remove the air cleaner resonator and duct

work.

(4) Remove the generator.

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Perform the Fuel System Pressure Release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel supply line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect heater hoses.

(9) Remove cylinder head covers and gaskets.

(10) Remove intake manifold and throttle body as

an assembly.

(11) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(12) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If tolerances

exceed 0.0508 mm (0.002 in.) replace the cylinder

head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.

(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

(4) Inspect pushrods. Replace worn or bent push-

rods.

INSTALLATION

(1) Clean all surfaces of cylinder block and cylin-

der heads.

(2) Clean cylinder block front and rear gasket sur-

faces using a suitable solvent.

CAUTION: The head gaskets are not interchange-

able between left and right sides. They are marked

ªLº and ªRº to indicate left and right sides.

(3) Position new cylinder head gaskets onto the

cylinder block.

9 - 200 ENGINE - 5.7LDR

CYLINDER HEAD (Continued)

Page 1424 of 2627

CAUTION: The head gaskets are marked ªTOPº to

indicate which side goes up.

(4) Position cylinder heads onto head gaskets and

cylinder block.

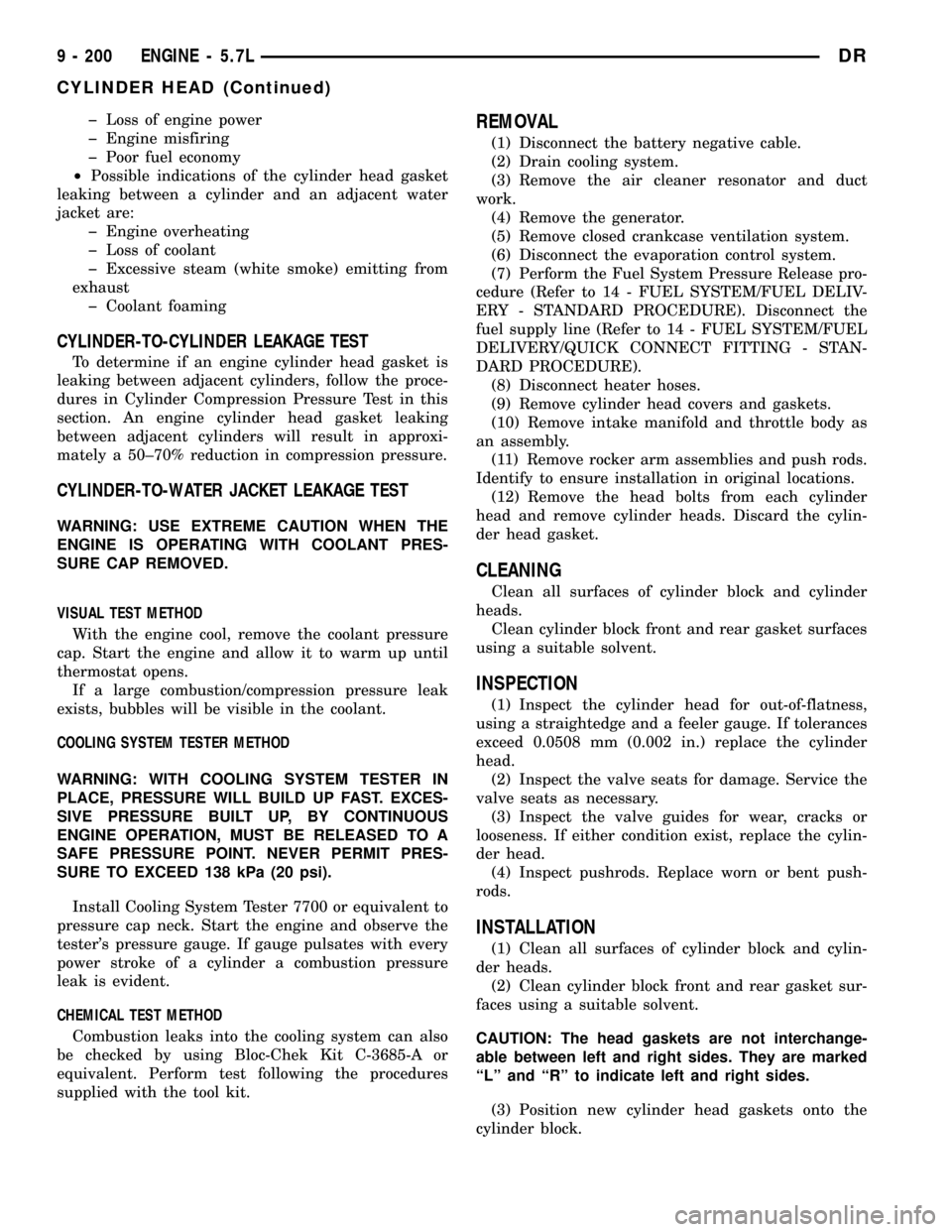

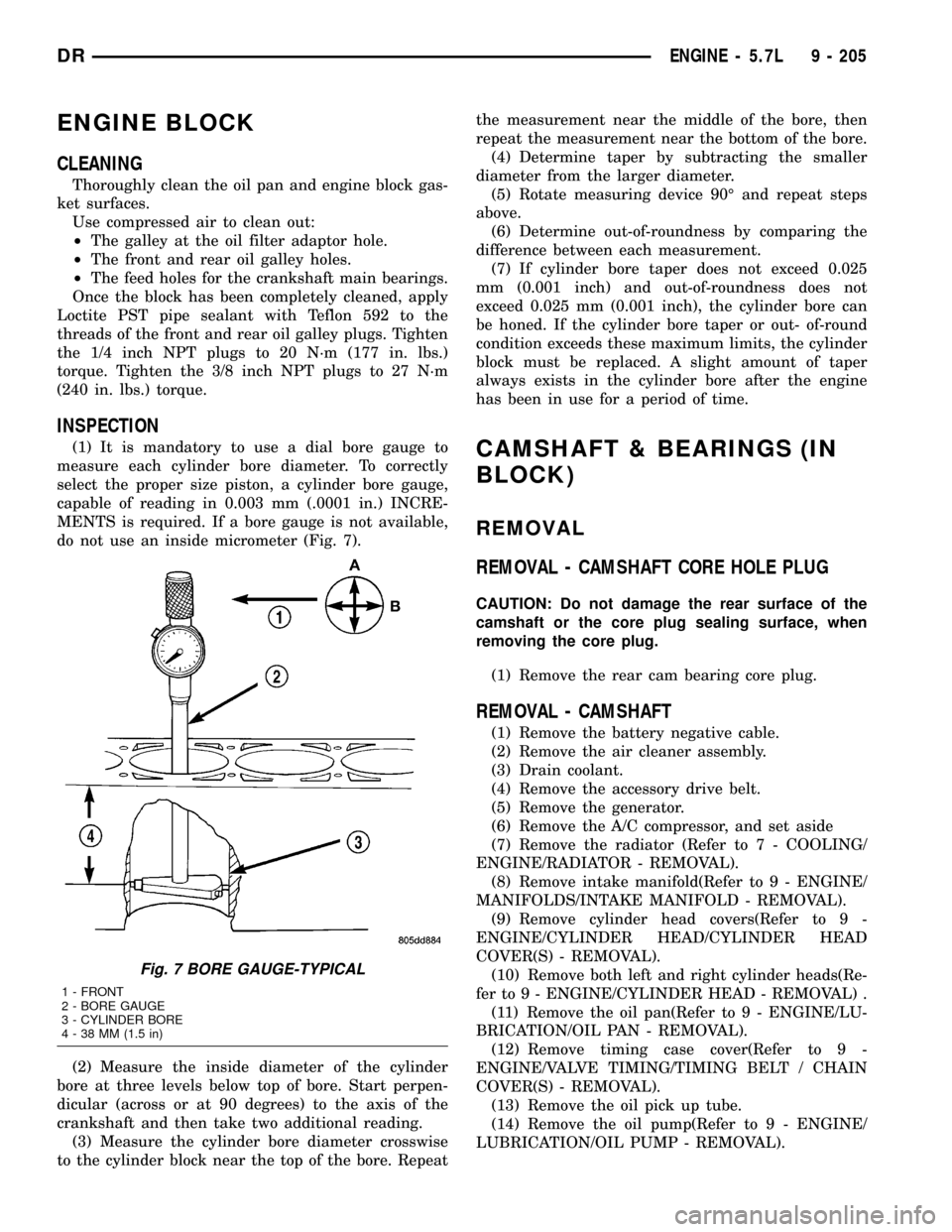

(5) Tighten the cylinder head bolts in three steps

(Fig. 4):

²Step 1Ð Snug tighten M12 cylinder head bolts,

in sequence, to 34 N´m (25 ft. lbs.) and M8 bolts to

20 N´m (15 ft. lbs.) torque.

²Step 2Ð Tighten M12 cylinder head bolts, in

sequence, to 54 N´m (40 ft. lbs.) and verify M8 bolts

to 20 N´m (15 ft. lbs.) torque..

²Step 3Ð Turn M12 cylinder head bolts, in

sequence, 90 degrees and tighten M8 bolts to 34 N´m

(25 ft. lbs.) torque.

(6) Install push rods and rocker arm assemblies in

their original position.

(7) Install the intake manifold and throttle body

assembly.

(8) If required, adjust spark plugs to specifications.

Install the plugs.

(9) Connect the heater hoses.

(10) Install the fuel supply line.

(11) Install the generator and drive belt.

(12) Install cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(13) Connect the evaporation control system.

(14) Install the air cleaner.

(15) Fill cooling system.

(16) Connect the negative cable to the battery.

(17) Start engine check for leaks.CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect coil on plug connectors.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

(3) Remove cylinder head cover retaining bolts,

and ground straps.

(4) Remove cylinder head cover.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the

engine cylinder head cover. Prolonged contact with

other objects may wear a hole in the cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2)

Install cylinder head cover and hand start all fas-

teners. Verify that all double ended studs are in the cor-

rect location and install left and right ground straps.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

NOTE: The right hand ground strap is located on

the front inboard stud. The left hand ground strap

is located on the rear inboard stud.

(3) Tighten cylinder head cover bolts and double

ended studs to 8 N´m (70 in. lbs). Begin torque

sequence in the middle of head cover and torque

bolts moving outward in a crisscross pattern from top

to bottom.

(4) Install ignition coil on plug, and torque fasten-

ers to 12 N´m (105 in. lbs)

(5) Connect, ignition coil electrical connectors.

(6) Install PCV hose.

(7) Connect battery negative cable.

Fig. 4 CYLINDER HEAD TIGHTENING SEQUENCE

DRENGINE - 5.7L 9 - 201

CYLINDER HEAD (Continued)

Page 1425 of 2627

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

DESCRIPTION - VALVE GUIDES

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide ream-

ing is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

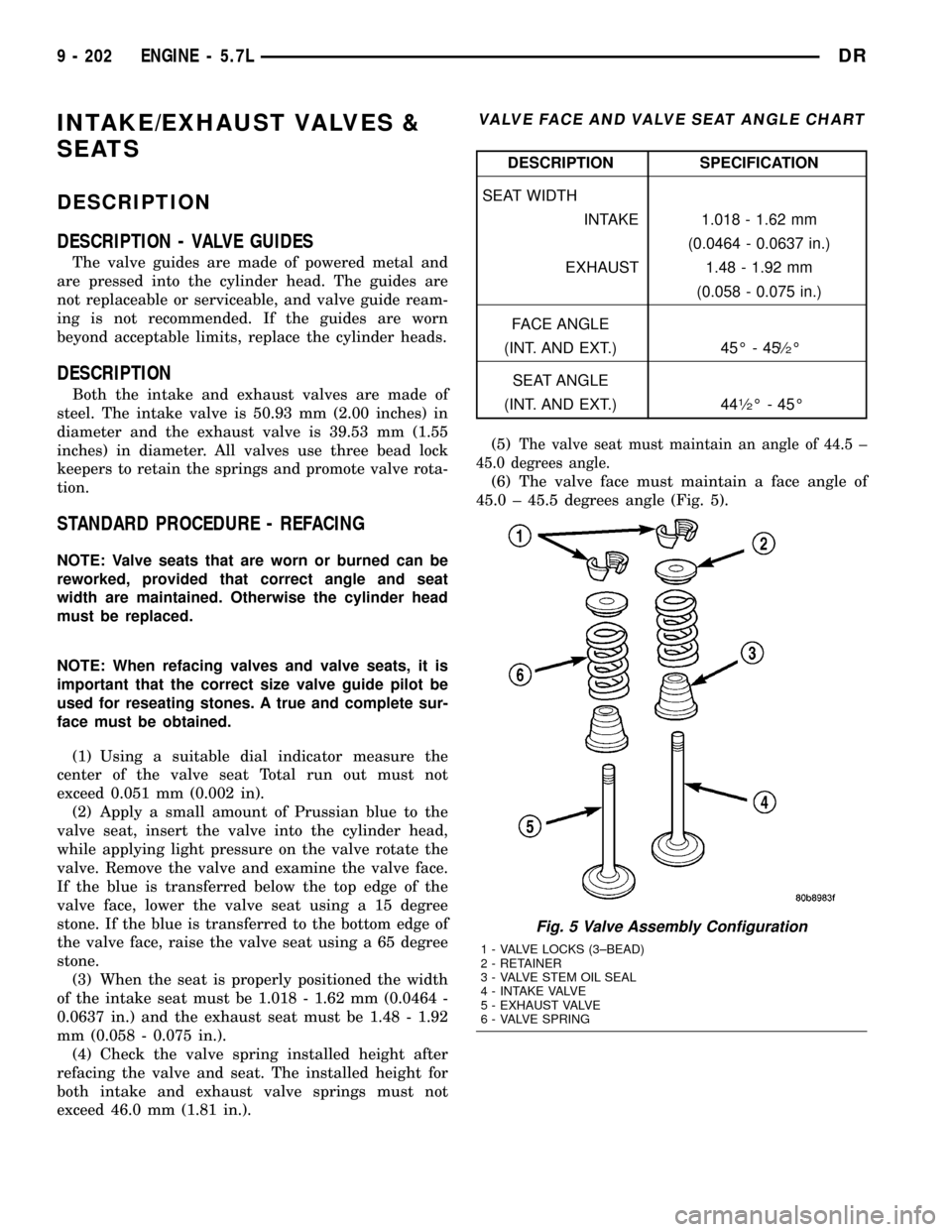

DESCRIPTION

Both the intake and exhaust valves are made of

steel. The intake valve is 50.93 mm (2.00 inches) in

diameter and the exhaust valve is 39.53 mm (1.55

inches) in diameter. All valves use three bead lock

keepers to retain the springs and promote valve rota-

tion.

STANDARD PROCEDURE - REFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.018 - 1.62 mm (0.0464 -

0.0637 in.) and the exhaust seat must be 1.48 - 1.92

mm (0.058 - 0.075 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 46.0 mm (1.81 in.).

VALVE FACE AND VALVE SEAT ANGLE CHART

DESCRIPTION SPECIFICATION

SEAT WIDTH

INTAKE 1.018 - 1.62 mm

(0.0464 - 0.0637 in.)

EXHAUST 1.48 - 1.92 mm

(0.058 - 0.075 in.)

FACE ANGLE

(INT. AND EXT.) 45É - 45

1¤2É

SEAT ANGLE

(INT. AND EXT.) 44

1¤2É - 45É

(5)

The valve seat must maintain an angle of 44.5 ±

45.0 degrees angle.

(6) The valve face must maintain a face angle of

45.0 ± 45.5 degrees angle (Fig. 5).

Fig. 5 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

9 - 202 ENGINE - 5.7LDR

Page 1426 of 2627

REMOVAL

(1) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(2) Compress valve springs using Valve Spring

Compressor Tool special tool # C-3422and adapter

8464.

(3) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(4) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

valve guides. Identify valves to ensure installation in

original location.

INSTALLATION

(1) Clean valves thoroughly. Discard burned,

warped and cracked valves.

(2) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(3) Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 inch), replace the valve.

(4) Coat valve stems with lubrication oil and insert

them in cylinder head.

(5) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(6) Install new seals on all valve guides. Install

valve springs and valve retainers.

(7) Compress valve springs with Valve Spring

Compressor Tool special tool # C- 3422and adapter

8464, install locks and release tool. If valves and/or

seats are ground, measure the installed height of

springs. Make sure the measurement is taken from

bottom of spring seat in cylinder head to the bottom

surface of spring retainer.

(8) Install cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

ROCKER ARM / ADJUSTER

ASSY

REMOVAL

(1) Remove cylinder head cover.(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(2) Loosen the rocker shafts using the following

sequence:Center, center-left, center-right, left,

right,.

CAUTION: The rocker shaft assemblies are not

interchangeable between intake and exhaust. The

intake rocker arms are marked with an ªIº.

(3) Remove the rocker shafts. Note location for

reassembly.CAUTION: The longer push rods are for the exhaust

side, and the shorter push rods are for intake side.

(4) Remove the pushrods. Note pushrod location

for reassembly.

INSTALLATION

CAUTION: The longer push rods are for the exhaust

side, and the shorter push rods are for intake side.

(1) Install the push rods in the same order as

removed.

CAUTION: Verify that pushrod is installed into

rocker arm and lifter correctly while installing

rocker shaft assembly. Recheck after rocker shaft

has been torqued to specification.

CAUTION: The rocker shaft assemblies are not

interchangeable between intake and exhaust. The

intake rocker arms are marked with the letter ªIº.

(2) Install rocker shaft assemblies in the same

order as removed.

CAUTION: Ensure that hold downs and rocker arms

are not overlapped when torquing bolts.

(3) Tighten the rocker shaft bolts to 22 N´m (195

in. lbs.) torque,using the following sequence:Center,

center-right, center-left, right, left.

CAUTION: DO NOT rotate or crank the engine dur-

ing or immediately after rocker arm installation.

Allow the hydraulic roller tappets adequate time to

bleed down (about 5 minutes).

(4) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

VALVE STEM SEALS

DESCRIPTION

The valve guide seals are made of rubber and

incorporate an integral steel valve spring seat. The

integral garter spring maintains consistent lubrica-

tion control to the valve stems.

DRENGINE - 5.7L 9 - 203

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1427 of 2627

VALVE SPRINGS

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove air cleaner assembly.

(3) Remove air intake resonator.

(4) Remove spark plug cables.

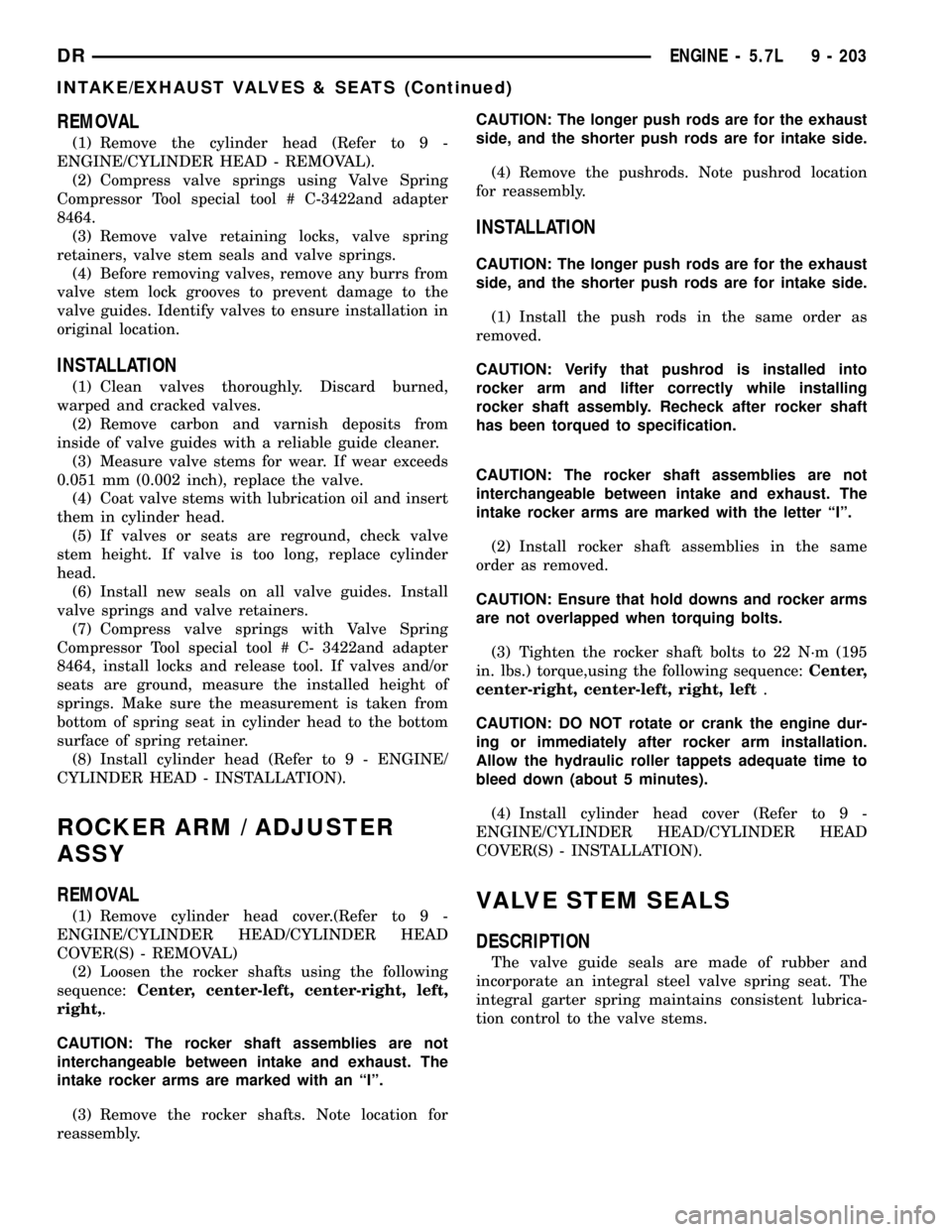

(5) Remove ignition coil connectors (Fig. 6).

(6) Remove ignition coils.

(7) Remove one spark plug.

(8) Remove valve cover.

CAUTION: The piston must be at TDC, and both

valves closed on the cylinder to be serviced.

NOTE: If removing intake valve spring, install spe-

cial tool# 9070, pushrod retaining plate, to retain

the intake pushrods.

(9) Remove exhaust/intake rocker arm shafts.

(10) Install spring compressor, special tool# 9065.

NOTE: All valve springs and seals are removed in

the same manner.(11) Charge cylinder with air.

NOTE: Tap the top of the valve spring retainer to

loosen the spring retainers locks.

(12) Compress valve spring and remove valve

retainer locks.

(13) Release spring compressor and remove valve

spring.

NOTE: The valve springs are interchangeable

between intake and exhaust.

(14) Remove valve seal.

INSTALLATION

(1) Install valve seal.

(2) Install valve spring.

(3) Using special tool# 9065, compress valve spring

and install valve spring retainer and locks.

(4) Release air charge in cylinder.

(5) Remove spring compressor tool # 9065.

CAUTION: Verify that the pushrods are fully seated

into lifter and rocker arm. Recheck after rocker arm

shaft has been torqued to specification.

(6) Install rocker arm shaft and pushrods(Refer to

9 - ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - INSTALLATION).

(7) Tighten the rocker shaft bolts to 22 N´m (195

in. lbs.) torque,using the following sequence:Center,

center-right, center-left, right, left.

(8) Remove special tool# 9070, pushrod retaining

plate, if used.

(9) Install cylinder head cover.

(10) Tighten cylinder head cover bolts and double

ended studs(Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

(11) Install spark plugs.

(12) Install ignition coil on plug, and torque fas-

teners to 12 N´m (105 in. lbs)

(13) Install ignition coil connectors.

(14) Install spark plug cables.

(15) Install air intake resonator.

(16) Install air cleaner assembly.

(17) Connect negative battery cable.

Fig. 6 IGNITION COIL R/I Ð 5.7L V-8

1 - SLIDE LOCK (SLIDE OUTWARD TO UNLOCK)

2 - SPARK PLUG CABLE (TO OPPOSITE CYLINDER BANK

SPARK PLUG)

3 - RELEASE LOCK / TAB (PUSH HERE)

4 - ELEC. CONNECTOR

5 - IGNITION COIL

6 - COIL MOUNTING BOLTS (2)

7 - SPARK PLUG CABLE (TO OPPOSITE CYLINDER BANK

IGNITION COIL)

9 - 204 ENGINE - 5.7LDR

Page 1428 of 2627

ENGINE BLOCK

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the 1/4 inch NPT plugs to 20 N´m (177 in. lbs.)

torque. Tighten the 3/8 inch NPT plugs to 27 N´m

(240 in. lbs.) torque.

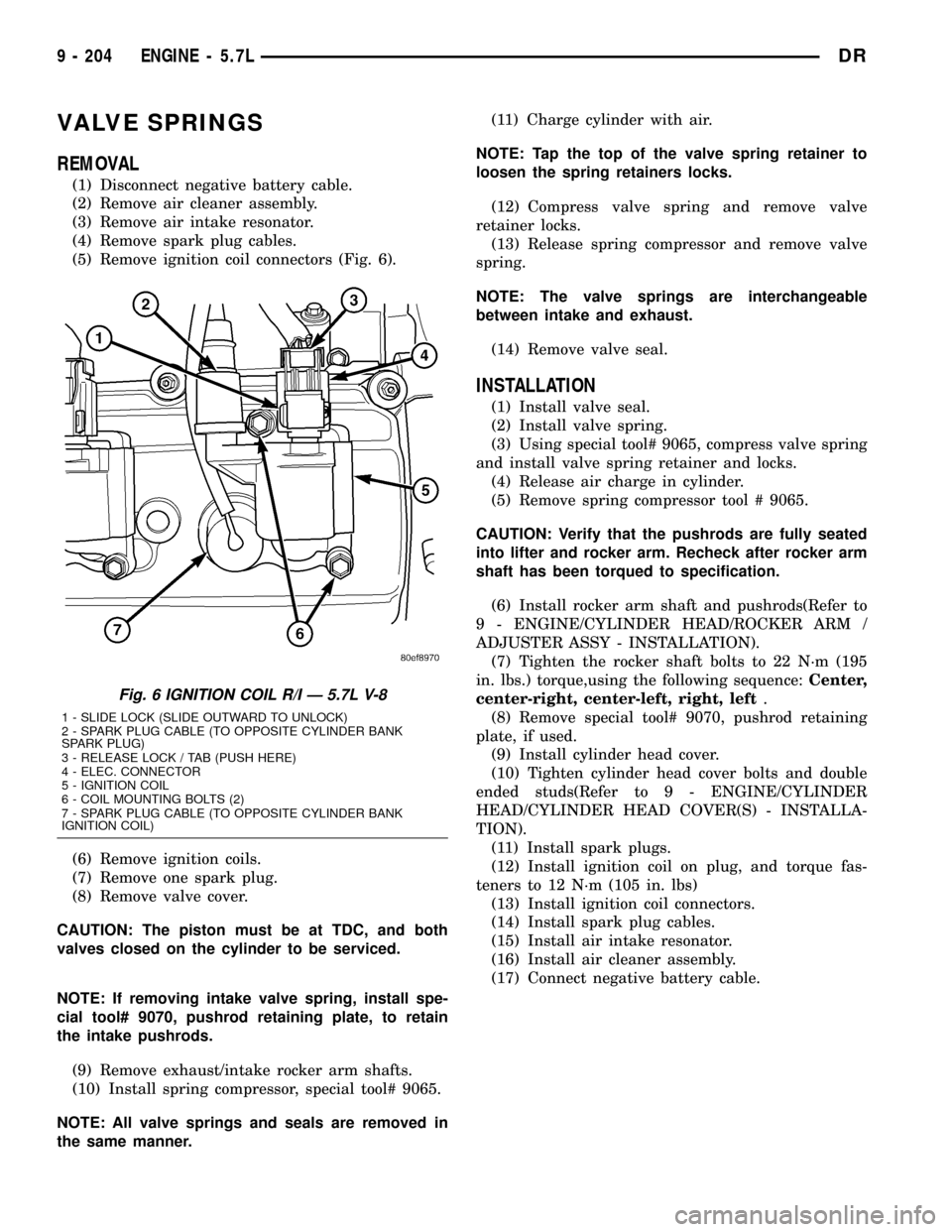

INSPECTION

(1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore gauge,

capable of reading in 0.003 mm (.0001 in.) INCRE-

MENTS is required. If a bore gauge is not available,

do not use an inside micrometer (Fig. 7).

(2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpen-

dicular (across or at 90 degrees) to the axis of the

crankshaft and then take two additional reading.

(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeatthe measurement near the middle of the bore, then

repeat the measurement near the bottom of the bore.

(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.

(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

block must be replaced. A slight amount of taper

always exists in the cylinder bore after the engine

has been in use for a period of time.CAMSHAFT & BEARINGS (IN

BLOCK)

REMOVAL

REMOVAL - CAMSHAFT CORE HOLE PLUG

CAUTION: Do not damage the rear surface of the

camshaft or the core plug sealing surface, when

removing the core plug.

(1) Remove the rear cam bearing core plug.

REMOVAL - CAMSHAFT

(1) Remove the battery negative cable.

(2) Remove the air cleaner assembly.

(3) Drain coolant.

(4) Remove the accessory drive belt.

(5) Remove the generator.

(6) Remove the A/C compressor, and set aside

(7) Remove the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - REMOVAL).

(8) Remove intake manifold(Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

(9) Remove cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(10) Remove both left and right cylinder heads(Re-

fer to 9 - ENGINE/CYLINDER HEAD - REMOVAL) .

(11) Remove the oil pan(Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(12) Remove timing case cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(13) Remove the oil pick up tube.

(14) Remove the oil pump(Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL).

Fig. 7 BORE GAUGE-TYPICAL

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 38 MM (1.5 in)

DRENGINE - 5.7L 9 - 205

Page 1429 of 2627

(15) Remove timing chain(Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(16) Remove camshaft tensioner/thrust plate

assembly.

NOTE: Identify tappets to ensure installation in orig-

inal location.

(17) Remove the retainer assembly and tappets.

(18) Install a long bolt into front of camshaft to aid

in removal of the camshaft. Remove camshaft, being

careful not to damage cam bearings with the cam

lobes.

INSPECTION

(1) The cam bearings are not serviceable. Do not

attempt to replace cam bearings for any reason.

INSTALLATION

INSTALLATION - CAMSHAFT CORE HOLE PLUG

CAUTION: The new core hole plug must be installed

to the proper depth or camshaft damage could

develope. The plug must be installed squarely in

the bore.

(1) Install a new core hole plug at the rear of cam-

shaft, using special tool # 9048. Clean plug and apply

mopartlock and seal adhesive to the edge of the

plug, before installing. The plug must be installed to

a depth of+/-0.25mm from the end of the machined

bevel, that is the end of the bevel that is closest to

the cam bearing.

INSTALLATION - CAMSHAFT

(1) Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft

(2) Install camshaft Tensioner plate assembly.

Tighten bolts to 28 N´m (250 in. lbs.) torque.

(3) Install timing chain and sprockets(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION) .

(4) Measure camshaft end play(Refer to 9 -

ENGINE - SPECIFICATIONS). If not within limits

install a new thrust plate.

(5) Install the oil pump(Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(6) Install the oil pick up tube.

(7) Each tappet reused must be installed in the

same position from which it was removed.When

camshaft is replaced, all of the tappets must be

replaced.(8) Install the tappets and retainer assembly(Refer

to 9 - ENGINE/ENGINE BLOCK/HYDRAULIC LIFT-

ERS (CAM IN BLOCK) - INSTALLATION).

(9) Install both left and right cylinder heads(Refer

to 9 - ENGINE/CYLINDER HEAD - INSTALLA-

TION) .

(10) Install pushrods

(11) Install rocker arms(Refer to 9 - ENGINE/CYL-

INDER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

(12) Install timing case cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(13) Install the oil pan(Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(14) Install cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(15) Install intake manifold(Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

(16) Install the A/C compressor, and set aside

(17) Install the generator.

(18) Install the accessory drive belt.

(19) Install the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION).

(20) Install the air cleaner assembly.

(21) Install the battery negative cable.

(22) Refill coolant.

(23) Refill engine oil.

(24) Start engine and check for leaks.

CRANKSHAFT

REMOVAL

(1) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(2) Remove the oil pan(Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(3) Remove the oil pump pickup.

(4) Remove the windage tray/oil pan gasket.

(5) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(6) Remove the oil pump(Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - REMOVAL).

(7) Remove the timing drive(Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(8) Identify rod bearing caps before removal.

Remove rod bearing caps with bearings.

(9) Identify main bearing caps before removal.

Remove main bearing caps and bearings one at a

time.

9 - 206 ENGINE - 5.7LDR

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1430 of 2627

(10) Remove the thrust washers.

(11) Remove the rear oil seal retainer(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT REAR

OIL SEAL RETAINE - REMOVAL).

(12) Remove the crankshaft out of the block.

(13) Remove and discard the crankshaft rear oil

seal.

(14) Remove and discard the front crankshaft oil

seal.

INSTALLATION

(1) Select the proper main bearings(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) .

(2) Install main bearings in block and caps, and

lubricate bearings.

(3) Position the crankshaft into the cylinder block.

(4) Install the thrust washers.

NOTE: The main cap crossbolts are torqued after

final torque of the main cap bolts. Always use a

new washer/seal on crossbolts.

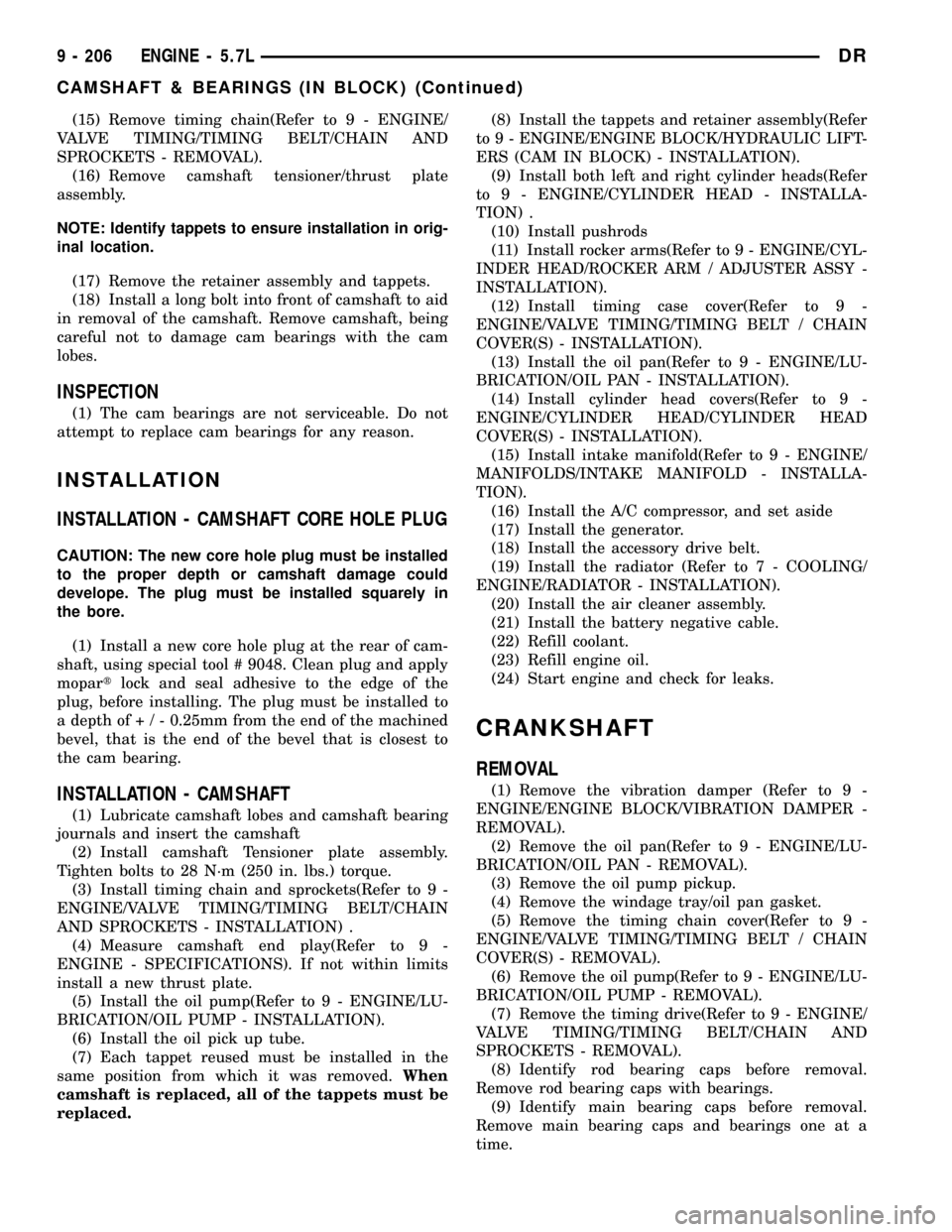

(5) Clean and oil all cap bolts. Install all main

bearing caps. Install all cap bolts and alternately

tighten in two steps using the following sequence

(Fig. 8).

²Step1±27N´m(20ft. lbs.) torque.

²Step2±Turnmain cap bolts an additional 90É.(6) Install the crossbolts with new washer/gasket.

Starting with crossbolt A (Fig. 8) torque each cross-

bolt to 28 N´m torque.

(7) Repeat crossbolt torque procedure.

(8) Measure crankshaft end play(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) .

(9) Position the connecting rods onto the crank-

shaft and install the rod bearing caps(Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - INSTALLATION).

(10) Install timing drive(Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(11) Install oil pump (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(12) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(13) Install the rear main seal and retainer(Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

REAR OIL SEAL RETAINE - INSTALLATION).

(14) Install the windage tray/oil pan gasket.

(15) Install the oil pick up tube.

(16) Install the oil pan(Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(17) Install the vibration damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(18) Install the engine(Refer to 9 - ENGINE -

INSTALLATION).

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE - CRANKSHAFT MAIN

BEARING - FITTING

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Crankshaft removed from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.0002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

CRANKSHAFT MAIN BEARING SELECTION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

Fig. 8 MAINCAP TIGHTENING SEQUENCE

1 - Stud Location

DRENGINE - 5.7L 9 - 207

CRANKSHAFT (Continued)