Causes DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1983 of 2627

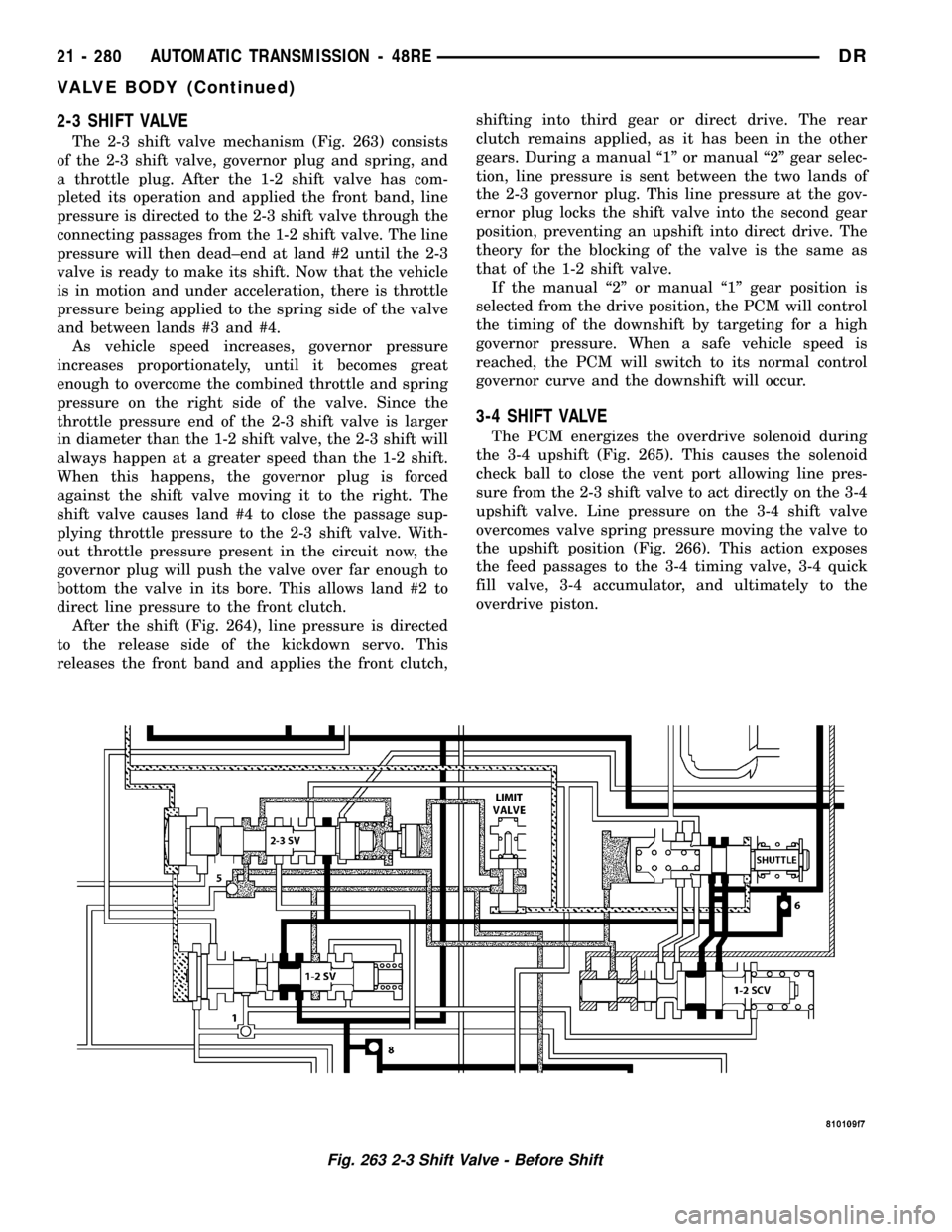

2-3 SHIFT VALVE

The 2-3 shift valve mechanism (Fig. 263) consists

of the 2-3 shift valve, governor plug and spring, and

a throttle plug. After the 1-2 shift valve has com-

pleted its operation and applied the front band, line

pressure is directed to the 2-3 shift valve through the

connecting passages from the 1-2 shift valve. The line

pressure will then dead±end at land #2 until the 2-3

valve is ready to make its shift. Now that the vehicle

is in motion and under acceleration, there is throttle

pressure being applied to the spring side of the valve

and between lands #3 and #4.

As vehicle speed increases, governor pressure

increases proportionately, until it becomes great

enough to overcome the combined throttle and spring

pressure on the right side of the valve. Since the

throttle pressure end of the 2-3 shift valve is larger

in diameter than the 1-2 shift valve, the 2-3 shift will

always happen at a greater speed than the 1-2 shift.

When this happens, the governor plug is forced

against the shift valve moving it to the right. The

shift valve causes land #4 to close the passage sup-

plying throttle pressure to the 2-3 shift valve. With-

out throttle pressure present in the circuit now, the

governor plug will push the valve over far enough to

bottom the valve in its bore. This allows land #2 to

direct line pressure to the front clutch.

After the shift (Fig. 264), line pressure is directed

to the release side of the kickdown servo. This

releases the front band and applies the front clutch,shifting into third gear or direct drive. The rear

clutch remains applied, as it has been in the other

gears. During a manual ª1º or manual ª2º gear selec-

tion, line pressure is sent between the two lands of

the 2-3 governor plug. This line pressure at the gov-

ernor plug locks the shift valve into the second gear

position, preventing an upshift into direct drive. The

theory for the blocking of the valve is the same as

that of the 1-2 shift valve.

If the manual ª2º or manual ª1º gear position is

selected from the drive position, the PCM will control

the timing of the downshift by targeting for a high

governor pressure. When a safe vehicle speed is

reached, the PCM will switch to its normal control

governor curve and the downshift will occur.

3-4 SHIFT VALVE

The PCM energizes the overdrive solenoid during

the 3-4 upshift (Fig. 265). This causes the solenoid

check ball to close the vent port allowing line pres-

sure from the 2-3 shift valve to act directly on the 3-4

upshift valve. Line pressure on the 3-4 shift valve

overcomes valve spring pressure moving the valve to

the upshift position (Fig. 266). This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston.

Fig. 263 2-3 Shift Valve - Before Shift

21 - 280 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 1987 of 2627

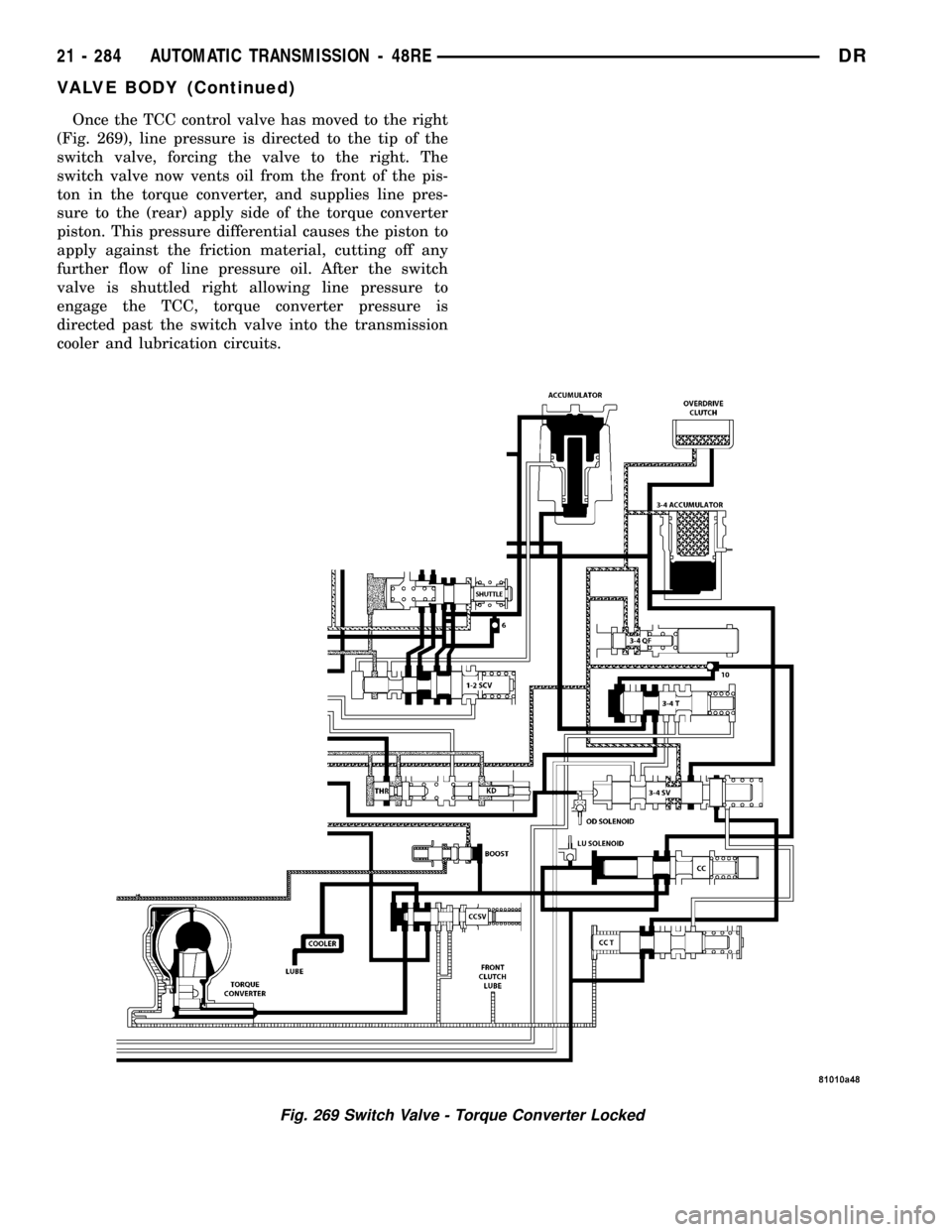

Once the TCC control valve has moved to the right

(Fig. 269), line pressure is directed to the tip of the

switch valve, forcing the valve to the right. The

switch valve now vents oil from the front of the pis-

ton in the torque converter, and supplies line pres-

sure to the (rear) apply side of the torque converter

piston. This pressure differential causes the piston to

apply against the friction material, cutting off any

further flow of line pressure oil. After the switch

valve is shuttled right allowing line pressure to

engage the TCC, torque converter pressure is

directed past the switch valve into the transmission

cooler and lubrication circuits.

Fig. 269 Switch Valve - Torque Converter Locked

21 - 284 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2014 of 2627

AUTOMATIC TRANSMISSION - 45RFE/545RFE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 45RFE/545RFE

DESCRIPTION........................312

OPERATION..........................313

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................314

DIAGNOSIS AND TESTING -

PRELIMINARY.......................314

DIAGNOSIS AND TESTING - ROAD

TESTING...........................314

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................316

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION....317

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................318

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................318

REMOVAL............................318

DISASSEMBLY........................320

CLEANING...........................326

INSPECTION.........................326

ASSEMBLY...........................326

INSTALLATION........................333

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............337

SPECIFICATIONS

TRANSMISSION.....................358

SPECIAL TOOLS

RFE TRANSMISSION.................359

4C RETAINER/BULKHEAD

DISASSEMBLY........................362

ASSEMBLY...........................363

ADAPTER HOUSING SEAL

REMOVAL............................364

INSTALLATION........................364

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

DESCRIPTION........................364

OPERATION..........................364

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......364

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................365

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............366

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................366DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................366

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................366

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............367

STANDARD PROCEDURE - TRANSMISSION

FILL...............................368

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................368

REMOVAL............................369

INSTALLATION........................370

ADJUSTMENTS

GEARSHIFT CABLE..................370

HOLDING CLUTCHES

DESCRIPTION........................371

OPERATION..........................372

INPUT CLUTCH ASSEMBLY

DESCRIPTION........................373

OPERATION..........................373

DISASSEMBLY........................374

ASSEMBLY...........................378

INPUT SPEED SENSOR

DESCRIPTION........................382

OPERATION..........................382

REMOVAL............................382

INSTALLATION........................382

LINE PRESSURE (LP) SENSOR

DESCRIPTION........................382

OPERATION..........................383

REMOVAL............................383

INSTALLATION........................383

LOW/REVERSE CLUTCH

DISASSEMBLY........................384

CLEANING...........................385

INSPECTION.........................385

ASSEMBLY...........................385

OIL PUMP

DESCRIPTION........................386

OPERATION..........................386

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................387

DISASSEMBLY........................388

CLEANING...........................390

INSPECTION.........................390

ASSEMBLY...........................390

OIL PUMP FRONT SEAL

REMOVAL............................391

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 311

Page 2069 of 2627

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has three primary causes.

(1) Internal clutch slippage, usually caused by low

line pressure, inadequate clutch apply pressure, or

clutch seal failure.

(2) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.

(3) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to replace contaminated converter after

repairThe use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The torque converter should also be replaced when-

ever a failure generates sludge and debris. This is

necessary because normal converter flushing proce-

dures will not remove all contaminants.

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the P (PARK)

and N (NEUTRAL) positions. Place the selector lever

in P (PARK) to be sure that the fluid level check is

accurate.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground.At normal operating temperature

(approximately 82 C. or 180 F.), the fluid level is cor-

rect if it is in the HOT region (cross-hatched area) on

the oil level indicator. The fluid level will be approx-

21 - 366 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2095 of 2627

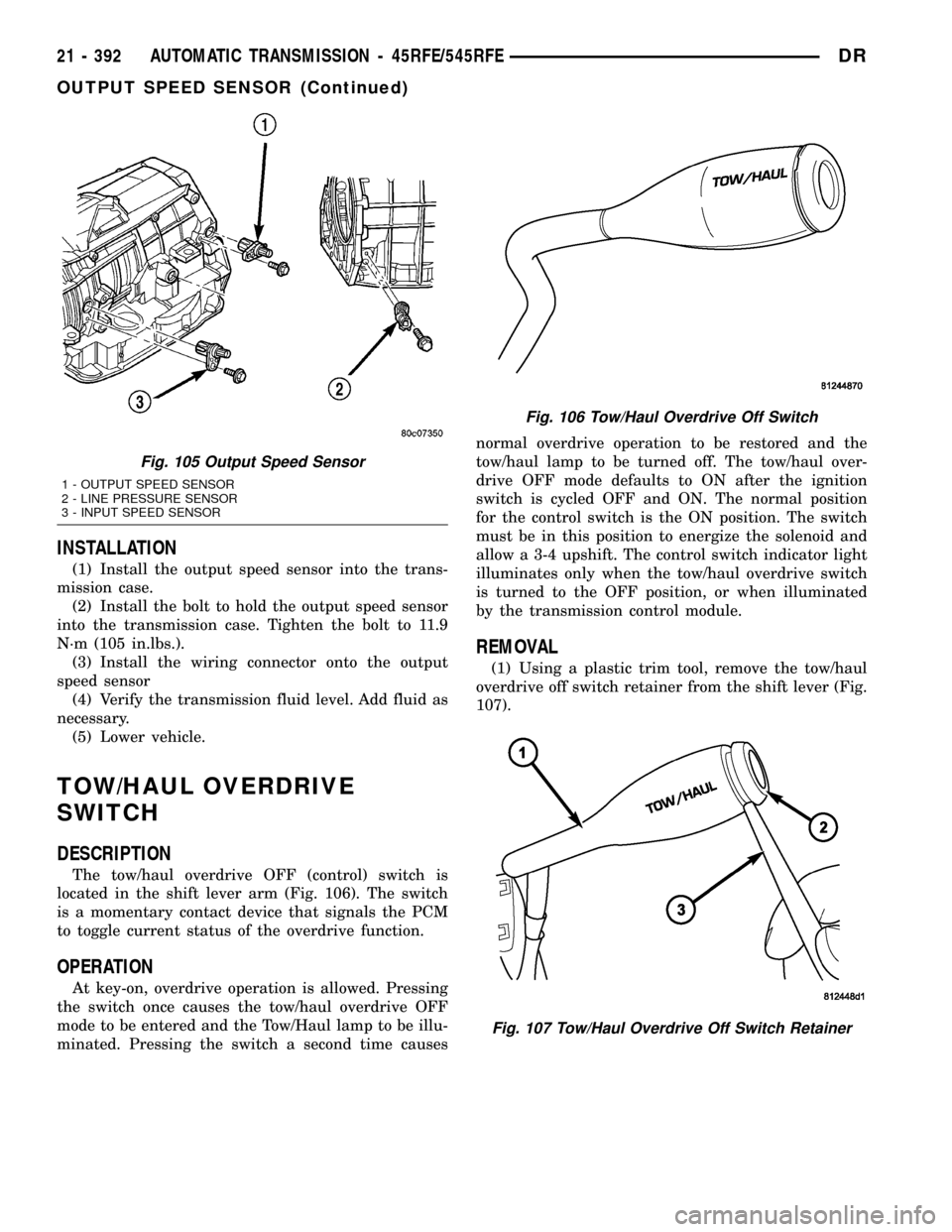

INSTALLATION

(1) Install the output speed sensor into the trans-

mission case.

(2) Install the bolt to hold the output speed sensor

into the transmission case. Tighten the bolt to 11.9

N´m (105 in.lbs.).

(3) Install the wiring connector onto the output

speed sensor

(4) Verify the transmission fluid level. Add fluid as

necessary.

(5) Lower vehicle.

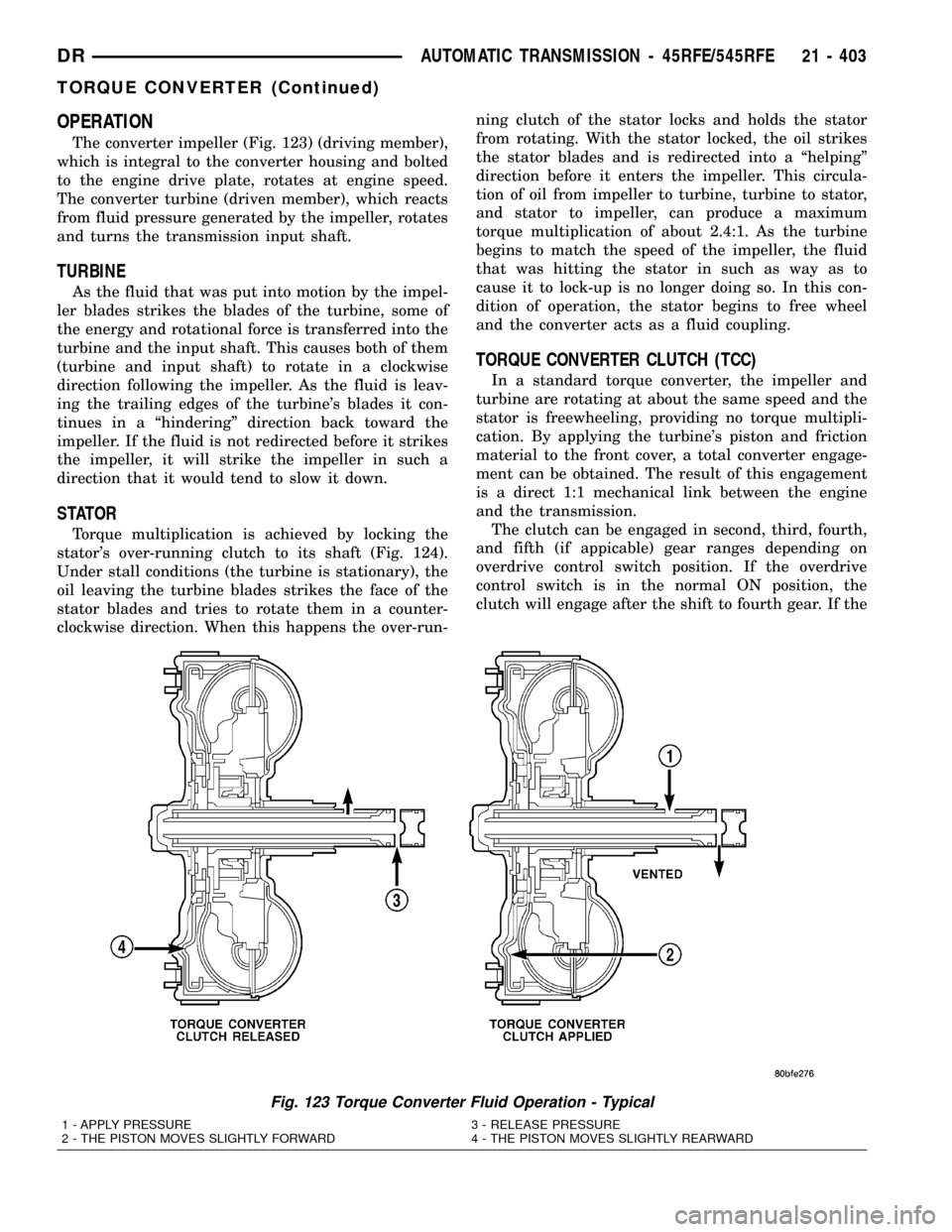

TOW/HAUL OVERDRIVE

SWITCH

DESCRIPTION

The tow/haul overdrive OFF (control) switch is

located in the shift lever arm (Fig. 106). The switch

is a momentary contact device that signals the PCM

to toggle current status of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing

the switch once causes the tow/haul overdrive OFF

mode to be entered and the Tow/Haul lamp to be illu-

minated. Pressing the switch a second time causesnormal overdrive operation to be restored and the

tow/haul lamp to be turned off. The tow/haul over-

drive OFF mode defaults to ON after the ignition

switch is cycled OFF and ON. The normal position

for the control switch is the ON position. The switch

must be in this position to energize the solenoid and

allow a 3-4 upshift. The control switch indicator light

illuminates only when the tow/haul overdrive switch

is turned to the OFF position, or when illuminated

by the transmission control module.

REMOVAL

(1) Using a plastic trim tool, remove the tow/haul

overdrive off switch retainer from the shift lever (Fig.

107).

Fig. 105 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

2 - LINE PRESSURE SENSOR

3 - INPUT SPEED SENSOR

Fig. 106 Tow/Haul Overdrive Off Switch

Fig. 107 Tow/Haul Overdrive Off Switch Retainer

21 - 392 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

OUTPUT SPEED SENSOR (Continued)

Page 2106 of 2627

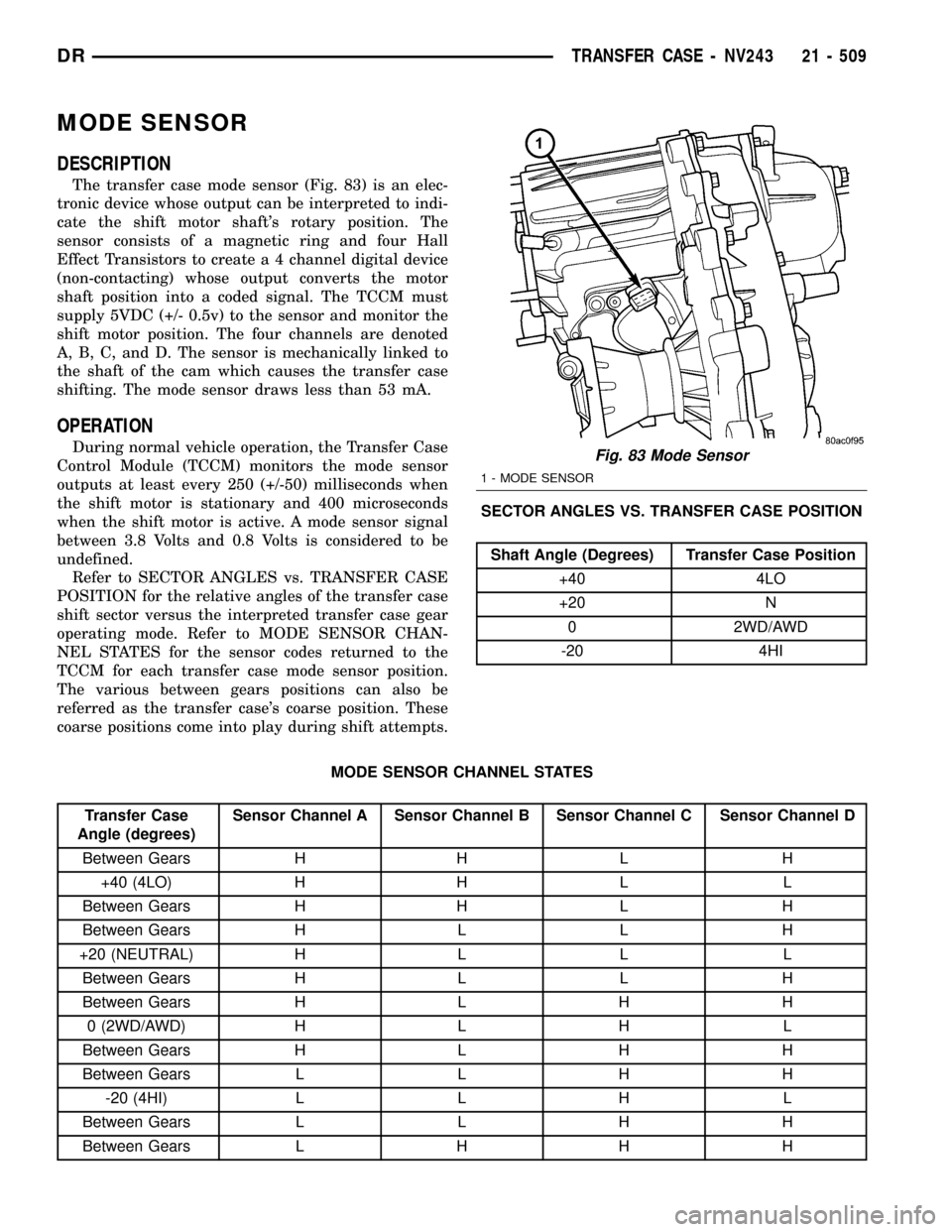

OPERATION

The converter impeller (Fig. 123) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 124).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the over-run-ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and

turbine are rotating at about the same speed and the

stator is freewheeling, providing no torque multipli-

cation. By applying the turbine's piston and friction

material to the front cover, a total converter engage-

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission.

The clutch can be engaged in second, third, fourth,

and fifth (if appicable) gear ranges depending on

overdrive control switch position. If the overdrive

control switch is in the normal ON position, the

clutch will engage after the shift to fourth gear. If the

Fig. 123 Torque Converter Fluid Operation - Typical

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 403

TORQUE CONVERTER (Continued)

Page 2212 of 2627

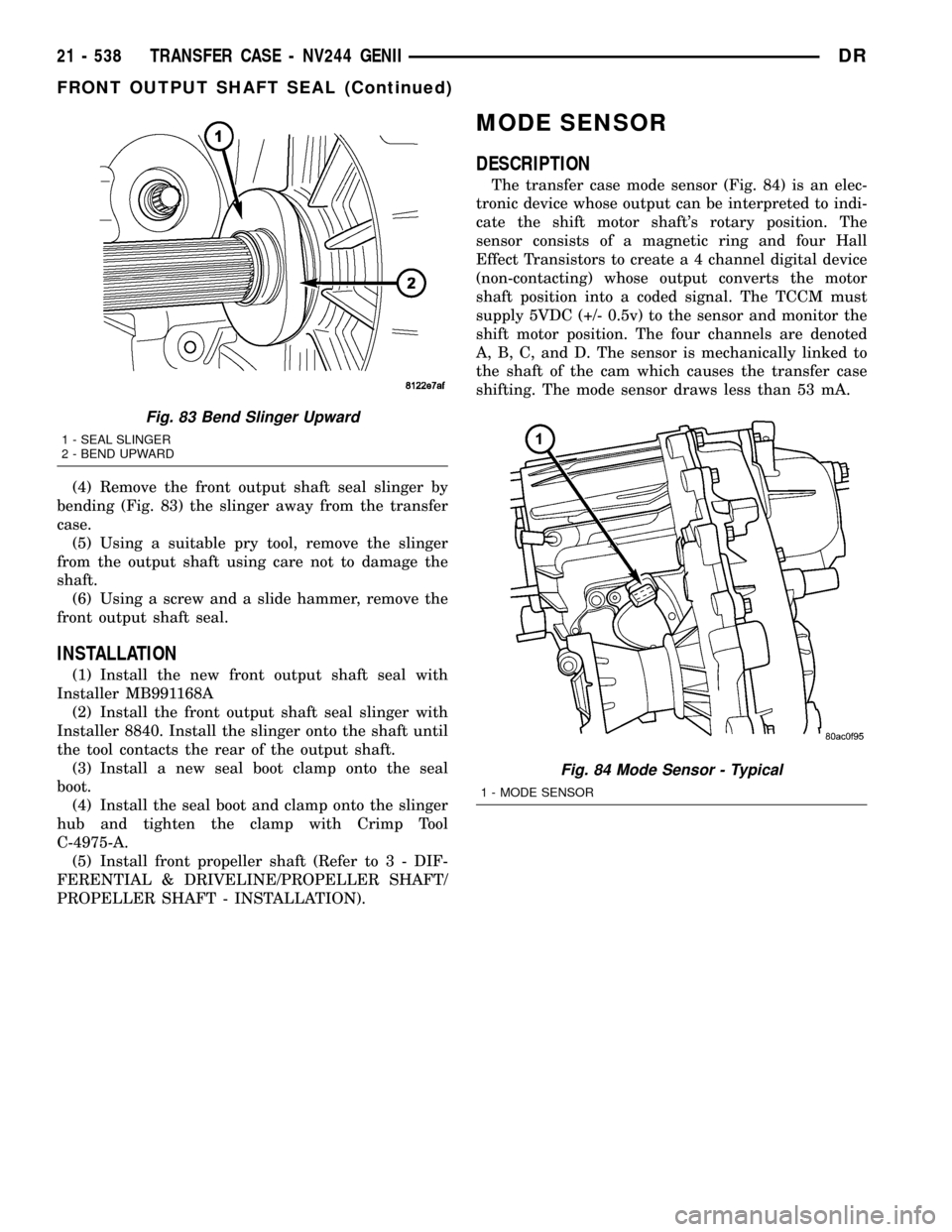

MODE SENSOR

DESCRIPTION

The transfer case mode sensor (Fig. 83) is an elec-

tronic device whose output can be interpreted to indi-

cate the shift motor shaft's rotary position. The

sensor consists of a magnetic ring and four Hall

Effect Transistors to create a 4 channel digital device

(non-contacting) whose output converts the motor

shaft position into a coded signal. The TCCM must

supply 5VDC (+/- 0.5v) to the sensor and monitor the

shift motor position. The four channels are denoted

A, B, C, and D. The sensor is mechanically linked to

the shaft of the cam which causes the transfer case

shifting. The mode sensor draws less than 53 mA.

OPERATION

During normal vehicle operation, the Transfer Case

Control Module (TCCM) monitors the mode sensor

outputs at least every 250 (+/-50) milliseconds when

the shift motor is stationary and 400 microseconds

when the shift motor is active. A mode sensor signal

between 3.8 Volts and 0.8 Volts is considered to be

undefined.

Refer to SECTOR ANGLES vs. TRANSFER CASE

POSITION for the relative angles of the transfer case

shift sector versus the interpreted transfer case gear

operating mode. Refer to MODE SENSOR CHAN-

NEL STATES for the sensor codes returned to the

TCCM for each transfer case mode sensor position.

The various between gears positions can also be

referred as the transfer case's coarse position. These

coarse positions come into play during shift attempts.SECTOR ANGLES VS. TRANSFER CASE POSITION

Shaft Angle (Degrees) Transfer Case Position

+40 4LO

+20 N

0 2WD/AWD

-20 4HI

MODE SENSOR CHANNEL STATES

Transfer Case

Angle (degrees)Sensor Channel A Sensor Channel B Sensor Channel C Sensor Channel D

Between Gears H H L H

+40 (4LO) H H L L

Between Gears H H L H

Between Gears H L L H

+20 (NEUTRAL) H L L L

Between Gears H L L H

Between Gears H L H H

0 (2WD/AWD) H L H L

Between Gears H L H H

Between Gears L L H H

-20 (4HI) L L H L

Between Gears L L H H

Between Gears L H H H

Fig. 83 Mode Sensor

1 - MODE SENSOR

DRTRANSFER CASE - NV243 21 - 509

Page 2241 of 2627

(4) Remove the front output shaft seal slinger by

bending (Fig. 83) the slinger away from the transfer

case.

(5) Using a suitable pry tool, remove the slinger

from the output shaft using care not to damage the

shaft.

(6) Using a screw and a slide hammer, remove the

front output shaft seal.

INSTALLATION

(1) Install the new front output shaft seal with

Installer MB991168A

(2) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(3) Install a new seal boot clamp onto the seal

boot.

(4) Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool

C-4975-A.

(5) Install front propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION).

MODE SENSOR

DESCRIPTION

The transfer case mode sensor (Fig. 84) is an elec-

tronic device whose output can be interpreted to indi-

cate the shift motor shaft's rotary position. The

sensor consists of a magnetic ring and four Hall

Effect Transistors to create a 4 channel digital device

(non-contacting) whose output converts the motor

shaft position into a coded signal. The TCCM must

supply 5VDC (+/- 0.5v) to the sensor and monitor the

shift motor position. The four channels are denoted

A, B, C, and D. The sensor is mechanically linked to

the shaft of the cam which causes the transfer case

shifting. The mode sensor draws less than 53 mA.

Fig. 83 Bend Slinger Upward

1 - SEAL SLINGER

2 - BEND UPWARD

Fig. 84 Mode Sensor - Typical

1 - MODE SENSOR

21 - 538 TRANSFER CASE - NV244 GENIIDR

FRONT OUTPUT SHAFT SEAL (Continued)

Page 2276 of 2627

MODE SENSOR

DESCRIPTION

The transfer case mode sensor (Fig. 94) is an elec-

tronic device whose output can be interpreted to indi-

cate the shift motor shaft's rotary position. The

sensor consists of a magnetic ring and four Hall

Effect Transistors to create a 4 channel digital device

(non-contacting) whose output converts the motor

shaft position into a coded signal. The TCCM must

supply 5VDC (+/- 0.5v) to the sensor and monitor the

shift motor position. The four channels are denoted

A, B, C, and D. The sensor is mechanically linked to

the shaft of the cam which causes the transfer case

shifting. The mode sensor draws less than 53 mA.

OPERATION

During normal vehicle operation, the Transfer Case

Control Module (TCCM) monitors the mode sensor

outputs at least every 250 (+/-50) milliseconds when

the shift motor is stationary and 400 microseconds

when the shift motor is active. A mode sensor signal

between 3.8 Volts and 0.8 Volts is considered to be

undefined.

Refer to SECTOR ANGLES vs. TRANSFER CASE

POSITION for the relative angles of the transfer case

shift sector versus the interpreted transfer case gear

operating mode. Refer to MODE SENSOR CHAN-

NEL STATES for the sensor codes returned to the

TCCM for each transfer case mode sensor position.

The various between gears positions can also be

referred as the transfer case's coarse position. These

coarse positions come into play during shift attempts.SECTOR ANGLES VS. TRANSFER CASE POSITION

Shaft Angle (Degrees) Transfer Case Position

+40 4LO

+20 N

0 2WD/AWD

-20 4HI

MODE SENSOR CHANNEL STATES

Transfer Case

Angle (degrees)Sensor Channel A Sensor Channel B Sensor Channel C Sensor Channel D

Between Gears H H L H

+40 (4LO) H H L L

Between Gears H H L H

Between Gears H L L H

+20 (NEUTRAL) H L L L

Between Gears H L L H

Between Gears H L H H

0 (2WD/AWD) H L H L

Between Gears H L H H

Between Gears L L H H

-20 (4HI) L L H L

Between Gears L L H H

Between Gears L H H H

Fig. 94 Mode Sensor

1 - MODE SENSOR

DRTRANSFER CASE - NV273 21 - 573

Page 2287 of 2627

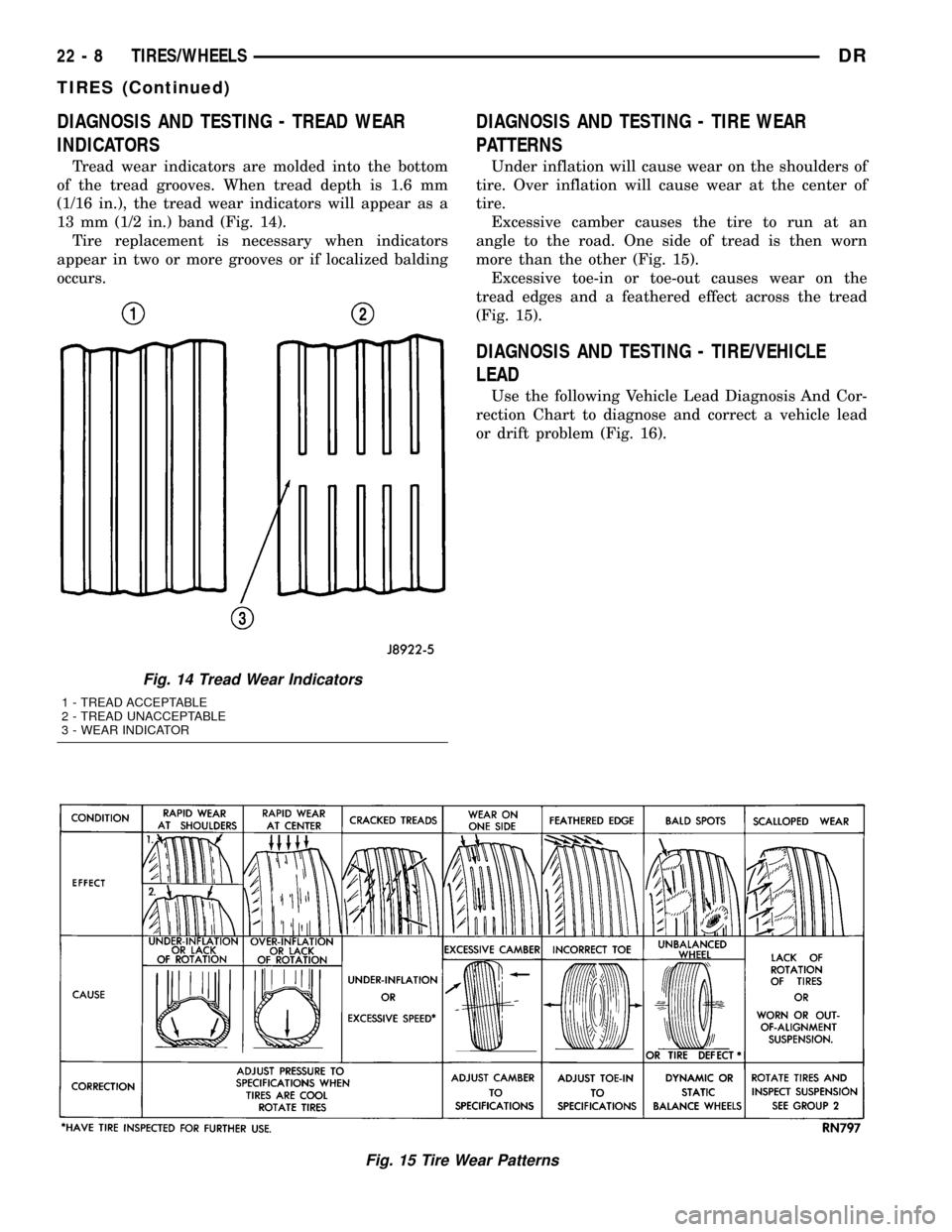

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 14).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 15).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 15).

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD

Use the following Vehicle Lead Diagnosis And Cor-

rection Chart to diagnose and correct a vehicle lead

or drift problem (Fig. 16).

Fig. 15 Tire Wear Patterns

Fig. 14 Tread Wear Indicators

1 - TREAD ACCEPTABLE

2 - TREAD UNACCEPTABLE

3 - WEAR INDICATOR

22 - 8 TIRES/WHEELSDR

TIRES (Continued)