Coil DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2536 of 2627

when a minimum discharge pressure of 2756 kPa

(400 psi) is reached.

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean that the valve is faulty.

The high pressure relief valve is a factory-cali-

brated unit. The valve cannot be adjusted or

repaired, and must not be removed or otherwise dis-

turbed. The valve is only serviced as a part of the

compressor assembly.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

When investigating an air conditioning related

noise, you must first know the conditions under

which the noise occurs. These conditions include:

weather, vehicle speed, transmission in gear or neu-

tral, engine speed, engine temperature, and any

other special conditions. Noises that develop during

air conditioning operation can often be misleading.

For example: What sounds like a failed front bearing

or connecting rod, may be caused by loose bolts, nuts,

mounting brackets, or a loose compressor clutch

assembly.

Drive belts are speed sensitive. At different engine

speeds and depending upon belt tension, belts can

develop noises that are mistaken for a compressor

noise. Improper belt tension can cause a misleading

noise when the compressor clutch is engaged, which

may not occur when the compressor clutch is disen-

gaged. Check the serpentine drive belt condition and

tension as described in Cooling before beginning this

procedure.

(1) Select a quiet area for testing. Duplicate the

complaint conditions as much as possible. Switch the

compressor on and off several times to clearly iden-

tify the compressor noise. Listen to the compressor

while the clutch is engaged and disengaged. Probe

the compressor with an engine stethoscope or a long

screwdriver with the handle held to your ear to bet-

ter localize the source of the noise.

(2) Loosen all of the compressor mounting hard-

ware and retighten. Tighten the compressor clutch

mounting nut. Be certain that the clutch coil is

mounted securely to the compressor, and that the

clutch plate and rotor are properly aligned and have

the correct air gap (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH - INSTALLATION).

(3) To duplicate a high-ambient temperature condi-

tion (high head pressure), restrict the air flow

through the condenser. Install a manifold gauge set

or a DRBIIItscan tool to be certain that the dis-

charge pressure does not exceed 2760 kPa (400 psi).(4) Check the refrigerant system plumbing for

incorrect routing, rubbing or interference, which can

cause unusual noises. Also check the refrigerant lines

for kinks or sharp bends that will restrict refrigerant

flow, which can cause noises (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE).

(5) If the noise is from opening and closing of the

high pressure relief valve, recover, evacuate and

recharge the refrigerant system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE), (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - REFRIGERANT SYSTEM EVACU-

ATE) and (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM CHARGE). If the high

pressure relief valve still does not seat properly,

replace the compressor (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/A/C COMPRES-

SOR - REMOVAL).

(6) If the noise is from liquid slugging on the suc-

tion line, replace the accumulator (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/AC-

CUMULATOR - REMOVAL) and check the refriger-

ant oil level and the refrigerant system charge (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/REFRIGERANT OIL - STANDARD PROCE-

DURE) (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/ACCUMULATOR -

REMOVAL). If after replacing the accumulator the

slugging condition still exists then replace the com-

pressor.(Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/A/C COMPRESSOR - REMOVAL).

(7) If the liquid slugging condition continues fol-

lowing accumulator replacement, replace the com-

pressor and repeat Step 1.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

NOTE: The A/C compressor may be removed and

repositioned without disconnecting the refrigerant

lines or discharging the refrigerant system. Dis-

charging is not necessary if servicing the compres-

sor clutch, clutch coil, engine, engine cylinder head

or the generator.

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

DRPLUMBING 24 - 49

A/C COMPRESSOR (Continued)

Page 2537 of 2627

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Disconnect the A/C compressor clutch coil wire

harness connector.

(5) Depending on engine usage, remove the bolt or

nuts that secure the suction and discharge line fit-

tings to the A/C compressor.

(6) Disconnect the suction and discharge line fit-

tings from the A/C compressor.

(7) Remove the O-ring seals from the suction and

discharge line fittings and discard.

(8) Install plugs in, or tape over all of the opened

refrigerant line fittings and the compressor ports.

(9) If equipped with the 5.7L Hemi engine, remove

the nuts and bolts that secure the generator and A/C

compressor support bracket and remove the bracket

from the engine.

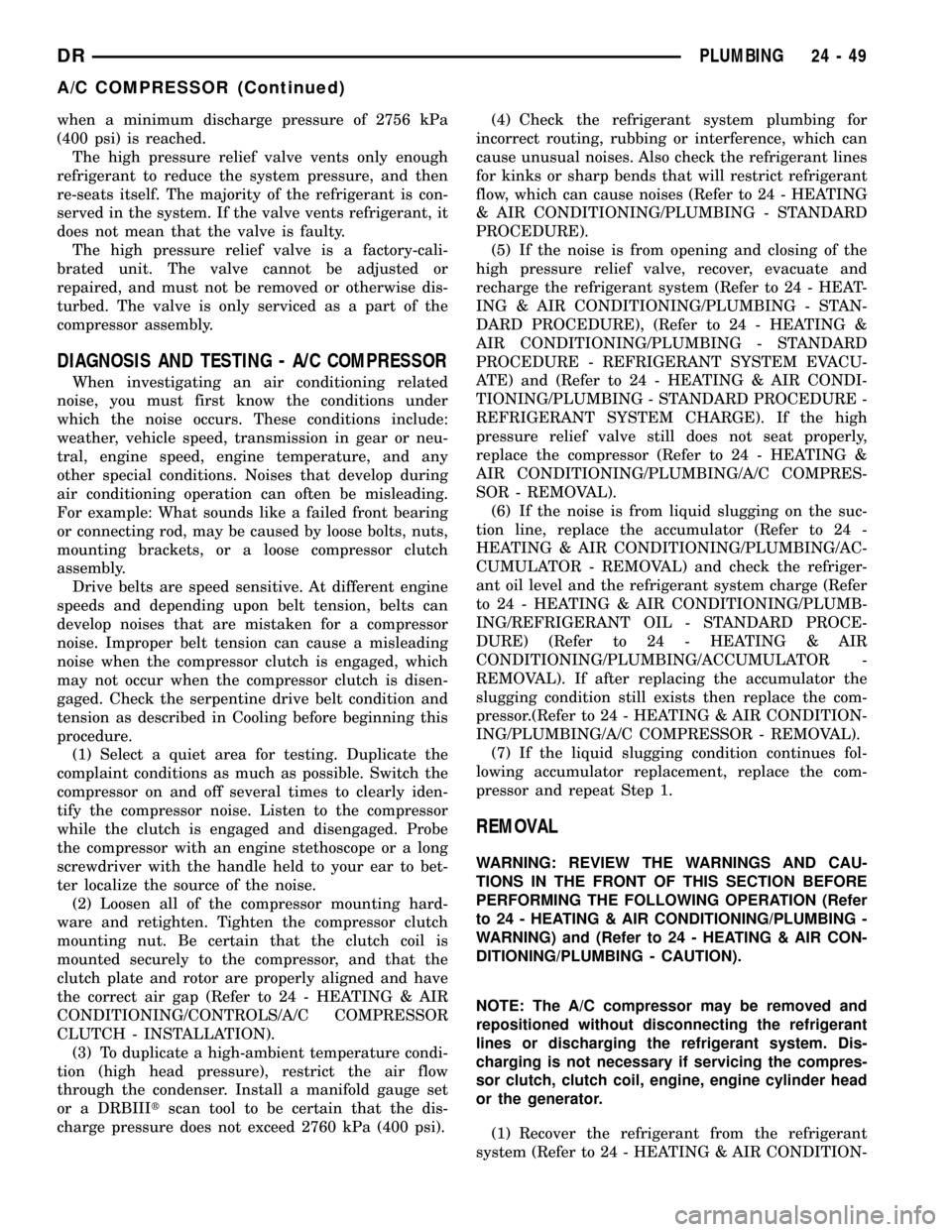

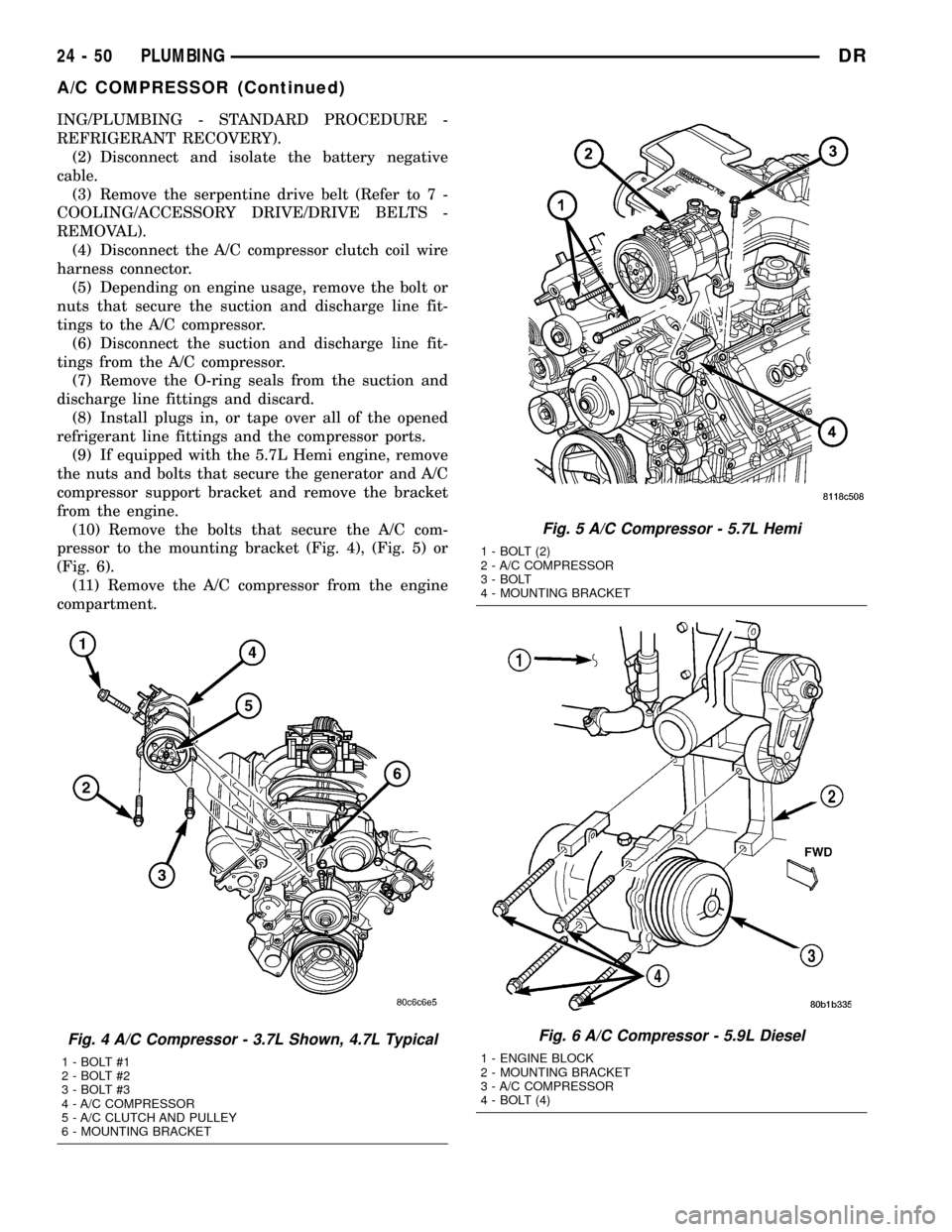

(10) Remove the bolts that secure the A/C com-

pressor to the mounting bracket (Fig. 4), (Fig. 5) or

(Fig. 6).

(11) Remove the A/C compressor from the engine

compartment.

Fig. 4 A/C Compressor - 3.7L Shown, 4.7L Typical

1 - BOLT #1

2 - BOLT #2

3 - BOLT #3

4 - A/C COMPRESSOR

5 - A/C CLUTCH AND PULLEY

6 - MOUNTING BRACKET

Fig. 5 A/C Compressor - 5.7L Hemi

1 - BOLT (2)

2 - A/C COMPRESSOR

3 - BOLT

4 - MOUNTING BRACKET

Fig. 6 A/C Compressor - 5.9L Diesel

1 - ENGINE BLOCK

2 - MOUNTING BRACKET

3 - A/C COMPRESSOR

4 - BOLT (4)

24 - 50 PLUMBINGDR

A/C COMPRESSOR (Continued)

Page 2538 of 2627

INSTALLATION

NOTE: If a replacement compressor is being

installed, be certain to check the refrigerant oil

level. See Refrigerant Oil Level in this group for the

procedures. Use only refrigerant oil of the type rec-

ommended for the compressor in the vehicle.

(1) Install the compressor onto the mounting

bracket.

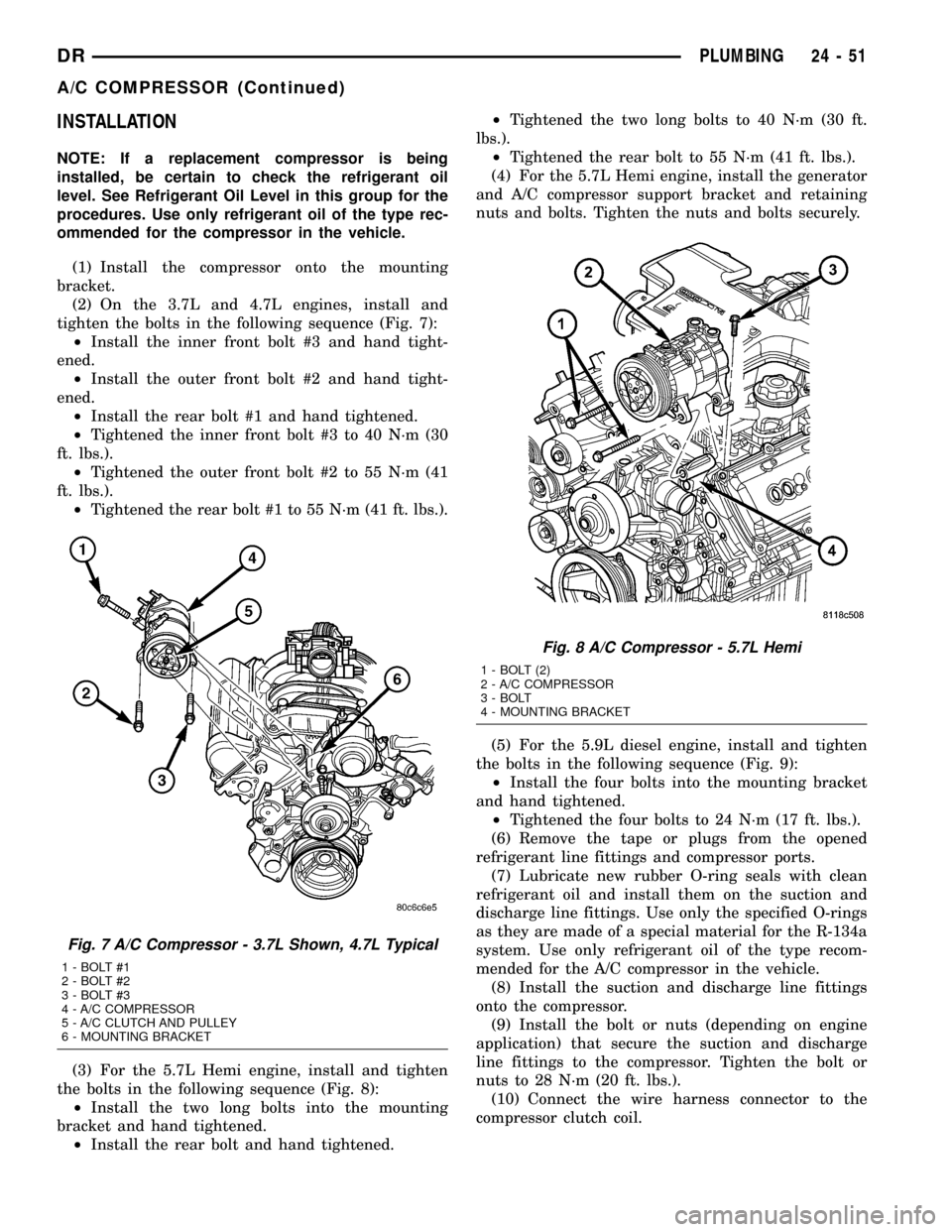

(2) On the 3.7L and 4.7L engines, install and

tighten the bolts in the following sequence (Fig. 7):

²Install the inner front bolt #3 and hand tight-

ened.

²Install the outer front bolt #2 and hand tight-

ened.

²Install the rear bolt #1 and hand tightened.

²Tightened the inner front bolt #3 to 40 N´m (30

ft. lbs.).

²Tightened the outer front bolt #2 to 55 N´m (41

ft. lbs.).

²Tightened the rear bolt #1 to 55 N´m (41 ft. lbs.).

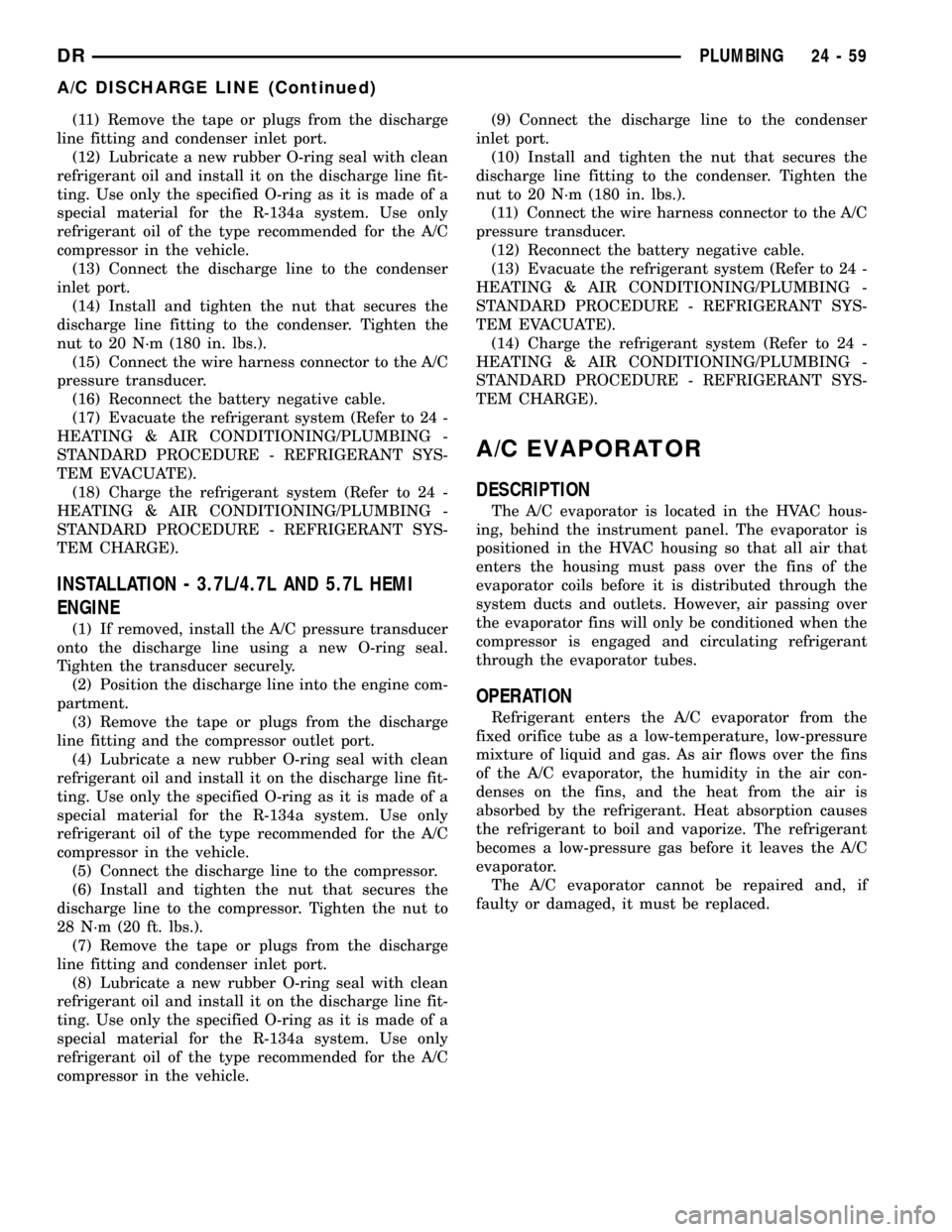

(3) For the 5.7L Hemi engine, install and tighten

the bolts in the following sequence (Fig. 8):

²Install the two long bolts into the mounting

bracket and hand tightened.

²Install the rear bolt and hand tightened.²Tightened the two long bolts to 40 N´m (30 ft.

lbs.).

²Tightened the rear bolt to 55 N´m (41 ft. lbs.).

(4) For the 5.7L Hemi engine, install the generator

and A/C compressor support bracket and retaining

nuts and bolts. Tighten the nuts and bolts securely.

(5) For the 5.9L diesel engine, install and tighten

the bolts in the following sequence (Fig. 9):

²Install the four bolts into the mounting bracket

and hand tightened.

²Tightened the four bolts to 24 N´m (17 ft. lbs.).

(6) Remove the tape or plugs from the opened

refrigerant line fittings and compressor ports.

(7) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the suction and

discharge line fittings. Use only the specified O-rings

as they are made of a special material for the R-134a

system. Use only refrigerant oil of the type recom-

mended for the A/C compressor in the vehicle.

(8) Install the suction and discharge line fittings

onto the compressor.

(9) Install the bolt or nuts (depending on engine

application) that secure the suction and discharge

line fittings to the compressor. Tighten the bolt or

nuts to 28 N´m (20 ft. lbs.).

(10) Connect the wire harness connector to the

compressor clutch coil.

Fig. 7 A/C Compressor - 3.7L Shown, 4.7L Typical

1 - BOLT #1

2 - BOLT #2

3 - BOLT #3

4 - A/C COMPRESSOR

5 - A/C CLUTCH AND PULLEY

6 - MOUNTING BRACKET

Fig. 8 A/C Compressor - 5.7L Hemi

1 - BOLT (2)

2 - A/C COMPRESSOR

3 - BOLT

4 - MOUNTING BRACKET

DRPLUMBING 24 - 51

A/C COMPRESSOR (Continued)

Page 2546 of 2627

(11) Remove the tape or plugs from the discharge

line fitting and condenser inlet port.

(12) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting. Use only the specified O-ring as it is made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(13) Connect the discharge line to the condenser

inlet port.

(14) Install and tighten the nut that secures the

discharge line fitting to the condenser. Tighten the

nut to 20 N´m (180 in. lbs.).

(15) Connect the wire harness connector to the A/C

pressure transducer.

(16) Reconnect the battery negative cable.

(17) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(18) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

INSTALLATION - 3.7L/4.7L AND 5.7L HEMI

ENGINE

(1) If removed, install the A/C pressure transducer

onto the discharge line using a new O-ring seal.

Tighten the transducer securely.

(2) Position the discharge line into the engine com-

partment.

(3) Remove the tape or plugs from the discharge

line fitting and the compressor outlet port.

(4) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting. Use only the specified O-ring as it is made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(5) Connect the discharge line to the compressor.

(6) Install and tighten the nut that secures the

discharge line to the compressor. Tighten the nut to

28 N´m (20 ft. lbs.).

(7) Remove the tape or plugs from the discharge

line fitting and condenser inlet port.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting. Use only the specified O-ring as it is made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.(9) Connect the discharge line to the condenser

inlet port.

(10) Install and tighten the nut that secures the

discharge line fitting to the condenser. Tighten the

nut to 20 N´m (180 in. lbs.).

(11) Connect the wire harness connector to the A/C

pressure transducer.

(12) Reconnect the battery negative cable.

(13) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(14) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

A/C EVAPORATOR

DESCRIPTION

The A/C evaporator is located in the HVAC hous-

ing, behind the instrument panel. The evaporator is

positioned in the HVAC housing so that all air that

enters the housing must pass over the fins of the

evaporator coils before it is distributed through the

system ducts and outlets. However, air passing over

the evaporator fins will only be conditioned when the

compressor is engaged and circulating refrigerant

through the evaporator tubes.

OPERATION

Refrigerant enters the A/C evaporator from the

fixed orifice tube as a low-temperature, low-pressure

mixture of liquid and gas. As air flows over the fins

of the A/C evaporator, the humidity in the air con-

denses on the fins, and the heat from the air is

absorbed by the refrigerant. Heat absorption causes

the refrigerant to boil and vaporize. The refrigerant

becomes a low-pressure gas before it leaves the A/C

evaporator.

The A/C evaporator cannot be repaired and, if

faulty or damaged, it must be replaced.

DRPLUMBING 24 - 59

A/C DISCHARGE LINE (Continued)

Page 2547 of 2627

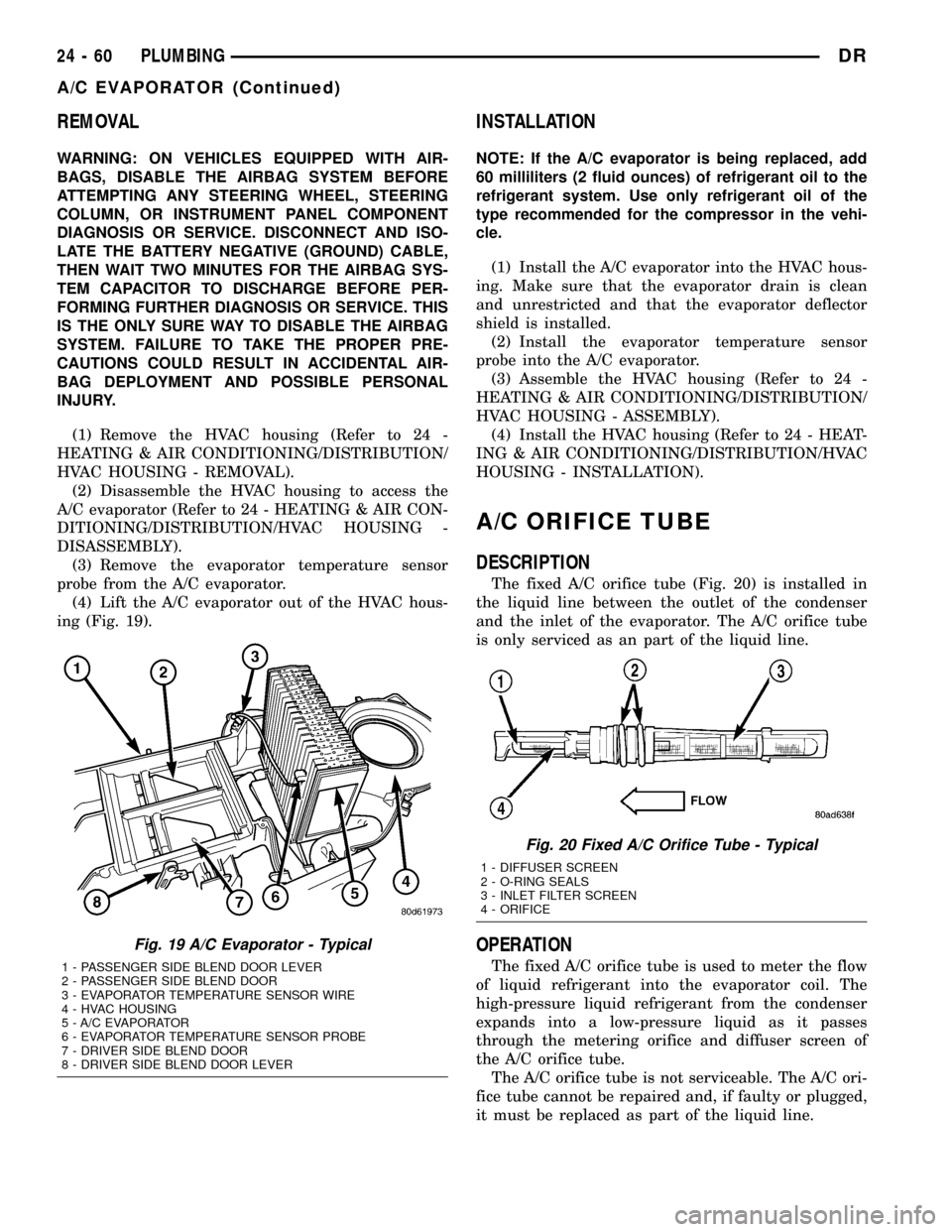

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL).

(2) Disassemble the HVAC housing to access the

A/C evaporator (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

DISASSEMBLY).

(3) Remove the evaporator temperature sensor

probe from the A/C evaporator.

(4) Lift the A/C evaporator out of the HVAC hous-

ing (Fig. 19).

INSTALLATION

NOTE: If the A/C evaporator is being replaced, add

60 milliliters (2 fluid ounces) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the compressor in the vehi-

cle.

(1) Install the A/C evaporator into the HVAC hous-

ing. Make sure that the evaporator drain is clean

and unrestricted and that the evaporator deflector

shield is installed.

(2) Install the evaporator temperature sensor

probe into the A/C evaporator.

(3) Assemble the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - ASSEMBLY).

(4) Install the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION).

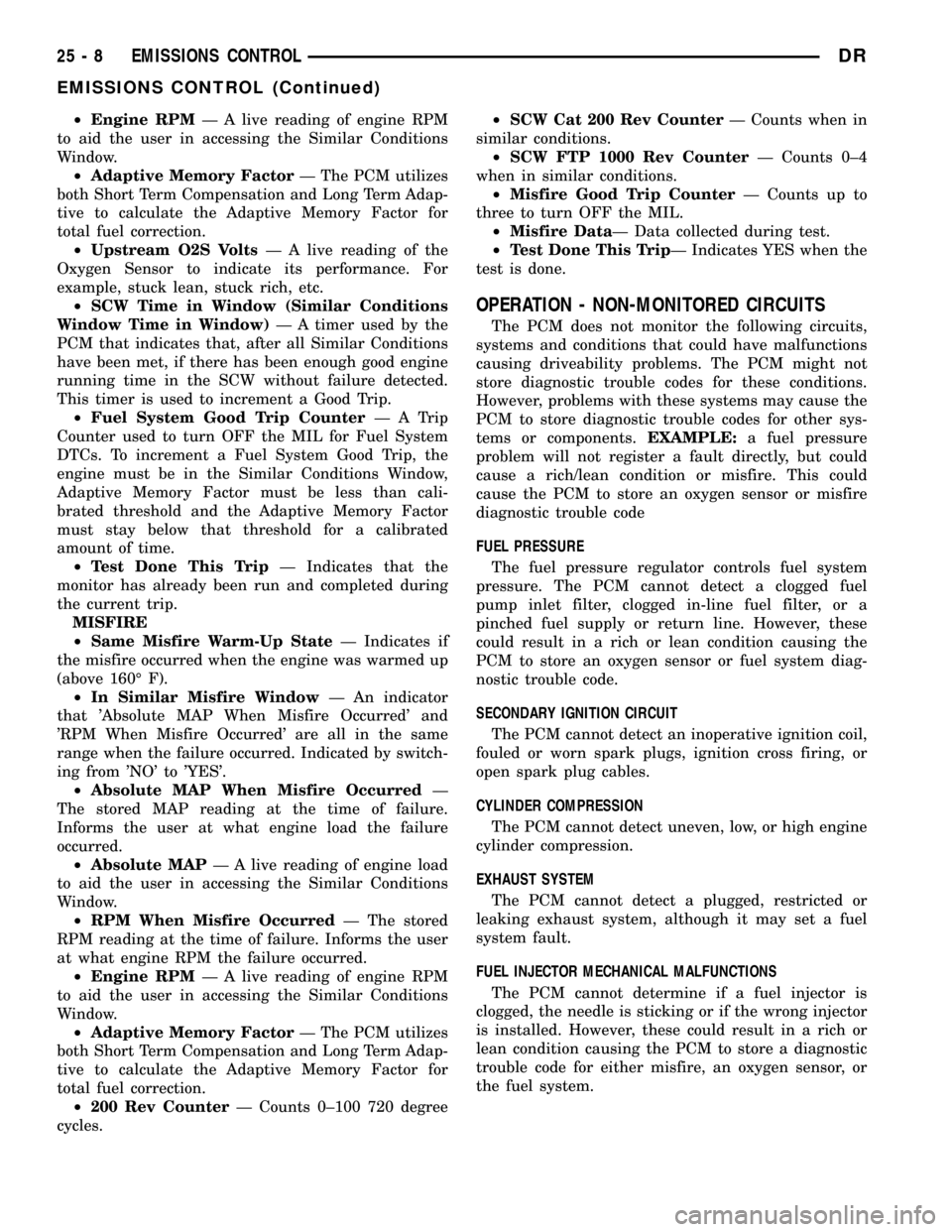

A/C ORIFICE TUBE

DESCRIPTION

The fixed A/C orifice tube (Fig. 20) is installed in

the liquid line between the outlet of the condenser

and the inlet of the evaporator. The A/C orifice tube

is only serviced as an part of the liquid line.

OPERATION

The fixed A/C orifice tube is used to meter the flow

of liquid refrigerant into the evaporator coil. The

high-pressure liquid refrigerant from the condenser

expands into a low-pressure liquid as it passes

through the metering orifice and diffuser screen of

the A/C orifice tube.

The A/C orifice tube is not serviceable. The A/C ori-

fice tube cannot be repaired and, if faulty or plugged,

it must be replaced as part of the liquid line.

Fig. 19 A/C Evaporator - Typical

1 - PASSENGER SIDE BLEND DOOR LEVER

2 - PASSENGER SIDE BLEND DOOR

3 - EVAPORATOR TEMPERATURE SENSOR WIRE

4 - HVAC HOUSING

5 - A/C EVAPORATOR

6 - EVAPORATOR TEMPERATURE SENSOR PROBE

7 - DRIVER SIDE BLEND DOOR

8 - DRIVER SIDE BLEND DOOR LEVER

Fig. 20 Fixed A/C Orifice Tube - Typical

1 - DIFFUSER SCREEN

2 - O-RING SEALS

3 - INLET FILTER SCREEN

4 - ORIFICE

24 - 60 PLUMBINGDR

A/C EVAPORATOR (Continued)

Page 2569 of 2627

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²Upstream O2S VoltsÐ A live reading of the

Oxygen Sensor to indicate its performance. For

example, stuck lean, stuck rich, etc.

²SCW Time in Window (Similar Conditions

Window Time in Window)Ð A timer used by the

PCM that indicates that, after all Similar Conditions

have been met, if there has been enough good engine

running time in the SCW without failure detected.

This timer is used to increment a Good Trip.

²Fuel System Good Trip CounterÐATrip

Counter used to turn OFF the MIL for Fuel System

DTCs. To increment a Fuel System Good Trip, the

engine must be in the Similar Conditions Window,

Adaptive Memory Factor must be less than cali-

brated threshold and the Adaptive Memory Factor

must stay below that threshold for a calibrated

amount of time.

²Test Done This TripÐ Indicates that the

monitor has already been run and completed during

the current trip.

MISFIRE

²Same Misfire Warm-Up StateÐ Indicates if

the misfire occurred when the engine was warmed up

(above 160É F).

²In Similar Misfire WindowÐ An indicator

that 'Absolute MAP When Misfire Occurred' and

'RPM When Misfire Occurred' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Misfire OccurredÐ

The stored MAP reading at the time of failure.

Informs the user at what engine load the failure

occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Misfire OccurredÐ The stored

RPM reading at the time of failure. Informs the user

at what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²200 Rev CounterÐ Counts 0±100 720 degree

cycles.²SCW Cat 200 Rev CounterÐ Counts when in

similar conditions.

²SCW FTP 1000 Rev CounterÐ Counts 0±4

when in similar conditions.

²Misfire Good Trip CounterÐ Counts up to

three to turn OFF the MIL.

²Misfire DataÐ Data collected during test.

²Test Done This TripÐ Indicates YES when the

test is done.

OPERATION - NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

causing driveability problems. The PCM might not

store diagnostic trouble codes for these conditions.

However, problems with these systems may cause the

PCM to store diagnostic trouble codes for other sys-

tems or components.EXAMPLE:a fuel pressure

problem will not register a fault directly, but could

cause a rich/lean condition or misfire. This could

cause the PCM to store an oxygen sensor or misfire

diagnostic trouble code

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system, although it may set a fuel

system fault.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

25 - 8 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2573 of 2627

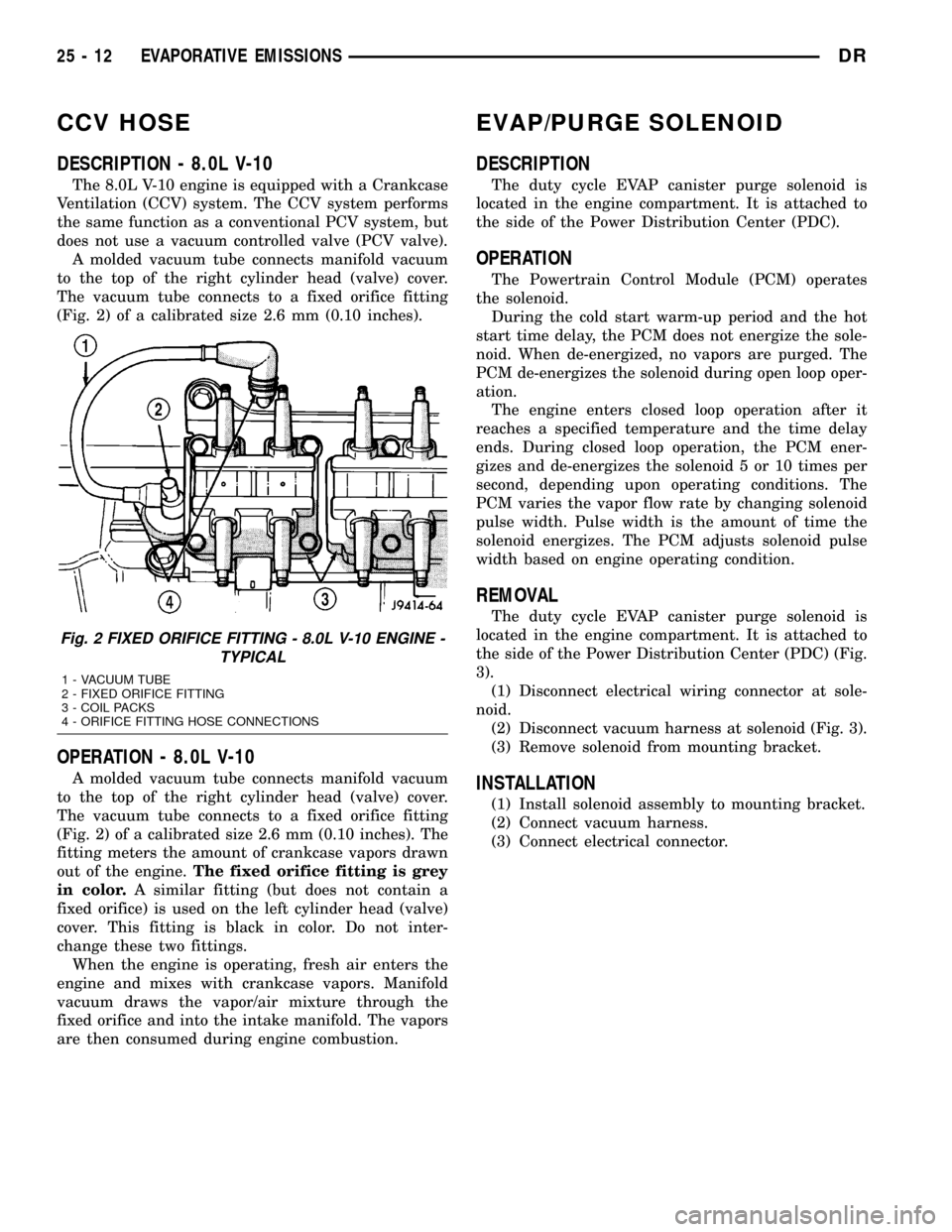

CCV HOSE

DESCRIPTION - 8.0L V-10

The 8.0L V-10 engine is equipped with a Crankcase

Ventilation (CCV) system. The CCV system performs

the same function as a conventional PCV system, but

does not use a vacuum controlled valve (PCV valve).

A molded vacuum tube connects manifold vacuum

to the top of the right cylinder head (valve) cover.

The vacuum tube connects to a fixed orifice fitting

(Fig. 2) of a calibrated size 2.6 mm (0.10 inches).

OPERATION - 8.0L V-10

A molded vacuum tube connects manifold vacuum

to the top of the right cylinder head (valve) cover.

The vacuum tube connects to a fixed orifice fitting

(Fig. 2) of a calibrated size 2.6 mm (0.10 inches). The

fitting meters the amount of crankcase vapors drawn

out of the engine.The fixed orifice fitting is grey

in color.A similar fitting (but does not contain a

fixed orifice) is used on the left cylinder head (valve)

cover. This fitting is black in color. Do not inter-

change these two fittings.

When the engine is operating, fresh air enters the

engine and mixes with crankcase vapors. Manifold

vacuum draws the vapor/air mixture through the

fixed orifice and into the intake manifold. The vapors

are then consumed during engine combustion.

EVAP/PURGE SOLENOID

DESCRIPTION

The duty cycle EVAP canister purge solenoid is

located in the engine compartment. It is attached to

the side of the Power Distribution Center (PDC).

OPERATION

The Powertrain Control Module (PCM) operates

the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM ener-

gizes and de-energizes the solenoid 5 or 10 times per

second, depending upon operating conditions. The

PCM varies the vapor flow rate by changing solenoid

pulse width. Pulse width is the amount of time the

solenoid energizes. The PCM adjusts solenoid pulse

width based on engine operating condition.

REMOVAL

The duty cycle EVAP canister purge solenoid is

located in the engine compartment. It is attached to

the side of the Power Distribution Center (PDC) (Fig.

3).

(1) Disconnect electrical wiring connector at sole-

noid.

(2) Disconnect vacuum harness at solenoid (Fig. 3).

(3) Remove solenoid from mounting bracket.

INSTALLATION

(1) Install solenoid assembly to mounting bracket.

(2) Connect vacuum harness.

(3) Connect electrical connector.

Fig. 2 FIXED ORIFICE FITTING - 8.0L V-10 ENGINE -

TYPICAL

1 - VACUUM TUBE

2 - FIXED ORIFICE FITTING

3 - COIL PACKS

4 - ORIFICE FITTING HOSE CONNECTIONS

25 - 12 EVAPORATIVE EMISSIONSDR

Page 2588 of 2627

INDEX

ABS - DESCRIPTION, BRAKES...........5-45

ABS - OPERATION, BRAKES.............5-45

ABS BRAKE BLEEDING - STANDARD

PROCEDURE.........................5-46

ABS INDICATOR - DESCRIPTION.........8J-17

ABS INDICATOR - OPERATION..........8J-17

A/C COMPRESSOR - DESCRIPTION......24-48

A/C COMPRESSOR - DIAGNOSIS AND

TESTING...........................24-49

A/C COMPRESSOR - OPERATION........24-48

A/C COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE...............24-10

A/C COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-10

A/C COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-13

A/C COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-14

A/C COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-13

A/C COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-14

A/C COMPRESSOR CLUTCH/COIL -

DESCRIPTION........................24-9

A/C COMPRESSOR CLUTCH/COIL -

INSPECTION........................24-11

A/C COMPRESSOR CLUTCH/COIL -

INSTALLATION.......................24-12

A/C COMPRESSOR CLUTCH/COIL -

OPERATION..........................24-9

A/C COMPRESSOR CLUTCH/COIL -

REMOVAL..........................24-10

A/C CONDENSER - DESCRIPTION........24-52

A/C CONDENSER - OPERATION..........24-52

A/C DISCHARGE LINE - DESCRIPTION....24-56

A/C EVAPORATOR - DESCRIPTION.......24-59

A/C EVAPORATOR - INSTALLATION......24-60

A/C EVAPORATOR - OPERATION.........24-59

A/C EVAPORATOR - REMOVAL..........24-60

A/C HEATER CONTROL - DESCRIPTION . . . 24-14

A/C HEATER CONTROL - INSTALLATION . . . 24-15

A/C HEATER CONTROL - REMOVAL......24-15

A/C ORIFICE TUBE - DESCRIPTION.......24-60

A/C ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-61

A/C ORIFICE TUBE - OPERATION........24-60

A/C PERFORMANCE - DIAGNOSIS AND

TESTING............................24-3

A/C PRESSURE TRANSDUCER -

DESCRIPTION.......................24-15

A/C PRESSURE TRANSDUCER -

DIAGNOSIS AND TESTING.............24-16

A/C PRESSURE TRANSDUCER -

INSTALLATION.......................24-16

A/C PRESSURE TRANSDUCER -

OPERATION.........................24-16

A/C PRESSURE TRANSDUCER -

REMOVAL..........................24-16

A/C SYSTEM - SPECIFICATIONS..........24-7

A/C SYSTEM, CAUTION................24-43

A/C SYSTEM, WARNING...............24-43

ACCELERATOR PEDAL - INSTALLATION . . . 14-21

ACCELERATOR PEDAL - REMOVAL.......14-21

ACCELERATOR PEDAL POSITION

SENSOR - DESCRIPTION.........14-22,14-68

ACCELERATOR PEDAL POSITION

SENSOR - INSTALLATION.........14-22,14-71

ACCELERATOR PEDAL POSITION

SENSOR - OPERATION...........14-22,14-68

ACCELERATOR PEDAL POSITION

SENSOR - REMOVAL.............14-22,14-68

ACCESSORY DRIVE BELT - DIAGNOSIS

AND TESTING....................7-24,7-27

ACCUMULATOR - DESCRIPTION.........24-61

ACCUMULATOR - DESCRIPTION........21-193

ACCUMULATOR - INSPECTION.........21-194

ACCUMULATOR - INSTALLATION........24-62

ACCUMULATOR - OPERATION..........24-61

ACCUMULATOR - OPERATION..........21-193

ACCUMULATOR - REMOVAL............24-61

ACM COVER - INSTALLATION

...........8O-10

ACM COVER - REMOVAL

..............8O-10

ACTUATION TEST MODE - DESCRIPTION,

CIRCUIT

.............................25-1

ACTUATOR - DESCRIPTION, BLEND

DOOR

.............................24-17

ACTUATOR - DESCRIPTION, DEFROST

DOOR

.............................24-20ACTUATOR - DESCRIPTION, FUEL

CONTROL..........................14-74

ACTUATOR - DESCRIPTION, MODE

DOOR.............................24-23

ACTUATOR - DESCRIPTION,

RECIRCULATION DOOR................24-24

ACTUATOR - INSTALLATION, BLEND

DOOR.............................24-18

ACTUATOR - INSTALLATION, DEFROST

DOOR.............................24-21

ACTUATOR - INSTALLATION, INSIDE

HANDLE.......................23-22,23-32

ACTUATOR - INSTALLATION, MODE

DOOR.............................24-23

ACTUATOR - INSTALLATION,

RECIRCULATION DOOR................24-25

ACTUATOR - OPERATION, BLEND DOOR . . 24-17

ACTUATOR - OPERATION, DEFROST

DOOR.............................24-21

ACTUATOR - OPERATION, FUEL

CONTROL..........................14-74

ACTUATOR - OPERATION, MODE DOOR . . . 24-23

ACTUATOR - OPERATION,

RECIRCULATION DOOR................24-24

ACTUATOR - REMOVAL, BLEND DOOR....24-17

ACTUATOR - REMOVAL, DEFROST DOOR . . 24-21

ACTUATOR - REMOVAL, FUEL CONTROL . . 14-74

ACTUATOR - REMOVAL, INSIDE HANDLE . 23-22,

23-31

ACTUATOR - REMOVAL, MODE DOOR....24-23

ACTUATOR - REMOVAL, RECIRCULATION

DOOR...............................24-24

ADAPTER HOUSING SEAL -

INSTALLATION...........21-128,21-364,21-85

ADAPTER HOUSING SEAL - REMOVAL . . 21-128,

21-364,21-85

ADAPTER MOUNT - INSTALLATION, DISC

BRAKE CALIPER......................5-22

ADHESIVE LOCATIONS -

SPECIFICATIONS, STRUCTURAL........23-112

ADJUSTABLE PEDAL MOTOR -

DESCRIPTION.........................5-6

ADJUSTABLE PEDAL MOTOR -

INSTALLATION.........................5-7

ADJUSTABLE PEDAL MOTOR - REMOVAL . . . 5-7

ADJUSTABLE PEDAL SWITCH -

INSTALLATION.........................5-6

ADJUSTABLE PEDAL SWITCH -

REMOVAL............................5-6

ADJUSTER - DIAGNOSIS AND TESTING,

HYDRAULIC LASH................9-125,9-32

ADJUSTER - INSTALLATION, SEAT BELT

TURNING LOOP.....................8O-55

ADJUSTER - REMOVAL, SEAT BELT

TURNING LOOP.....................8O-55

ADJUSTER ASSEMBLY - DESCRIPTION,

ROCKER ARM.......................9-125

ADJUSTER ASSEMBLY - INSTALLATION,

ROCKER ARM.......................9-126

ADJUSTER ASSEMBLY - REMOVAL,

ROCKER ARM.......................9-126

ADJUSTER ASSY - CLEANING, ROCKER

ARM ..............................9-262

ADJUSTER ASSY - DESCRIPTION,

ROCKER ARM.......................9-261

ADJUSTER ASSY - INSPECTION,

ROCKER ARM.......................9-262

ADJUSTER ASSY - INSTALLATION,

ROCKER ARM..................9-203,9-263

ADJUSTER ASSY - REMOVAL, ROCKER

ARM .........................9-203,9-261

ADJUSTING TOOL - ADJUSTMENT, WITH . . . 5-42

AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE.................8O-7

AIR CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING..........................21-317

AIR CLEANER ELEMENT - INSTALLATION

. 9-107,

9-21,9-249

AIR CLEANER ELEMENT - REMOVAL

. 9-107,9-21,

9-248

AIR CONDITIONER - DESCRIPTION,

HEATER

.............................24-1

AIR CONDITIONER - OPERATION,

HEATER

.............................24-1

AIR CONTROL MOTOR - DESCRIPTION,

IDLE

...............................14-28AIR CONTROL MOTOR - INSTALLATION,

IDLE...............................14-29

AIR CONTROL MOTOR - OPERATION,

IDLE...............................14-28

AIR CONTROL MOTOR - REMOVAL, IDLE . . 14-29

AIR COOLER AND PLUMBING -

CLEANING, CHARGE..................11-17

AIR COOLER AND PLUMBING -

DESCRIPTION, CHARGE...............11-16

AIR COOLER AND PLUMBING -

INSPECTION, CHARGE.................11-17

AIR COOLER AND PLUMBING -

INSTALLATION, CHARGE...............11-17

AIR COOLER AND PLUMBING -

OPERATION, CHARGE.................11-16

AIR COOLER AND PLUMBING -

REMOVAL, CHARGE..................11-17

AIR COOLER SYSTEM - LEAKS -

DIAGNOSIS AND TESTING, CHARGE......11-16

AIR DAM - INSTALLATION, FRONT........13-2

AIR DAM - REMOVAL, FRONT...........13-2

AIR HEATER - DESCRIPTION, INTAKE.....14-80

AIR HEATER - INSTALLATION, INTAKE....14-80

AIR HEATER - OPERATION, INTAKE......14-80

AIR HEATER - REMOVAL, INTAKE........14-80

AIR HEATER RELAY - DESCRIPTION,

INTAKE ............................14-82

AIR HEATER RELAY - INSTALLATION,

INTAKE ............................14-82

AIR HEATER RELAY - OPERATION,

INTAKE ............................14-82

AIR HEATER RELAY - REMOVAL, INTAKE . . 14-82

AIR INTAKE SYSTEM - INSTALLATION....9-199

AIR INTAKE SYSTEM - REMOVAL........9-199

AIR OUTLETS - DESCRIPTION..........24-26

AIR OUTLETS - INSTALLATION..........24-27

AIR OUTLETS - REMOVAL.............24-26

AIR TEMPERATURE SENSOR -

DESCRIPTION, INTAKE................14-30

AIR TEMPERATURE SENSOR -

INSTALLATION, INTAKE................14-31

AIR TEMPERATURE SENSOR -

OPERATION, INTAKE..................14-30

AIR TEMPERATURE SENSOR -

REMOVAL, INTAKE...................14-30

AIR TEMPERATURE SENSOR/MAP

SENSOR - DESCRIPTION, INTAKE........14-82

AIR TEMPERATURE SENSOR/MAP

SENSOR - INSTALLATION, INTAKE.......14-82

AIR TEMPERATURE SENSOR/MAP

SENSOR - OPERATION, INTAKE.........14-82

AIR TEMPERATURE SENSOR/MAP

SENSOR - REMOVAL, INTAKE...........14-82

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - DESCRIPTION, INLET.........14-79

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - INSTALLATION, INLET........14-79

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - OPERATION, INLET..........14-79

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - REMOVAL, INLET............14-79

AIR TESTING TRANSMISSION CLUTCH

AND BAND OPERATION - DIAGNOSIS

AND TESTING......................21-144

AIR TO OIL COOLER - INSTALLATION.....7-70

AIR TO OIL COOLER - REMOVAL.........7-69

AIRBAG - ASSEMBLY, DRIVER..........8O-26

AIRBAG - DESCRIPTION, DRIVER........8O-23

AIRBAG - DESCRIPTION, PASSENGER....8O-39

AIRBAG - DESCRIPTION, SIDE CURTAIN . . 8O-56

AIRBAG - DISASSEMBLY, DRIVER.......8O-25

AIRBAG - INSTALLATION, DRIVER.......8O-28

AIRBAG - INSTALLATION, PASSENGER . . . 8O-41

AIRBAG - INSTALLATION, SIDE CURTAIN . . 8O-58

AIRBAG - OPERATION, DRIVER.........8O-23

AIRBAG - OPERATION, PASSENGER......8O-40

AIRBAG - OPERATION, SIDE CURTAIN....8O-56

AIRBAG - REMOVAL, DRIVER...........8O-24

AIRBAG - REMOVAL, PASSENGER.......8O-40

AIRBAG - REMOVAL, SIDE CURTAIN.....8O-57

AIRBAG CONTROL MODULE -

DESCRIPTION

.......................8O-11

AIRBAG CONTROL MODULE -

INSTALLATION

......................8O-13

AIRBAG CONTROL MODULE -

OPERATION

.........................8O-11

AIRBAG CONTROL MODULE - REMOVAL

. . 8O-12

AIRBAG INDICATOR - DESCRIPTION

......8J-18

DRINDEX 1

Description Group-Page Description Group-Page Description Group-Page

Page 2589 of 2627

AIRBAG INDICATOR - OPERATION.......8J-18

AIRBAG ON/OFF SWITCH -

DESCRIPTION, PASSENGER............8O-42

AIRBAG ON/OFF SWITCH -

INSTALLATION, PASSENGER...........8O-44

AIRBAG ON/OFF SWITCH - OPERATION,

PASSENGER........................8O-43

AIRBAG ON/OFF SWITCH - REMOVAL,

PASSENGER........................8O-43

AJAR INDICATOR - DESCRIPTION, DOOR . . 8J-23

AJAR INDICATOR - OPERATION, DOOR . . . 8J-23

AJAR SWITCH - DESCRIPTION, DOOR....8L-27

AJAR SWITCH - OPERATION, DOOR......8L-27

ALIGNMENT - DESCRIPTION, WHEEL.......2-1

ALIGNMENT - OPERATION, WHEEL........2-2

ALIGNMENT LINK/COIL SUSPENSION -

STANDARD PROCEDURE.................2-5

ALIGNMENT, SPECIAL TOOLS - WHEEL.....2-7

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD PROCEDURE........21-158,21-318

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-10

AMBIENT TEMP SENSOR - OPERATION . . 8M-10

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS AND TESTING.............8M-10

AMBIENT TEMPERATURE SENSOR

CIRCUIT - DIAGNOSIS AND TESTING....8M-10

AMPLIFIER - DESCRIPTION.............8A-3

AMPLIFIER - INSTALLATION.............8A-4

AMPLIFIER - OPERATION...............8A-3

AMPLIFIER - REMOVAL................8A-3

ANCHOR - DESCRIPTION, CHILD

RESTRAINT.........................8O-15

ANCHOR - INSTALLATION, CHILD

RESTRAINT.........................8O-18

ANCHOR - OPERATION, CHILD

RESTRAINT.........................8O-17

ANCHOR - REMOVAL, CHILD RESTRAINT . 8O-17

ANCHOR & RIGHT OUTBOARD -

INSTALLATION, CENTER...............8O-50

ANCHOR & RIGHT OUTBOARD -

REMOVAL, CENTER...................8O-49

ANTENNA - NAVIGATION -

INSTALLATION.......................8A-6

ANTENNA - NAVIGATION - REMOVAL......8A-6

ANTENNA BODY & CABLE -

DESCRIPTION........................8A-4

ANTENNA BODY & CABLE -

INSTALLATION.......................8A-6

ANTENNA BODY & CABLE - OPERATION . . . 8A-4

ANTENNA BODY & CABLE - REMOVAL.....8A-6

ANTENNA BODY AND CABLE -

DIAGNOSIS AND TESTING..............8A-4

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL..................8A-7

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL..................8A-7

ANTILOCK - DIAGNOSIS AND TESTING,

REAR WHEEL........................5-48

ANTILOCK BRAKE - DESCRIPTION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER

........................8E-3

ANTILOCK BRAKE - OPERATION,

CONTROLLER

........................8E-3

ANTILOCK BRAKE - REMOVAL,

CONTROLLER

........................8E-3

A-PILLAR TRIM/GRAB HANDLE -

INSTALLATION

.......................23-63

A-PILLAR TRIM/GRAB HANDLE -

REMOVAL

..........................23-63

A-PILLAR WEATHERSTRIP RETAINER -

INSTALLATION

.......................23-91

A-PILLAR WEATHERSTRIP RETAINER -

REMOVAL

..........................23-91

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL

........9-137,9-209,9-65

ARM / ADJUSTER ASSEMBLY -

DESCRIPTION, ROCKER

...............9-125

ARM / ADJUSTER ASSEMBLY -

INSTALLATION, ROCKER

...............9-126

ARM / ADJUSTER ASSEMBLY -

REMOVAL, ROCKER

..................9-126

ARM / ADJUSTER ASSY - CLEANING,

ROCKER

............................9-262

ARM / ADJUSTER ASSY - DESCRIPTION,

ROCKER

............................9-261ARM / ADJUSTER ASSY - INSPECTION,

ROCKER............................9-262

ARM / ADJUSTER ASSY -

INSTALLATION, ROCKER..........9-203,9-263

ARM / ADJUSTER ASSY - REMOVAL,

ROCKER......................9-203,9-261

ARM - DESCRIPTION, ROCKER......9-31,9-37

ARM - DESCRIPTION, WIPER...........8R-17

ARM - INSTALLATION, LOWER

SUSPENSION.........................2-38

ARM - INSTALLATION, PITMAN.........19-37

ARM - INSTALLATION, ROCKER..........9-31

ARM - INSTALLATION, UPPER CONTROL . . . 2-28

ARM - INSTALLATION, WIPER..........8R-18

ARM - OPERATION, WIPER............8R-18

ARM - REMOVAL, LOWER SUSPENSION . . . 2-38

ARM - REMOVAL, PITMAN.............19-36

ARM - REMOVAL, ROCKER..........9-31,9-37

ARM - REMOVAL, UPPER CONTROL......2-28

ARM - REMOVAL, WIPER..............8R-18

ARM BUSHINGS - 2WD (LD) -

INSTALLATION, LOWER CONTROL........2-15

ARM BUSHINGS - 2WD (LD) -

REMOVAL, LOWER CONTROL............2-13

ARM BUSHINGS - 4WD (LD) -

INSTALLATION, LOWER CONTROL........2-14

ARM BUSHINGS - 4WD (LD) -

REMOVAL, LOWER CONTROL............2-13

ARMREST / SEAT BACK - INSTALLATION,

CENTER.............................23-77

ARMREST / SEAT BACK - REMOVAL,

CENTER............................23-76

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-5

ASD SENSE - PCM INPUT - OPERATION....8I-5

ASH RECEIVER - INSTALLATION.........23-51

ASH RECEIVER - REMOVAL............23-50

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-1

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION.......................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

DIAGNOSIS AND TESTING.............8N-11

AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

REMOVAL..........................8N-12

AUTOMATIC LOCKING RETRACTOR -

DESCRIPTION.......................8O-14

AUTOMATIC LOCKING RETRACTOR -

OPERATION.........................8O-14

AUTOMATIC TRANSMISSION -

45RFE/545RFE - DESCRIPTION.........21-312

AUTOMATIC TRANSMISSION -

45RFE/545RFE - OPERATION...........21-313

AUTOMATIC TRANSMISSION - 48RE -

DESCRIPTION......................21-132

AUTOMATIC TRANSMISSION - 48RE -

OPERATION........................21-134

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING......21-140,21-314

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-4

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-5

AUXILIARY SPRING BUMPERS (3500) -

INSTALLATION........................2-43

AUXILIARY SPRING BUMPERS (3500) -

REMOVAL...........................2-43

AXLE - 10 1/2 AA - ADJUSTMENTS,

REAR..............................3-116

AXLE - 10 1/2 AA - DIAGNOSIS AND

TESTING, REAR......................3-112

AXLE - 10 1/2 AA - INSTALLATION,

REAR..............................3-116

AXLE - 10 1/2 AA - REMOVAL, REAR.....3-115

AXLE - 10 1/2 AA - SPECIAL TOOLS,

REAR..............................3-120

AXLE - 10 1/2 AA - SPECIFICATIONS,

REAR

..............................3-120

AXLE - 11 1/2 AA - ADJUSTMENTS,

REAR

..............................3-144

AXLE - 11 1/2 AA - DIAGNOSIS AND

TESTING, REAR

......................3-140

AXLE - 11 1/2 AA - INSTALLATION,

REAR

..............................3-144

AXLE - 11 1/2 AA - REMOVAL, REAR

.....3-143AXLE - 11 1/2 AA - SPECIAL TOOLS,

REAR..............................3-148

AXLE - 11 1/2 AA - SPECIFICATIONS,

REAR..............................3-148

AXLE - 9 1/4 - ADJUSTMENTS, REAR.....3-83

AXLE - 9 1/4 - DIAGNOSIS AND

TESTING, REAR.......................3-80

AXLE - 9 1/4 - INSTALLATION, REAR......3-83

AXLE - 9 1/4 - REMOVAL, REAR..........3-83

AXLE - 9 1/4 - SPECIAL TOOLS, REAR.....3-90

AXLE - 9 1/4 - SPECIFICATIONS, REAR....3-90

AXLE - 9 1/4 AA - ADJUSTMENTS,

FRONT..............................3-59

AXLE - 9 1/4 AA - DIAGNOSIS AND

TESTING, FRONT......................3-54

AXLE - 9 1/4 AA - INSTALLATION,

FRONT..............................3-58

AXLE - 9 1/4 AA - REMOVAL, FRONT......3-57

AXLE - 9 1/4 AA - SPECIAL TOOLS,

FRONT..............................3-64

AXLE - 9 1/4 AA - SPECIFICATIONS,

FRONT..............................3-63

AXLE - C205F - ADJUSTMENTS, FRONT....3-32

AXLE - C205F - DIAGNOSIS AND

TESTING, FRONT......................3-27

AXLE - C205F - INSTALLATION, FRONT....3-31

AXLE - C205F - REMOVAL, FRONT........3-31

AXLE - C205F - SPECIAL TOOLS, FRONT . . . 3-40

AXLE - C205F - SPECIFICATIONS, FRONT . . . 3-39

AXLE - DESCRIPTION.....................0-4

AXLE BEARINGS - INSTALLATION . . 3-125,3-153,

3-44,3-95

AXLE BEARINGS - REMOVAL . . 3-125,3-152,3-43,

3-95

AXLE SHAFT SEALS - INSTALLATION . 3-43,3-70,

3-94

AXLE SHAFT SEALS - REMOVAL . 3-43,3-69,3-94

AXLE SHAFTS - ASSEMBLY.............3-69

AXLE SHAFTS - DISASSEMBLY...........3-68

AXLE SHAFTS - INSTALLATION....3-124,3-152,

3-43,3-69,3-94

AXLE SHAFTS - REMOVAL....3-124,3-152,3-43,

3-67,3-93

BACK - INSTALLATION, CENTER

ARMREST / SEAT....................23-77

BACK - REAR - INSTALLATION, SEAT.....23-83

BACK - REAR - REMOVAL, SEAT........23-83

BACK - REMOVAL, CENTER ARMREST /

SEAT ..............................23-76

BACK CUSHION / COVER - FRONT -

INSTALLATION, SEAT.................23-82

BACK CUSHION / COVER - FRONT -

REMOVAL, SEAT.....................23-82

BACK CUSHION / COVER - REAR -

INSTALLATION, SEAT.................23-84

BACK CUSHION / COVER - REAR -

REMOVAL, SEAT.....................23-84

BACK HINGE - INSTALLATION, CENTER

SEAT ..............................23-79

BACK HINGE - REMOVAL, CENTER SEAT . . 23-78

BACK INERTIA HINGE COVER -

INSTALLATION, CENTER SEAT..........23-77

BACK INERTIA HINGE COVER -

REMOVAL, CENTER SEAT..............23-77

BACK LID - INSTALLATION, CENTER

SEAT ..............................23-79

BACK LID - REMOVAL, CENTER SEAT....23-79

BACK PANEL TRIM - INSTALLATION,

REAR CAB..........................23-69

BACK PANEL TRIM - REMOVAL, REAR

CAB

...............................23-68

BACK REAR - FOOTMANS LOOP

BRACKETS - INSTALLATION, SEAT

.......23-85

BACK REAR - FOOTMANS LOOP

BRACKETS - REMOVAL, SEAT

...........23-85

BACKLITE - INSTALLATION

.............23-86

BACKLITE - REMOVAL

.................23-86

BACKLITE VENT GLASS - INSTALLATION

. . 23-87

BACKLITE VENT GLASS - REMOVAL

......23-87

BACKUP LAMP SWITCH - DESCRIPTION

. . . 8L-8

BACKUP LAMP SWITCH - DIAGNOSIS

AND TESTING

........................8L-8

BACKUP LAMP SWITCH - OPERATION

.....8L-8

BALANCE - STANDARD PROCEDURE,

TIRE AND WHEEL

.....................22-4

BALANCE SHAFT - INSTALLATION

........9-80

BALANCE SHAFT - REMOVAL

............9-80

2 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2592 of 2627

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF..........21-201,21-366

BUSHING - INSTALLATION.............19-19

BUSHING - INSTALLATION, TORSION

BAR CROSS MEMBER..................2-15

BUSHING - REMOVAL.................19-19

BUSHING - REMOVAL, TORSION BAR

CROSSMEMBER......................2-13

BUSHING AND SEAL - INSTALLATION,

EXTENSION HOUSING................21-440

BUSHING AND SEAL - REMOVAL,

EXTENSION HOUSING................21-440

BUSHINGS - 2WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-15

BUSHINGS - 2WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-13

BUSHINGS - 4WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-14

BUSHINGS - 4WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-13

BUSHINGS - INSTALLATION.............2-43

BUSHINGS - REMOVAL.................2-43

BUZZ, SQUEAK & RATTLE - STANDARD

PROCEDURE........................23-11

BYPASS - DESCRIPTION, WATER PUMP . . . 7-59

BYPASS - OPERATION, WATER PUMP.....7-60

C205F - ADJUSTMENTS, FRONT AXLE.....3-32

C205F - DIAGNOSIS AND TESTING,

FRONT AXLE.........................3-27

C205F - INSTALLATION, FRONT AXLE.....3-31

C205F - REMOVAL, FRONT AXLE...........3-31

C205F - SPECIAL TOOLS, FRONT AXLE....3-40

C205F - SPECIFICATIONS, FRONT AXLE....3-39

CAB - INSTALLATION, QUAD......8O-36,8O-61

CAB - INSTALLATION, STANDARD . . 8O-35,8O-61

CAB - REMOVAL, QUAD..........8O-33,8O-60

CAB - REMOVAL, STANDARD......8O-32,8O-59

CAB BACK PANEL TRIM -

INSTALLATION, REAR.................23-69

CAB BACK PANEL TRIM - REMOVAL,

REAR..............................23-68

CAB CLEARANCE LAMP - INSTALLATION . . 8L-12

CAB CLEARANCE LAMP - REMOVAL.....8L-11

CABLE - ADJUSTMENTS, THROTTLE

VALVE ............................21-254

CABLE - DESCRIPTION.................8P-4

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, SPARK PLUG.....8I-21

CABLE - DESCRIPTION, THROTTLE

VALVE ............................21-253

CABLE - DIAGNOSIS AND TESTING,

ANTENNA BODY......................8A-4

CABLE - DIAGNOSIS AND TESTING,

GEARSHIFT..................21-210,21-368

CABLE - INSTALLATION................8P-5

CABLE - INSTALLATION, ANTENNA BODY . . 8A-6

CABLE - INSTALLATION, CHECK.........23-15

CABLE - INSTALLATION, FRONT

PARKING BRAKE......................5-38

CABLE - INSTALLATION, GEARSHIFT....21-211,

21-370

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA......................8A-7

CABLE - INSTALLATION, LEFT REAR......5-39

CABLE - INSTALLATION, REAR PARK

BRAKE..............................5-38

CABLE - INSTALLATION, RIGHT REAR.....5-38

CABLE - INSTALLATION, SPARK PLUG....8I-22

CABLE - INSTALLATION, THROTTLE

CONTROL.....................14-40,14-84

CABLE - OPERATION...................8P-4

CABLE - OPERATION, ANTENNA BODY

.....8A-4

CABLE - OPERATION, SPARK PLUG

.......8I-21

CABLE - REMOVAL

....................8P-4

CABLE - REMOVAL, ANTENNA BODY

......8A-6

CABLE - REMOVAL, CHECK

.............23-15

CABLE - REMOVAL, FRONT PARKING

BRAKE

..............................5-36

CABLE - REMOVAL, GEARSHIFT

. . 21-210,21-369

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA

...........................8A-7

CABLE - REMOVAL, LEFT REAR

..........5-38

CABLE - REMOVAL, REAR PARK BRAKE

. . . 5-37

CABLE - REMOVAL, RIGHT REAR

.........5-37

CABLE - REMOVAL, SPARK PLUG

........8I-22

CABLE - REMOVAL, THROTTLE

CONTROL

.....................14-38,14-83CABLE, ADJUSTMENTS - GEARSHIFT . . . 21-212,

21-370

CABLE RESISTANCE, SPECIFICATIONS -

SPARK PLUG.........................8I-4

CABLE ROUTING, 5.7L V-8 ENGINE -

FIRING ORDER........................8I-4

CABLE/HANDLE ASSEMBLY -

INSTALLATION, LATCH RELEASE........23-47

CABLE/HANDLE ASSEMBLY - REMOVAL,

LATCH RELEASE.....................23-47

CABLES - DESCRIPTION, BATTERY.......8F-14

CABLES - DIAGNOSIS AND TESTING,

BATTERY...........................8F-15

CABLES - INSTALLATION, BATTERY......8F-17

CABLES - OPERATION, BATTERY........8F-15

CABLES - REMOVAL, BATTERY..........8F-16

CALIBRATION - STANDARD PROCEDURE,

COMPASS...........................8M-3

CALIPER ADAPTER MOUNT -

INSTALLATION, DISC BRAKE............5-22

CALIPERS - DESCRIPTION, DISC BRAKE . . . 5-16

CALIPERS - OPERATION, DISC BRAKE.....5-16

CAM BORE REPAIR - STANDARD

PROCEDURE........................9-267

CAMBER AND CASTER ADJUSTMENT -

STANDARD PROCEDURE.................2-4

CAMBER, CASTER AND TOE

ADJUSTMENT - STANDARD

PROCEDURE..........................2-4

CAM/OVERDRIVE PISTON RETAINER -

ASSEMBLY, OVERRUNNING CLUTCH....21-237

CAM/OVERDRIVE PISTON RETAINER -

CLEANING, OVERRUNNING CLUTCH.....21-236

CAM/OVERDRIVE PISTON RETAINER -

DESCRIPTION, OVERRUNNING CLUTCH . . 21-236

CAM/OVERDRIVE PISTON RETAINER -

DISASSEMBLY, OVERRUNNING

CLUTCH...........................21-236

CAM/OVERDRIVE PISTON RETAINER -

INSPECTION, OVERRUNNING CLUTCH . . . 21-237

CAM/OVERDRIVE PISTON RETAINER -

OPERATION, OVERRUNNING CLUTCH....21-236

CAMSHAFT - INSTALLATION.......9-206,9-271

CAMSHAFT - REMOVAL..........9-205,9-268

CAMSHAFT BEARINGS - INSTALLATION . . . 9-271

CAMSHAFT BEARINGS - REMOVAL......9-268

CAMSHAFT CORE HOLE PLUG -

INSTALLATION.......................9-206

CAMSHAFT CORE HOLE PLUG -

REMOVAL..........................9-205

CAMSHAFT POSITION SENSOR -

DESCRIPTION.......................14-71

CAMSHAFT POSITION SENSOR -

DESCRIPTION.........................8I-7

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................14-72

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................8I-10

CAMSHAFT POSITION SENSOR -

OPERATION.........................14-71

CAMSHAFT POSITION SENSOR -

OPERATION..........................8I-7

CAMSHAFT POSITION SENSOR -

REMOVAL..........................14-72

CAMSHAFT POSITION SENSOR -

REMOVAL............................8I-9

CAMSHAFT(S) - DESCRIPTION.......9-25,9-35

CAMSHAFT(S) - INSTALLATION......9-27,9-36

CAMSHAFT(S) - LEFT - DESCRIPTION....9-114

CAMSHAFT(S) - LEFT - INSTALLATION....9-116

CAMSHAFT(S) - LEFT - REMOVAL.......9-115

CAMSHAFT(S) - REMOVAL..........9-25,9-35

CAMSHAFT(S) - RIGHT - DESCRIPTION . . . 9-119

CAMSHAFT(S) - RIGHT - INSTALLATION . . 9-120

CAMSHAFT(S) - RIGHT - REMOVAL......9-119

CANISTER - DESCRIPTION, VAPOR......25-22

CANISTER - INSTALLATION, VAPOR......25-22

CANISTER - OPERATION, VAPOR........25-22

CANISTER - REMOVAL, VAPOR..........25-22

CAP - DESCRIPTION, FUEL FILLER.......25-13

CAP - DESCRIPTION, RADIATOR

PRESSURE

..........................7-57

CAP - DIAGNOSIS AND TESTING,

RADIATOR

...........................7-58

CAP - OPERATION, FUEL FILLER

........25-13

CAP - OPERATION, RADIATOR

PRESSURE

..........................7-58

CAPACITIES, SPECIFICATIONS - FLUID

......0-5CAPACITOR - DESCRIPTION, IGNITION

COIL...............................8I-21

CAPACITOR - INSTALLATION, IGNITION

COIL...............................8I-21

CAPACITOR - OPERATION, IGNITION

COIL...............................8I-21

CAPACITOR - REMOVAL, IGNITION COIL . . . 8I-21

CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING, RADIATOR.....7-58

CARDAN UNIVERSAL JOINTS -

ASSEMBLY, DOUBLE...................3-17

CARDAN UNIVERSAL JOINTS -

DISASSEMBLY, DOUBLE................3-16

CARGO BOX - INSTALLATION...........23-37

CARGO BOX - INSTALLATION, WITH.....8L-22,

8L-23,8L-24,8L-7,8L-9

CARGO BOX - INSTALLATION, WITHOUT . . 8L-22,

8L-23,8L-24,8L-8,8L-9

CARGO BOX - REMOVAL...............23-37

CARGO BOX - REMOVAL, WITH....8L-22,8L-24,

8L-7,8L-9

CARGO BOX - REMOVAL, WITHOUT.....8L-22,

8L-23,8L-24,8L-7,8L-9

CARGO BOX - TIE DOWN -

INSTALLATION.......................23-38

CARGO BOX - TIE DOWN - REMOVAL....23-38

CARGO LAMP INDICATOR -

DESCRIPTION.......................8J-20

CARGO LAMP INDICATOR - OPERATION . . 8J-20

CARPETS AND FLOOR MATS -

INSTALLATION.......................23-65

CARPETS AND FLOOR MATS - REMOVAL . . . 23-65

CASCADE OVERFLOW VALVE -

DESCRIPTION.......................14-66

CASCADE OVERFLOW VALVE -

OPERATION.........................14-66

CASE - DESCRIPTION, TRANSFER.........0-4

CASE - NV241 GENII - ASSEMBLY,

TRANSFER.........................21-428

CASE - NV241 GENII - CLEANING,

TRANSFER.........................21-426

CASE - NV241 GENII - DESCRIPTION,

TRANSFER.........................21-415

CASE - NV241 GENII - DIAGNOSIS AND

TESTING, TRANSFER.................21-416

CASE - NV241 GENII - DISASSEMBLY,

TRANSFER.........................21-417

CASE - NV241 GENII - INSPECTION,

TRANSFER.........................21-426

CASE - NV241 GENII - INSTALLATION,

TRANSFER.........................21-438

CASE - NV241 GENII - OPERATION,

TRANSFER.........................21-415

CASE - NV241 GENII - REMOVAL,

TRANSFER.........................21-417

CASE - NV243 - ASSEMBLY, TRANSFER . . 21-496

CASE - NV243 - CLEANING, TRANSFER . . 21-493

CASE - NV243 - DESCRIPTION,

TRANSFER.........................21-482

CASE - NV243 - DIAGNOSIS AND

TESTING, TRANSFER.................21-483

CASE - NV243 - DISASSEMBLY,

TRANSFER.........................21-484

CASE - NV243 - INSPECTION, TRANSFER . 21-493

CASE - NV243 - INSTALLATION,

TRANSFER.........................21-505

CASE - NV243 - OPERATION, TRANSFER . 21-483

CASE - NV243 - REMOVAL, TRANSFER . . 21-484

CASE - NV244 - DIAGNOSIS AND

TESTING, TRANSFER.................21-513

CASE - NV244 GENII - ASSEMBLY,

TRANSFER.........................21-525

CASE - NV244 GENII - CLEANING,

TRANSFER.........................21-523

CASE - NV244 GENII - DESCRIPTION,

TRANSFER.........................21-512

CASE - NV244 GENII - DISASSEMBLY,

TRANSFER.........................21-514

CASE - NV244 GENII - INSPECTION,

TRANSFER.........................21-523

CASE - NV244 GENII - INSTALLATION,

TRANSFER

.........................21-534

CASE - NV244 GENII - OPERATION,

TRANSFER

.........................21-513

CASE - NV244 GENII - REMOVAL,

TRANSFER

.........................21-514

CASE - NV271 - ASSEMBLY, TRANSFER

. . 21-461

CASE - NV271 - CLEANING, TRANSFER

. . 21-459

DRINDEX 5

Description Group-Page Description Group-Page Description Group-Page