Engine Installation DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1349 of 2627

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

REMOVAL

NOTE: Disconnect the battery negative cable to pre-

vent accidental starter engagement.

(1) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) For rocker arm removal on cylinders 3 and 5

Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(3) For rocker arm removal on cylinders 2 and 8

Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

(4) For rocker arm removal on cylinders 4 and 6

Rotate the crankshaft until cylinder #3 is at TDC

compression stroke.

(5) For rocker arm removal on cylinders 1 and 7

Rotate the crankshaft until cylinder #2 is at TDC

compression stroke.

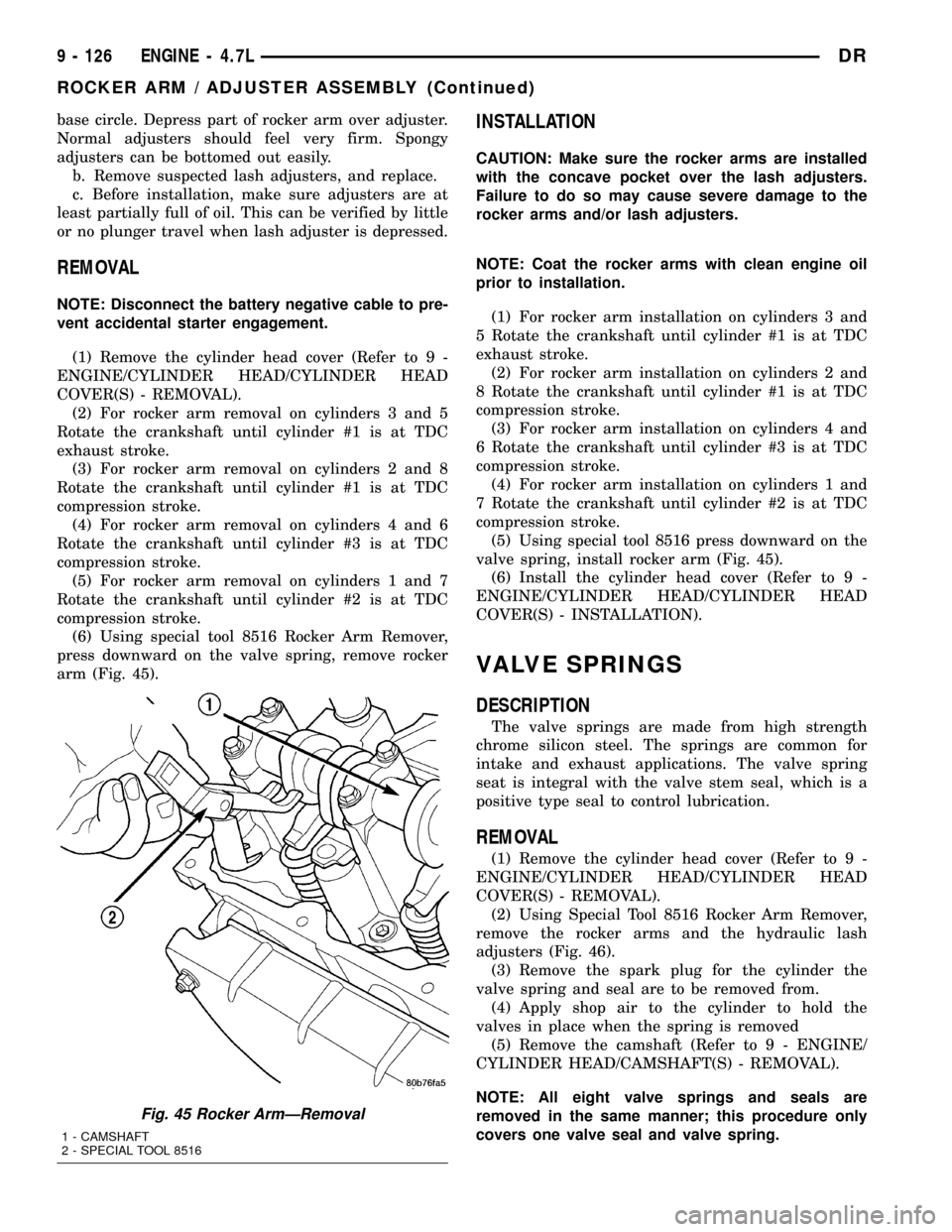

(6) Using special tool 8516 Rocker Arm Remover,

press downward on the valve spring, remove rocker

arm (Fig. 45).

INSTALLATION

CAUTION: Make sure the rocker arms are installed

with the concave pocket over the lash adjusters.

Failure to do so may cause severe damage to the

rocker arms and/or lash adjusters.

NOTE: Coat the rocker arms with clean engine oil

prior to installation.

(1) For rocker arm installation on cylinders 3 and

5 Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(2) For rocker arm installation on cylinders 2 and

8 Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

(3) For rocker arm installation on cylinders 4 and

6 Rotate the crankshaft until cylinder #3 is at TDC

compression stroke.

(4) For rocker arm installation on cylinders 1 and

7 Rotate the crankshaft until cylinder #2 is at TDC

compression stroke.

(5) Using special tool 8516 press downward on the

valve spring, install rocker arm (Fig. 45).

(6) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

VALVE SPRINGS

DESCRIPTION

The valve springs are made from high strength

chrome silicon steel. The springs are common for

intake and exhaust applications. The valve spring

seat is integral with the valve stem seal, which is a

positive type seal to control lubrication.

REMOVAL

(1) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

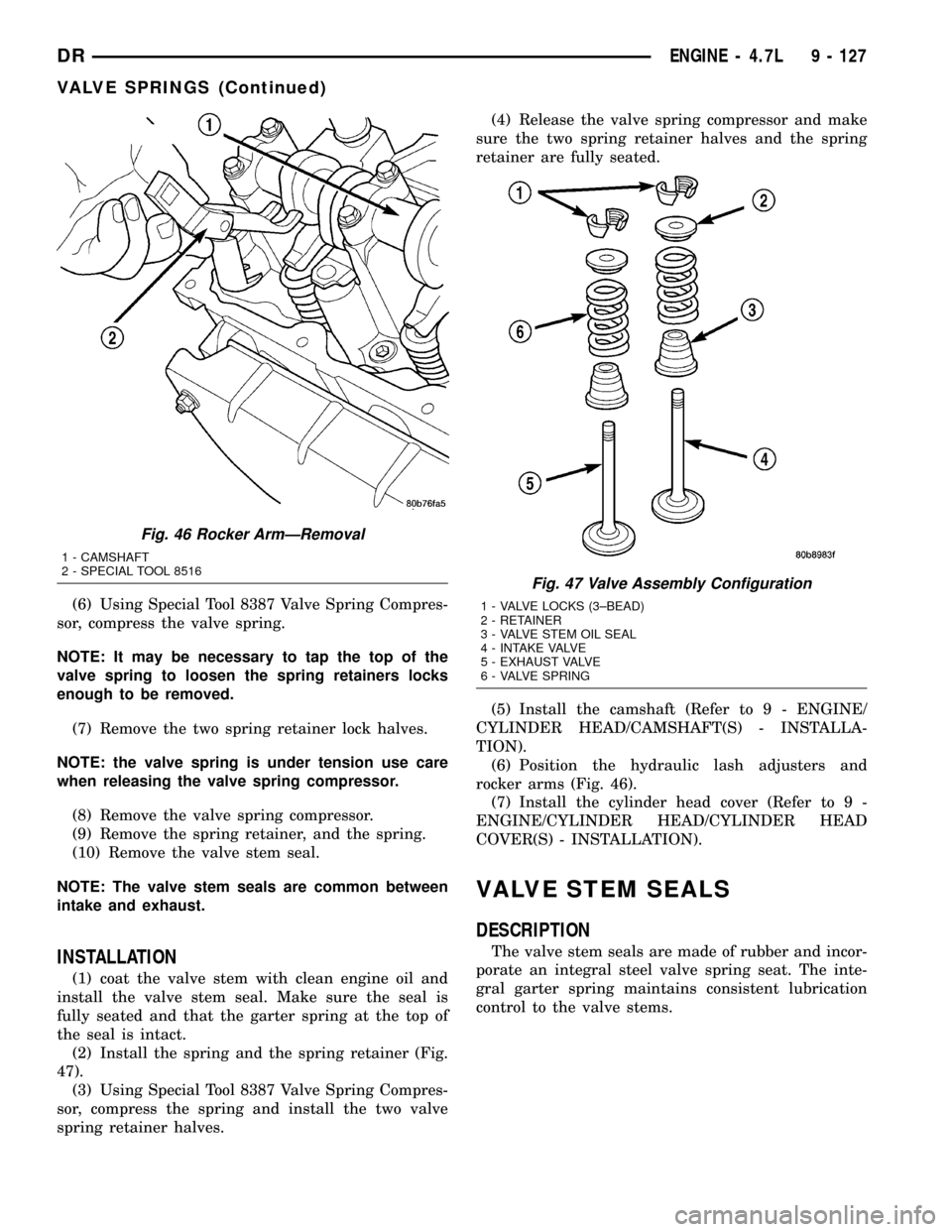

(2) Using Special Tool 8516 Rocker Arm Remover,

remove the rocker arms and the hydraulic lash

adjusters (Fig. 46).

(3) Remove the spark plug for the cylinder the

valve spring and seal are to be removed from.

(4) Apply shop air to the cylinder to hold the

valves in place when the spring is removed

(5) Remove the camshaft (Refer to 9 - ENGINE/

CYLINDER HEAD/CAMSHAFT(S) - REMOVAL).

NOTE: All eight valve springs and seals are

removed in the same manner; this procedure only

covers one valve seal and valve spring.

Fig. 45 Rocker ArmÐRemoval

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

9 - 126 ENGINE - 4.7LDR

ROCKER ARM / ADJUSTER ASSEMBLY (Continued)

Page 1350 of 2627

(6) Using Special Tool 8387 Valve Spring Compres-

sor, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(7) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(8) Remove the valve spring compressor.

(9) Remove the spring retainer, and the spring.

(10) Remove the valve stem seal.

NOTE: The valve stem seals are common between

intake and exhaust.

INSTALLATION

(1) coat the valve stem with clean engine oil and

install the valve stem seal. Make sure the seal is

fully seated and that the garter spring at the top of

the seal is intact.

(2) Install the spring and the spring retainer (Fig.

47).

(3) Using Special Tool 8387 Valve Spring Compres-

sor, compress the spring and install the two valve

spring retainer halves.(4) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.

(5) Install the camshaft (Refer to 9 - ENGINE/

CYLINDER HEAD/CAMSHAFT(S) - INSTALLA-

TION).

(6) Position the hydraulic lash adjusters and

rocker arms (Fig. 46).

(7) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

VALVE STEM SEALS

DESCRIPTION

The valve stem seals are made of rubber and incor-

porate an integral steel valve spring seat. The inte-

gral garter spring maintains consistent lubrication

control to the valve stems.

Fig. 46 Rocker ArmÐRemoval

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

Fig. 47 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

DRENGINE - 4.7L 9 - 127

VALVE SPRINGS (Continued)

Page 1353 of 2627

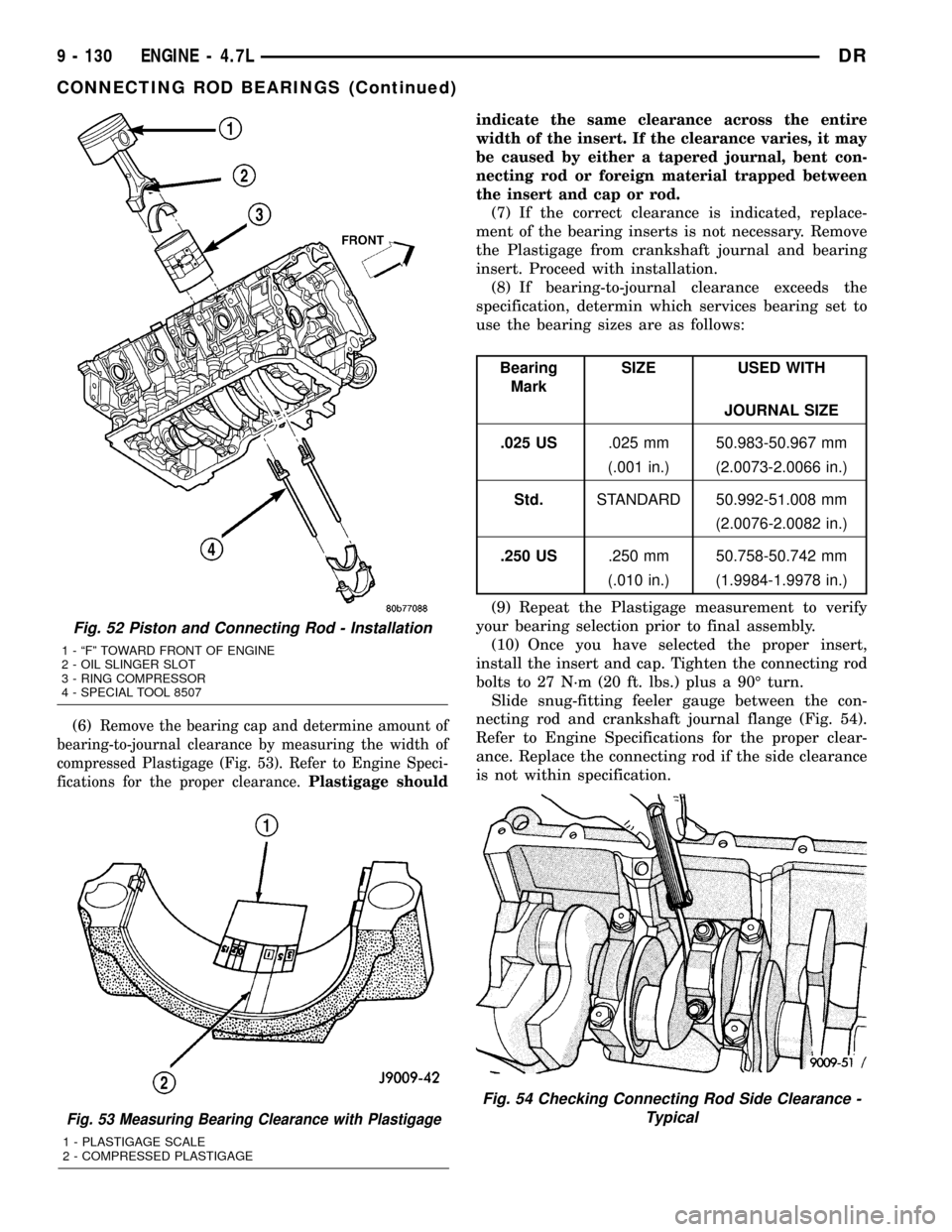

(6)Remove the bearing cap and determine amount of

bearing-to-journal clearance by measuring the width of

compressed Plastigage (Fig. 53). Refer to Engine Speci-

fications for the proper clearance.Plastigage shouldindicate the same clearance across the entire

width of the insert. If the clearance varies, it may

be caused by either a tapered journal, bent con-

necting rod or foreign material trapped between

the insert and cap or rod.

(7) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

Bearing

MarkSIZE USED WITH

JOURNAL SIZE

.025 US.025 mm 50.983-50.967 mm

(.001 in.) (2.0073-2.0066 in.)

Std.STANDARD 50.992-51.008 mm

(2.0076-2.0082 in.)

.250 US.250 mm 50.758-50.742 mm

(.010 in.) (1.9984-1.9978 in.)

(9) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(10) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 27 N´m (20 ft. lbs.) plus a 90É turn.

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange (Fig. 54).

Refer to Engine Specifications for the proper clear-

ance. Replace the connecting rod if the side clearance

is not within specification.

Fig. 53 Measuring Bearing Clearance with Plastigage

1 - PLASTIGAGE SCALE

2 - COMPRESSED PLASTIGAGE

Fig. 52 Piston and Connecting Rod - Installation

1 - ªFº TOWARD FRONT OF ENGINE

2 - OIL SLINGER SLOT

3 - RING COMPRESSOR

4 - SPECIAL TOOL 8507

Fig. 54 Checking Connecting Rod Side Clearance -

Typical

9 - 130 ENGINE - 4.7LDR

CONNECTING ROD BEARINGS (Continued)

Page 1354 of 2627

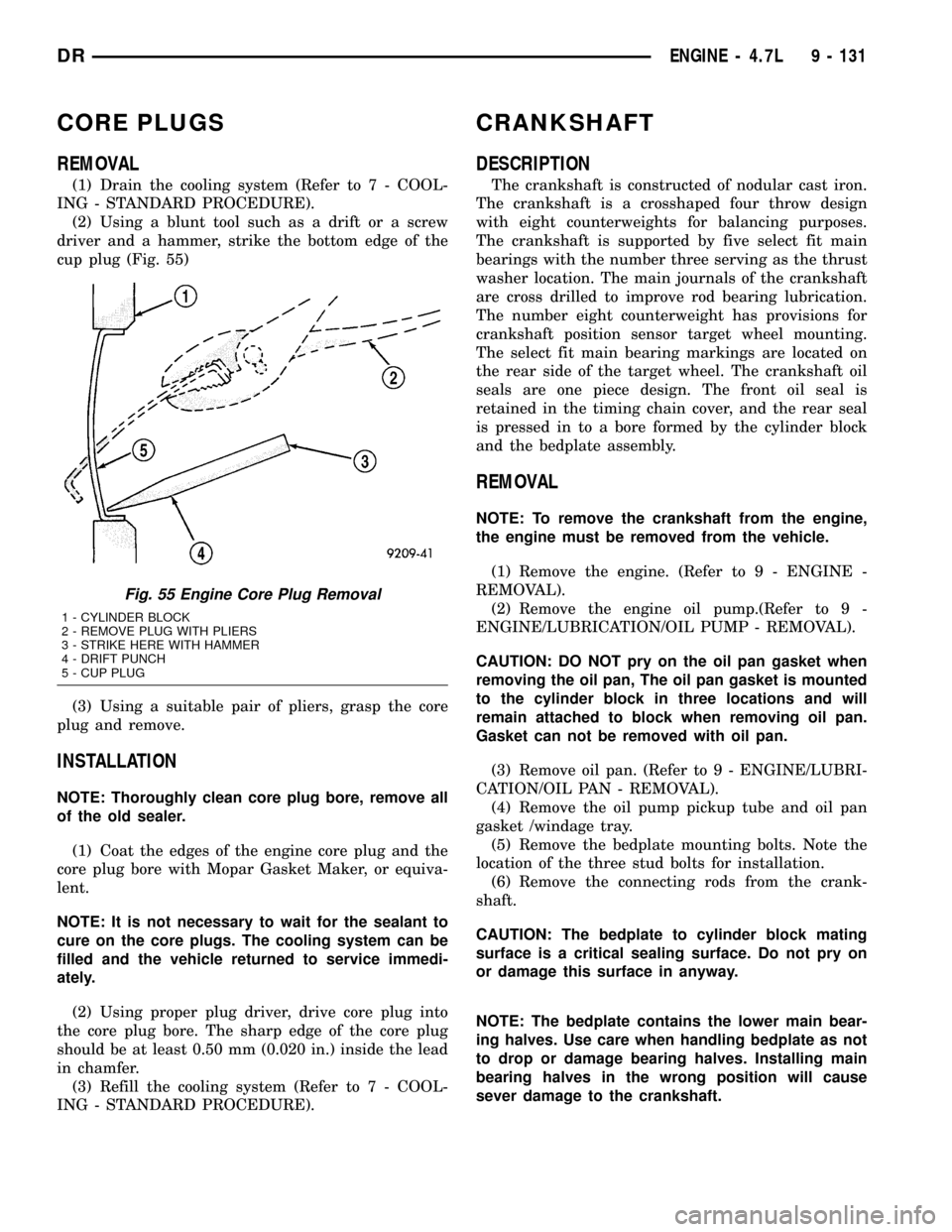

CORE PLUGS

REMOVAL

(1) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(2) Using a blunt tool such as a drift or a screw

driver and a hammer, strike the bottom edge of the

cup plug (Fig. 55)

(3) Using a suitable pair of pliers, grasp the core

plug and remove.

INSTALLATION

NOTE: Thoroughly clean core plug bore, remove all

of the old sealer.

(1) Coat the edges of the engine core plug and the

core plug bore with Mopar Gasket Maker, or equiva-

lent.

NOTE: It is not necessary to wait for the sealant to

cure on the core plugs. The cooling system can be

filled and the vehicle returned to service immedi-

ately.

(2) Using proper plug driver, drive core plug into

the core plug bore. The sharp edge of the core plug

should be at least 0.50 mm (0.020 in.) inside the lead

in chamfer.

(3) Refill the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron.

The crankshaft is a crosshaped four throw design

with eight counterweights for balancing purposes.

The crankshaft is supported by five select fit main

bearings with the number three serving as the thrust

washer location. The main journals of the crankshaft

are cross drilled to improve rod bearing lubrication.

The number eight counterweight has provisions for

crankshaft position sensor target wheel mounting.

The select fit main bearing markings are located on

the rear side of the target wheel. The crankshaft oil

seals are one piece design. The front oil seal is

retained in the timing chain cover, and the rear seal

is pressed in to a bore formed by the cylinder block

and the bedplate assembly.

REMOVAL

NOTE: To remove the crankshaft from the engine,

the engine must be removed from the vehicle.

(1) Remove the engine. (Refer to 9 - ENGINE -

REMOVAL).

(2) Remove the engine oil pump.(Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - REMOVAL).

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when removing oil pan.

Gasket can not be removed with oil pan.

(3) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

(4) Remove the oil pump pickup tube and oil pan

gasket /windage tray.

(5) Remove the bedplate mounting bolts. Note the

location of the three stud bolts for installation.

(6) Remove the connecting rods from the crank-

shaft.

CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as not

to drop or damage bearing halves. Installing main

bearing halves in the wrong position will cause

sever damage to the crankshaft.

Fig. 55 Engine Core Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

DRENGINE - 4.7L 9 - 131

Page 1355 of 2627

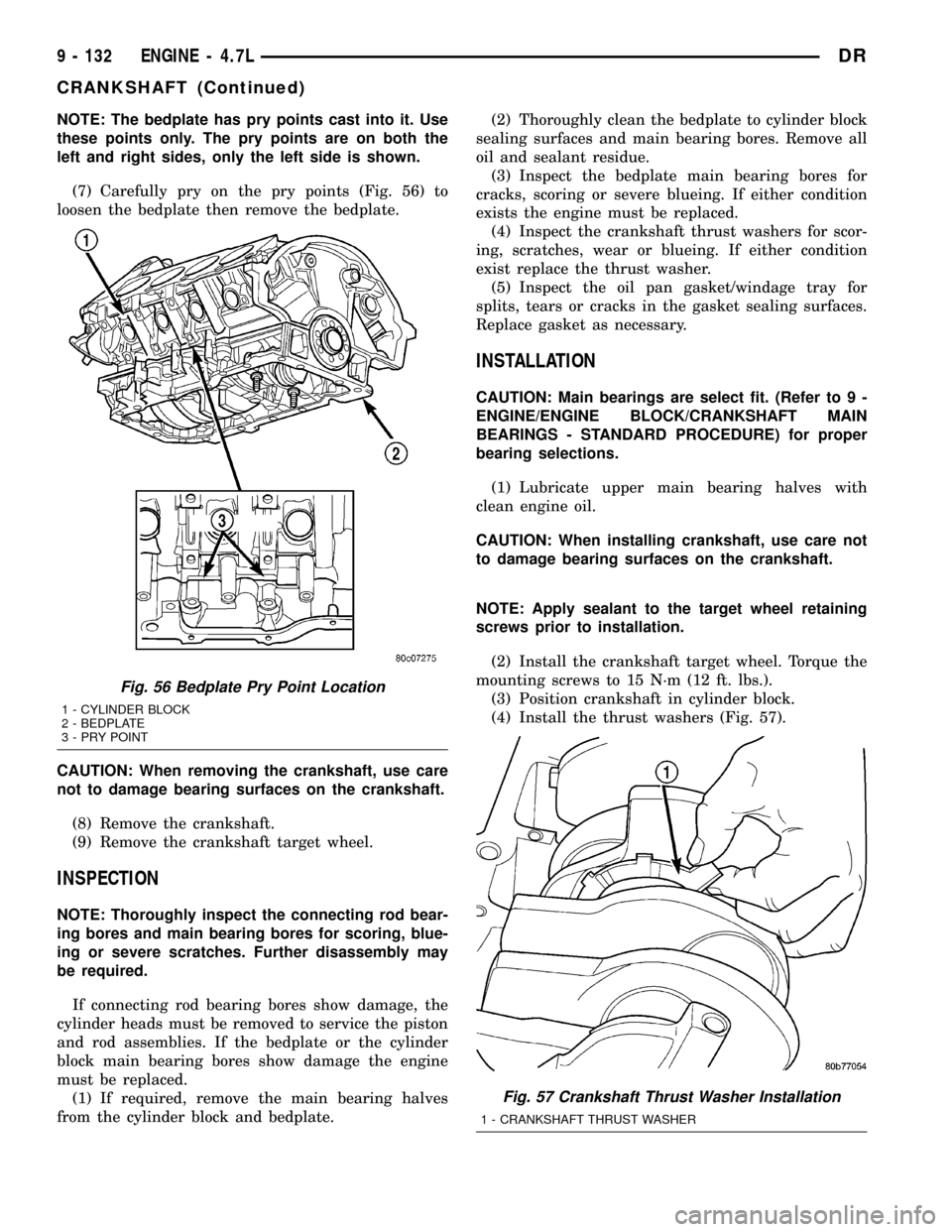

NOTE: The bedplate has pry points cast into it. Use

these points only. The pry points are on both the

left and right sides, only the left side is shown.

(7) Carefully pry on the pry points (Fig. 56) to

loosen the bedplate then remove the bedplate.

CAUTION: When removing the crankshaft, use care

not to damage bearing surfaces on the crankshaft.

(8) Remove the crankshaft.

(9) Remove the crankshaft target wheel.

INSPECTION

NOTE: Thoroughly inspect the connecting rod bear-

ing bores and main bearing bores for scoring, blue-

ing or severe scratches. Further disassembly may

be required.

If connecting rod bearing bores show damage, the

cylinder heads must be removed to service the piston

and rod assemblies. If the bedplate or the cylinder

block main bearing bores show damage the engine

must be replaced.

(1) If required, remove the main bearing halves

from the cylinder block and bedplate.(2) Thoroughly clean the bedplate to cylinder block

sealing surfaces and main bearing bores. Remove all

oil and sealant residue.

(3) Inspect the bedplate main bearing bores for

cracks, scoring or severe blueing. If either condition

exists the engine must be replaced.

(4) Inspect the crankshaft thrust washers for scor-

ing, scratches, wear or blueing. If either condition

exist replace the thrust washer.

(5) Inspect the oil pan gasket/windage tray for

splits, tears or cracks in the gasket sealing surfaces.

Replace gasket as necessary.

INSTALLATION

CAUTION: Main bearings are select fit. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) for proper

bearing selections.

(1) Lubricate upper main bearing halves with

clean engine oil.

CAUTION: When installing crankshaft, use care not

to damage bearing surfaces on the crankshaft.

NOTE: Apply sealant to the target wheel retaining

screws prior to installation.

(2) Install the crankshaft target wheel. Torque the

mounting screws to 15 N´m (12 ft. lbs.).

(3) Position crankshaft in cylinder block.

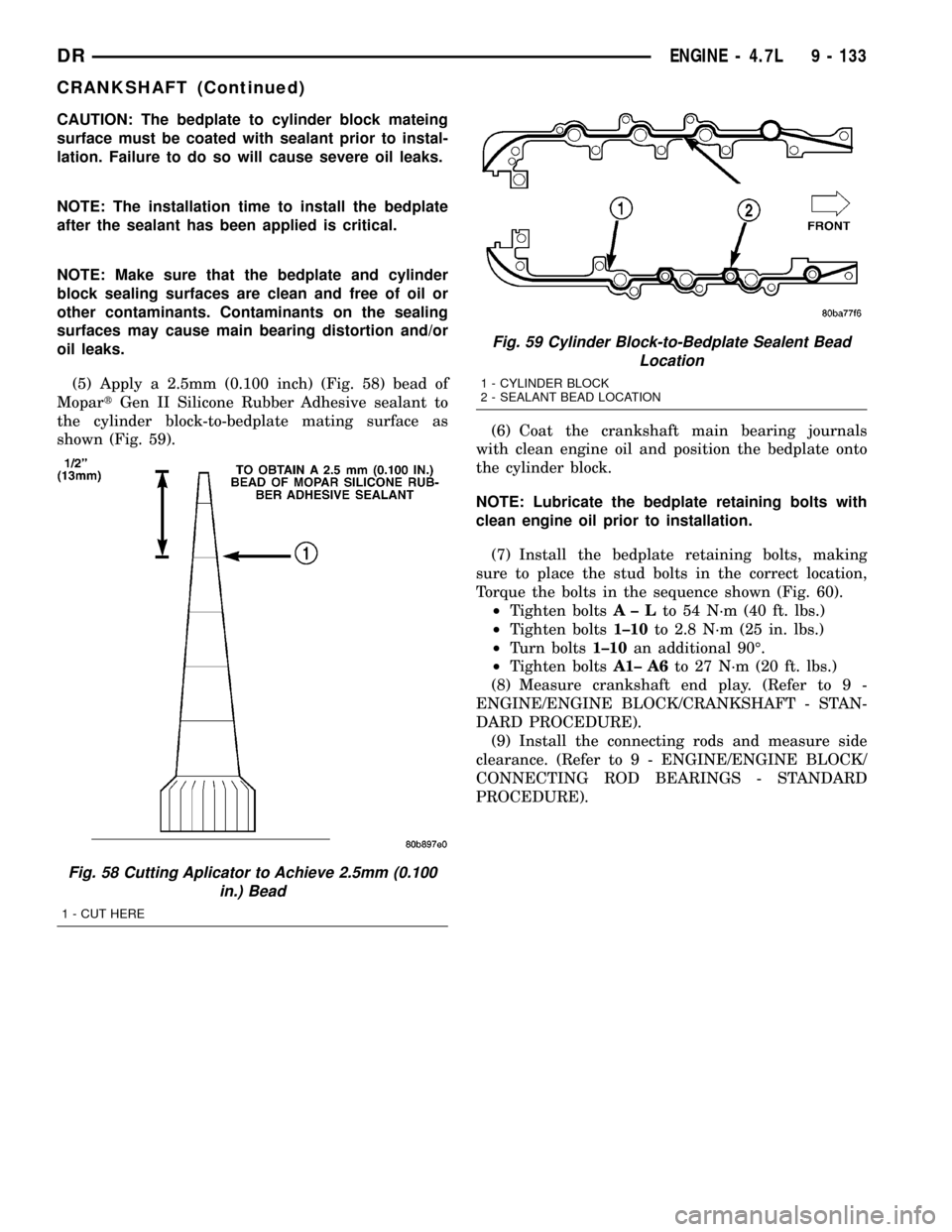

(4) Install the thrust washers (Fig. 57).

Fig. 56 Bedplate Pry Point Location

1 - CYLINDER BLOCK

2 - BEDPLATE

3 - PRY POINT

Fig. 57 Crankshaft Thrust Washer Installation

1 - CRANKSHAFT THRUST WASHER

9 - 132 ENGINE - 4.7LDR

CRANKSHAFT (Continued)

Page 1356 of 2627

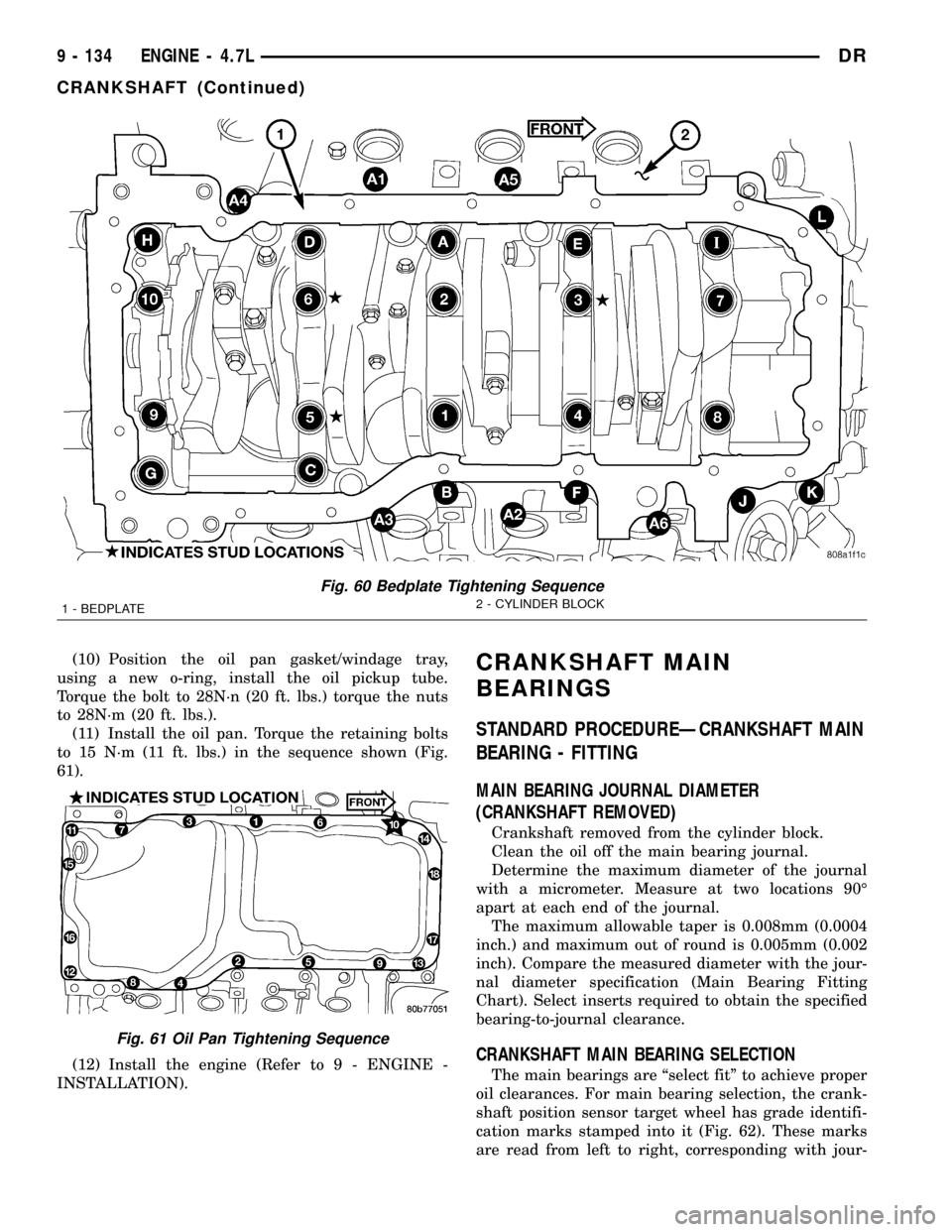

CAUTION: The bedplate to cylinder block mateing

surface must be coated with sealant prior to instal-

lation. Failure to do so will cause severe oil leaks.

NOTE: The installation time to install the bedplate

after the sealant has been applied is critical.

NOTE: Make sure that the bedplate and cylinder

block sealing surfaces are clean and free of oil or

other contaminants. Contaminants on the sealing

surfaces may cause main bearing distortion and/or

oil leaks.

(5) Apply a 2.5mm (0.100 inch) (Fig. 58) bead of

MopartGen II Silicone Rubber Adhesive sealant to

the cylinder block-to-bedplate mating surface as

shown (Fig. 59).(6) Coat the crankshaft main bearing journals

with clean engine oil and position the bedplate onto

the cylinder block.

NOTE: Lubricate the bedplate retaining bolts with

clean engine oil prior to installation.

(7) Install the bedplate retaining bolts, making

sure to place the stud bolts in the correct location,

Torque the bolts in the sequence shown (Fig. 60).

²Tighten boltsA± Lto 54 N´m (40 ft. lbs.)

²Tighten bolts1±10to 2.8 N´m (25 in. lbs.)

²Turn bolts1±10an additional 90É.

²Tighten boltsA1± A6to 27 N´m (20 ft. lbs.)

(8) Measure crankshaft end play. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT - STAN-

DARD PROCEDURE).

(9) Install the connecting rods and measure side

clearance. (Refer to 9 - ENGINE/ENGINE BLOCK/

CONNECTING ROD BEARINGS - STANDARD

PROCEDURE).

Fig. 58 Cutting Aplicator to Achieve 2.5mm (0.100

in.) Bead

1 - CUT HERE

Fig. 59 Cylinder Block-to-Bedplate Sealent Bead

Location

1 - CYLINDER BLOCK

2 - SEALANT BEAD LOCATION

DRENGINE - 4.7L 9 - 133

CRANKSHAFT (Continued)

Page 1357 of 2627

(10) Position the oil pan gasket/windage tray,

using a new o-ring, install the oil pickup tube.

Torque the bolt to 28N´n (20 ft. lbs.) torque the nuts

to 28N´m (20 ft. lbs.).

(11) Install the oil pan. Torque the retaining bolts

to 15 N´m (11 ft. lbs.) in the sequence shown (Fig.

61).

(12) Install the engine (Refer to 9 - ENGINE -

INSTALLATION).CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDUREÐCRANKSHAFT MAIN

BEARING - FITTING

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Crankshaft removed from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

CRANKSHAFT MAIN BEARING SELECTION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 62). These marks

are read from left to right, corresponding with jour-

Fig. 60 Bedplate Tightening Sequence

1 - BEDPLATE2 - CYLINDER BLOCK

Fig. 61 Oil Pan Tightening Sequence

9 - 134 ENGINE - 4.7LDR

CRANKSHAFT (Continued)

Page 1359 of 2627

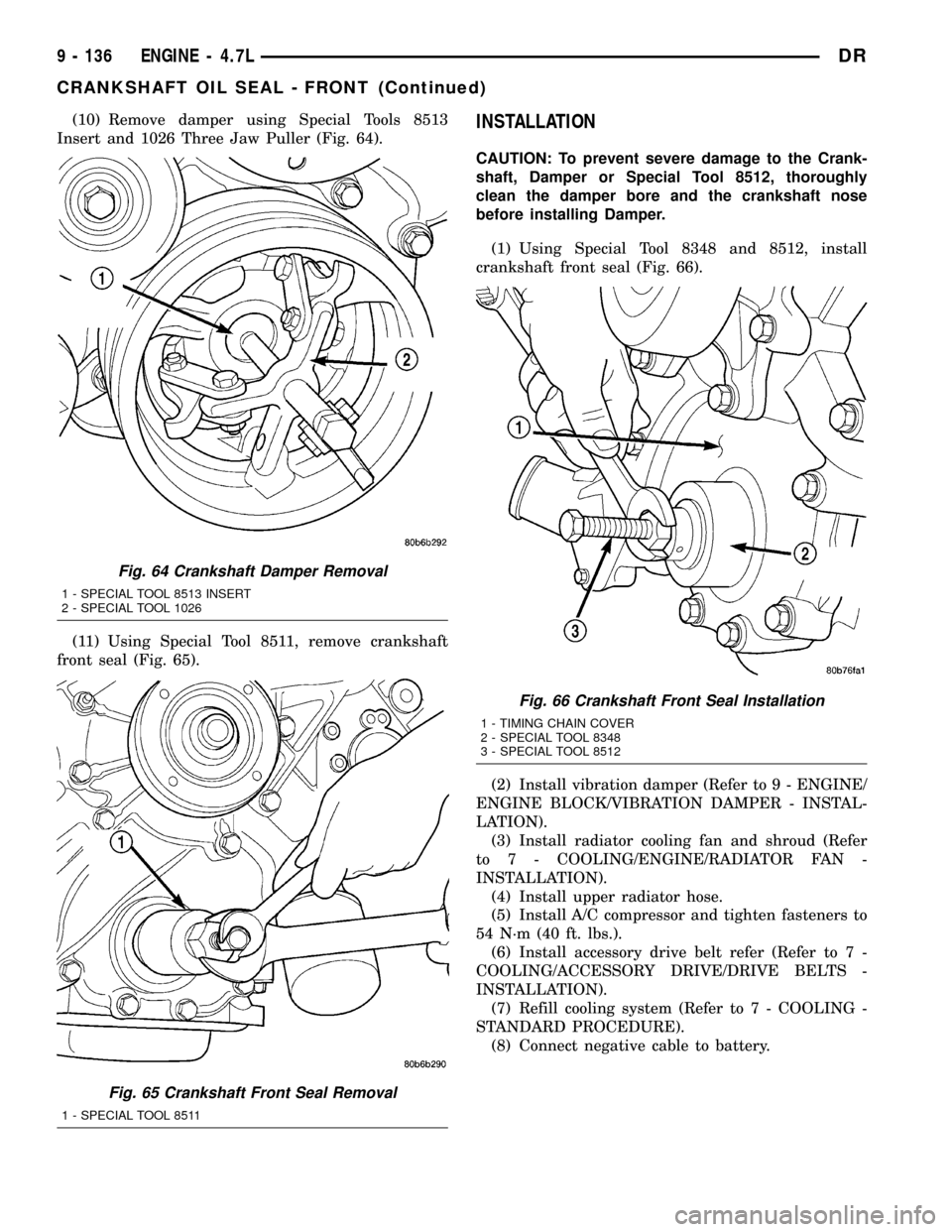

(10) Remove damper using Special Tools 8513

Insert and 1026 Three Jaw Puller (Fig. 64).

(11) Using Special Tool 8511, remove crankshaft

front seal (Fig. 65).INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

(1) Using Special Tool 8348 and 8512, install

crankshaft front seal (Fig. 66).

(2) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(3) Install radiator cooling fan and shroud (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(4) Install upper radiator hose.

(5) Install A/C compressor and tighten fasteners to

54 N´m (40 ft. lbs.).

(6) Install accessory drive belt refer (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(7) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(8) Connect negative cable to battery.

Fig. 64 Crankshaft Damper Removal

1 - SPECIAL TOOL 8513 INSERT

2 - SPECIAL TOOL 1026

Fig. 65 Crankshaft Front Seal Removal

1 - SPECIAL TOOL 8511

Fig. 66 Crankshaft Front Seal Installation

1 - TIMING CHAIN COVER

2 - SPECIAL TOOL 8348

3 - SPECIAL TOOL 8512

9 - 136 ENGINE - 4.7LDR

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1361 of 2627

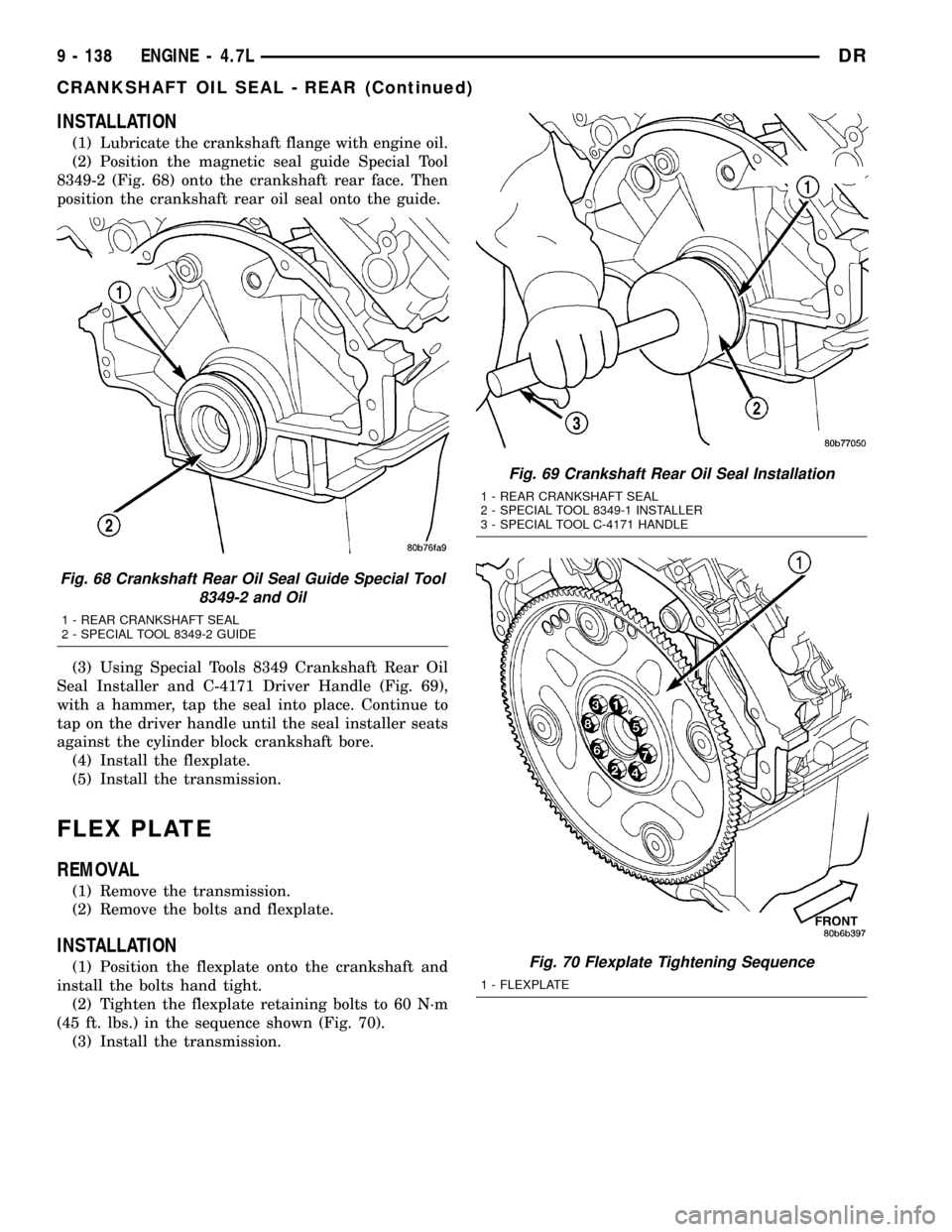

INSTALLATION

(1) Lubricate the crankshaft flange with engine oil.

(2) Position the magnetic seal guide Special Tool

8349-2 (Fig. 68) onto the crankshaft rear face. Then

position the crankshaft rear oil seal onto the guide.

(3) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle (Fig. 69),

with a hammer, tap the seal into place. Continue to

tap on the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(4) Install the flexplate.

(5) Install the transmission.

FLEX PLATE

REMOVAL

(1) Remove the transmission.

(2) Remove the bolts and flexplate.

INSTALLATION

(1) Position the flexplate onto the crankshaft and

install the bolts hand tight.

(2) Tighten the flexplate retaining bolts to 60 N´m

(45 ft. lbs.) in the sequence shown (Fig. 70).

(3) Install the transmission.

Fig. 68 Crankshaft Rear Oil Seal Guide Special Tool

8349-2 and Oil

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349-2 GUIDE

Fig. 69 Crankshaft Rear Oil Seal Installation

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349-1 INSTALLER

3 - SPECIAL TOOL C-4171 HANDLE

Fig. 70 Flexplate Tightening Sequence

1 - FLEXPLATE

9 - 138 ENGINE - 4.7LDR

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1362 of 2627

PISTON & CONNECTING ROD

DESCRIPTION

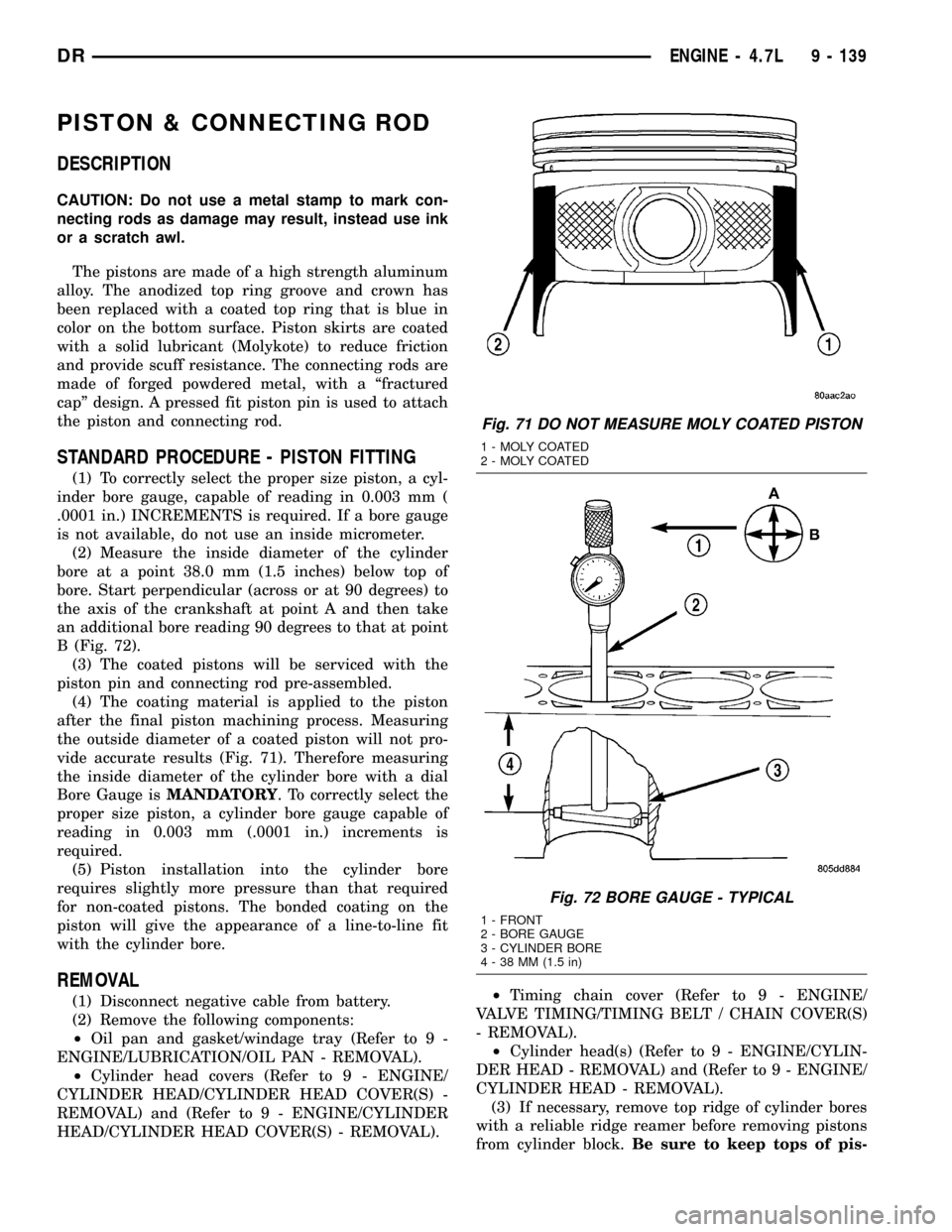

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

or a scratch awl.

The pistons are made of a high strength aluminum

alloy. The anodized top ring groove and crown has

been replaced with a coated top ring that is blue in

color on the bottom surface. Piston skirts are coated

with a solid lubricant (Molykote) to reduce friction

and provide scuff resistance. The connecting rods are

made of forged powdered metal, with a ªfractured

capº design. A pressed fit piston pin is used to attach

the piston and connecting rod.

STANDARD PROCEDURE - PISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (

.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 72).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled.

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 71). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components:

²Oil pan and gasket/windage tray (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).

²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - REMOVAL).²Timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL).

²Cylinder head(s) (Refer to 9 - ENGINE/CYLIN-

DER HEAD - REMOVAL) and (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(3) If necessary, remove top ridge of cylinder bores

with a reliable ridge reamer before removing pistons

from cylinder block.Be sure to keep tops of pis-

Fig. 71 DO NOT MEASURE MOLY COATED PISTON

1 - MOLY COATED

2 - MOLY COATED

Fig. 72 BORE GAUGE - TYPICAL

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 38 MM (1.5 in)

DRENGINE - 4.7L 9 - 139