Engine torque spec DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1604 of 2627

(4) Install MAP sensor mounting bolts (screws).

Refer to Torque Specifications.

(5) Connect electrical connector.

5.7L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted to the front of the intake manifold air ple-

num box (Fig. 24).

(1) Clean MAP sensor mounting hole at intake

manifold.

(2) Check MAP sensor o-ring seal for cuts or tears.

(3) Position sensor into manifold.

(4) Rotate sensor 1/4 turn clockwise for installa-

tion.

(5) Connect electrical connector.

OXYGEN SENSOR

DESCRIPTION

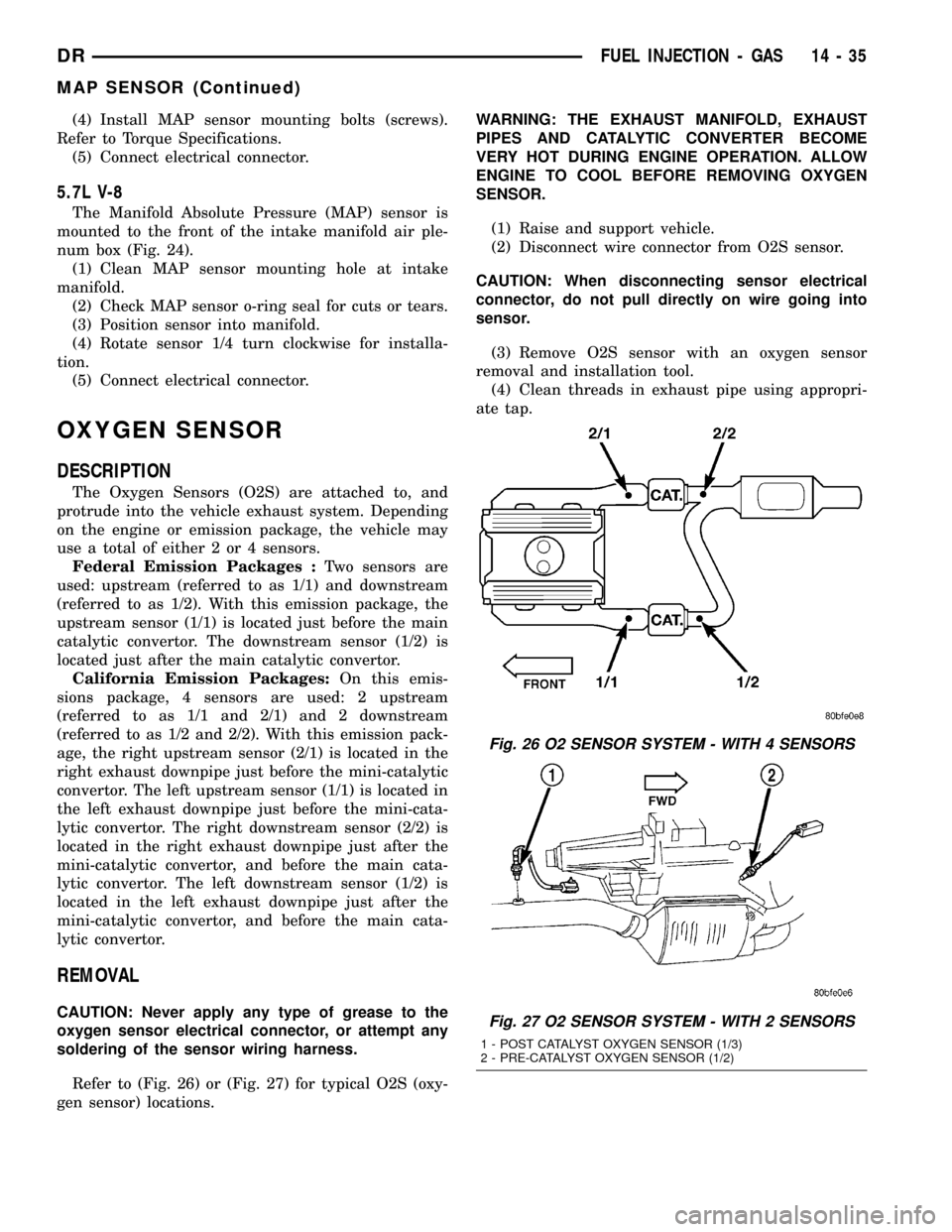

The Oxygen Sensors (O2S) are attached to, and

protrude into the vehicle exhaust system. Depending

on the engine or emission package, the vehicle may

use a total of either 2 or 4 sensors.

Federal Emission Packages :Two sensors are

used: upstream (referred to as 1/1) and downstream

(referred to as 1/2). With this emission package, the

upstream sensor (1/1) is located just before the main

catalytic convertor. The downstream sensor (1/2) is

located just after the main catalytic convertor.

California Emission Packages:On this emis-

sions package, 4 sensors are used: 2 upstream

(referred to as 1/1 and 2/1) and 2 downstream

(referred to as 1/2 and 2/2). With this emission pack-

age, the right upstream sensor (2/1) is located in the

right exhaust downpipe just before the mini-catalytic

convertor. The left upstream sensor (1/1) is located in

the left exhaust downpipe just before the mini-cata-

lytic convertor. The right downstream sensor (2/2) is

located in the right exhaust downpipe just after the

mini-catalytic convertor, and before the main cata-

lytic convertor. The left downstream sensor (1/2) is

located in the left exhaust downpipe just after the

mini-catalytic convertor, and before the main cata-

lytic convertor.

REMOVAL

CAUTION: Never apply any type of grease to the

oxygen sensor electrical connector, or attempt any

soldering of the sensor wiring harness.

Refer to (Fig. 26) or (Fig. 27) for typical O2S (oxy-

gen sensor) locations.WARNING: THE EXHAUST MANIFOLD, EXHAUST

PIPES AND CATALYTIC CONVERTER BECOME

VERY HOT DURING ENGINE OPERATION. ALLOW

ENGINE TO COOL BEFORE REMOVING OXYGEN

SENSOR.

(1) Raise and support vehicle.

(2) Disconnect wire connector from O2S sensor.

CAUTION: When disconnecting sensor electrical

connector, do not pull directly on wire going into

sensor.

(3) Remove O2S sensor with an oxygen sensor

removal and installation tool.

(4) Clean threads in exhaust pipe using appropri-

ate tap.

Fig. 26 O2 SENSOR SYSTEM - WITH 4 SENSORS

Fig. 27 O2 SENSOR SYSTEM - WITH 2 SENSORS

1 - POST CATALYST OXYGEN SENSOR (1/3)

2 - PRE-CATALYST OXYGEN SENSOR (1/2)

DRFUEL INJECTION - GAS 14 - 35

MAP SENSOR (Continued)

Page 1607 of 2627

4.7L V-8

(1) Clean throttle body-to-intake manifold o-ring.(2) Clean mating surfaces of throttle body and

intake manifold.

(3) Install throttle body to intake manifold by posi-

tioning throttle body to manifold alignment pins.

(4) Install three mounting bolts. Tighten bolts to

12 N´m (105 in. lbs.) torque.

(5) Install control cables.

(6) Install vacuum line to throttle body.

(7) Install electrical connectors.

(8) Install air plenum.

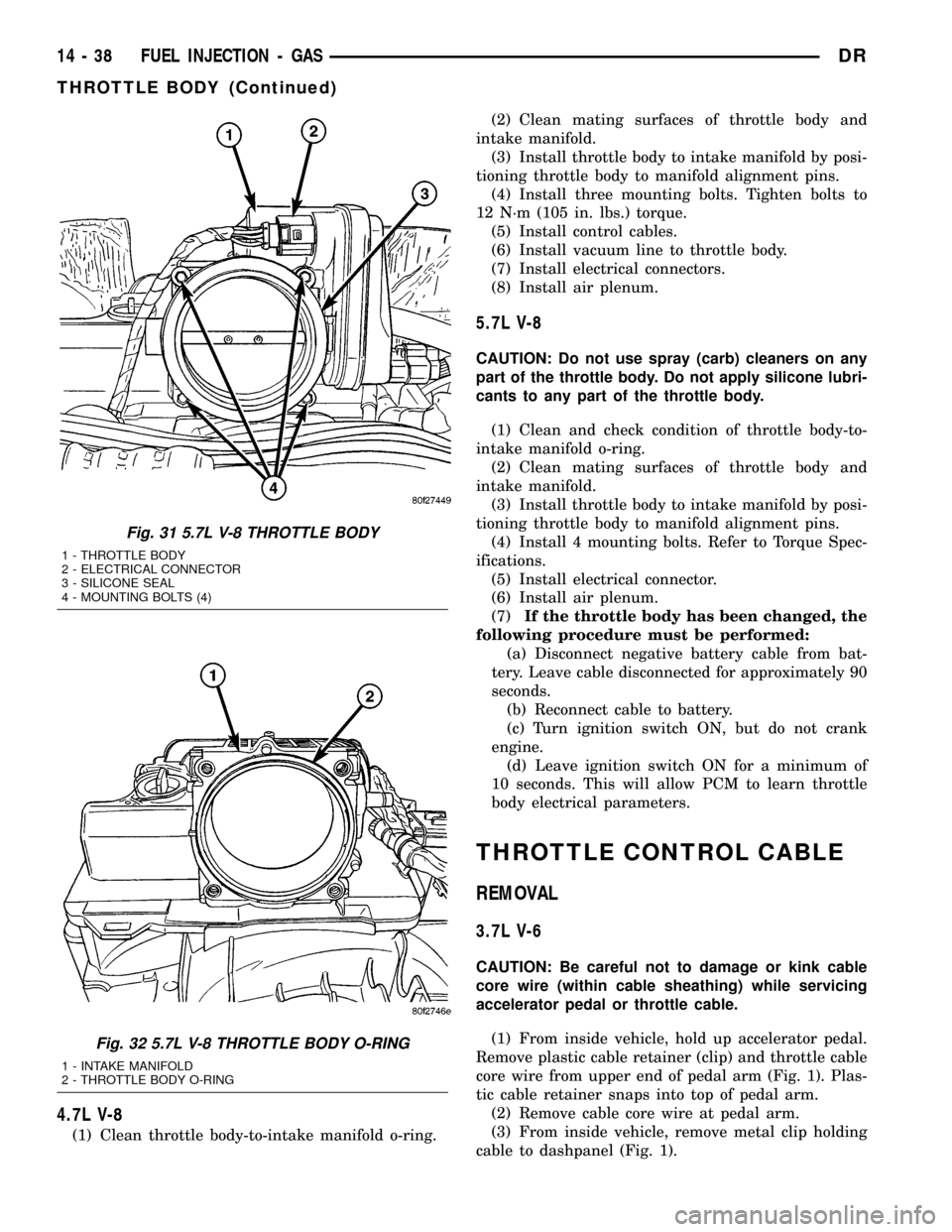

5.7L V-8

CAUTION: Do not use spray (carb) cleaners on any

part of the throttle body. Do not apply silicone lubri-

cants to any part of the throttle body.

(1) Clean and check condition of throttle body-to-

intake manifold o-ring.

(2) Clean mating surfaces of throttle body and

intake manifold.

(3) Install throttle body to intake manifold by posi-

tioning throttle body to manifold alignment pins.

(4) Install 4 mounting bolts. Refer to Torque Spec-

ifications.

(5) Install electrical connector.

(6) Install air plenum.

(7)If the throttle body has been changed, the

following procedure must be performed:

(a) Disconnect negative battery cable from bat-

tery. Leave cable disconnected for approximately 90

seconds.

(b) Reconnect cable to battery.

(c) Turn ignition switch ON, but do not crank

engine.

(d) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn throttle

body electrical parameters.

THROTTLE CONTROL CABLE

REMOVAL

3.7L V-6

CAUTION: Be careful not to damage or kink cable

core wire (within cable sheathing) while servicing

accelerator pedal or throttle cable.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of pedal arm (Fig. 1). Plas-

tic cable retainer snaps into top of pedal arm.

(2) Remove cable core wire at pedal arm.

(3) From inside vehicle, remove metal clip holding

cable to dashpanel (Fig. 1).

Fig. 31 5.7L V-8 THROTTLE BODY

1 - THROTTLE BODY

2 - ELECTRICAL CONNECTOR

3 - SILICONE SEAL

4 - MOUNTING BOLTS (4)

Fig. 32 5.7L V-8 THROTTLE BODY O-RING

1 - INTAKE MANIFOLD

2 - THROTTLE BODY O-RING

14 - 38 FUEL INJECTION - GASDR

THROTTLE BODY (Continued)

Page 1613 of 2627

FUEL DELIVERY - DIESEL

TABLE OF CONTENTS

page page

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM.....45

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER

DRAINING AT FUEL FILTER..............47

STANDARD PROCEDURES - CLEANING

FUEL SYSTEM PARTS.................47

STANDARD PROCEDURE - FUEL SYSTEM

PRIMING............................47

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL . 48

TORQUE - FUEL SYSTEM - DIESEL

ENGINE.............................48

SPECIAL TOOLS

DIESEL FUEL SYSTEM.................49

FUEL FILTER / WATER SEPARATOR

DESCRIPTION.........................50

OPERATION...........................50

REMOVAL.............................50

INSTALLATION.........................50

FUEL HEATER

DESCRIPTION.........................51

OPERATION...........................51

DIAGNOSIS AND TESTING - FUEL HEATER . . . 52

REMOVAL

REMOVAL/INSTALLATION...............52

FUEL HEATER RELAY

DESCRIPTION.........................52

OPERATION...........................52

REMOVAL.............................52

INSTALLATION.........................53

FUEL INJECTION PUMP

DESCRIPTION.........................53

OPERATION...........................53

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING........................53

REMOVAL.............................54

INSTALLATION.........................55

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION.........................57

OPERATION...........................57

REMOVAL

REMOVAL/INSTALLATION...............57FUEL LINES

DESCRIPTION.........................57

OPERATION...........................57

DIAGNOSIS AND TESTING - HIGH-

PRESSURE FUEL LINE LEAKS...........58

REMOVAL.............................58

INSTALLATION.........................60

FUEL PRESSURE SENSOR

DESCRIPTION.........................60

OPERATION...........................60

REMOVAL.............................60

INSTALLATION.........................61

FUEL PRESSURE LIMITING VALVE

DESCRIPTION.........................61

OPERATION...........................61

REMOVAL.............................61

INSTALLATION.........................61

FUEL TANK

DESCRIPTION - DIESEL..................62

REMOVAL - DIESEL.....................62

INSTALLATION - DIESEL.................62

FUEL TANK MODULE

DESCRIPTION.........................63

OPERATION...........................63

REMOVAL.............................63

INSTALLATION.........................64

FUEL TRANSFER PUMP

DESCRIPTION.........................64

OPERATION...........................64

REMOVAL.............................64

INSTALLATION.........................65

CASCADE OVERFLOW VALVE

DESCRIPTION.........................66

OPERATION...........................66

REMOVAL

REMOVAL/INSTALLATION...............66

WATER IN FUEL SENSOR

DESCRIPTION.........................66

OPERATION...........................66

REMOVAL.............................66

FUEL DRAIN CIRCUIT

OPERATION...........................67

14 - 44 FUEL DELIVERY - DIESELDR

Page 1617 of 2627

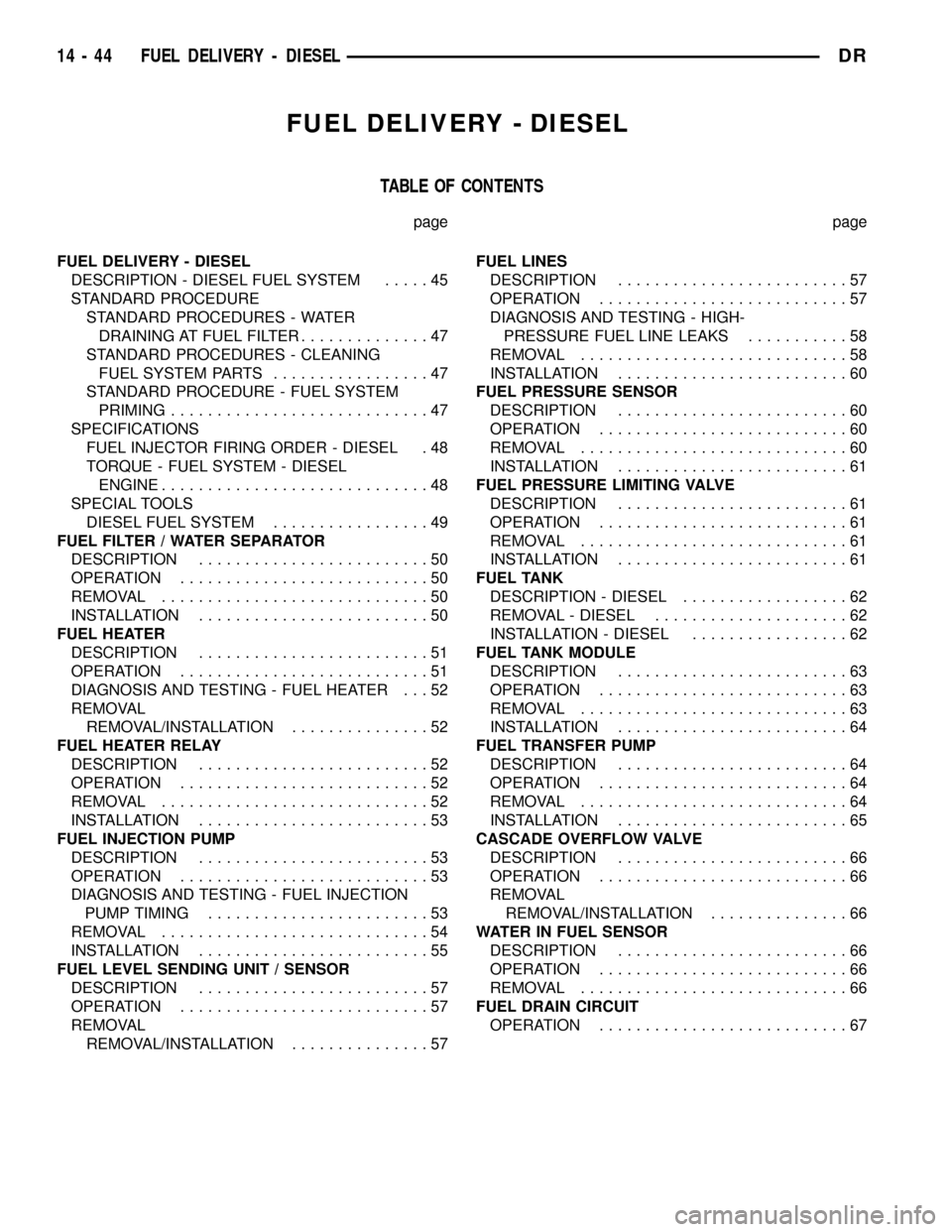

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL

1±5±3±6±2±4

TORQUE - FUEL SYSTEM - DIESEL ENGINE

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket Mounting 12 - 105

Accelerator Pedal Position Sensor

Bracket-to-Battery Tray Bolts3-30

Crankshaft Position Sensor 9 80

Camshaft Position Sensor 9 - 80

Engine Coolant Temperature Sensor 18 15 160

Rear Engine Lift Bracket Bolts 77 56 -

Fuel Connector Nut at Cylinder Head 50 37 -

Fuel Filler Hose Clamp at Tank 3 - 30

Fuel Filler Housing-to-Body Screws 2 - 17

Fuel Filter Lid 34 25 -

Fuel Filter Drain Valve Screws 1.5 - 14

Fuel Heater Element Screws 1.5 - 14

Fuel Pump Module Lock Ring 54 40 -

Fuel Line Banjo Fitting Bolts 24 18 -

Fuel Line Fittings (High-Pressure - Pump

to Rail)37 27 -

Fuel Line Fittings (High-Pressure -

Cylinder head to Rail)30 22 -

Bracket Over #6 Fuel Line (Bolts) 43 32 -

Fuel Injector Solenoid Nuts 1.25 - 11

Fuel Injection Pump-to-Gear Shaft Nut 105 77 -

Fuel Injection Pump Mounting Nuts 24 18 -

Fuel Line Support Clamps (High-

Pressure)24 18 -

Fuel Pressure Sensor 70 52 -

Fuel Pressure Limiting Valve (Banjo Bolt) 24 17 -

Fuel Pressure Limiting Valve (In Fuel

Rail)70 52 -

Fuel Rail Mounting Bolts 24 18 200

Fuel Tank Mounting Straps 41 30 -

Map Sensor Mounting Screws 1 - 9

ECM-to-Engine Bracket Mounting Bolts 24 18 -

ECM Electrical Harness Connector 3 - 27

Water-In-Fuel Sensor 4.5 - 39

14 - 48 FUEL DELIVERY - DIESELDR

FUEL DELIVERY - DIESEL (Continued)

Page 1627 of 2627

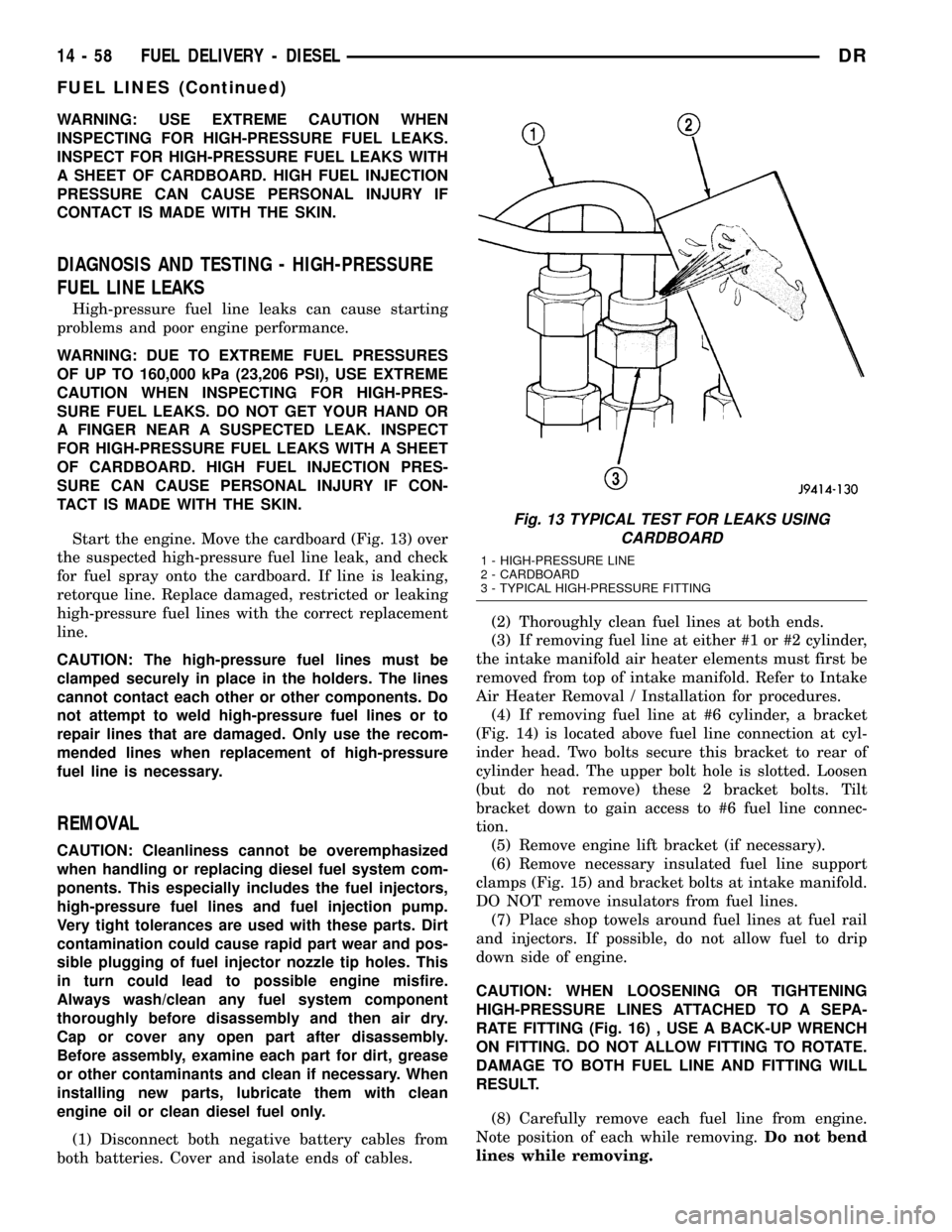

WARNING: USE EXTREME CAUTION WHEN

INSPECTING FOR HIGH-PRESSURE FUEL LEAKS.

INSPECT FOR HIGH-PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

DIAGNOSIS AND TESTING - HIGH-PRESSURE

FUEL LINE LEAKS

High-pressure fuel line leaks can cause starting

problems and poor engine performance.

WARNING: DUE TO EXTREME FUEL PRESSURES

OF UP TO 160,000 kPa (23,206 PSI), USE EXTREME

CAUTION WHEN INSPECTING FOR HIGH-PRES-

SURE FUEL LEAKS. DO NOT GET YOUR HAND OR

A FINGER NEAR A SUSPECTED LEAK. INSPECT

FOR HIGH-PRESSURE FUEL LEAKS WITH A SHEET

OF CARDBOARD. HIGH FUEL INJECTION PRES-

SURE CAN CAUSE PERSONAL INJURY IF CON-

TACT IS MADE WITH THE SKIN.

Start the engine. Move the cardboard (Fig. 13) over

the suspected high-pressure fuel line leak, and check

for fuel spray onto the cardboard. If line is leaking,

retorque line. Replace damaged, restricted or leaking

high-pressure fuel lines with the correct replacement

line.

CAUTION: The high-pressure fuel lines must be

clamped securely in place in the holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high-pressure

fuel line is necessary.

REMOVAL

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Disconnect both negative battery cables from

both batteries. Cover and isolate ends of cables.(2) Thoroughly clean fuel lines at both ends.

(3) If removing fuel line at either #1 or #2 cylinder,

the intake manifold air heater elements must first be

removed from top of intake manifold. Refer to Intake

Air Heater Removal / Installation for procedures.

(4) If removing fuel line at #6 cylinder, a bracket

(Fig. 14) is located above fuel line connection at cyl-

inder head. Two bolts secure this bracket to rear of

cylinder head. The upper bolt hole is slotted. Loosen

(but do not remove) these 2 bracket bolts. Tilt

bracket down to gain access to #6 fuel line connec-

tion.

(5) Remove engine lift bracket (if necessary).

(6) Remove necessary insulated fuel line support

clamps (Fig. 15) and bracket bolts at intake manifold.

DO NOT remove insulators from fuel lines.

(7) Place shop towels around fuel lines at fuel rail

and injectors. If possible, do not allow fuel to drip

down side of engine.

CAUTION: WHEN LOOSENING OR TIGHTENING

HIGH-PRESSURE LINES ATTACHED TO A SEPA-

RATE FITTING (Fig. 16) , USE A BACK-UP WRENCH

ON FITTING. DO NOT ALLOW FITTING TO ROTATE.

DAMAGE TO BOTH FUEL LINE AND FITTING WILL

RESULT.

(8) Carefully remove each fuel line from engine.

Note position of each while removing.Do not bend

lines while removing.

Fig. 13 TYPICAL TEST FOR LEAKS USING

CARDBOARD

1 - HIGH-PRESSURE LINE

2 - CARDBOARD

3 - TYPICAL HIGH-PRESSURE FITTING

14 - 58 FUEL DELIVERY - DIESELDR

FUEL LINES (Continued)

Page 1629 of 2627

INSTALLATION

All high-pressure fuel lines are of the same length

and inside diameter. Correct high-pressure fuel line

usage and installation is critical to smooth engine

operation.

CAUTION: Anytime a high-pressure line is removed

from the engine, its fuel connector nut at the cylin-

der head must first be retorqued. Refer to Torque

Specifications.

(1) Tighten fuel lines at high pressure injector con-

nector. Refer to Torque Specifications.

(2) Position fuel line support clamp(s) to fuel

line(s). Install clamp nuts/bolts and tighten finger

tight.

(3) Position proper fuel line to proper injector on

engine. Tighten fittings hand tight at both ends of

line.

(4) Tighten fuel lines at fuel rail. Refer to Torque

Specifications.

(5) Tighten clamp/support nuts and bolts. Refer to

Torque Specifications.

(6) Install engine lifting bracket and bolt. Refer to

Torque Specifications.

(7) If fuel line at either #1 or #2 cylinder has been

replaced, install intake manifold air heater elements

to top of intake manifold. Refer to Intake Air Heater

Removal / Installation for procedures.

(8) If fuel line at #6 cylinder has been replaced, tilt

metal bracket upward and tighten 2 bolts at rear of

cylinder head. Refer to Torque Specifications.

(9) Install remaining fuel line support clamps and

bracket bolts at intake manifold. Refer to Torque

Specifications.

(10) Connect both negative battery cables to both

batteries.

(11) Prime fuel system. Refer to Fuel System

Priming.

(12) Check lines/fittings for leaks.

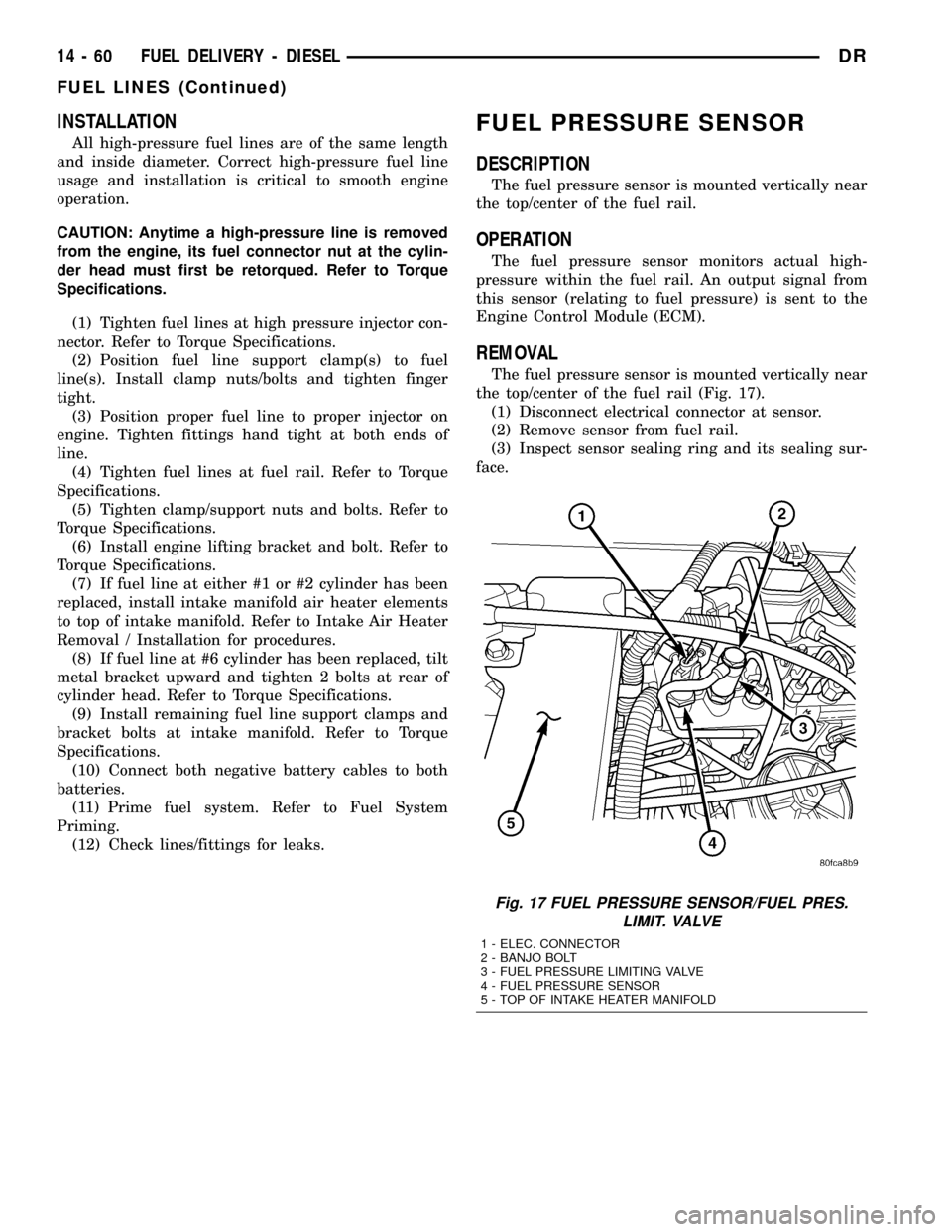

FUEL PRESSURE SENSOR

DESCRIPTION

The fuel pressure sensor is mounted vertically near

the top/center of the fuel rail.

OPERATION

The fuel pressure sensor monitors actual high-

pressure within the fuel rail. An output signal from

this sensor (relating to fuel pressure) is sent to the

Engine Control Module (ECM).

REMOVAL

The fuel pressure sensor is mounted vertically near

the top/center of the fuel rail (Fig. 17).

(1) Disconnect electrical connector at sensor.

(2) Remove sensor from fuel rail.

(3) Inspect sensor sealing ring and its sealing sur-

face.

Fig. 17 FUEL PRESSURE SENSOR/FUEL PRES.

LIMIT. VALVE

1 - ELEC. CONNECTOR

2 - BANJO BOLT

3 - FUEL PRESSURE LIMITING VALVE

4 - FUEL PRESSURE SENSOR

5 - TOP OF INTAKE HEATER MANIFOLD

14 - 60 FUEL DELIVERY - DIESELDR

FUEL LINES (Continued)

Page 1630 of 2627

INSTALLATION

(1) Inspect fuel pressure sensor sealing surface.

(2) Lubricate sensor threads with clean diesel fuel.

(3) Install sensor into fuel rail.

(4) To prevent leaks, sensormustbe tightened to

prescribed torque. Refer to Torque Specifications.

(5) Connect electrical connector to sensor.

(6) Start engine and check for fuel leaks.

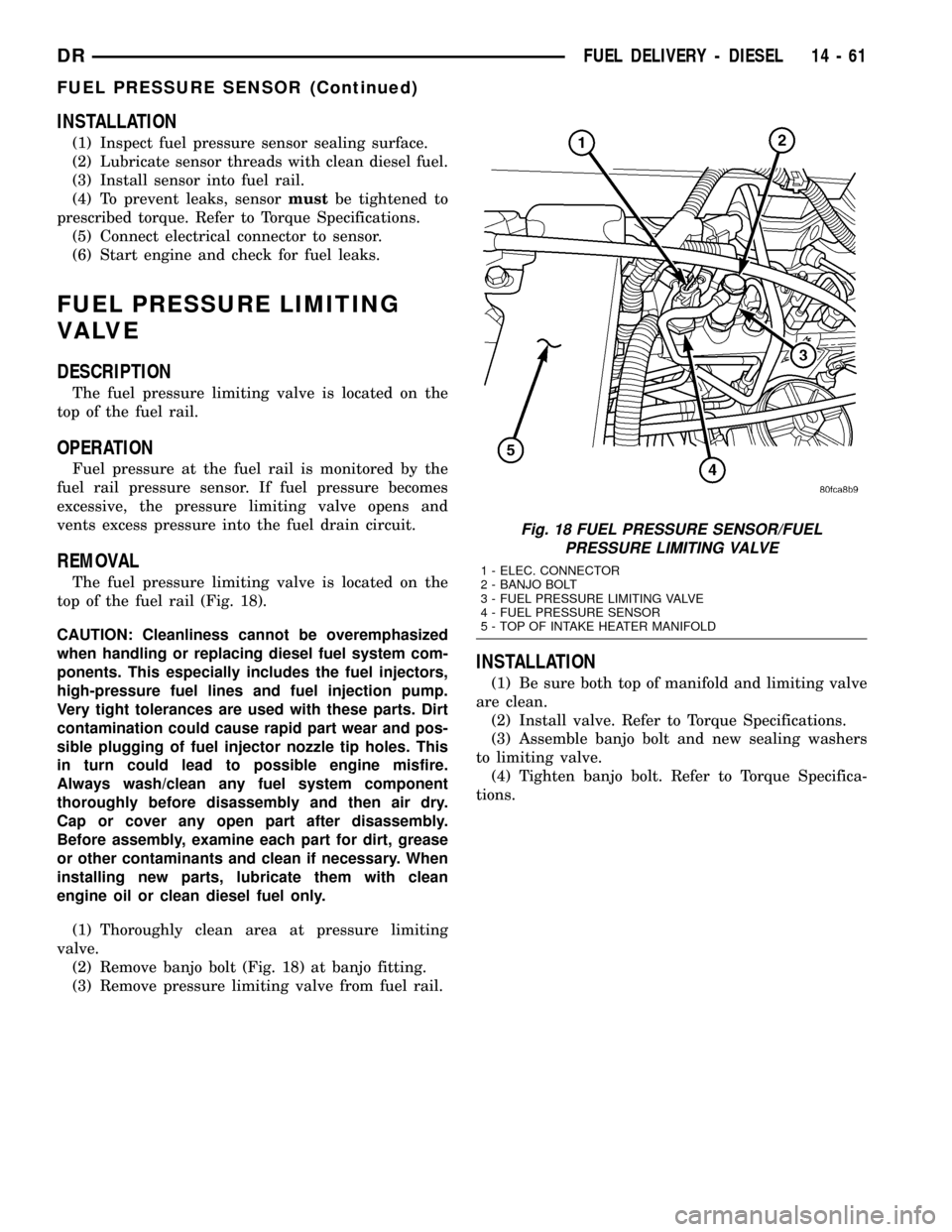

FUEL PRESSURE LIMITING

VA LV E

DESCRIPTION

The fuel pressure limiting valve is located on the

top of the fuel rail.

OPERATION

Fuel pressure at the fuel rail is monitored by the

fuel rail pressure sensor. If fuel pressure becomes

excessive, the pressure limiting valve opens and

vents excess pressure into the fuel drain circuit.

REMOVAL

The fuel pressure limiting valve is located on the

top of the fuel rail (Fig. 18).

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Thoroughly clean area at pressure limiting

valve.

(2) Remove banjo bolt (Fig. 18) at banjo fitting.

(3) Remove pressure limiting valve from fuel rail.

INSTALLATION

(1) Be sure both top of manifold and limiting valve

are clean.

(2) Install valve. Refer to Torque Specifications.

(3) Assemble banjo bolt and new sealing washers

to limiting valve.

(4) Tighten banjo bolt. Refer to Torque Specifica-

tions.

Fig. 18 FUEL PRESSURE SENSOR/FUEL

PRESSURE LIMITING VALVE

1 - ELEC. CONNECTOR

2 - BANJO BOLT

3 - FUEL PRESSURE LIMITING VALVE

4 - FUEL PRESSURE SENSOR

5 - TOP OF INTAKE HEATER MANIFOLD

DRFUEL DELIVERY - DIESEL 14 - 61

FUEL PRESSURE SENSOR (Continued)

Page 1631 of 2627

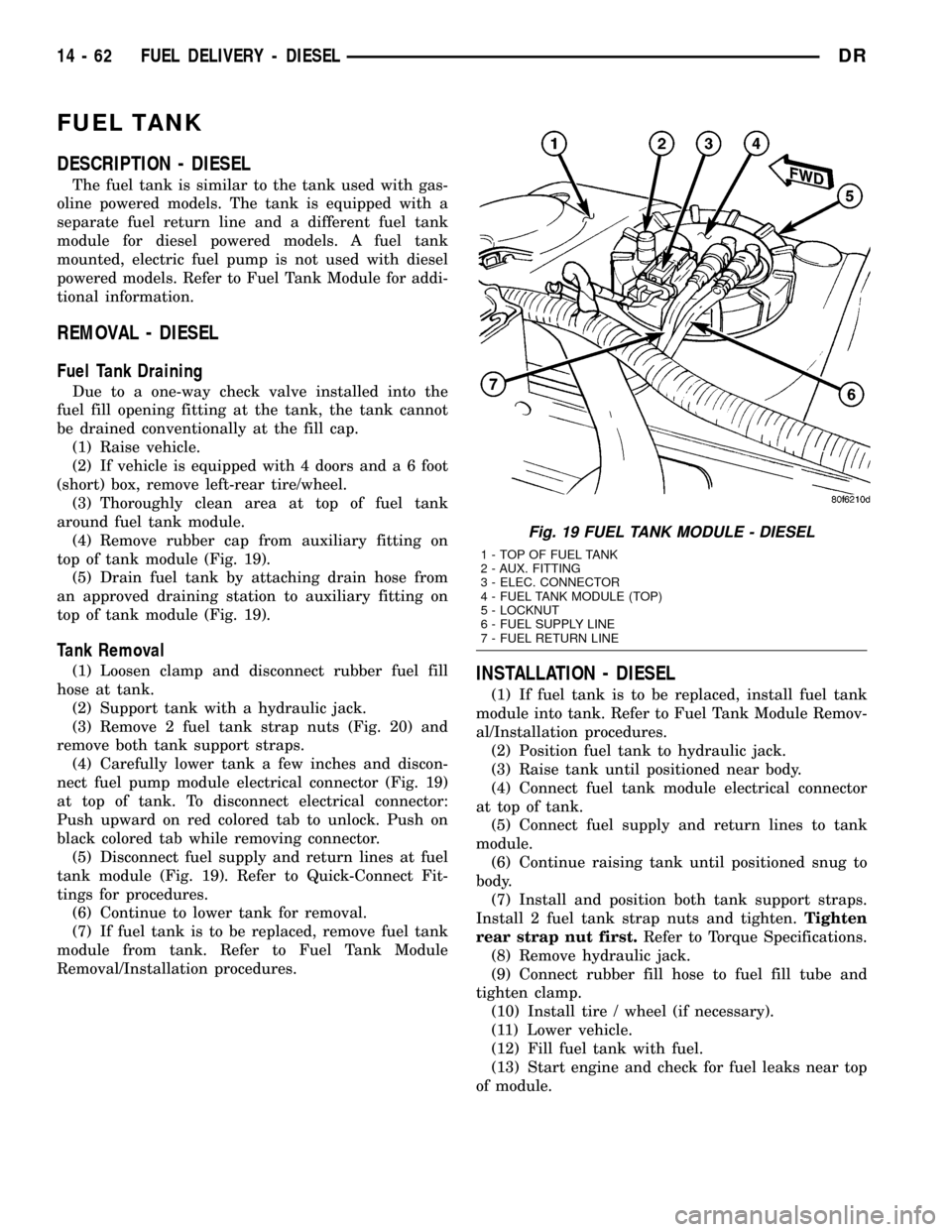

FUEL TANK

DESCRIPTION - DIESEL

The fuel tank is similar to the tank used with gas-

oline powered models. The tank is equipped with a

separate fuel return line and a different fuel tank

module for diesel powered models. A fuel tank

mounted, electric fuel pump is not used with diesel

powered models. Refer to Fuel Tank Module for addi-

tional information.

REMOVAL - DIESEL

Fuel Tank Draining

Due to a one-way check valve installed into the

fuel fill opening fitting at the tank, the tank cannot

be drained conventionally at the fill cap.

(1) Raise vehicle.

(2) If vehicle is equipped with 4 doors and a 6 foot

(short) box, remove left-rear tire/wheel.

(3) Thoroughly clean area at top of fuel tank

around fuel tank module.

(4) Remove rubber cap from auxiliary fitting on

top of tank module (Fig. 19).

(5) Drain fuel tank by attaching drain hose from

an approved draining station to auxiliary fitting on

top of tank module (Fig. 19).

Tank Removal

(1) Loosen clamp and disconnect rubber fuel fill

hose at tank.

(2) Support tank with a hydraulic jack.

(3) Remove 2 fuel tank strap nuts (Fig. 20) and

remove both tank support straps.

(4) Carefully lower tank a few inches and discon-

nect fuel pump module electrical connector (Fig. 19)

at top of tank. To disconnect electrical connector:

Push upward on red colored tab to unlock. Push on

black colored tab while removing connector.

(5) Disconnect fuel supply and return lines at fuel

tank module (Fig. 19). Refer to Quick-Connect Fit-

tings for procedures.

(6) Continue to lower tank for removal.

(7) If fuel tank is to be replaced, remove fuel tank

module from tank. Refer to Fuel Tank Module

Removal/Installation procedures.INSTALLATION - DIESEL

(1) If fuel tank is to be replaced, install fuel tank

module into tank. Refer to Fuel Tank Module Remov-

al/Installation procedures.

(2) Position fuel tank to hydraulic jack.

(3) Raise tank until positioned near body.

(4) Connect fuel tank module electrical connector

at top of tank.

(5) Connect fuel supply and return lines to tank

module.

(6) Continue raising tank until positioned snug to

body.

(7) Install and position both tank support straps.

Install 2 fuel tank strap nuts and tighten.Tighten

rear strap nut first.Refer to Torque Specifications.

(8) Remove hydraulic jack.

(9) Connect rubber fill hose to fuel fill tube and

tighten clamp.

(10) Install tire / wheel (if necessary).

(11) Lower vehicle.

(12) Fill fuel tank with fuel.

(13) Start engine and check for fuel leaks near top

of module.

Fig. 19 FUEL TANK MODULE - DIESEL

1 - TOP OF FUEL TANK

2 - AUX. FITTING

3 - ELEC. CONNECTOR

4 - FUEL TANK MODULE (TOP)

5 - LOCKNUT

6 - FUEL SUPPLY LINE

7 - FUEL RETURN LINE

14 - 62 FUEL DELIVERY - DIESELDR

Page 1633 of 2627

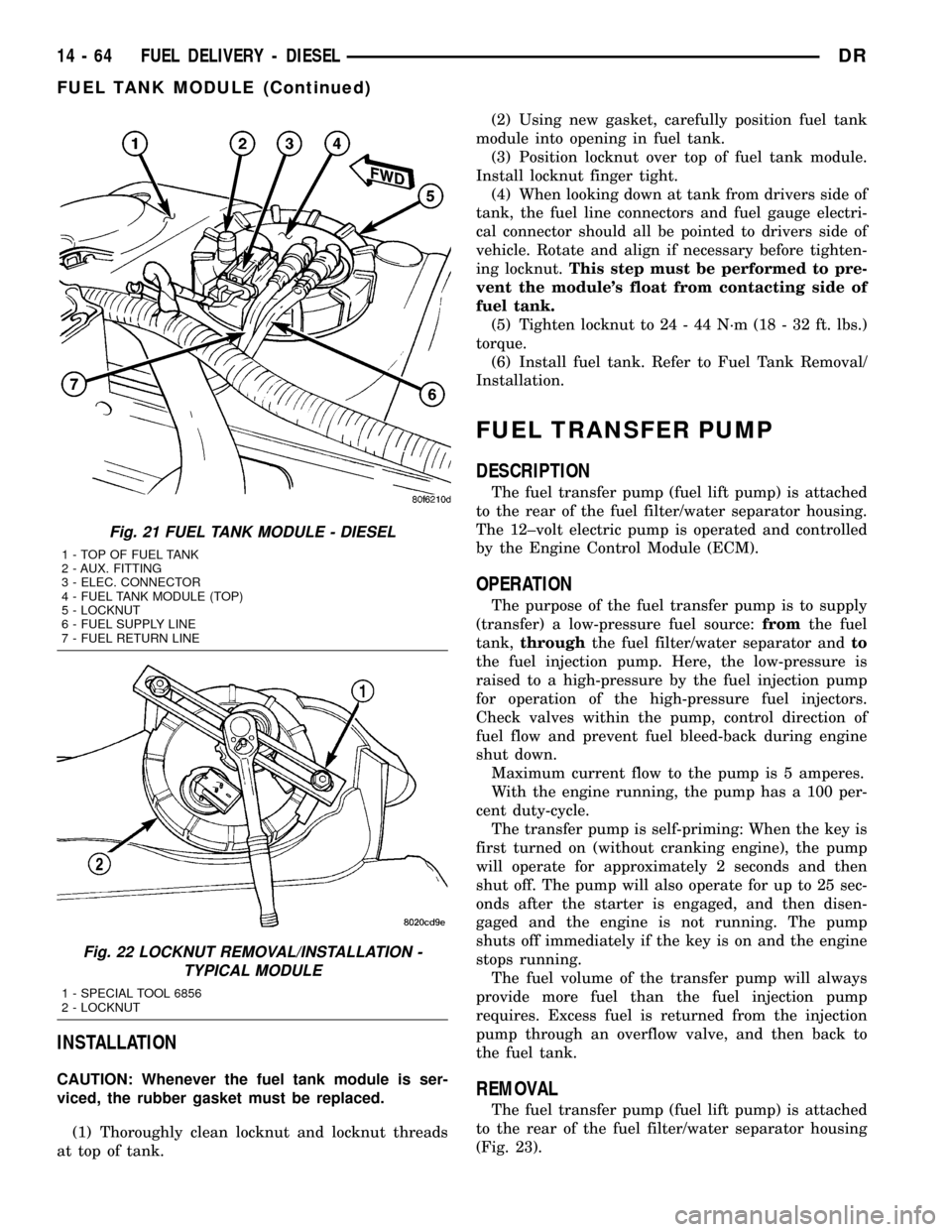

INSTALLATION

CAUTION: Whenever the fuel tank module is ser-

viced, the rubber gasket must be replaced.

(1) Thoroughly clean locknut and locknut threads

at top of tank.(2) Using new gasket, carefully position fuel tank

module into opening in fuel tank.

(3) Position locknut over top of fuel tank module.

Install locknut finger tight.

(4) When looking down at tank from drivers side of

tank, the fuel line connectors and fuel gauge electri-

cal connector should all be pointed to drivers side of

vehicle. Rotate and align if necessary before tighten-

ing locknut.This step must be performed to pre-

vent the module's float from contacting side of

fuel tank.

(5) Tighten locknut to 24 - 44 N´m (18 - 32 ft. lbs.)

torque.

(6) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

FUEL TRANSFER PUMP

DESCRIPTION

The fuel transfer pump (fuel lift pump) is attached

to the rear of the fuel filter/water separator housing.

The 12±volt electric pump is operated and controlled

by the Engine Control Module (ECM).

OPERATION

The purpose of the fuel transfer pump is to supply

(transfer) a low-pressure fuel source:fromthe fuel

tank,throughthe fuel filter/water separator andto

the fuel injection pump. Here, the low-pressure is

raised to a high-pressure by the fuel injection pump

for operation of the high-pressure fuel injectors.

Check valves within the pump, control direction of

fuel flow and prevent fuel bleed-back during engine

shut down.

Maximum current flow to the pump is 5 amperes.

With the engine running, the pump has a 100 per-

cent duty-cycle.

The transfer pump is self-priming: When the key is

first turned on (without cranking engine), the pump

will operate for approximately 2 seconds and then

shut off. The pump will also operate for up to 25 sec-

onds after the starter is engaged, and then disen-

gaged and the engine is not running. The pump

shuts off immediately if the key is on and the engine

stops running.

The fuel volume of the transfer pump will always

provide more fuel than the fuel injection pump

requires. Excess fuel is returned from the injection

pump through an overflow valve, and then back to

the fuel tank.

REMOVAL

The fuel transfer pump (fuel lift pump) is attached

to the rear of the fuel filter/water separator housing

(Fig. 23).

Fig. 21 FUEL TANK MODULE - DIESEL

1 - TOP OF FUEL TANK

2 - AUX. FITTING

3 - ELEC. CONNECTOR

4 - FUEL TANK MODULE (TOP)

5 - LOCKNUT

6 - FUEL SUPPLY LINE

7 - FUEL RETURN LINE

Fig. 22 LOCKNUT REMOVAL/INSTALLATION -

TYPICAL MODULE

1 - SPECIAL TOOL 6856

2 - LOCKNUT

14 - 64 FUEL DELIVERY - DIESELDR

FUEL TANK MODULE (Continued)

Page 1640 of 2627

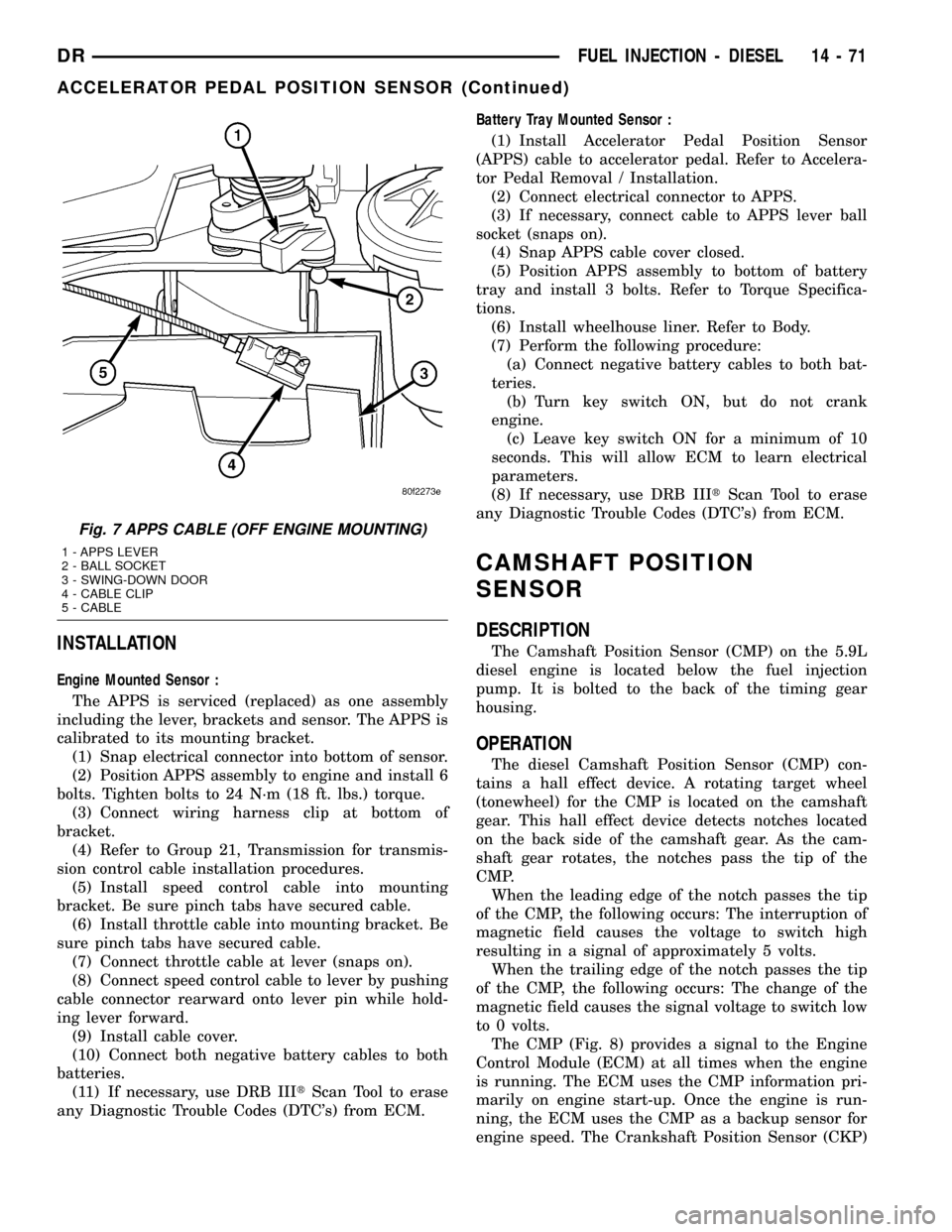

INSTALLATION

Engine Mounted Sensor :

The APPS is serviced (replaced) as one assembly

including the lever, brackets and sensor. The APPS is

calibrated to its mounting bracket.

(1) Snap electrical connector into bottom of sensor.

(2) Position APPS assembly to engine and install 6

bolts. Tighten bolts to 24 N´m (18 ft. lbs.) torque.

(3) Connect wiring harness clip at bottom of

bracket.

(4) Refer to Group 21, Transmission for transmis-

sion control cable installation procedures.

(5) Install speed control cable into mounting

bracket. Be sure pinch tabs have secured cable.

(6) Install throttle cable into mounting bracket. Be

sure pinch tabs have secured cable.

(7) Connect throttle cable at lever (snaps on).

(8) Connect speed control cable to lever by pushing

cable connector rearward onto lever pin while hold-

ing lever forward.

(9) Install cable cover.

(10) Connect both negative battery cables to both

batteries.

(11) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from ECM.Battery Tray Mounted Sensor :

(1) Install Accelerator Pedal Position Sensor

(APPS) cable to accelerator pedal. Refer to Accelera-

tor Pedal Removal / Installation.

(2) Connect electrical connector to APPS.

(3) If necessary, connect cable to APPS lever ball

socket (snaps on).

(4) Snap APPS cable cover closed.

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7) Perform the following procedure:

(a) Connect negative battery cables to both bat-

teries.

(b) Turn key switch ON, but do not crank

engine.

(c) Leave key switch ON for a minimum of 10

seconds. This will allow ECM to learn electrical

parameters.

(8) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from ECM.

CAMSHAFT POSITION

SENSOR

DESCRIPTION

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

housing.

OPERATION

The diesel Camshaft Position Sensor (CMP) con-

tains a hall effect device. A rotating target wheel

(tonewheel) for the CMP is located on the camshaft

gear. This hall effect device detects notches located

on the back side of the camshaft gear. As the cam-

shaft gear rotates, the notches pass the tip of the

CMP.

When the leading edge of the notch passes the tip

of the CMP, the following occurs: The interruption of

magnetic field causes the voltage to switch high

resulting in a signal of approximately 5 volts.

When the trailing edge of the notch passes the tip

of the CMP, the following occurs: The change of the

magnetic field causes the signal voltage to switch low

to 0 volts.

The CMP (Fig. 8) provides a signal to the Engine

Control Module (ECM) at all times when the engine

is running. The ECM uses the CMP information pri-

marily on engine start-up. Once the engine is run-

ning, the ECM uses the CMP as a backup sensor for

engine speed. The Crankshaft Position Sensor (CKP)

Fig. 7 APPS CABLE (OFF ENGINE MOUNTING)

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

DRFUEL INJECTION - DIESEL 14 - 71

ACCELERATOR PEDAL POSITION SENSOR (Continued)