ECO mode DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 352 of 2627

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain the coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

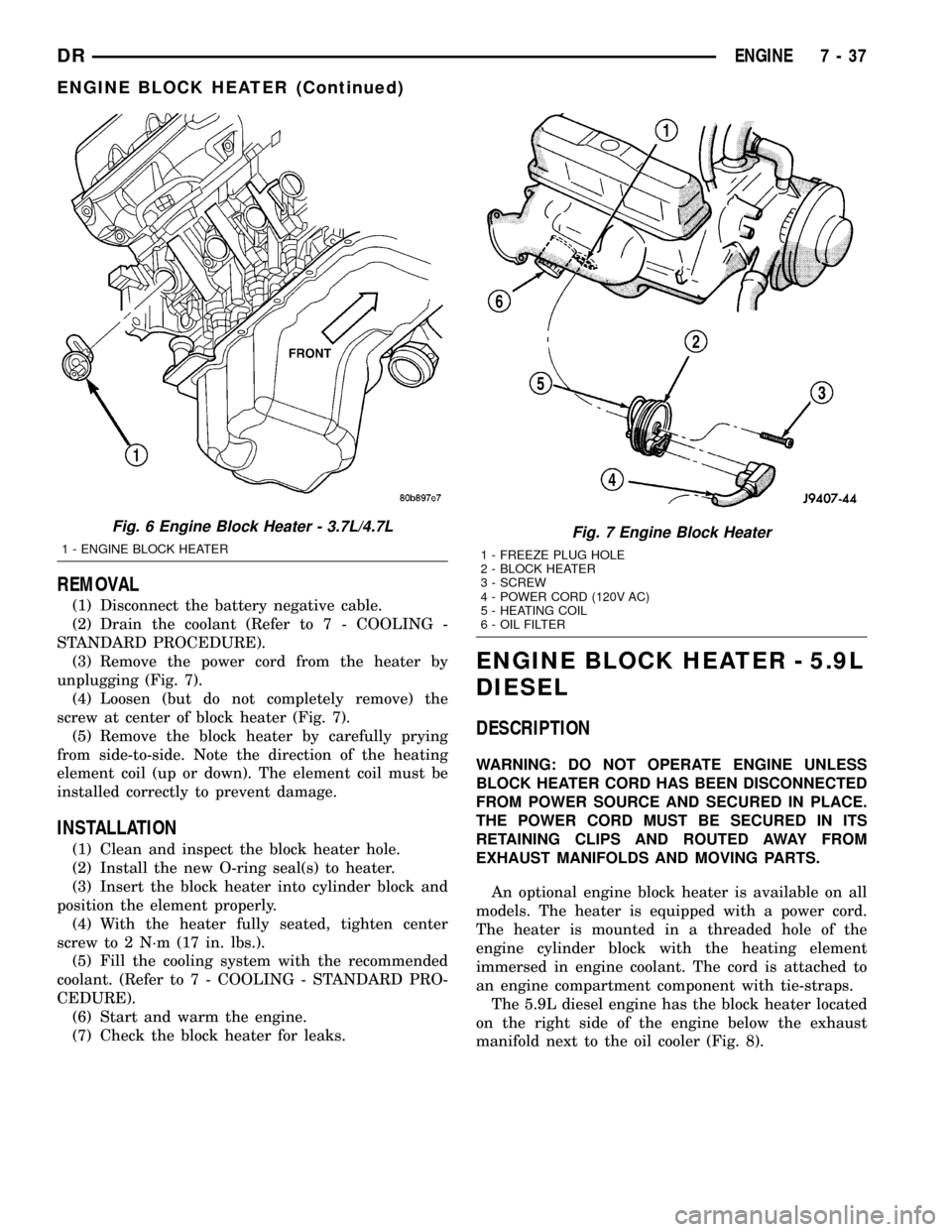

(3) Remove the power cord from the heater by

unplugging (Fig. 7).

(4) Loosen (but do not completely remove) the

screw at center of block heater (Fig. 7).

(5) Remove the block heater by carefully prying

from side-to-side. Note the direction of the heating

element coil (up or down). The element coil must be

installed correctly to prevent damage.

INSTALLATION

(1) Clean and inspect the block heater hole.

(2) Install the new O-ring seal(s) to heater.

(3) Insert the block heater into cylinder block and

position the element properly.

(4) With the heater fully seated, tighten center

screw to 2 N´m (17 in. lbs.).

(5) Fill the cooling system with the recommended

coolant. (Refer to 7 - COOLING - STANDARD PRO-

CEDURE).

(6) Start and warm the engine.

(7) Check the block heater for leaks.

ENGINE BLOCK HEATER - 5.9L

DIESEL

DESCRIPTION

WARNING: DO NOT OPERATE ENGINE UNLESS

BLOCK HEATER CORD HAS BEEN DISCONNECTED

FROM POWER SOURCE AND SECURED IN PLACE.

THE POWER CORD MUST BE SECURED IN ITS

RETAINING CLIPS AND ROUTED AWAY FROM

EXHAUST MANIFOLDS AND MOVING PARTS.

An optional engine block heater is available on all

models. The heater is equipped with a power cord.

The heater is mounted in a threaded hole of the

engine cylinder block with the heating element

immersed in engine coolant. The cord is attached to

an engine compartment component with tie-straps.

The 5.9L diesel engine has the block heater located

on the right side of the engine below the exhaust

manifold next to the oil cooler (Fig. 8).

Fig. 6 Engine Block Heater - 3.7L/4.7L

1 - ENGINE BLOCK HEATER

Fig. 7 Engine Block Heater

1 - FREEZE PLUG HOLE

2 - BLOCK HEATER

3 - SCREW

4 - POWER CORD (120V AC)

5 - HEATING COIL

6 - OIL FILTER

DRENGINE 7 - 37

ENGINE BLOCK HEATER (Continued)

Page 357 of 2627

DIAGNOSIS AND TESTINGÐTHERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

indicated by the instrument panel gauge or by poor

heater performance unless a DTC is present. Refer to

the Diagnosis section of this group for other probable

causes.

The DTC can also be accessed through the

DRBIIItscan tool. Refer to the appropriate Power-

train Diagnostic Procedures information for diagnos-

tic information and operation of the DRBIIItscan

tool.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE COOLING SYSTEM HOT

AND PRESSURIZED. SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

If the thermostat is being replaced, be sure that

the replacement is the specified thermostat for the

vehicle model and engine type.

Factory installed thermostat housings on 5.9L

engine is installed on a gasket with an anti-stick

coating. This will aid in gasket removal and clean-up.

(1) Disconnect the negative battery cable.

(2) Drain the cooling system until the coolant level

is below the thermostat (Refer to 7 - COOLING -

STANDARD PROCEDURE).

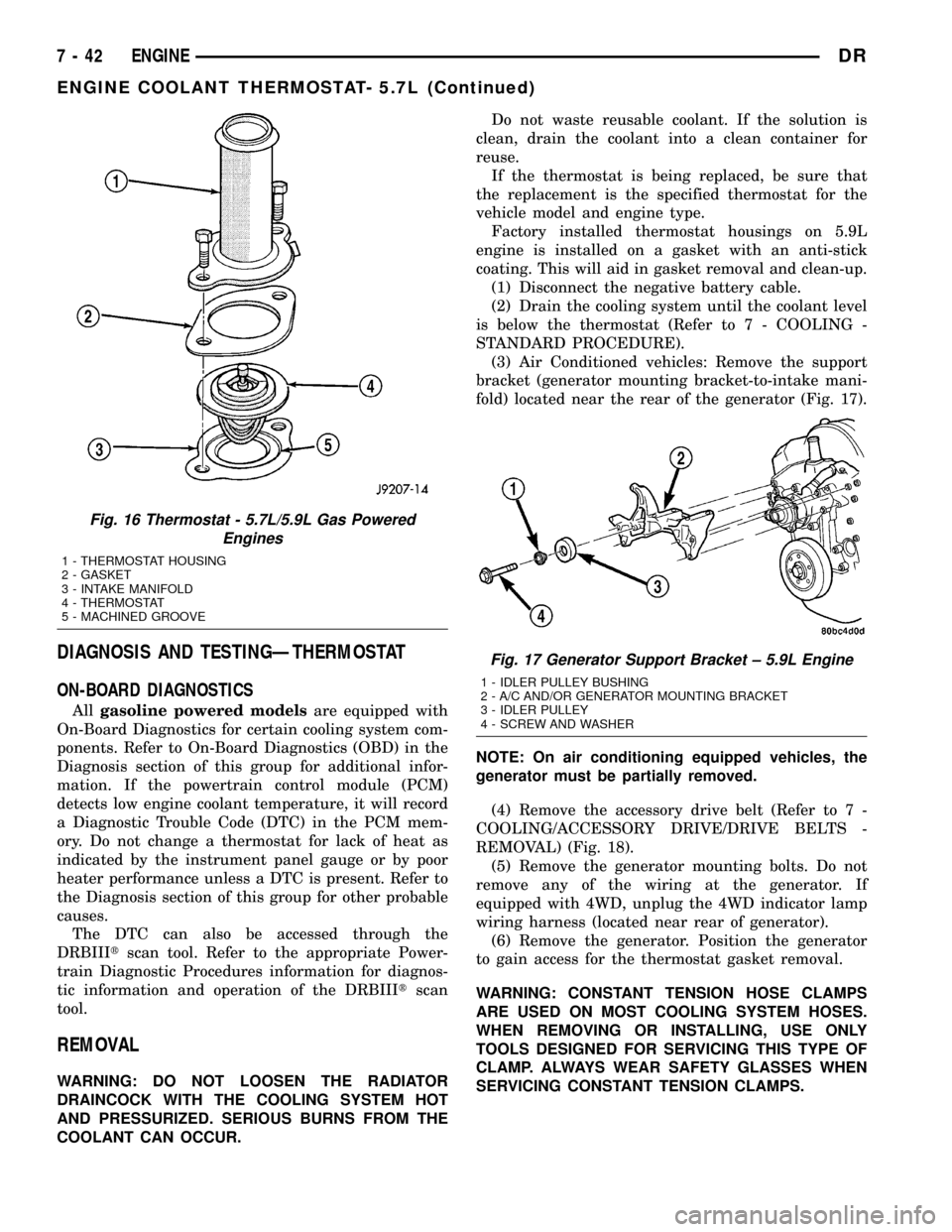

(3) Air Conditioned vehicles: Remove the support

bracket (generator mounting bracket-to-intake mani-

fold) located near the rear of the generator (Fig. 17).

NOTE: On air conditioning equipped vehicles, the

generator must be partially removed.

(4) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL) (Fig. 18).

(5) Remove the generator mounting bolts. Do not

remove any of the wiring at the generator. If

equipped with 4WD, unplug the 4WD indicator lamp

wiring harness (located near rear of generator).

(6) Remove the generator. Position the generator

to gain access for the thermostat gasket removal.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

Fig. 16 Thermostat - 5.7L/5.9L Gas Powered

Engines

1 - THERMOSTAT HOUSING

2 - GASKET

3 - INTAKE MANIFOLD

4 - THERMOSTAT

5 - MACHINED GROOVE

Fig. 17 Generator Support Bracket ± 5.9L Engine

1 - IDLER PULLEY BUSHING

2 - A/C AND/OR GENERATOR MOUNTING BRACKET

3 - IDLER PULLEY

4 - SCREW AND WASHER

7 - 42 ENGINEDR

ENGINE COOLANT THERMOSTAT- 5.7L (Continued)

Page 359 of 2627

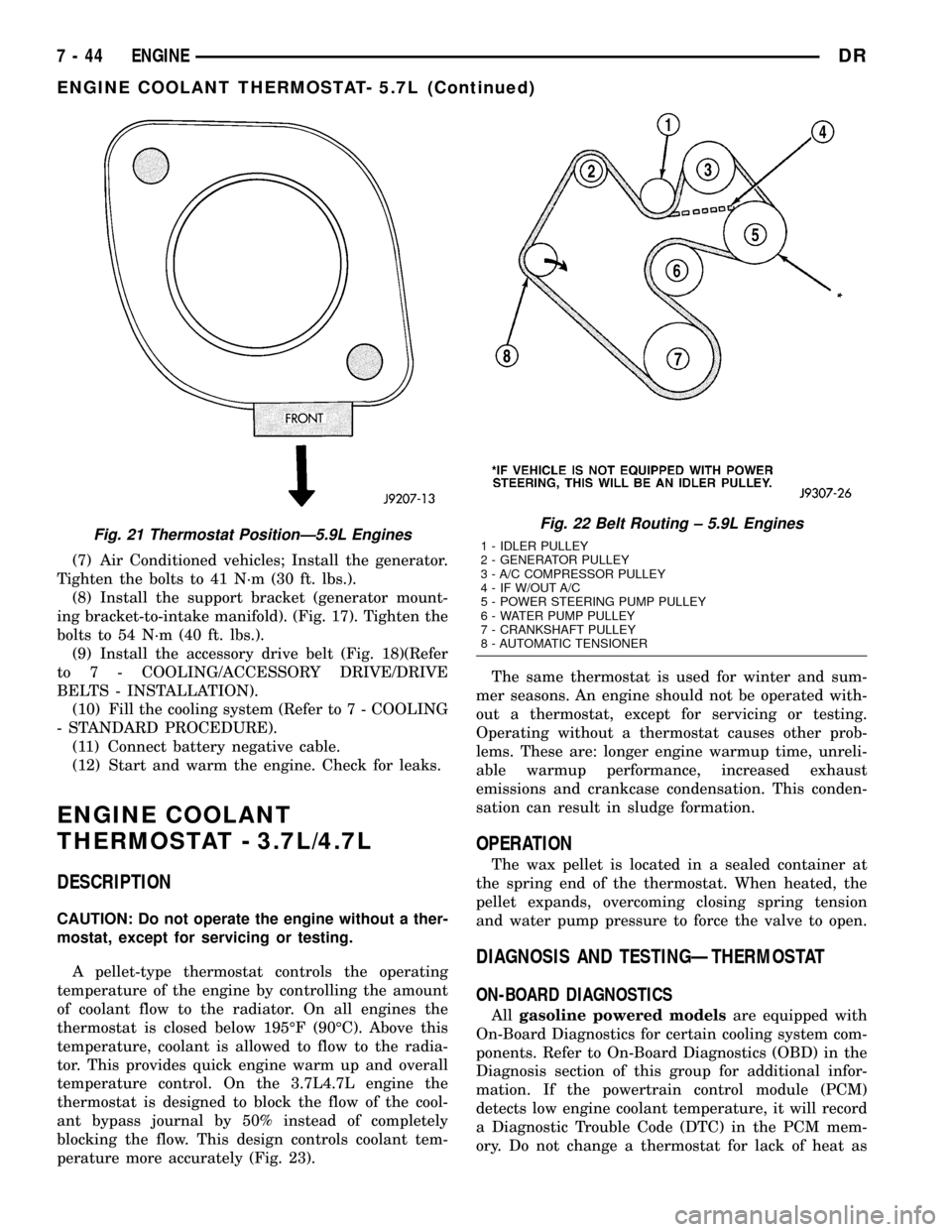

(7) Air Conditioned vehicles; Install the generator.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(8) Install the support bracket (generator mount-

ing bracket-to-intake manifold). (Fig. 17). Tighten the

bolts to 54 N´m (40 ft. lbs.).

(9) Install the accessory drive belt (Fig. 18)(Refer

to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION).

(10) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(11) Connect battery negative cable.

(12) Start and warm the engine. Check for leaks.

ENGINE COOLANT

THERMOSTAT - 3.7L/4.7L

DESCRIPTION

CAUTION: Do not operate the engine without a ther-

mostat, except for servicing or testing.

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warm up and overall

temperature control. On the 3.7L4.7L engine the

thermostat is designed to block the flow of the cool-

ant bypass journal by 50% instead of completely

blocking the flow. This design controls coolant tem-

perature more accurately (Fig. 23).The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

emissions and crankcase condensation. This conden-

sation can result in sludge formation.

OPERATION

The wax pellet is located in a sealed container at

the spring end of the thermostat. When heated, the

pellet expands, overcoming closing spring tension

and water pump pressure to force the valve to open.

DIAGNOSIS AND TESTINGÐTHERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

Fig. 21 Thermostat PositionÐ5.9L EnginesFig. 22 Belt Routing ± 5.9L Engines

1 - IDLER PULLEY

2 - GENERATOR PULLEY

3 - A/C COMPRESSOR PULLEY

4 - IF W/OUT A/C

5 - POWER STEERING PUMP PULLEY

6 - WATER PUMP PULLEY

7 - CRANKSHAFT PULLEY

8 - AUTOMATIC TENSIONER

7 - 44 ENGINEDR

ENGINE COOLANT THERMOSTAT- 5.7L (Continued)

Page 363 of 2627

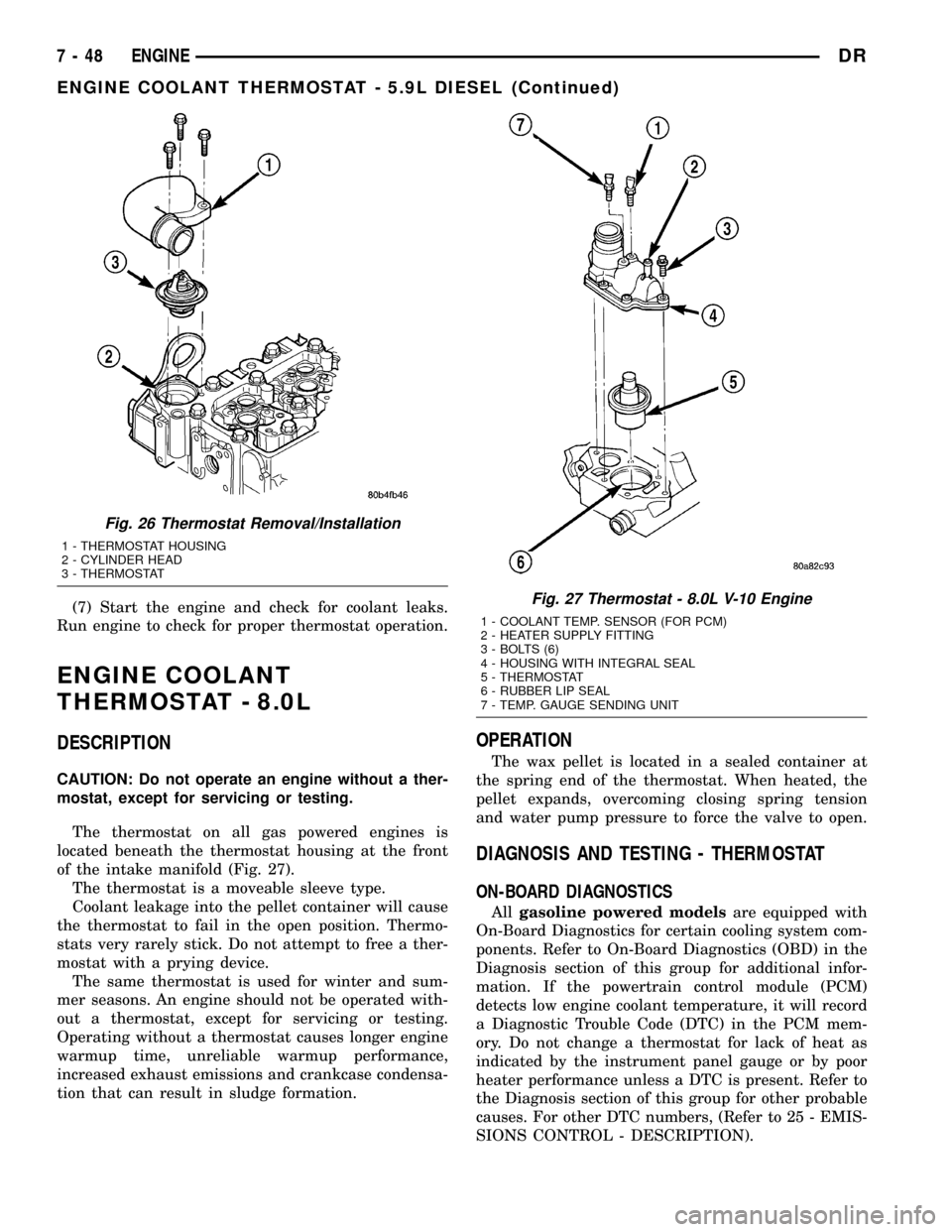

(7) Start the engine and check for coolant leaks.

Run engine to check for proper thermostat operation.

ENGINE COOLANT

THERMOSTAT - 8.0L

DESCRIPTION

CAUTION: Do not operate an engine without a ther-

mostat, except for servicing or testing.

The thermostat on all gas powered engines is

located beneath the thermostat housing at the front

of the intake manifold (Fig. 27).

The thermostat is a moveable sleeve type.

Coolant leakage into the pellet container will cause

the thermostat to fail in the open position. Thermo-

stats very rarely stick. Do not attempt to free a ther-

mostat with a prying device.

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes longer engine

warmup time, unreliable warmup performance,

increased exhaust emissions and crankcase condensa-

tion that can result in sludge formation.

OPERATION

The wax pellet is located in a sealed container at

the spring end of the thermostat. When heated, the

pellet expands, overcoming closing spring tension

and water pump pressure to force the valve to open.

DIAGNOSIS AND TESTING - THERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

indicated by the instrument panel gauge or by poor

heater performance unless a DTC is present. Refer to

the Diagnosis section of this group for other probable

causes. For other DTC numbers, (Refer to 25 - EMIS-

SIONS CONTROL - DESCRIPTION).

Fig. 26 Thermostat Removal/Installation

1 - THERMOSTAT HOUSING

2 - CYLINDER HEAD

3 - THERMOSTAT

Fig. 27 Thermostat - 8.0L V-10 Engine

1 - COOLANT TEMP. SENSOR (FOR PCM)

2 - HEATER SUPPLY FITTING

3 - BOLTS (6)

4 - HOUSING WITH INTEGRAL SEAL

5 - THERMOSTAT

6 - RUBBER LIP SEAL

7 - TEMP. GAUGE SENDING UNIT

7 - 48 ENGINEDR

ENGINE COOLANT THERMOSTAT - 5.9L DIESEL (Continued)

Page 383 of 2627

REMOVAL

(1) Disconnect the battery negative cable.

(2) Place a drain pan under the oil cooler lines.

(3) Disconnect the transmission oil cooler line

quick-connect fitting at the cooler outlet using the

quick connect release tool 6935. Plug the cooler lines

to prevent oil leakage.

(4) Unsnap the transmission cooler tubes from the

radiator tank clips.

(5) Remove the bolt attaching the transmission

cooler to the radiator.

(6) Remove oil cooler from the vehicle. Take care

not to damage the radiator core or transmission

cooler tubes.

INSTALLATION

(1) Position the transmission cooler tubes to the

front of the radiator by sliding brackets into slots on

radiator inlet tank.

(2) Snap the transmission cooler tubes into the

clips on the side of the radiator tank.

(3) Install the transmission cooler attaching bolt.

Tighten the bolt to 16 N´m (140 in. lbs.).

(4) Inspect the quick connect fittings for debris

and install the quick connect fitting on the cooler

tube until an audible ªclickº is heard. Pull apart the

connection to verify proper installation and install

the secondary latches.

(5) Connect the battery negative cable.

(6) Start the engine and check all fittings for

leaks.

(7) Check the fluid level in the automatic trans-

mission. Refer to the appropriate transmission sec-

tion(Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 45RFE/545RFE/FLUID - STANDARD

PROCEDURE) or(Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 46RE/FLUID - STAN-

DARD PROCEDURE).

TRANS COOLER - 5.9L DIESEL

DESCRIPTION

All diesel models equipped with an automatic

transmission are equipped with both a main water-

to-oil cooler and a separate air-to-oil cooler. Both cool-

ers are supplied as standard equipment on diesel

engine powered models when equipped with an auto-

matic transmission.

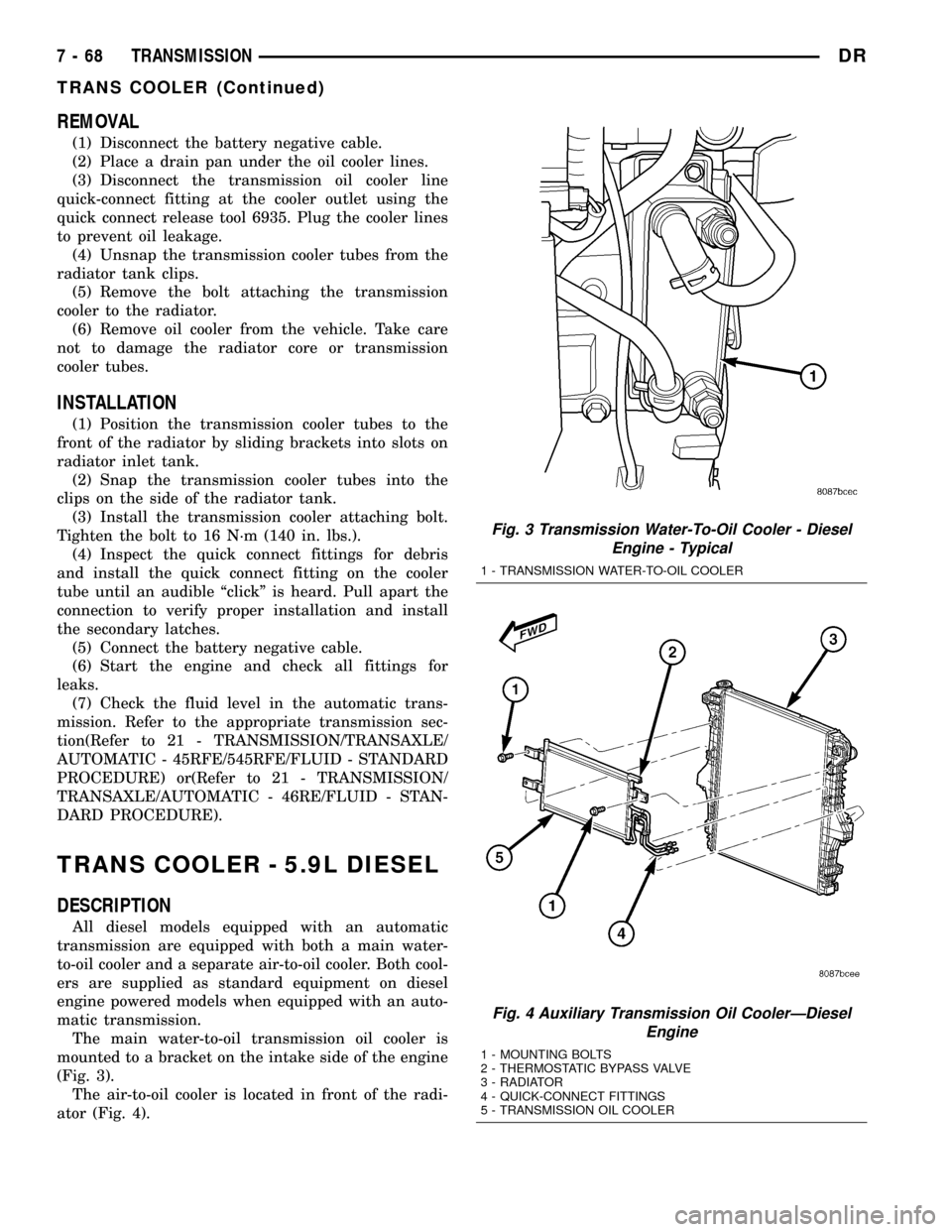

The main water-to-oil transmission oil cooler is

mounted to a bracket on the intake side of the engine

(Fig. 3).

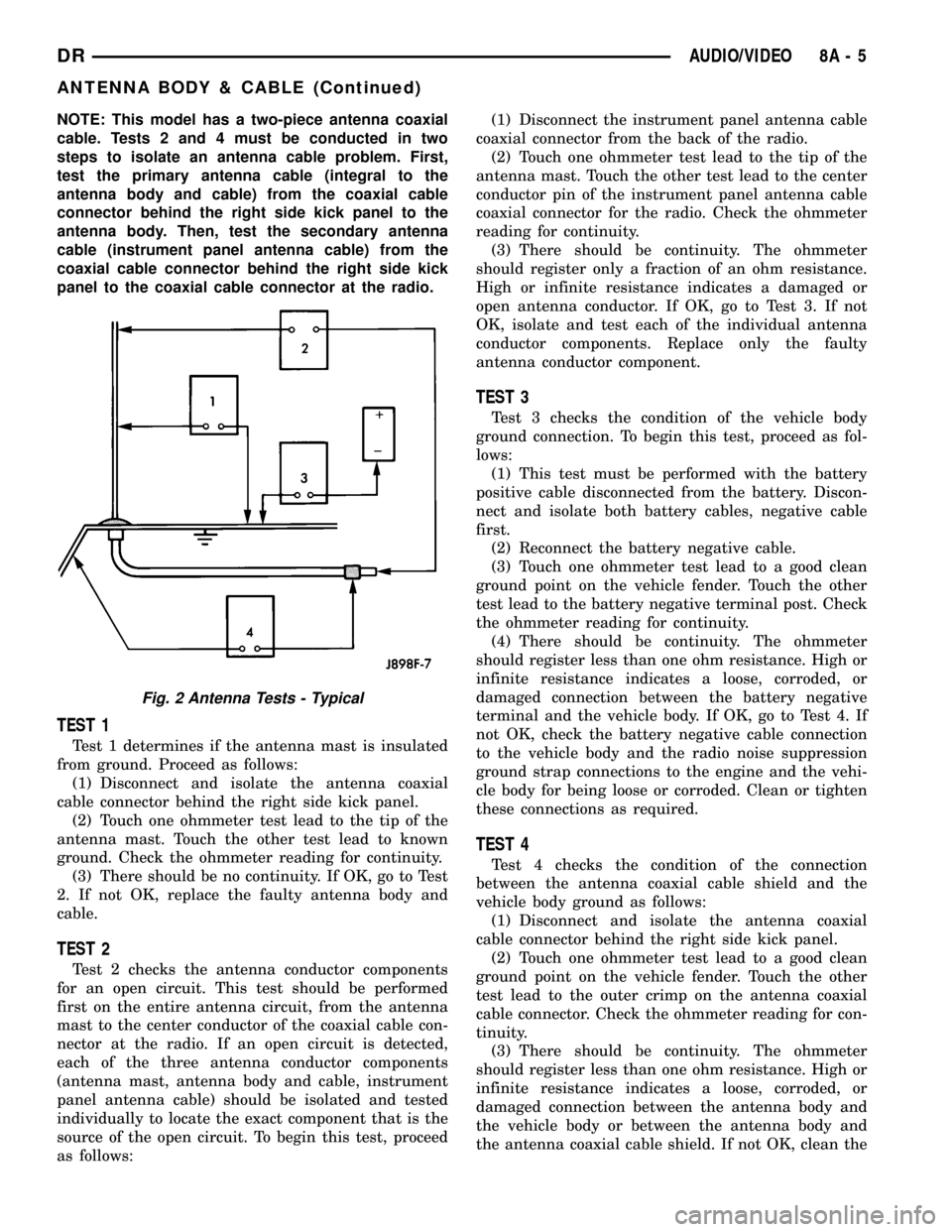

The air-to-oil cooler is located in front of the radi-

ator (Fig. 4).

Fig. 3 Transmission Water-To-Oil Cooler - Diesel

Engine - Typical

1 - TRANSMISSION WATER-TO-OIL COOLER

Fig. 4 Auxiliary Transmission Oil CoolerÐDiesel

Engine

1 - MOUNTING BOLTS

2 - THERMOSTATIC BYPASS VALVE

3 - RADIATOR

4 - QUICK-CONNECT FITTINGS

5 - TRANSMISSION OIL COOLER

7 - 68 TRANSMISSIONDR

TRANS COOLER (Continued)

Page 390 of 2627

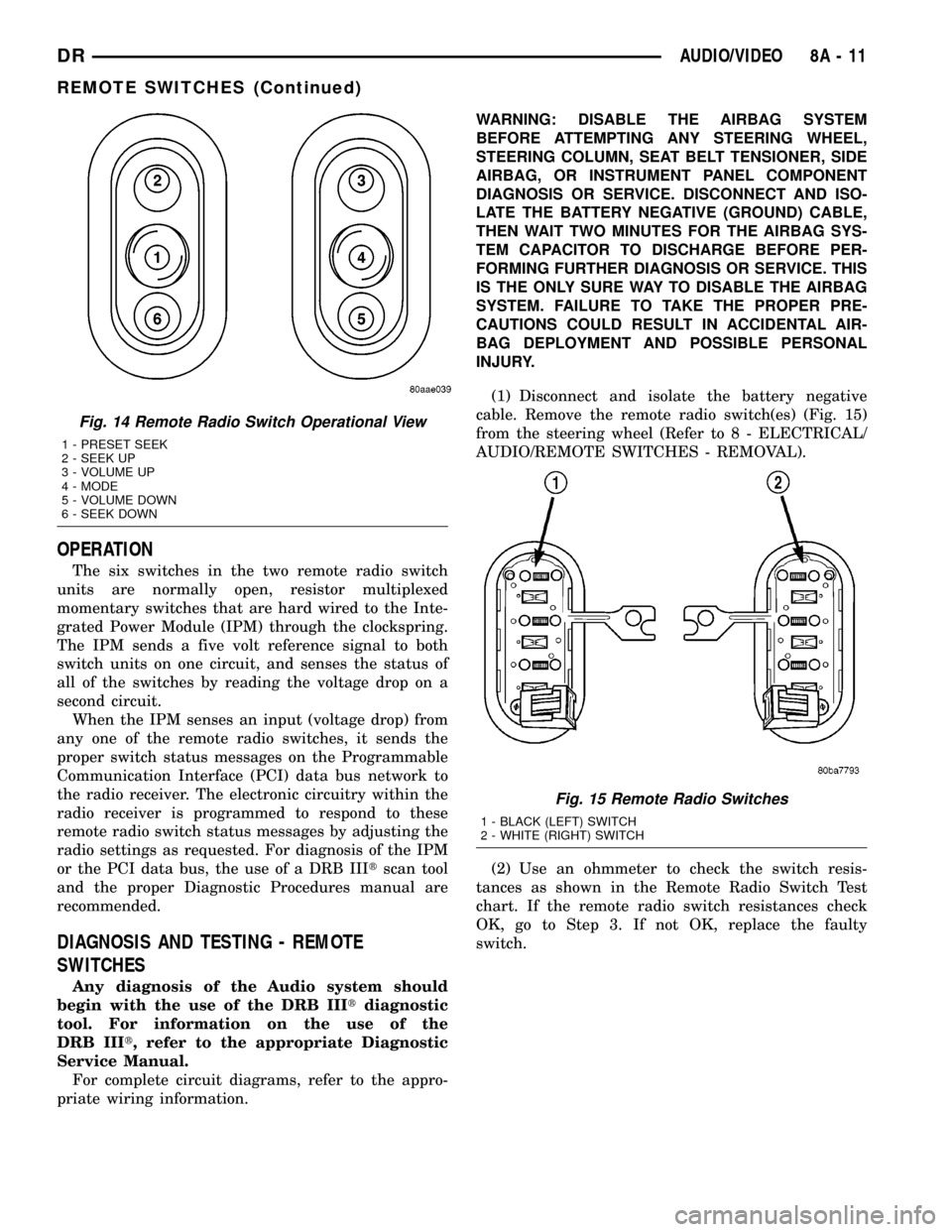

NOTE: This model has a two-piece antenna coaxial

cable. Tests 2 and 4 must be conducted in two

steps to isolate an antenna cable problem. First,

test the primary antenna cable (integral to the

antenna body and cable) from the coaxial cable

connector behind the right side kick panel to the

antenna body. Then, test the secondary antenna

cable (instrument panel antenna cable) from the

coaxial cable connector behind the right side kick

panel to the coaxial cable connector at the radio.

TEST 1

Test 1 determines if the antenna mast is insulated

from ground. Proceed as follows:

(1) Disconnect and isolate the antenna coaxial

cable connector behind the right side kick panel.

(2) Touch one ohmmeter test lead to the tip of the

antenna mast. Touch the other test lead to known

ground. Check the ohmmeter reading for continuity.

(3) There should be no continuity. If OK, go to Test

2. If not OK, replace the faulty antenna body and

cable.

TEST 2

Test 2 checks the antenna conductor components

for an open circuit. This test should be performed

first on the entire antenna circuit, from the antenna

mast to the center conductor of the coaxial cable con-

nector at the radio. If an open circuit is detected,

each of the three antenna conductor components

(antenna mast, antenna body and cable, instrument

panel antenna cable) should be isolated and tested

individually to locate the exact component that is the

source of the open circuit. To begin this test, proceed

as follows:(1) Disconnect the instrument panel antenna cable

coaxial connector from the back of the radio.

(2) Touch one ohmmeter test lead to the tip of the

antenna mast. Touch the other test lead to the center

conductor pin of the instrument panel antenna cable

coaxial connector for the radio. Check the ohmmeter

reading for continuity.

(3) There should be continuity. The ohmmeter

should register only a fraction of an ohm resistance.

High or infinite resistance indicates a damaged or

open antenna conductor. If OK, go to Test 3. If not

OK, isolate and test each of the individual antenna

conductor components. Replace only the faulty

antenna conductor component.

TEST 3

Test 3 checks the condition of the vehicle body

ground connection. To begin this test, proceed as fol-

lows:

(1) This test must be performed with the battery

positive cable disconnected from the battery. Discon-

nect and isolate both battery cables, negative cable

first.

(2) Reconnect the battery negative cable.

(3) Touch one ohmmeter test lead to a good clean

ground point on the vehicle fender. Touch the other

test lead to the battery negative terminal post. Check

the ohmmeter reading for continuity.

(4) There should be continuity. The ohmmeter

should register less than one ohm resistance. High or

infinite resistance indicates a loose, corroded, or

damaged connection between the battery negative

terminal and the vehicle body. If OK, go to Test 4. If

not OK, check the battery negative cable connection

to the vehicle body and the radio noise suppression

ground strap connections to the engine and the vehi-

cle body for being loose or corroded. Clean or tighten

these connections as required.

TEST 4

Test 4 checks the condition of the connection

between the antenna coaxial cable shield and the

vehicle body ground as follows:

(1) Disconnect and isolate the antenna coaxial

cable connector behind the right side kick panel.

(2) Touch one ohmmeter test lead to a good clean

ground point on the vehicle fender. Touch the other

test lead to the outer crimp on the antenna coaxial

cable connector. Check the ohmmeter reading for con-

tinuity.

(3) There should be continuity. The ohmmeter

should register less than one ohm resistance. High or

infinite resistance indicates a loose, corroded, or

damaged connection between the antenna body and

the vehicle body or between the antenna body and

the antenna coaxial cable shield. If not OK, clean the

Fig. 2 Antenna Tests - Typical

DRAUDIO/VIDEO 8A - 5

ANTENNA BODY & CABLE (Continued)

Page 396 of 2627

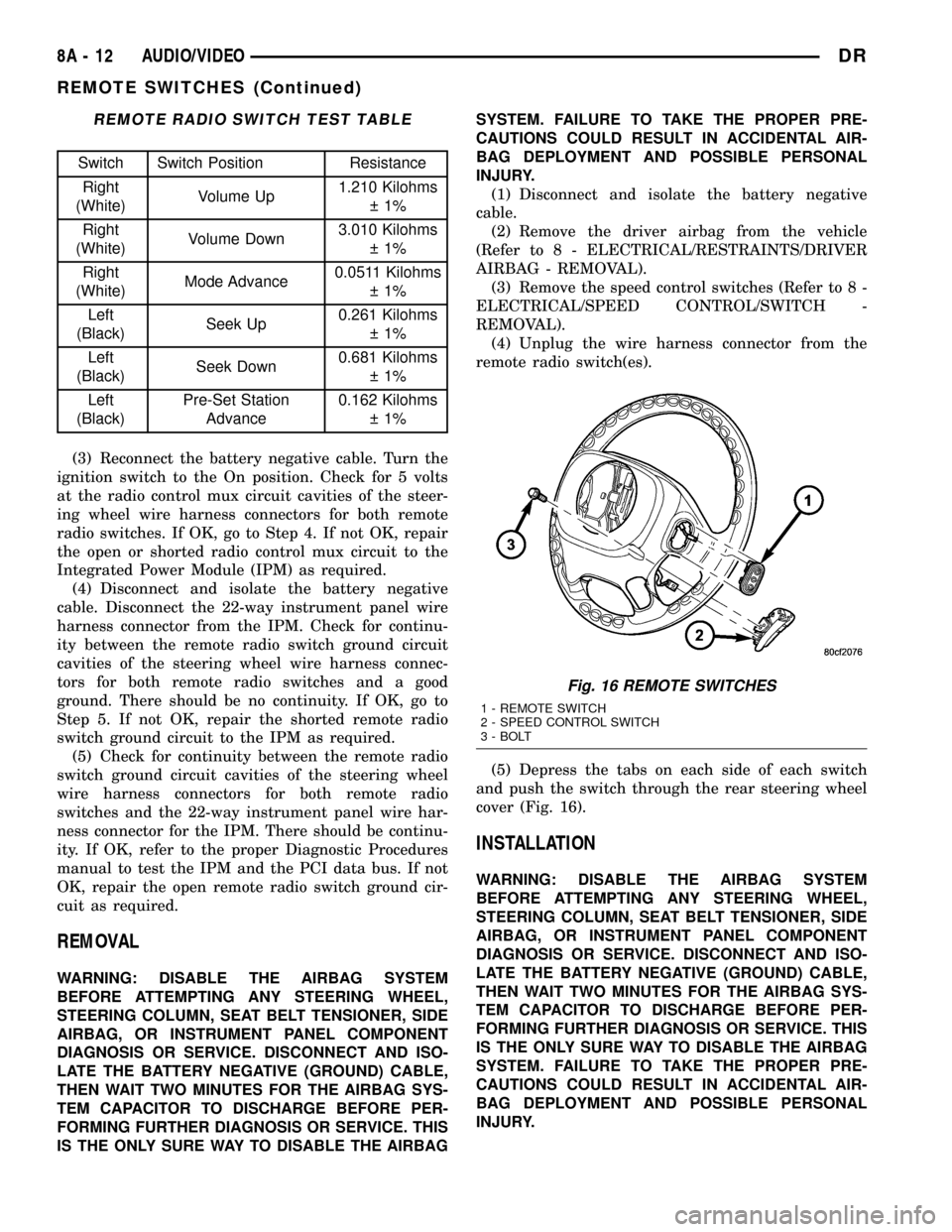

OPERATION

The six switches in the two remote radio switch

units are normally open, resistor multiplexed

momentary switches that are hard wired to the Inte-

grated Power Module (IPM) through the clockspring.

The IPM sends a five volt reference signal to both

switch units on one circuit, and senses the status of

all of the switches by reading the voltage drop on a

second circuit.

When the IPM senses an input (voltage drop) from

any one of the remote radio switches, it sends the

proper switch status messages on the Programmable

Communication Interface (PCI) data bus network to

the radio receiver. The electronic circuitry within the

radio receiver is programmed to respond to these

remote radio switch status messages by adjusting the

radio settings as requested. For diagnosis of the IPM

or the PCI data bus, the use of a DRB IIItscan tool

and the proper Diagnostic Procedures manual are

recommended.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the

DRB IIIt, refer to the appropriate Diagnostic

Service Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information.WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the remote radio switch(es) (Fig. 15)

from the steering wheel (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).

(2) Use an ohmmeter to check the switch resis-

tances as shown in the Remote Radio Switch Test

chart. If the remote radio switch resistances check

OK, go to Step 3. If not OK, replace the faulty

switch.

Fig. 14 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

Fig. 15 Remote Radio Switches

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

DRAUDIO/VIDEO 8A - 11

REMOTE SWITCHES (Continued)

Page 397 of 2627

REMOTE RADIO SWITCH TEST TABLE

Switch Switch Position Resistance

Right

(White)Volume Up1.210 Kilohms

1%

Right

(White)Volume Down3.010 Kilohms

1%

Right

(White)Mode Advance0.0511 Kilohms

1%

Left

(Black)Seek Up0.261 Kilohms

1%

Left

(Black)Seek Down0.681 Kilohms

1%

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

1%

(3) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for 5 volts

at the radio control mux circuit cavities of the steer-

ing wheel wire harness connectors for both remote

radio switches. If OK, go to Step 4. If not OK, repair

the open or shorted radio control mux circuit to the

Integrated Power Module (IPM) as required.

(4) Disconnect and isolate the battery negative

cable. Disconnect the 22-way instrument panel wire

harness connector from the IPM. Check for continu-

ity between the remote radio switch ground circuit

cavities of the steering wheel wire harness connec-

tors for both remote radio switches and a good

ground. There should be no continuity. If OK, go to

Step 5. If not OK, repair the shorted remote radio

switch ground circuit to the IPM as required.

(5) Check for continuity between the remote radio

switch ground circuit cavities of the steering wheel

wire harness connectors for both remote radio

switches and the 22-way instrument panel wire har-

ness connector for the IPM. There should be continu-

ity. If OK, refer to the proper Diagnostic Procedures

manual to test the IPM and the PCI data bus. If not

OK, repair the open remote radio switch ground cir-

cuit as required.

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAGSYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver airbag from the vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(3) Remove the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

REMOVAL).

(4) Unplug the wire harness connector from the

remote radio switch(es).

(5) Depress the tabs on each side of each switch

and push the switch through the rear steering wheel

cover (Fig. 16).

INSTALLATION

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 16 REMOTE SWITCHES

1 - REMOTE SWITCH

2 - SPEED CONTROL SWITCH

3 - BOLT

8A - 12 AUDIO/VIDEODR

REMOTE SWITCHES (Continued)

Page 403 of 2627

Engine Control Module (ECM) over the PCI data bus

to illuminate the check gauges indicator for a coolant

temperature high condition.

²Fasten Seat Belt Warning- The instrument

cluster chime tone generator will generate repetitive

chimes at a slow rate each time the ignition switch is

turned to the On or Start positions to announce that

the hard wired inputs from the seat belt switch and

the ignition switch indicate that the driver side front

seat belt is not fastened. The chimes will continue to

sound for a duration of about six seconds, until the

driver side front seat belt is fastened, or until the

ignition switch is turned to the Off position, which-

ever occurs first.

²Head/Park Lamps-On Warning- The instru-

ment cluster chime tone generator will generate

repetitive chimes at a slow rate to announce that the

hard wired inputs from the driver door ajar switch,

the ignition switch, and the exterior lighting circuitry

of the headlamp switch indicate that the exterior

lamps are turned On with the driver door opened

and the ignition switch in the Off position. The

chimes will continue to sound until the exterior

lamps are turned Off, the driver door is closed, or the

ignition switch is turned to the On position, or the

battery protection time-out expires, whichever occurs

first.

²Key-In-Ignition Warning- The instrument

cluster chime tone generator will generate repetitive

chimes at a slow rate to announce that the hard

wired inputs from the driver door ajar switch, the

ignition switch, and the key-in ignition circuitry of

the ignition switch indicate that the key is in the

ignition lock cylinder with the driver door opened

and the ignition switch in the Off position. The

chimes will continue to sound until the key is

removed from the ignition lock cylinder, the driver

door is closed, or the ignition switch is turned to the

On position, whichever occurs first.

²Low Fuel Warning- The instrument cluster

chime tone generator will generate one chime tone

when the low fuel indicator is illuminated by the

instrument cluster. The instrument cluster uses a

percent tank full message input received from the

PCM over the PCI data bus indicating that there is

less than about one-eighth tank of fuel remaining to

illuminate the low fuel indicator. This chime feature

will only occur once in an ignition cycle.

²Low Oil Pressure Warning (Diesel Engine

Only)- The instrument cluster chime tone generator

will generate repetitive chimes at a fast rate when

the check gauges indicator is illuminated for a low oil

pressure condition. The instrument cluster uses

engine speed and oil pressure message inputs

received from the diesel Engine Control Module

(ECM) over the PCI data bus indicating that theengine is running and that the oil pressure is low to

illuminate the check gauges indicator. The chimes

will continue to sound for five seconds, until the

engine oil pressure message indicates that the oil

pressure is not low, or until the engine speed mes-

sage indicates that the engine is not running, which-

ever occurs first. This chime tone will only occur once

in an ignition cycle.

²Low Wash Warning- The instrument cluster

chime tone generator will generate one chime tone

when the low washer fluid indicator is illuminated by

the instrument cluster. The instrument cluster uses a

message input received from the Front Control Mod-

ule (FCM) over the PCI data bus indicating that

washer fluid level is low within the washer reservoir.

This chime feature will only occur once in an ignition

cycle.

²Overspeed Warning- The instrument cluster

chime tone generator will generate one chime tone to

announce that a vehicle speed message input

received from the PCM over the PCI data bus indi-

cates that the vehicle speed is above a pre-programed

limit.

²Park Brake Reminder- The instrument clus-

ter chime tone generator will generate ten repetitive

chimes at a slow rate to announce that the hard

wired input from the park brake switch and a vehicle

speed message input received from the PCM over the

PCI data bus indicates that the park brake is applied

and the vehicle is moving. This chime feature will

repeat each time the input conditions are met.

²Sentry Key Immobilizer System ªCustomer

Learnº Mode Announcement- This chime feature

is only active on vehicles equipped with the optional

Sentry Key Immobilizer System (SKIS) and sold in

markets where the optional ªCustomer Learnº pro-

gramming feature is available. The instrument clus-

ter chime tone generator will generate one chime to

announce that a status message input received from

the Sentry Key Immobilizer Module (SKIM) over the

PCI data bus indicates that the SKIS is in the ªCus-

tomer Learnº mode, which is used for programming

additional sentry key transponders.

²Transmission Temperature High Warning

(Automatic Transmission only)- The instrument

cluster chime tone generator will generate repetitive

chimes at a slow rate when the transmission temper-

ature indicator is illuminated for a high or critical

transmission fluid temperature condition. The instru-

ment cluster uses transmission temperature message

inputs received from the Transmission Control Mod-

ule (TCM) over the PCI data bus to illuminate the

indicator for a transmission temperature high condi-

tion.

²Turn Signal On Warning- The instrument

cluster chime tone generator will generate repetitive

8B - 2 CHIME/BUZZERDR

CHIME WARNING SYSTEM (Continued)

Page 412 of 2627

FRONT CONTROL MODULE

DESCRIPTION

The Front Control Module (FCM) is a micro con-

troller based module located in the left front corner

of the engine compartment. On this model the inte-

grated power module must be positioned aside in

order to access the front control module. The front

control module mates to the power distribution cen-

ter to form the Integrated Power Module (IPM). The

integrated power module connects directly to the bat-

tery and provides the primary means of circuit pro-

tection and power distribution for all vehicle

electrical systems. The front control module controls

power to some of these vehicle systems electrical and

electromechanical loads based on inputs received

from hard wired switch inputs and data received on

the PCI bus circuit (J1850).

For information on theIntegrated Power Mod-

ule Refer to the Power Distribution Sectionof

the service manual.

OPERATION

As messages are sent over the PCI bus circuit, the

front control module reads these messages and con-

trols power to some of the vehicles electrical systems

by completing the circuit to ground (low side driver)

or completing the circuit to 12 volt power (high side

driver). The following functions areControlledby

the Front Control Module:

²Headlamp Power with Voltage Regulation

²Windshield Wiper ªON/OFFº Relay Actuation

²Windshield Wiper ªHI/LOº Relay Actuation

²Windshield Washer Pump Motor

²Fog Lamp Relay Actuation

²Park Lamp Relay Actuation

²Horn Relay Actuation

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection

²Power Ground

²Ambient Temperature Sensing

²Ignition Switch Run

²Washer Fluid Level Switch

²Windshield Wiper Park Switch

²PCI Bus Circuit

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRI-

CAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3) Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straightfrom the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the inte-

grated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - INSTALLATION).

(4) Connect the positive and negative battery

cables.

DRELECTRONIC CONTROL MODULES 8E - 5