Passenger Window DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1089 of 2627

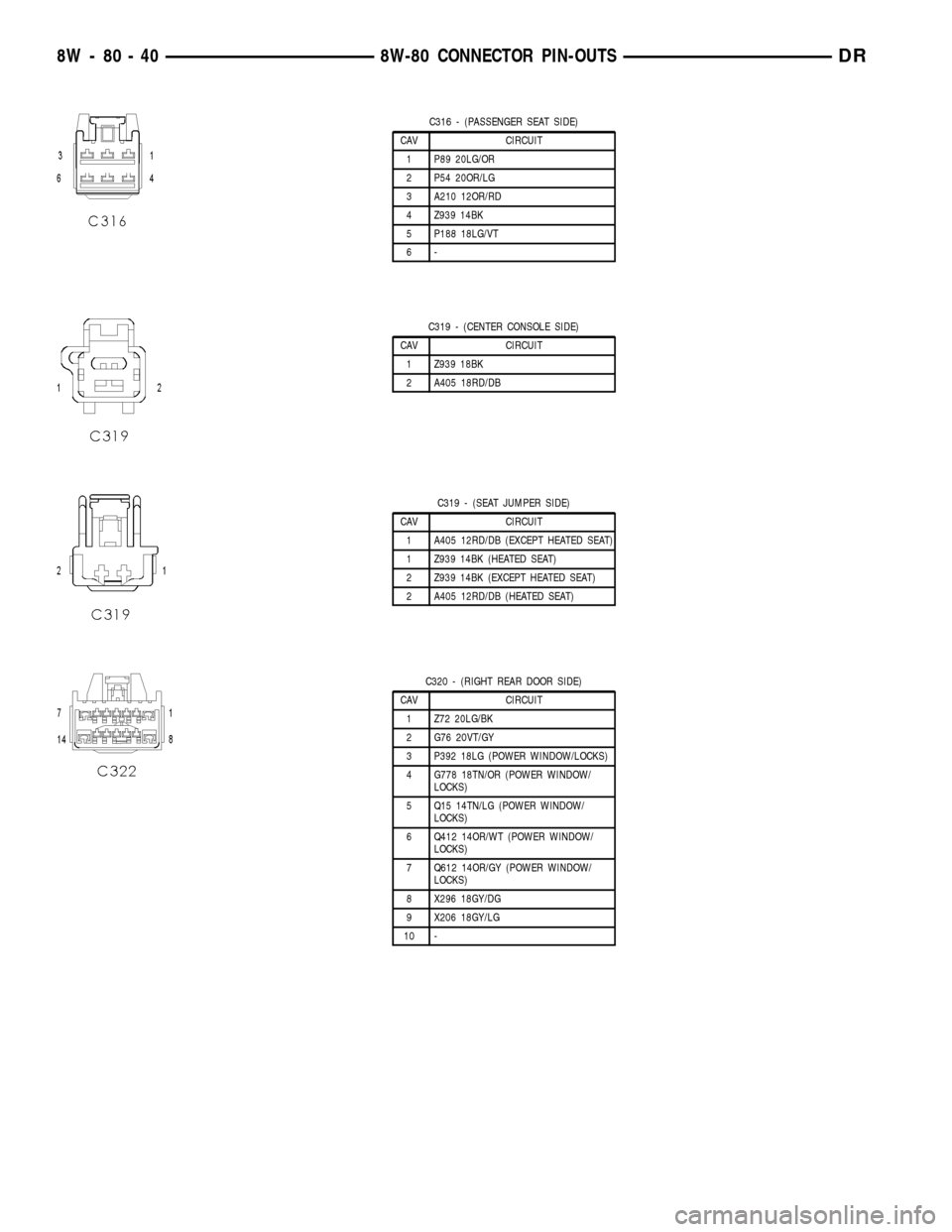

C316 - (PASSENGER SEAT SIDE)

CAV CIRCUIT

1 P89 20LG/OR

2 P54 20OR/LG

3 A210 12OR/RD

4 Z939 14BK

5 P188 18LG/VT

6-

C319 - (CENTER CONSOLE SIDE)

CAV CIRCUIT

1 Z939 18BK

2 A405 18RD/DB

C319 - (SEAT JUMPER SIDE)

CAV CIRCUIT

1 A405 12RD/DB (EXCEPT HEATED SEAT)

1 Z939 14BK (HEATED SEAT)

2 Z939 14BK (EXCEPT HEATED SEAT)

2 A405 12RD/DB (HEATED SEAT)

C320 - (RIGHT REAR DOOR SIDE)

CAV CIRCUIT

1 Z72 20LG/BK

2 G76 20VT/GY

3 P392 18LG (POWER WINDOW/LOCKS)

4 G778 18TN/OR (POWER WINDOW/

LOCKS)

5 Q15 14TN/LG (POWER WINDOW/

LOCKS)

6 Q412 14OR/WT (POWER WINDOW/

LOCKS)

7 Q612 14OR/GY (POWER WINDOW/

LOCKS)

8 X296 18GY/DG

9 X206 18GY/LG

10 -

8W - 80 - 40 8W-80 CONNECTOR PIN-OUTSDR

Page 1135 of 2627

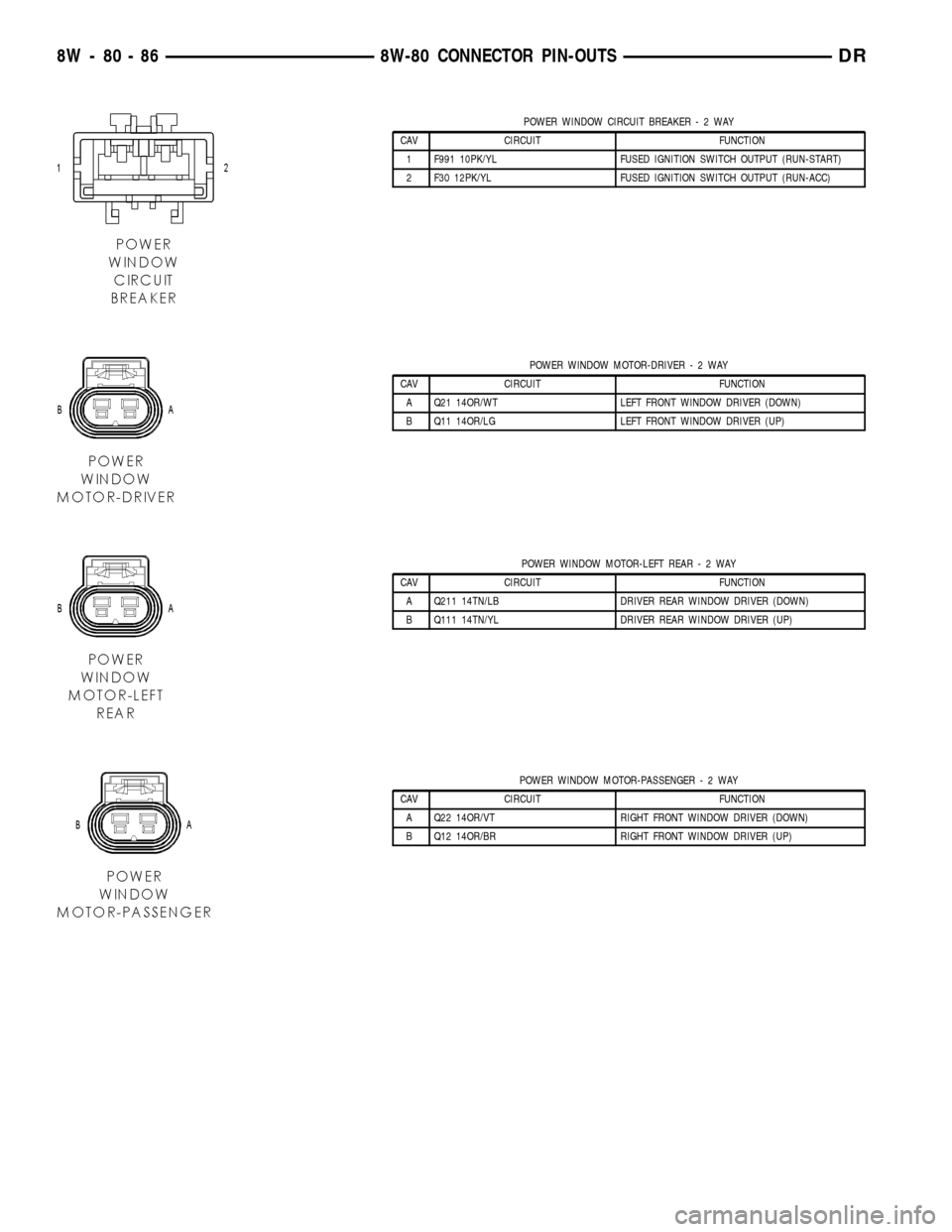

POWER WINDOW CIRCUIT BREAKER-2WAY

CAV CIRCUIT FUNCTION

1 F991 10PK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

2 F30 12PK/YL FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

POWER WINDOW MOTOR-DRIVER-2WAY

CAV CIRCUIT FUNCTION

A Q21 14OR/WT LEFT FRONT WINDOW DRIVER (DOWN)

B Q11 14OR/LG LEFT FRONT WINDOW DRIVER (UP)

POWER WINDOW MOTOR-LEFT REAR-2WAY

CAV CIRCUIT FUNCTION

A Q211 14TN/LB DRIVER REAR WINDOW DRIVER (DOWN)

B Q111 14TN/YL DRIVER REAR WINDOW DRIVER (UP)

POWER WINDOW MOTOR-PASSENGER-2WAY

CAV CIRCUIT FUNCTION

A Q22 14OR/VT RIGHT FRONT WINDOW DRIVER (DOWN)

B Q12 14OR/BR RIGHT FRONT WINDOW DRIVER (UP)

8W - 80 - 86 8W-80 CONNECTOR PIN-OUTSDR

Page 1136 of 2627

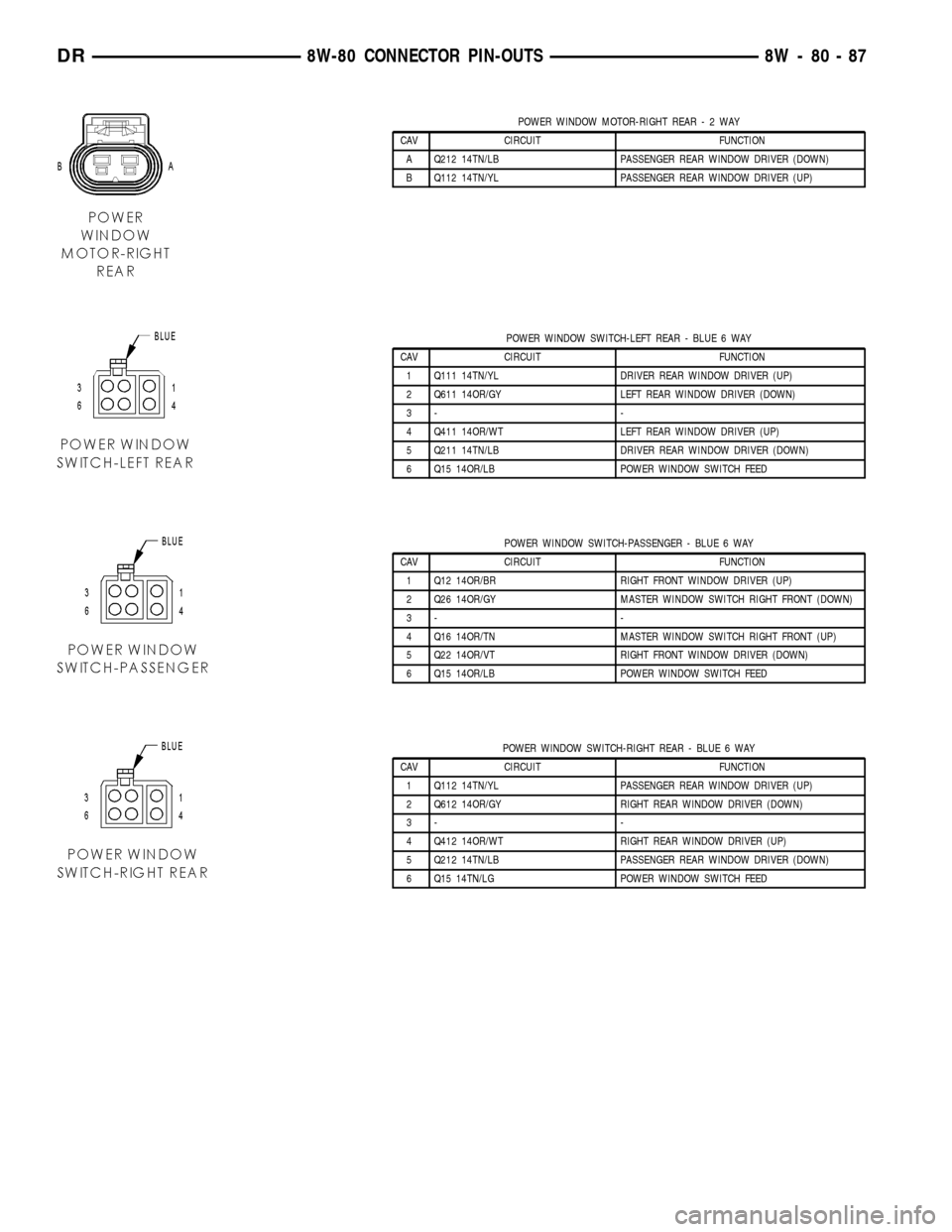

POWER WINDOW MOTOR-RIGHT REAR-2WAY

CAV CIRCUIT FUNCTION

A Q212 14TN/LB PASSENGER REAR WINDOW DRIVER (DOWN)

B Q112 14TN/YL PASSENGER REAR WINDOW DRIVER (UP)

POWER WINDOW SWITCH-LEFT REAR - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q111 14TN/YL DRIVER REAR WINDOW DRIVER (UP)

2 Q611 14OR/GY LEFT REAR WINDOW DRIVER (DOWN)

3- -

4 Q411 14OR/WT LEFT REAR WINDOW DRIVER (UP)

5 Q211 14TN/LB DRIVER REAR WINDOW DRIVER (DOWN)

6 Q15 14OR/LB POWER WINDOW SWITCH FEED

POWER WINDOW SWITCH-PASSENGER - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q12 14OR/BR RIGHT FRONT WINDOW DRIVER (UP)

2 Q26 14OR/GY MASTER WINDOW SWITCH RIGHT FRONT (DOWN)

3- -

4 Q16 14OR/TN MASTER WINDOW SWITCH RIGHT FRONT (UP)

5 Q22 14OR/VT RIGHT FRONT WINDOW DRIVER (DOWN)

6 Q15 14OR/LB POWER WINDOW SWITCH FEED

POWER WINDOW SWITCH-RIGHT REAR - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q112 14TN/YL PASSENGER REAR WINDOW DRIVER (UP)

2 Q612 14OR/GY RIGHT REAR WINDOW DRIVER (DOWN)

3- -

4 Q412 14OR/WT RIGHT REAR WINDOW DRIVER (UP)

5 Q212 14TN/LB PASSENGER REAR WINDOW DRIVER (DOWN)

6 Q15 14TN/LG POWER WINDOW SWITCH FEED

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 87

Page 1159 of 2627

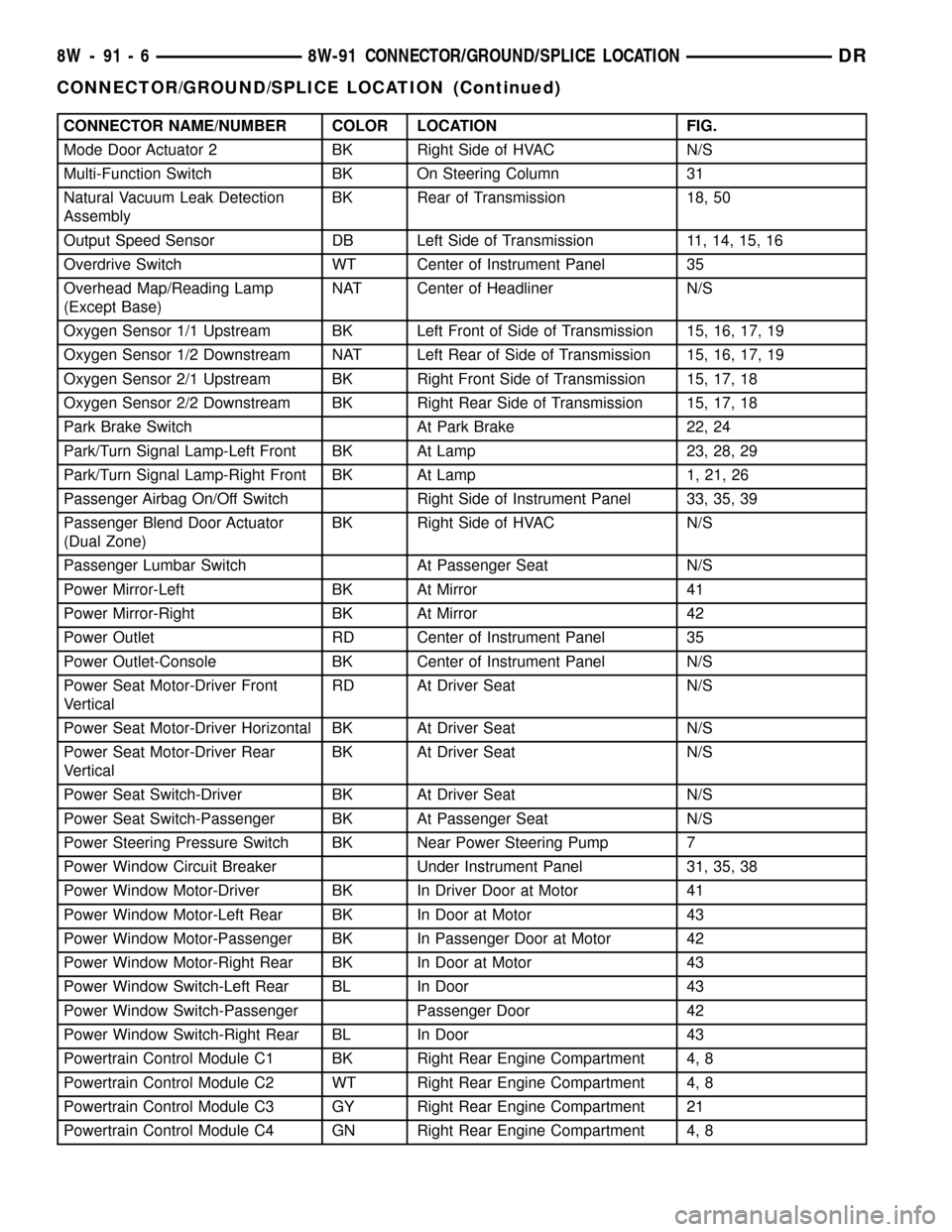

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Mode Door Actuator 2 BK Right Side of HVAC N/S

Multi-Function Switch BK On Steering Column 31

Natural Vacuum Leak Detection

AssemblyBK Rear of Transmission 18, 50

Output Speed Sensor DB Left Side of Transmission 11, 14, 15, 16

Overdrive Switch WT Center of Instrument Panel 35

Overhead Map/Reading Lamp

(Except Base)NAT Center of Headliner N/S

Oxygen Sensor 1/1 Upstream BK Left Front of Side of Transmission 15, 16, 17, 19

Oxygen Sensor 1/2 Downstream NAT Left Rear of Side of Transmission 15, 16, 17, 19

Oxygen Sensor 2/1 Upstream BK Right Front Side of Transmission 15, 17, 18

Oxygen Sensor 2/2 Downstream BK Right Rear Side of Transmission 15, 17, 18

Park Brake Switch At Park Brake 22, 24

Park/Turn Signal Lamp-Left Front BK At Lamp 23, 28, 29

Park/Turn Signal Lamp-Right Front BK At Lamp 1, 21, 26

Passenger Airbag On/Off Switch Right Side of Instrument Panel 33, 35, 39

Passenger Blend Door Actuator

(Dual Zone)BK Right Side of HVAC N/S

Passenger Lumbar Switch At Passenger Seat N/S

Power Mirror-Left BK At Mirror 41

Power Mirror-Right BK At Mirror 42

Power Outlet RD Center of Instrument Panel 35

Power Outlet-Console BK Center of Instrument Panel N/S

Power Seat Motor-Driver Front

VerticalRD At Driver Seat N/S

Power Seat Motor-Driver Horizontal BK At Driver Seat N/S

Power Seat Motor-Driver Rear

VerticalBK At Driver Seat N/S

Power Seat Switch-Driver BK At Driver Seat N/S

Power Seat Switch-Passenger BK At Passenger Seat N/S

Power Steering Pressure Switch BK Near Power Steering Pump 7

Power Window Circuit Breaker Under Instrument Panel 31, 35, 38

Power Window Motor-Driver BK In Driver Door at Motor 41

Power Window Motor-Left Rear BK In Door at Motor 43

Power Window Motor-Passenger BK In Passenger Door at Motor 42

Power Window Motor-Right Rear BK In Door at Motor 43

Power Window Switch-Left Rear BL In Door 43

Power Window Switch-Passenger Passenger Door 42

Power Window Switch-Right Rear BL In Door 43

Powertrain Control Module C1 BK Right Rear Engine Compartment 4, 8

Powertrain Control Module C2 WT Right Rear Engine Compartment 4, 8

Powertrain Control Module C3 GY Right Rear Engine Compartment 21

Powertrain Control Module C4 GN Right Rear Engine Compartment 4, 8

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 2297 of 2627

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-

cle. For hoisting recommendations (Refer to LUBRI-

CATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE).

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

DIAGNOSIS AND TESTING - WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

23 - 2 BODYDR

BODY (Continued)

Page 2488 of 2627

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - ENGINE COOLING

SYSTEM REQUIREMENTS...............1

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

OPERATION - HEATER AND AIR

CONDITIONER........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE.......................3DIAGNOSIS AND TESTING - HEATER

PERFORMANCE TEST..................6

SPECIFICATIONS - A/C SYSTEM............7

CONTROLS.............................9

DISTRIBUTION..........................26

PLUMBING.............................41

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - ENGINE COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the heating,

ventilation and air conditioning (HVAC) system, the

engine cooling system must be properly maintained.

The use of a bug screen is not recommended. Any

obstructions in front of the radiator or A/C condenser

will reduce the performance of the A/C and engine

cooling systems.

The engine cooling system includes the radiator,

thermostat, radiator hoses and the engine coolant

pump. Refer to Cooling for more information before

opening or attempting any service to the engine cool-

ing system.

DESCRIPTION - HEATER AND AIR

CONDITIONER

A manually controlled single zone type heating-air

conditioning system or a manually controlled dual

zone type heating-air conditioning system is available

on this model.

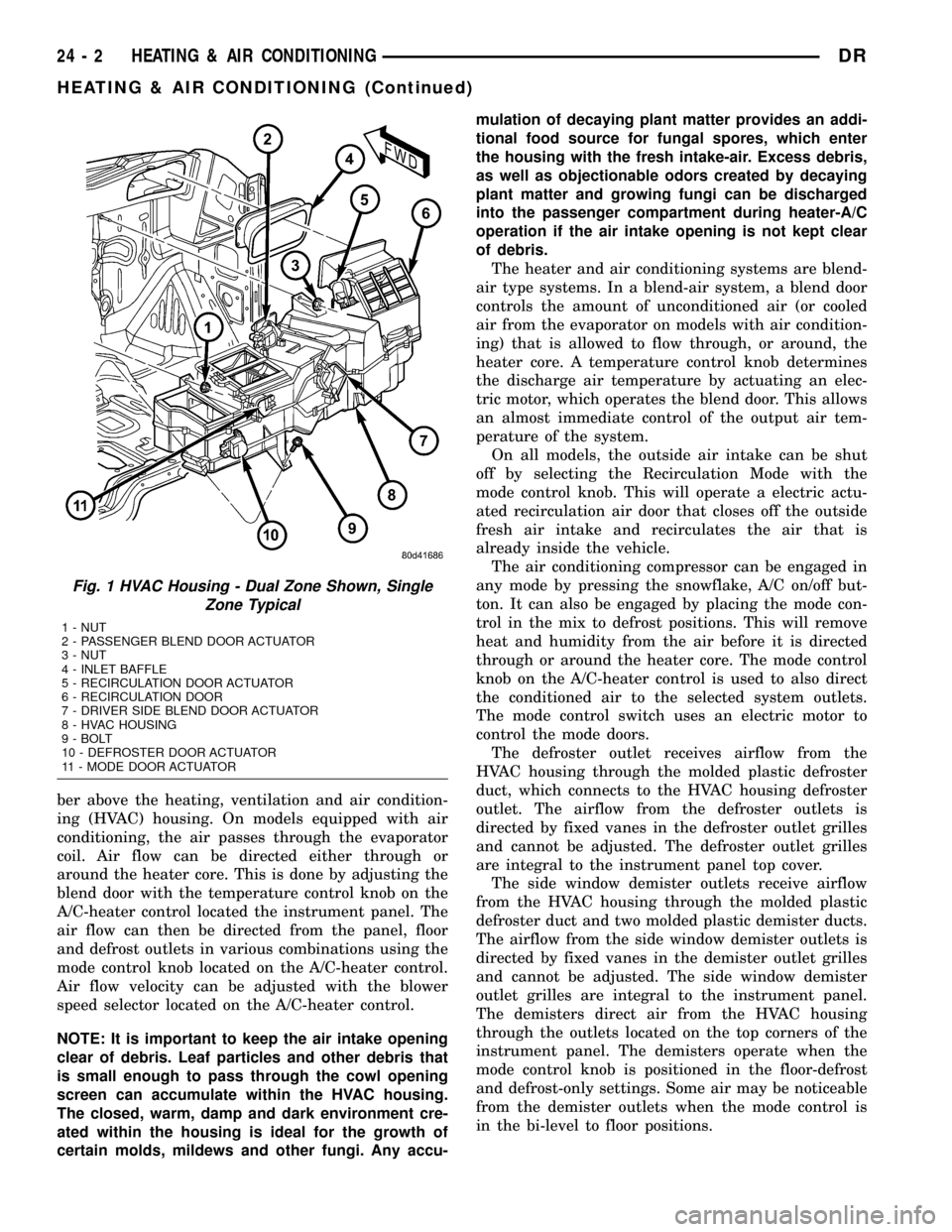

All vehicles are equipped with a common heater,

ventilation and air conditioning (HVAC) housing (Fig.

1). The system combines air conditioning, heating,

and ventilating capabilities in a single unit housing

mounted within the passenger compartment under

the instrument panel. The HVAC housing includes:

²Blower motor

²Blower motor resistor block²Heater core

²Evaporator coil

²Blend door and actuator

²Defrost door and actuator

²Mode door and actuator

²Recirculation door and actuator

Based upon the system and mode selected, condi-

tioned air can exit the HVAC housing through one or

a combination of the three main housing outlets:

defrost, panel or floor. The defrost outlet is located on

the top of the housing, the panel outlet is located on

the face of the housing and the floor outlet is located

on the bottom of the housing. Once the conditioned

air exits the unit housing, it is further directed

through molded plastic ducts to the various outlets in

the vehicle interior. These outlets and their locations

are as follows:

²Defroster Outlet- A single large defroster out-

let is located in the center of the instrument panel

top cover, near the base of the windshield.

²Side Window Demister Outlets- There are

two side window demister outlets, one is located at

each outboard end of the instrument panel top cover,

near the belt line at the A-pillars.

²Panel Outlets- There are four panel outlets in

the instrument panel, one located near each outboard

end of the instrument panel facing the rear of the

vehicle and two located near the top of the instru-

ment panel center bezel.

²Front Floor Outlets- There are two front floor

outlets, one located above each side of the floor panel

center tunnel near the dash panel.

OPERATION - HEATER AND AIR CONDITIONER

The heating and air conditioning systems pulls

outside (ambient) air through the cowl opening at the

base of the windshield, then into the plenum cham-

DRHEATING & AIR CONDITIONING 24 - 1

Page 2489 of 2627

ber above the heating, ventilation and air condition-

ing (HVAC) housing. On models equipped with air

conditioning, the air passes through the evaporator

coil. Air flow can be directed either through or

around the heater core. This is done by adjusting the

blend door with the temperature control knob on the

A/C-heater control located the instrument panel. The

air flow can then be directed from the panel, floor

and defrost outlets in various combinations using the

mode control knob located on the A/C-heater control.

Air flow velocity can be adjusted with the blower

speed selector located on the A/C-heater control.

NOTE: It is important to keep the air intake opening

clear of debris. Leaf particles and other debris that

is small enough to pass through the cowl opening

screen can accumulate within the HVAC housing.

The closed, warm, damp and dark environment cre-

ated within the housing is ideal for the growth of

certain molds, mildews and other fungi. Any accu-mulation of decaying plant matter provides an addi-

tional food source for fungal spores, which enter

the housing with the fresh intake-air. Excess debris,

as well as objectionable odors created by decaying

plant matter and growing fungi can be discharged

into the passenger compartment during heater-A/C

operation if the air intake opening is not kept clear

of debris.

The heater and air conditioning systems are blend-

air type systems. In a blend-air system, a blend door

controls the amount of unconditioned air (or cooled

air from the evaporator on models with air condition-

ing) that is allowed to flow through, or around, the

heater core. A temperature control knob determines

the discharge air temperature by actuating an elec-

tric motor, which operates the blend door. This allows

an almost immediate control of the output air tem-

perature of the system.

On all models, the outside air intake can be shut

off by selecting the Recirculation Mode with the

mode control knob. This will operate a electric actu-

ated recirculation air door that closes off the outside

fresh air intake and recirculates the air that is

already inside the vehicle.

The air conditioning compressor can be engaged in

any mode by pressing the snowflake, A/C on/off but-

ton. It can also be engaged by placing the mode con-

trol in the mix to defrost positions. This will remove

heat and humidity from the air before it is directed

through or around the heater core. The mode control

knob on the A/C-heater control is used to also direct

the conditioned air to the selected system outlets.

The mode control switch uses an electric motor to

control the mode doors.

The defroster outlet receives airflow from the

HVAC housing through the molded plastic defroster

duct, which connects to the HVAC housing defroster

outlet. The airflow from the defroster outlets is

directed by fixed vanes in the defroster outlet grilles

and cannot be adjusted. The defroster outlet grilles

are integral to the instrument panel top cover.

The side window demister outlets receive airflow

from the HVAC housing through the molded plastic

defroster duct and two molded plastic demister ducts.

The airflow from the side window demister outlets is

directed by fixed vanes in the demister outlet grilles

and cannot be adjusted. The side window demister

outlet grilles are integral to the instrument panel.

The demisters direct air from the HVAC housing

through the outlets located on the top corners of the

instrument panel. The demisters operate when the

mode control knob is positioned in the floor-defrost

and defrost-only settings. Some air may be noticeable

from the demister outlets when the mode control is

in the bi-level to floor positions.

Fig. 1 HVAC Housing - Dual Zone Shown, Single

Zone Typical

1 - NUT

2 - PASSENGER BLEND DOOR ACTUATOR

3 - NUT

4 - INLET BAFFLE

5 - RECIRCULATION DOOR ACTUATOR

6 - RECIRCULATION DOOR

7 - DRIVER SIDE BLEND DOOR ACTUATOR

8 - HVAC HOUSING

9 - BOLT

10 - DEFROSTER DOOR ACTUATOR

11 - MODE DOOR ACTUATOR

24 - 2 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2490 of 2627

The panel outlets receive airflow from the HVAC

housing through a molded plastic main panel duct,

center panel duct and two end panel ducts. The two

end panel ducts direct airflow to the left and right

instrument panel outlets, while the center panel duct

directs airflow to the two center panel outlets. Each

of these outlets can be individually adjusted to direct

the flow of air.

The floor outlets receive airflow from the HVAC

housing through the floor distribution duct. The front

floor outlets are integral to the molded plastic floor

distribution duct, which is secured to the bottom of

the housing. The floor outlets cannot be adjusted.

The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a fixed

orifice tube in the liquid line near the condenser out-

let tube to meter refrigerant flow to the evaporator

coil. To maintain minimum evaporator temperature

and prevent evaporator freezing, a evaporator tem-

perature sensor is used. The JTEC control module is

programmed to respond to the evaporator tempera-

ture sensor input by cycling the air conditioning com-

pressor clutch as necessary to optimize air

conditioning system performance and to protect the

system from evaporator freezing.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

HVAC housing, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to Recirculation

mode, only air from the passenger compartment

passes through the evaporator. As the passenger com-

partment air dehumidifies, A/C performance levels

rise.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature ofthe moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Wring-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from their

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

PERFORMANCE TEST PROCEDURE

Review Safety Warnings and Cautions before per-

forming this procedure (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). Air temperature in test

room and on vehicle must be 21É C (70É F) minimum

for this test.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer and a manifold gauge set

or A/C recycling/charging station.

(2) Set the A/C-heater mode control in the Recircu-

lation Mode position, the temperature control knob in

the full cool position, and the blower motor switch to

the highest speed position.

(3) Start the engine and hold at 1,000 rpm with

the A/C compressor clutch engaged.

(4) The engine should be warmed up to operating

temperature with the doors closed and windows

open.

(5) Insert a thermometer in the driver side center

panel A/C-heater outlet and operate the engine for

five minutes.

(6) The compressor clutch may cycle, depending

upon the ambient temperature and humidity.

(7) With the compressor clutch engaged, record the

discharge air temperature and the compressor dis-

charge pressure.

(8) If the discharge air temperature fails to meet

the specifications in the A/C Performance Tempera-

ture chart, refer to the Pressure Diagnosis chart.

DRHEATING & AIR CONDITIONING 24 - 3

HEATING & AIR CONDITIONING (Continued)

Page 2619 of 2627

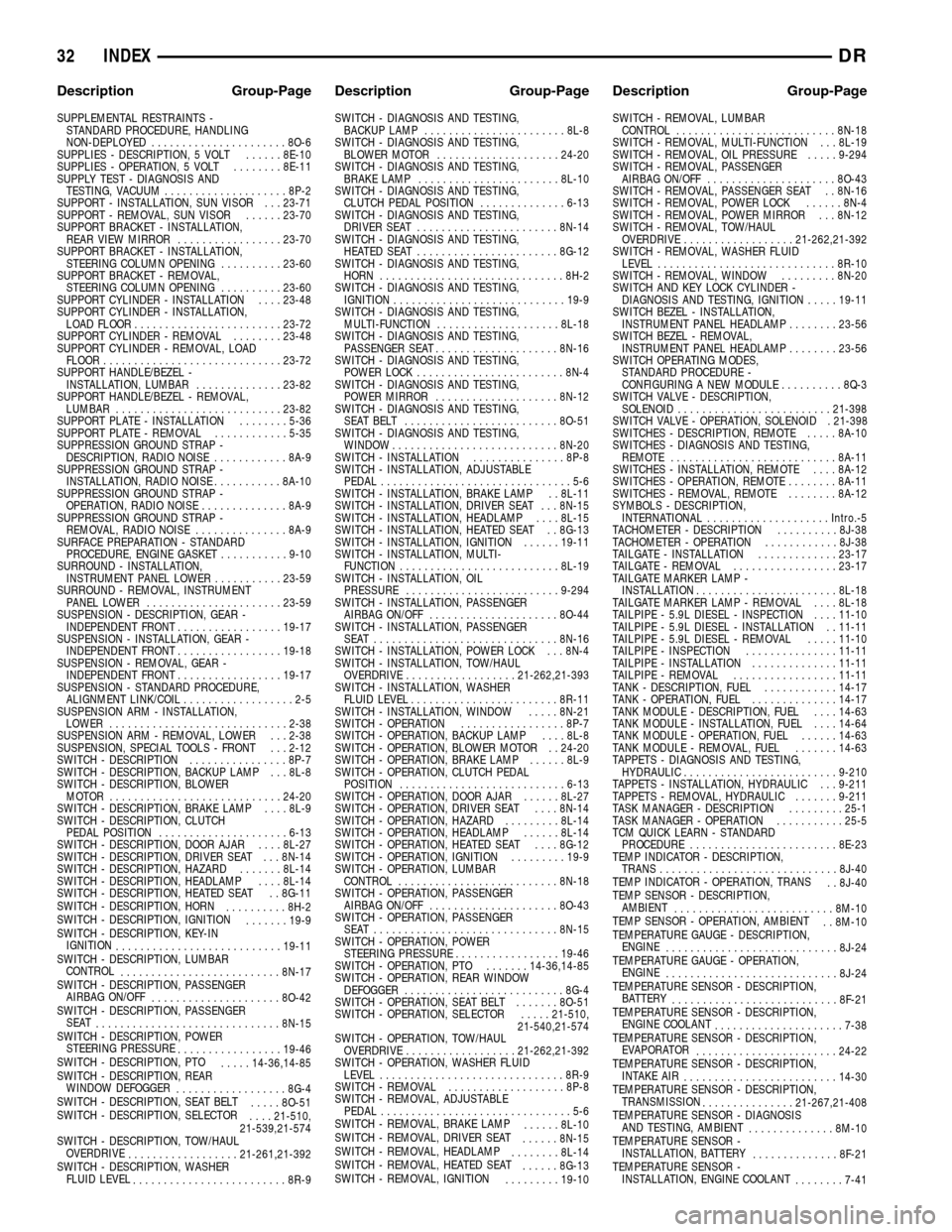

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE, HANDLING

NON-DEPLOYED......................8O-6

SUPPLIES - DESCRIPTION, 5 VOLT......8E-10

SUPPLIES - OPERATION, 5 VOLT........8E-11

SUPPLY TEST - DIAGNOSIS AND

TESTING, VACUUM....................8P-2

SUPPORT - INSTALLATION, SUN VISOR . . . 23-71

SUPPORT - REMOVAL, SUN VISOR......23-70

SUPPORT BRACKET - INSTALLATION,

REAR VIEW MIRROR.................23-70

SUPPORT BRACKET - INSTALLATION,

STEERING COLUMN OPENING..........23-60

SUPPORT BRACKET - REMOVAL,

STEERING COLUMN OPENING..........23-60

SUPPORT CYLINDER - INSTALLATION....23-48

SUPPORT CYLINDER - INSTALLATION,

LOAD FLOOR........................23-72

SUPPORT CYLINDER - REMOVAL........23-48

SUPPORT CYLINDER - REMOVAL, LOAD

FLOOR.............................23-72

SUPPORT HANDLE/BEZEL -

INSTALLATION, LUMBAR..............23-82

SUPPORT HANDLE/BEZEL - REMOVAL,

LUMBAR...........................23-82

SUPPORT PLATE - INSTALLATION........5-36

SUPPORT PLATE - REMOVAL............5-35

SUPPRESSION GROUND STRAP -

DESCRIPTION, RADIO NOISE............8A-9

SUPPRESSION GROUND STRAP -

INSTALLATION, RADIO NOISE...........8A-10

SUPPRESSION GROUND STRAP -

OPERATION, RADIO NOISE..............8A-9

SUPPRESSION GROUND STRAP -

REMOVAL, RADIO NOISE...............8A-9

SURFACE PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET...........9-10

SURROUND - INSTALLATION,

INSTRUMENT PANEL LOWER...........23-59

SURROUND - REMOVAL, INSTRUMENT

PANEL LOWER......................23-59

SUSPENSION - DESCRIPTION, GEAR -

INDEPENDENT FRONT.................19-17

SUSPENSION - INSTALLATION, GEAR -

INDEPENDENT FRONT.................19-18

SUSPENSION - REMOVAL, GEAR -

INDEPENDENT FRONT.................19-17

SUSPENSION - STANDARD PROCEDURE,

ALIGNMENT LINK/COIL..................2-5

SUSPENSION ARM - INSTALLATION,

LOWER.............................2-38

SUSPENSION ARM - REMOVAL, LOWER . . . 2-38

SUSPENSION, SPECIAL TOOLS - FRONT . . . 2-12

SWITCH - DESCRIPTION................8P-7

SWITCH - DESCRIPTION, BACKUP LAMP . . . 8L-8

SWITCH - DESCRIPTION, BLOWER

MOTOR............................24-20

SWITCH - DESCRIPTION, BRAKE LAMP....8L-9

SWITCH - DESCRIPTION, CLUTCH

PEDAL POSITION.....................6-13

SWITCH - DESCRIPTION, DOOR AJAR....8L-27

SWITCH - DESCRIPTION, DRIVER SEAT . . . 8N-14

SWITCH - DESCRIPTION, HAZARD.......8L-14

SWITCH - DESCRIPTION, HEADLAMP....8L-14

SWITCH - DESCRIPTION, HEATED SEAT . . 8G-11

SWITCH - DESCRIPTION, HORN

..........8H-2

SWITCH - DESCRIPTION, IGNITION

.......19-9

SWITCH - DESCRIPTION, KEY-IN

IGNITION

...........................19-11

SWITCH - DESCRIPTION, LUMBAR

CONTROL

..........................8N-17

SWITCH - DESCRIPTION, PASSENGER

AIRBAG ON/OFF

.....................8O-42

SWITCH - DESCRIPTION, PASSENGER

SEAT

..............................8N-15

SWITCH - DESCRIPTION, POWER

STEERING PRESSURE

.................19-46

SWITCH - DESCRIPTION, PTO

.....14-36,14-85

SWITCH - DESCRIPTION, REAR

WINDOW DEFOGGER

..................8G-4

SWITCH - DESCRIPTION, SEAT BELT

.....8O-51

SWITCH - DESCRIPTION, SELECTOR

....21-510,

21-539,21-574

SWITCH - DESCRIPTION, TOW/HAUL

OVERDRIVE

..................21-261,21-392

SWITCH - DESCRIPTION, WASHER

FLUID LEVEL

.........................8R-9SWITCH - DIAGNOSIS AND TESTING,

BACKUP LAMP.......................8L-8

SWITCH - DIAGNOSIS AND TESTING,

BLOWER MOTOR....................24-20

SWITCH - DIAGNOSIS AND TESTING,

BRAKE LAMP.......................8L-10

SWITCH - DIAGNOSIS AND TESTING,

CLUTCH PEDAL POSITION..............6-13

SWITCH - DIAGNOSIS AND TESTING,

DRIVER SEAT.......................8N-14

SWITCH - DIAGNOSIS AND TESTING,

HEATED SEAT .......................8G-12

SWITCH - DIAGNOSIS AND TESTING,

HORN..............................8H-2

SWITCH - DIAGNOSIS AND TESTING,

IGNITION............................19-9

SWITCH - DIAGNOSIS AND TESTING,

MULTI-FUNCTION....................8L-18

SWITCH - DIAGNOSIS AND TESTING,

PASSENGER SEAT....................8N-16

SWITCH - DIAGNOSIS AND TESTING,

POWER LOCK........................8N-4

SWITCH - DIAGNOSIS AND TESTING,

POWER MIRROR....................8N-12

SWITCH - DIAGNOSIS AND TESTING,

SEAT BELT .........................8O-51

SWITCH - DIAGNOSIS AND TESTING,

WINDOW...........................8N-20

SWITCH - INSTALLATION...............8P-8

SWITCH - INSTALLATION, ADJUSTABLE

PEDAL...............................5-6

SWITCH - INSTALLATION, BRAKE LAMP . . 8L-11

SWITCH - INSTALLATION, DRIVER SEAT . . . 8N-15

SWITCH - INSTALLATION, HEADLAMP....8L-15

SWITCH - INSTALLATION, HEATED SEAT . . 8G-13

SWITCH - INSTALLATION, IGNITION......19-11

SWITCH - INSTALLATION, MULTI-

FUNCTION..........................8L-19

SWITCH - INSTALLATION, OIL

PRESSURE.........................9-294

SWITCH - INSTALLATION, PASSENGER

AIRBAG ON/OFF.....................8O-44

SWITCH - INSTALLATION, PASSENGER

SEAT ..............................8N-16

SWITCH - INSTALLATION, POWER LOCK . . . 8N-4

SWITCH - INSTALLATION, TOW/HAUL

OVERDRIVE..................21-262,21-393

SWITCH - INSTALLATION, WASHER

FLUID LEVEL........................8R-11

SWITCH - INSTALLATION, WINDOW.....8N-21

SWITCH - OPERATION.................8P-7

SWITCH - OPERATION, BACKUP LAMP....8L-8

SWITCH - OPERATION, BLOWER MOTOR . . 24-20

SWITCH - OPERATION, BRAKE LAMP......8L-9

SWITCH - OPERATION, CLUTCH PEDAL

POSITION...........................6-13

SWITCH - OPERATION, DOOR AJAR......8L-27

SWITCH - OPERATION, DRIVER SEAT....8N-14

SWITCH - OPERATION, HAZARD.........8L-14

SWITCH - OPERATION, HEADLAMP......8L-14

SWITCH - OPERATION, HEATED SEAT....8G-12

SWITCH - OPERATION, IGNITION.........19-9

SWITCH - OPERATION, LUMBAR

CONTROL..........................8N-18

SWITCH - OPERATION, PASSENGER

AIRBAG ON/OFF.....................8O-43

SWITCH - OPERATION, PASSENGER

SEAT ..............................8N-15

SWITCH - OPERATION, POWER

STEERING PRESSURE.................19-46

SWITCH - OPERATION, PTO.......14-36,14-85

SWITCH - OPERATION, REAR WINDOW

DEFOGGER..........................8G-4

SWITCH - OPERATION, SEAT BELT.......8O-51

SWITCH - OPERATION, SELECTOR.....21-510,

21-540,21-574

SWITCH - OPERATION, TOW/HAUL

OVERDRIVE..................21-262,21-392

SWITCH - OPERATION, WASHER FLUID

LEVEL..............................8R-9

SWITCH - REMOVAL...................8P-8

SWITCH - REMOVAL, ADJUSTABLE

PEDAL...............................5-6

SWITCH - REMOVAL, BRAKE LAMP

......8L-10

SWITCH - REMOVAL, DRIVER SEAT

......8N-15

SWITCH - REMOVAL, HEADLAMP

........8L-14

SWITCH - REMOVAL, HEATED SEAT

......8G-13

SWITCH - REMOVAL, IGNITION

.........19-10SWITCH - REMOVAL, LUMBAR

CONTROL..........................8N-18

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-19

SWITCH - REMOVAL, OIL PRESSURE.....9-294

SWITCH - REMOVAL, PASSENGER

AIRBAG ON/OFF.....................8O-43

SWITCH - REMOVAL, PASSENGER SEAT . . 8N-16

SWITCH - REMOVAL, POWER LOCK......8N-4

SWITCH - REMOVAL, POWER MIRROR . . . 8N-12

SWITCH - REMOVAL, TOW/HAUL

OVERDRIVE..................21-262,21-392

SWITCH - REMOVAL, WASHER FLUID

LEVEL.............................8R-10

SWITCH - REMOVAL, WINDOW.........8N-20

SWITCH AND KEY LOCK CYLINDER -

DIAGNOSIS AND TESTING, IGNITION.....19-11

SWITCH BEZEL - INSTALLATION,

INSTRUMENT PANEL HEADLAMP........23-56

SWITCH BEZEL - REMOVAL,

INSTRUMENT PANEL HEADLAMP........23-56

SWITCH OPERATING MODES,

STANDARD PROCEDURE -

CONFIGURING A NEW MODULE..........8Q-3

SWITCH VALVE - DESCRIPTION,

SOLENOID.........................21-398

SWITCH VALVE - OPERATION, SOLENOID . 21-398

SWITCHES - DESCRIPTION, REMOTE.....8A-10

SWITCHES - DIAGNOSIS AND TESTING,

REMOTE...........................8A-11

SWITCHES - INSTALLATION, REMOTE....8A-12

SWITCHES - OPERATION, REMOTE........8A-11

SWITCHES - REMOVAL, REMOTE........8A-12

SYMBOLS - DESCRIPTION,

INTERNATIONAL....................Intro.-5

TACHOMETER - DESCRIPTION..........8J-38

TACHOMETER - OPERATION............8J-38

TAILGATE - INSTALLATION.............23-17

TAILGATE - REMOVAL.................23-17

TAILGATE MARKER LAMP -

INSTALLATION.......................8L-18

TAILGATE MARKER LAMP - REMOVAL....8L-18

TAILPIPE - 5.9L DIESEL - INSPECTION....11-10

TAILPIPE - 5.9L DIESEL - INSTALLATION . . 11-11

TAILPIPE - 5.9L DIESEL - REMOVAL.....11-10

TAILPIPE - INSPECTION...............11-11

TAILPIPE - INSTALLATION..............11-11

TAILPIPE - REMOVAL.................11-11

TANK - DESCRIPTION, FUEL............14-17

TANK - OPERATION, FUEL..............14-17

TANK MODULE - DESCRIPTION, FUEL....14-63

TANK MODULE - INSTALLATION, FUEL....14-64

TANK MODULE - OPERATION, FUEL......14-63

TANK MODULE - REMOVAL, FUEL.......14-63

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC.........................9-210

TAPPETS - INSTALLATION, HYDRAULIC . . . 9-211

TAPPETS - REMOVAL, HYDRAULIC.......9-211

TASK MANAGER - DESCRIPTION.........25-1

TASK MANAGER - OPERATION...........25-5

TCM QUICK LEARN - STANDARD

PROCEDURE........................8E-23

TEMP INDICATOR - DESCRIPTION,

TRANS.............................8J-40

TEMP INDICATOR - OPERATION, TRANS

. . 8J-40

TEMP SENSOR - DESCRIPTION,

AMBIENT

..........................8M-10

TEMP SENSOR - OPERATION, AMBIENT

. . 8M-10

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE

............................8J-24

TEMPERATURE GAUGE - OPERATION,

ENGINE

............................8J-24

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY

...........................8F-21

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT

.....................7-38

TEMPERATURE SENSOR - DESCRIPTION,

EVAPORATOR

.......................24-22

TEMPERATURE SENSOR - DESCRIPTION,

INTAKE AIR

.........................14-30

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION

...............21-267,21-408

TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT

..............8M-10

TEMPERATURE SENSOR -

INSTALLATION, BATTERY

..............8F-21

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT

........7-41

32 INDEXDR

Description Group-Page Description Group-Page Description Group-Page