RELAY CONNECTORS DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 735 of 2627

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

resistance in these circuits use a meter with a 10 -

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle's

electrical system can cause damage to the equip-

ment and provide false readings.

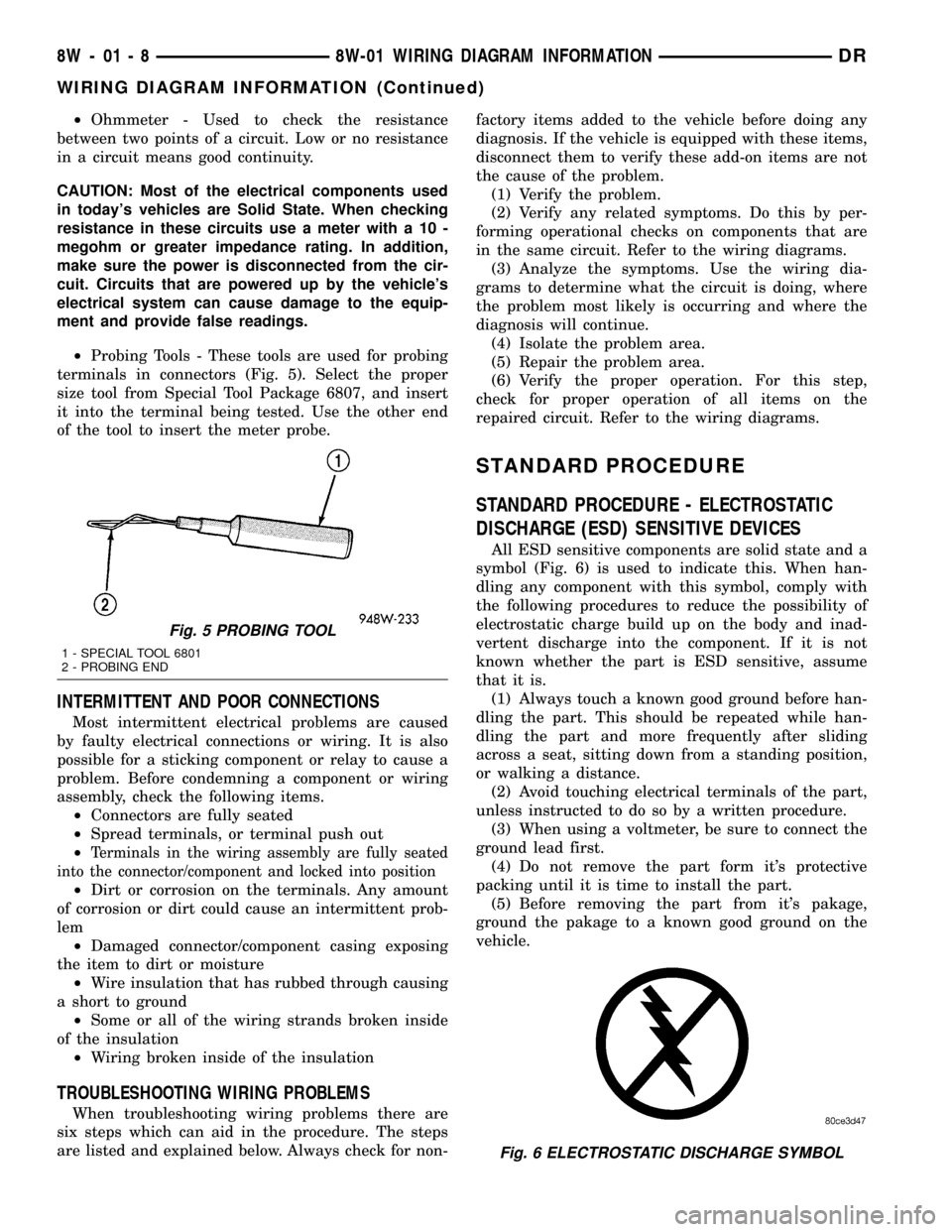

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 5). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly, check the following items.

²Connectors are fully seated

²Spread terminals, or terminal push out

²

Terminals in the wiring assembly are fully seated

into the connector/component and locked into position

²Dirt or corrosion on the terminals. Any amount

of corrosion or dirt could cause an intermittent prob-

lem

²Damaged connector/component casing exposing

the item to dirt or moisture

²Wire insulation that has rubbed through causing

a short to ground

²Some or all of the wiring strands broken inside

of the insulation

²Wiring broken inside of the insulation

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,

disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem area.

(6) Verify the proper operation. For this step,

check for proper operation of all items on the

repaired circuit. Refer to the wiring diagrams.

STANDARD PROCEDURE

STANDARD PROCEDURE - ELECTROSTATIC

DISCHARGE (ESD) SENSITIVE DEVICES

All ESD sensitive components are solid state and a

symbol (Fig. 6) is used to indicate this. When han-

dling any component with this symbol, comply with

the following procedures to reduce the possibility of

electrostatic charge build up on the body and inad-

vertent discharge into the component. If it is not

known whether the part is ESD sensitive, assume

that it is.

(1) Always touch a known good ground before han-

dling the part. This should be repeated while han-

dling the part and more frequently after sliding

across a seat, sitting down from a standing position,

or walking a distance.

(2) Avoid touching electrical terminals of the part,

unless instructed to do so by a written procedure.

(3) When using a voltmeter, be sure to connect the

ground lead first.

(4) Do not remove the part form it's protective

packing until it is time to install the part.

(5) Before removing the part from it's pakage,

ground the pakage to a known good ground on the

vehicle.

Fig. 5 PROBING TOOL

1 - SPECIAL TOOL 6801

2 - PROBING END

Fig. 6 ELECTROSTATIC DISCHARGE SYMBOL

8W - 01 - 8 8W-01 WIRING DIAGRAM INFORMATIONDR

WIRING DIAGRAM INFORMATION (Continued)

Page 745 of 2627

Component Page

Manifold Absolute Pressure Sensor........ 8W-30

Mode Door Actuators................... 8W-42

Multi-Function Switch............ 8W-40, 52, 53

Natural Vacuum Leak Detection Assembly . . 8W-30

Output Speed Sensor................... 8W-31

Overhead Map/Reading Lamp......... 8W-44, 49

Oxygen Sensor Downstream Relay........ 8W-30

Oxygen Sensors....................... 8W-30

Park Brake Switch.................... 8W-40

Park Lamp Relay................... 8W-50, 52

Park/Turn Signal Lamps............. 8W-50, 52

Power Mirrors........................ 8W-62

Power Outlets........................ 8W-41

Power Seat Motors.................... 8W-63

Power Seat Switches................... 8W-63

Power Steering Pressure Switch.......... 8W-30

Power Window Circuit Breaker........... 8W-10

Power Window Motors.................. 8W-60

Power Window Switches................ 8W-60

Powertrain Control Module.............. 8W-30

PTCS............................... 8W-10

PTO Switch.......................... 8W-30

Radio............................... 8W-47

Rear Window Defogger Relay............ 8W-48

Recirculation Door Actuator............. 8W-42

Remote Radio Switches................. 8W-47

Seat Belt Pretensioners................. 8W-43

Seat Belt Switch-Driver................ 8W-40

Seat Belt Tensioner Reducer............. 8W-40

Seat Heater Interface Module............ 8W-63

Sentry Key Immobilizer Module.......... 8W-39

Side Impact Sensors................... 8W-43

Speakers............................ 8W-47Component Page

Speed Control Servo................... 8W-33

Speed Control Switches................. 8W-33

Splices.............................. 8W-70

Starter Motor........................ 8W-21

Starter Motor Relay................... 8W-21

Tail/Stop Lamp....................... 8W-52

Tail/Stop/Turn Signal Lamps.......... 8W-51, 52

Tail/Turn Lamp....................... 8W-52

Tailgate Lamp........................ 8W-51

Throttle Position Sensor................ 8W-30

Tow/Haul Overdrive Switch........... 8W-30, 31

Trailer Tow Connectors................. 8W-54

Trailer Tow Relays.................... 8W-54

Transfer Case Control Module............ 8W-31

Transfer Case Mode Sensor.............. 8W-31

Transfer Case Selector Switch............ 8W-31

Transfer Case Shift Motor............... 8W-31

Transmission Control Relay............. 8W-31

Transmission Range Sensor.............. 8W-31

Transmission Solenoid Assembly.......... 8W-31

Transmission Solenoid/TRS Assembly...... 8W-31

Underhood Lamp...................... 8W-44

Vacuum Pump........................ 8W-30

Vistronic Fan Drive................. 8W-30, 70

Washer Fluid Level Switch.............. 8W-53

Washer Pump Motor-Front.............. 8W-53

Water In Fuel Sensor.................. 8W-30

Wheel Speed Sensors................... 8W-35

Wiper High/Low Relay................. 8W-53

Wiper Motor-Front.................... 8W-53

Wiper On/Off Relay.................... 8W-53

8W - 02 - 2 8W-02 COMPONENT INDEXDR

Page 1218 of 2627

INTEGRATED POWER MODULE

DESCRIPTION

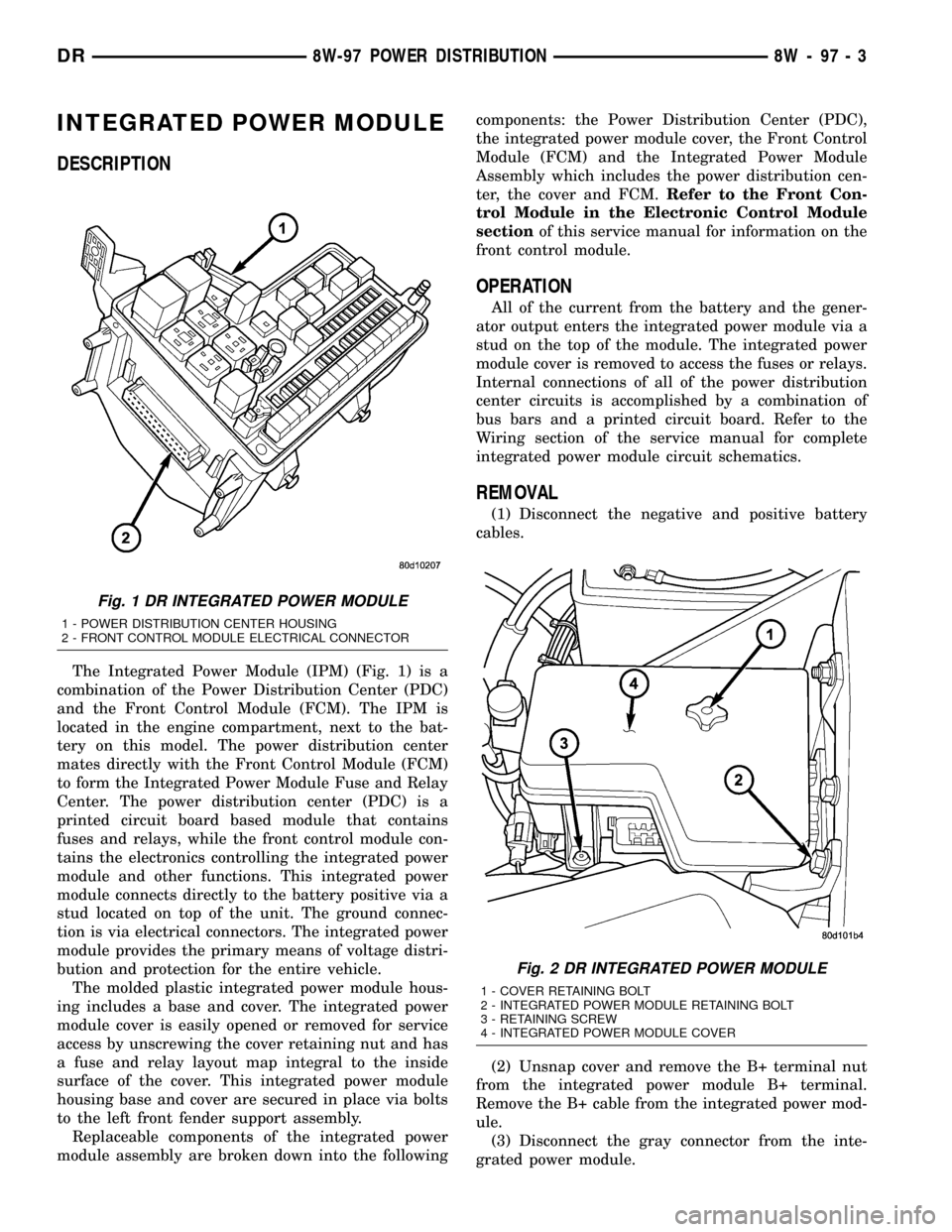

The Integrated Power Module (IPM) (Fig. 1) is a

combination of the Power Distribution Center (PDC)

and the Front Control Module (FCM). The IPM is

located in the engine compartment, next to the bat-

tery on this model. The power distribution center

mates directly with the Front Control Module (FCM)

to form the Integrated Power Module Fuse and Relay

Center. The power distribution center (PDC) is a

printed circuit board based module that contains

fuses and relays, while the front control module con-

tains the electronics controlling the integrated power

module and other functions. This integrated power

module connects directly to the battery positive via a

stud located on top of the unit. The ground connec-

tion is via electrical connectors. The integrated power

module provides the primary means of voltage distri-

bution and protection for the entire vehicle.

The molded plastic integrated power module hous-

ing includes a base and cover. The integrated power

module cover is easily opened or removed for service

access by unscrewing the cover retaining nut and has

a fuse and relay layout map integral to the inside

surface of the cover. This integrated power module

housing base and cover are secured in place via bolts

to the left front fender support assembly.

Replaceable components of the integrated power

module assembly are broken down into the followingcomponents: the Power Distribution Center (PDC),

the integrated power module cover, the Front Control

Module (FCM) and the Integrated Power Module

Assembly which includes the power distribution cen-

ter, the cover and FCM.Refer to the Front Con-

trol Module in the Electronic Control Module

sectionof this service manual for information on the

front control module.

OPERATION

All of the current from the battery and the gener-

ator output enters the integrated power module via a

stud on the top of the module. The integrated power

module cover is removed to access the fuses or relays.

Internal connections of all of the power distribution

center circuits is accomplished by a combination of

bus bars and a printed circuit board. Refer to the

Wiring section of the service manual for complete

integrated power module circuit schematics.

REMOVAL

(1) Disconnect the negative and positive battery

cables.

(2) Unsnap cover and remove the B+ terminal nut

from the integrated power module B+ terminal.

Remove the B+ cable from the integrated power mod-

ule.

(3) Disconnect the gray connector from the inte-

grated power module.

Fig. 1 DR INTEGRATED POWER MODULE

1 - POWER DISTRIBUTION CENTER HOUSING

2 - FRONT CONTROL MODULE ELECTRICAL CONNECTOR

Fig. 2 DR INTEGRATED POWER MODULE

1 - COVER RETAINING BOLT

2 - INTEGRATED POWER MODULE RETAINING BOLT

3 - RETAINING SCREW

4 - INTEGRATED POWER MODULE COVER

DR8W-97 POWER DISTRIBUTION 8W - 97 - 3

Page 1220 of 2627

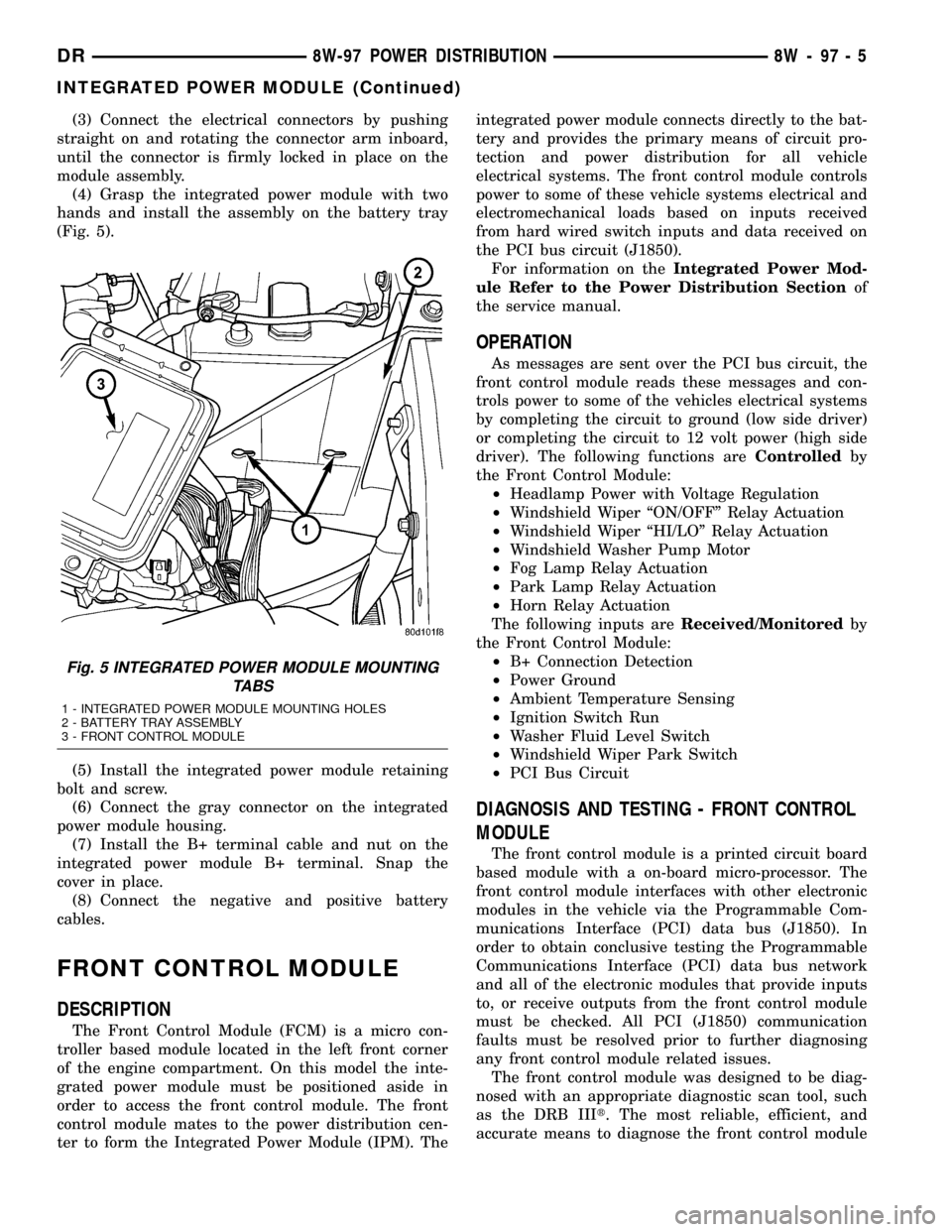

(3) Connect the electrical connectors by pushing

straight on and rotating the connector arm inboard,

until the connector is firmly locked in place on the

module assembly.

(4) Grasp the integrated power module with two

hands and install the assembly on the battery tray

(Fig. 5).

(5) Install the integrated power module retaining

bolt and screw.

(6) Connect the gray connector on the integrated

power module housing.

(7) Install the B+ terminal cable and nut on the

integrated power module B+ terminal. Snap the

cover in place.

(8) Connect the negative and positive battery

cables.

FRONT CONTROL MODULE

DESCRIPTION

The Front Control Module (FCM) is a micro con-

troller based module located in the left front corner

of the engine compartment. On this model the inte-

grated power module must be positioned aside in

order to access the front control module. The front

control module mates to the power distribution cen-

ter to form the Integrated Power Module (IPM). Theintegrated power module connects directly to the bat-

tery and provides the primary means of circuit pro-

tection and power distribution for all vehicle

electrical systems. The front control module controls

power to some of these vehicle systems electrical and

electromechanical loads based on inputs received

from hard wired switch inputs and data received on

the PCI bus circuit (J1850).

For information on theIntegrated Power Mod-

ule Refer to the Power Distribution Sectionof

the service manual.

OPERATION

As messages are sent over the PCI bus circuit, the

front control module reads these messages and con-

trols power to some of the vehicles electrical systems

by completing the circuit to ground (low side driver)

or completing the circuit to 12 volt power (high side

driver). The following functions areControlledby

the Front Control Module:

²Headlamp Power with Voltage Regulation

²Windshield Wiper ªON/OFFº Relay Actuation

²Windshield Wiper ªHI/LOº Relay Actuation

²Windshield Washer Pump Motor

²Fog Lamp Relay Actuation

²Park Lamp Relay Actuation

²Horn Relay Actuation

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection

²Power Ground

²Ambient Temperature Sensing

²Ignition Switch Run

²Washer Fluid Level Switch

²Windshield Wiper Park Switch

²PCI Bus Circuit

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

Fig. 5 INTEGRATED POWER MODULE MOUNTING

TABS

1 - INTEGRATED POWER MODULE MOUNTING HOLES

2 - BATTERY TRAY ASSEMBLY

3 - FRONT CONTROL MODULE

DR8W-97 POWER DISTRIBUTION 8W - 97 - 5

INTEGRATED POWER MODULE (Continued)

Page 1464 of 2627

(10) Drain engine oil. Remove and discard the oil

filter (Refer to 9 - ENGINE/LUBRICATION/OIL FIL-

TER - REMOVAL).

(11) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(12) Install a new oil filter (Refer to 9 - ENGINE/

LUBRICATION/OIL FILTER - INSTALLATION).

(13) Fill engine crankcase with the specified

amount and grade of oil (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES - SPECIFICA-

TIONS).

(14) Connect the negative cable(s) to the battery.

(15) Start the engine and check for any leaks.

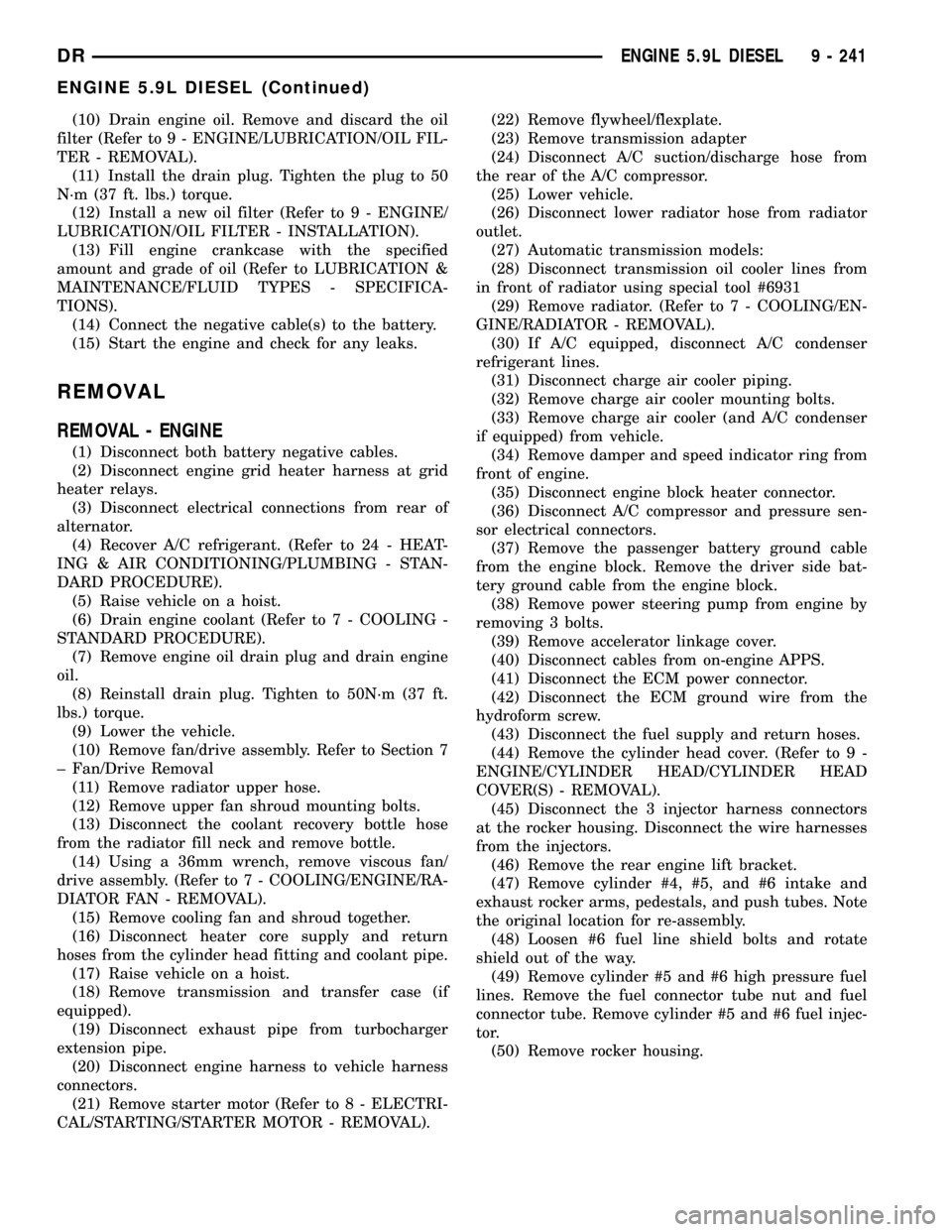

REMOVAL

REMOVAL - ENGINE

(1) Disconnect both battery negative cables.

(2) Disconnect engine grid heater harness at grid

heater relays.

(3) Disconnect electrical connections from rear of

alternator.

(4) Recover A/C refrigerant. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

(5) Raise vehicle on a hoist.

(6) Drain engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Remove engine oil drain plug and drain engine

oil.

(8) Reinstall drain plug. Tighten to 50N´m (37 ft.

lbs.) torque.

(9) Lower the vehicle.

(10) Remove fan/drive assembly. Refer to Section 7

± Fan/Drive Removal

(11) Remove radiator upper hose.

(12) Remove upper fan shroud mounting bolts.

(13) Disconnect the coolant recovery bottle hose

from the radiator fill neck and remove bottle.

(14) Using a 36mm wrench, remove viscous fan/

drive assembly. (Refer to 7 - COOLING/ENGINE/RA-

DIATOR FAN - REMOVAL).

(15) Remove cooling fan and shroud together.

(16) Disconnect heater core supply and return

hoses from the cylinder head fitting and coolant pipe.

(17) Raise vehicle on a hoist.

(18) Remove transmission and transfer case (if

equipped).

(19) Disconnect exhaust pipe from turbocharger

extension pipe.

(20) Disconnect engine harness to vehicle harness

connectors.

(21) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).(22) Remove flywheel/flexplate.

(23) Remove transmission adapter

(24) Disconnect A/C suction/discharge hose from

the rear of the A/C compressor.

(25) Lower vehicle.

(26) Disconnect lower radiator hose from radiator

outlet.

(27) Automatic transmission models:

(28) Disconnect transmission oil cooler lines from

in front of radiator using special tool #6931

(29) Remove radiator. (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(30) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(31) Disconnect charge air cooler piping.

(32) Remove charge air cooler mounting bolts.

(33) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(34) Remove damper and speed indicator ring from

front of engine.

(35) Disconnect engine block heater connector.

(36) Disconnect A/C compressor and pressure sen-

sor electrical connectors.

(37) Remove the passenger battery ground cable

from the engine block. Remove the driver side bat-

tery ground cable from the engine block.

(38) Remove power steering pump from engine by

removing 3 bolts.

(39) Remove accelerator linkage cover.

(40) Disconnect cables from on-engine APPS.

(41) Disconnect the ECM power connector.

(42) Disconnect the ECM ground wire from the

hydroform screw.

(43) Disconnect the fuel supply and return hoses.

(44) Remove the cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(45) Disconnect the 3 injector harness connectors

at the rocker housing. Disconnect the wire harnesses

from the injectors.

(46) Remove the rear engine lift bracket.

(47) Remove cylinder #4, #5, and #6 intake and

exhaust rocker arms, pedestals, and push tubes. Note

the original location for re-assembly.

(48) Loosen #6 fuel line shield bolts and rotate

shield out of the way.

(49) Remove cylinder #5 and #6 high pressure fuel

lines. Remove the fuel connector tube nut and fuel

connector tube. Remove cylinder #5 and #6 fuel injec-

tor.

(50) Remove rocker housing.

DRENGINE 5.9L DIESEL 9 - 241

ENGINE 5.9L DIESEL (Continued)

Page 1466 of 2627

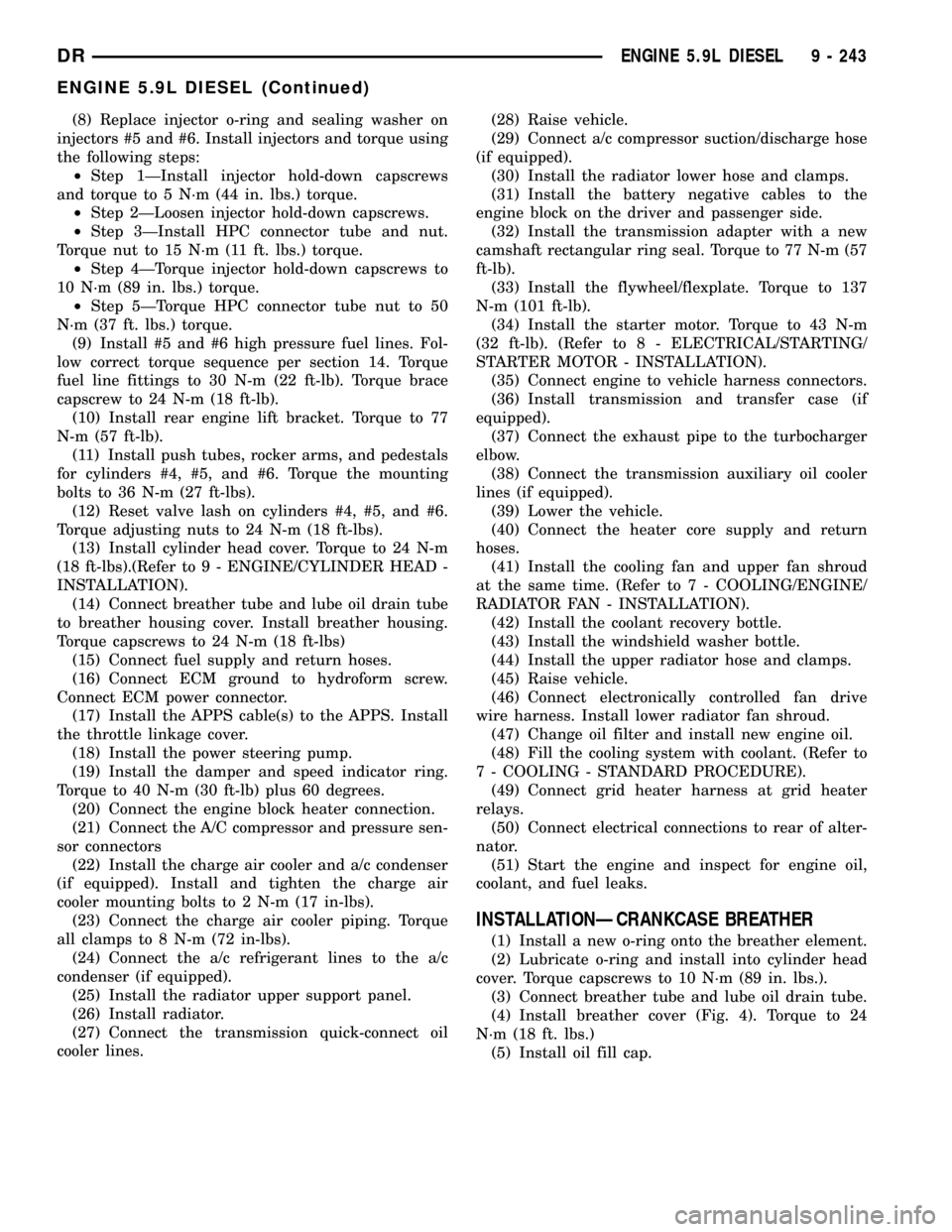

(8) Replace injector o-ring and sealing washer on

injectors #5 and #6. Install injectors and torque using

the following steps:

²Step 1ÐInstall injector hold-down capscrews

and torque to 5 N´m (44 in. lbs.) torque.

²Step 2ÐLoosen injector hold-down capscrews.

²Step 3ÐInstall HPC connector tube and nut.

Torque nut to 15 N´m (11 ft. lbs.) torque.

²Step 4ÐTorque injector hold-down capscrews to

10 N´m (89 in. lbs.) torque.

²Step 5ÐTorque HPC connector tube nut to 50

N´m (37 ft. lbs.) torque.

(9) Install #5 and #6 high pressure fuel lines. Fol-

low correct torque sequence per section 14. Torque

fuel line fittings to 30 N-m (22 ft-lb). Torque brace

capscrew to 24 N-m (18 ft-lb).

(10) Install rear engine lift bracket. Torque to 77

N-m (57 ft-lb).

(11) Install push tubes, rocker arms, and pedestals

for cylinders #4, #5, and #6. Torque the mounting

bolts to 36 N-m (27 ft-lbs).

(12) Reset valve lash on cylinders #4, #5, and #6.

Torque adjusting nuts to 24 N-m (18 ft-lbs).

(13) Install cylinder head cover. Torque to 24 N-m

(18 ft-lbs).(Refer to 9 - ENGINE/CYLINDER HEAD -

INSTALLATION).

(14) Connect breather tube and lube oil drain tube

to breather housing cover. Install breather housing.

Torque capscrews to 24 N-m (18 ft-lbs)

(15) Connect fuel supply and return hoses.

(16) Connect ECM ground to hydroform screw.

Connect ECM power connector.

(17) Install the APPS cable(s) to the APPS. Install

the throttle linkage cover.

(18) Install the power steering pump.

(19) Install the damper and speed indicator ring.

Torque to 40 N-m (30 ft-lb) plus 60 degrees.

(20) Connect the engine block heater connection.

(21) Connect the A/C compressor and pressure sen-

sor connectors

(22) Install the charge air cooler and a/c condenser

(if equipped). Install and tighten the charge air

cooler mounting bolts to 2 N-m (17 in-lbs).

(23) Connect the charge air cooler piping. Torque

all clamps to 8 N-m (72 in-lbs).

(24) Connect the a/c refrigerant lines to the a/c

condenser (if equipped).

(25) Install the radiator upper support panel.

(26) Install radiator.

(27) Connect the transmission quick-connect oil

cooler lines.(28) Raise vehicle.

(29) Connect a/c compressor suction/discharge hose

(if equipped).

(30) Install the radiator lower hose and clamps.

(31) Install the battery negative cables to the

engine block on the driver and passenger side.

(32) Install the transmission adapter with a new

camshaft rectangular ring seal. Torque to 77 N-m (57

ft-lb).

(33) Install the flywheel/flexplate. Torque to 137

N-m (101 ft-lb).

(34) Install the starter motor. Torque to 43 N-m

(32 ft-lb). (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(35) Connect engine to vehicle harness connectors.

(36) Install transmission and transfer case (if

equipped).

(37) Connect the exhaust pipe to the turbocharger

elbow.

(38) Connect the transmission auxiliary oil cooler

lines (if equipped).

(39) Lower the vehicle.

(40) Connect the heater core supply and return

hoses.

(41) Install the cooling fan and upper fan shroud

at the same time. (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - INSTALLATION).

(42) Install the coolant recovery bottle.

(43) Install the windshield washer bottle.

(44) Install the upper radiator hose and clamps.

(45) Raise vehicle.

(46) Connect electronically controlled fan drive

wire harness. Install lower radiator fan shroud.

(47) Change oil filter and install new engine oil.

(48) Fill the cooling system with coolant. (Refer to

7 - COOLING - STANDARD PROCEDURE).

(49) Connect grid heater harness at grid heater

relays.

(50) Connect electrical connections to rear of alter-

nator.

(51) Start the engine and inspect for engine oil,

coolant, and fuel leaks.

INSTALLATIONÐCRANKCASE BREATHER

(1) Install a new o-ring onto the breather element.

(2) Lubricate o-ring and install into cylinder head

cover. Torque capscrews to 10 N´m (89 in. lbs.).

(3) Connect breather tube and lube oil drain tube.

(4) Install breather cover (Fig. 4). Torque to 24

N´m (18 ft. lbs.)

(5) Install oil fill cap.

DRENGINE 5.9L DIESEL 9 - 243

ENGINE 5.9L DIESEL (Continued)

Page 1651 of 2627

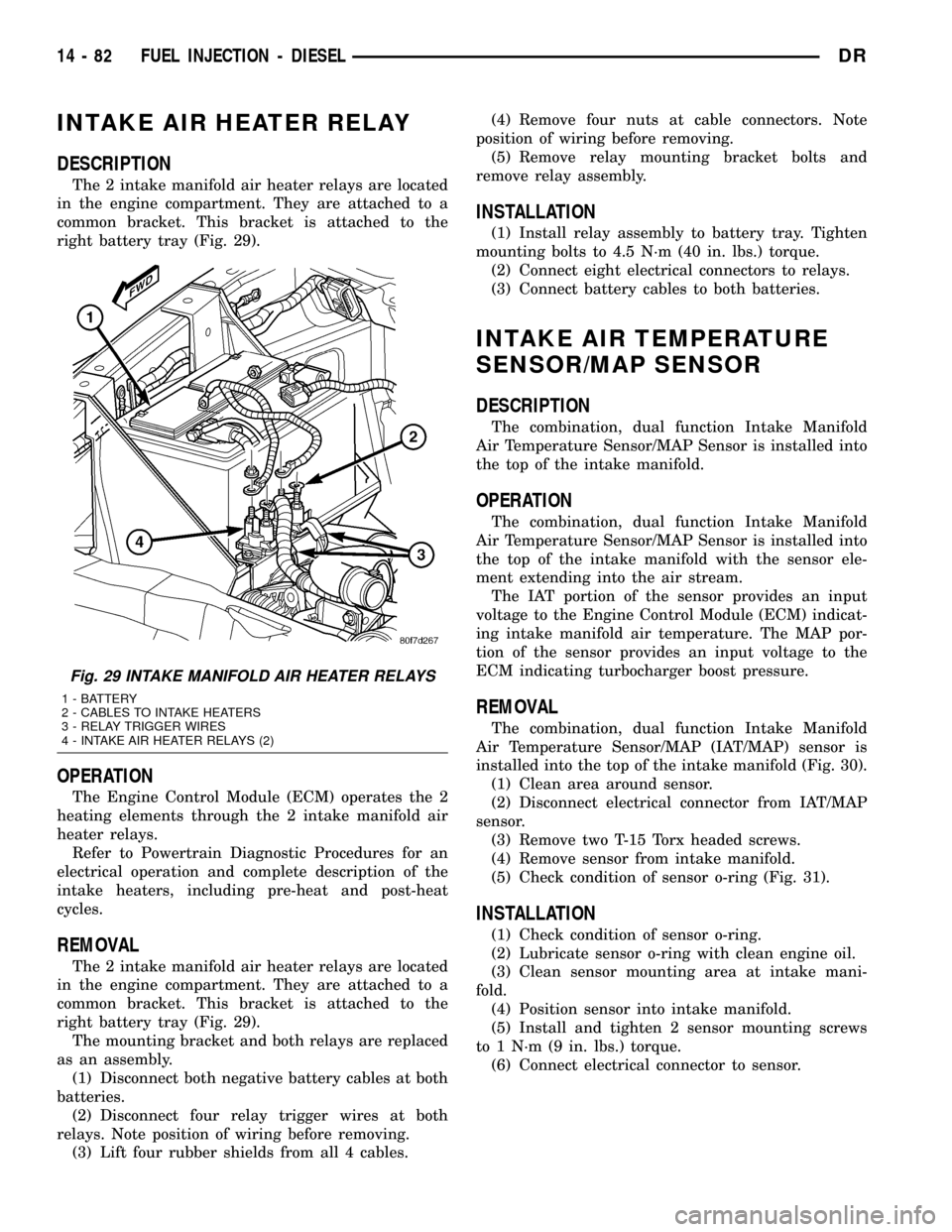

INTAKE AIR HEATER RELAY

DESCRIPTION

The 2 intake manifold air heater relays are located

in the engine compartment. They are attached to a

common bracket. This bracket is attached to the

right battery tray (Fig. 29).

OPERATION

The Engine Control Module (ECM) operates the 2

heating elements through the 2 intake manifold air

heater relays.

Refer to Powertrain Diagnostic Procedures for an

electrical operation and complete description of the

intake heaters, including pre-heat and post-heat

cycles.

REMOVAL

The 2 intake manifold air heater relays are located

in the engine compartment. They are attached to a

common bracket. This bracket is attached to the

right battery tray (Fig. 29).

The mounting bracket and both relays are replaced

as an assembly.

(1) Disconnect both negative battery cables at both

batteries.

(2) Disconnect four relay trigger wires at both

relays. Note position of wiring before removing.

(3) Lift four rubber shields from all 4 cables.(4) Remove four nuts at cable connectors. Note

position of wiring before removing.

(5) Remove relay mounting bracket bolts and

remove relay assembly.

INSTALLATION

(1) Install relay assembly to battery tray. Tighten

mounting bolts to 4.5 N´m (40 in. lbs.) torque.

(2) Connect eight electrical connectors to relays.

(3) Connect battery cables to both batteries.

INTAKE AIR TEMPERATURE

SENSOR/MAP SENSOR

DESCRIPTION

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP Sensor is installed into

the top of the intake manifold.

OPERATION

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP Sensor is installed into

the top of the intake manifold with the sensor ele-

ment extending into the air stream.

The IAT portion of the sensor provides an input

voltage to the Engine Control Module (ECM) indicat-

ing intake manifold air temperature. The MAP por-

tion of the sensor provides an input voltage to the

ECM indicating turbocharger boost pressure.

REMOVAL

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP (IAT/MAP) sensor is

installed into the top of the intake manifold (Fig. 30).

(1) Clean area around sensor.

(2) Disconnect electrical connector from IAT/MAP

sensor.

(3) Remove two T-15 Torx headed screws.

(4) Remove sensor from intake manifold.

(5) Check condition of sensor o-ring (Fig. 31).

INSTALLATION

(1) Check condition of sensor o-ring.

(2) Lubricate sensor o-ring with clean engine oil.

(3) Clean sensor mounting area at intake mani-

fold.

(4) Position sensor into intake manifold.

(5) Install and tighten 2 sensor mounting screws

to 1 N´m (9 in. lbs.) torque.

(6) Connect electrical connector to sensor.

Fig. 29 INTAKE MANIFOLD AIR HEATER RELAYS

1 - BATTERY

2 - CABLES TO INTAKE HEATERS

3 - RELAY TRIGGER WIRES

4 - INTAKE AIR HEATER RELAYS (2)

14 - 82 FUEL INJECTION - DIESELDR

Page 1858 of 2627

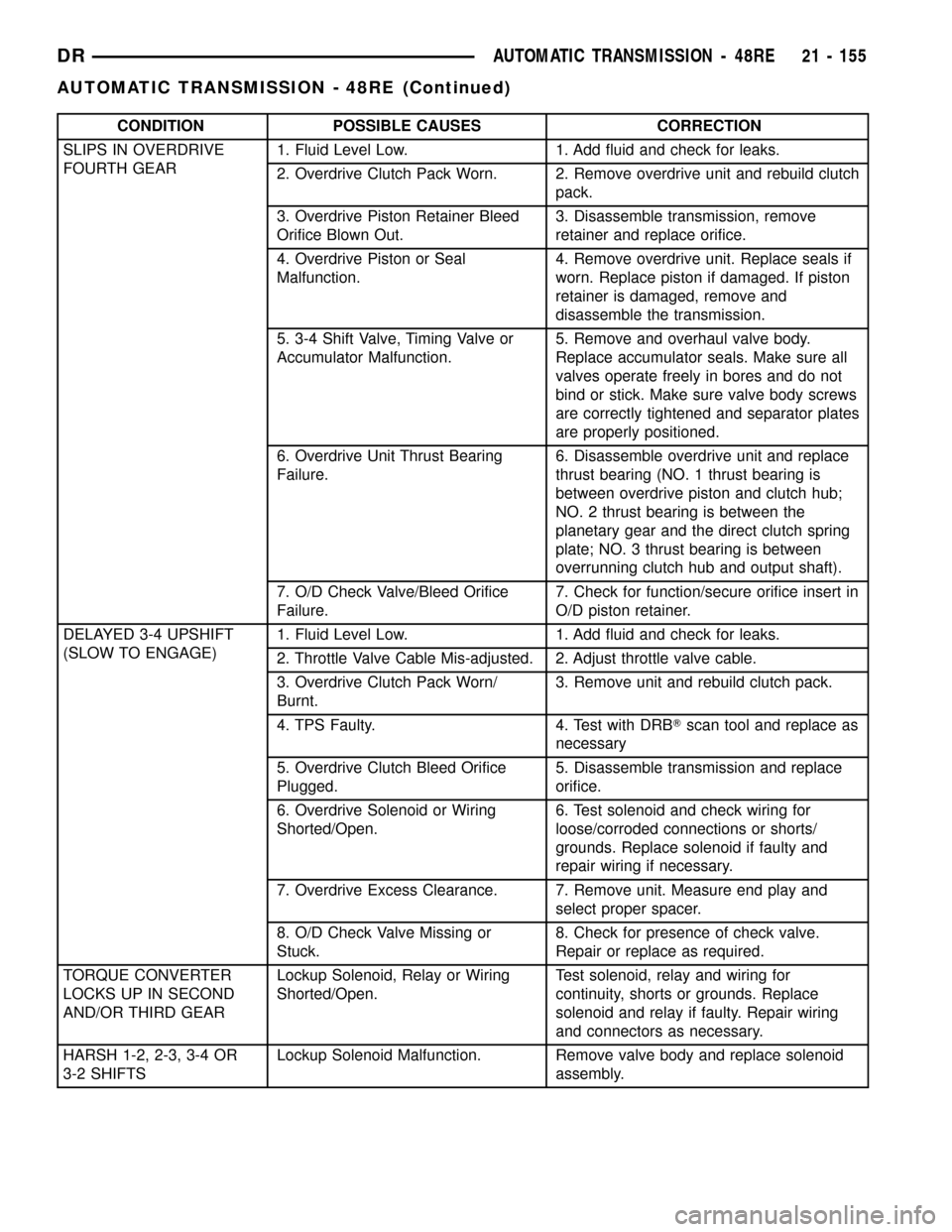

CONDITION POSSIBLE CAUSES CORRECTION

SLIPS IN OVERDRIVE

FOURTH GEAR1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Overdrive Clutch Pack Worn. 2. Remove overdrive unit and rebuild clutch

pack.

3. Overdrive Piston Retainer Bleed

Orifice Blown Out.3. Disassemble transmission, remove

retainer and replace orifice.

4. Overdrive Piston or Seal

Malfunction.4. Remove overdrive unit. Replace seals if

worn. Replace piston if damaged. If piston

retainer is damaged, remove and

disassemble the transmission.

5. 3-4 Shift Valve, Timing Valve or

Accumulator Malfunction.5. Remove and overhaul valve body.

Replace accumulator seals. Make sure all

valves operate freely in bores and do not

bind or stick. Make sure valve body screws

are correctly tightened and separator plates

are properly positioned.

6. Overdrive Unit Thrust Bearing

Failure.6. Disassemble overdrive unit and replace

thrust bearing (NO. 1 thrust bearing is

between overdrive piston and clutch hub;

NO. 2 thrust bearing is between the

planetary gear and the direct clutch spring

plate; NO. 3 thrust bearing is between

overrunning clutch hub and output shaft).

7. O/D Check Valve/Bleed Orifice

Failure.7. Check for function/secure orifice insert in

O/D piston retainer.

DELAYED 3-4 UPSHIFT

(SLOW TO ENGAGE)1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Throttle Valve Cable Mis-adjusted. 2. Adjust throttle valve cable.

3. Overdrive Clutch Pack Worn/

Burnt.3. Remove unit and rebuild clutch pack.

4. TPS Faulty. 4. Test with DRBTscan tool and replace as

necessary

5. Overdrive Clutch Bleed Orifice

Plugged.5. Disassemble transmission and replace

orifice.

6. Overdrive Solenoid or Wiring

Shorted/Open.6. Test solenoid and check wiring for

loose/corroded connections or shorts/

grounds. Replace solenoid if faulty and

repair wiring if necessary.

7. Overdrive Excess Clearance. 7. Remove unit. Measure end play and

select proper spacer.

8. O/D Check Valve Missing or

Stuck.8. Check for presence of check valve.

Repair or replace as required.

TORQUE CONVERTER

LOCKS UP IN SECOND

AND/OR THIRD GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

HARSH 1-2, 2-3, 3-4 OR

3-2 SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

DRAUTOMATIC TRANSMISSION - 48RE 21 - 155

AUTOMATIC TRANSMISSION - 48RE (Continued)