Serpentine belt DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 455 of 2627

INSTALLATION

3.7L / 4.7L

(1) Position generator to engine and install 2 hor-

izontal bolts and 1 vertical bolt.

(2) Tighten all 3 bolts. Refer to Torque Specifica-

tions.

(3) Snap field wire connector into rear of genera-

tor.

(4) Install B+ terminal eyelet to generator output

stud. Tighten mounting nut. Refer to Torque Specifi-

cations.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump may be rotating in the wrong direction

if the belt is installed incorrectly, causing the

engine to overheat. Refer to belt routing label in

engine compartment, or refer to Belt Schematics in

7, Cooling System.

(5) Install generator drive belt. Refer to 7, Cooling

System for procedure.

(6) Install negative battery cable to battery.5.7L

(1) Position generator to engine and install 2

mounting bolts.

(2) Tighten bolts. Refer to Torque Specifications.

(3) Position support bracket to front of generator

and install bolt and nuts. Tighten bolt / nuts. Refer

to Torque Specifications.

(4) Snap field wire connector into rear of genera-

tor.

(5) Install B+ terminal eyelet to generator output

stud. Tighten mounting nut. Refer to Torque Specifi-

cations.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump may be rotating in the wrong direction

if the belt is installed incorrectly, causing the

engine to overheat. Refer to belt routing label in

engine compartment, or refer to Belt Schematics in

7, Cooling System.

(6) Install generator drive belt. Refer to 7, Cooling

System for procedure.

(7) Install negative battery cable to battery.

5.9L Diesel

(1) Position generator to upper and lower mount-

ing brackets and install upper bolt and lower bolt /

nut.

(2) Tighten all bolts / nut. Refer to Torque Specifi-

cations.

(3) Snap field wire connector into rear of genera-

tor.

(4) Install B+ terminal eyelet to generator output

stud. Tighten mounting nut. Refer to Torque Specifi-

cations.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump may be rotating in the wrong direction

if the belt is installed incorrectly, causing the

engine to overheat. Refer to belt routing label in

engine compartment, or refer to Belt Schematics in

7, Cooling System.

(5) Install generator drive belt. Refer to 7, Cooling

System for procedure.

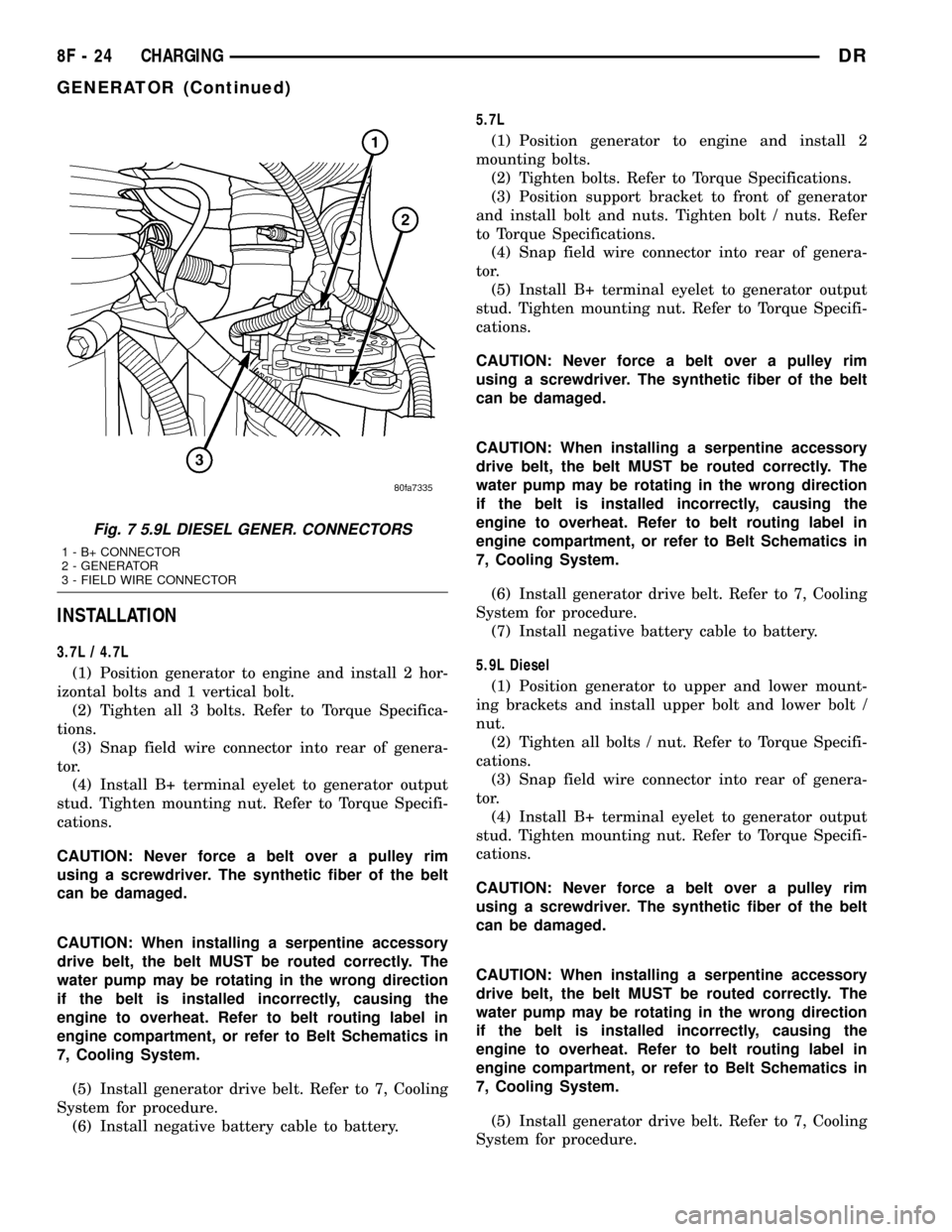

Fig. 7 5.9L DIESEL GENER. CONNECTORS

1 - B+ CONNECTOR

2 - GENERATOR

3 - FIELD WIRE CONNECTOR

8F - 24 CHARGINGDR

GENERATOR (Continued)

Page 1696 of 2627

(8) Fill the system with fluid and perform Steering

Pump Initial Operation, (Refer to 19 - STEERING/

PUMP - STANDARD PROCEDURE).

(9) Start the engine and run it for fifteen minutes

then stop the engine.

(10) Remove the return line/lines from the pump

and plug the pump port/ports.

(11) Pour fresh fluid into the reservoir and check

the draining fluid for contamination. If the fluid is

still contaminated, then flush the system again.

(12) Install the return line/lines and perform

Steering Pump Initial Operation, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

REMOVAL

REMOVAL - GAS

(1) Drain and siphon the power steering fluid from

the reservoir.

(2) Remove the serpentine belt.

CAUTION: Do not remove the fitting on the pump

that the high pressure hose screws into. The fitting

may come loose unless it is backed up using

another wrench. If the fitting does come loose, it

must be retightened before continuing. (57 - 67Nm,

40 - 50 lbft) If this fitting comes out of the pump

body, the internal spring and valve parts will fall out

of the pump and they cannot be reinstalled prop-

erly. If this occurs the pump needs to be replaced

with a new pump.

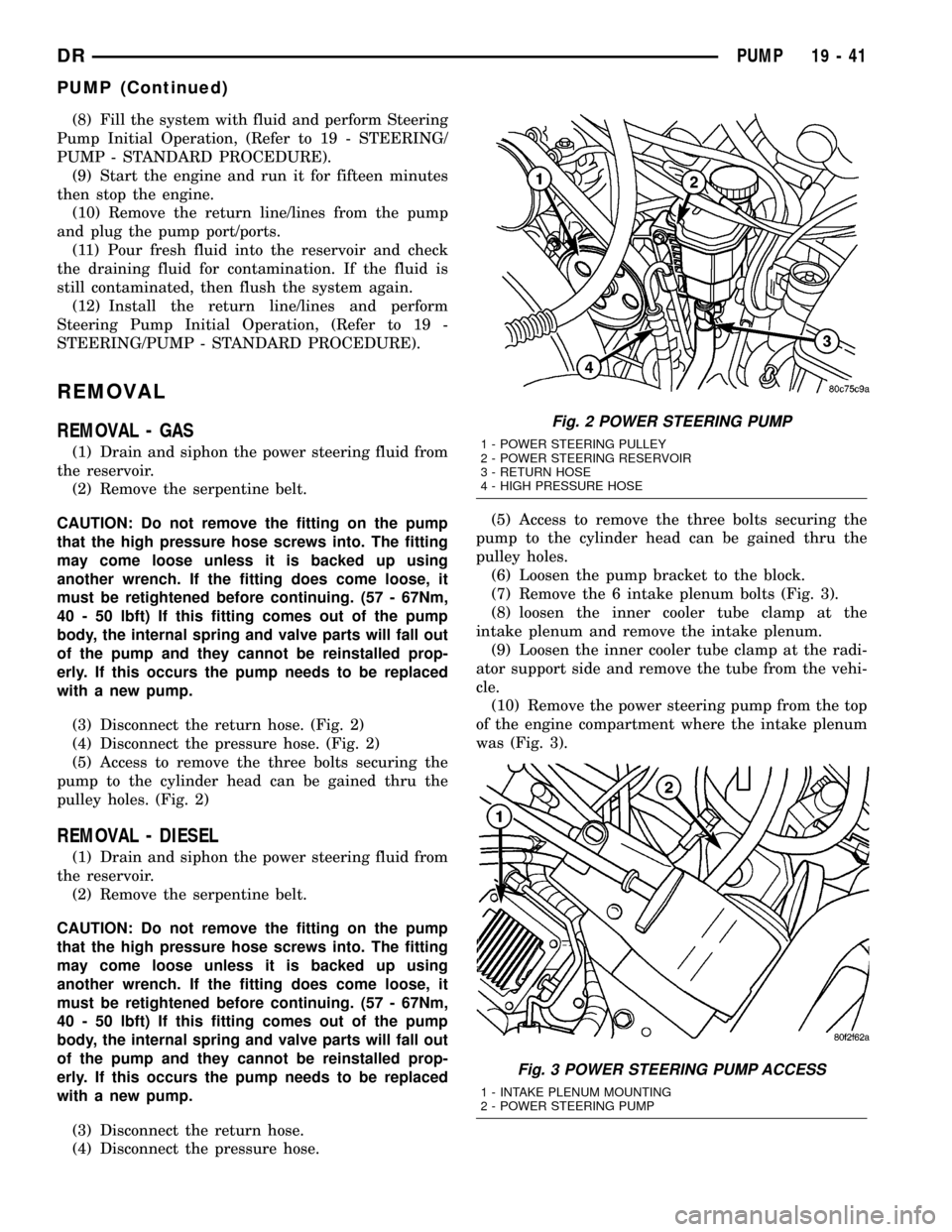

(3) Disconnect the return hose. (Fig. 2)

(4) Disconnect the pressure hose. (Fig. 2)

(5) Access to remove the three bolts securing the

pump to the cylinder head can be gained thru the

pulley holes. (Fig. 2)

REMOVAL - DIESEL

(1) Drain and siphon the power steering fluid from

the reservoir.

(2) Remove the serpentine belt.

CAUTION: Do not remove the fitting on the pump

that the high pressure hose screws into. The fitting

may come loose unless it is backed up using

another wrench. If the fitting does come loose, it

must be retightened before continuing. (57 - 67Nm,

40 - 50 lbft) If this fitting comes out of the pump

body, the internal spring and valve parts will fall out

of the pump and they cannot be reinstalled prop-

erly. If this occurs the pump needs to be replaced

with a new pump.

(3) Disconnect the return hose.

(4) Disconnect the pressure hose.(5) Access to remove the three bolts securing the

pump to the cylinder head can be gained thru the

pulley holes.

(6) Loosen the pump bracket to the block.

(7) Remove the 6 intake plenum bolts (Fig. 3).

(8) loosen the inner cooler tube clamp at the

intake plenum and remove the intake plenum.

(9) Loosen the inner cooler tube clamp at the radi-

ator support side and remove the tube from the vehi-

cle.

(10) Remove the power steering pump from the top

of the engine compartment where the intake plenum

was (Fig. 3).

Fig. 2 POWER STEERING PUMP

1 - POWER STEERING PULLEY

2 - POWER STEERING RESERVOIR

3 - RETURN HOSE

4 - HIGH PRESSURE HOSE

Fig. 3 POWER STEERING PUMP ACCESS

1 - INTAKE PLENUM MOUNTING

2 - POWER STEERING PUMP

DRPUMP 19 - 41

PUMP (Continued)

Page 1697 of 2627

INSTALLATION

INSTALLATION - GAS

(1) Align the pump with the mounting holes in the

left cylinder head.

(2) Install 3 pump mounting bolts through the pul-

ley access holes. Tighten the bolts to 28 N´m (21 ft.

lbs.).

(3) Reconnect the pressure line and return hose to

the pump and reservoir. Tighten the pressure line to

37 N´m (27 ft. lbs.).

(4) Install the serpentine drive belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(5) Fill the power steering pump, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - DIESEL

(1) Set the power steering pump in place in the

engine compartment from the top (Fig. 3).(2) Install the inner cooler tube.

(3) Tighten the inner cooler tube clamp at the

radiator support side.

(4) Install the 6 intake plenum bolts (Fig. 3).

(5) Tighten the inner cooler tube clamp at the

intake plenum.

(6) Install 3 pump mounting bolts through the pul-

ley access holes. Tighten the bolts to 28 N´m (21 ft.

lbs.).

(7) Tighten the pump bracket to the block.

(8) Reconnect the pressure line and return hose to

the pump and reservoir. Tighten the pressure line to

37 N´m (27 ft. lbs.).

(9) Install the serpentine drive belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(10) Fill the power steering pump, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

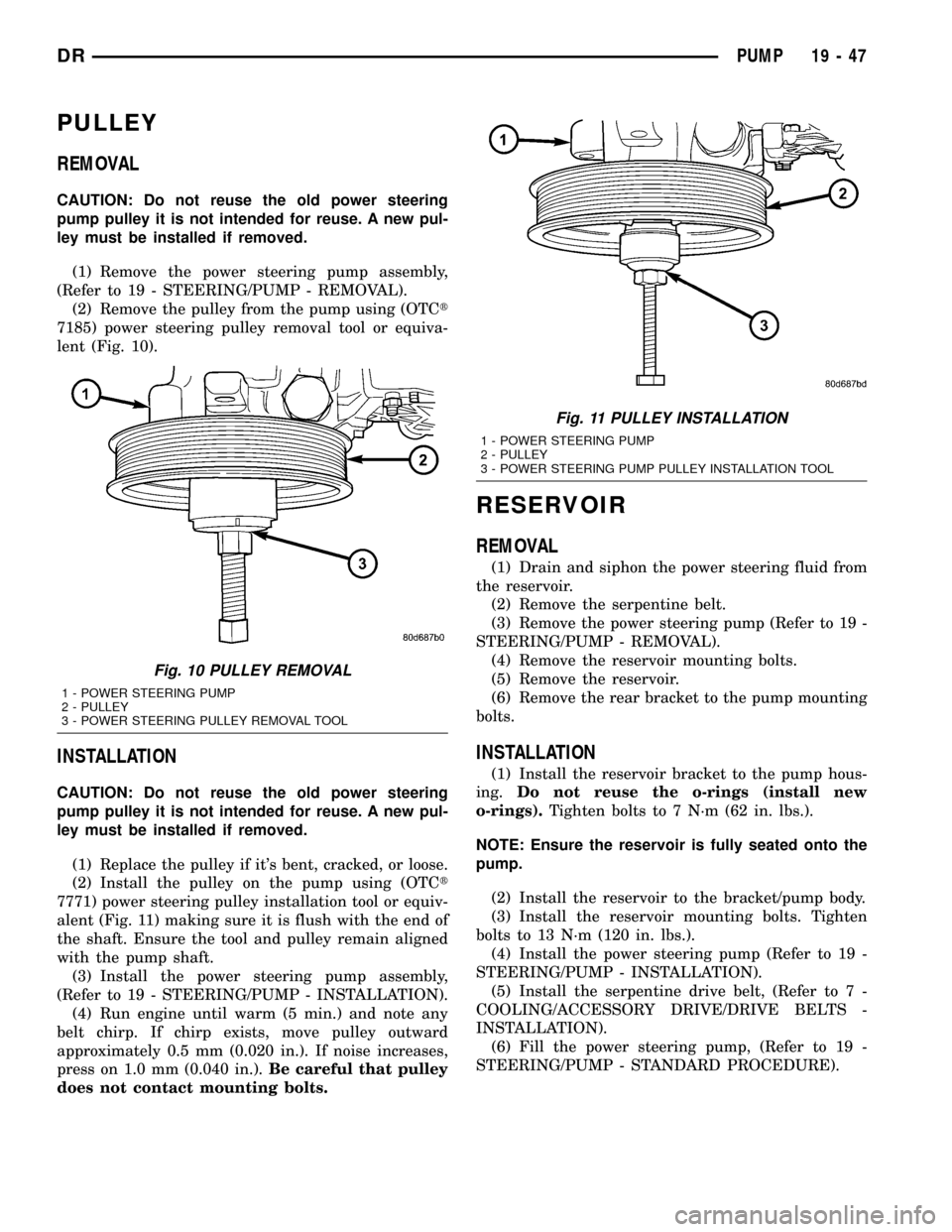

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Power Steering Pressure

Switch10 Ð 80

Power Steering Line

Pressure Line32 23 Ð

Power Steering Line

Return Line

HD51 38 Ð

Power Steering Line

Return Line

LD70 52 Ð

Power Steering Line

Pressure Line To Pump37 27 Ð

Power Steering Pump

Mounting Bolts28 27 Ð

Power Steering Pump

Reservoir Bolts13 10 120

Power Steering Pump

Bracket Bolts5562

19 - 42 PUMPDR

PUMP (Continued)

Page 1702 of 2627

PULLEY

REMOVAL

CAUTION: Do not reuse the old power steering

pump pulley it is not intended for reuse. A new pul-

ley must be installed if removed.

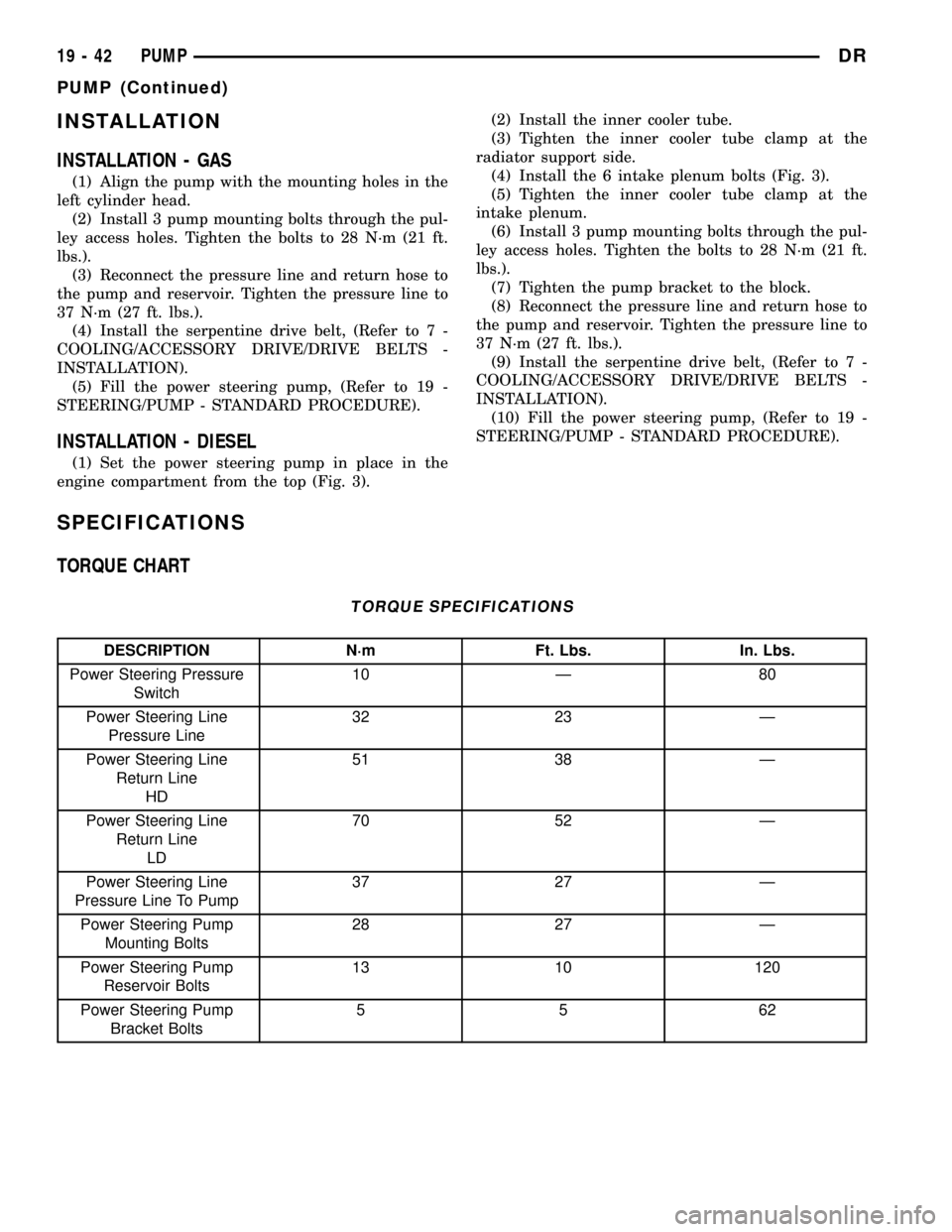

(1) Remove the power steering pump assembly,

(Refer to 19 - STEERING/PUMP - REMOVAL).

(2) Remove the pulley from the pump using (OTCt

7185) power steering pulley removal tool or equiva-

lent (Fig. 10).

INSTALLATION

CAUTION: Do not reuse the old power steering

pump pulley it is not intended for reuse. A new pul-

ley must be installed if removed.

(1) Replace the pulley if it's bent, cracked, or loose.

(2) Install the pulley on the pump using (OTCt

7771) power steering pulley installation tool or equiv-

alent (Fig. 11) making sure it is flush with the end of

the shaft. Ensure the tool and pulley remain aligned

with the pump shaft.

(3) Install the power steering pump assembly,

(Refer to 19 - STEERING/PUMP - INSTALLATION).

(4) Run engine until warm (5 min.) and note any

belt chirp. If chirp exists, move pulley outward

approximately 0.5 mm (0.020 in.). If noise increases,

press on 1.0 mm (0.040 in.).Be careful that pulley

does not contact mounting bolts.

RESERVOIR

REMOVAL

(1) Drain and siphon the power steering fluid from

the reservoir.

(2) Remove the serpentine belt.

(3) Remove the power steering pump (Refer to 19 -

STEERING/PUMP - REMOVAL).

(4) Remove the reservoir mounting bolts.

(5) Remove the reservoir.

(6) Remove the rear bracket to the pump mounting

bolts.

INSTALLATION

(1) Install the reservoir bracket to the pump hous-

ing.Do not reuse the o-rings (install new

o-rings).Tighten bolts to 7 N´m (62 in. lbs.).

NOTE: Ensure the reservoir is fully seated onto the

pump.

(2) Install the reservoir to the bracket/pump body.

(3) Install the reservoir mounting bolts. Tighten

bolts to 13 N´m (120 in. lbs.).

(4) Install the power steering pump (Refer to 19 -

STEERING/PUMP - INSTALLATION).

(5) Install the serpentine drive belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(6) Fill the power steering pump, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

Fig. 10 PULLEY REMOVAL

1 - POWER STEERING PUMP

2 - PULLEY

3 - POWER STEERING PULLEY REMOVAL TOOL

Fig. 11 PULLEY INSTALLATION

1 - POWER STEERING PUMP

2 - PULLEY

3 - POWER STEERING PUMP PULLEY INSTALLATION TOOL

DRPUMP 19 - 47

Page 2496 of 2627

CONTROLS

TABLE OF CONTENTS

page page

A/C COMPRESSOR CLUTCH/COIL

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - A/C

COMPRESSOR CLUTCH COIL...........10

STANDARD PROCEDURE - A/C

COMPRESSOR CLUTCH BREAK-IN.......10

REMOVAL.............................10

INSPECTION..........................11

INSTALLATION.........................12

A/C COMPRESSOR CLUTCH RELAY

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................14

INSTALLATION.........................14

A/C HEATER CONTROL

DESCRIPTION.........................14

REMOVAL.............................15

INSTALLATION.........................15

A/C PRESSURE TRANSDUCER

DESCRIPTION.........................15

OPERATION...........................16

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER.......................16

REMOVAL.............................16

INSTALLATION.........................16

BLEND DOOR ACTUATOR

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................18

BLOWER MOTOR RESISTOR BLOCK

DESCRIPTION.........................18OPERATION...........................18

DIAGNOSIS AND TESTING - BLOWER

MOTOR RESISTOR BLOCK..............19

REMOVAL.............................19

INSTALLATION.........................19

BLOWER MOTOR SWITCH

DESCRIPTION.........................20

OPERATION...........................20

DIAGNOSIS AND TESTING - BLOWER

MOTOR SWITCH......................20

DEFROST DOOR ACTUATOR

DESCRIPTION.........................20

OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................21

EVAPORATOR TEMPERATURE SENSOR

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................22

MODE DOOR ACTUATOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................23

INSTALLATION.........................23

RECIRCULATION DOOR ACTUATOR

DESCRIPTION.........................24

OPERATION...........................24

REMOVAL.............................24

INSTALLATION.........................25

A/C COMPRESSOR CLUTCH/

COIL

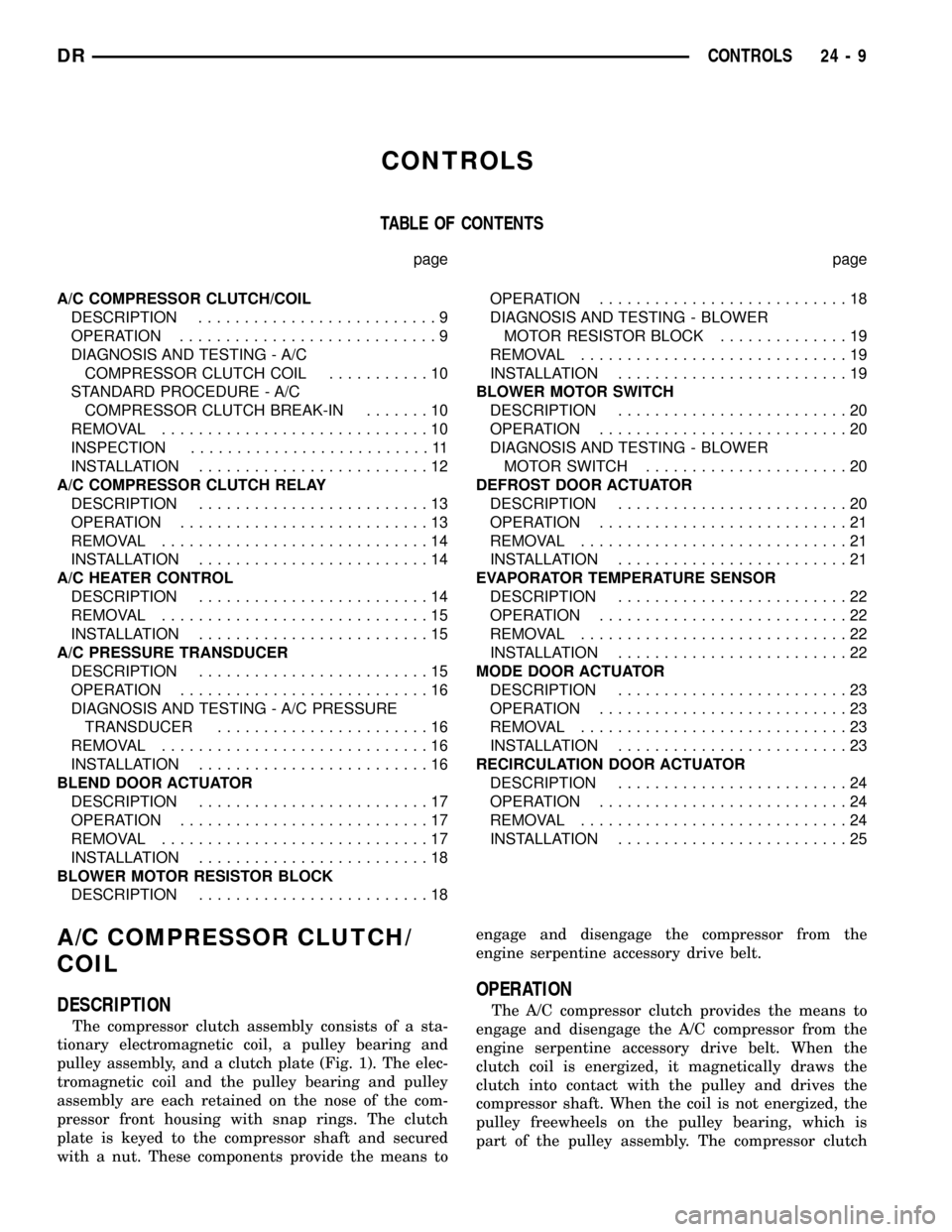

DESCRIPTION

The compressor clutch assembly consists of a sta-

tionary electromagnetic coil, a pulley bearing and

pulley assembly, and a clutch plate (Fig. 1). The elec-

tromagnetic coil and the pulley bearing and pulley

assembly are each retained on the nose of the com-

pressor front housing with snap rings. The clutch

plate is keyed to the compressor shaft and secured

with a nut. These components provide the means toengage and disengage the compressor from the

engine serpentine accessory drive belt.

OPERATION

The A/C compressor clutch provides the means to

engage and disengage the A/C compressor from the

engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch into contact with the pulley and drives the

compressor shaft. When the coil is not energized, the

pulley freewheels on the pulley bearing, which is

part of the pulley assembly. The compressor clutch

DRCONTROLS 24 - 9

Page 2497 of 2627

and coil are the only serviced parts on the compres-

sor.

A/C compressor clutch engagement is controlled by

several components: the A/C-heater control, A/C pres-

sure transducer, A/C compressor clutch relay, evapo-

rator temperature sensor and the powertrain control

module (PCM). The PCM may delay compressor

clutch engagement for up to thirty seconds (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION).

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). The battery must

be fully-charged before performing the following

tests. Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the A/C-heater controls in any A/C mode,

and the blower motor switch in the lowest speed

position, start the engine and run it at normal idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRB IIItscan tool and (Refer to

Appropriate Diagnostic Information) for testing of thecompressor clutch circuit and PCM control. The fol-

lowing components must be checked and repaired as

required before you can complete testing of the clutch

coil:

²Fuses in the junction block and the power distri-

bution center (PDC)

²A/C-heater control

²A/C compressor clutch relay

²A/C pressure transducer

²Evaporator temperature sensor

²Powertrain control module (PCM)

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is within

specifications with the electrical system voltage at

11.5 to 12.5 volts (Refer to 24 - HEATING & AIR

CONDITIONING - SPECIFICATIONS). This should

only be checked with the work area temperature at

21É C (70É F). If system voltage is more than 12.5

volts, add electrical loads by turning on electrical

accessories until the system voltage drops below 12.5

volts.

(a) If the clutch coil current reading is above

specifications, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

STANDARD PROCEDURE - A/C COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C-heater control to the

Recirculation Mode, the blower motor switch in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces and provide a higher

compressor clutch torque capability.

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, rotor, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Disconnect the compressor clutch coil wire har-

ness connector.

(4) Remove the bolts that secure the compressor to

the mounting bracket.

(5) Remove the compressor from the mounting

bracket. Support the compressor in the engine com-

partment while servicing the clutch.

Fig. 1 Compressor Clutch - Typical

1 - CLUTCH PLATE

2 - SHAFT KEY (not used on KJ)

3 - ROTOR

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

24 - 10 CONTROLSDR

A/C COMPRESSOR CLUTCH/COIL (Continued)

Page 2536 of 2627

when a minimum discharge pressure of 2756 kPa

(400 psi) is reached.

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean that the valve is faulty.

The high pressure relief valve is a factory-cali-

brated unit. The valve cannot be adjusted or

repaired, and must not be removed or otherwise dis-

turbed. The valve is only serviced as a part of the

compressor assembly.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

When investigating an air conditioning related

noise, you must first know the conditions under

which the noise occurs. These conditions include:

weather, vehicle speed, transmission in gear or neu-

tral, engine speed, engine temperature, and any

other special conditions. Noises that develop during

air conditioning operation can often be misleading.

For example: What sounds like a failed front bearing

or connecting rod, may be caused by loose bolts, nuts,

mounting brackets, or a loose compressor clutch

assembly.

Drive belts are speed sensitive. At different engine

speeds and depending upon belt tension, belts can

develop noises that are mistaken for a compressor

noise. Improper belt tension can cause a misleading

noise when the compressor clutch is engaged, which

may not occur when the compressor clutch is disen-

gaged. Check the serpentine drive belt condition and

tension as described in Cooling before beginning this

procedure.

(1) Select a quiet area for testing. Duplicate the

complaint conditions as much as possible. Switch the

compressor on and off several times to clearly iden-

tify the compressor noise. Listen to the compressor

while the clutch is engaged and disengaged. Probe

the compressor with an engine stethoscope or a long

screwdriver with the handle held to your ear to bet-

ter localize the source of the noise.

(2) Loosen all of the compressor mounting hard-

ware and retighten. Tighten the compressor clutch

mounting nut. Be certain that the clutch coil is

mounted securely to the compressor, and that the

clutch plate and rotor are properly aligned and have

the correct air gap (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH - INSTALLATION).

(3) To duplicate a high-ambient temperature condi-

tion (high head pressure), restrict the air flow

through the condenser. Install a manifold gauge set

or a DRBIIItscan tool to be certain that the dis-

charge pressure does not exceed 2760 kPa (400 psi).(4) Check the refrigerant system plumbing for

incorrect routing, rubbing or interference, which can

cause unusual noises. Also check the refrigerant lines

for kinks or sharp bends that will restrict refrigerant

flow, which can cause noises (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE).

(5) If the noise is from opening and closing of the

high pressure relief valve, recover, evacuate and

recharge the refrigerant system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE), (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - REFRIGERANT SYSTEM EVACU-

ATE) and (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM CHARGE). If the high

pressure relief valve still does not seat properly,

replace the compressor (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/A/C COMPRES-

SOR - REMOVAL).

(6) If the noise is from liquid slugging on the suc-

tion line, replace the accumulator (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/AC-

CUMULATOR - REMOVAL) and check the refriger-

ant oil level and the refrigerant system charge (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/REFRIGERANT OIL - STANDARD PROCE-

DURE) (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/ACCUMULATOR -

REMOVAL). If after replacing the accumulator the

slugging condition still exists then replace the com-

pressor.(Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/A/C COMPRESSOR - REMOVAL).

(7) If the liquid slugging condition continues fol-

lowing accumulator replacement, replace the com-

pressor and repeat Step 1.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

NOTE: The A/C compressor may be removed and

repositioned without disconnecting the refrigerant

lines or discharging the refrigerant system. Dis-

charging is not necessary if servicing the compres-

sor clutch, clutch coil, engine, engine cylinder head

or the generator.

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

DRPLUMBING 24 - 49

A/C COMPRESSOR (Continued)

Page 2537 of 2627

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Disconnect the A/C compressor clutch coil wire

harness connector.

(5) Depending on engine usage, remove the bolt or

nuts that secure the suction and discharge line fit-

tings to the A/C compressor.

(6) Disconnect the suction and discharge line fit-

tings from the A/C compressor.

(7) Remove the O-ring seals from the suction and

discharge line fittings and discard.

(8) Install plugs in, or tape over all of the opened

refrigerant line fittings and the compressor ports.

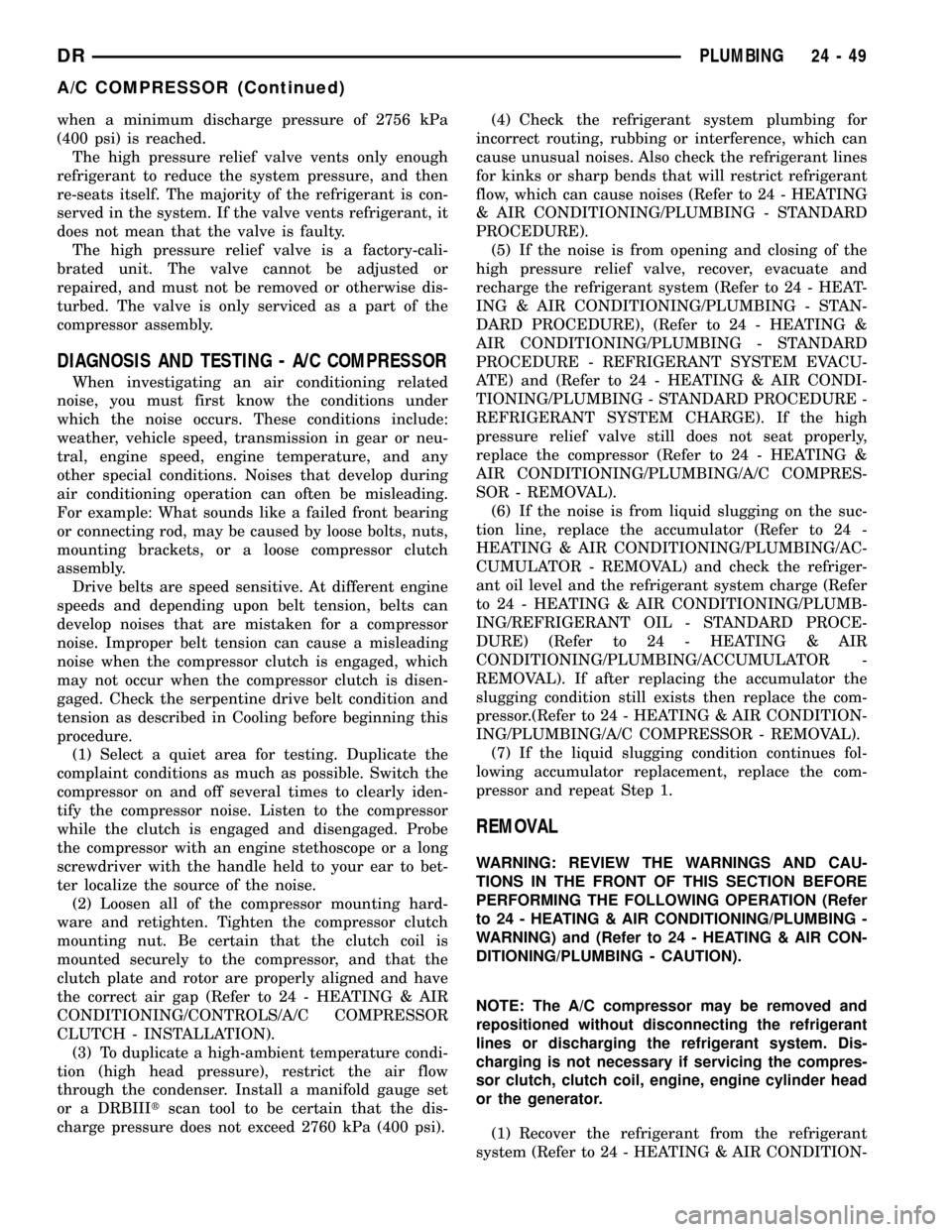

(9) If equipped with the 5.7L Hemi engine, remove

the nuts and bolts that secure the generator and A/C

compressor support bracket and remove the bracket

from the engine.

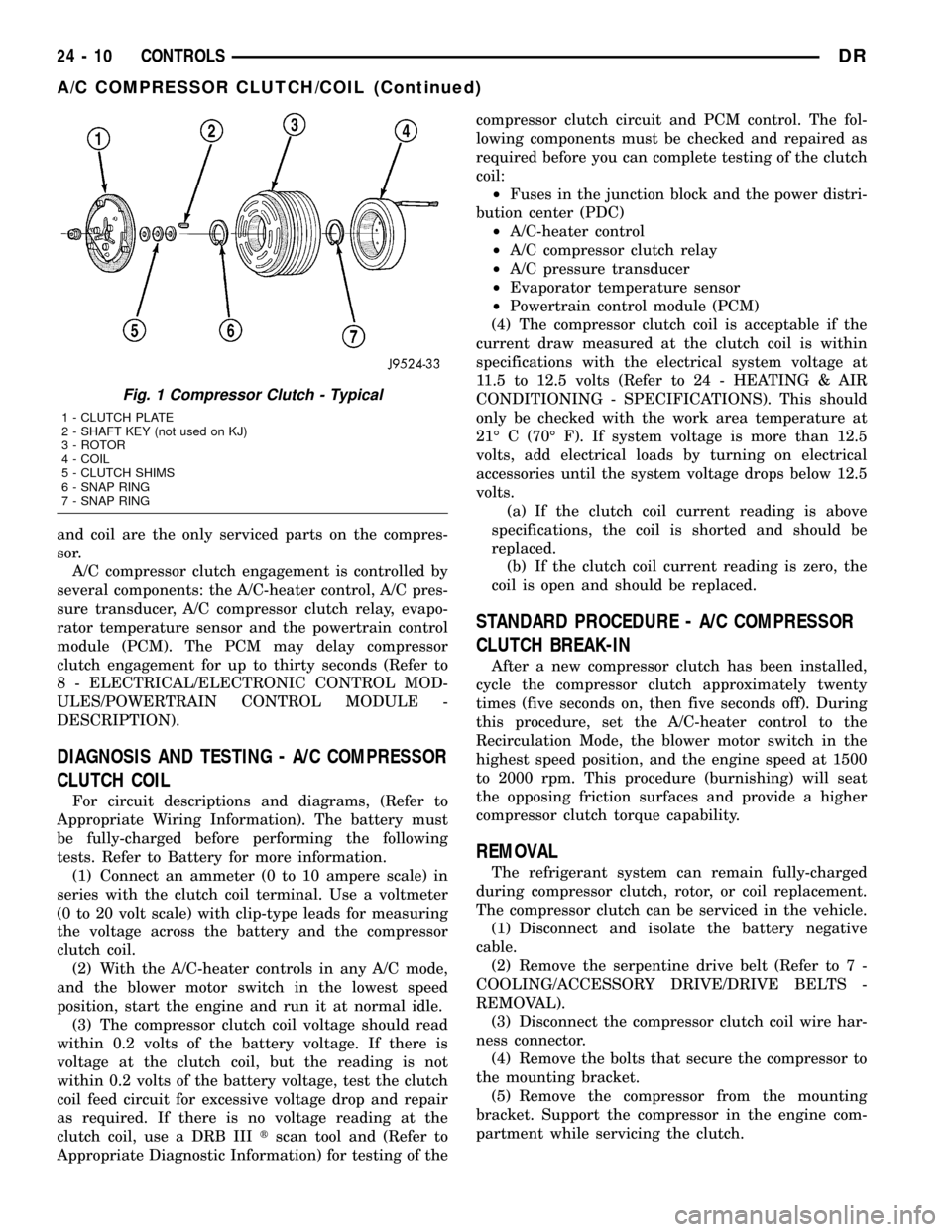

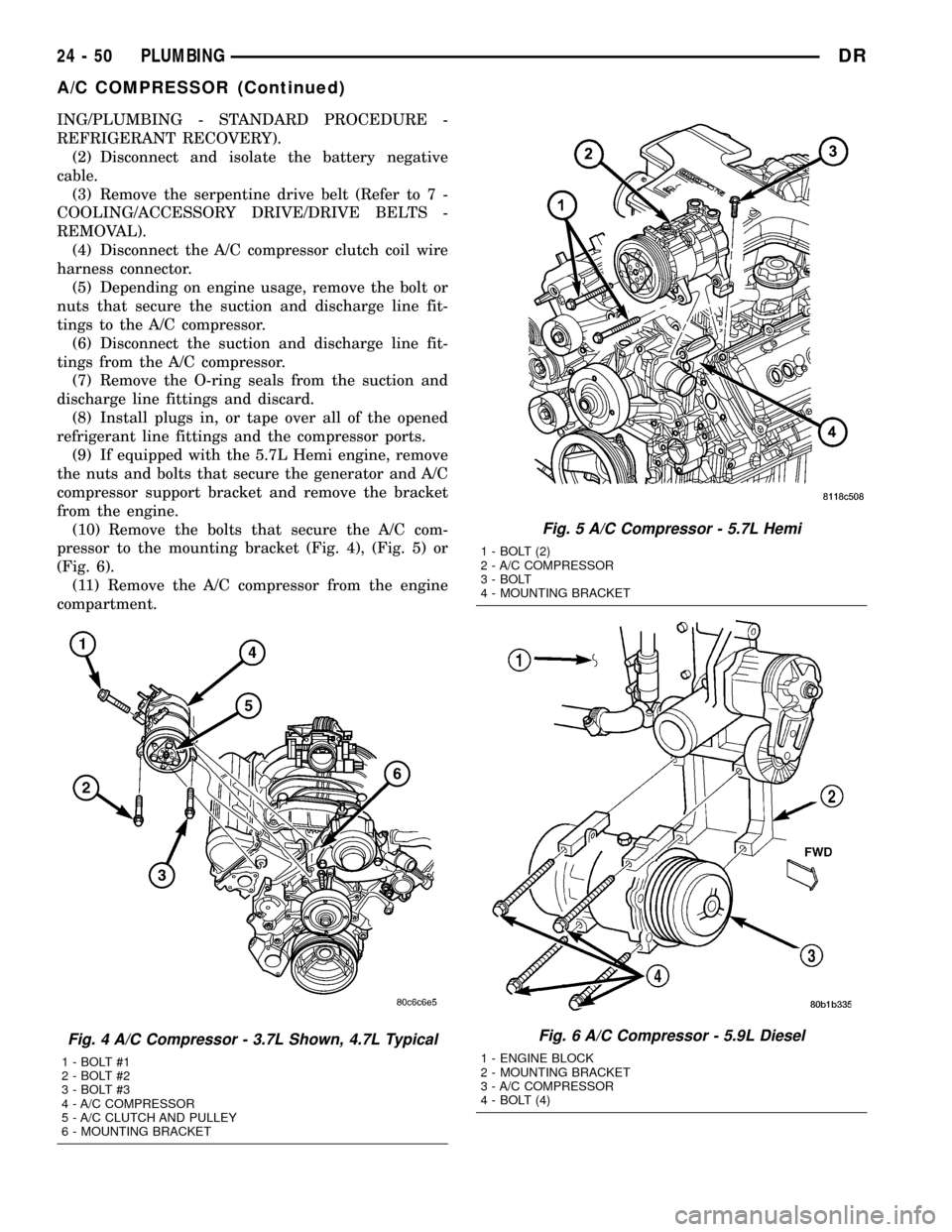

(10) Remove the bolts that secure the A/C com-

pressor to the mounting bracket (Fig. 4), (Fig. 5) or

(Fig. 6).

(11) Remove the A/C compressor from the engine

compartment.

Fig. 4 A/C Compressor - 3.7L Shown, 4.7L Typical

1 - BOLT #1

2 - BOLT #2

3 - BOLT #3

4 - A/C COMPRESSOR

5 - A/C CLUTCH AND PULLEY

6 - MOUNTING BRACKET

Fig. 5 A/C Compressor - 5.7L Hemi

1 - BOLT (2)

2 - A/C COMPRESSOR

3 - BOLT

4 - MOUNTING BRACKET

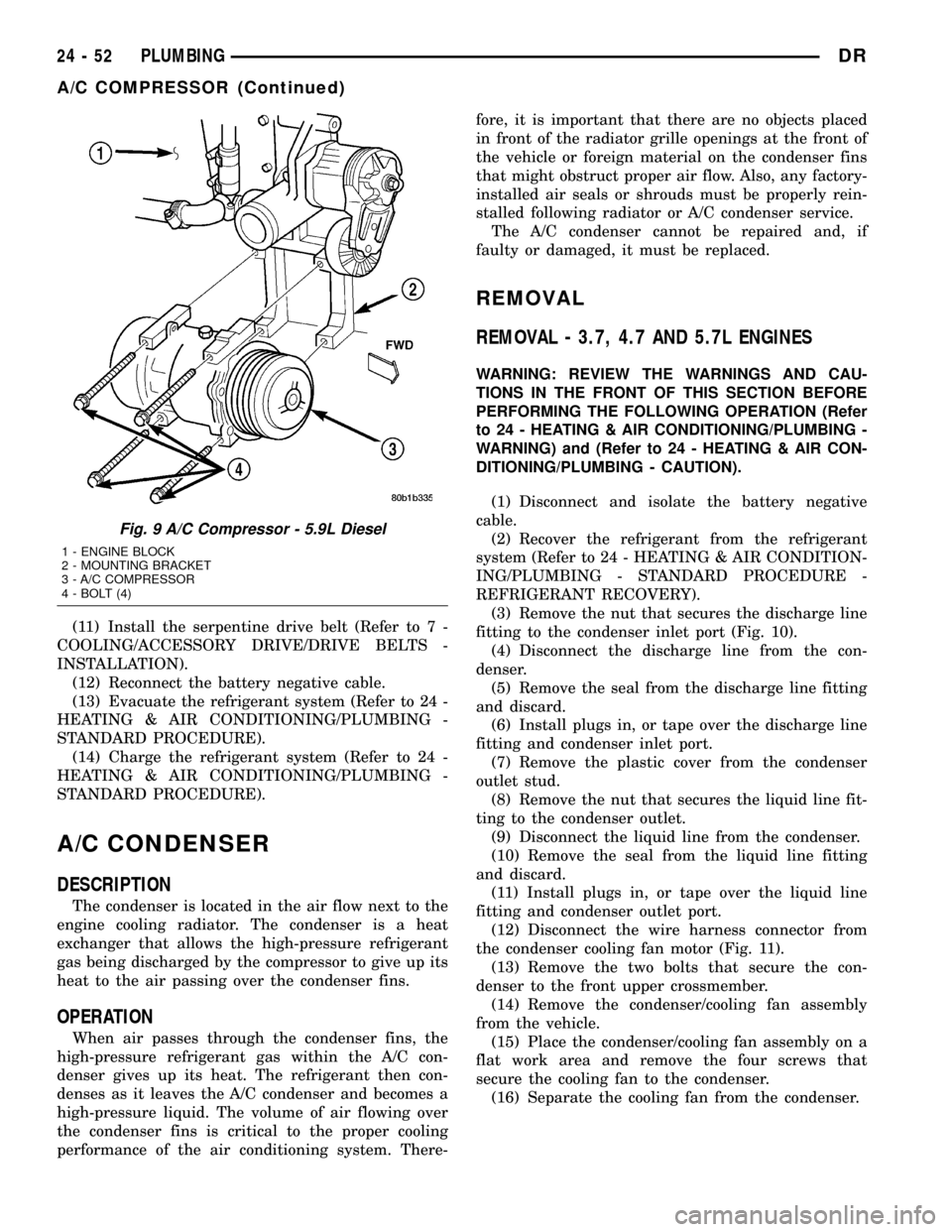

Fig. 6 A/C Compressor - 5.9L Diesel

1 - ENGINE BLOCK

2 - MOUNTING BRACKET

3 - A/C COMPRESSOR

4 - BOLT (4)

24 - 50 PLUMBINGDR

A/C COMPRESSOR (Continued)

Page 2539 of 2627

(11) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(12) Reconnect the battery negative cable.

(13) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(14) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

A/C CONDENSER

DESCRIPTION

The condenser is located in the air flow next to the

engine cooling radiator. The condenser is a heat

exchanger that allows the high-pressure refrigerant

gas being discharged by the compressor to give up its

heat to the air passing over the condenser fins.

OPERATION

When air passes through the condenser fins, the

high-pressure refrigerant gas within the A/C con-

denser gives up its heat. The refrigerant then con-

denses as it leaves the A/C condenser and becomes a

high-pressure liquid. The volume of air flowing over

the condenser fins is critical to the proper cooling

performance of the air conditioning system. There-fore, it is important that there are no objects placed

in front of the radiator grille openings at the front of

the vehicle or foreign material on the condenser fins

that might obstruct proper air flow. Also, any factory-

installed air seals or shrouds must be properly rein-

stalled following radiator or A/C condenser service.

The A/C condenser cannot be repaired and, if

faulty or damaged, it must be replaced.

REMOVAL

REMOVAL - 3.7, 4.7 AND 5.7L ENGINES

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Remove the nut that secures the discharge line

fitting to the condenser inlet port (Fig. 10).

(4) Disconnect the discharge line from the con-

denser.

(5) Remove the seal from the discharge line fitting

and discard.

(6) Install plugs in, or tape over the discharge line

fitting and condenser inlet port.

(7) Remove the plastic cover from the condenser

outlet stud.

(8) Remove the nut that secures the liquid line fit-

ting to the condenser outlet.

(9) Disconnect the liquid line from the condenser.

(10) Remove the seal from the liquid line fitting

and discard.

(11) Install plugs in, or tape over the liquid line

fitting and condenser outlet port.

(12) Disconnect the wire harness connector from

the condenser cooling fan motor (Fig. 11).

(13) Remove the two bolts that secure the con-

denser to the front upper crossmember.

(14) Remove the condenser/cooling fan assembly

from the vehicle.

(15) Place the condenser/cooling fan assembly on a

flat work area and remove the four screws that

secure the cooling fan to the condenser.

(16) Separate the cooling fan from the condenser.

Fig. 9 A/C Compressor - 5.9L Diesel

1 - ENGINE BLOCK

2 - MOUNTING BRACKET

3 - A/C COMPRESSOR

4 - BOLT (4)

24 - 52 PLUMBINGDR

A/C COMPRESSOR (Continued)