Tow plug DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1261 of 2627

VALVE GUIDE SEALS

DESCRIPTION

The valve guide seals are made of rubber and

incorporate an integral steel valve spring seat. The

integral garter spring maintains consistent lubrica-

tion control to the valve stems.

VALVE SPRINGS

DESCRIPTION

The valve springs are made from high strength

chrome silicon steel. There are different springs for

intake and exhaust applications. The exhaust spring

has an external damper. The valve spring seat is

integral with the valve stem seal, which is a positive

type seal to control lubrication.

REMOVAL

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Using Special Tool 8516 Valve Spring Compres-

sor, remove the rocker arms and the hydraulic lash

adjusters.

(3) Remove the spark plug for the cylinder the

valve spring and seal are to be removed from.

(4) Apply shop air to the cylinder to hold the

valves in place when the spring is removed.

NOTE: All six valve springs and seals are removed

in the same manner; this procedure only covers

one valve seal and valve spring.

(5) Using Special Tool 8387 Valve Spring Compres-

sor, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(6) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(7) Remove the valve spring compressor.

NOTE: The valve springs are NOT common between

intake and exhaust.

(8) Remove the spring retainer, and the spring.

(9) Remove the valve stem seal.

NOTE: The valve stem seals are common between

intake and exhaust.

INSTALLATION

NOTE: All six valve springs and seals are removed

in the same manner; this procedure only covers

one valve seal and valve spring.

(1) Apply shop air to the cylinder to hold the

valves in place while the spring is installed.

NOTE: The valve stem seals are common between

intake and exhaust.

(2) Install the valve stem seal.

NOTE: The valve springs are NOT common between

intake and exhaust.

(3) Install the spring retainer, and the spring.

(4) Using Special Tool 8387 Valve Spring Compres-

sor, compress the valve spring.

(5) Install the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(6) Remove the valve spring compressor.

(7) Disconnect the shop air to the cylinder.

(8) Install the spark plug for the cylinder the valve

spring and seal was installed on.

(9) Using Special Tool 8516 Valve Spring Compres-

sor, install the rocker arms and the hydraulic lash

adjusters.

(10) Install the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron. The block

is a closed deck design with the left bank forward. To

provide high rigidity and improved NVH an

enhanced compacted graphite bedplate is bolted to

the block. The block design allows coolant flow

between the cylinders bores, and an internal coolant

bypass to a single poppet inlet thermostat is included

in the cast aluminum front cover.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

9 - 38 ENGINE - 3.7LDR

Page 1351 of 2627

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron. The block

is a closed deck design with the left bank forward. To

provide high rigidity and improved NVH an

enhanced compacted graphite bedplate is bolted to

the block. The block design allows coolant flow

between the cylinders bores, and an internal coolant

bypass to a single poppet inlet thermostat is included

in the cast aluminum front cover.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

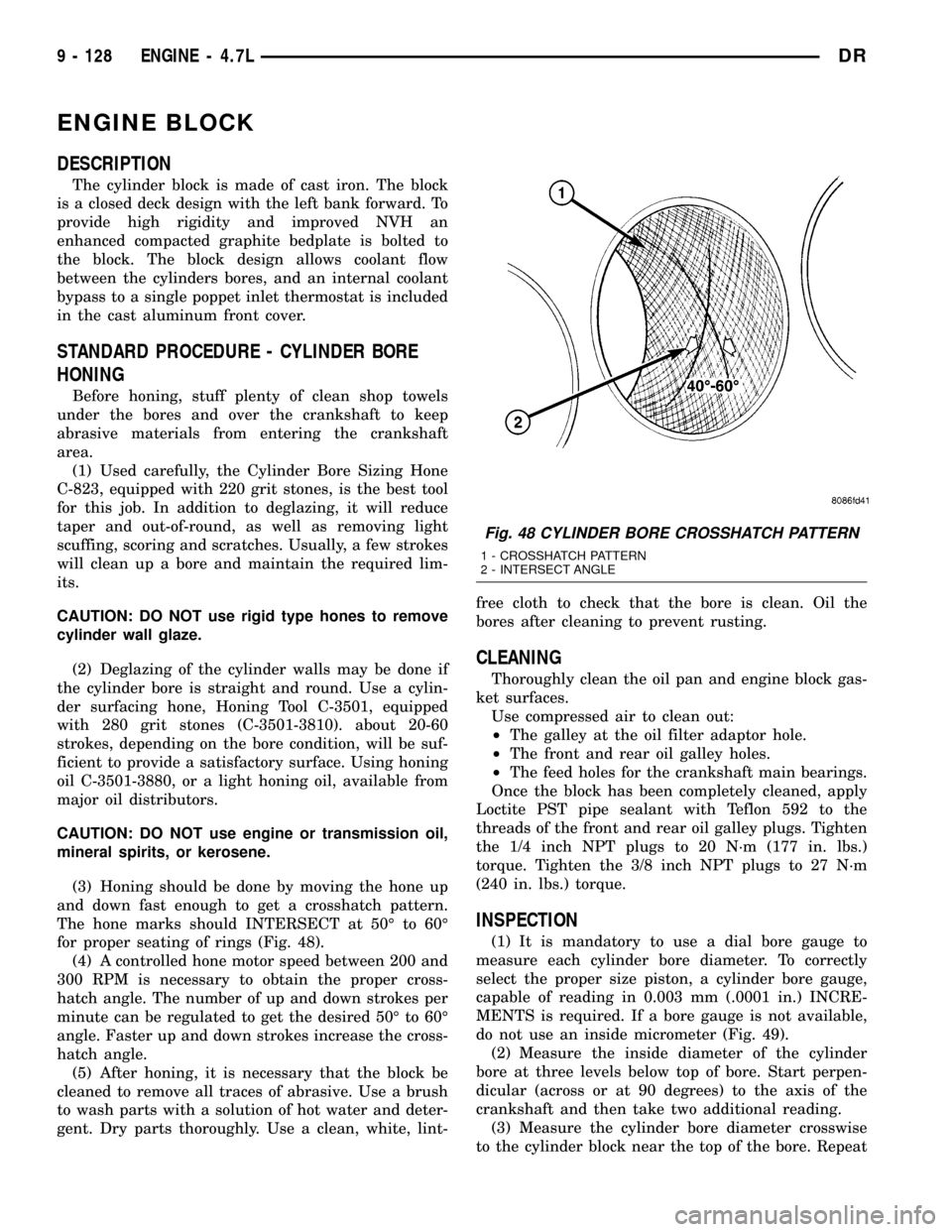

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 48).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the 1/4 inch NPT plugs to 20 N´m (177 in. lbs.)

torque. Tighten the 3/8 inch NPT plugs to 27 N´m

(240 in. lbs.) torque.

INSPECTION

(1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore gauge,

capable of reading in 0.003 mm (.0001 in.) INCRE-

MENTS is required. If a bore gauge is not available,

do not use an inside micrometer (Fig. 49).

(2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpen-

dicular (across or at 90 degrees) to the axis of the

crankshaft and then take two additional reading.

(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

Fig. 48 CYLINDER BORE CROSSHATCH PATTERN

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

9 - 128 ENGINE - 4.7LDR

Page 1413 of 2627

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE OIL CONSUMPTION OR

SPARK PLUGS OIL FOULED1. CCV System malfunction 1. (Refer to 25 - EMISSIONS

CONTROL/EVAPORATIVE

EMISSIONS - DESCRIPTION) for

correct operation

2. Defective valve stem seal(s) 2. Repair or replace seal(s)

3. Worn or broken piston rings 3. Hone cylinder bores. Install new

rings

4. Scuffed pistons/cylinder walls 4. Hone cylinder bores and replace

pistons as required

5. Carbon in oil control ring groove 5. Remove rings and de-carbon piston

6. Worn valve guides 6. Inspect/replace valve guides as

necessary

7. Piston rings fitted too tightly in

grooves7. Remove rings and check ring end

gap and side clearance. Replace if

necessary

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

REMOVAL

(1) Perform the Fuel System Pressure Release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE).

(2) Disconnect the battery negative cable.

(3) Remove the air cleaner resonator and duct

work as an assembly.

(4) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

9 - 190 ENGINE - 5.7LDR

ENGINE - 5.7L (Continued)

Page 1462 of 2627

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION/LEAKAGE TESTS

CYLINDER COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure batteries are completely charged and the

engine starter motor is in good operating condition.

Otherwise, the indicated compression pressures may

not be valid for diagnostic purposes.

(1) Disconnect the fuel inlet line to the fuel trans-

fer pump. Plug the fuel line from the fuel tank.

(2) Start the engine and idle until the engine stalls

(runs out of fuel).

(3) Disconnect all three injector wire harness con-

nectors at the rocker housing.

(4) Remove the breather cover and cylinder head

cover.

(5) Remove the high pressure fuel line between the

cylinder head and fuel rail for the cylinder to be

tested. Use tool# 9011 to cap this fuel rail on the cyl-

inder being tested.

(6) Remove the exhaust rocker lever.

(7) Use Tool 9010 to remove the injector and cop-

per sealing washer.

(8) Install the exhaust rocker lever and torque to

36 N´m (27 ft. lbs.).

(9) Cover the remaining rocker levers with clean

shop towels to prevent any oil splatter under the

hood.

(10) Place a rag over the compression test tool fit-

ting. Crank the engine for 2±3 seconds to purge any

fuel that may have drained into the cylinder when

the injector was removed.

(11) Connect the compression test gauge.

(12) Crank the engine for 5 seconds and record the

pressure reading. Repeat this step three times and

calculate the average of the three readings.

NOTE: The minimum cylinder pressure is 350 psi.

Cylinder pressure should be within 20% from cylin-

der to cylinder.

(13) Combustion pressure leakage can be checked

if cylinder pressure is below the specification. Per-

form the leakage test procedure on each cylinder

according to the tester manufacturer instructions.

(14) Upon completion of the test check an erase

any engine related fault codes.

CYLINDER COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss

(1) Start and operate the engine until it attains

normal operating temperature.

(2) Remove the breather cover and cylinder head

cover.

(3) Disconnect all three injector wire harness con-

nectors at the rocker housing.

(4) Bring the cylinder to be tested to TDC.

(5) Remove the high pressure fuel line between the

cylinder head and the fuel rail for the cylinder to be

tested.

(6) Install capping Tool 9011 onto the rail.

(7) Remove the high pressure connector nut and

high pressure connector with Tool 9015.

(8) Remove the exhaust and intake rocker lever.

(9) Use Tool 9010 to remove the injector and cop-

per sealing washer.

(10) Install compression test Tool 9007 into the

injector bore.

(11) Connect the leakage tester and perform the

leakage test procedure on each cylinder according to

the tester manufacturer's instructions.

(12) Upon completion of the test check and erase

any engine related fault codes.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

DRENGINE 5.9L DIESEL 9 - 239

ENGINE 5.9L DIESEL (Continued)

Page 1572 of 2627

(2) Remove fuel pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(3) Start and run engine until it stalls.

(4) Attempt restarting engine until it will no

longer run.

(5) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(6) Unplug connector from any fuel injector.

(7) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.

(8) Connect other end of jumper wire to positive

side of battery.(9) Connect one end of a second jumper wire to

remaining injector terminal.

CAUTION: Powering an injector for more than a few

seconds will permanently damage the injector.

(10) Momentarily touch other end of jumper wire

to negative terminal of battery for no more than a

few seconds.

(11) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(12) Disconnect quick-connect fitting at fuel rail.

Refer to Quick-Connect Fittings.

(13) Return fuel pump relay to PDC.

(14) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRBtscan tool must be

used to erase a DTC.

SPECIFICATIONS

FUEL SYSTEM PRESSURE

58 psi +/- 2 psi

TORQUE - FUEL SYSTEM - EXCEPT DIESEL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket

Mounting12 - 105

Accelerator Pedal Position

Sensor Bracket-to-Battery

Tray Bolts3-30

Crankshaft Position

Sensor - 3.7L28 21 -

Crankshaft Position

Sensor - 4.7L28 21 -

Crankshaft Position

Sensor - 5.7L12 - 105 (+/-20)

Camshaft Position Sensor

- 3.7L12 - 106

Camshaft Position Sensor

- 4.7L12 - 106

Camshaft Position Sensor

- 5.7L12 9 105 (+/-) 20

Engine Coolant

Temperature Sensor -

3.7L11 - 9 6

Engine Coolant

Temperature Sensor -

4.7L11 - 9 6

DRFUEL DELIVERY - GAS 14 - 3

FUEL DELIVERY - GAS (Continued)

Page 1627 of 2627

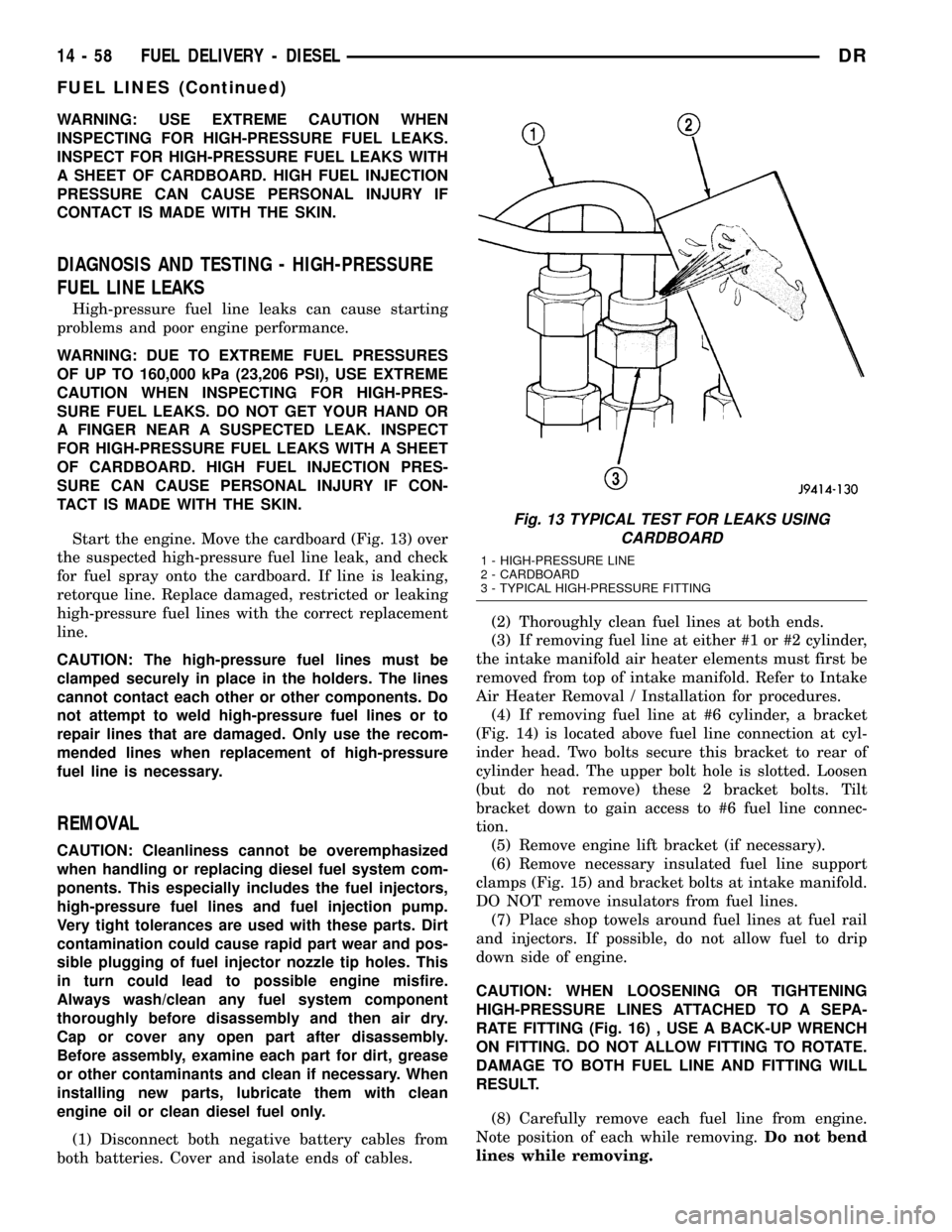

WARNING: USE EXTREME CAUTION WHEN

INSPECTING FOR HIGH-PRESSURE FUEL LEAKS.

INSPECT FOR HIGH-PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

DIAGNOSIS AND TESTING - HIGH-PRESSURE

FUEL LINE LEAKS

High-pressure fuel line leaks can cause starting

problems and poor engine performance.

WARNING: DUE TO EXTREME FUEL PRESSURES

OF UP TO 160,000 kPa (23,206 PSI), USE EXTREME

CAUTION WHEN INSPECTING FOR HIGH-PRES-

SURE FUEL LEAKS. DO NOT GET YOUR HAND OR

A FINGER NEAR A SUSPECTED LEAK. INSPECT

FOR HIGH-PRESSURE FUEL LEAKS WITH A SHEET

OF CARDBOARD. HIGH FUEL INJECTION PRES-

SURE CAN CAUSE PERSONAL INJURY IF CON-

TACT IS MADE WITH THE SKIN.

Start the engine. Move the cardboard (Fig. 13) over

the suspected high-pressure fuel line leak, and check

for fuel spray onto the cardboard. If line is leaking,

retorque line. Replace damaged, restricted or leaking

high-pressure fuel lines with the correct replacement

line.

CAUTION: The high-pressure fuel lines must be

clamped securely in place in the holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high-pressure

fuel line is necessary.

REMOVAL

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Disconnect both negative battery cables from

both batteries. Cover and isolate ends of cables.(2) Thoroughly clean fuel lines at both ends.

(3) If removing fuel line at either #1 or #2 cylinder,

the intake manifold air heater elements must first be

removed from top of intake manifold. Refer to Intake

Air Heater Removal / Installation for procedures.

(4) If removing fuel line at #6 cylinder, a bracket

(Fig. 14) is located above fuel line connection at cyl-

inder head. Two bolts secure this bracket to rear of

cylinder head. The upper bolt hole is slotted. Loosen

(but do not remove) these 2 bracket bolts. Tilt

bracket down to gain access to #6 fuel line connec-

tion.

(5) Remove engine lift bracket (if necessary).

(6) Remove necessary insulated fuel line support

clamps (Fig. 15) and bracket bolts at intake manifold.

DO NOT remove insulators from fuel lines.

(7) Place shop towels around fuel lines at fuel rail

and injectors. If possible, do not allow fuel to drip

down side of engine.

CAUTION: WHEN LOOSENING OR TIGHTENING

HIGH-PRESSURE LINES ATTACHED TO A SEPA-

RATE FITTING (Fig. 16) , USE A BACK-UP WRENCH

ON FITTING. DO NOT ALLOW FITTING TO ROTATE.

DAMAGE TO BOTH FUEL LINE AND FITTING WILL

RESULT.

(8) Carefully remove each fuel line from engine.

Note position of each while removing.Do not bend

lines while removing.

Fig. 13 TYPICAL TEST FOR LEAKS USING

CARDBOARD

1 - HIGH-PRESSURE LINE

2 - CARDBOARD

3 - TYPICAL HIGH-PRESSURE FITTING

14 - 58 FUEL DELIVERY - DIESELDR

FUEL LINES (Continued)

Page 1707 of 2627

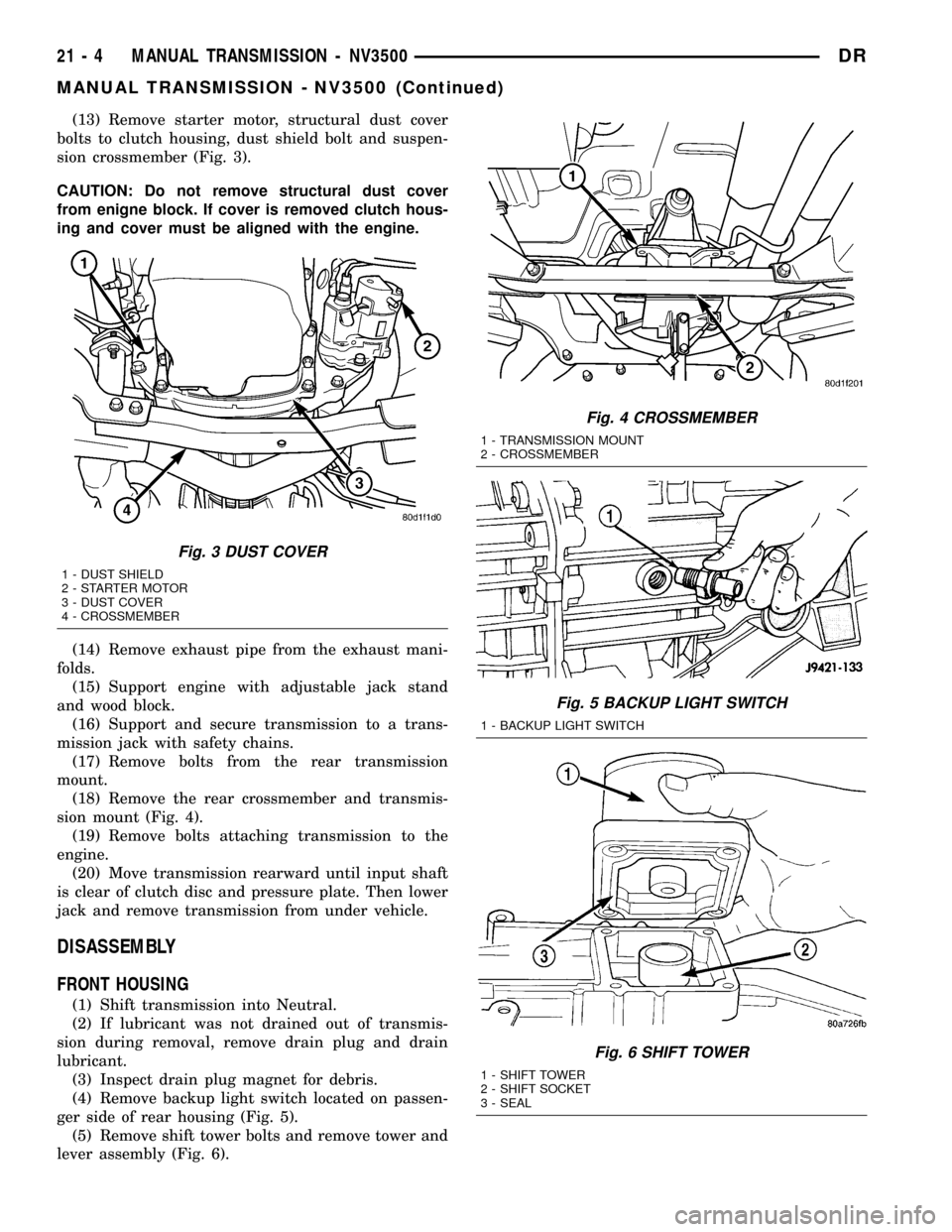

(13) Remove starter motor, structural dust cover

bolts to clutch housing, dust shield bolt and suspen-

sion crossmember (Fig. 3).

CAUTION: Do not remove structural dust cover

from enigne block. If cover is removed clutch hous-

ing and cover must be aligned with the engine.

(14) Remove exhaust pipe from the exhaust mani-

folds.

(15) Support engine with adjustable jack stand

and wood block.

(16) Support and secure transmission to a trans-

mission jack with safety chains.

(17) Remove bolts from the rear transmission

mount.

(18) Remove the rear crossmember and transmis-

sion mount (Fig. 4).

(19) Remove bolts attaching transmission to the

engine.

(20) Move transmission rearward until input shaft

is clear of clutch disc and pressure plate. Then lower

jack and remove transmission from under vehicle.

DISASSEMBLY

FRONT HOUSING

(1) Shift transmission into Neutral.

(2) If lubricant was not drained out of transmis-

sion during removal, remove drain plug and drain

lubricant.

(3) Inspect drain plug magnet for debris.

(4) Remove backup light switch located on passen-

ger side of rear housing (Fig. 5).

(5) Remove shift tower bolts and remove tower and

lever assembly (Fig. 6).

Fig. 3 DUST COVER

1 - DUST SHIELD

2 - STARTER MOTOR

3 - DUST COVER

4 - CROSSMEMBER

Fig. 4 CROSSMEMBER

1 - TRANSMISSION MOUNT

2 - CROSSMEMBER

Fig. 5 BACKUP LIGHT SWITCH

1 - BACKUP LIGHT SWITCH

Fig. 6 SHIFT TOWER

1 - SHIFT TOWER

2 - SHIFT SOCKET

3 - SEAL

21 - 4 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1741 of 2627

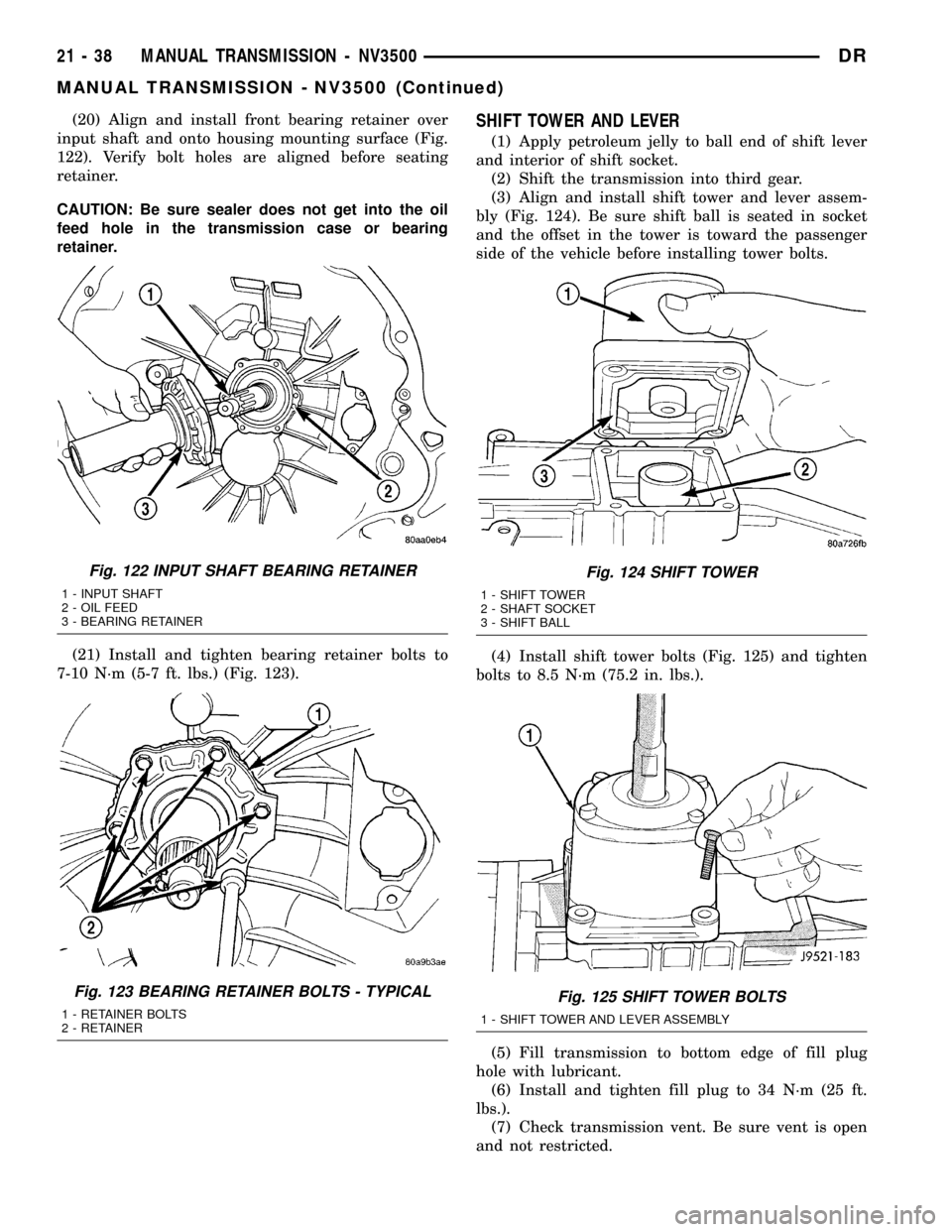

(20) Align and install front bearing retainer over

input shaft and onto housing mounting surface (Fig.

122). Verify bolt holes are aligned before seating

retainer.

CAUTION: Be sure sealer does not get into the oil

feed hole in the transmission case or bearing

retainer.

(21) Install and tighten bearing retainer bolts to

7-10 N´m (5-7 ft. lbs.) (Fig. 123).SHIFT TOWER AND LEVER

(1) Apply petroleum jelly to ball end of shift lever

and interior of shift socket.

(2) Shift the transmission into third gear.

(3) Align and install shift tower and lever assem-

bly (Fig. 124). Be sure shift ball is seated in socket

and the offset in the tower is toward the passenger

side of the vehicle before installing tower bolts.

(4) Install shift tower bolts (Fig. 125) and tighten

bolts to 8.5 N´m (75.2 in. lbs.).

(5) Fill transmission to bottom edge of fill plug

hole with lubricant.

(6) Install and tighten fill plug to 34 N´m (25 ft.

lbs.).

(7) Check transmission vent. Be sure vent is open

and not restricted.

Fig. 122 INPUT SHAFT BEARING RETAINER

1 - INPUT SHAFT

2 - OIL FEED

3 - BEARING RETAINER

Fig. 123 BEARING RETAINER BOLTS - TYPICAL

1 - RETAINER BOLTS

2 - RETAINER

Fig. 124 SHIFT TOWER

1 - SHIFT TOWER

2 - SHAFT SOCKET

3 - SHIFT BALL

Fig. 125 SHIFT TOWER BOLTS

1 - SHIFT TOWER AND LEVER ASSEMBLY

21 - 38 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1742 of 2627

INSTALLATION

NOTE: If a new transmission is being installed, use

all components supplied with the new transmission.

For example, if a new shift tower is supplied, do not

re-use the original shift tower.

(1) Clean transmission front housing mounting

surface.

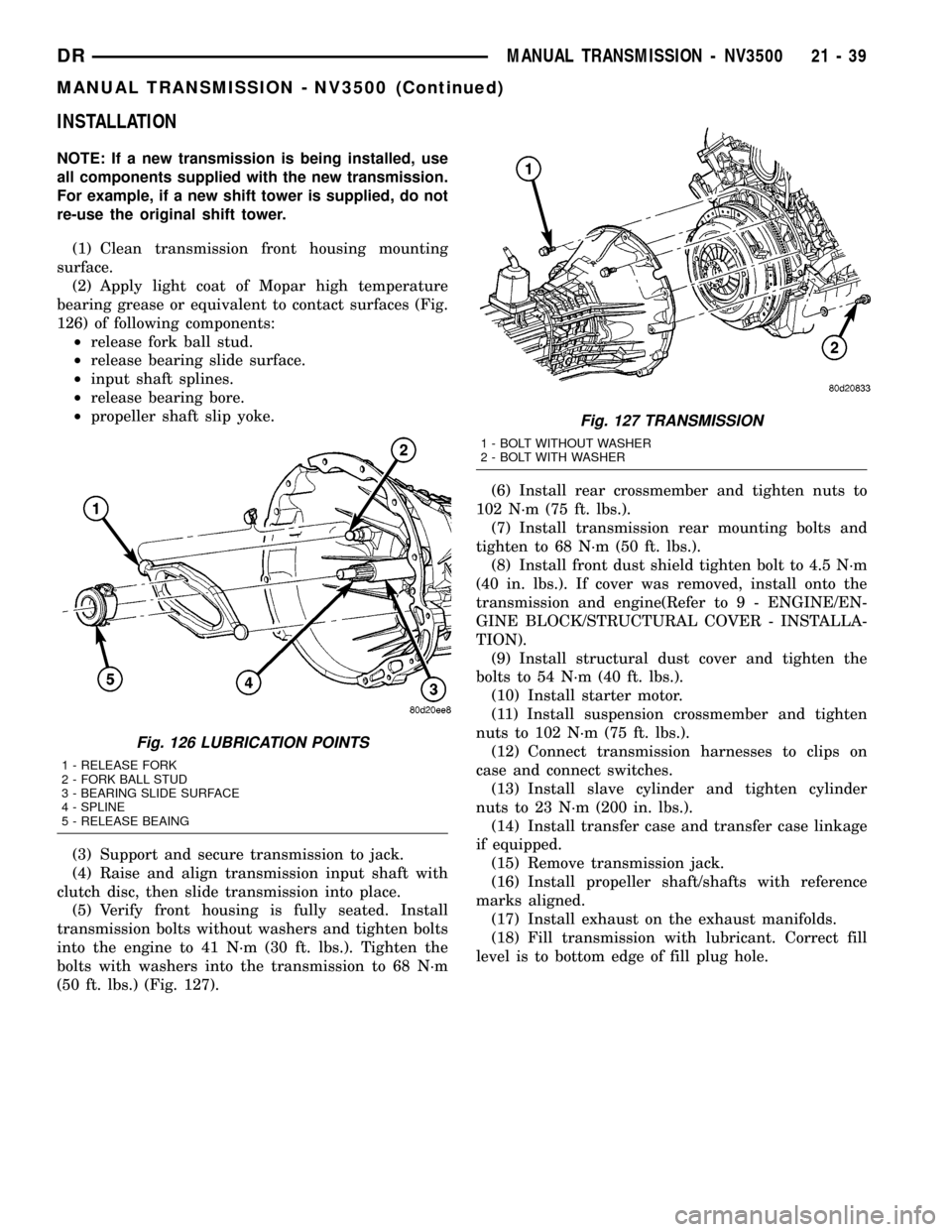

(2) Apply light coat of Mopar high temperature

bearing grease or equivalent to contact surfaces (Fig.

126) of following components:

²release fork ball stud.

²release bearing slide surface.

²input shaft splines.

²release bearing bore.

²propeller shaft slip yoke.

(3) Support and secure transmission to jack.

(4) Raise and align transmission input shaft with

clutch disc, then slide transmission into place.

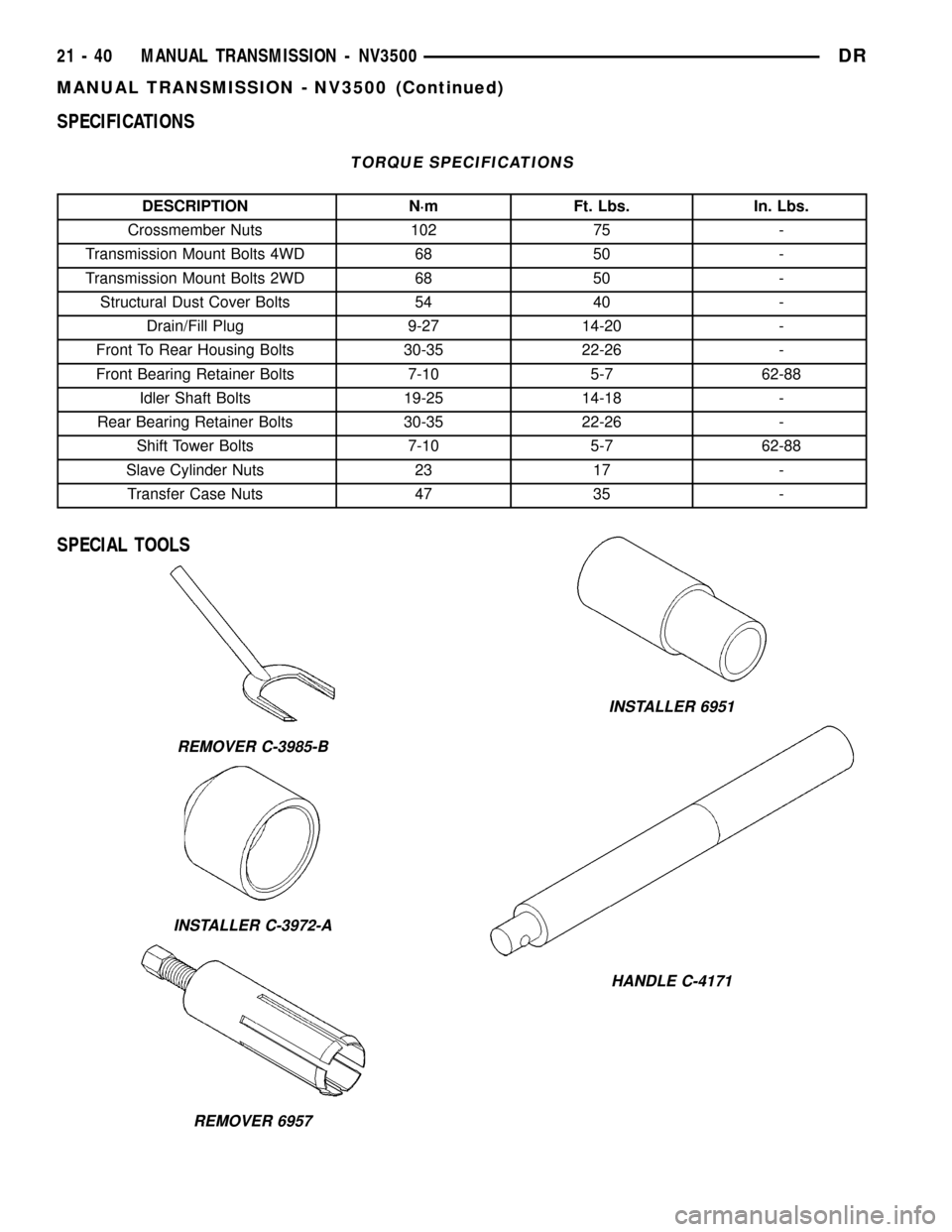

(5) Verify front housing is fully seated. Install

transmission bolts without washers and tighten bolts

into the engine to 41 N´m (30 ft. lbs.). Tighten the

bolts with washers into the transmission to 68 N´m

(50 ft. lbs.) (Fig. 127).(6) Install rear crossmember and tighten nuts to

102 N´m (75 ft. lbs.).

(7) Install transmission rear mounting bolts and

tighten to 68 N´m (50 ft. lbs.).

(8) Install front dust shield tighten bolt to 4.5 N´m

(40 in. lbs.). If cover was removed, install onto the

transmission and engine(Refer to 9 - ENGINE/EN-

GINE BLOCK/STRUCTURAL COVER - INSTALLA-

TION).

(9) Install structural dust cover and tighten the

bolts to 54 N´m (40 ft. lbs.).

(10) Install starter motor.

(11) Install suspension crossmember and tighten

nuts to 102 N´m (75 ft. lbs.).

(12) Connect transmission harnesses to clips on

case and connect switches.

(13) Install slave cylinder and tighten cylinder

nuts to 23 N´m (200 in. lbs.).

(14) Install transfer case and transfer case linkage

if equipped.

(15) Remove transmission jack.

(16) Install propeller shaft/shafts with reference

marks aligned.

(17) Install exhaust on the exhaust manifolds.

(18) Fill transmission with lubricant. Correct fill

level is to bottom edge of fill plug hole.

Fig. 126 LUBRICATION POINTS

1 - RELEASE FORK

2 - FORK BALL STUD

3 - BEARING SLIDE SURFACE

4 - SPLINE

5 - RELEASE BEAING

Fig. 127 TRANSMISSION

1 - BOLT WITHOUT WASHER

2 - BOLT WITH WASHER

DRMANUAL TRANSMISSION - NV3500 21 - 39

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1743 of 2627

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Crossmember Nuts 102 75 -

Transmission Mount Bolts 4WD 68 50 -

Transmission Mount Bolts 2WD 68 50 -

Structural Dust Cover Bolts 54 40 -

Drain/Fill Plug 9-27 14-20 -

Front To Rear Housing Bolts 30-35 22-26 -

Front Bearing Retainer Bolts 7-10 5-7 62-88

Idler Shaft Bolts 19-25 14-18 -

Rear Bearing Retainer Bolts 30-35 22-26 -

Shift Tower Bolts 7-10 5-7 62-88

Slave Cylinder Nuts 23 17 -

Transfer Case Nuts 47 35 -

SPECIAL TOOLS

REMOVER C-3985-B

INSTALLER C-3972-A

REMOVER 6957

INSTALLER 6951

HANDLE C-4171

21 - 40 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)