belt DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 31 of 2627

![DODGE RAM 1500 1998 2.G User Guide Miles 82,500 90,000 97,500 100,000 105,000

(Kilometers) (132 000) (144 000) (156 000) (160 000) (168 000)

[Months] [66] [72] [78] [84]

Change engine oil and engine oil filter. X² XL²X² XL²

Lubrica DODGE RAM 1500 1998 2.G User Guide Miles 82,500 90,000 97,500 100,000 105,000

(Kilometers) (132 000) (144 000) (156 000) (160 000) (168 000)

[Months] [66] [72] [78] [84]

Change engine oil and engine oil filter. X² XL²X² XL²

Lubrica](/img/12/5702/w960_5702-30.png)

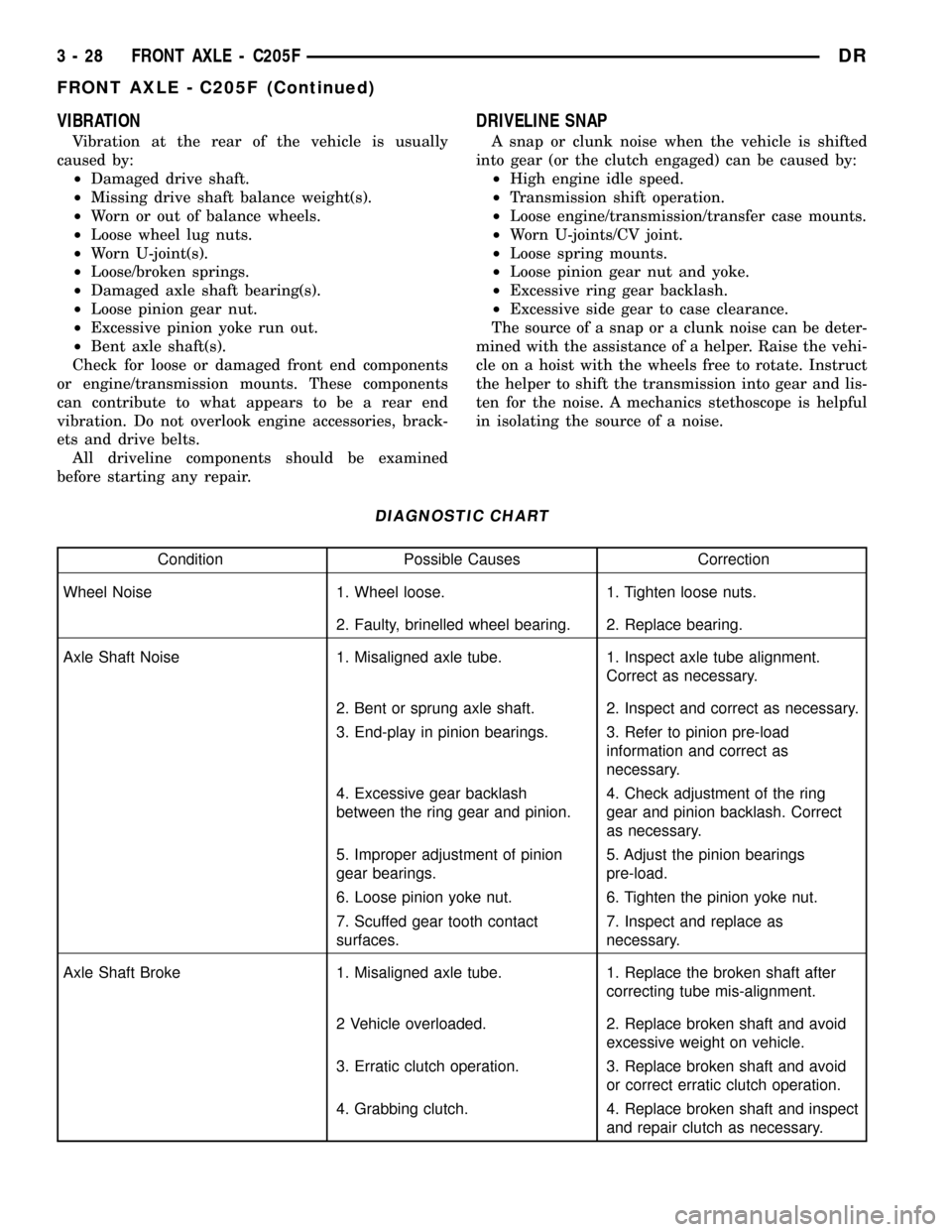

Miles 82,500 90,000 97,500 100,000 105,000

(Kilometers) (132 000) (144 000) (156 000) (160 000) (168 000)

[Months] [66] [72] [78] [84]

Change engine oil and engine oil filter. X² XL²X² XL²

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XXXX X

Flush and replace engine coolant, if not

done at 60 mos.X

Check transfer case fluid level (4X4). X

Inspect drive belt, replace as required. X

Inspect fan hub. X

Inspect damper. X

Inspect water pump weep hole for

blockage.XX

Replace fuel filter element. Clean the water

in fuel sensor.XX

Inspect front wheel bearings. X

Inspect brake linings. X

Inspect and adjust parking brake if

necessary.X

Drain and refill automatic transmission fluid.

Replace filter and adjust bands.X

Miles 112,500 120,000 127,500 135,000 142,500 150,000

(Kilometers) (181 000) (193 000) (205 000) (217 000) (229 000) (241 000)

[Months] [90] [96] [102] [108] [114] [150]

Change engine oil and engine

oil filter.X² XL²X²XL²X² XL²

Lubricate outer tie rod ends

2500/3500 (4X4) models only.XXXXX X

Flush and replace engine

coolant, if it has been 160

000 km (100, 000 miles) or 60

months since last change.X

Inspect drive belt, replace as

required.XX

Drain and refill transfer case

fluid (4X4).X

Check tranfer case fluid level

(4X4).X

Inspect fan hub. X X

Inspect damper. X X

Inspect water pump weep

hole for blockage.XXX

Replace fuel filter element.

Clean the water in fuel

sensor.XXX

0 - 18 LUBRICATION & MAINTENANCEDR

MAINTENANCE SCHEDULES (Continued)

Page 32 of 2627

![DODGE RAM 1500 1998 2.G User Guide Miles 112,500 120,000 127,500 135,000 142,500 150,000

(Kilometers) (181 000) (193 000) (205 000) (217 000) (229 000) (241 000)

[Months] [90] [96] [102] [108] [114] [150]

Inspect front wheel bearings. DODGE RAM 1500 1998 2.G User Guide Miles 112,500 120,000 127,500 135,000 142,500 150,000

(Kilometers) (181 000) (193 000) (205 000) (217 000) (229 000) (241 000)

[Months] [90] [96] [102] [108] [114] [150]

Inspect front wheel bearings.](/img/12/5702/w960_5702-31.png)

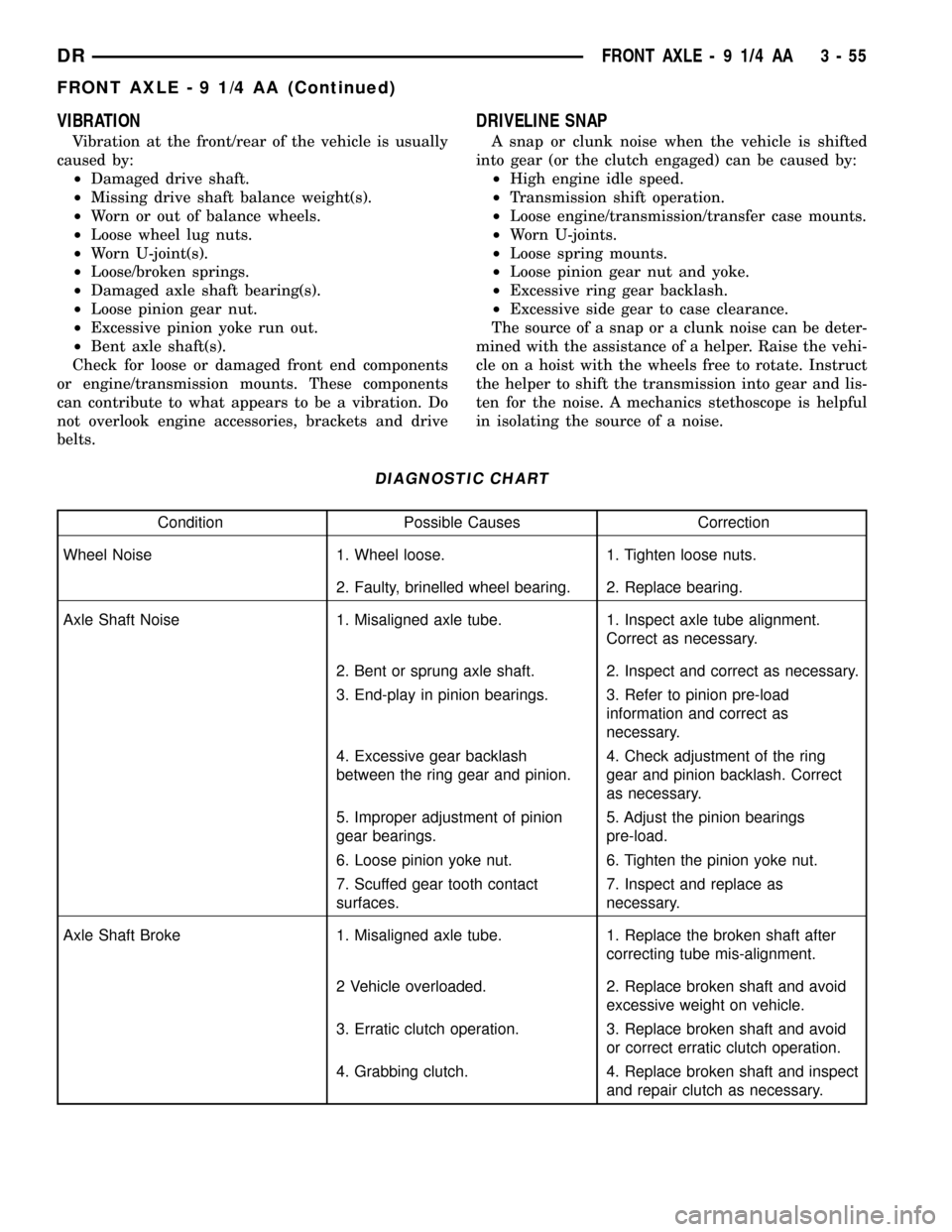

Miles 112,500 120,000 127,500 135,000 142,500 150,000

(Kilometers) (181 000) (193 000) (205 000) (217 000) (229 000) (241 000)

[Months] [90] [96] [102] [108] [114] [150]

Inspect front wheel bearings. X X

Inspect brake linings. X X

Inspect and adjust parking

brake if necessary.XX

Adjust valve lash clearance.X

²LTier 1 EPA (250 hp or 305 hp) Engines Only

(see engine data label for your engine type)

²² California LEV (235 hp) Engines Only (see

engine data label for your engine type)

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN THE BATTERY SYSTEM SEC-

TION OF THE SERVICE MANUAL. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY - STAN-

DARD PROCEDURE)

²DO NOT JUMP START A FROZEN BATTERY,

PERSONAL INJURY CAN RESULT.

²IF EQUIPPED, DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR.

²DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

²DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

²DO NOT USE OPEN FLAME NEAR BATTERY.

²REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

²WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO

EXCEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible.

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

DRLUBRICATION & MAINTENANCE 0 - 19

MAINTENANCE SCHEDULES (Continued)

Page 109 of 2627

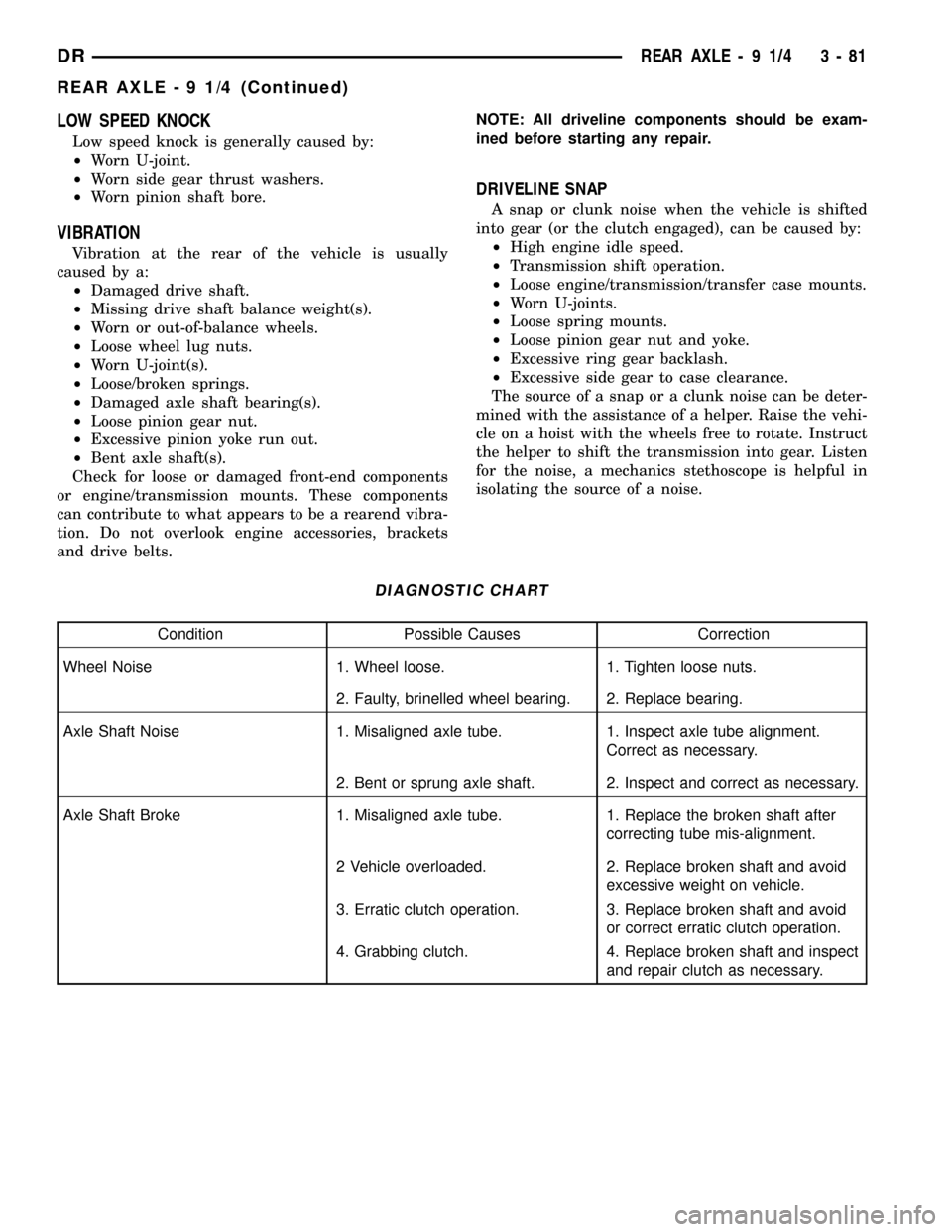

VIBRATION

Vibration at the rear of the vehicle is usually

caused by:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out of balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear end

vibration. Do not overlook engine accessories, brack-

ets and drive belts.

All driveline components should be examined

before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged) can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints/CV joint.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear and lis-

ten for the noise. A mechanics stethoscope is helpful

in isolating the source of a noise.

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

3. End-play in pinion bearings. 3. Refer to pinion pre-load

information and correct as

necessary.

4. Excessive gear backlash

between the ring gear and pinion.4. Check adjustment of the ring

gear and pinion backlash. Correct

as necessary.

5. Improper adjustment of pinion

gear bearings.5. Adjust the pinion bearings

pre-load.

6. Loose pinion yoke nut. 6. Tighten the pinion yoke nut.

7. Scuffed gear tooth contact

surfaces.7. Inspect and replace as

necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

3 - 28 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 136 of 2627

VIBRATION

Vibration at the front/rear of the vehicle is usually

caused by:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out of balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front end components

or engine/transmission mounts. These components

can contribute to what appears to be a vibration. Do

not overlook engine accessories, brackets and drive

belts.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged) can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear and lis-

ten for the noise. A mechanics stethoscope is helpful

in isolating the source of a noise.

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

3. End-play in pinion bearings. 3. Refer to pinion pre-load

information and correct as

necessary.

4. Excessive gear backlash

between the ring gear and pinion.4. Check adjustment of the ring

gear and pinion backlash. Correct

as necessary.

5. Improper adjustment of pinion

gear bearings.5. Adjust the pinion bearings

pre-load.

6. Loose pinion yoke nut. 6. Tighten the pinion yoke nut.

7. Scuffed gear tooth contact

surfaces.7. Inspect and replace as

necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

DRFRONT AXLE - 9 1/4 AA 3 - 55

FRONT AXLE - 9 1/4 AA (Continued)

Page 162 of 2627

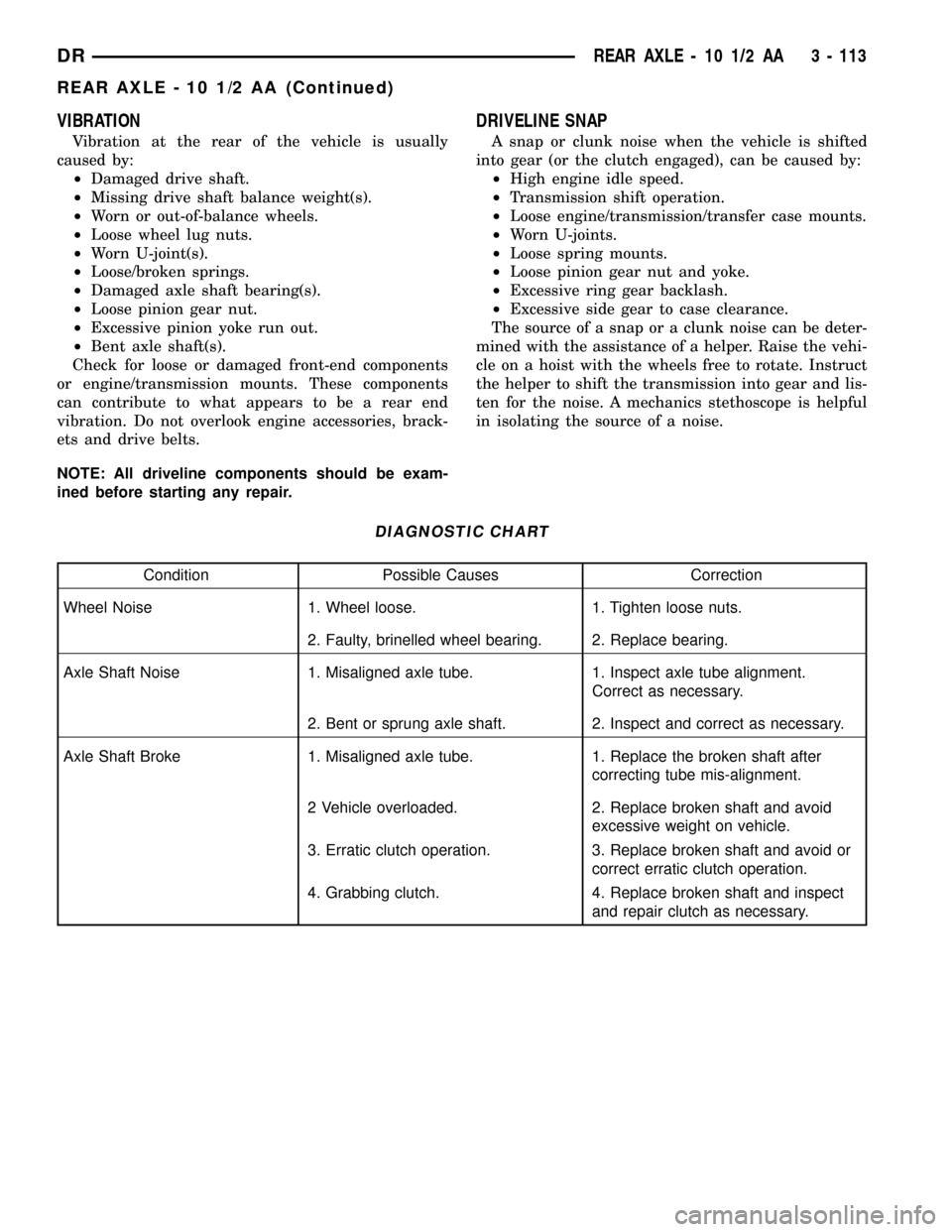

LOW SPEED KNOCK

Low speed knock is generally caused by:

²Worn U-joint.

²Worn side gear thrust washers.

²Worn pinion shaft bore.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

DRREAR AXLE - 9 1/4 3 - 81

REAR AXLE - 9 1/4 (Continued)

Page 194 of 2627

VIBRATION

Vibration at the rear of the vehicle is usually

caused by:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear end

vibration. Do not overlook engine accessories, brack-

ets and drive belts.

NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear and lis-

ten for the noise. A mechanics stethoscope is helpful

in isolating the source of a noise.

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid or

correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

DRREAR AXLE - 10 1/2 AA 3 - 113

REAR AXLE - 10 1/2 AA (Continued)

Page 222 of 2627

VIBRATION

Vibration at the rear of the vehicle is usually

caused by:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear end

vibration. Do not overlook engine accessories, brack-

ets and drive belts.

NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear and lis-

ten for the noise. A mechanics stethoscope is helpful

in isolating the source of a noise.

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid or

correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

DRREAR AXLE - 11 1/2 AA 3 - 141

REAR AXLE - 11 1/2 AA (Continued)

Page 280 of 2627

HYDRAULIC BOOSTER DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Slow Brake Pedal Return 1. Excessive seal friction in booster. 1. Replace booster.

2. Faulty spool valve action. 2. Replace booster.

3. Restriction in booster return hose. 3. Replace hose.

4. Damaged input rod. 4. Replace booster.

Excessive Brake Pedal

Effort.1. Internal or external seal leakage. 1. Replace booster.

2. Faulty steering pump. 2. Replace pump.

Brakes Self Apply 1. Dump valve faulty. 1. Replace booster.

2. Contamination in hydraulic

system.2. Flush hydraulic system and replace

booster.

3. Restriction in booster return hose. 3. Replace hose.

Booster Chatter, Pedal

Vibration1. Slipping pump belt. 1. Replace power steering belt.

2. Low pump fluid level. 2. Fill pump and check for leaks.

Grabbing Brakes 1. Low pump flow. 1. Test and repair/replace pump.

2. Faulty spool valve action. 2. Replace booster.

STANDARD PROCEDURE - BLEEDING

The hydraulic booster is generally self-bleeding,

this procedure will normally bleed the air from the

booster. Normal driving and operation of the unit will

remove any remaining trapped air.

(1) Fill power steering pump reservoir.

(2) Disconnect fuel shutdown relay and crank the

engine for several seconds, Refer to Fuel System for

relay location and WARNING.

(3) Check fluid level and add if necessary.

(4) Connect fuel shutdown relay and start the

engine.

(5) Turn the steering wheel slowly from lock to

lock twice.

(6) Stop the engine and discharge the accumulator

by depressing the brake pedal 5 times.

(7) Start the engine and turn the steering wheel

slowly from lock to lock twice.

(8) Turn off the engine and check fluid level and

add if necessary.

NOTE: If fluid foaming occurs, wait for foam to dis-

sipate and repeat steps 7 and 8.

REMOVAL

NOTE: If the booster is being replaced because the

power steering fluid is contaminated, flush the

power steering system before replacing the booster.

(1) With engine off depress the brake pedal 5

times to discharge the accumulator.

(2) Remove brake lines from master cylinder.

(3) Remove mounting nuts from the master cylin-

der.

(4) Remove the bracket from the hydraulic booster

lines and master cylinder mounting studs.

(5) Remove the master cylinder.

(6) Remove the return hose and the two pressure

lines from the hydraulic booster (Fig. 55).

(7) Remove the booster push rod clip, washer and

rod remove from the brake pedal.

(8) Remove the mounting nuts from the hydraulic

booster and remove the booster.

DRBRAKES - BASE 5 - 31

HYDRO-BOOST BRAKE BOOSTER (Continued)

Page 318 of 2627

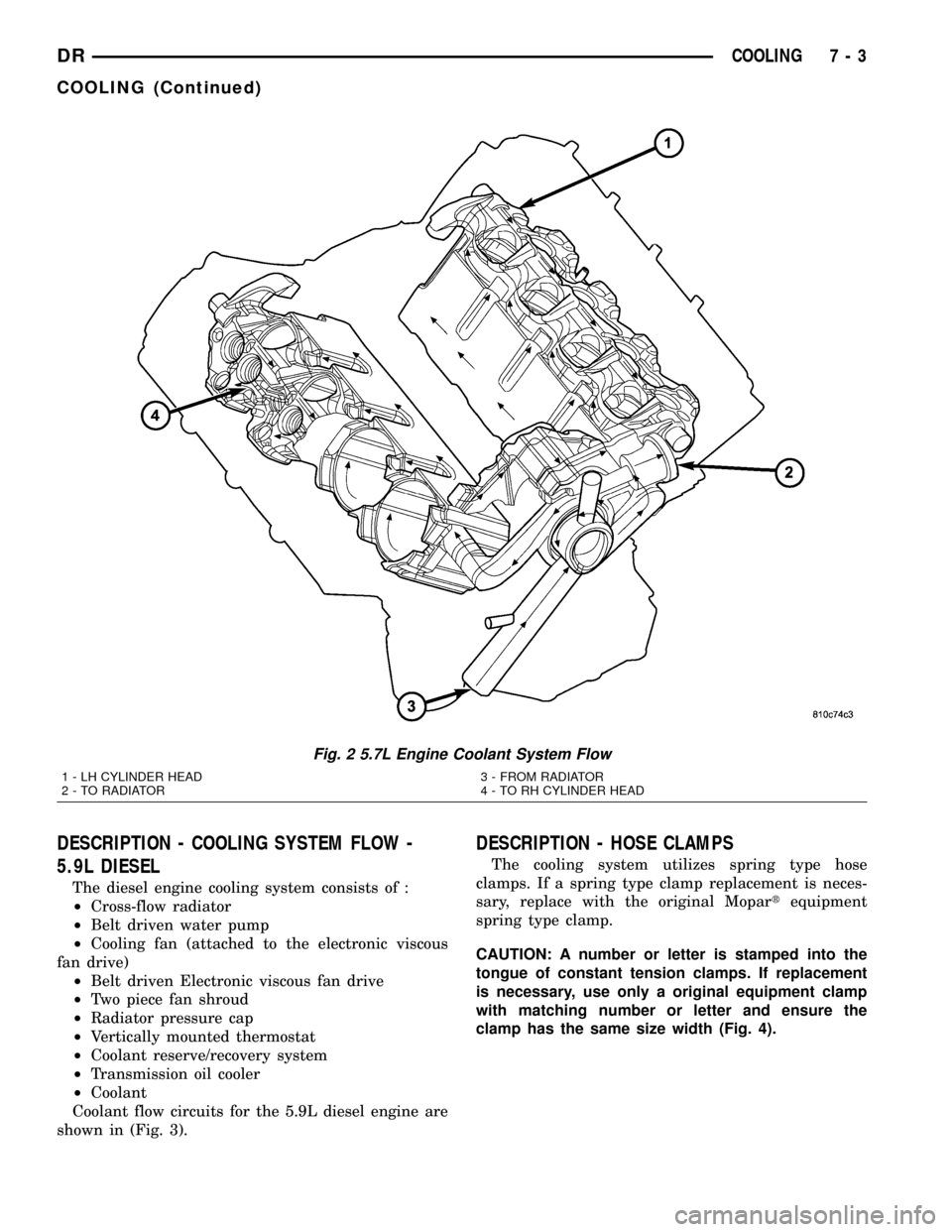

DESCRIPTION - COOLING SYSTEM FLOW -

5.9L DIESEL

The diesel engine cooling system consists of :

²Cross-flow radiator

²Belt driven water pump

²Cooling fan (attached to the electronic viscous

fan drive)

²Belt driven Electronic viscous fan drive

²Two piece fan shroud

²Radiator pressure cap

²Vertically mounted thermostat

²Coolant reserve/recovery system

²Transmission oil cooler

²Coolant

Coolant flow circuits for the 5.9L diesel engine are

shown in (Fig. 3).

DESCRIPTION - HOSE CLAMPS

The cooling system utilizes spring type hose

clamps. If a spring type clamp replacement is neces-

sary, replace with the original Mopartequipment

spring type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter and ensure the

clamp has the same size width (Fig. 4).

Fig. 2 5.7L Engine Coolant System Flow

1 - LH CYLINDER HEAD

2 - TO RADIATOR3 - FROM RADIATOR

4 - TO RH CYLINDER HEAD

DRCOOLING 7 - 3

COOLING (Continued)

Page 322 of 2627

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINECOOLANT THERMOSTAT - REMOVAL). Remove

accessory drive belt (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of the top of the thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

DIAGNOSIS AND TESTING - COOLING SYSTEM DIESEL ENGINE

COOLING SYSTEM DIAGNOSIS - DIESEL ENGINE

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READS

LOW1. Vehicle is equipped with a heavy

duty cooling system.1. None. System operating normally.

NOTE: Information on dash cluster

is displayed based on broadcast

datd from ECM. DTC will be set for

engine sensore circuit concern.2. Thermostat stuck open 2. Inspect and test thermostat.

3. Coolant level low. 3. Fill cooling system. (Refer to 7 -

COOLING - STANDARD

PROCEDURE)

4. Temperature gauge not

functioning correctly.4. Check cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING)

5. Engine sensor stuck in range 5. Monitor sensor with DRB III to

verify sensor reading changes with

increasing temperature.

6. Engine sensor failed out of

range.A DTC will be set.

7. Electronically Controlled Vicsous

Fan Drive not operating properly.7. Check Electronically Controlled

Viscous Fan Drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

DRCOOLING 7 - 7

COOLING (Continued)