headlamp DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 513 of 2627

²Exterior Lighting Fail-safe- In the absence of

a headlamp switch input, the EMIC will turn on the

cluster illumination lamps and provide electronic

headlamp low beam and park lamp request messages

to the Front Control Module (FCM) located on the

Integrated Power Module (IPM) for default exterior

lamp operation. The FCM will also provide default

park lamp and headlamp low beam operation and the

EMIC will turn on the cluster illumination lamps if

there is a failure of the electronic data bus commu-

nication between the EMIC and the FCM.

²Heated Seat Control- The EMIC monitors

inputs from the ignition switch and electronic engine

speed messages from the Powertrain Control Module

(PCM) to control a high side driver output to the

heated seat switch Light Emitting Diode (LED) indi-

cators. This input allows the heated seat switches to

wake up the heated seat module if the switch is actu-

ated. The EMIC will de-energize the heated seat

switch LED indicators, which deactivates the heated

seat system, if the ignition switch is turned to any

position except On or Start, or if the engine speed

message indicates zero. (Refer to 8 - ELECTRICAL/

HEATED SEATS - DESCRIPTION).

²Interior Lamp Load Shedding- The EMIC

provides a battery saver feature which will automat-

ically turn off all interior lamps that remain on after

a timed interval of about fifteen minutes.

²Interior Lamps - Enhanced Accident

Response- The EMIC monitors inputs from the Air-

bag Control Module (ACM) and the Powertrain Con-

trol Module (PCM) to automatically turn on the

interior lighting after an airbag deployment event

ten seconds after the vehicle speed is zero. The inte-

rior lighting remains illuminated until the key is

removed from the ignition switch lock cylinder, at

which time the interior lighting returns to normal

operation and control. This feature, like all other

enhanced accident response features, is dependent

upon a functional vehicle electrical system following

the vehicle impact event.

²Interior Lighting Control- The EMIC moni-

tors inputs from the interior lighting switch, the door

ajar switches, the cargo lamp switch, the reading

lamp switches, and the Remote Keyless Entry (RKE)

module to provide courtesy lamp control. This

includes support for timed illuminated entry with

theater-style fade-to-off and courtesy illumination

defeat features.

²Lamp Out Indicator Control- The EMIC

monitors electronic lamp outage messages from the

Front Control Module (FCM) located on the Inte-

grated Power Module (IPM) in order to provide lamp

out indicator control for the headlamps (low and high

beams), turn signal lamps, and the brake lamps

(excluding CHMSL).²Panel Lamps Dimming Control- The EMIC

provides a hard wired 12-volt Pulse-Width Modulated

(PWM) output that synchronizes the dimming level

of all hard wired panel lamps dimmer controlled

lamps with that of the cluster illumination lamps.

²Parade Mode- The EMIC provides a parade

mode (also known as funeral mode) that allows all

Vacuum-Fluorescent Display (VFD) units in the vehi-

cle to be illuminated at full (daytime) intensity while

driving during daylight hours with the exterior

lamps turned on.

²Power Locks- The EMIC monitors inputs from

the power lock switches and the Remote Keyless

Entry (RKE) receiver module (optional) to provide

control of the power lock motors through high side

driver outputs to the power lock motors. This

includes support for rolling door locks (also known as

automatic door locks), automatic door unlock, a door

lock inhibit mode, and central locking (with the

optional Vehicle Theft Security System only). (Refer

to 8 - ELECTRICAL/POWER LOCKS - DESCRIP-

TION).

²Remote Keyless Entry- The EMIC supports

the optional Remote Keyless Entry (RKE) system fea-

tures, including support for the RKE Lock, Unlock

(with optional driver-door-only unlock, and unlock-

all-doors), Panic, audible chirp, optical chirp, illumi-

nated entry modes, an RKE programming mode, as

well as optional Vehicle Theft Security System

(VTSS) arming (when the proper VTSS arming con-

ditions are met) and disarming.

²Remote Radio Switch Interface- The EMIC

monitors inputs from the optional remote radio

switches and then provides the appropriate electronic

data bus messages to the radio to select the radio

operating mode, volume control, preset station scan

and station seek features.

²Rolling Door Locks- The EMIC provides sup-

port for the power lock system rolling door locks fea-

ture (also known as automatic door locks). This

feature will automatically lock all unlocked doors

each time the vehicle speed reaches twenty-four kilo-

meters-per-hour (fifteen miles-per-hour). Following

an automatic lock event, if the driver side front door

is opened first after the ignition is turned to the Off

position, all doors will be automatically unlocked.

²Turn Signal & Hazard Warning Lamp Con-

trol- The EMIC provides electronic turn and hazard

lamp request messages to the Front Control Module

(FCM) located on the Integrated Power Module (IPM)

for turn and hazard lamp control. The EMIC also

provides an audible click at one of two rates to emu-

late normal and bulb out turn or hazard flasher oper-

ation based upon electronic lamp outage messages

from the FCM, and provides an audible turn signal

on chime warning if a turn is signalled continuously

8J - 4 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 517 of 2627

sage-controlled functions of the cluster by lighting

the appropriate indicators, positioning the gauge nee-

dles at several predetermined calibration points

across the gauge faces, and illuminating all segments

of the odometer/trip odometer and gear selector indi-

cator Vacuum-Fluorescent Display (VFD) units.

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). See the owner's

manual in the vehicle glove box for more information

on the features, use and operation of the EMIC.

GAUGES

All gauges receive battery current through the

EMIC circuitry only when the ignition switch is in

the On or Start positions. With the ignition switch in

the Off position battery current is not supplied to

any gauges, and the EMIC circuitry is programmed

to move all of the gauge needles back to the low end

of their respective scales. Therefore, the gauges do

not accurately indicate any vehicle condition unless

the ignition switch is in the On or Start positions.

All of the EMIC gauges are air core magnetic

units. Two fixed electromagnetic coils are located

within each gauge. These coils are wrapped at right

angles to each other around a movable permanent

magnet. The movable magnet is suspended within

the coils on one end of a pivot shaft, while the gauge

needle is attached to the other end of the shaft. One

of the coils has a fixed current flowing through it to

maintain a constant magnetic field strength. Current

flow through the second coil changes, which causes

changes in its magnetic field strength. The current

flowing through the second coil is changed by the

EMIC circuitry in response to messages received over

the PCI data bus. The gauge needle moves as the

movable permanent magnet aligns itself to the

changing magnetic fields created around it by the

electromagnets.

The gauges are diagnosed using the EMIC self-di-

agnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the electronic data bus message inputs to the EMIC

that control each gauge require the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Specific operation details for each gauge may

be found elsewhere in this service information.

VACUUM-FLUORESCENT DISPLAYS

The Vacuum-Fluorescent Display (VFD) units are

soldered to the EMIC electronic circuit board. With

the ignition switch in the Off or Accessory positions,

the odometer display is activated when the driver

door is opened (Rental Car mode) and is deactivated

when the driver door is closed. Otherwise, both dis-

play units are active when the ignition switch is inthe On or Start positions, and inactive when the igni-

tion switch is in the Off or Accessory positions.

The illumination intensity of the VFD units is con-

trolled by the EMIC circuitry based upon an input

from the headlamp switch and a dimming level input

received from the headlamp dimmer switch. The

EMIC synchronizes the illumination intensity of

other VFD units with that of the units in the EMIC

by sending electronic dimming level messages to

other electronic modules in the vehicle over the PCI

data bus.

The EMIC VFD units have several display capabil-

ities including odometer, trip odometer, engine hours,

gear selector indication (PRNDL) for models with an

automatic transmission, several warning or reminder

indications, and various diagnostic information when

certain fault conditions exist. An odometer/trip odom-

eter switch on the EMIC circuit board is used to con-

trol some of the display modes. This switch is

actuated manually by depressing the odometer/trip

odometer switch button that extends through the

lower edge of the cluster lens, just left of the tachom-

eter. Actuating this switch momentarily with the

ignition switch in the On position will toggle the

VFD between the odometer and trip odometer modes.

Depressing the switch button for about two seconds

while the VFD is in the trip odometer mode will

reset the trip odometer value to zero. While in the

odometer mode with the ignition switch in the On

position and the engine not running, depressing this

switch for about six seconds will display the engine

hours information. Holding this switch depressed

while turning the ignition switch from the Off posi-

tion to the On position will initiate the EMIC self-di-

agnostic actuator test. Refer to the appropriate

diagnostic information for additional details on this

VFD function. The EMIC microprocessor remembers

which display mode is active when the ignition

switch is turned to the Off position, and returns the

VFD display to that mode when the ignition switch is

turned On again.

The VFD units are diagnosed using the EMIC self-

diagnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the electronic data bus message inputs to the EMIC

that control some of the VFD functions requires the

use of a DRBIIItscan tool. Refer to the appropriate

diagnostic information. Specific operation details for

the odometer, the trip odometer, the gear selector

indicator and the various warning and reminder indi-

cator functions of the VFD may be found elsewhere

in this service information.

8J - 8 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 518 of 2627

INDICATORS

Indicators are located in various positions within

the EMIC and are all connected to the EMIC elec-

tronic circuit board. The cargo lamp indicator, door

ajar indicator, high beam indicator, and turn signal

indicators operate based upon hard wired inputs to

the EMIC. The brake indicator is controlled by PCI

data bus messages from the Controller Antilock

Brake (CAB) as well as by hard wired park brake

switch inputs to the EMIC. The seatbelt indicator is

controlled by the EMIC programming, PCI data bus

messages from the Airbag Control Module (ACM),

and a hard wired seat belt switch input to the EMIC.

The Malfunction Indicator Lamp (MIL) is normally

controlled by PCI data bus messages from the Pow-

ertrain Control Module (PCM); however, if the EMIC

loses PCI data bus communication, the EMIC cir-

cuitry will automatically turn the MIL on until PCI

data bus communication is restored. The EMIC uses

PCI data bus messages from the Front Control Mod-

ule (FCM), the PCM, the diesel engine only Engine

Control Module (ECM), the ACM, the CAB, and the

Sentry Key Immobilizer Module (SKIM) to control all

of the remaining indicators.

The various EMIC indicators are controlled by dif-

ferent strategies; some receive fused ignition switch

output from the EMIC circuitry and have a switched

ground, while others are grounded through the EMIC

circuitry and have a switched battery feed. However,

all indicators are completely controlled by the EMIC

microprocessor based upon various hard wired and

electronic message inputs. All indicators are illumi-

nated at a fixed intensity, which is not affected by

the selected illumination intensity of the EMIC gen-

eral illumination lamps.

In addition, certain indicators in this instrument

cluster are automatically configured or self-config-

ured. This feature allows the configurable indicators

to be enabled by the EMIC circuitry for compatibility

with certain optional equipment. The EMIC defaults

for the ABS indicator and airbag indicator are

enabled, and these configuration settings must be

programmatically disabled in the EMIC using a

DRBIIItscan tool for vehicles that do not have this

equipment. The automatically configured or self-con-

figured indicators remain latent in each EMIC at all

times and will be active only when the EMIC

receives the appropriate PCI message inputs for that

optional system or equipment.

The hard wired indicator inputs may be diagnosed

using conventional diagnostic methods. However, the

EMIC circuitry and PCI bus message controlled indi-

cators are diagnosed using the EMIC self-diagnosticactuator test. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING).

Proper testing of the PCI data bus and the electronic

message inputs to the EMIC that control an indicator

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information. Specific details of

the operation for each indicator may be found else-

where in this service information.

CLUSTER ILLUMINATION

The EMIC has several illumination lamps that are

illuminated when the exterior lighting is turned on

with the headlamp switch. The illumination intensity

of these lamps is adjusted when the interior lighting

thumbwheel on the headlamp switch is rotated (down

to dim, up to brighten) to one of six available minor

detent positions. The EMIC monitors a resistor mul-

tiplexed input from the headlamp switch on a dim-

mer input circuit. In response to that input, the

EMIC electronic circuitry converts a 12-volt input it

receives from a fuse in the Integrated Power Module

(IPM) on a hard wired panel lamps dimmer switch

signal circuit into a 12-volt Pulse Width Modulated

(PWM) output. The EMIC uses this PWM output to

power the cluster illumination lamps and the VFD

units on the EMIC circuit board, then provides a syn-

chronized PWM output on the various hard wired

fused panel lamps dimmer switch signal circuits to

control and synchronize the illumination intensity of

other incandescent illumination lamps in the vehicle.

The cluster illumination lamps are grounded at all

times.

The EMIC also sends electronic dimming level

messages over the PCI data bus to other electronic

modules in the vehicle to control and synchronize the

illumination intensity of their VFD units to that of

the EMIC VFD units. In addition, the thumbwheel

on the headlamp switch has a Parade Mode position

to provide a parade mode. The EMIC monitors the

request for this mode from the headlamp switch,

then sends an electronic dimming level message over

the PCI data bus to illuminate all VFD units in the

vehicle at full (daytime) intensity for easier visibility

when driving in daylight with the exterior lighting

turned on.

The hard wired headlamp switch and EMIC panel

lamps dimmer inputs and outputs may be diagnosed

using conventional diagnostic methods. However,

proper testing of the PWM output of the EMIC and

the electronic dimming level messages sent by the

EMIC over the PCI data bus requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

DRINSTRUMENT CLUSTER 8J - 9

INSTRUMENT CLUSTER (Continued)

Page 519 of 2627

INPUT AND OUTPUT CIRCUITS

HARD WIRED INPUTS

The hard wired inputs to the EMIC include the fol-

lowing:

²Brake Lamp Switch Output

²Driver Cylinder Lock Switch Sense

²Driver Door Ajar Switch Sense

²Driver Door Lock Switch MUX - with

Power Locks

²Fused B(+) - Ignition-Off Draw

²Fused B(+) - Power Lock Feed - with Power

Locks

²Fused Ignition Switch Output (Accessory-

Run)

²Fused Ignition Switch Output (Off-Run-

Start)

²Fused Ignition Switch Output (Run-Start)

²Headlamp Dimmer Switch MUX

²Headlamp Switch MUX

²Horn Relay Control

²Key-In Ignition Switch Sense

²Left Rear Door Ajar Switch Sense

²Panel Lamps Dimmer Switch Signal

²Park Brake Switch Sense

²Passenger Door Ajar Switch Sense

²Passenger Door Lock Switch MUX - with

Power Locks

²Radio Control MUX

²Right Rear Door Ajar Switch Sense

²RKE Supply - with RKE

²Seat Belt Switch Sense

²Transmission Range Sensor MUX - with

Auto Trans

²Turn/Hazard Switch MUX

²Washer/Beam Select Switch MUX

²Wiper Switch MUX

Refer to the appropriate wiring information for

additional details.

HARD WIRED OUTPUTS

The hard wired outputs of the EMIC include the

following:

²Accessory Switch Bank Illumination Driver

²BTSI Driver - with Auto Trans

²Cargo Lamp Driver

²Dome/Overhead Lamp Driver

²Driver Door Unlock Driver - with Power

Locks

²Headlamp Switch Illumination Driver

²Heated Seat Switch Indicator Driver - with

Heated Seats

²Heater-A/C Control Illumination Driver

²Left Door Lock Driver - with Power Locks

²Left Rear Door Unlock Driver - with Power

Locks²Map/Glove Box Lamp Driver

²Radio Illumination Driver

²Right Door Lock Driver - with Power Locks

²Right Door Unlock Driver - with Power

Locks

²Transfer Case Switch Illumination Driver -

with Four-Wheel Drive

Refer to the appropriate wiring information for

additional details.

GROUNDS

The EMIC receives and supplies a ground path to

several switches and sensors through the following

hard wired circuits:

²Ground - Illumination (2 Circuits)

²Ground - Power Lock - with Power Locks

²Ground - Signal

²Headlamp Switch Return

²Multi-Function Switch Return

²Transmission Range Sensor Return - with

Auto Trans

Refer to the appropriate wiring information for

additional details.

COMMUNICATION

The EMIC has provisions for the following commu-

nication circuits:

²PCI Data Bus

²RKE Program Serial Data - with RKE

²RKE Transmit Serial Data - with RKE

Refer to the appropriate wiring information for

additional details.

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER

If all of the instrument cluster gauges and/or indi-

cators are inoperative, refer to PRELIMINARY

DIAGNOSIS. If an individual gauge or Programma-

ble Communications Interface (PCI) data bus mes-

sage-controlled indicator is inoperative, refer to

ACTUATOR TEST. If an individual hard wired indi-

cator is inoperative, refer to the diagnosis and testing

information for that specific indicator.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

8J - 10 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 522 of 2627

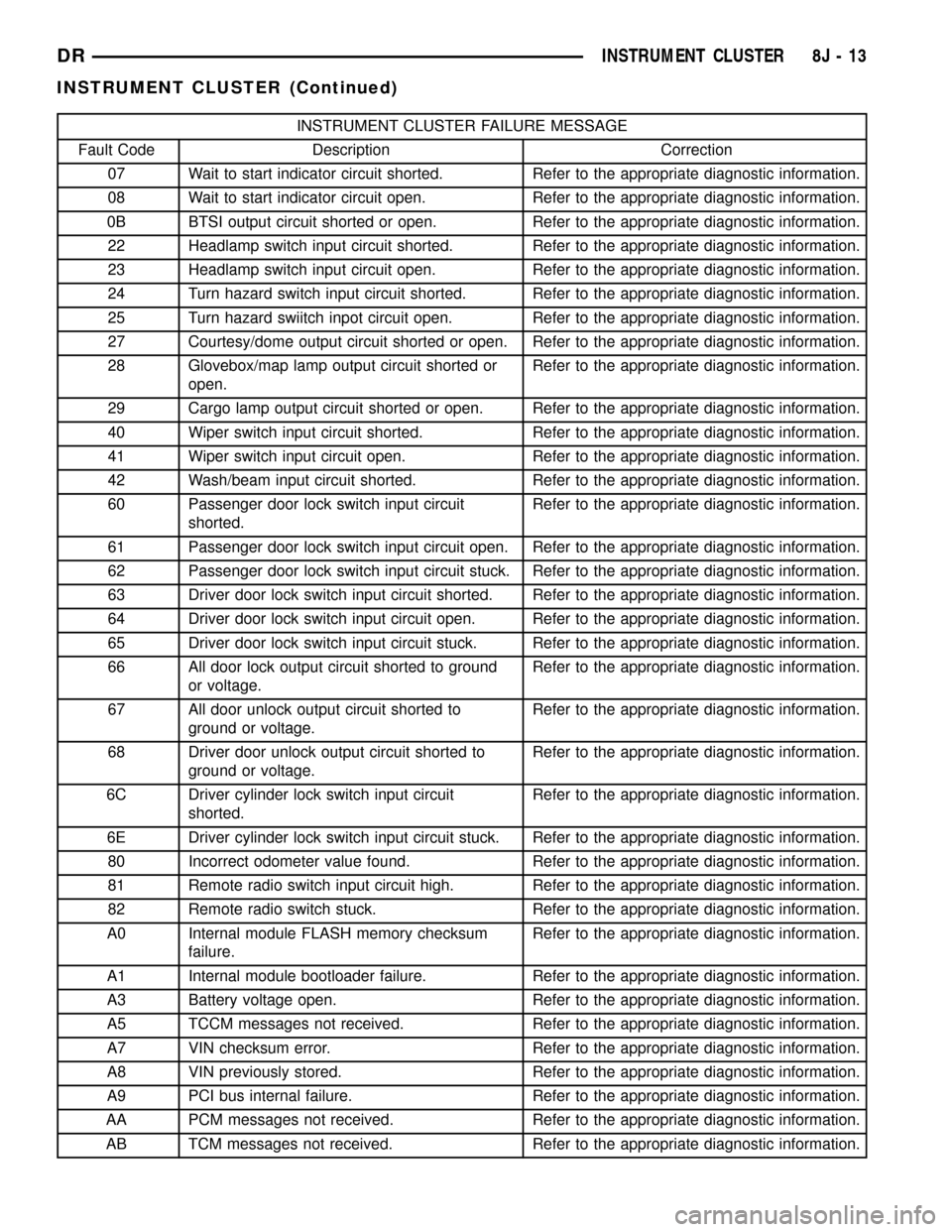

INSTRUMENT CLUSTER FAILURE MESSAGE

Fault Code Description Correction

07 Wait to start indicator circuit shorted. Refer to the appropriate diagnostic information.

08 Wait to start indicator circuit open. Refer to the appropriate diagnostic information.

0B BTSI output circuit shorted or open. Refer to the appropriate diagnostic information.

22 Headlamp switch input circuit shorted. Refer to the appropriate diagnostic information.

23 Headlamp switch input circuit open. Refer to the appropriate diagnostic information.

24 Turn hazard switch input circuit shorted. Refer to the appropriate diagnostic information.

25 Turn hazard swiitch inpot circuit open. Refer to the appropriate diagnostic information.

27 Courtesy/dome output circuit shorted or open. Refer to the appropriate diagnostic information.

28 Glovebox/map lamp output circuit shorted or

open.Refer to the appropriate diagnostic information.

29 Cargo lamp output circuit shorted or open. Refer to the appropriate diagnostic information.

40 Wiper switch input circuit shorted. Refer to the appropriate diagnostic information.

41 Wiper switch input circuit open. Refer to the appropriate diagnostic information.

42 Wash/beam input circuit shorted. Refer to the appropriate diagnostic information.

60 Passenger door lock switch input circuit

shorted.Refer to the appropriate diagnostic information.

61 Passenger door lock switch input circuit open. Refer to the appropriate diagnostic information.

62 Passenger door lock switch input circuit stuck. Refer to the appropriate diagnostic information.

63 Driver door lock switch input circuit shorted. Refer to the appropriate diagnostic information.

64 Driver door lock switch input circuit open. Refer to the appropriate diagnostic information.

65 Driver door lock switch input circuit stuck. Refer to the appropriate diagnostic information.

66 All door lock output circuit shorted to ground

or voltage.Refer to the appropriate diagnostic information.

67 All door unlock output circuit shorted to

ground or voltage.Refer to the appropriate diagnostic information.

68 Driver door unlock output circuit shorted to

ground or voltage.Refer to the appropriate diagnostic information.

6C Driver cylinder lock switch input circuit

shorted.Refer to the appropriate diagnostic information.

6E Driver cylinder lock switch input circuit stuck. Refer to the appropriate diagnostic information.

80 Incorrect odometer value found. Refer to the appropriate diagnostic information.

81 Remote radio switch input circuit high. Refer to the appropriate diagnostic information.

82 Remote radio switch stuck. Refer to the appropriate diagnostic information.

A0 Internal module FLASH memory checksum

failure.Refer to the appropriate diagnostic information.

A1 Internal module bootloader failure. Refer to the appropriate diagnostic information.

A3 Battery voltage open. Refer to the appropriate diagnostic information.

A5 TCCM messages not received. Refer to the appropriate diagnostic information.

A7 VIN checksum error. Refer to the appropriate diagnostic information.

A8 VIN previously stored. Refer to the appropriate diagnostic information.

A9 PCI bus internal failure. Refer to the appropriate diagnostic information.

AA PCM messages not received. Refer to the appropriate diagnostic information.

AB TCM messages not received. Refer to the appropriate diagnostic information.

DRINSTRUMENT CLUSTER 8J - 13

INSTRUMENT CLUSTER (Continued)

Page 530 of 2627

cluster programming, a hard wired multiplex input

received by the cluster from the headlamp panel

lamps dimmer switch on the headlamp dimmer

switch mux circuit, and electronic unlock request

messages received from the optional Remote Keyless

Entry (RKE) receiver module. The cargo lamp indica-

tor Light Emitting Diode (LED) is completely con-

trolled by the instrument cluster logic circuit, and

that logic will allow only this indicator to operate

whenever the instrument cluster receives a battery

current input on the fused ignition switch output

(run-start) circuit. Therefore, the LED will always be

off when the ignition switch is in any position except

On or Start. The LED only illuminates when it is

provided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

cargo lamp indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the cargo lamp indicator is

illuminated for about two seconds as a bulb test.

²Cargo Lamp-On Input- Each time the cluster

detects a cargo lamp-on input from the headlamp

switch on the headlamp dimmer switch mux circuit,

the cargo lamp and the cargo lamp indicator will be

illuminated. The cargo lamp and indicator remain

illuminated until the cluster receives a cargo lamp-off

input from the headlamp switch, or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Actuator Test- Each time the cluster is put

through the actuator test, the cargo lamp indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

The instrument cluster continually monitors the

headlamp dimmer switch circuit to determine the

proper interior lamps features and panel lamps illu-

mination levels to provide. The cluster then energizes

and de-energizes a low side driver circuit to control

the exterior cargo lamp. Each time the instrument

cluster energizes the cargo lamp driver and the igni-

tion switch is in the On or start positions, the cluster

also turns on the cargo lamp indicator. For further

diagnosis of the cargo lamp indicator or the instru-

ment cluster circuitry that controls the indicator,

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). For proper

diagnosis of the cargo lamp or the headlamp switch

inputs to the instrument cluster that control the

cargo lamp indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.CHECK GAUGES INDICATOR

DESCRIPTION

A check gauges indicator is standard equipment on

all instrument clusters (Fig. 12). On vehicles

equipped with a gasoline engine, the check gauges

indicator is located near the lower edge of the instru-

ment cluster, between the tachometer and the speed-

ometer. On vehicles equipped with a diesel engine,

the check gauges indicator is located on the left side

of the instrument cluster, to the left of the voltage

gauge. The check gauges indicator consists of a sten-

cil-like cutout of the words ªCHECK GAGESº in the

opaque layer of the instrument cluster overlay. The

dark outer layer of the overlay prevents the indicator

from being clearly visible when it is not illuminated.

A red Light Emitting Diode (LED) behind the cutout

in the opaque layer of the overlay causes the

ªCHECK GAGESº text to appear in red through the

translucent outer layer of the overlay when the indi-

cator is illuminated from behind by the LED, which

is soldered onto the instrument cluster electronic cir-

cuit board. The check gauges indicator is serviced as

a unit with the instrument cluster.

OPERATION

The check gauges indicator gives an indication to

the vehicle operator when certain instrument cluster

gauge readings reflect a condition requiring immedi-

ate attention. This indicator is controlled by a tran-

sistor on the instrument cluster circuit board based

upon cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) on vehicles equipped with a gasoline

engine, or from the Engine Control Module (ECM) on

vehicles equipped with a diesel engine over the Pro-

grammable Communications Interface (PCI) data

bus. The check gauges indicator Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the LED will always be off when the ignition switch

is in any position except On or Start. The LED only

illuminates when it is provided a path to ground by

the instrument cluster transistor. The instrument

cluster will turn on the check gauges indicator for

the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the check gauges indicator

is illuminated for about two seconds as a bulb test.

Fig. 12 Check Gauges Indicator

DRINSTRUMENT CLUSTER 8J - 21

CARGO LAMP INDICATOR (Continued)

Page 536 of 2627

the PCM or ECM indicating the percent tank full is

less than empty, the gauge needle is moved to the far

left end of the gauge scale and the low fuel indicator

is illuminated immediately. This message would indi-

cate that the fuel tank sender input to the PCM or

ECM is a short circuit.

²More Than Full Percent Tank Full Message

- Each time the cluster receives a message from the

PCM or ECM indicating the percent tank full is more

than full, the gauge needle is moved to the far left

end of the gauge scale and the low fuel indicator is

illuminated immediately. This message would indi-

cate that the fuel tank sender input to the PCM or

ECM is an open circuit.

²Communication Error- If the cluster fails to

receive a percent tank full message, it will hold the

gauge needle at the last indication about five seconds

or until the ignition switch is turned to the Off posi-

tion, whichever occurs first. After five seconds, the

cluster will move the gauge needle to the low end of

the gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the fuel gauge needle will

be swept to several calibration points on the gauge

scale in a prescribed sequence in order to confirm the

functionality of the gauge and the cluster control cir-

cuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the fuel tank sending unit to deter-

mine the level of the fuel in the fuel tank. On

vehicles with a diesel engine, the ECM continually

monitors the fuel tank sending unit to determine the

level of the fuel in the fuel tank. The PCM or ECM

then sends the proper fuel level messages to the

instrument cluster. For further diagnosis of the fuel

gauge or the instrument cluster circuitry that con-

trols the gauge, (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING).

For proper diagnosis of the fuel tank sending unit,

the PCM, the ECM, the PCI data bus, or the elec-

tronic message inputs to the instrument cluster that

control the fuel gauge, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

GEAR SELECTOR INDICATOR

DESCRIPTION

An electronic automatic transmission gear selector

indicator is standard factory-installed equipment onthis model. The gear selector indicator information is

displayed in a Vacuum-Fluorescent Display (VFD)

unit. The VFD is soldered onto the cluster electronic

circuit board and is visible through a window with a

smoked clear lens located on the lower edge of the

speedometer gauge dial face of the cluster overlay.

The dark lens over the VFD prevents the indicator

from being clearly visible when it is not illuminated.

The gear selector indicator displays the following

characters from left to right: ªP,º ªR,º ªN,º ªD,º ª2,º

and ª1º (Fig. 18). Respectively, these characters rep-

resent the park, reverse, neutral, drive, second gear,

and first gear positions of the transmission gear

selector lever on the steering column. The VFD illu-

minates a rectangular box around the character that

represents the currently selected lever position.

The gear selector indicator characters and graphics

appear in the same blue-green color and at the same

lighting level as the odometer/trip odometer informa-

tion when illuminated by the instrument cluster elec-

tronic circuit board. During daylight hours (exterior

lamps Off) the gear selector indicator VFD is illumi-

nated at full brightness for clear visibility. At night

(exterior lamps are On) the VFD lighting level is

adjusted with the other cluster illumination lamps

using the panel lamps dimmer thumbwheel on the

headlamp switch. However, a ªParadeº mode position

of the panel lamps dimmer thumbwheel allows the

VFD to be illuminated at full brightness when the

vehicle is driven in daylight hours with the exterior

lamps turned On. The gear selector indicator VFD is

serviced as a unit with the instrument cluster.

OPERATION

The electronic gear selector indicator gives an indi-

cation to the vehicle operator of the transmission

gear that has been selected with the automatic trans-

mission gear selector lever. This indicator is con-

trolled by the instrument cluster circuit board based

upon cluster programming. The cluster circuitry

automatically configures itself for the proper trans-

mission and automatic transmission model based

upon the hard wired transmission range sensor mux

circuit input to the cluster. The gear selector indica-

tor information is displayed by a dedicated Vacuum

Fluorescent Display (VFD) unit on the instrument

cluster electronic circuit board, and the VFD will not

display the gear selector indicator information after

the ignition switch is turned to the Off position. The

instrument cluster circuitry configures the gear selec-

tor indicator VFD based upon the following inputs

from the transmission range sensor:

²Open Circuit- If the cluster is configured for

an automatic transmission and the transmission

range sensor mux circuit is open, the cluster circuitry

controls the gear selector indicator display based

Fig. 18 Gear Selector Indicator

DRINSTRUMENT CLUSTER 8J - 27

FUEL GAUGE (Continued)

Page 537 of 2627

upon electronic messages received from the electronic

Transmission Control Module (TCM) over the Pro-

grammable Communications Interface (PCI) data

bus. If the transmission range sensor mux circuit is

open and no electronic messages are received from

the TCM within two seconds, the instrument cluster

circuitry will not display any gear selector position

until the condition is resolved or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Resolved Circuit- If the transmission range

sensor mux circuit is resolved, the cluster circuitry

controls the gear selector indicator display based

upon the resistance value of the hard wired input

from the transmission range sensor. If the cluster is

configured for an automatic transmission with a

transmission range sensor input and detects a short

to ground or an open in the transmission range sen-

sor mux input, the instrument cluster circuitry will

not display any gear selector position in the VFD.

The VFD display for the short-to-ground and open

circuit conditions will continue until the condition is

resolved or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the gear selector indicator

VFD will display all of its characters at once during

the VFD portion of the test to confirm the function-

ality of the VFD and the cluster control circuitry.

On models with a TCM, the TCM continually mon-

itors the transmission range sensor, then sends the

proper gear selector indicator position messages to

the instrument cluster. On models without a TCM,

the instrument cluster continually monitors the hard

wired transmission range sensor multiplexed input.

For further diagnosis of the gear selector indicator or

the instrument cluster circuitry that controls this

function, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). For fur-

ther diagnosis of the transmission range sensor on

models without a TCM, (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RE/TRANS-

MISSION RANGE SENSOR - DIAGNOSIS AND

TESTING) or (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 46RE/TRANSMISSION

RANGE SENSOR - DIAGNOSIS AND TESTING).

On models with a TCM, for proper diagnosis of the

transmission range sensor, the TCM, the PCI data

bus, or the electronic message inputs to the instru-

ment cluster that control the gear selector indicator,

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.HIGH BEAM INDICATOR

DESCRIPTION

A high beam indicator is standard equipment on

all instrument clusters (Fig. 19). The high beam indi-

cator is located near the upper edge of the instru-

ment cluster, between the tachometer and the

speedometer. The high beam indicator consists of a

stencil-like cutout of the International Control and

Display Symbol icon for ªHigh Beamº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when the it is not illuminated. A

blue Light Emitting Diode (LED) behind the cutout

in the opaque layer of the overlay causes the icon to

appear in blue through the translucent outer layer of

the overlay when the indicator is illuminated from

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The high

beam indicator is serviced as a unit with the instru-

ment cluster.

OPERATION

The high beam indicator gives an indication to the

vehicle operator whenever the headlamp high beams

are illuminated. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and a hard wired

multiplex input received by the cluster from the

headlamp beam select switch circuitry of the multi-

function switch on the washer/beam select switch

mux circuit. The high beam indicator Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will allow

this indicator to operate whenever the instrument

cluster receives a battery current input on the fused

B(+) circuit. Therefore, the LED can be illuminated

regardless of the ignition switch position. The LED

only illuminates when it is provided a path to ground

by the instrument cluster transistor. The instrument

cluster will turn on the high beam indicator for the

following reasons:

²High Beam Headlamps-On Input- Each time

the cluster detects a high beam headlamps-on input

from the headlamp beam select switch circuitry of

the multi-function switch on the washer/beam select

switch mux circuit, the headlamp high beams and

the high beam indicator will be illuminated. The

headlamp high beams and the high beam indicator

remain illuminated until the cluster receives a high

beam headlamps-off input from the multi-function

switch, or until the exterior lamp load shedding (bat-

Fig. 19 High Beam Indicator

8J - 28 INSTRUMENT CLUSTERDR

GEAR SELECTOR INDICATOR (Continued)

Page 538 of 2627

tery saver) timed interval expires, whichever occurs

first.

²Actuator Test- Each time the cluster is put

through the actuator test, the high beam indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

The instrument cluster continually monitors the

headlamp switch and the multi-function switch to

determine the proper headlamp low beam and high

beam control. The instrument cluster then sends the

proper low beam and high beam lamp-on and lamp-

off messages to the Front Control Module (FCM) over

the Programmable Communications Interface (PCI)

data bus and turns the high beam indicator on or off

accordingly. For further diagnosis of the high beam

indicator or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the headlamps, or

the headlamp switch and multi-function switch

inputs to the instrument cluster that control the high

beam indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

LAMP OUT INDICATOR

DESCRIPTION

A lamp out indicator is standard equipment on all

instrument clusters (Fig. 20). The lamp out indicator

consists of the words ªLAMP OUTº, which appear in

the lower portion of the odometer/trip odometer Vac-

uum-Fluorescent Display (VFD) unit. The VFD is sol-

dered onto the cluster electronic circuit board and is

visible through a window with a smoked clear lens

located on the lower edge of the tachometer gauge

dial face of the cluster overlay. The dark lens over

the VFD prevents the indicator from being clearly

visible when it is not illuminated. The words ªLAMP

OUTº appear in an amber color and at the same

lighting level as the odometer/trip odometer informa-

tion when they are illuminated by the instrument

cluster electronic circuit board. The lamp out indica-

tor is serviced as a unit with the VFD in the instru-

ment cluster.

OPERATION

The lamp out indicator gives an indication to the

vehicle operator when an exterior lamp has failed.

This indicator is controlled by the instrument clustercircuit board based upon cluster programming and

electronic messages received by the cluster from the

Front Control Module (FCM) over the Programmable

Communications Interface (PCI) data bus. The lamp

out indicator is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the indicator will always be off when the ignition

switch is in any position except On or Start. The

indicator only illuminates when it is switched to

ground by the instrument cluster circuitry. The

instrument cluster will turn on the lamp out indica-

tor for the following reasons:

²Lamp Out Indicator Lamp-On Message-

Each time the cluster receives a lamp out indicator

lamp-on message from the FCM indicating that an

inoperative headlamp (low or high beam), turn signal

lamp, or brake lamp (excluding Center High

Mounted Stop Lamp [CHMSL]) circuit has been

detected, the lamp out indicator is illuminated. The

indicator remains illuminated until the cluster

receives a lamp out indicator lamp-off message from

the FCM or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the lamp out indicator will

be turned on, then off again during the VFD portion

of the test to confirm the functionality of the VFD

and the cluster control circuitry.

The FCM monitors each of the headlamp, turn sig-

nal lamp, and brake lamp (except CHMSL) circuits to

determine the condition of these exterior lamps. The

FCM then sends the proper lamp out indicator

lamp-on and lamp-off messages to the instrument

cluster. For further diagnosis of the lamp out indica-

tor or the instrument cluster circuitry that controls

the indicator, (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING).

For proper diagnosis of the exterior lighting system

circuits, the FCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the lamp out indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

Fig. 20 Lamp Out Indicator

DRINSTRUMENT CLUSTER 8J - 29

HIGH BEAM INDICATOR (Continued)

Page 541 of 2627

ODOMETER

DESCRIPTION

An odometer and trip odometer are standard

equipment in all instrument clusters (Fig. 23). The

odometer, trip odometer, and engine hours informa-

tion are displayed in a common electronic, blue-green

Vacuum-Fluorescent Display (VFD). The VFD is sol-

dered onto the cluster electronic circuit board and is

visible through a window with a smoked clear lens

located on the lower edge of the tachometer gauge

dial face of the cluster overlay. The dark lens over

the VFD prevents it from being clearly visible when

it is not illuminated. However, the odometer, trip

odometer, and engine hours information are not dis-

played simultaneously. The trip odometer reset

switch on the instrument cluster circuit board toggles

the display between odometer and trip odometer

modes by depressing the odometer/trip odometer

switch button that extends through the lower edge of

the cluster lens, just left of the odometer VFD. When

the trip odometer information is displayed, the word

ªTRIPº is also illuminated in the upper right corner

of the VFD in a blue-green color and at the same

lighting level as the trip odometer information. The

engine hours information replaces the selected odom-

eter or trip odometer information whenever the igni-

tion switch is in the On position and the engine is

not running.

The odometer, trip odometer, and engine hours

information is stored in the instrument cluster mem-

ory. This information can be increased when the

proper inputs are provided to the instrument cluster,

but the information cannot be decreased. The odom-

eter can display values up to 999,999 kilometers

(999,999 miles). The odometer latches at these val-

ues, and will not roll over to zero. The trip odometer

can display values up to 9,999.9 kilometers (9,999.9

miles) before it rolls over to zero. The odometer dis-

play does not have a decimal point and will not show

values less than a full unit (kilometer or mile), while

the trip odometer display does have a decimal point

and will show tenths of a unit (kilometer or mile).

The unit of measure (kilometers or miles) for the

odometer and trip odometer display is not shown in

the VFD. The unit of measure for the instrument

cluster odometer/trip odometer is selected at the time

that it is manufactured, and cannot be changed.

Engine hours are displayed in the format, ªhr9999º.The cluster will accumulate values up to 9,999 hours

before the display rolls over to zero.

The odometer has a ªRental Carº mode, which will

illuminate the odometer information in the VFD

whenever the driver side front door is opened with

the ignition switch in the Off or Accessory positions.

During daylight hours (exterior lamps are Off) the

VFD is illuminated at full brightness for clear visibil-

ity. At night (exterior lamps are On) the VFD lighting

level is adjusted with the other cluster illumination

lamps using the panel lamps dimmer thumbwheel on

the headlamp switch. However, a ªParadeº mode

position of the panel lamps dimmer thumbwheel

allows the VFD to be illuminated at full brightness if

the exterior lamps are turned On during daylight

hours.

The VFD, the trip odometer switch, and the trip

odometer switch button are serviced as a unit with

the instrument cluster.

OPERATION

The odometer and trip odometer give an indication

to the vehicle operator of the distance the vehicle has

traveled. The engine hours give an indication of the

cumulative engine-on time. This indicator is con-

trolled by the instrument cluster circuitry based

upon cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) over the Programmable Communica-

tions Interface (PCI) data bus. The odometer, trip

odometer and engine hours information is displayed

by the instrument cluster Vacuum Fluorescent Dis-

play (VFD). The VFD will display the odometer infor-

mation whenever any door is opened with the

ignition switch in the Off or Accessory positions, and

will display the last previously selected odometer or

trip odometer information when the ignition switch is

turned to the On or Start positions. The instrument

cluster circuitry controls the VFD and provides the

following features:

²Odometer/Trip Odometer Display Toggling-

Actuating the trip odometer reset switch button

momentarily with the VFD illuminated will toggle

the display between the odometer and trip odometer

information. Each time the VFD is illuminated with

the ignition switch in the On or Start positions, the

display will automatically return to the last mode

previously selected (odometer or trip odometer).

²Engine Hours Display Toggling- When the

trip odometer reset switch button is pressed and held

for longer than about six seconds with the ignition

switch in the On position and the engine speed mes-

sage from the PCM is zero, the trip odometer infor-

mation will be momentarily displayed, then the

engine hours information will be displayed. The VFD

must be displaying the odometer information when

Fig. 23 Odometer Display

8J - 32 INSTRUMENT CLUSTERDR