steering wheel adjustment DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 36 of 2627

SUSPENSION

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT......................1

FRONT - INDEPENDENT FRONT SUSPENSION..8FRONT - LINK/COIL......................29

REAR.................................41

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - PRE-ALIGNMENT

INSPECTION..........................2

STANDARD PROCEDURE

STANDARD PROCEDURE - HEIGHT

MEASUREMENT - 4WD (LD)..............3

STANDARD PROCEDURE - HEIGHT

ADJUSTMENT - 4WD (LD)................3

STANDARD PROCEDURE - CAMBER AND

CASTER ADJUSTMENT..................4STANDARD PROCEDURE - TOE

ADJUSTMENT.........................4

STANDARD PROCEDURE - CAMBER,

CASTER AND TOE ADJUSTMENT..........4

STANDARD PROCEDURE - ALIGNMENT

LINK/COIL SUSPENSION.................5

SPECIFICATIONS

ALIGNMENT..........................6

SPECIAL TOOLS

WHEEL ALIGNMENT....................7

WHEEL ALIGNMENT

DESCRIPTION

NOTE: Suspension components with rubber/ure-

thane bushings should be tightened with the vehi-

cle at normal ride height. It is important to have the

springs supporting the weight of the vehicle when

the fasteners are torqued. If springs are not at their

normal ride position, vehicle ride comfort could be

affected and premature bushing wear may occur.

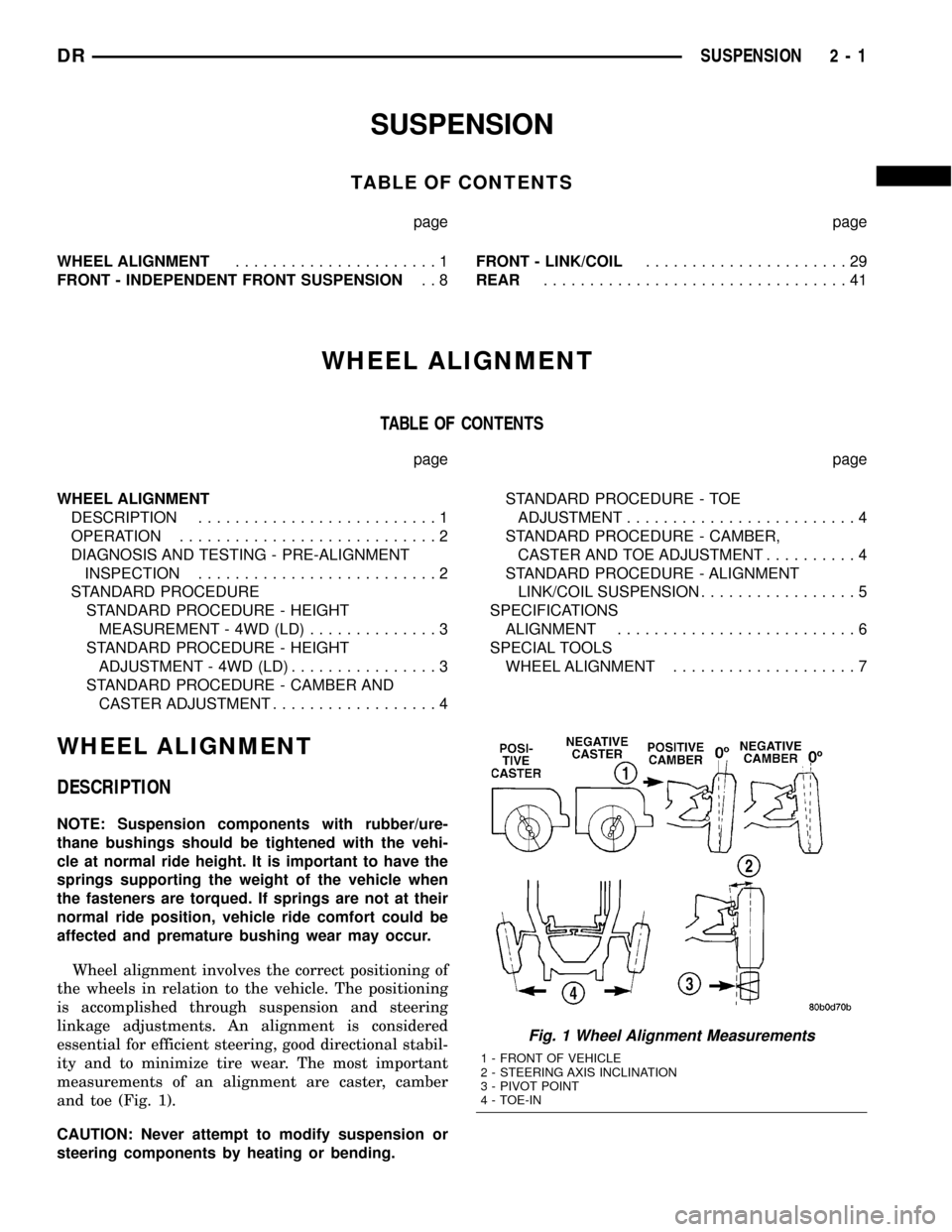

Wheel alignment involves the correct positioning of

the wheels in relation to the vehicle. The positioning

is accomplished through suspension and steering

linkage adjustments. An alignment is considered

essential for efficient steering, good directional stabil-

ity and to minimize tire wear. The most important

measurements of an alignment are caster, camber

and toe (Fig. 1).

CAUTION: Never attempt to modify suspension or

steering components by heating or bending.

Fig. 1 Wheel Alignment Measurements

1 - FRONT OF VEHICLE

2 - STEERING AXIS INCLINATION

3 - PIVOT POINT

4 - TOE-IN

DRSUSPENSION 2 - 1

Page 37 of 2627

OPERATION

²CASTERis the forward or rearward tilt of the

steering knuckle from vertical. Tilting the top of the

knuckle forward provides less positive caster. Tilting

the top of the knuckle rearward provides more posi-

tive caster. Positive caster promotes directional sta-

bility. This angle enables the front wheels to return

to a straight ahead position after turns (Fig. 1)

²CAMBERis the inward or outward tilt of the

wheel relative to the center of the vehicle. Tilting the

top of the wheel inward provides negative camber.

Tilting the top of the wheel outward provides positive

camber. Incorrect camber will cause wear on the

inside or outside edge of the tire (Fig. 1)

²TOEis the difference between the leading inside

edges and trailing inside edges of the front tires.

Wheel toe position out of specification cause's unsta-

ble steering, uneven tire wear and steering wheel off-

center. The wheel toe position is thefinalfront

wheel alignment adjustment (Fig. 1)

²THRUST ANGLEis the angle of the rear axle

relative to the centerline of the vehicle. Incorrect

thrust angle can cause off-center steering and exces-sive tire wear. This angle is not adjustable, damaged

component(s) must be replaced to correct the thrust

angle (Fig. 1)

DIAGNOSIS AND TESTING - PRE-ALIGNMENT

INSPECTION

Before starting wheel alignment, the following

inspection and necessary corrections must be com-

pleted. Refer to Suspension and Steering System

Diagnosis Chart below for additional information.

(1) Inspect tires for size, air pressure and tread

wear.

(2) Inspect front wheel bearings for wear.

(3) Inspect front wheels for excessive radial or lat-

eral runout and balance.

(4) Inspect ball studs, linkage pivot points and

steering gear for looseness, roughness or binding.

(5) Inspect suspension components for wear and

noise.

(6) On 4x4 vehicles check suspension height (LD

only).

(7) Road test the vehicle.

SUSPENSION AND STEERING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FRONT END NOISE 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Loose or worn steering or

suspension components.3. Tighten or replace components as

necessary.

EXCESSIVE PLAY IN

STEERING1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Loose or worn steering gear. 3. Replace steering gear.

FRONT WHEELS SHIMMY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tires worn or out of balance. 3. Replace or balance tires.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE INSTABILITY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

2 - 2 WHEEL ALIGNMENTDR

WHEEL ALIGNMENT (Continued)

Page 38 of 2627

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE STEERING

EFFORT1. Loose or worn steering gear. 1. Replace steering gear.

2. Column coupler binding. 2. Replace coupler.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE PULLS TO ONE

SIDE1. Tire pressure. 1. Adjust tire pressure.

2. Tire. 2. Criss-Cross Front Tires.

3. Alignment. 3. Align vehicle to specifications.

4. Loose or worn steering or

suspension components.4. Tighten or replace components as

necessary.

5. Radial tire lead. 5. Rotate or replace tire as necessary.

6. Brake pull. 6. Repair brake as necessary.

7. Weak or broken spring. 7. Replace spring.

8. Ride height (LD) 4WD only. 8. Measure and adjust ride height. (LD

only)

STANDARD PROCEDURE

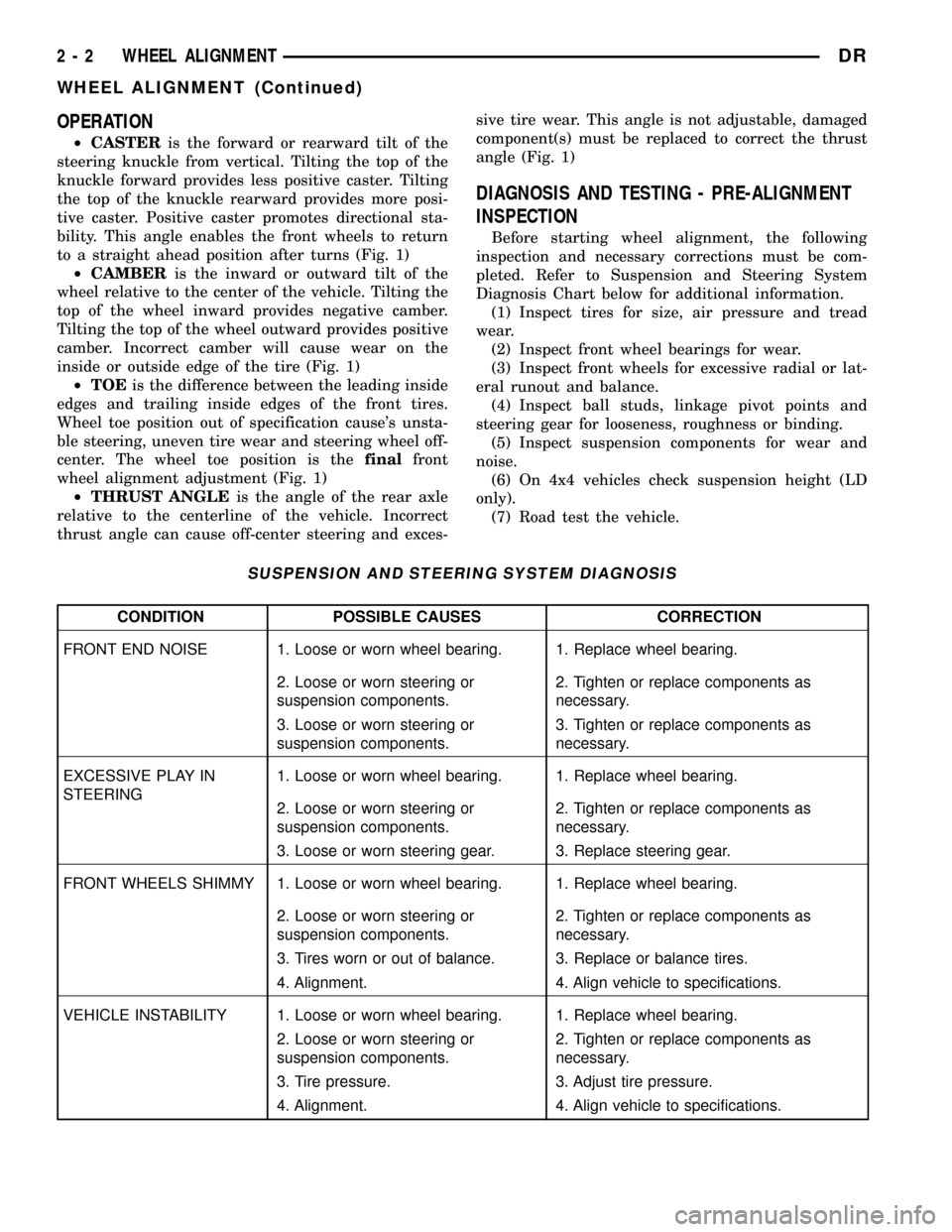

STANDARD PROCEDURE - HEIGHT

MEASUREMENT - 4WD (LD)

The vehicle suspension height MUST be measured

and adjusted before performing wheel alignment pro-

cedure. Also when front suspension components have

been replaced. This measure must be performed with

the vehicle supporting it's own weight and taken on

both sides of the vehicle.

(1) Inspect tires and set to correct pressure.

(2) Jounce the front of the vehicle.

(3) Measure and record the height from the ground

at the centerline of the rear lower control arm bolt

front tip (Fig. 2).

(4) Measure and record the height from the ground

at the front spindle centerline (Static Load Radius)

(Fig. 2).

(5) Subtract the first measurement from the sec-

ond measurement. The difference between the two

measurement should be 58 mm (2.3 inches) 3mm

(0.12 inches).

(6) If value is greater than 61 mm (2.4 inches),

tighten the torsion bar bolt until the specification is

achieved (Refer to 2 - SUSPENSION/WHEEL

ALIGNMENT - STANDARD PROCEDURE).

(7) If value is less than 55 mm (2.1 inches), loosen

the torsion bar bolt until the specification is achieve-

d,(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT

- STANDARD PROCEDURE).

(8) Repeat the previous steps until the ride height

is within specifications.

STANDARD PROCEDURE - HEIGHT

ADJUSTMENT - 4WD (LD)

The vehicle suspension height MUST be measured

and adjusted before performing wheel alignment pro-

cedure (Refer to 2 - SUSPENSION/WHEEL ALIGN-

MENT - STANDARD PROCEDURE). Also when

front suspension components have been replaced.

This measurement must be performed with the vehi-

cle supporting it's own weight and taken on both

sides of the vehicle.

Fig. 2 HEIGHT MESUREMENT

1 - HEIGHT FROM THE GROUND AT THE FRONT SPINDLE

CENTERLINE (STATIC LOAD RADIUS)

2 - CENTERLINE OF THE REAR LOWER CONTROL ARM BOLT

FRONT TIP

3 - GROUND LINE

DRWHEEL ALIGNMENT 2 - 3

WHEEL ALIGNMENT (Continued)

Page 39 of 2627

To adjust the vehicle height turn the torsion bar

adjustment bolt CLOCKWISE to raise the vehicle

and COUNTER CLOCKWISE to lower the vehicle.

CAUTION: ALWAYS raise the vehicle to the correct

suspension height, NEVER lower the vehicle to

obtain the correct suspension height. If the vehicle

suspension height is too high, lower the vehicle

below the height specification. Then raise the vehi-

cle to the correct suspension height specification.

This will insure the vehicle maintains the proper

suspension height.

NOTE: If a height adjustment has been made, per-

form height measurement again on both sides of

the vehicle.

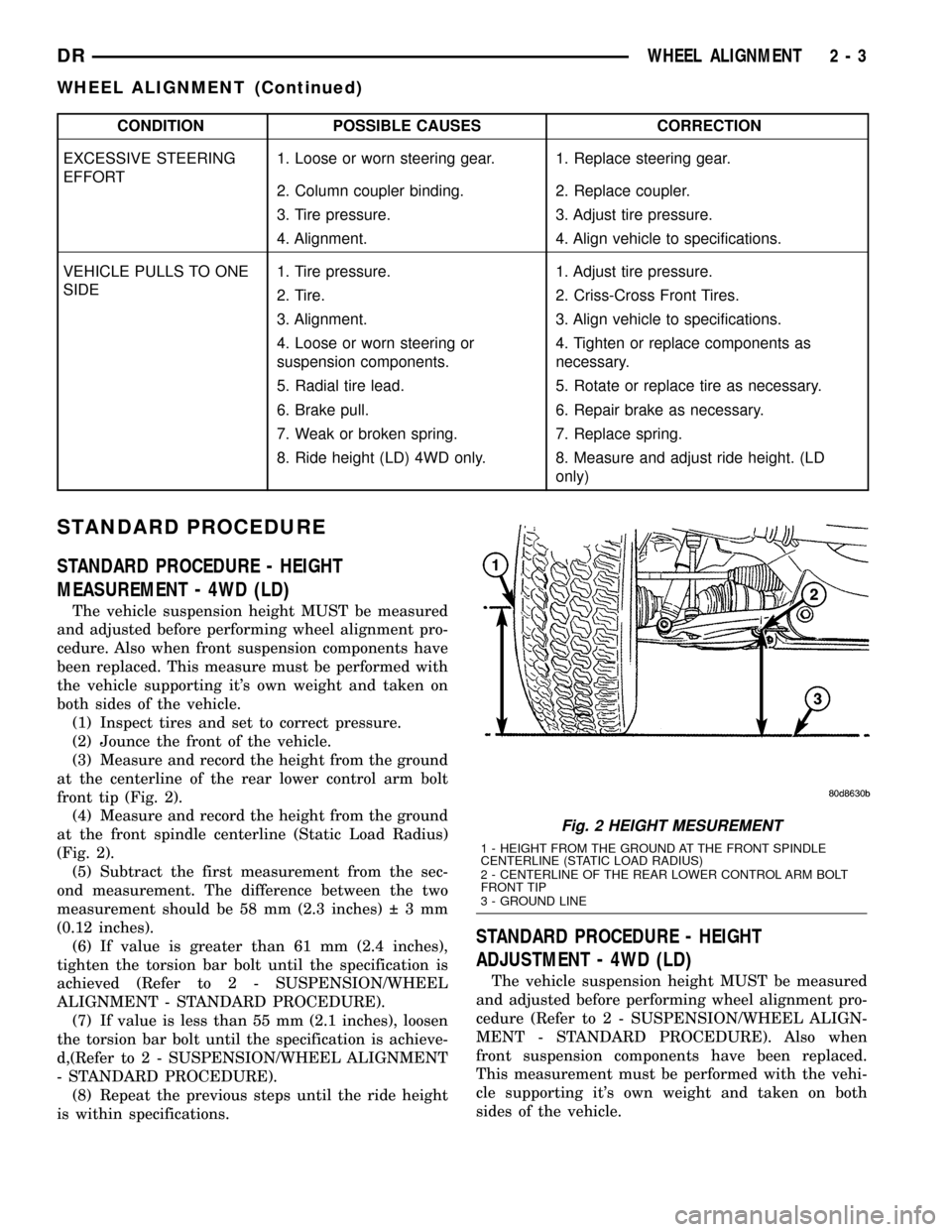

STANDARD PROCEDURE - CAMBER AND

CASTER ADJUSTMENT

NOTE: 4X4 (LD) SUSPENSION HEIGHT MEASURE-

MENT MUST BE PERFORMED BEFORE AN ALIGN-

MENT.

NOTE: When the upper control arm pivot bolts are

loosened the upper control arm will normally go

inwards toward the frame automatically with the

weight of the vehicle.

Camber and caster angle adjustments involve

changing the position of the upper control arm incon-

junction with the slotted holes in the frame brackets,

Install special tool 8876 between the top of the upper

control arm bracket and the upper control arm (on

1500 series 4X2 & 4X4). Install special tool 8876

between the bottom of the upper control arm bracket

pressing the tool against the frame and the upper

control arm (on 2500/3500 series 4X2) in order to

move the upper control arm outwards for proper

adjustment with the vehicle at normal ride height

(Fig. 3).

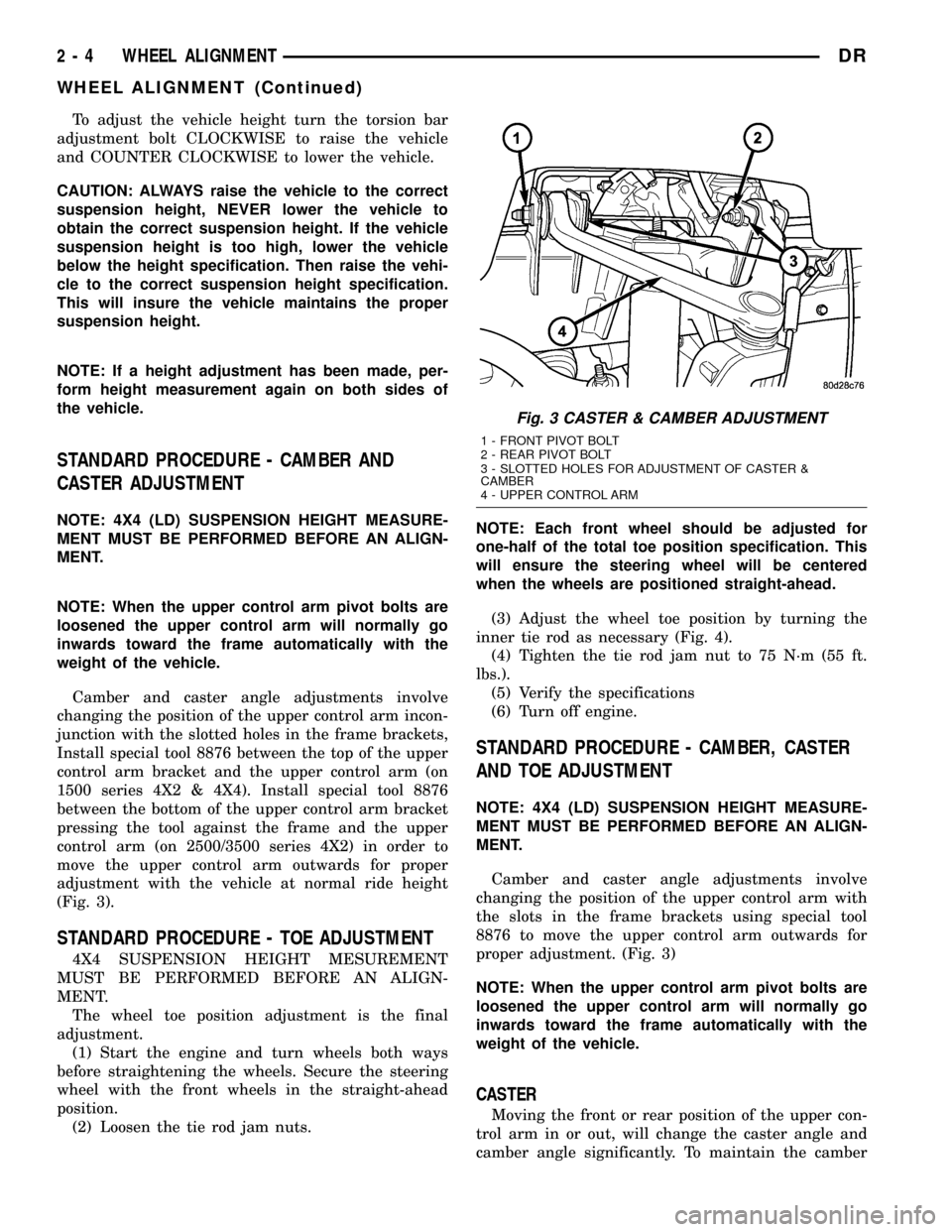

STANDARD PROCEDURE - TOE ADJUSTMENT

4X4 SUSPENSION HEIGHT MESUREMENT

MUST BE PERFORMED BEFORE AN ALIGN-

MENT.

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.

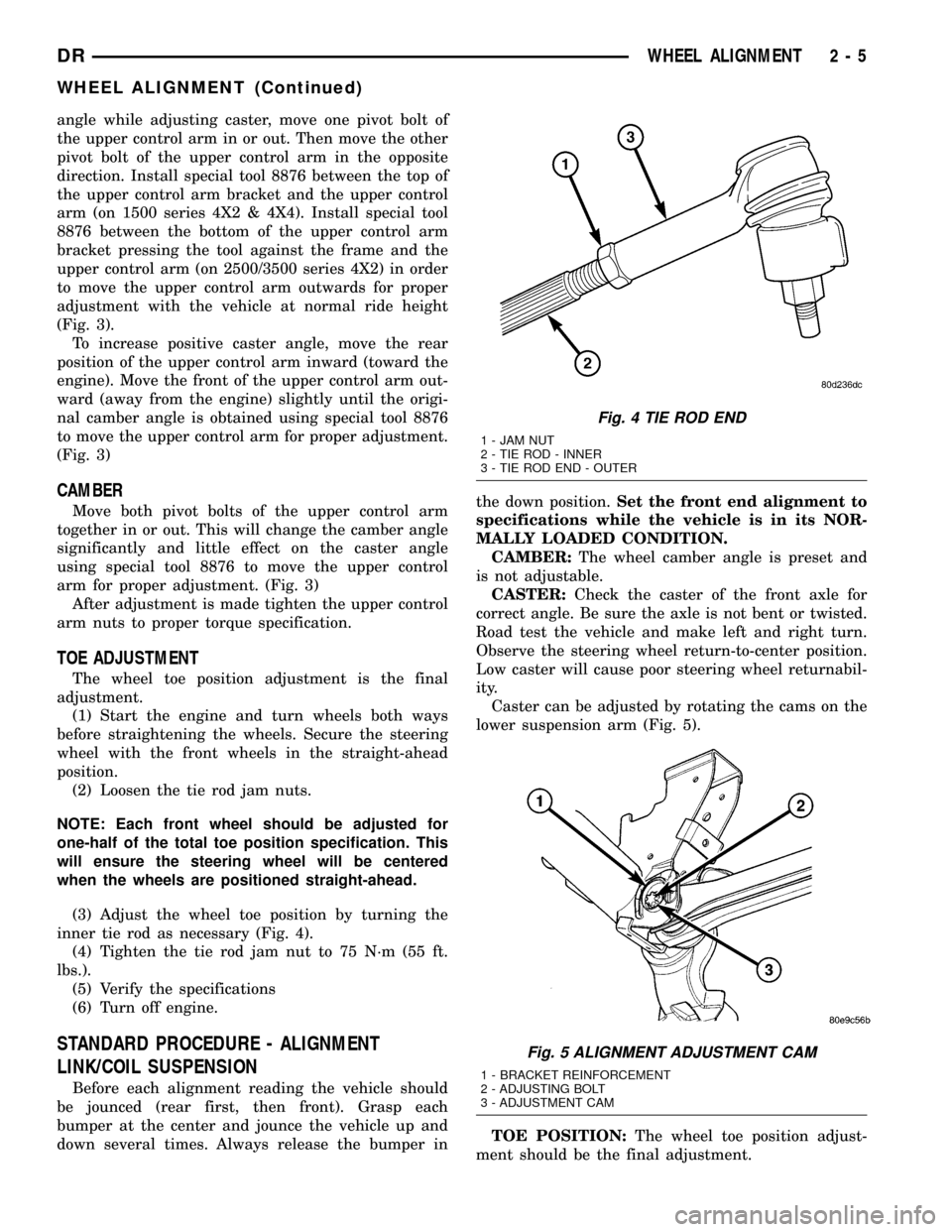

(2) Loosen the tie rod jam nuts.NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the

inner tie rod as necessary (Fig. 4).

(4) Tighten the tie rod jam nut to 75 N´m (55 ft.

lbs.).

(5) Verify the specifications

(6) Turn off engine.

STANDARD PROCEDURE - CAMBER, CASTER

AND TOE ADJUSTMENT

NOTE: 4X4 (LD) SUSPENSION HEIGHT MEASURE-

MENT MUST BE PERFORMED BEFORE AN ALIGN-

MENT.

Camber and caster angle adjustments involve

changing the position of the upper control arm with

the slots in the frame brackets using special tool

8876 to move the upper control arm outwards for

proper adjustment. (Fig. 3)

NOTE: When the upper control arm pivot bolts are

loosened the upper control arm will normally go

inwards toward the frame automatically with the

weight of the vehicle.

CASTER

Moving the front or rear position of the upper con-

trol arm in or out, will change the caster angle and

camber angle significantly. To maintain the camber

Fig. 3 CASTER & CAMBER ADJUSTMENT

1 - FRONT PIVOT BOLT

2 - REAR PIVOT BOLT

3 - SLOTTED HOLES FOR ADJUSTMENT OF CASTER &

CAMBER

4 - UPPER CONTROL ARM

2 - 4 WHEEL ALIGNMENTDR

WHEEL ALIGNMENT (Continued)

Page 40 of 2627

angle while adjusting caster, move one pivot bolt of

the upper control arm in or out. Then move the other

pivot bolt of the upper control arm in the opposite

direction. Install special tool 8876 between the top of

the upper control arm bracket and the upper control

arm (on 1500 series 4X2 & 4X4). Install special tool

8876 between the bottom of the upper control arm

bracket pressing the tool against the frame and the

upper control arm (on 2500/3500 series 4X2) in order

to move the upper control arm outwards for proper

adjustment with the vehicle at normal ride height

(Fig. 3).

To increase positive caster angle, move the rear

position of the upper control arm inward (toward the

engine). Move the front of the upper control arm out-

ward (away from the engine) slightly until the origi-

nal camber angle is obtained using special tool 8876

to move the upper control arm for proper adjustment.

(Fig. 3)

CAMBER

Move both pivot bolts of the upper control arm

together in or out. This will change the camber angle

significantly and little effect on the caster angle

using special tool 8876 to move the upper control

arm for proper adjustment. (Fig. 3)

After adjustment is made tighten the upper control

arm nuts to proper torque specification.

TOE ADJUSTMENT

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.

(2) Loosen the tie rod jam nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the

inner tie rod as necessary (Fig. 4).

(4) Tighten the tie rod jam nut to 75 N´m (55 ft.

lbs.).

(5) Verify the specifications

(6) Turn off engine.

STANDARD PROCEDURE - ALIGNMENT

LINK/COIL SUSPENSION

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down several times. Always release the bumper inthe down position.Set the front end alignment to

specifications while the vehicle is in its NOR-

MALLY LOADED CONDITION.

CAMBER:The wheel camber angle is preset and

is not adjustable.

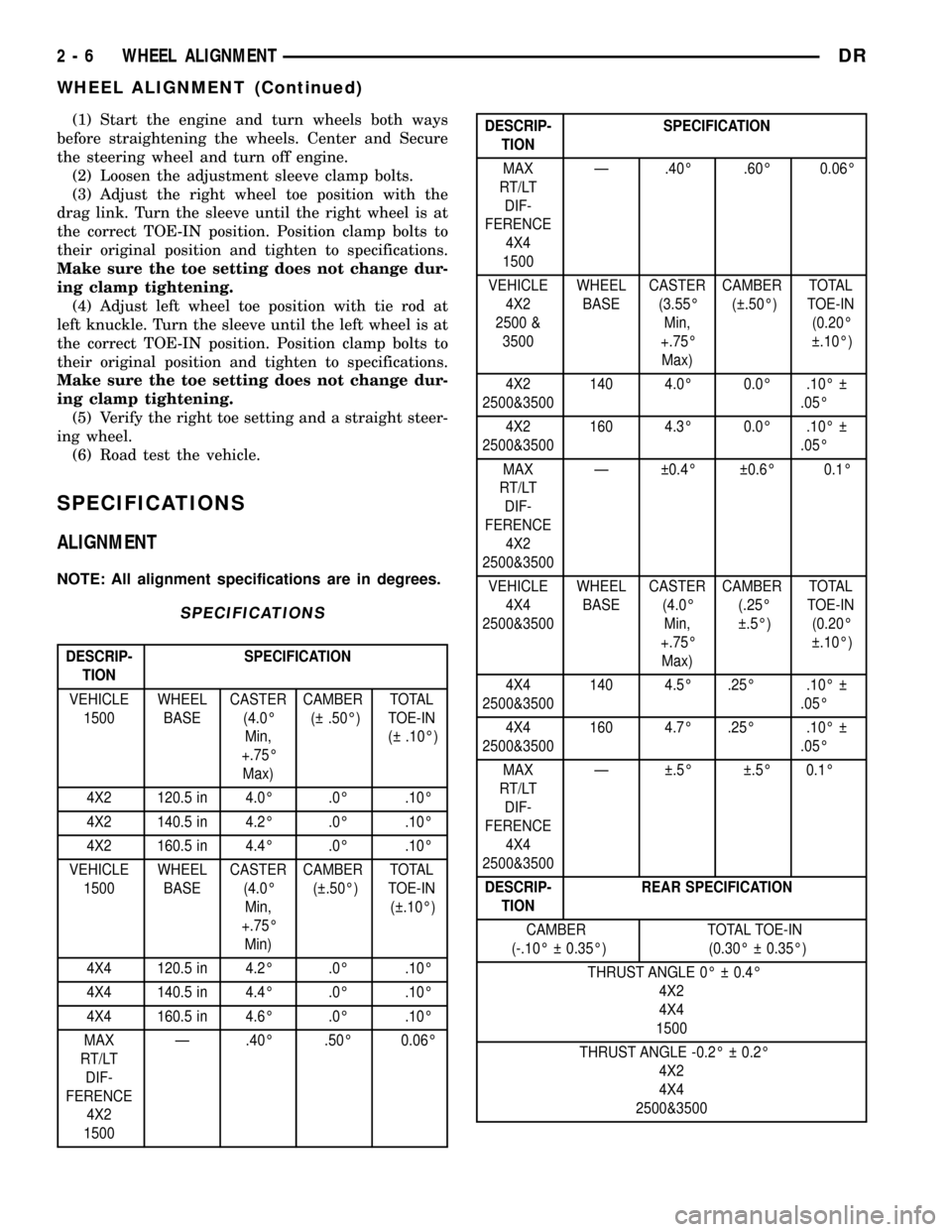

CASTER:Check the caster of the front axle for

correct angle. Be sure the axle is not bent or twisted.

Road test the vehicle and make left and right turn.

Observe the steering wheel return-to-center position.

Low caster will cause poor steering wheel returnabil-

ity.

Caster can be adjusted by rotating the cams on the

lower suspension arm (Fig. 5).

TOE POSITION:The wheel toe position adjust-

ment should be the final adjustment.

Fig. 4 TIE ROD END

1 - JAM NUT

2 - TIE ROD - INNER

3 - TIE ROD END - OUTER

Fig. 5 ALIGNMENT ADJUSTMENT CAM

1 - BRACKET REINFORCEMENT

2 - ADJUSTING BOLT

3 - ADJUSTMENT CAM

DRWHEEL ALIGNMENT 2 - 5

WHEEL ALIGNMENT (Continued)

Page 41 of 2627

(1) Start the engine and turn wheels both ways

before straightening the wheels. Center and Secure

the steering wheel and turn off engine.

(2) Loosen the adjustment sleeve clamp bolts.

(3) Adjust the right wheel toe position with the

drag link. Turn the sleeve until the right wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(4) Adjust left wheel toe position with tie rod at

left knuckle. Turn the sleeve until the left wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(5) Verify the right toe setting and a straight steer-

ing wheel.

(6) Road test the vehicle.

SPECIFICATIONS

ALIGNMENT

NOTE: All alignment specifications are in degrees.

SPECIFICATIONS

DESCRIP-

TIONSPECIFICATION

VEHICLE

1500WHEEL

BASECASTER

(4.0É

Min,

+.75É

Max)CAMBER

( .50É)TOTAL

TOE-IN

( .10É)

4X2 120.5 in 4.0É .0É .10É

4X2 140.5 in 4.2É .0É .10É

4X2 160.5 in 4.4É .0É .10É

VEHICLE

1500WHEEL

BASECASTER

(4.0É

Min,

+.75É

Min)CAMBER

( .50É)TOTAL

TOE-IN

( .10É)

4X4 120.5 in 4.2É .0É .10É

4X4 140.5 in 4.4É .0É .10É

4X4 160.5 in 4.6É .0É .10É

MAX

RT/LT

DIF-

FERENCE

4X2

1500Ð .40É .50É 0.06É

DESCRIP-

TIONSPECIFICATION

MAX

RT/LT

DIF-

FERENCE

4X4

1500Ð .40É .60É 0.06É

VEHICLE

4X2

2500 &

3500WHEEL

BASECASTER

(3.55É

Min,

+.75É

Max)CAMBER

( .50É)TOTAL

TOE-IN

(0.20É

.10É)

4X2

2500&3500140 4.0É 0.0É .10É

.05É

4X2

2500&3500160 4.3É 0.0É .10É

.05É

MAX

RT/LT

DIF-

FERENCE

4X2

2500&3500Ð 0.4É 0.6É 0.1É

VEHICLE

4X4

2500&3500WHEEL

BASECASTER

(4.0É

Min,

+.75É

Max)CAMBER

(.25É

.5É)TOTAL

TOE-IN

(0.20É

.10É)

4X4

2500&3500140 4.5É .25É .10É

.05É

4X4

2500&3500160 4.7É .25É .10É

.05É

MAX

RT/LT

DIF-

FERENCE

4X4

2500&3500Ð .5É .5É 0.1É

DESCRIP-

TIONREAR SPECIFICATION

CAMBER

(-.10É 0.35É)TOTAL TOE-IN

(0.30É 0.35É)

THRUST ANGLE 0É 0.4É

4X2

4X4

1500

THRUST ANGLE -0.2É 0.2É

4X2

4X4

2500&3500

2 - 6 WHEEL ALIGNMENTDR

WHEEL ALIGNMENT (Continued)

Page 62 of 2627

INSTALLATION

CAUTION: The left and right side torsion bars are

NOT interchangeable. The bars are identified and

stamped R or L, for right or left. The bars do not

have a front or rear end and can be installed with

either end facing forward.

(1) Insert torsion bar ends into anchor and suspen-

sion arm.

(2) Position the anchor in the frame crossmember.

(3) Install Special Tool - 8686 to the anchor and

the crossmember (Fig. 30).

(4) Increase the tension on the anchor in order to

load the torsion bar.

(5) Install the adjustment bolt and the adjuster

nut.

(6) Turn adjustment bolt clockwise the recorded

amount of turns.

(7) Remove tool - 8686 from the torsion bar cross-

member (Fig. 30).

(8) Install the transfer case skid plate (Refer to 13

- FRAME & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION).

(9) Lower vehicle and adjust the front suspension

height (Refer to 2 - SUSPENSION/WHEEL ALIGN-

MENT - STANDARD PROCEDURE).

(10) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

UPPER BALL JOINT

DIAGNOSIS AND TESTING - UPPER BALL

JOINT

NOTE: If the ball joint is equipped with a lubrication

fitting, grease the joint then road test the vehicle

before performing test.

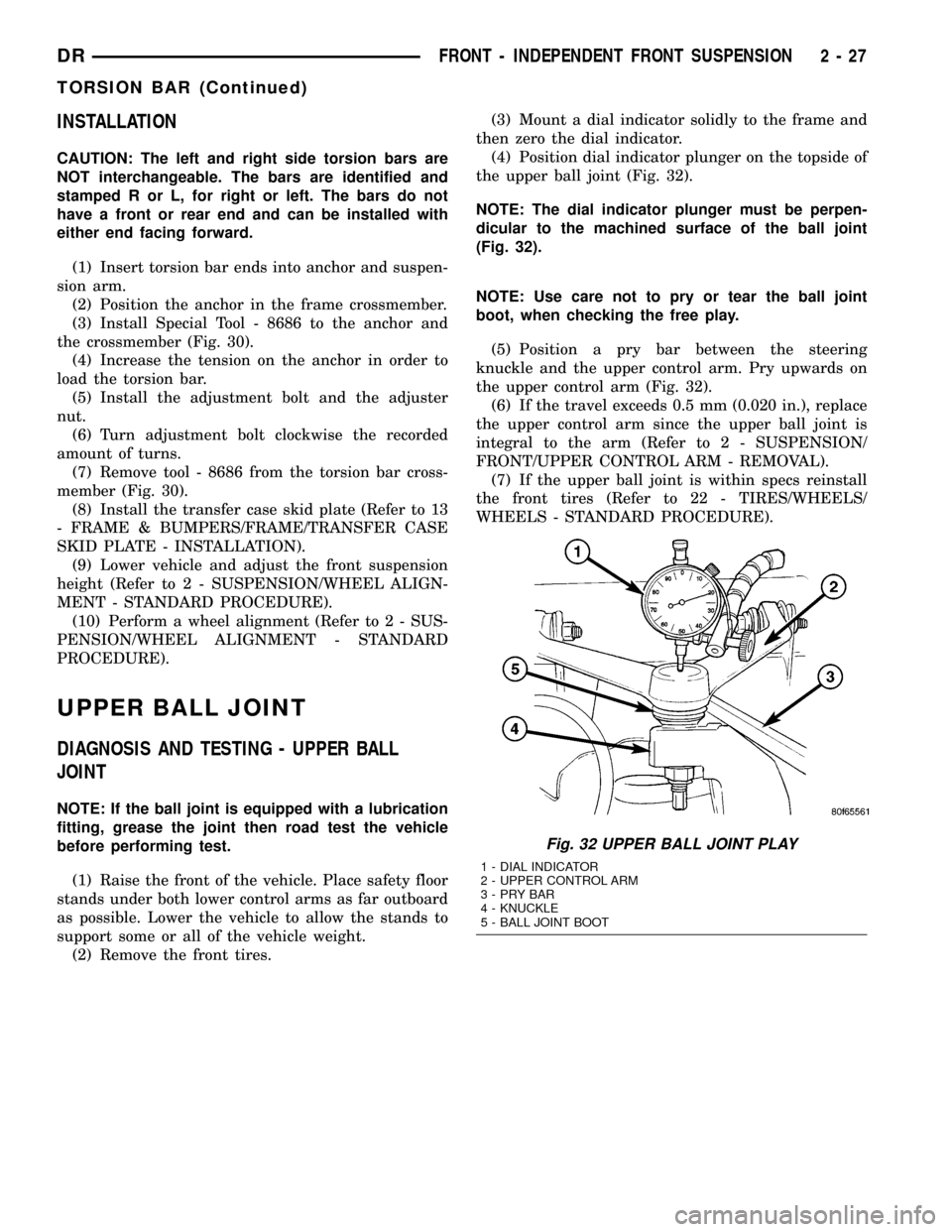

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.(3) Mount a dial indicator solidly to the frame and

then zero the dial indicator.

(4) Position dial indicator plunger on the topside of

the upper ball joint (Fig. 32).

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the ball joint

(Fig. 32).

NOTE: Use care not to pry or tear the ball joint

boot, when checking the free play.

(5) Position a pry bar between the steering

knuckle and the upper control arm. Pry upwards on

the upper control arm (Fig. 32).

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the upper control arm since the upper ball joint is

integral to the arm (Refer to 2 - SUSPENSION/

FRONT/UPPER CONTROL ARM - REMOVAL).

(7) If the upper ball joint is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

Fig. 32 UPPER BALL JOINT PLAY

1 - DIAL INDICATOR

2 - UPPER CONTROL ARM

3-PRYBAR

4 - KNUCKLE

5 - BALL JOINT BOOT

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 27

TORSION BAR (Continued)

Page 138 of 2627

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

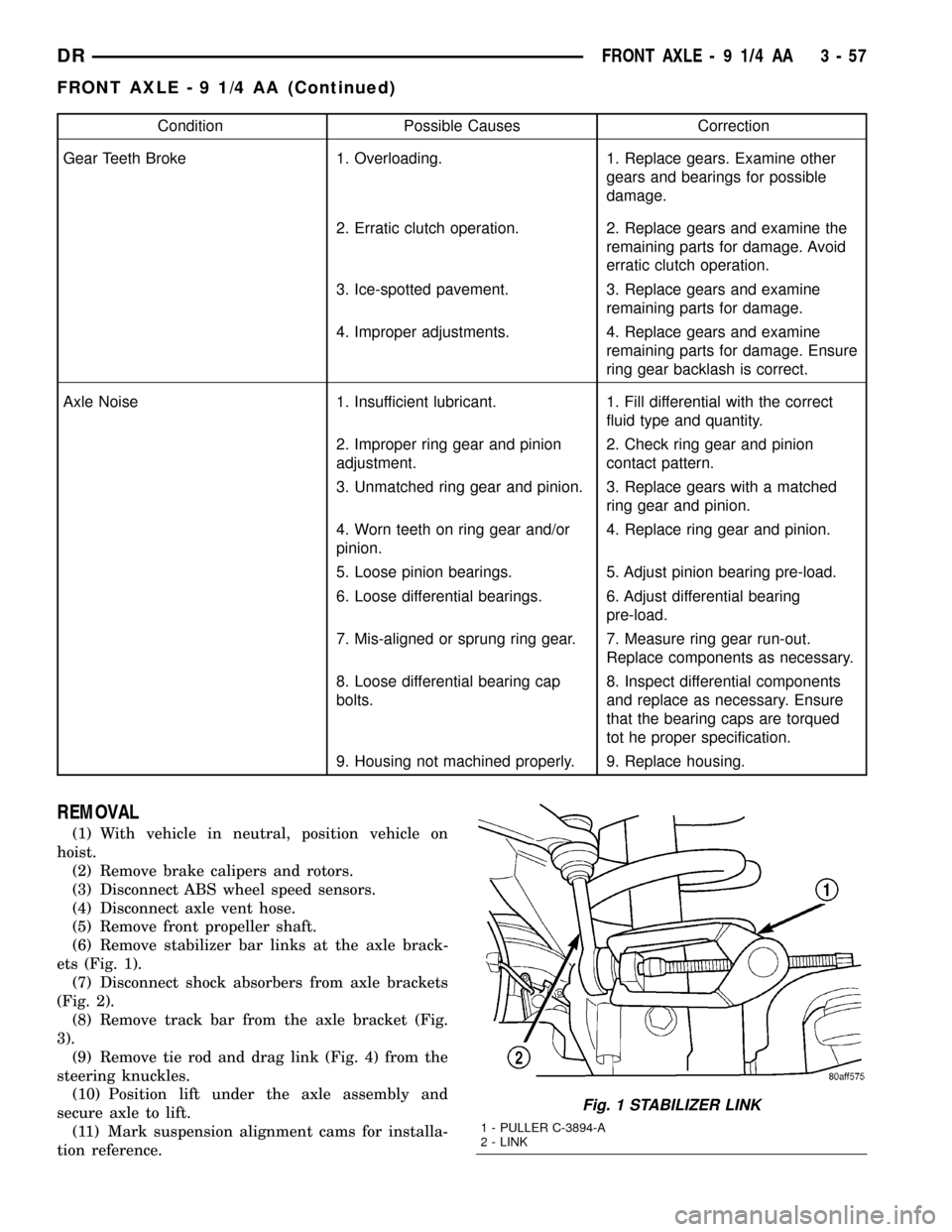

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove brake calipers and rotors.

(3) Disconnect ABS wheel speed sensors.

(4) Disconnect axle vent hose.

(5) Remove front propeller shaft.

(6) Remove stabilizer bar links at the axle brack-

ets (Fig. 1).

(7) Disconnect shock absorbers from axle brackets

(Fig. 2).

(8) Remove track bar from the axle bracket (Fig.

3).

(9) Remove tie rod and drag link (Fig. 4) from the

steering knuckles.

(10) Position lift under the axle assembly and

secure axle to lift.

(11) Mark suspension alignment cams for installa-

tion reference.

Fig. 1 STABILIZER LINK

1 - PULLER C-3894-A

2 - LINK

DRFRONT AXLE - 9 1/4 AA 3 - 57

FRONT AXLE - 9 1/4 AA (Continued)

Page 140 of 2627

(7) Connect track bar to the axle bracket and

install the bolt. Do not tighten at this time.

(8) Install shock absorber and tighten bolts to 121

N´m (89 ft. lbs.).

(9) Install stabilizer bar link to the axle bracket.

Tighten the nut to 68 N´m (50 ft. lbs.).

(10) Install drag link and tie rod to the steering

knuckles and tighten the nuts to 108 N´m (80 ft.

lbs.).

(11) Install ABS wheel speed sensors.

(12) Install rotors and brake calipers.

(13) Connect the axle vent hose.

(14) Install front propeller shaft.

(15) With vehicle on the ground, tighten upper

suspension arm nuts at axle to 149 N´m (110 ft. lbs.).

Tighten upper suspension arm nuts at frame to 149

N´m (110 ft. lbs.).

(16) With vehicle on the ground, tighten lower sus-

pension arm nuts at axle to 190 N´m (140 ft. lbs.).

Tighten the lower suspension arm nuts at frame to

190 N´m (140 ft. lbs.).

(17) Tighten track bar bolt at the axle bracket to

176 N´m (130 ft. lbs.).

(18) Check front wheel alignment.

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets. Compensation for pinion depth variance is

achieved with a select shim. located between the rear

pinion bearing and pinion gear head.

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

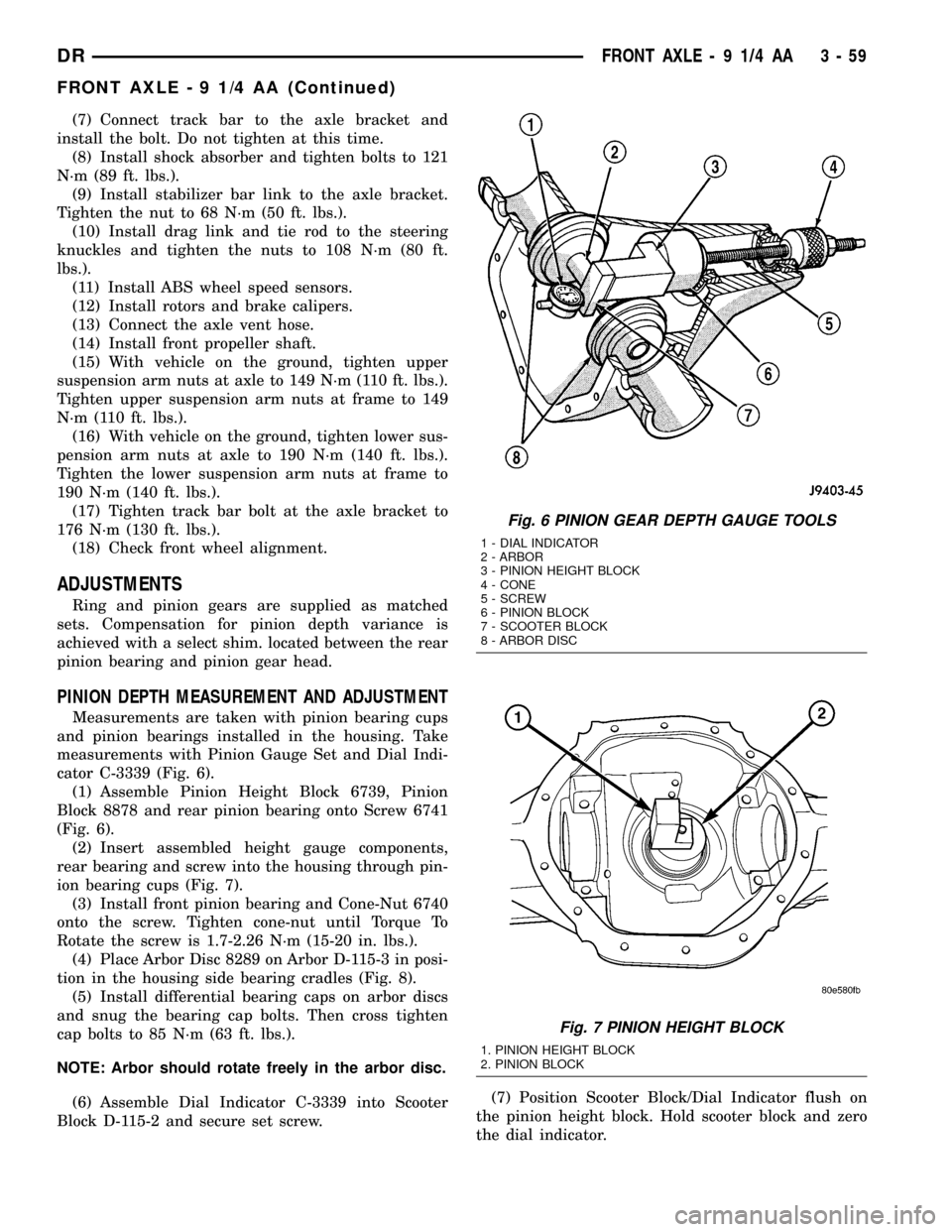

cator C-3339 (Fig. 6).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8878 and rear pinion bearing onto Screw 6741

(Fig. 6).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 7).

(3) Install front pinion bearing and Cone-Nut 6740

onto the screw. Tighten cone-nut until Torque To

Rotate the screw is 1.7-2.26 N´m (15-20 in. lbs.).

(4) Place Arbor Disc 8289 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 8).

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 85 N´m (63 ft. lbs.).

NOTE: Arbor should rotate freely in the arbor disc.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

Fig. 6 PINION GEAR DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 7 PINION HEIGHT BLOCK

1. PINION HEIGHT BLOCK

2. PINION BLOCK

DRFRONT AXLE - 9 1/4 AA 3 - 59

FRONT AXLE - 9 1/4 AA (Continued)

Page 251 of 2627

FLUID RESERVOIR

REMOVAL.............................23

INSTALLATION.........................24

BRAKE JUNCTION BLOCK

REMOVAL.............................24

INSTALLATION.........................24

MASTER CYLINDER

DESCRIPTION.........................24

OPERATION...........................25

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER...........25

STANDARD PROCEDURE - MASTER

CYLINDER BLEEDING..................26

REMOVAL

REMOVAL - ALL EXCEPT HYDROBOOST . . . 26

REMOVAL - HYDROBOOST.............26

INSTALLATION

INSTALLATION - ALL EXCEPT

HYDROBOOST.......................27

INSTALLATION - HYDROBOOST..........27

PEDAL

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................28

INSTALLATION.........................28

POWER BRAKE BOOSTER

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

INSTALLATION.........................29

HYDRO-BOOST BRAKE BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER...........................30

STANDARD PROCEDURE - BLEEDING......31

REMOVAL.............................31

INSTALLATION.........................32

ROTORS

DIAGNOSIS AND TESTING

DISC BRAKE ROTOR..................32

REMOVAL

REMOVAL - FRONT....................33

REMOVAL - REAR.....................34REMOVAL - REAR DUAL WHEELS........34

INSTALLATION

INSTALLATION - FRONT................34

INSTALLATION - REAR.................34

INSTALLATION - REAR DUAL WHEELS....35

SUPPORT PLATE

REMOVAL.............................35

INSTALLATION.........................36

PARKING BRAKE

DESCRIPTION.........................36

OPERATION...........................36

CABLES

REMOVAL

REMOVAL - FRONT PARKING BRAKE

CABLE..............................36

REMOVAL - REAR PARK BRAKE CABLE . . . 37

REMOVAL - RIGHT REAR CABLE.........37

REMOVAL - LEFT REAR CABLE..........38

INSTALLATION

INSTALLATION - FRONT PARKING BRAKE

CABLE..............................38

INSTALLATION - REAR PARK BRAKE

CABLE..............................38

INSTALLATION - RIGHT REAR CABLE.....38

INSTALLATION - LEFT REAR CABLE......39

SHOES

REMOVAL.............................39

CLEANING - REAR DRUM IN HAT BRAKE....39

INSPECTION - REAR DRUM IN HAT BRAKE . . 39

INSTALLATION.........................40

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES . . 41

ADJUSTMENT - WITH ADJUSTING TOOL . . . 42

PEDAL

REMOVAL.............................42

INSTALLATION.........................42

CABLE TENSIONER

ADJUSTMENTS

ADJUSTMENT........................43

RELEASE HANDLE

REMOVAL.............................44

INSTALLATION.........................44

BRAKES - BASE

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake pads,

calipers, brake drum in hat rotor in the rear, rotors,

brake lines, master cylinder, booster, and parking

brake components.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

5 - 2 BRAKES - BASEDR