rear light DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 178 of 2627

(10) If rotating torque is low, use Holder 6719 to

hold the companion flange and tighten pinion nut in

6.8 N´m (5 ft. lbs.) increments until proper rotating

torque is achieved.

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

NOTE: The seal replacement is unacceptable if the

final pinion nut torque is less than 285 N´m (210 ft.

lbs.).

(11) Install propeller shaft with the installation

reference marks aligned.

(12) Tighten the companion flange bolts to 108

N´m (80 ft. lbs.).

(13) Install brake rotors.

(14) Check the differential lubricant level.

DIFFERENTIAL COVER

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove drain plug.

(3) Remove cover bolts.

(4) Remove cover and drain lubricant.

INSTALLATION

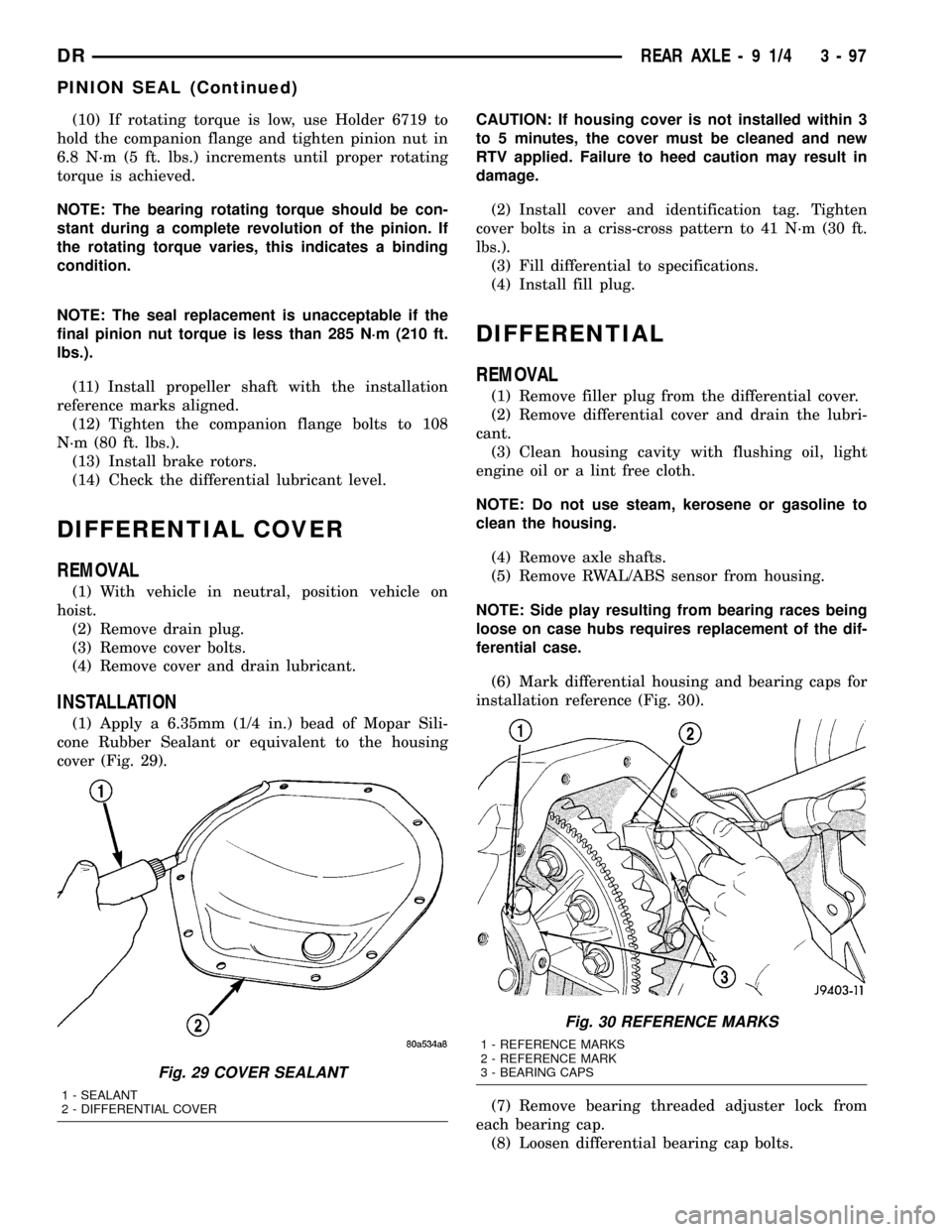

(1) Apply a 6.35mm (1/4 in.) bead of Mopar Sili-

cone Rubber Sealant or equivalent to the housing

cover (Fig. 29).CAUTION: If housing cover is not installed within 3

to 5 minutes, the cover must be cleaned and new

RTV applied. Failure to heed caution may result in

damage.

(2) Install cover and identification tag. Tighten

cover bolts in a criss-cross pattern to 41 N´m (30 ft.

lbs.).

(3) Fill differential to specifications.

(4) Install fill plug.

DIFFERENTIAL

REMOVAL

(1) Remove filler plug from the differential cover.

(2) Remove differential cover and drain the lubri-

cant.

(3) Clean housing cavity with flushing oil, light

engine oil or a lint free cloth.

NOTE: Do not use steam, kerosene or gasoline to

clean the housing.

(4) Remove axle shafts.

(5) Remove RWAL/ABS sensor from housing.

NOTE: Side play resulting from bearing races being

loose on case hubs requires replacement of the dif-

ferential case.

(6) Mark differential housing and bearing caps for

installation reference (Fig. 30).

(7) Remove bearing threaded adjuster lock from

each bearing cap.

(8) Loosen differential bearing cap bolts.

Fig. 29 COVER SEALANT

1 - SEALANT

2 - DIFFERENTIAL COVER

Fig. 30 REFERENCE MARKS

1 - REFERENCE MARKS

2 - REFERENCE MARK

3 - BEARING CAPS

DRREAR AXLE - 9 1/4 3 - 97

PINION SEAL (Continued)

Page 185 of 2627

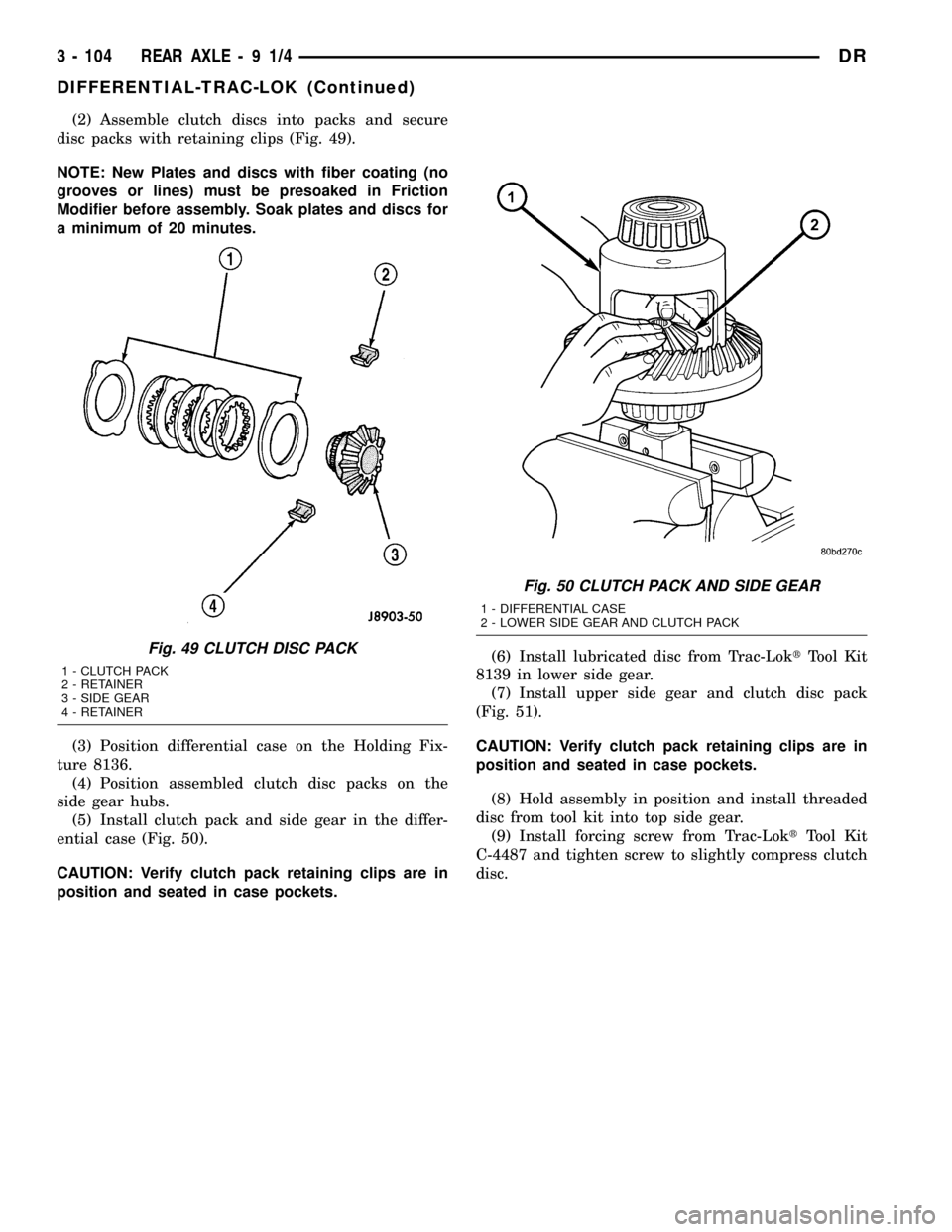

(2) Assemble clutch discs into packs and secure

disc packs with retaining clips (Fig. 49).

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.

(3) Position differential case on the Holding Fix-

ture 8136.

(4) Position assembled clutch disc packs on the

side gear hubs.

(5) Install clutch pack and side gear in the differ-

ential case (Fig. 50).

CAUTION: Verify clutch pack retaining clips are in

position and seated in case pockets.(6) Install lubricated disc from Trac-LoktTool Kit

8139 in lower side gear.

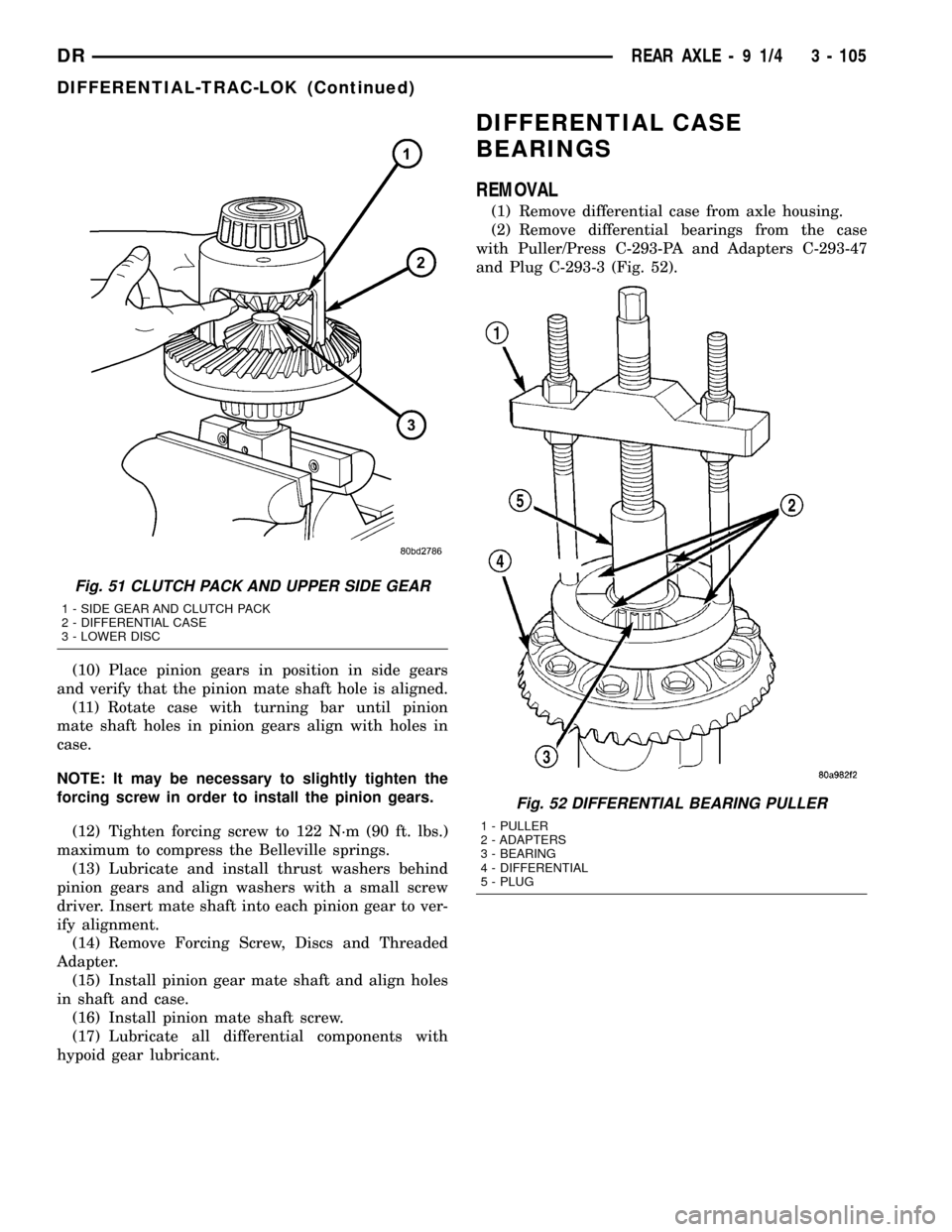

(7) Install upper side gear and clutch disc pack

(Fig. 51).

CAUTION: Verify clutch pack retaining clips are in

position and seated in case pockets.

(8) Hold assembly in position and install threaded

disc from tool kit into top side gear.

(9) Install forcing screw from Trac-LoktTool Kit

C-4487 and tighten screw to slightly compress clutch

disc.

Fig. 49 CLUTCH DISC PACK

1 - CLUTCH PACK

2 - RETAINER

3 - SIDE GEAR

4 - RETAINER

Fig. 50 CLUTCH PACK AND SIDE GEAR

1 - DIFFERENTIAL CASE

2 - LOWER SIDE GEAR AND CLUTCH PACK

3 - 104 REAR AXLE-91/4DR

DIFFERENTIAL-TRAC-LOK (Continued)

Page 186 of 2627

(10) Place pinion gears in position in side gears

and verify that the pinion mate shaft hole is aligned.

(11) Rotate case with turning bar until pinion

mate shaft holes in pinion gears align with holes in

case.

NOTE: It may be necessary to slightly tighten the

forcing screw in order to install the pinion gears.

(12) Tighten forcing screw to 122 N´m (90 ft. lbs.)

maximum to compress the Belleville springs.

(13) Lubricate and install thrust washers behind

pinion gears and align washers with a small screw

driver. Insert mate shaft into each pinion gear to ver-

ify alignment.

(14) Remove Forcing Screw, Discs and Threaded

Adapter.

(15) Install pinion gear mate shaft and align holes

in shaft and case.

(16) Install pinion mate shaft screw.

(17) Lubricate all differential components with

hypoid gear lubricant.

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove differential case from axle housing.

(2) Remove differential bearings from the case

with Puller/Press C-293-PA and Adapters C-293-47

and Plug C-293-3 (Fig. 52).

Fig. 51 CLUTCH PACK AND UPPER SIDE GEAR

1 - SIDE GEAR AND CLUTCH PACK

2 - DIFFERENTIAL CASE

3 - LOWER DISC

Fig. 52 DIFFERENTIAL BEARING PULLER

1 - PULLER

2 - ADAPTERS

3 - BEARING

4 - DIFFERENTIAL

5 - PLUG

DRREAR AXLE - 9 1/4 3 - 105

DIFFERENTIAL-TRAC-LOK (Continued)

Page 190 of 2627

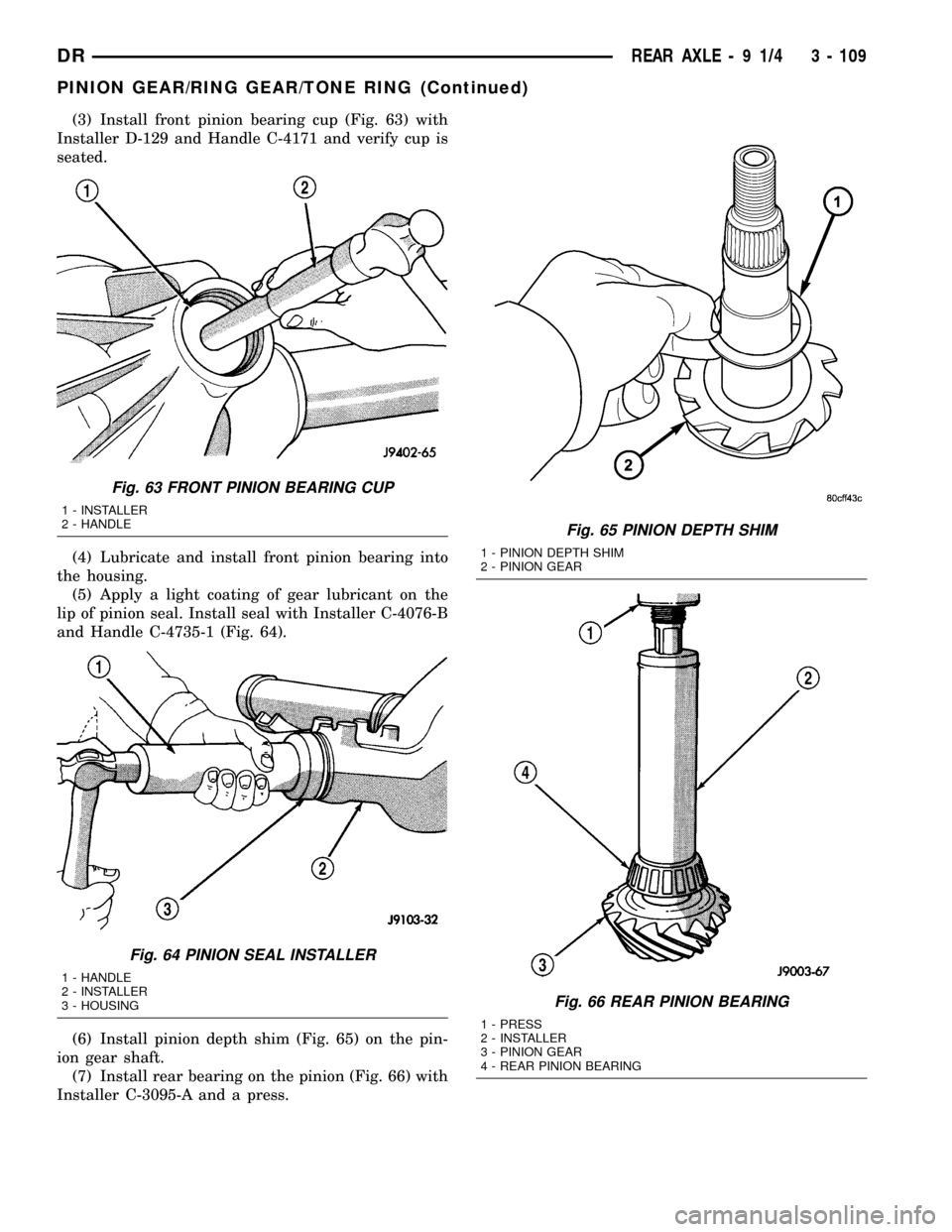

(3) Install front pinion bearing cup (Fig. 63) with

Installer D-129 and Handle C-4171 and verify cup is

seated.

(4) Lubricate and install front pinion bearing into

the housing.

(5) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with Installer C-4076-B

and Handle C-4735-1 (Fig. 64).

(6) Install pinion depth shim (Fig. 65) on the pin-

ion gear shaft.

(7) Install rear bearing on the pinion (Fig. 66) with

Installer C-3095-A and a press.

Fig. 63 FRONT PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 64 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

3 - HOUSING

Fig. 65 PINION DEPTH SHIM

1 - PINION DEPTH SHIM

2 - PINION GEAR

Fig. 66 REAR PINION BEARING

1 - PRESS

2 - INSTALLER

3 - PINION GEAR

4 - REAR PINION BEARING

DRREAR AXLE - 9 1/4 3 - 109

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 193 of 2627

REAR AXLE - 10 1/2 AA

TABLE OF CONTENTS

page page

REAR AXLE - 10 1/2 AA

DIAGNOSIS AND TESTING...............112

REMOVAL............................115

INSTALLATION........................116

ADJUSTMENTS.......................116

SPECIFICATIONS......................120

SPECIAL TOOLS.......................120

AXLE SHAFTS

REMOVAL............................124

INSTALLATION........................124

AXLE BEARINGS

REMOVAL............................125

INSTALLATION........................125

PINION SEAL

REMOVAL............................126

INSTALLATION........................126

DIFFERENTIAL

REMOVAL............................127DISASSEMBLY........................128

ASSEMBLY...........................129

INSTALLATION........................130

DIFFERENTIAL TRAC-RITE

DESCRIPTION........................131

OPERATION..........................131

DISASSEMBLY........................131

CLEANING...........................132

INSPECTION.........................132

ASSEMBLY...........................133

DIFFERENTIAL CASE BEARINGS

REMOVAL............................134

INSTALLATION........................134

PINION GEAR/RING GEAR/TONE RING

REMOVAL............................134

INSTALLATION........................137

REAR AXLE - 10 1/2 AA

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, incorrect pinion depth, tooth

contact, worn/damaged gears, or the carrier housing

not having the proper offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly check for:

²Insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. The side gears are loaded dur-

ing turns. They usually do not cause noise during

straight-ahead driving when the gears are unloaded.

A worn pinion shaft can also cause a snapping or a

knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearingshave a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Differential bearingsusually produce a low pitch

noise. Differential bearing noise is similar to pinion

bearing noise. The pitch of differential bearing noise

is also constant and varies only with vehicle speed.

Axle shaft bearingsproduce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 m.p.h.

LOW SPEED KNOCK

Low speed knock is generally caused by:

²Worn U-joint(s).

²Worn side-gear thrust washers.

²Worn pinion shaft bore.

3 - 112 REAR AXLE - 10 1/2 AADR

Page 199 of 2627

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the def-

erential bearings.

(9) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup, then tighten

it until it makes contact.

(10) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(11) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(12) Tighten bearing cap bolts to 115 N´m (85 ft.

lbs.).

(13) Tighten adjuster lock bolts to 33 N´m (24 ft.

lbs.).

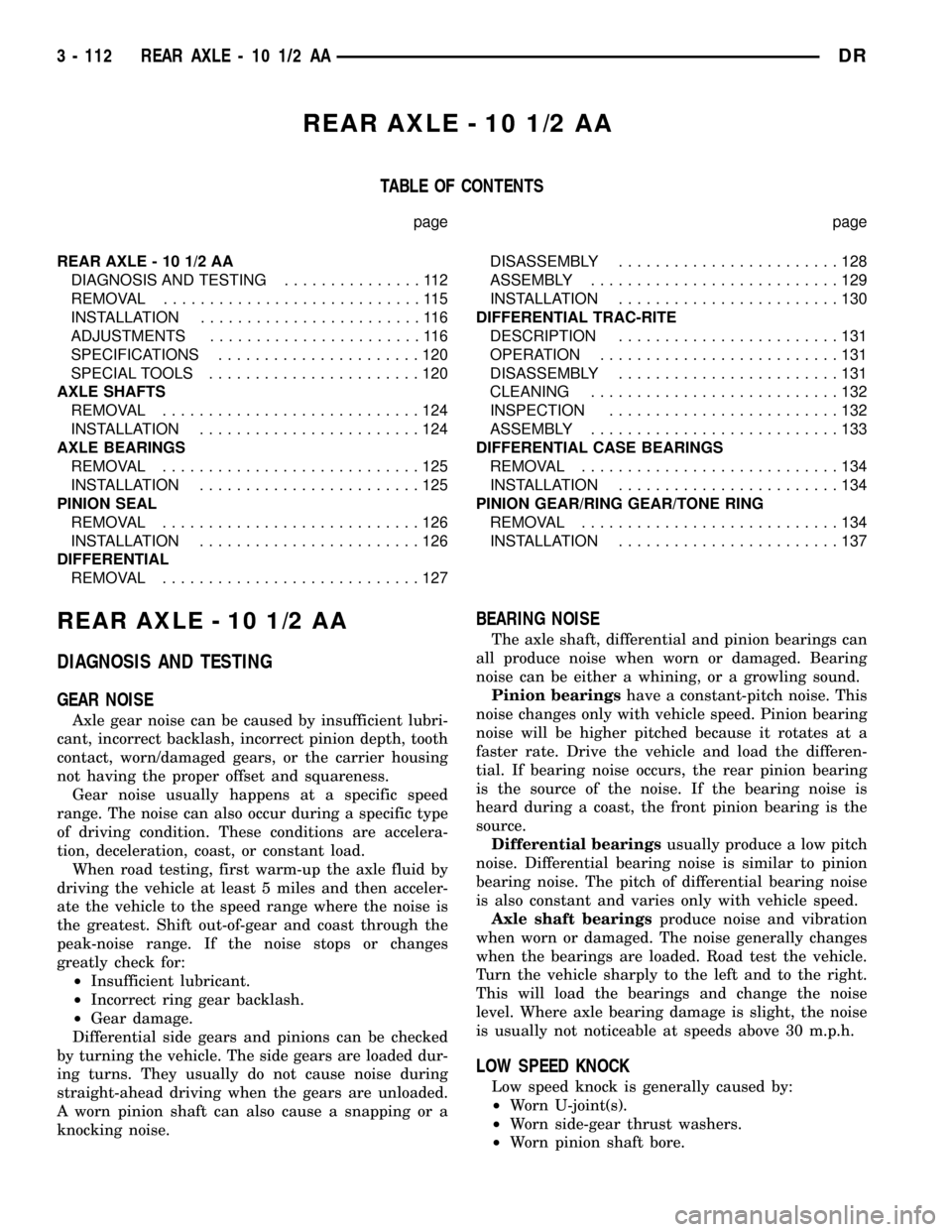

(14) Measure ring gear backlash with a Dial Indi-

cator C-3339 and Dial Indicator Stud L-4438 at eight

points around the drive side of the ring gear (Fig. 9).

The backlash should be 0.08-0.25 mm (0.003-0.010

in) with a preferred backlash of 0.13-0.18 mm (0.005-

0.007 in).

NOTE: Backlash measurement should not vary

more than 0.05 mm (0.002 in) between measuring

points. If measurement does vary inspect the gears

for burrs, the differential case flange and ring gear

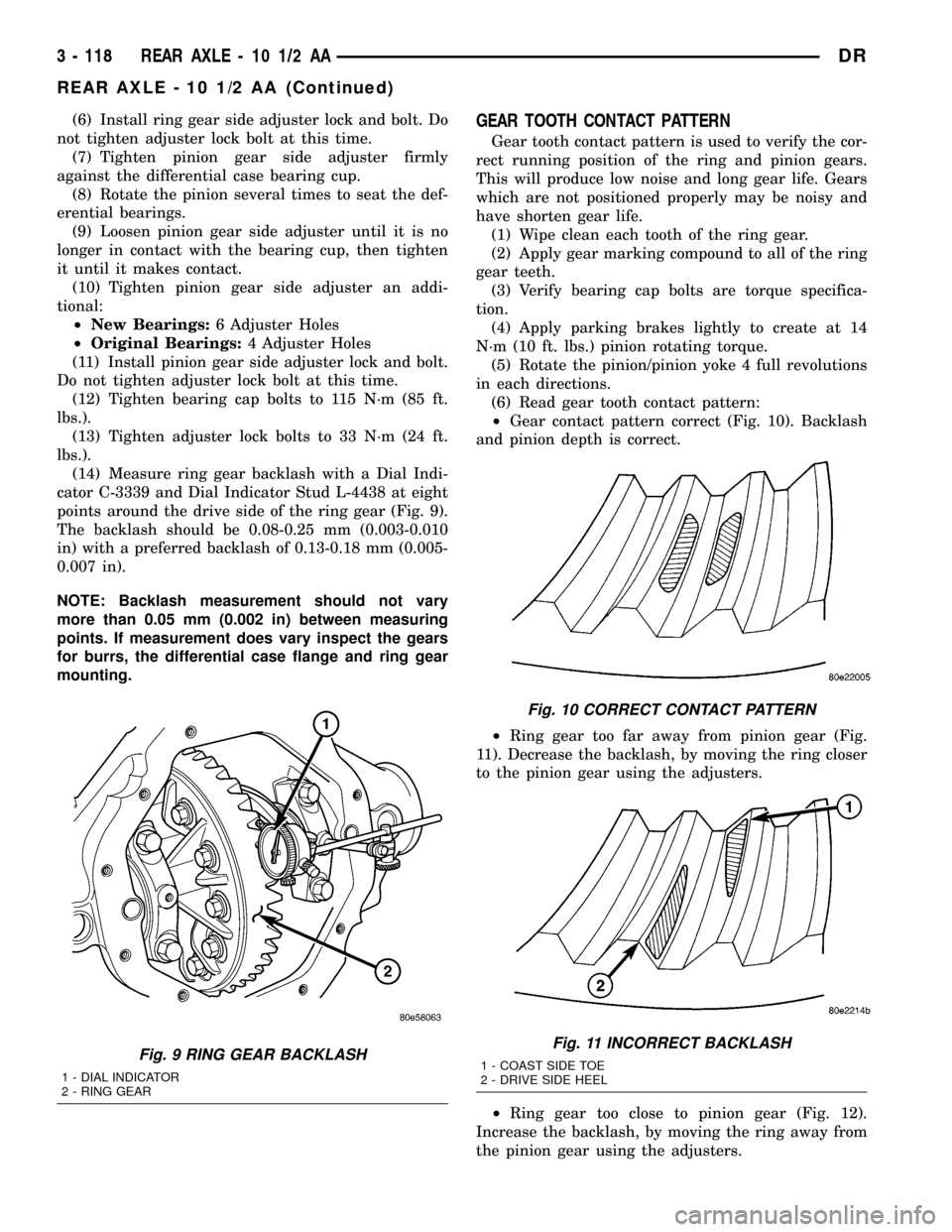

mounting.GEAR TOOTH CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

²Gear contact pattern correct (Fig. 10). Backlash

and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig.

11). Decrease the backlash, by moving the ring closer

to the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 12).

Increase the backlash, by moving the ring away from

the pinion gear using the adjusters.

Fig. 9 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

Fig. 10 CORRECT CONTACT PATTERN

Fig. 11 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

3 - 118 REAR AXLE - 10 1/2 AADR

REAR AXLE - 10 1/2 AA (Continued)

Page 207 of 2627

(8)Install retainer ring with ring end in the key slot.

(9) Install new axle shaft gasket and install axle

shaft.

PINION SEAL

REMOVAL

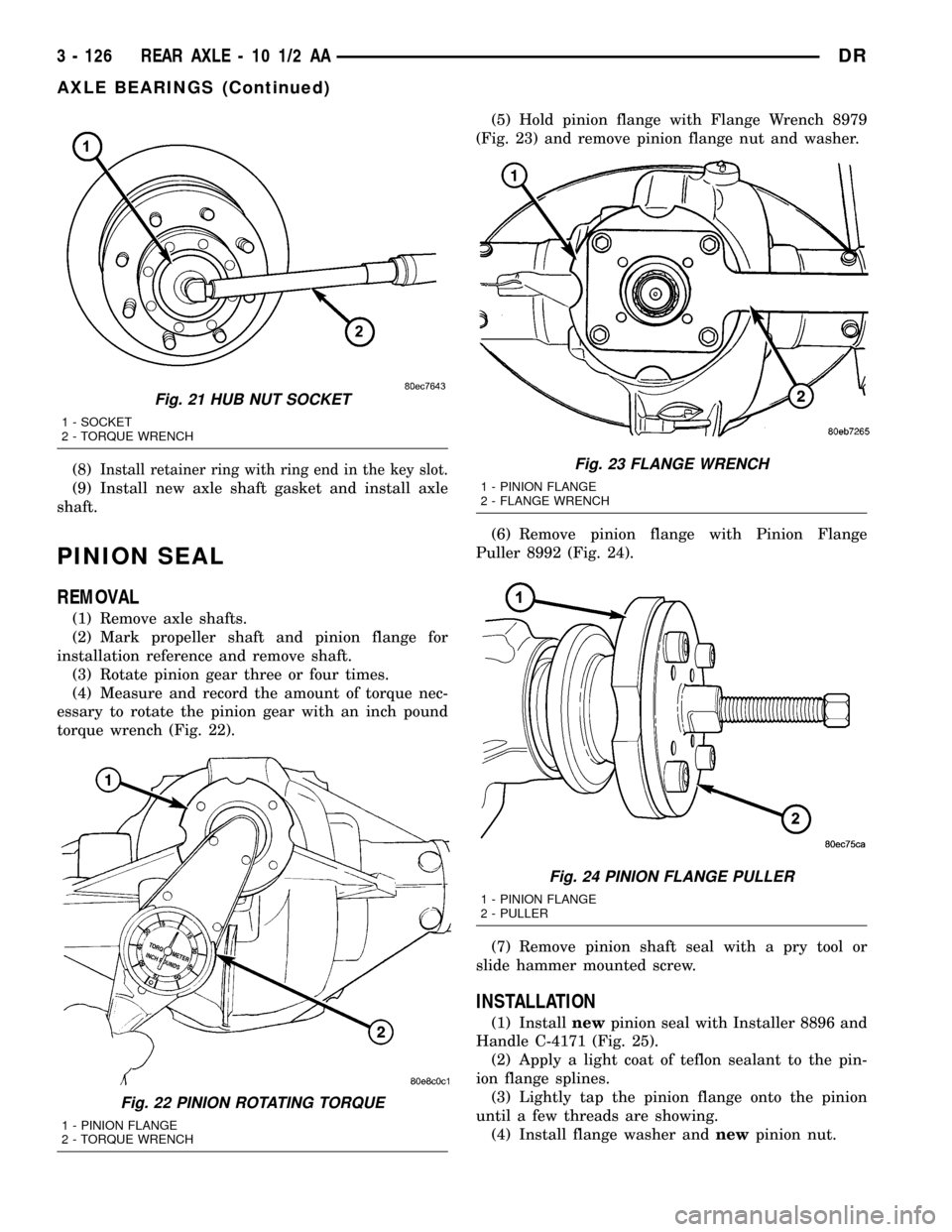

(1) Remove axle shafts.

(2) Mark propeller shaft and pinion flange for

installation reference and remove shaft.

(3) Rotate pinion gear three or four times.

(4) Measure and record the amount of torque nec-

essary to rotate the pinion gear with an inch pound

torque wrench (Fig. 22).(5) Hold pinion flange with Flange Wrench 8979

(Fig. 23) and remove pinion flange nut and washer.

(6) Remove pinion flange with Pinion Flange

Puller 8992 (Fig. 24).

(7) Remove pinion shaft seal with a pry tool or

slide hammer mounted screw.

INSTALLATION

(1) Installnewpinion seal with Installer 8896 and

Handle C-4171 (Fig. 25).

(2) Apply a light coat of teflon sealant to the pin-

ion flange splines.

(3) Lightly tap the pinion flange onto the pinion

until a few threads are showing.

(4) Install flange washer andnewpinion nut.

Fig. 21 HUB NUT SOCKET

1 - SOCKET

2 - TORQUE WRENCH

Fig. 22 PINION ROTATING TORQUE

1 - PINION FLANGE

2 - TORQUE WRENCH

Fig. 23 FLANGE WRENCH

1 - PINION FLANGE

2 - FLANGE WRENCH

Fig. 24 PINION FLANGE PULLER

1 - PINION FLANGE

2 - PULLER

3 - 126 REAR AXLE - 10 1/2 AADR

AXLE BEARINGS (Continued)

Page 211 of 2627

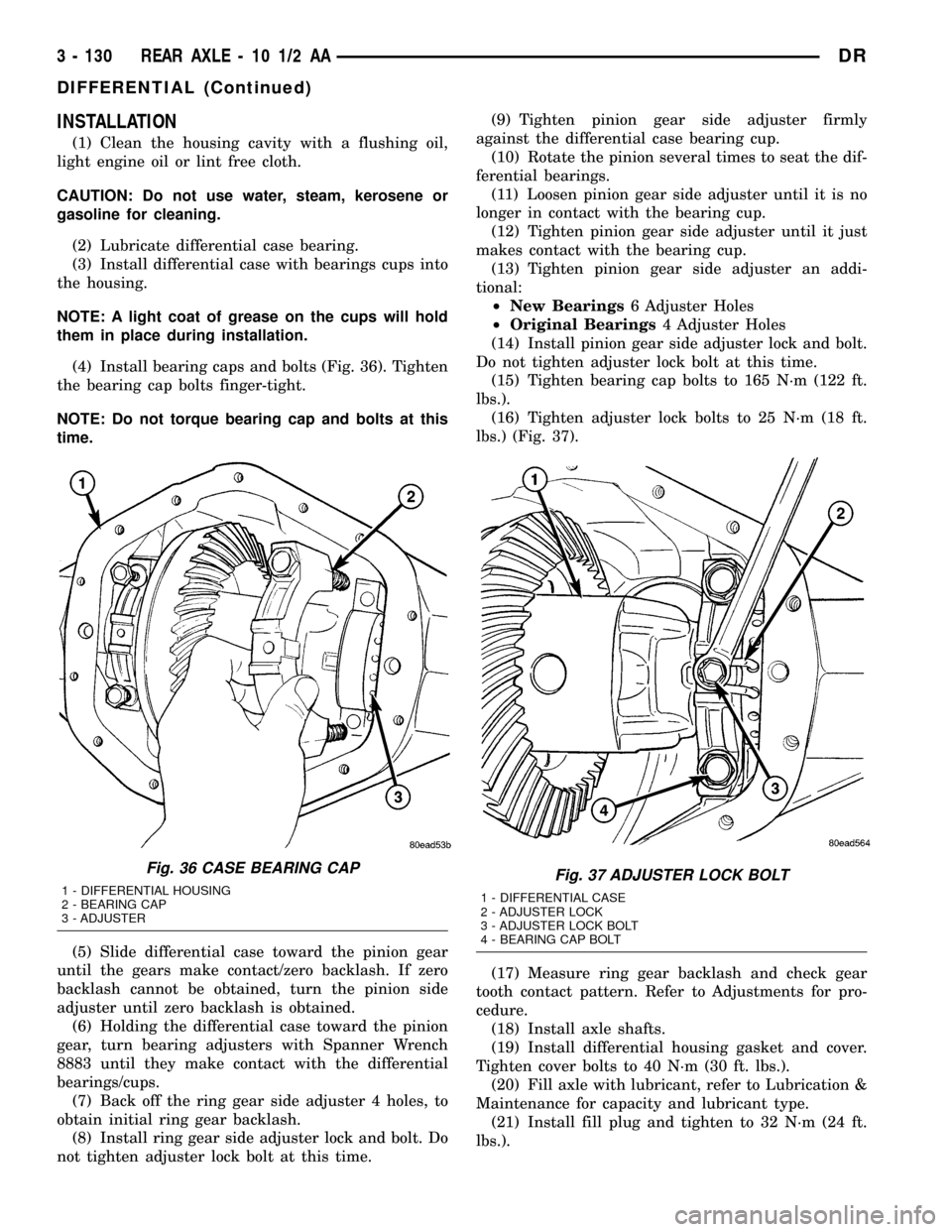

INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

NOTE: A light coat of grease on the cups will hold

them in place during installation.

(4) Install bearing caps and bolts (Fig. 36). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 165 N´m (122 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).

Fig. 36 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTERFig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 130 REAR AXLE - 10 1/2 AADR

DIFFERENTIAL (Continued)

Page 213 of 2627

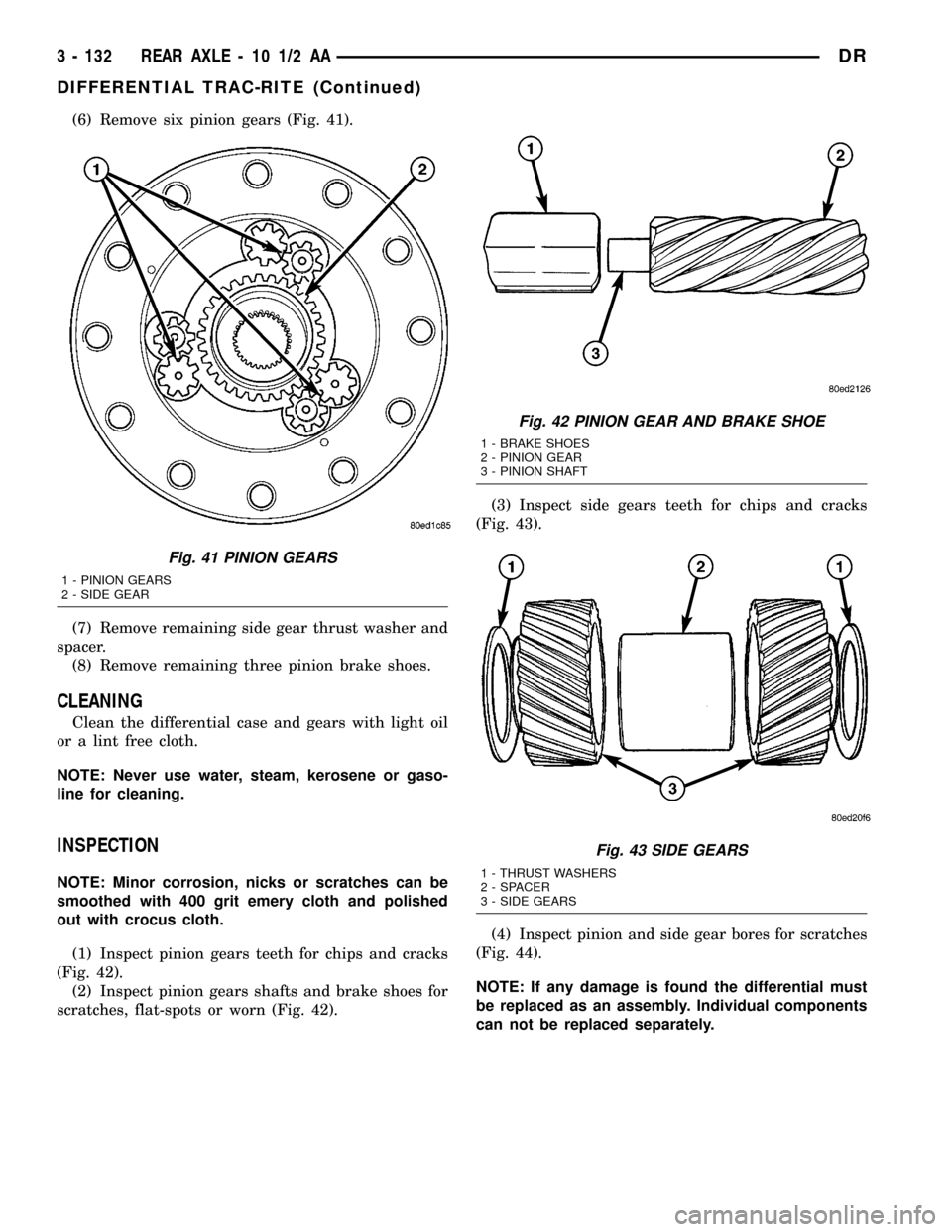

(6) Remove six pinion gears (Fig. 41).

(7) Remove remaining side gear thrust washer and

spacer.

(8) Remove remaining three pinion brake shoes.

CLEANING

Clean the differential case and gears with light oil

or a lint free cloth.

NOTE: Never use water, steam, kerosene or gaso-

line for cleaning.

INSPECTION

NOTE: Minor corrosion, nicks or scratches can be

smoothed with 400 grit emery cloth and polished

out with crocus cloth.

(1) Inspect pinion gears teeth for chips and cracks

(Fig. 42).

(2) Inspect pinion gears shafts and brake shoes for

scratches, flat-spots or worn (Fig. 42).(3) Inspect side gears teeth for chips and cracks

(Fig. 43).

(4) Inspect pinion and side gear bores for scratches

(Fig. 44).

NOTE: If any damage is found the differential must

be replaced as an assembly. Individual components

can not be replaced separately.

Fig. 41 PINION GEARS

1 - PINION GEARS

2 - SIDE GEAR

Fig. 42 PINION GEAR AND BRAKE SHOE

1 - BRAKE SHOES

2 - PINION GEAR

3 - PINION SHAFT

Fig. 43 SIDE GEARS

1 - THRUST WASHERS

2 - SPACER

3 - SIDE GEARS

3 - 132 REAR AXLE - 10 1/2 AADR

DIFFERENTIAL TRAC-RITE (Continued)

Page 219 of 2627

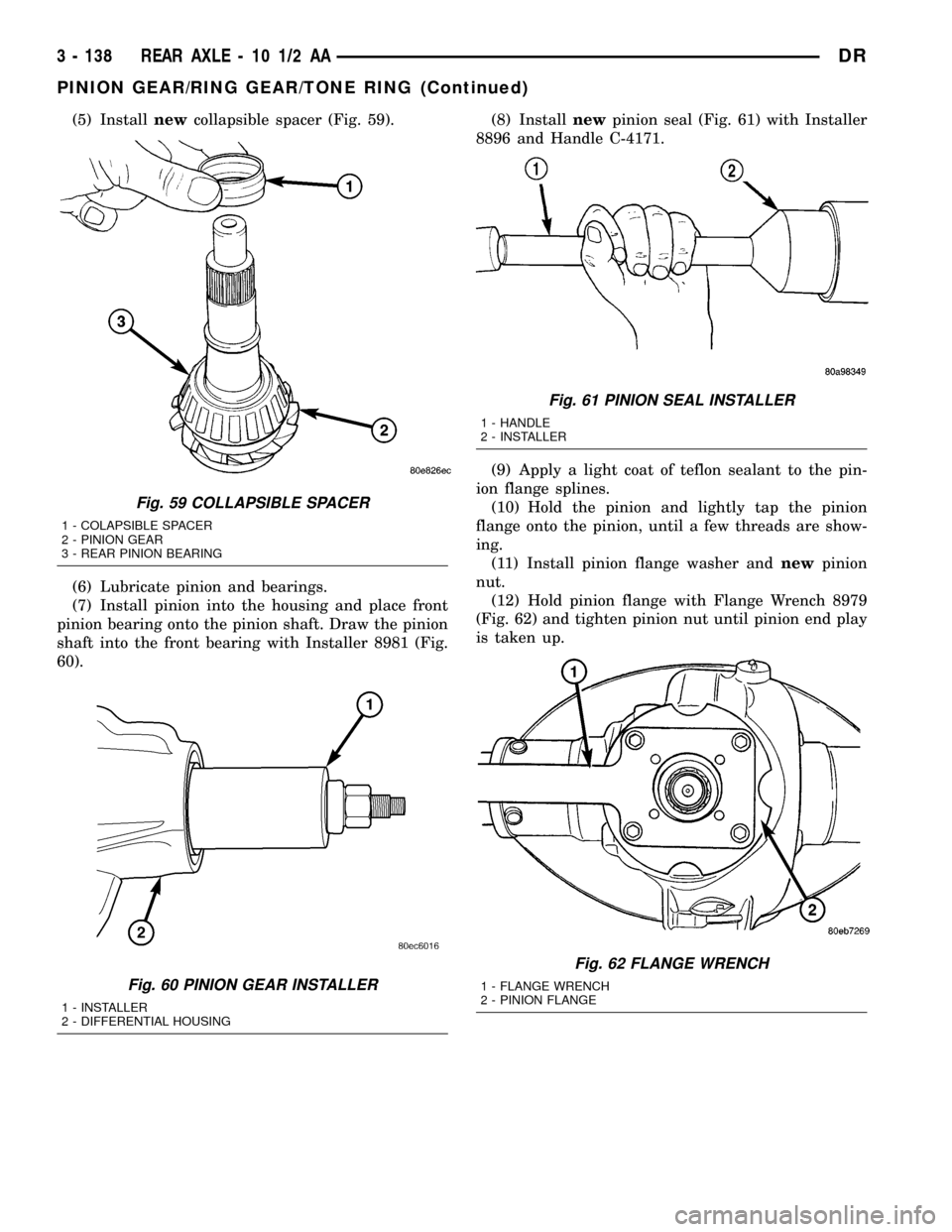

(5) Installnewcollapsible spacer (Fig. 59).

(6) Lubricate pinion and bearings.

(7) Install pinion into the housing and place front

pinion bearing onto the pinion shaft. Draw the pinion

shaft into the front bearing with Installer 8981 (Fig.

60).(8) Installnewpinion seal (Fig. 61) with Installer

8896 and Handle C-4171.

(9) Apply a light coat of teflon sealant to the pin-

ion flange splines.

(10) Hold the pinion and lightly tap the pinion

flange onto the pinion, until a few threads are show-

ing.

(11) Install pinion flange washer andnewpinion

nut.

(12) Hold pinion flange with Flange Wrench 8979

(Fig. 62) and tighten pinion nut until pinion end play

is taken up.

Fig. 59 COLLAPSIBLE SPACER

1 - COLAPSIBLE SPACER

2 - PINION GEAR

3 - REAR PINION BEARING

Fig. 60 PINION GEAR INSTALLER

1 - INSTALLER

2 - DIFFERENTIAL HOUSING

Fig. 61 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 62 FLANGE WRENCH

1 - FLANGE WRENCH

2 - PINION FLANGE

3 - 138 REAR AXLE - 10 1/2 AADR

PINION GEAR/RING GEAR/TONE RING (Continued)