tailgate DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1053 of 2627

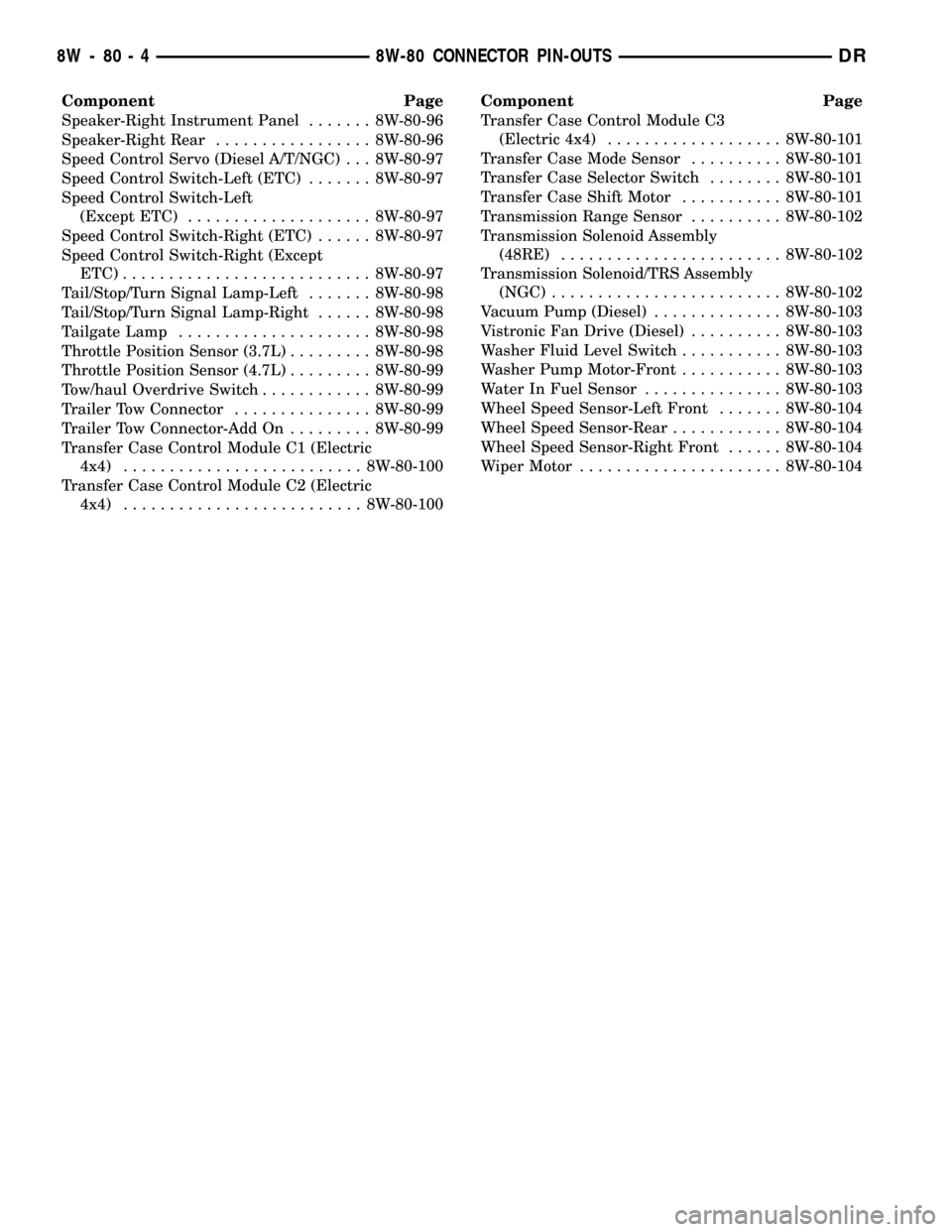

Component Page

Speaker-Right Instrument Panel....... 8W-80-96

Speaker-Right Rear................. 8W-80-96

Speed Control Servo (Diesel A/T/NGC) . . . 8W-80-97

Speed Control Switch-Left (ETC)....... 8W-80-97

Speed Control Switch-Left

(Except ETC).................... 8W-80-97

Speed Control Switch-Right (ETC)...... 8W-80-97

Speed Control Switch-Right (Except

ETC)........................... 8W-80-97

Tail/Stop/Turn Signal Lamp-Left....... 8W-80-98

Tail/Stop/Turn Signal Lamp-Right...... 8W-80-98

Tailgate Lamp..................... 8W-80-98

Throttle Position Sensor (3.7L)......... 8W-80-98

Throttle Position Sensor (4.7L)......... 8W-80-99

Tow/haul Overdrive Switch............ 8W-80-99

Trailer Tow Connector............... 8W-80-99

Trailer Tow Connector-Add On......... 8W-80-99

Transfer Case Control Module C1 (Electric

4x4).......................... 8W-80-100

Transfer Case Control Module C2 (Electric

4x4).......................... 8W-80-100Component Page

Transfer Case Control Module C3

(Electric 4x4)................... 8W-80-101

Transfer Case Mode Sensor.......... 8W-80-101

Transfer Case Selector Switch........ 8W-80-101

Transfer Case Shift Motor........... 8W-80-101

Transmission Range Sensor.......... 8W-80-102

Transmission Solenoid Assembly

(48RE)........................ 8W-80-102

Transmission Solenoid/TRS Assembly

(NGC)......................... 8W-80-102

Vacuum Pump (Diesel).............. 8W-80-103

Vistronic Fan Drive (Diesel).......... 8W-80-103

Washer Fluid Level Switch........... 8W-80-103

Washer Pump Motor-Front........... 8W-80-103

Water In Fuel Sensor............... 8W-80-103

Wheel Speed Sensor-Left Front....... 8W-80-104

Wheel Speed Sensor-Rear............ 8W-80-104

Wheel Speed Sensor-Right Front...... 8W-80-104

Wiper Motor...................... 8W-80-104

8W - 80 - 4 8W-80 CONNECTOR PIN-OUTSDR

Page 1147 of 2627

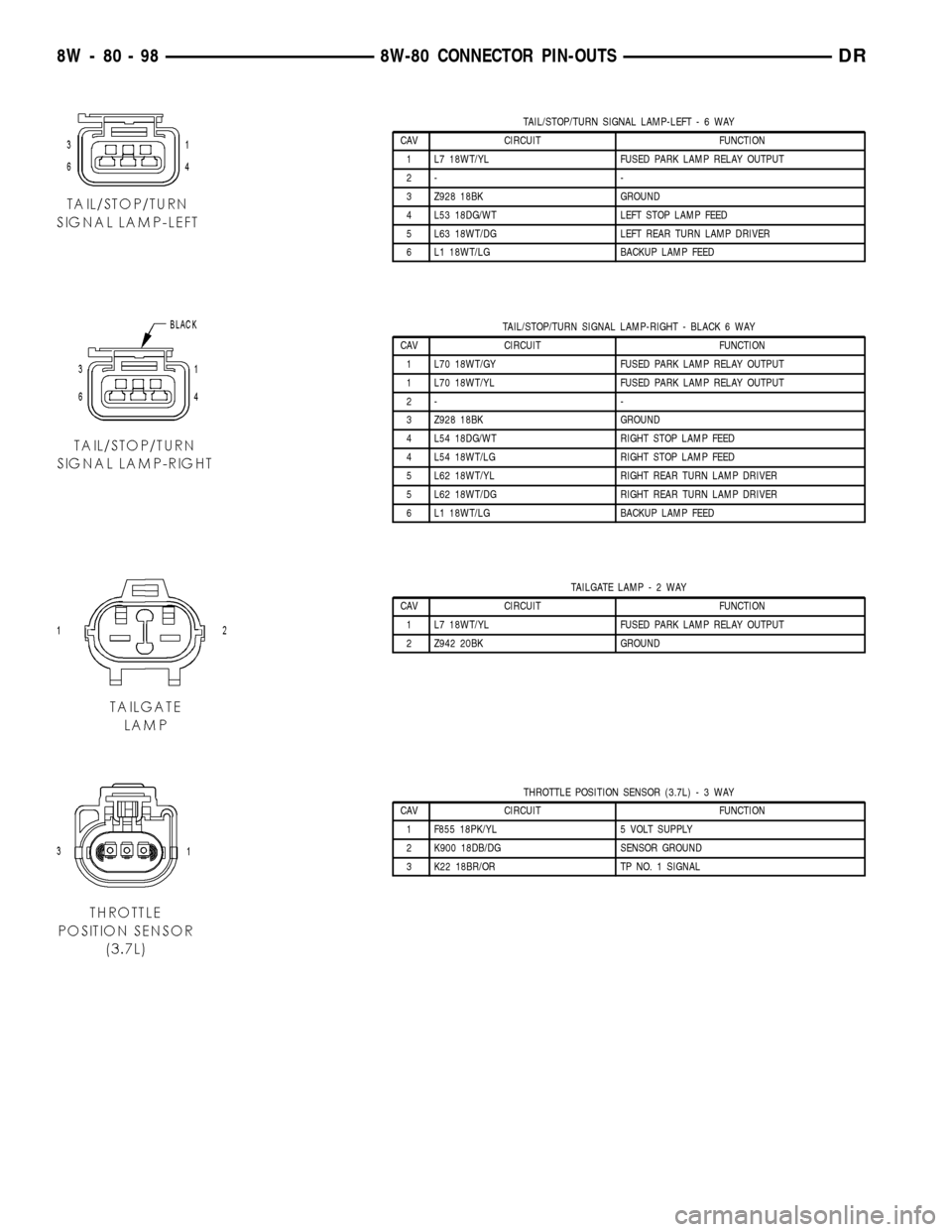

TAIL/STOP/TURN SIGNAL LAMP-LEFT-6WAY

CAV CIRCUIT FUNCTION

1 L7 18WT/YL FUSED PARK LAMP RELAY OUTPUT

2- -

3 Z928 18BK GROUND

4 L53 18DG/WT LEFT STOP LAMP FEED

5 L63 18WT/DG LEFT REAR TURN LAMP DRIVER

6 L1 18WT/LG BACKUP LAMP FEED

TAIL/STOP/TURN SIGNAL LAMP-RIGHT - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 L70 18WT/GY FUSED PARK LAMP RELAY OUTPUT

1 L70 18WT/YL FUSED PARK LAMP RELAY OUTPUT

2- -

3 Z928 18BK GROUND

4 L54 18DG/WT RIGHT STOP LAMP FEED

4 L54 18WT/LG RIGHT STOP LAMP FEED

5 L62 18WT/YL RIGHT REAR TURN LAMP DRIVER

5 L62 18WT/DG RIGHT REAR TURN LAMP DRIVER

6 L1 18WT/LG BACKUP LAMP FEED

TAILGATE LAMP-2WAY

CAV CIRCUIT FUNCTION

1 L7 18WT/YL FUSED PARK LAMP RELAY OUTPUT

2 Z942 20BK GROUND

THROTTLE POSITION SENSOR (3.7L)-3WAY

CAV CIRCUIT FUNCTION

1 F855 18PK/YL 5 VOLT SUPPLY

2 K900 18DB/DG SENSOR GROUND

3 K22 18BR/OR TP NO. 1 SIGNAL

8W - 80 - 98 8W-80 CONNECTOR PIN-OUTSDR

Page 2296 of 2627

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 1

DIAGNOSIS AND TESTING - WIND NOISE . . . 2

STANDARD PROCEDURE

STANDARD PROCEDURE - BODY

LUBRICATION.........................3

STANDARD PROCEDURE - HEAT STAKING . . 3

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - BUZZ, SQUEAK

& RATTLE...........................11

SPECIFICATIONS - TORQUE..............12SPECIAL TOOLS

BODY..............................14

TAILGATE..............................15

DOOR - FRONT.........................18

DOORS - REAR.........................28

EXTERIOR.............................36

HOOD.................................46

INSTRUMENT PANEL.....................49

INTERIOR..............................62

PAINT.................................73

SEATS................................75

STATIONARY GLASS.....................86

WEATHERSTRIP/SEALS...................91

BODY STRUCTURE......................95

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE AN OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL ± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

²DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

²Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

²Always have a fire extinguisher ready for use

when welding.

²Disconnect the negative (-) cable clamp from

the battery when servicing electrical components

that are live when the ignition is OFF. Damage to

electrical system can result.²Do not use abrasive chemicals or compounds

on painted surfaces. Damage to finish can result.

²Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

²Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

DRBODY 23 - 1

Page 2308 of 2627

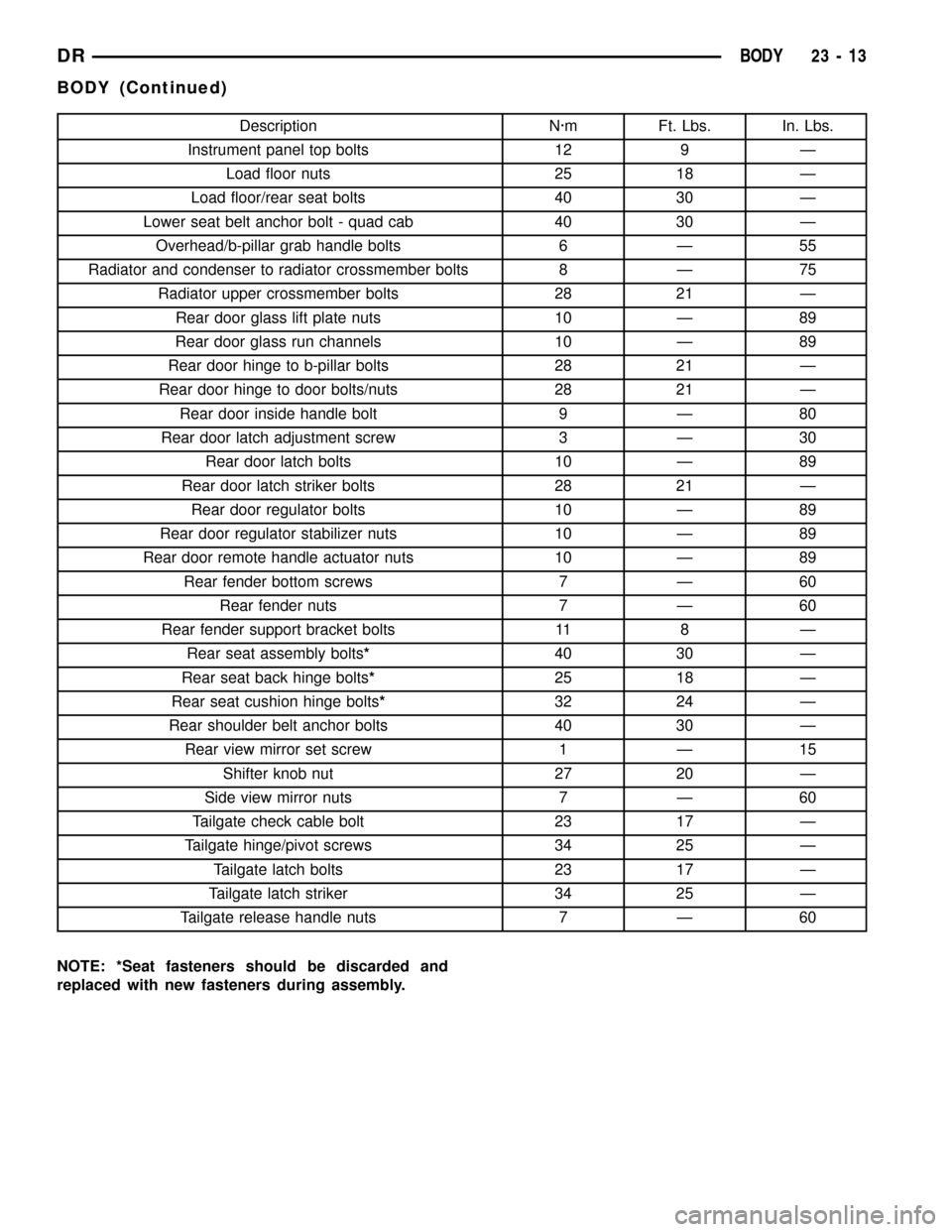

Description N´m Ft. Lbs. In. Lbs.

Instrument panel top bolts 12 9 Ð

Load floor nuts 25 18 Ð

Load floor/rear seat bolts 40 30 Ð

Lower seat belt anchor bolt - quad cab 40 30 Ð

Overhead/b-pillar grab handle bolts 6 Ð 55

Radiator and condenser to radiator crossmember bolts 8 Ð 75

Radiator upper crossmember bolts 28 21 Ð

Rear door glass lift plate nuts 10 Ð 89

Rear door glass run channels 10 Ð 89

Rear door hinge to b-pillar bolts 28 21 Ð

Rear door hinge to door bolts/nuts 28 21 Ð

Rear door inside handle bolt 9 Ð 80

Rear door latch adjustment screw 3 Ð 30

Rear door latch bolts 10 Ð 89

Rear door latch striker bolts 28 21 Ð

Rear door regulator bolts 10 Ð 89

Rear door regulator stabilizer nuts 10 Ð 89

Rear door remote handle actuator nuts 10 Ð 89

Rear fender bottom screws 7 Ð 60

Rear fender nuts 7 Ð 60

Rear fender support bracket bolts 11 8 Ð

Rear seat assembly bolts*40 30 Ð

Rear seat back hinge bolts*25 18 Ð

Rear seat cushion hinge bolts*32 24 Ð

Rear shoulder belt anchor bolts 40 30 Ð

Rear view mirror set screw 1 Ð 15

Shifter knob nut 27 20 Ð

Side view mirror nuts 7 Ð 60

Tailgate check cable bolt 23 17 Ð

Tailgate hinge/pivot screws 34 25 Ð

Tailgate latch bolts 23 17 Ð

Tailgate latch striker 34 25 Ð

Tailgate release handle nuts 7 Ð 60

NOTE: *Seat fasteners should be discarded and

replaced with new fasteners during assembly.

DRBODY 23 - 13

BODY (Continued)

Page 2310 of 2627

TAILGATE

TABLE OF CONTENTS

page page

CHECK CABLE

REMOVAL.............................15

INSTALLATION.........................15

COVER

REMOVAL.............................16

INSTALLATION.........................16

HINGE

REMOVAL.............................16

INSTALLATION.........................16

LATCH

REMOVAL.............................16INSTALLATION.........................16

LATCH STRIKER

REMOVAL.............................16

INSTALLATION.........................17

RELEASE HANDLE/LATCH REMOTE

REMOVAL.............................17

INSTALLATION.........................17

TAILGATE

REMOVAL.............................17

INSTALLATION.........................17

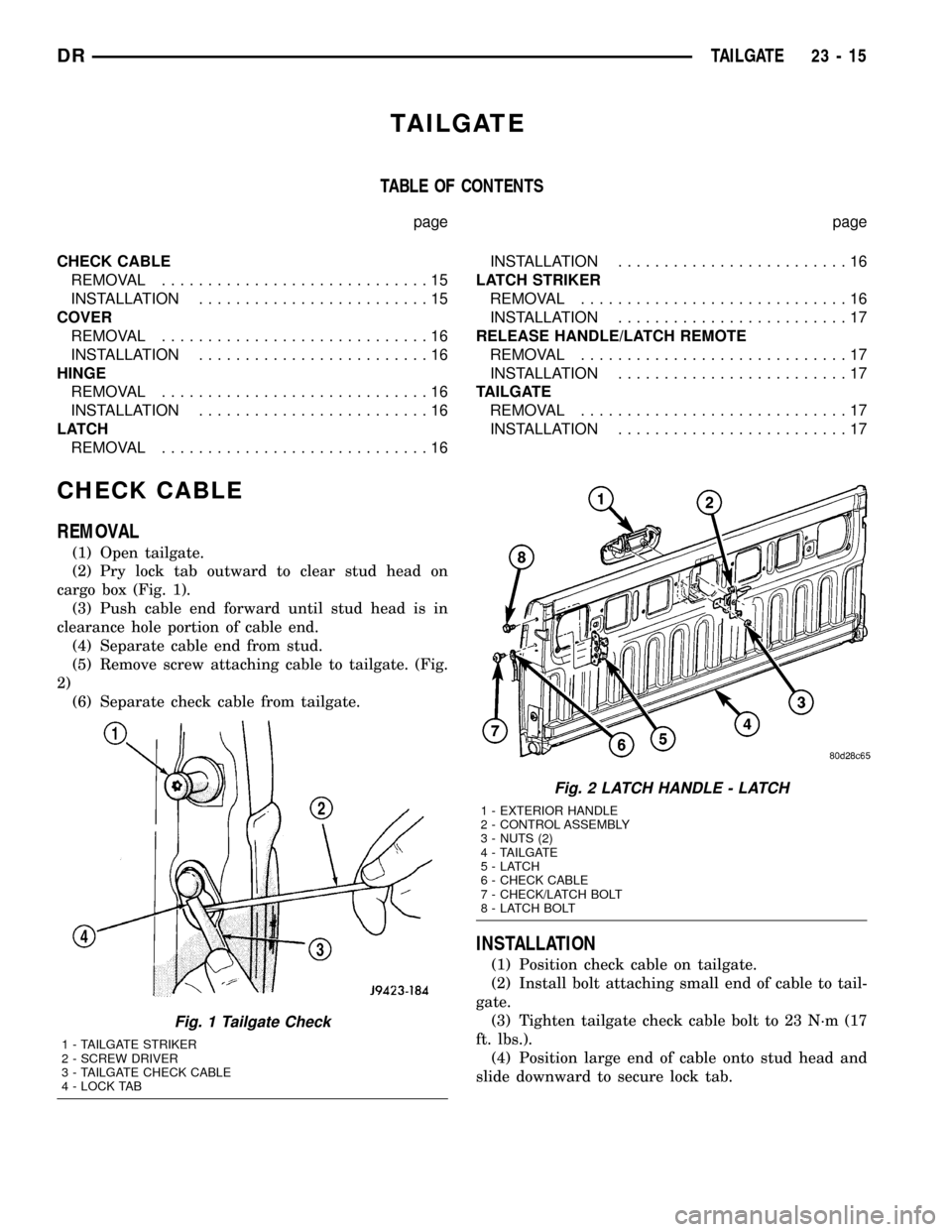

CHECK CABLE

REMOVAL

(1) Open tailgate.

(2) Pry lock tab outward to clear stud head on

cargo box (Fig. 1).

(3) Push cable end forward until stud head is in

clearance hole portion of cable end.

(4) Separate cable end from stud.

(5) Remove screw attaching cable to tailgate. (Fig.

2)

(6) Separate check cable from tailgate.

INSTALLATION

(1) Position check cable on tailgate.

(2) Install bolt attaching small end of cable to tail-

gate.

(3) Tighten tailgate check cable bolt to 23 N´m (17

ft. lbs.).

(4) Position large end of cable onto stud head and

slide downward to secure lock tab.

Fig. 1 Tailgate Check

1 - TAILGATE STRIKER

2 - SCREW DRIVER

3 - TAILGATE CHECK CABLE

4 - LOCK TAB

Fig. 2 LATCH HANDLE - LATCH

1 - EXTERIOR HANDLE

2 - CONTROL ASSEMBLY

3 - NUTS (2)

4 - TAILGATE

5-LATCH

6 - CHECK CABLE

7 - CHECK/LATCH BOLT

8 - LATCH BOLT

DRTAILGATE 23 - 15

Page 2311 of 2627

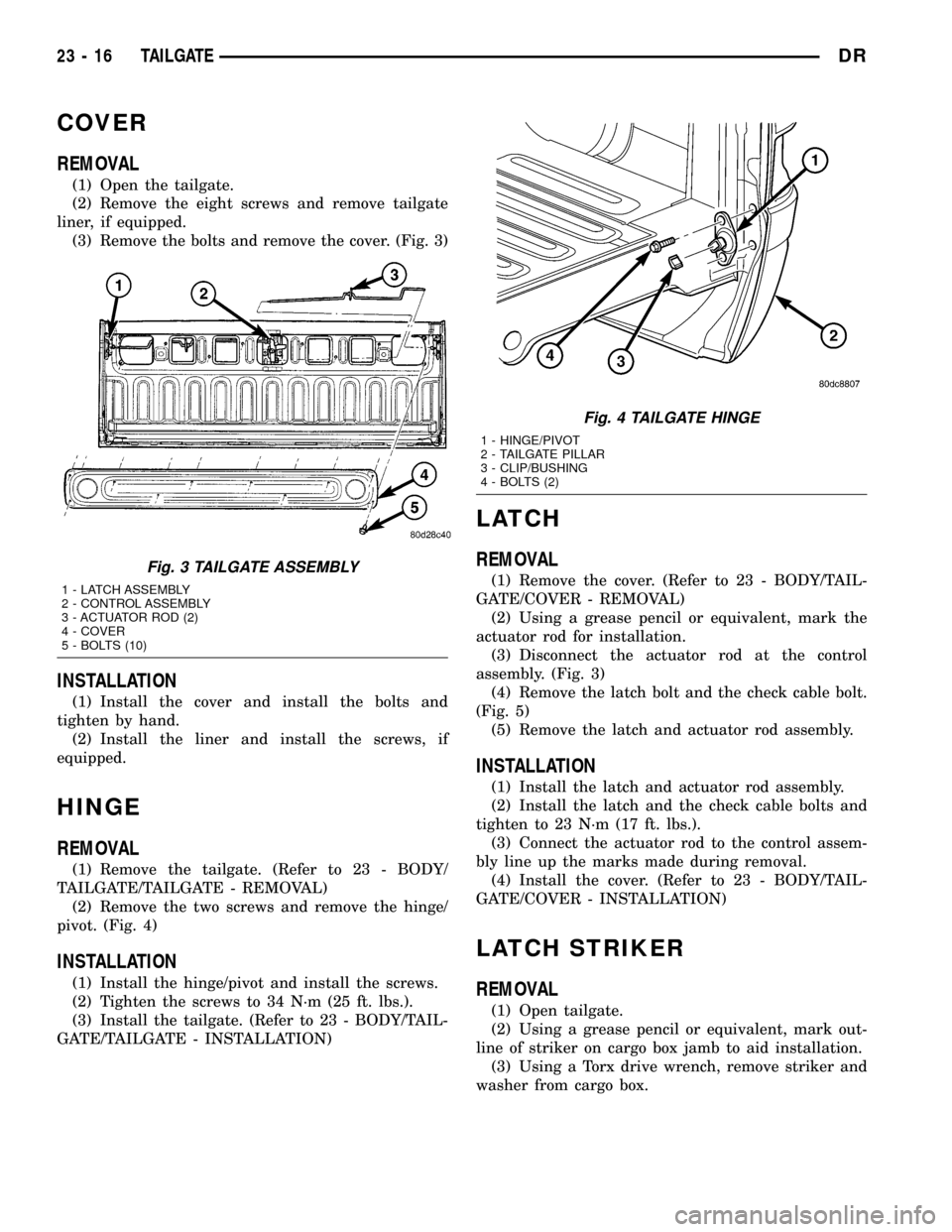

COVER

REMOVAL

(1) Open the tailgate.

(2) Remove the eight screws and remove tailgate

liner, if equipped.

(3) Remove the bolts and remove the cover. (Fig. 3)

INSTALLATION

(1) Install the cover and install the bolts and

tighten by hand.

(2) Install the liner and install the screws, if

equipped.

HINGE

REMOVAL

(1) Remove the tailgate. (Refer to 23 - BODY/

TAILGATE/TAILGATE - REMOVAL)

(2) Remove the two screws and remove the hinge/

pivot. (Fig. 4)

INSTALLATION

(1) Install the hinge/pivot and install the screws.

(2) Tighten the screws to 34 N´m (25 ft. lbs.).

(3) Install the tailgate. (Refer to 23 - BODY/TAIL-

GATE/TAILGATE - INSTALLATION)

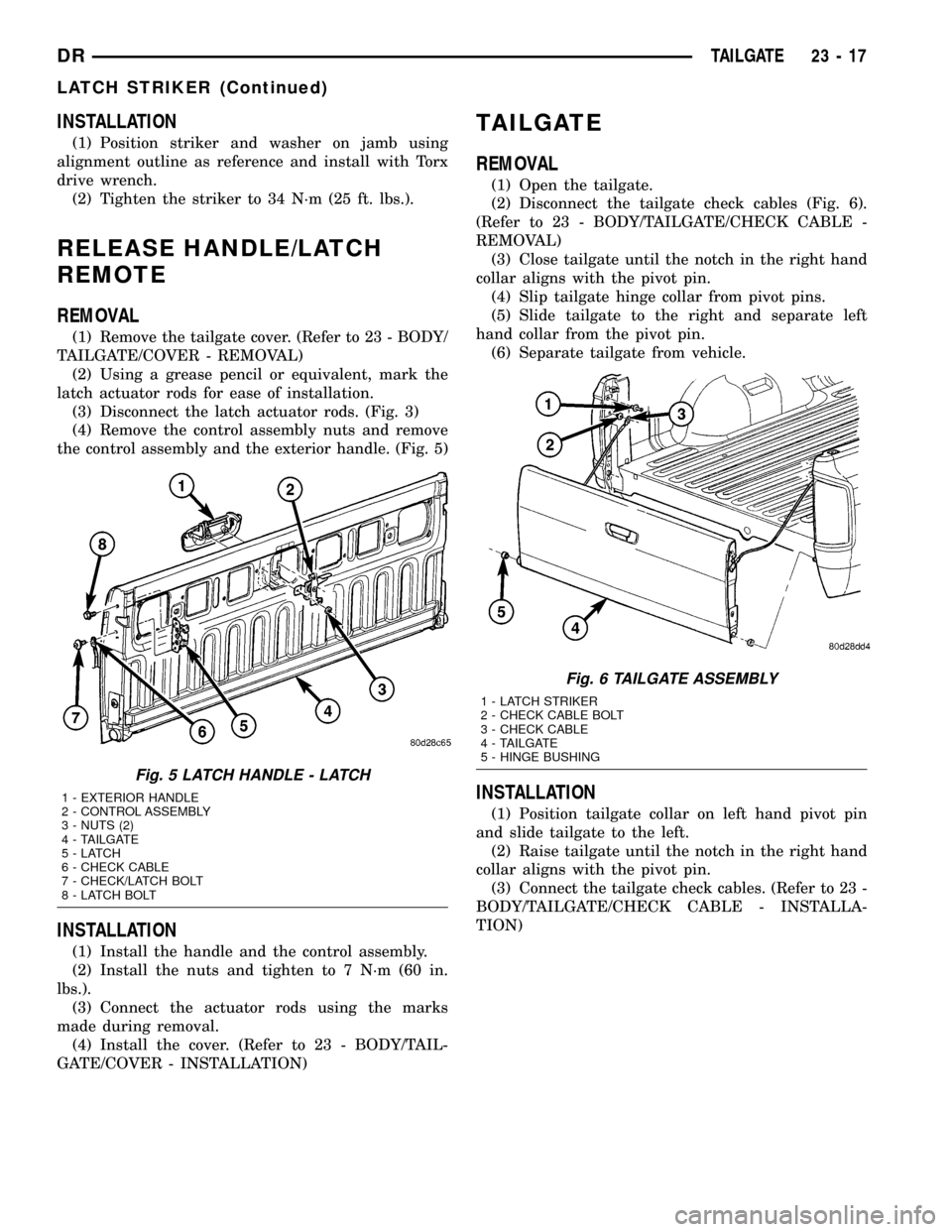

LATCH

REMOVAL

(1) Remove the cover. (Refer to 23 - BODY/TAIL-

GATE/COVER - REMOVAL)

(2) Using a grease pencil or equivalent, mark the

actuator rod for installation.

(3) Disconnect the actuator rod at the control

assembly. (Fig. 3)

(4) Remove the latch bolt and the check cable bolt.

(Fig. 5)

(5) Remove the latch and actuator rod assembly.

INSTALLATION

(1) Install the latch and actuator rod assembly.

(2) Install the latch and the check cable bolts and

tighten to 23 N´m (17 ft. lbs.).

(3) Connect the actuator rod to the control assem-

bly line up the marks made during removal.

(4) Install the cover. (Refer to 23 - BODY/TAIL-

GATE/COVER - INSTALLATION)

LATCH STRIKER

REMOVAL

(1) Open tailgate.

(2) Using a grease pencil or equivalent, mark out-

line of striker on cargo box jamb to aid installation.

(3) Using a Torx drive wrench, remove striker and

washer from cargo box.

Fig. 3 TAILGATE ASSEMBLY

1 - LATCH ASSEMBLY

2 - CONTROL ASSEMBLY

3 - ACTUATOR ROD (2)

4 - COVER

5 - BOLTS (10)

Fig. 4 TAILGATE HINGE

1 - HINGE/PIVOT

2 - TAILGATE PILLAR

3 - CLIP/BUSHING

4 - BOLTS (2)

23 - 16 TAILGATEDR

Page 2312 of 2627

INSTALLATION

(1) Position striker and washer on jamb using

alignment outline as reference and install with Torx

drive wrench.

(2) Tighten the striker to 34 N´m (25 ft. lbs.).

RELEASE HANDLE/LATCH

REMOTE

REMOVAL

(1) Remove the tailgate cover. (Refer to 23 - BODY/

TAILGATE/COVER - REMOVAL)

(2) Using a grease pencil or equivalent, mark the

latch actuator rods for ease of installation.

(3) Disconnect the latch actuator rods. (Fig. 3)

(4) Remove the control assembly nuts and remove

the control assembly and the exterior handle. (Fig. 5)

INSTALLATION

(1) Install the handle and the control assembly.

(2) Install the nuts and tighten to 7 N´m (60 in.

lbs.).

(3) Connect the actuator rods using the marks

made during removal.

(4) Install the cover. (Refer to 23 - BODY/TAIL-

GATE/COVER - INSTALLATION)

TAILGATE

REMOVAL

(1) Open the tailgate.

(2) Disconnect the tailgate check cables (Fig. 6).

(Refer to 23 - BODY/TAILGATE/CHECK CABLE -

REMOVAL)

(3) Close tailgate until the notch in the right hand

collar aligns with the pivot pin.

(4) Slip tailgate hinge collar from pivot pins.

(5) Slide tailgate to the right and separate left

hand collar from the pivot pin.

(6) Separate tailgate from vehicle.

INSTALLATION

(1) Position tailgate collar on left hand pivot pin

and slide tailgate to the left.

(2) Raise tailgate until the notch in the right hand

collar aligns with the pivot pin.

(3) Connect the tailgate check cables. (Refer to 23 -

BODY/TAILGATE/CHECK CABLE - INSTALLA-

TION)

Fig. 5 LATCH HANDLE - LATCH

1 - EXTERIOR HANDLE

2 - CONTROL ASSEMBLY

3 - NUTS (2)

4 - TAILGATE

5-LATCH

6 - CHECK CABLE

7 - CHECK/LATCH BOLT

8 - LATCH BOLT

Fig. 6 TAILGATE ASSEMBLY

1 - LATCH STRIKER

2 - CHECK CABLE BOLT

3 - CHECK CABLE

4 - TAILGATE

5 - HINGE BUSHING

DRTAILGATE 23 - 17

LATCH STRIKER (Continued)

Page 2393 of 2627

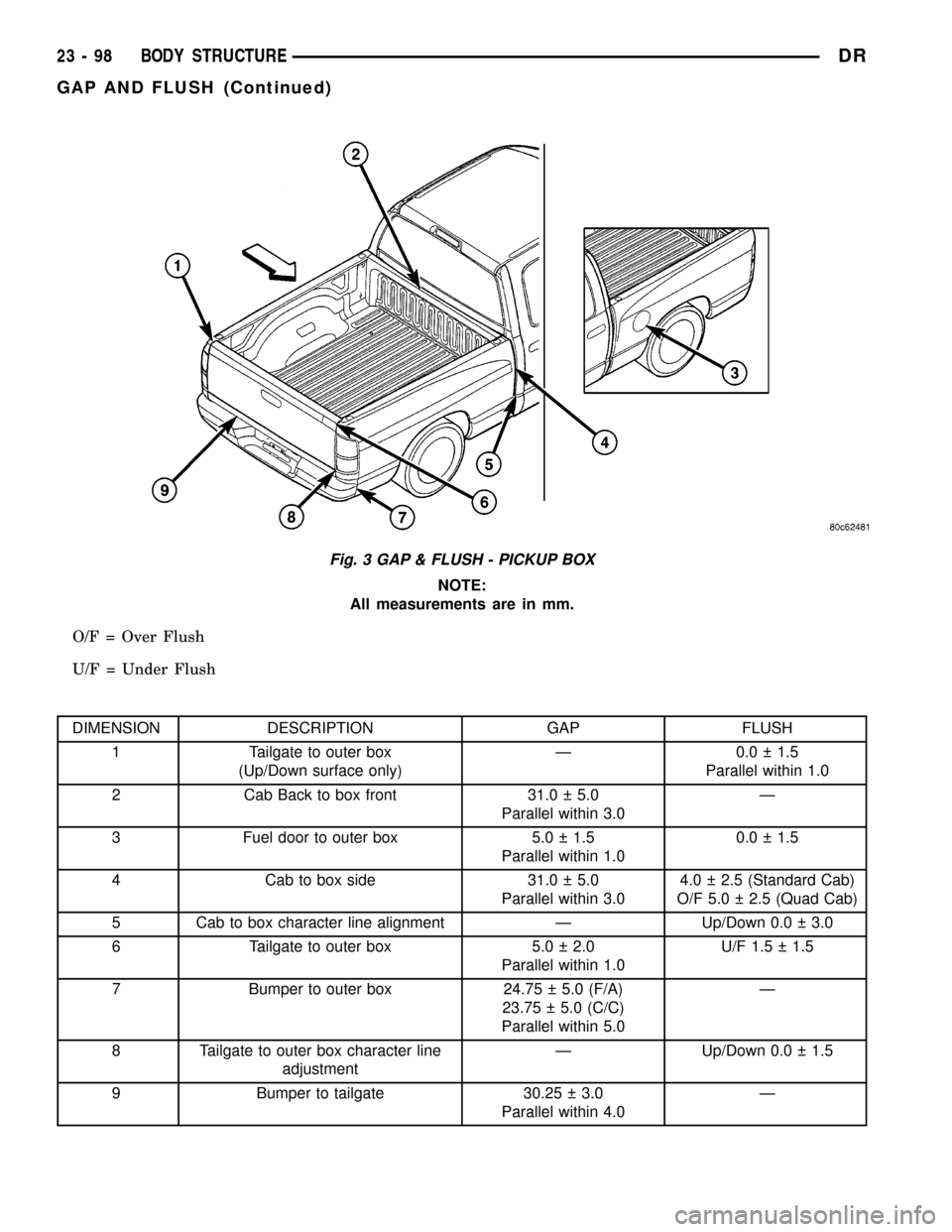

NOTE:

All measurements are in mm.

O/F = Over Flush

U/F = Under Flush

DIMENSION DESCRIPTION GAP FLUSH

1 Tailgate to outer box

(Up/Down surface only)Ð 0.0 1.5

Parallel within 1.0

2 Cab Back to box front 31.0 5.0

Parallel within 3.0Ð

3 Fuel door to outer box 5.0 1.5

Parallel within 1.00.0 1.5

4 Cab to box side 31.0 5.0

Parallel within 3.04.0 2.5 (Standard Cab)

O/F 5.0 2.5 (Quad Cab)

5 Cab to box character line alignment Ð Up/Down 0.0 3.0

6 Tailgate to outer box 5.0 2.0

Parallel within 1.0U/F 1.5 1.5

7 Bumper to outer box 24.75 5.0 (F/A)

23.75 5.0 (C/C)

Parallel within 5.0Ð

8 Tailgate to outer box character line

adjustmentÐ Up/Down 0.0 1.5

9 Bumper to tailgate 30.25 3.0

Parallel within 4.0Ð

Fig. 3 GAP & FLUSH - PICKUP BOX

23 - 98 BODY STRUCTUREDR

GAP AND FLUSH (Continued)

Page 2417 of 2627

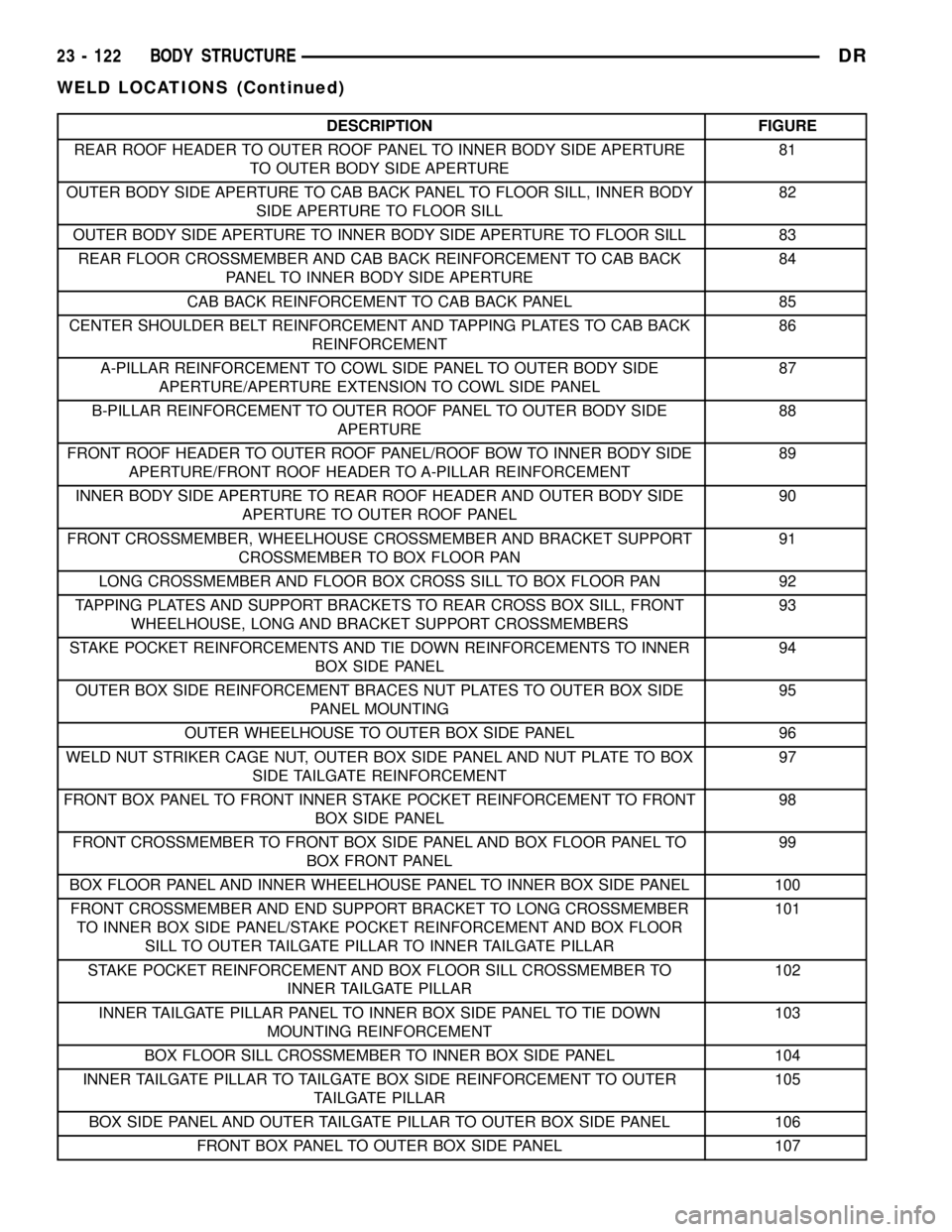

DESCRIPTION FIGURE

REAR ROOF HEADER TO OUTER ROOF PANEL TO INNER BODY SIDE APERTURE

TO OUTER BODY SIDE APERTURE81

OUTER BODY SIDE APERTURE TO CAB BACK PANEL TO FLOOR SILL, INNER BODY

SIDE APERTURE TO FLOOR SILL82

OUTER BODY SIDE APERTURE TO INNER BODY SIDE APERTURE TO FLOOR SILL 83

REAR FLOOR CROSSMEMBER AND CAB BACK REINFORCEMENT TO CAB BACK

PANEL TO INNER BODY SIDE APERTURE84

CAB BACK REINFORCEMENT TO CAB BACK PANEL 85

CENTER SHOULDER BELT REINFORCEMENT AND TAPPING PLATES TO CAB BACK

REINFORCEMENT86

A-PILLAR REINFORCEMENT TO COWL SIDE PANEL TO OUTER BODY SIDE

APERTURE/APERTURE EXTENSION TO COWL SIDE PANEL87

B-PILLAR REINFORCEMENT TO OUTER ROOF PANEL TO OUTER BODY SIDE

APERTURE88

FRONT ROOF HEADER TO OUTER ROOF PANEL/ROOF BOW TO INNER BODY SIDE

APERTURE/FRONT ROOF HEADER TO A-PILLAR REINFORCEMENT89

INNER BODY SIDE APERTURE TO REAR ROOF HEADER AND OUTER BODY SIDE

APERTURE TO OUTER ROOF PANEL90

FRONT CROSSMEMBER, WHEELHOUSE CROSSMEMBER AND BRACKET SUPPORT

CROSSMEMBER TO BOX FLOOR PAN91

LONG CROSSMEMBER AND FLOOR BOX CROSS SILL TO BOX FLOOR PAN 92

TAPPING PLATES AND SUPPORT BRACKETS TO REAR CROSS BOX SILL, FRONT

WHEELHOUSE, LONG AND BRACKET SUPPORT CROSSMEMBERS93

STAKE POCKET REINFORCEMENTS AND TIE DOWN REINFORCEMENTS TO INNER

BOX SIDE PANEL94

OUTER BOX SIDE REINFORCEMENT BRACES NUT PLATES TO OUTER BOX SIDE

PANEL MOUNTING95

OUTER WHEELHOUSE TO OUTER BOX SIDE PANEL 96

WELD NUT STRIKER CAGE NUT, OUTER BOX SIDE PANEL AND NUT PLATE TO BOX

SIDE TAILGATE REINFORCEMENT97

FRONT BOX PANEL TO FRONT INNER STAKE POCKET REINFORCEMENT TO FRONT

BOX SIDE PANEL98

FRONT CROSSMEMBER TO FRONT BOX SIDE PANEL AND BOX FLOOR PANEL TO

BOX FRONT PANEL99

BOX FLOOR PANEL AND INNER WHEELHOUSE PANEL TO INNER BOX SIDE PANEL 100

FRONT CROSSMEMBER AND END SUPPORT BRACKET TO LONG CROSSMEMBER

TO INNER BOX SIDE PANEL/STAKE POCKET REINFORCEMENT AND BOX FLOOR

SILL TO OUTER TAILGATE PILLAR TO INNER TAILGATE PILLAR101

STAKE POCKET REINFORCEMENT AND BOX FLOOR SILL CROSSMEMBER TO

INNER TAILGATE PILLAR102

INNER TAILGATE PILLAR PANEL TO INNER BOX SIDE PANEL TO TIE DOWN

MOUNTING REINFORCEMENT103

BOX FLOOR SILL CROSSMEMBER TO INNER BOX SIDE PANEL 104

INNER TAILGATE PILLAR TO TAILGATE BOX SIDE REINFORCEMENT TO OUTER

TAILGATE PILLAR105

BOX SIDE PANEL AND OUTER TAILGATE PILLAR TO OUTER BOX SIDE PANEL 106

FRONT BOX PANEL TO OUTER BOX SIDE PANEL 107

23 - 122 BODY STRUCTUREDR

WELD LOCATIONS (Continued)

Page 2418 of 2627

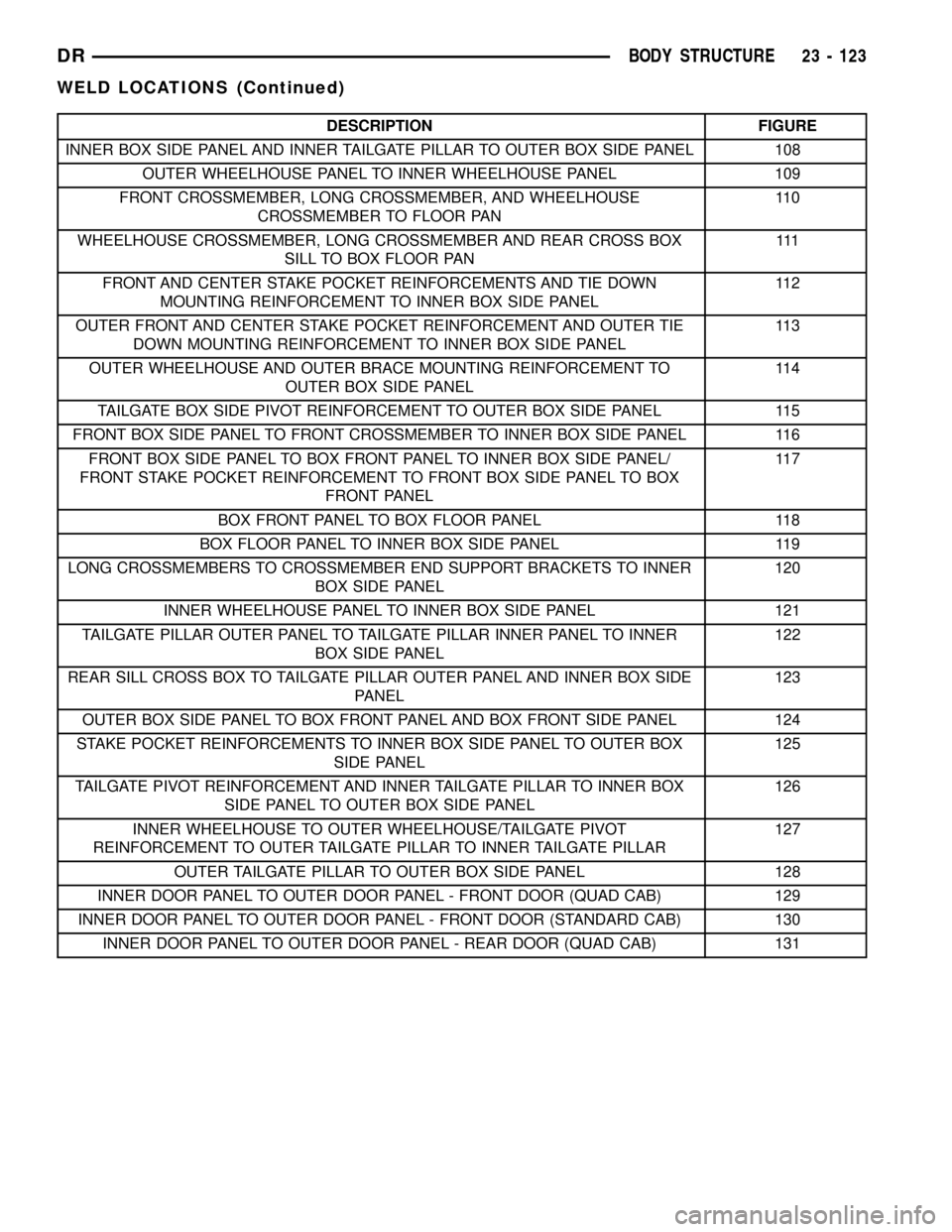

DESCRIPTION FIGURE

INNER BOX SIDE PANEL AND INNER TAILGATE PILLAR TO OUTER BOX SIDE PANEL 108

OUTER WHEELHOUSE PANEL TO INNER WHEELHOUSE PANEL 109

FRONT CROSSMEMBER, LONG CROSSMEMBER, AND WHEELHOUSE

CROSSMEMBER TO FLOOR PAN11 0

WHEELHOUSE CROSSMEMBER, LONG CROSSMEMBER AND REAR CROSS BOX

SILL TO BOX FLOOR PAN111

FRONT AND CENTER STAKE POCKET REINFORCEMENTS AND TIE DOWN

MOUNTING REINFORCEMENT TO INNER BOX SIDE PANEL11 2

OUTER FRONT AND CENTER STAKE POCKET REINFORCEMENT AND OUTER TIE

DOWN MOUNTING REINFORCEMENT TO INNER BOX SIDE PANEL11 3

OUTER WHEELHOUSE AND OUTER BRACE MOUNTING REINFORCEMENT TO

OUTER BOX SIDE PANEL11 4

TAILGATE BOX SIDE PIVOT REINFORCEMENT TO OUTER BOX SIDE PANEL 115

FRONT BOX SIDE PANEL TO FRONT CROSSMEMBER TO INNER BOX SIDE PANEL 116

FRONT BOX SIDE PANEL TO BOX FRONT PANEL TO INNER BOX SIDE PANEL/

FRONT STAKE POCKET REINFORCEMENT TO FRONT BOX SIDE PANEL TO BOX

FRONT PANEL11 7

BOX FRONT PANEL TO BOX FLOOR PANEL 118

BOX FLOOR PANEL TO INNER BOX SIDE PANEL 119

LONG CROSSMEMBERS TO CROSSMEMBER END SUPPORT BRACKETS TO INNER

BOX SIDE PANEL120

INNER WHEELHOUSE PANEL TO INNER BOX SIDE PANEL 121

TAILGATE PILLAR OUTER PANEL TO TAILGATE PILLAR INNER PANEL TO INNER

BOX SIDE PANEL122

REAR SILL CROSS BOX TO TAILGATE PILLAR OUTER PANEL AND INNER BOX SIDE

PANEL123

OUTER BOX SIDE PANEL TO BOX FRONT PANEL AND BOX FRONT SIDE PANEL 124

STAKE POCKET REINFORCEMENTS TO INNER BOX SIDE PANEL TO OUTER BOX

SIDE PANEL125

TAILGATE PIVOT REINFORCEMENT AND INNER TAILGATE PILLAR TO INNER BOX

SIDE PANEL TO OUTER BOX SIDE PANEL126

INNER WHEELHOUSE TO OUTER WHEELHOUSE/TAILGATE PIVOT

REINFORCEMENT TO OUTER TAILGATE PILLAR TO INNER TAILGATE PILLAR127

OUTER TAILGATE PILLAR TO OUTER BOX SIDE PANEL 128

INNER DOOR PANEL TO OUTER DOOR PANEL - FRONT DOOR (QUAD CAB) 129

INNER DOOR PANEL TO OUTER DOOR PANEL - FRONT DOOR (STANDARD CAB) 130

INNER DOOR PANEL TO OUTER DOOR PANEL - REAR DOOR (QUAD CAB) 131

DRBODY STRUCTURE 23 - 123

WELD LOCATIONS (Continued)