Power control DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1598 of 2627

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

REMOVAL

3.7L V-6

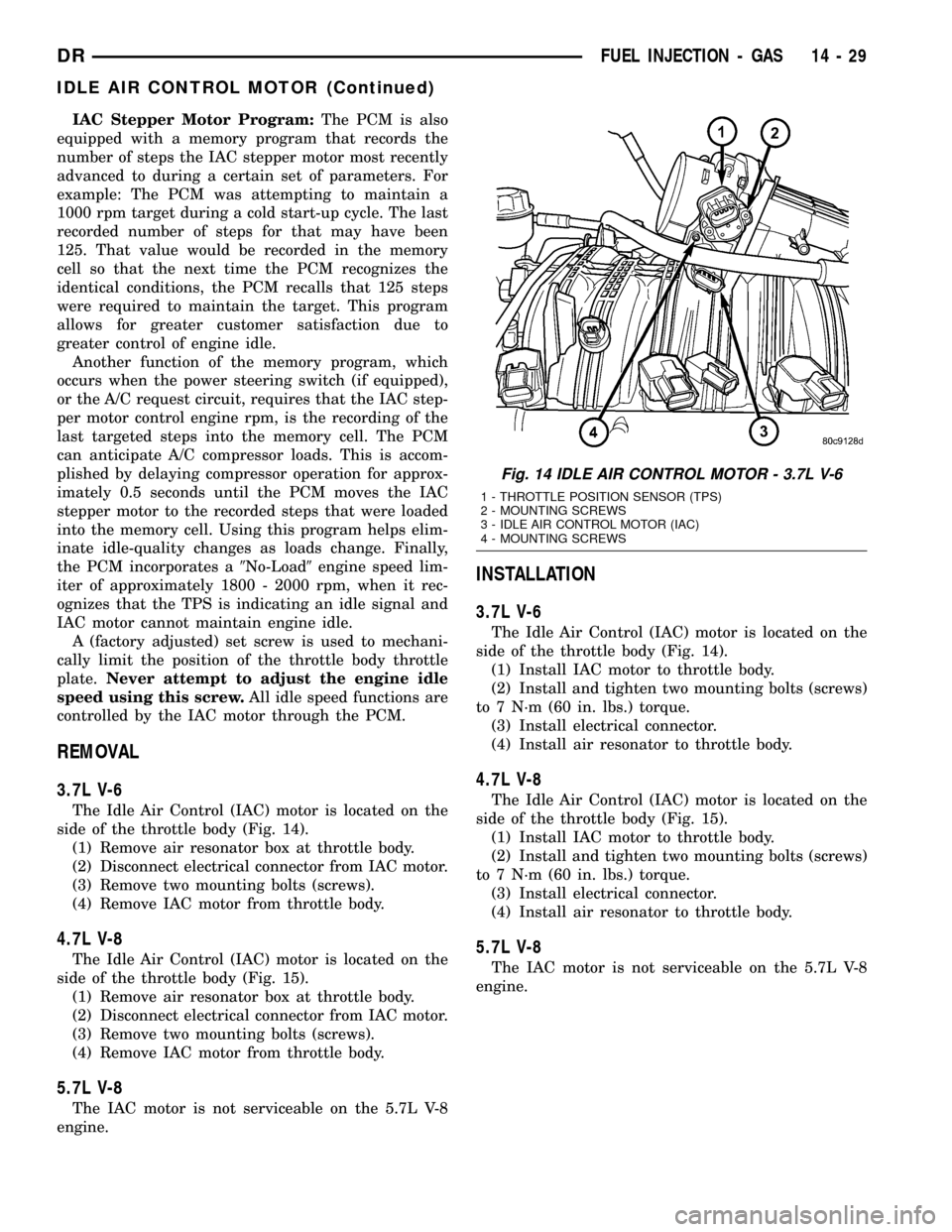

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 14).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

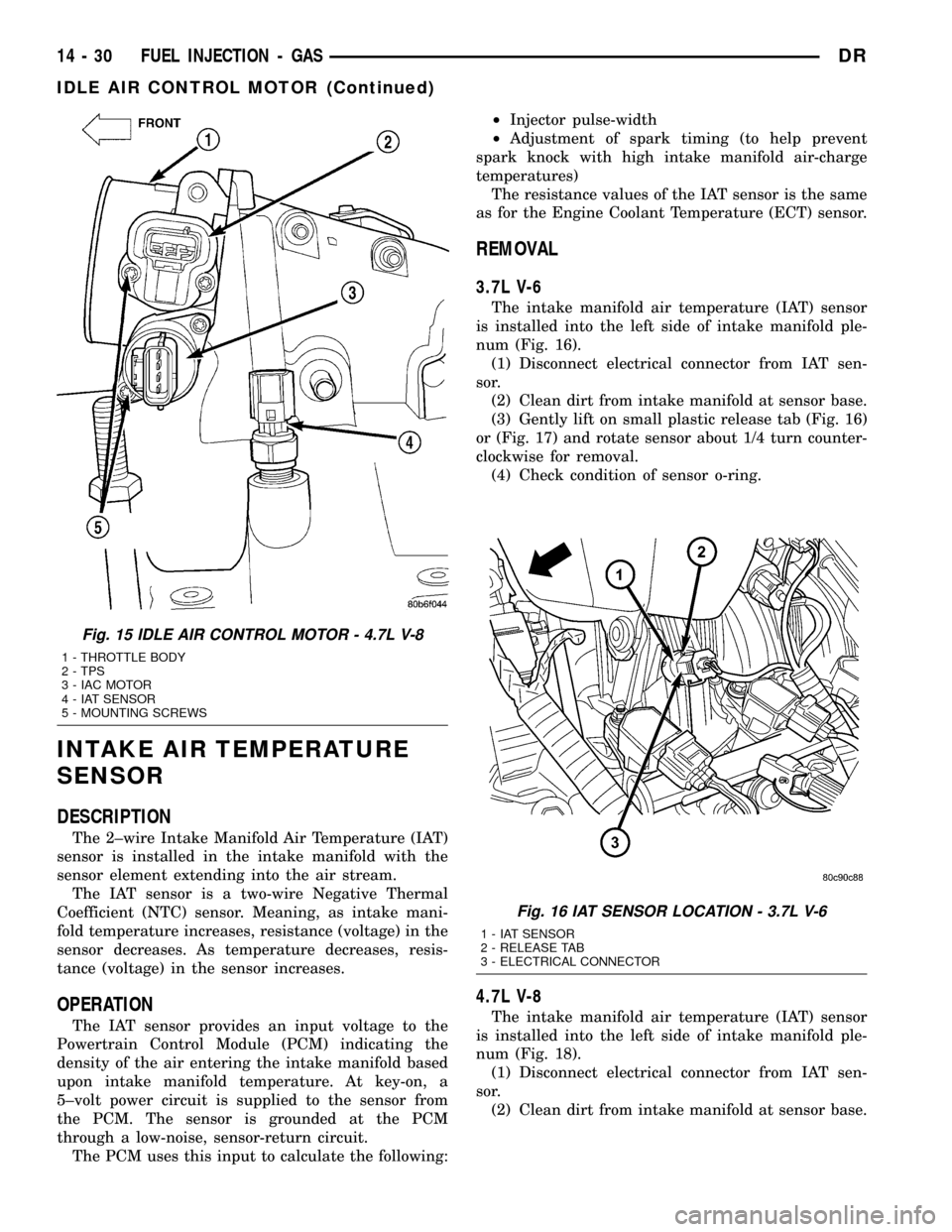

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 15).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

INSTALLATION

3.7L V-6

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 14).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 15).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

Fig. 14 IDLE AIR CONTROL MOTOR - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

DRFUEL INJECTION - GAS 14 - 29

IDLE AIR CONTROL MOTOR (Continued)

Page 1599 of 2627

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION

The 2±wire Intake Manifold Air Temperature (IAT)

sensor is installed in the intake manifold with the

sensor element extending into the air stream.

The IAT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as intake mani-

fold temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

The IAT sensor provides an input voltage to the

Powertrain Control Module (PCM) indicating the

density of the air entering the intake manifold based

upon intake manifold temperature. At key-on, a

5±volt power circuit is supplied to the sensor from

the PCM. The sensor is grounded at the PCM

through a low-noise, sensor-return circuit.

The PCM uses this input to calculate the following:²Injector pulse-width

²Adjustment of spark timing (to help prevent

spark knock with high intake manifold air-charge

temperatures)

The resistance values of the IAT sensor is the same

as for the Engine Coolant Temperature (ECT) sensor.

REMOVAL

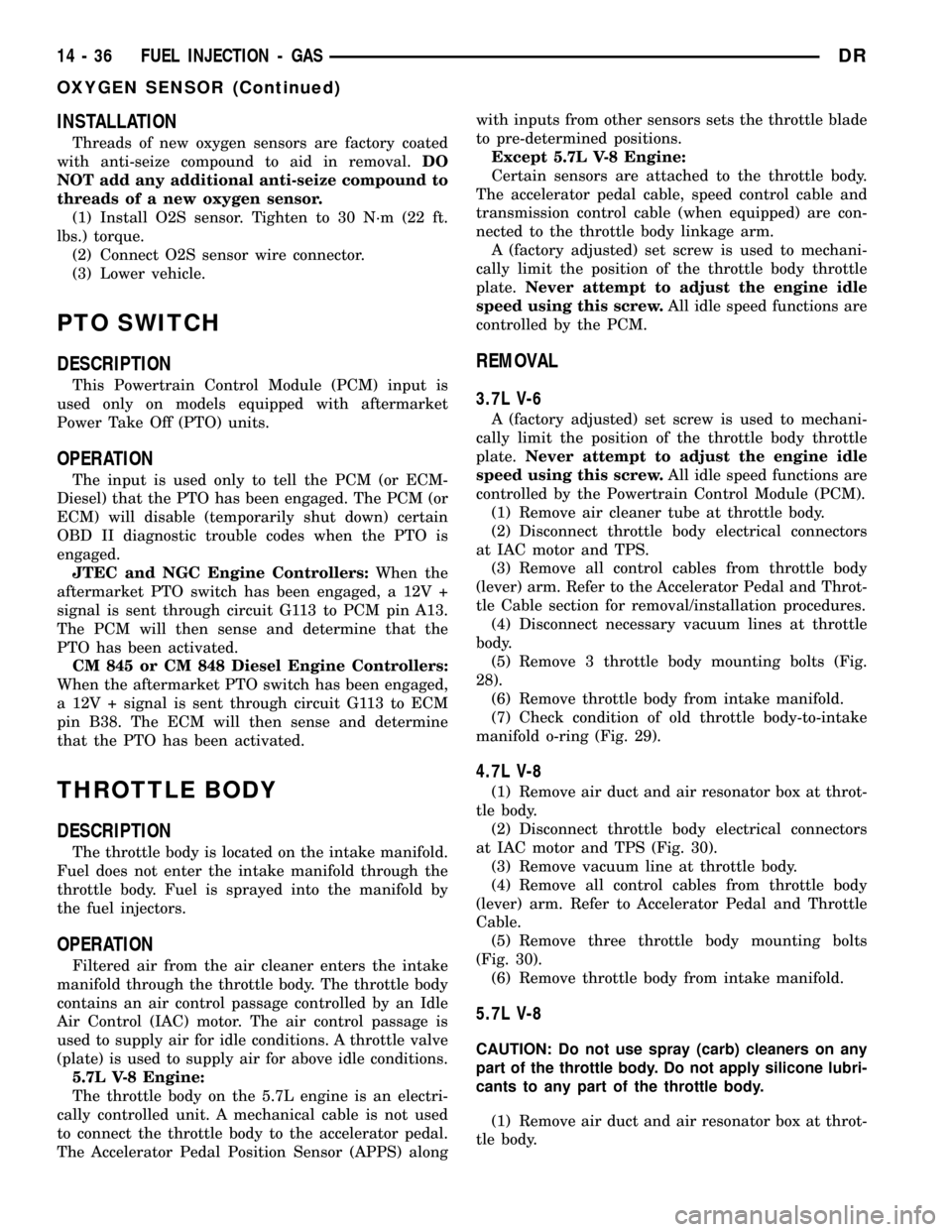

3.7L V-6

The intake manifold air temperature (IAT) sensor

is installed into the left side of intake manifold ple-

num (Fig. 16).

(1) Disconnect electrical connector from IAT sen-

sor.

(2) Clean dirt from intake manifold at sensor base.

(3) Gently lift on small plastic release tab (Fig. 16)

or (Fig. 17) and rotate sensor about 1/4 turn counter-

clockwise for removal.

(4) Check condition of sensor o-ring.

4.7L V-8

The intake manifold air temperature (IAT) sensor

is installed into the left side of intake manifold ple-

num (Fig. 18).

(1) Disconnect electrical connector from IAT sen-

sor.

(2) Clean dirt from intake manifold at sensor base.

Fig. 15 IDLE AIR CONTROL MOTOR - 4.7L V-8

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR

5 - MOUNTING SCREWS

Fig. 16 IAT SENSOR LOCATION - 3.7L V-6

1 - IAT SENSOR

2 - RELEASE TAB

3 - ELECTRICAL CONNECTOR

14 - 30 FUEL INJECTION - GASDR

IDLE AIR CONTROL MOTOR (Continued)

Page 1601 of 2627

(3) Position sensor into intake manifold and rotate

clockwise until past release tab.

(4) Install electrical connector.

5.7L V-8

The intake manifold air temperature (IAT) sensor

is installed into the front of the intake manifold air

box plenum (Fig. 19).

(1) Check condition of sensor o-ring.

(2) Clean sensor mounting hole in intake manifold.

(3) Position sensor into intake manifold and rotate

clockwise until past release tab.

(4) Install electrical connector.

MAP SENSOR

DESCRIPTION

3.7L V-6

The Manifold Absolute Pressure (MAP) sensor is

mounted into the front of the intake manifold with 2

screws.

4.7L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted into the front of the intake manifold with 2

screws.

5.7L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted to the front of the intake manifold air ple-

num box.

OPERATION

The MAP sensor is used as an input to the Power-

train Control Module (PCM). It contains a silicon

based sensing unit to provide data on the manifold

vacuum that draws the air/fuel mixture into the com-

bustion chamber. The PCM requires this information

to determine injector pulse width and spark advance.

When manifold absolute pressure (MAP) equals

Barometric pressure, the pulse width will be at max-

imum.

A 5 volt reference is supplied from the PCM and

returns a voltage signal to the PCM that reflects

manifold pressure. The zero pressure reading is 0.5V

and full scale is 4.5V. For a pressure swing of 0±15

psi, the voltage changes 4.0V. To operate the sensor,

it is supplied a regulated 4.8 to 5.1 volts. Ground is

provided through the low-noise, sensor return circuit

at the PCM.

The MAP sensor input is the number one contrib-

utor to fuel injector pulse width. The most important

function of the MAP sensor is to determine baromet-

ric pressure. The PCM needs to know if the vehicle is

at sea level or at a higher altitude, because the air

density changes with altitude. It will also help to cor-

rect for varying barometric pressure. Barometric

pressure and altitude have a direct inverse correla-

tion; as altitude goes up, barometric goes down. At

key-on, the PCM powers up and looks at MAP volt-

age, and based upon the voltage it sees, it knows the

current barometric pressure (relative to altitude).

Once the engine starts, the PCM looks at the voltage

again, continuously every 12 milliseconds, and com-

pares the current voltage to what it was at key-on.

The difference between current voltage and what it

was at key-on, is manifold vacuum.

During key-on (engine not running) the sensor

reads (updates) barometric pressure. A normal range

can be obtained by monitoring a known good sensor.

As the altitude increases, the air becomes thinner

(less oxygen). If a vehicle is started and driven to a

very different altitude than where it was at key-on,

the barometric pressure needs to be updated. Any

time the PCM sees Wide Open Throttle (WOT), based

upon Throttle Position Sensor (TPS) angle and RPM,

it will update barometric pressure in the MAP mem-

ory cell. With periodic updates, the PCM can make

its calculations more effectively.

The PCM uses the MAP sensor input to aid in cal-

culating the following:

²Manifold pressure

²Barometric pressure

Fig. 20 5.7L IAT SENSOR R/I

1 - FRONT OF INTAKE MANIFOLD PLENUM

2 - IAT SENSOR

3 - RELEASE TAB

14 - 32 FUEL INJECTION - GASDR

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 1605 of 2627

INSTALLATION

Threads of new oxygen sensors are factory coated

with anti-seize compound to aid in removal.DO

NOT add any additional anti-seize compound to

threads of a new oxygen sensor.

(1) Install O2S sensor. Tighten to 30 N´m (22 ft.

lbs.) torque.

(2) Connect O2S sensor wire connector.

(3) Lower vehicle.

PTO SWITCH

DESCRIPTION

This Powertrain Control Module (PCM) input is

used only on models equipped with aftermarket

Power Take Off (PTO) units.

OPERATION

The input is used only to tell the PCM (or ECM-

Diesel) that the PTO has been engaged. The PCM (or

ECM) will disable (temporarily shut down) certain

OBD II diagnostic trouble codes when the PTO is

engaged.

JTEC and NGC Engine Controllers:When the

aftermarket PTO switch has been engaged, a 12V +

signal is sent through circuit G113 to PCM pin A13.

The PCM will then sense and determine that the

PTO has been activated.

CM 845 or CM 848 Diesel Engine Controllers:

When the aftermarket PTO switch has been engaged,

a 12V + signal is sent through circuit G113 to ECM

pin B38. The ECM will then sense and determine

that the PTO has been activated.

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold.

Fuel does not enter the intake manifold through the

throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

5.7L V-8 Engine:

The throttle body on the 5.7L engine is an electri-

cally controlled unit. A mechanical cable is not used

to connect the throttle body to the accelerator pedal.

The Accelerator Pedal Position Sensor (APPS) alongwith inputs from other sensors sets the throttle blade

to pre-determined positions.

Except 5.7L V-8 Engine:

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable and

transmission control cable (when equipped) are con-

nected to the throttle body linkage arm.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

3.7L V-6

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Remove air cleaner tube at throttle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS.

(3) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section for removal/installation procedures.

(4) Disconnect necessary vacuum lines at throttle

body.

(5) Remove 3 throttle body mounting bolts (Fig.

28).

(6) Remove throttle body from intake manifold.

(7) Check condition of old throttle body-to-intake

manifold o-ring (Fig. 29).

4.7L V-8

(1) Remove air duct and air resonator box at throt-

tle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS (Fig. 30).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to Accelerator Pedal and Throttle

Cable.

(5) Remove three throttle body mounting bolts

(Fig. 30).

(6) Remove throttle body from intake manifold.

5.7L V-8

CAUTION: Do not use spray (carb) cleaners on any

part of the throttle body. Do not apply silicone lubri-

cants to any part of the throttle body.

(1) Remove air duct and air resonator box at throt-

tle body.

14 - 36 FUEL INJECTION - GASDR

OXYGEN SENSOR (Continued)

Page 1610 of 2627

(11) Install air resonator tube to throttle body.

(12) Before starting engine, operate accelerator

pedal to check for any binding.

5.7L V-8

(1) Attach cable to Accelerator Pedal Position Sen-

sor (APPS). Refer to APPS Removal / Installation.

(2) Push cable housing into rubber grommet and

through opening in dash panel.

(3) From inside vehicle, install clip holding cable

to dashpanel (Fig. 1).

(4) From inside vehicle, slide throttle cable core

wire into opening in top of pedal arm.

(5) Push cable retainer (clip) into pedal arm open-

ing until it snaps in place.

(6) Before starting engine, operate accelerator

pedal to check for any binding.

(7) If necessary, use DRB IIItScan Tool to erase

any APPS Diagnostic Trouble Codes (DTC's) from

PCM.

THROTTLE POSITION SENSOR

DESCRIPTION

The 3-wire Throttle Position Sensor (TPS) is

mounted on the throttle body and is connected to the

throttle blade shaft.

The 5.7L V-8 engine does not use a separate TPS

on the throttle body.

OPERATION

The 5.7L V-8 engine does not use a separate Throt-

tle Position Sensor (TPS) on the throttle body.

The 3±wire TPS provides the Powertrain Control

Module (PCM) with an input signal (voltage) that

represents the throttle blade position of the throttle

body. The sensor is connected to the throttle blade

shaft. As the position of the throttle blade changes,

the output voltage of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS.

This will vary in an approximate range of from .26

volts at minimum throttle opening (idle), to 4.49 volts

at wide open throttle. Along with inputs from other

sensors, the PCM uses the TPS input to determine

current engine operating conditions. In response to

engine operating conditions, the PCM will adjust fuel

injector pulse width and ignition timing.The PCM needs to identify the actions and position

of the throttle blade at all times. This information is

needed to assist in performing the following calcula-

tions:

²Ignition timing advance

²Fuel injection pulse-width

²Idle (learned value or minimum TPS)

²Off-idle (0.06 volt)

²Wide Open Throttle (WOT) open loop (2.608

volts above learned idle voltage)

²Deceleration fuel lean out

²Fuel cutoff during cranking at WOT (2.608 volts

above learned idle voltage)

²A/C WOT cutoff (certain automatic transmis-

sions only)

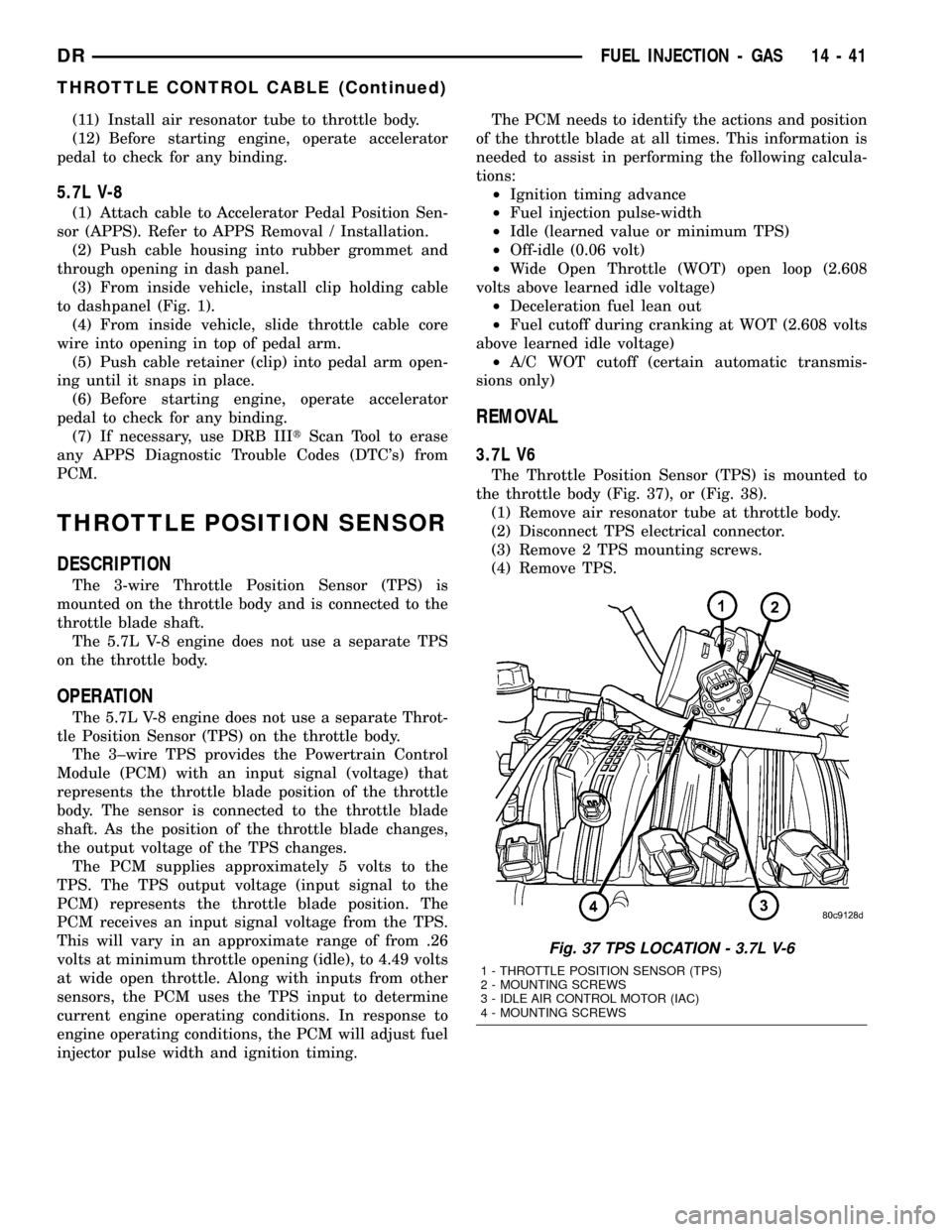

REMOVAL

3.7L V6

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 37), or (Fig. 38).

(1) Remove air resonator tube at throttle body.

(2) Disconnect TPS electrical connector.

(3) Remove 2 TPS mounting screws.

(4) Remove TPS.

Fig. 37 TPS LOCATION - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

DRFUEL INJECTION - GAS 14 - 41

THROTTLE CONTROL CABLE (Continued)

Page 1621 of 2627

The fuel heater element and fuel heater relay

are not computer controlled.

The heater element operates on 12 volts, 300 watts

at 0 degrees F.

DIAGNOSIS AND TESTING - FUEL HEATER

The fuel heater is used to prevent diesel fuel from

waxing during cold weather operation.

NOTE: The fuel heater element, fuel heater relay

and fuel heater temperature sensor are not con-

trolled by the Engine Control Module (ECM).

A malfunctioning fuel heater can cause a wax

build-up in the fuel filter/water separator. Wax

build-up in the filter/separator can cause engine

starting problems and prevent the engine from rev-

ving up. It can also cause blue or white fog-like

exhaust. If the heater is not operating in cold tem-

peratures, the engine may not operate due to fuel

waxing.

The fuel heater assembly is located on the side of

fuel filter housing.

The heater assembly is equipped with a built-in

fuel temperature sensor (thermostat) that senses fuel

temperature. When fuel temperature drops below 45

degrees 8 degrees F, the sensor allows current to

flow to built-in heater element to warm fuel. When

fuel temperature rises above 75 degrees 8 degrees

F, the sensor stops current flow to heater element

(circuit is open).

Voltage to operate fuel heater element is supplied

from ignition switch, through fuel heater relay (also

refer to Fuel Heater Relay), to fuel temperature sen-

sor and on to fuel heater element.

The heater element operates on 12 volts, 300 watts

at 0 degrees F. As temperature increases, power

requirements decrease.

A minimum of 7 volts is required to operate the

fuel heater. The resistance value of the heater ele-

ment is less than 1 ohm (cold) and up to 1000 ohms

warm.

TESTING

(1) Disconnect electrical connector from thermostat

(Fig. 3).

Ambient temperature must be below the circuit

close temperature. If necessary, induce this ambient

temperature by placing ice packs on thermostat to

produce an effective ambient temperature below cir-

cuit close temperature.

Measure resistance across two pins. Operating

range is 0.3 Ð 0.45 Ohms.

(2) If resistance is out of range, remove thermostat

and check resistance across terminal connections of

heater. The heater can be checked at room tempera-

ture. Operating range is 0.3 - 0.45 Ohms.(3) Replace heater if resistance is not within oper-

ating range.

(4) If heater is within operating range, replace

heater thermostat.

REMOVAL

REMOVAL/INSTALLATION

The fuel heater/element/sensor assembly is located

inside of the fuel filter housing. Refer to Fuel Filter/

Water Separator Removal/Installation for procedures.

FUEL HEATER RELAY

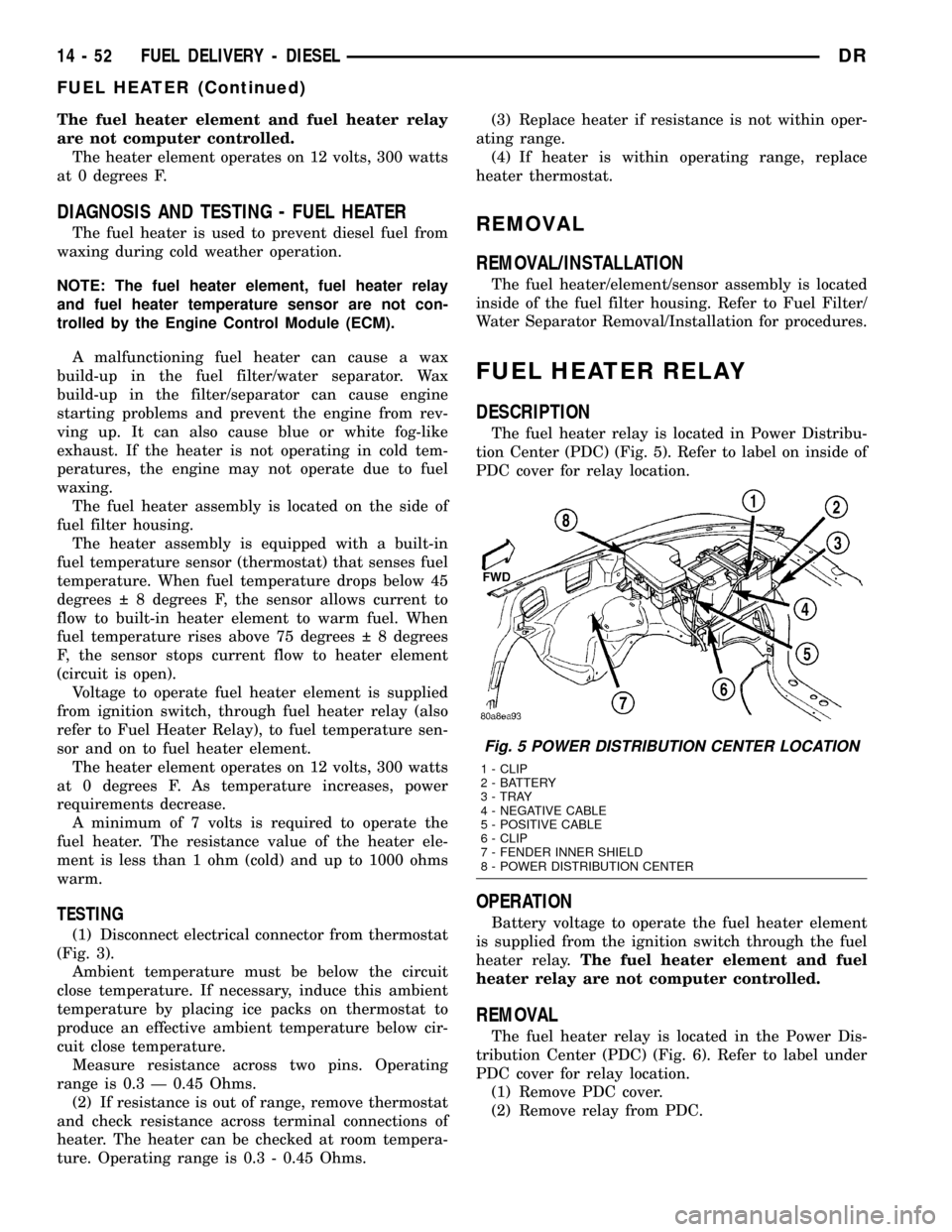

DESCRIPTION

The fuel heater relay is located in Power Distribu-

tion Center (PDC) (Fig. 5). Refer to label on inside of

PDC cover for relay location.

OPERATION

Battery voltage to operate the fuel heater element

is supplied from the ignition switch through the fuel

heater relay.The fuel heater element and fuel

heater relay are not computer controlled.

REMOVAL

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 6). Refer to label under

PDC cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

Fig. 5 POWER DISTRIBUTION CENTER LOCATION

1 - CLIP

2 - BATTERY

3 - TRAY

4 - NEGATIVE CABLE

5 - POSITIVE CABLE

6 - CLIP

7 - FENDER INNER SHIELD

8 - POWER DISTRIBUTION CENTER

14 - 52 FUEL DELIVERY - DIESELDR

FUEL HEATER (Continued)

Page 1622 of 2627

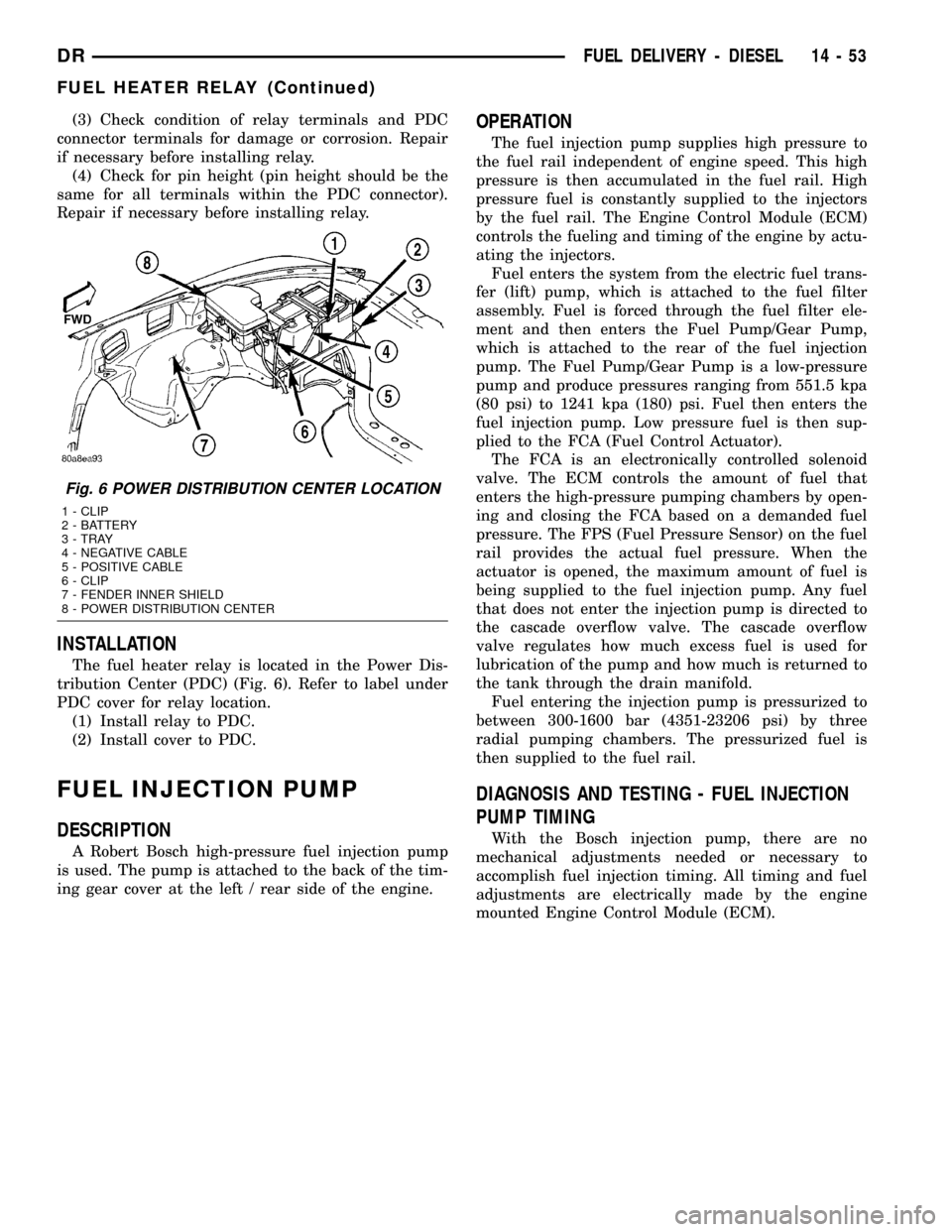

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 6). Refer to label under

PDC cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

FUEL INJECTION PUMP

DESCRIPTION

A Robert Bosch high-pressure fuel injection pump

is used. The pump is attached to the back of the tim-

ing gear cover at the left / rear side of the engine.

OPERATION

The fuel injection pump supplies high pressure to

the fuel rail independent of engine speed. This high

pressure is then accumulated in the fuel rail. High

pressure fuel is constantly supplied to the injectors

by the fuel rail. The Engine Control Module (ECM)

controls the fueling and timing of the engine by actu-

ating the injectors.

Fuel enters the system from the electric fuel trans-

fer (lift) pump, which is attached to the fuel filter

assembly. Fuel is forced through the fuel filter ele-

ment and then enters the Fuel Pump/Gear Pump,

which is attached to the rear of the fuel injection

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FCA based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail provides the actual fuel pressure. When the

actuator is opened, the maximum amount of fuel is

being supplied to the fuel injection pump. Any fuel

that does not enter the injection pump is directed to

the cascade overflow valve. The cascade overflow

valve regulates how much excess fuel is used for

lubrication of the pump and how much is returned to

the tank through the drain manifold.

Fuel entering the injection pump is pressurized to

between 300-1600 bar (4351-23206 psi) by three

radial pumping chambers. The pressurized fuel is

then supplied to the fuel rail.

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING

With the Bosch injection pump, there are no

mechanical adjustments needed or necessary to

accomplish fuel injection timing. All timing and fuel

adjustments are electrically made by the engine

mounted Engine Control Module (ECM).

Fig. 6 POWER DISTRIBUTION CENTER LOCATION

1 - CLIP

2 - BATTERY

3 - TRAY

4 - NEGATIVE CABLE

5 - POSITIVE CABLE

6 - CLIP

7 - FENDER INNER SHIELD

8 - POWER DISTRIBUTION CENTER

DRFUEL DELIVERY - DIESEL 14 - 53

FUEL HEATER RELAY (Continued)

Page 1626 of 2627

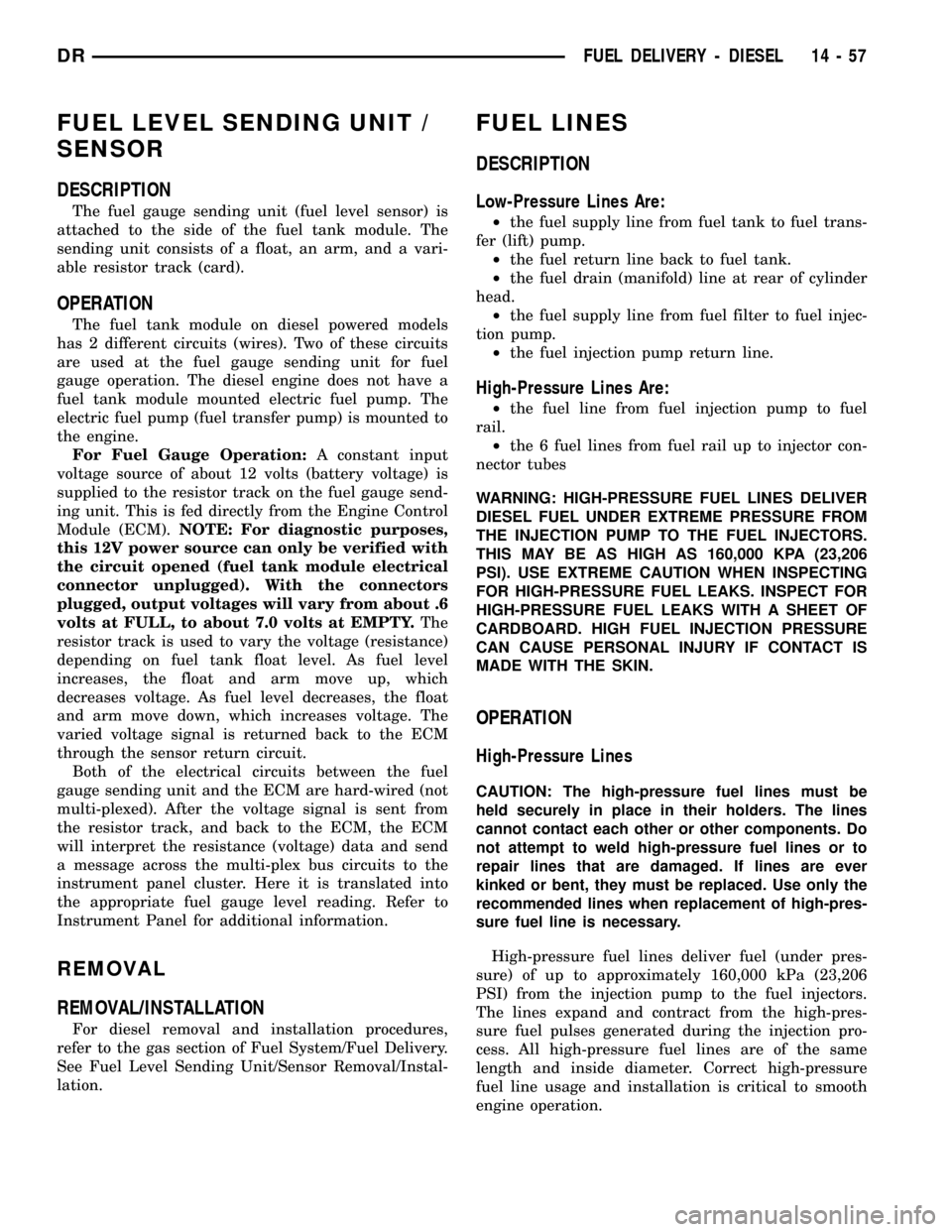

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel tank module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel tank module on diesel powered models

has 2 different circuits (wires). Two of these circuits

are used at the fuel gauge sending unit for fuel

gauge operation. The diesel engine does not have a

fuel tank module mounted electric fuel pump. The

electric fuel pump (fuel transfer pump) is mounted to

the engine.

For Fuel Gauge Operation:A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Engine Control

Module (ECM).NOTE: For diagnostic purposes,

this 12V power source can only be verified with

the circuit opened (fuel tank module electrical

connector unplugged). With the connectors

plugged, output voltages will vary from about .6

volts at FULL, to about 7.0 volts at EMPTY.The

resistor track is used to vary the voltage (resistance)

depending on fuel tank float level. As fuel level

increases, the float and arm move up, which

decreases voltage. As fuel level decreases, the float

and arm move down, which increases voltage. The

varied voltage signal is returned back to the ECM

through the sensor return circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the ECM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the ECM, the ECM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

REMOVAL

REMOVAL/INSTALLATION

For diesel removal and installation procedures,

refer to the gas section of Fuel System/Fuel Delivery.

See Fuel Level Sending Unit/Sensor Removal/Instal-

lation.

FUEL LINES

DESCRIPTION

Low-Pressure Lines Are:

²the fuel supply line from fuel tank to fuel trans-

fer (lift) pump.

²the fuel return line back to fuel tank.

²the fuel drain (manifold) line at rear of cylinder

head.

²the fuel supply line from fuel filter to fuel injec-

tion pump.

²the fuel injection pump return line.

High-Pressure Lines Are:

²the fuel line from fuel injection pump to fuel

rail.

²the 6 fuel lines from fuel rail up to injector con-

nector tubes

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 160,000 KPA (23,206

PSI). USE EXTREME CAUTION WHEN INSPECTING

FOR HIGH-PRESSURE FUEL LEAKS. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

OPERATION

High-Pressure Lines

CAUTION: The high-pressure fuel lines must be

held securely in place in their holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. If lines are ever

kinked or bent, they must be replaced. Use only the

recommended lines when replacement of high-pres-

sure fuel line is necessary.

High-pressure fuel lines deliver fuel (under pres-

sure) of up to approximately 160,000 kPa (23,206

PSI) from the injection pump to the fuel injectors.

The lines expand and contract from the high-pres-

sure fuel pulses generated during the injection pro-

cess. All high-pressure fuel lines are of the same

length and inside diameter. Correct high-pressure

fuel line usage and installation is critical to smooth

engine operation.

DRFUEL DELIVERY - DIESEL 14 - 57

Page 1649 of 2627

INTAKE AIR HEATER

DESCRIPTION

The intake manifold air heater element assembly

is located in the top of the intake manifold.

OPERATION

The air heater elements are used to heat incoming

air to the intake manifold. This is done to help

engine starting and improve driveability with cool or

cold outside temperatures.

Electrical supply for the 2 air heater elements is

controlled by the Engine Control Module (ECM)

through the 2 air heater relays. Refer to Intake Man-

ifold Air Heater Relays for more information.

Two heavy-duty cables connect the 2 air heater ele-

ments to the 2 air heater relays. Each of these cables

will supply approximately 95 amps at 12 volts to an

individual heating element within the heater block

assembly.

Refer to the Powertrain Diagnostic Procedures

manual for electrical operation and complete descrip-

tion of the intake heaters, including pre-heat and

post-heat cycles.

REMOVAL

If servicing either of the heater elements, the

entire block/element assembly must be replaced.

(1) Disconnect both negative battery cables at both

batteries. Cover and isolate ends of both cables.

(2) Remove both the intake manifold air intake

tube (above injection pump), and its rubber connector

hose (Fig. 26).

(3) Lift 2 rubber covers (Fig. 27) to gain access to 2

positive (+) cable nuts. Remove these 2 nuts (Fig. 28)

and remove 2 cables from studs.

(4) Disconnect ground strap (Fig. 27) at heater ele-

ment stud.

(5) Remove wiring harness clips.

(6) Remove engine oil dipstick tube bracket from

air inlet connection and fuel filter housing.

(7) Remove 4 housing mounting bolts (Fig. 27) and

remove heater element assembly.

INSTALLATION

If servicing either of the heater elements, the

entire block/element assembly must be replaced.

(1) Using 2 new gaskets, position element assem-

bly and air housing to intake manifold.

(2) Install ground cable to air housing.

(3) Install 4 housing bolts and tighten to 24 N´m

(18 ft. lbs.) torque.

(4) Connect 2 positive (+) heater cables at cable

mounting studs.Do not allow either of the cable

eyelets to contact any other metal source other

than the cable nuts/studs.

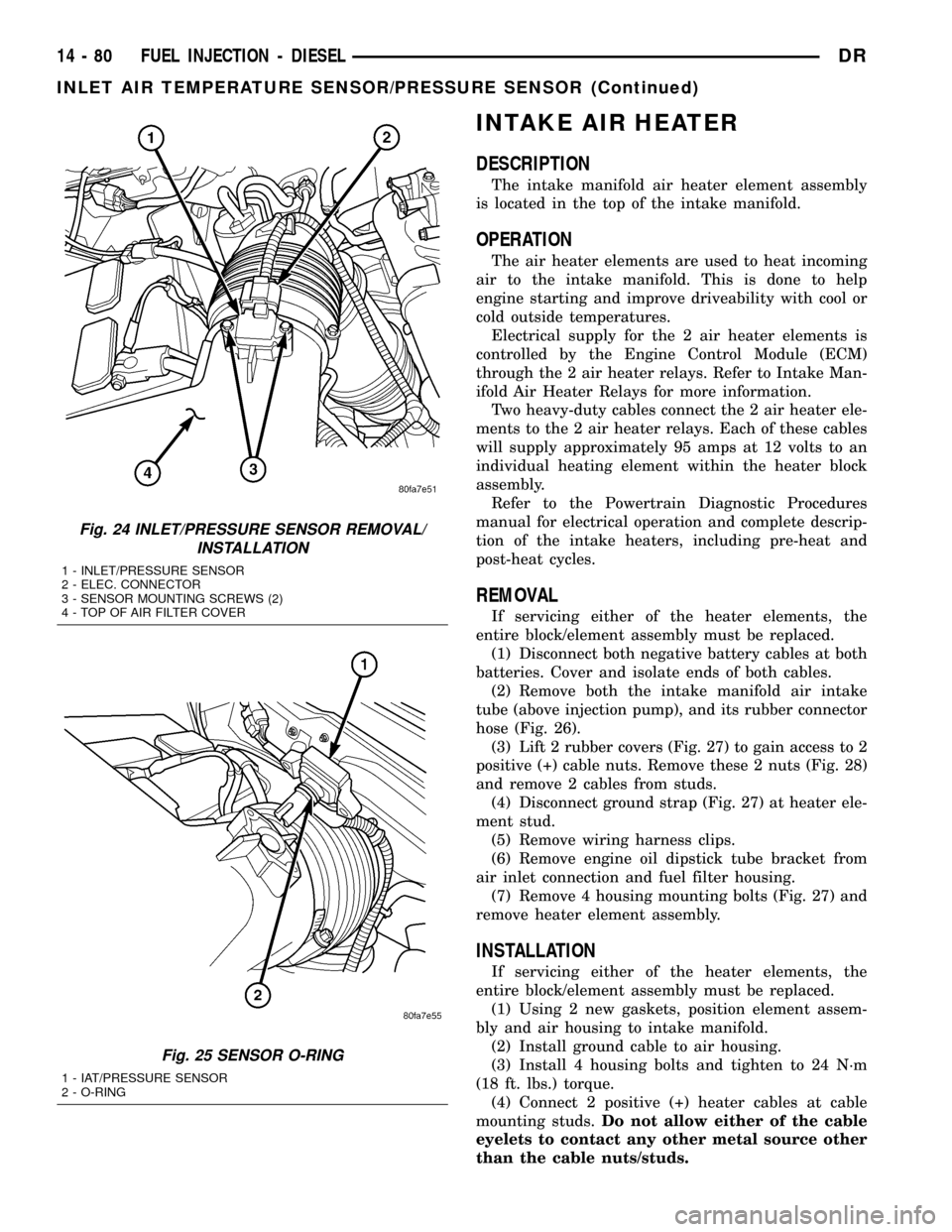

Fig. 24 INLET/PRESSURE SENSOR REMOVAL/

INSTALLATION

1 - INLET/PRESSURE SENSOR

2 - ELEC. CONNECTOR

3 - SENSOR MOUNTING SCREWS (2)

4 - TOP OF AIR FILTER COVER

Fig. 25 SENSOR O-RING

1 - IAT/PRESSURE SENSOR

2 - O-RING

14 - 80 FUEL INJECTION - DIESELDR

INLET AIR TEMPERATURE SENSOR/PRESSURE SENSOR (Continued)

Page 1651 of 2627

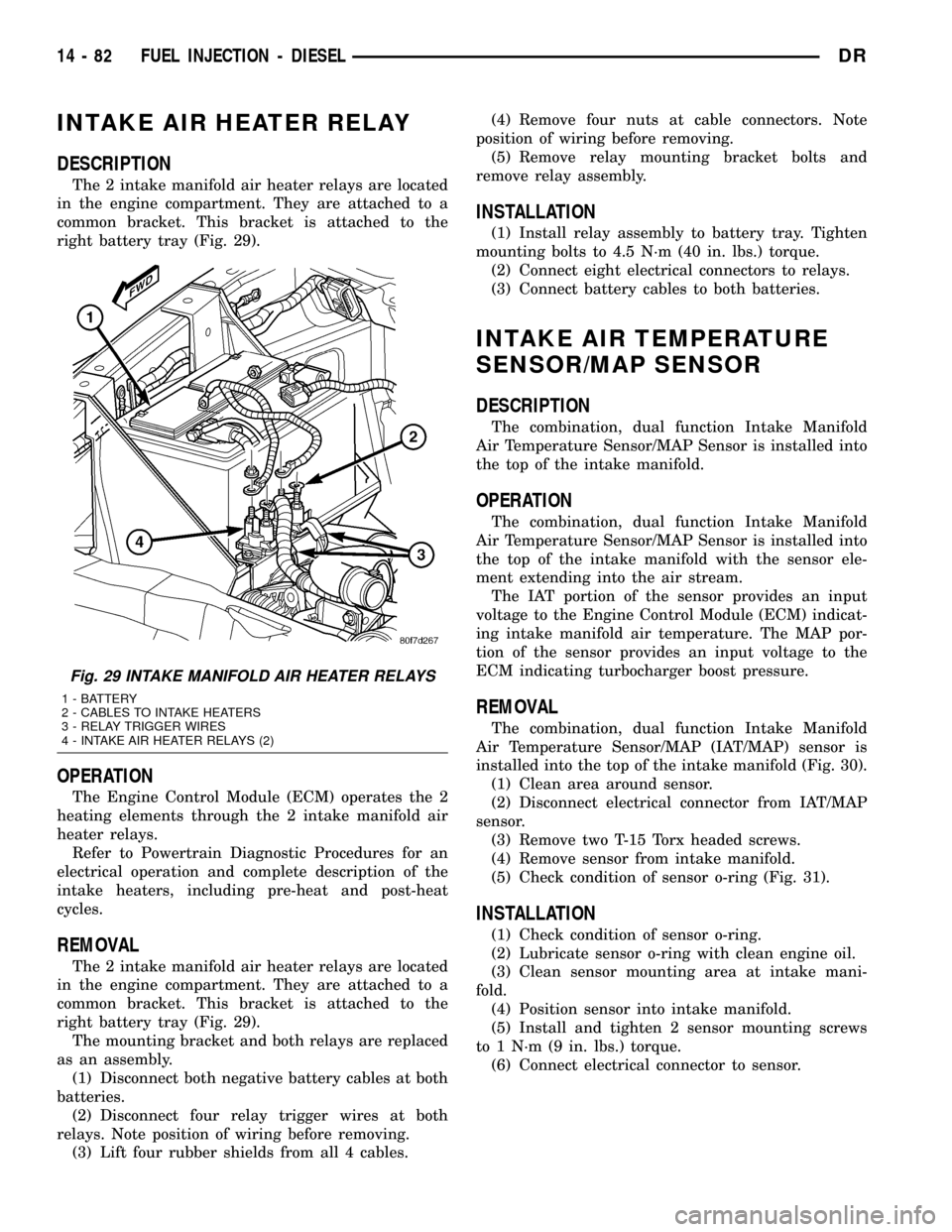

INTAKE AIR HEATER RELAY

DESCRIPTION

The 2 intake manifold air heater relays are located

in the engine compartment. They are attached to a

common bracket. This bracket is attached to the

right battery tray (Fig. 29).

OPERATION

The Engine Control Module (ECM) operates the 2

heating elements through the 2 intake manifold air

heater relays.

Refer to Powertrain Diagnostic Procedures for an

electrical operation and complete description of the

intake heaters, including pre-heat and post-heat

cycles.

REMOVAL

The 2 intake manifold air heater relays are located

in the engine compartment. They are attached to a

common bracket. This bracket is attached to the

right battery tray (Fig. 29).

The mounting bracket and both relays are replaced

as an assembly.

(1) Disconnect both negative battery cables at both

batteries.

(2) Disconnect four relay trigger wires at both

relays. Note position of wiring before removing.

(3) Lift four rubber shields from all 4 cables.(4) Remove four nuts at cable connectors. Note

position of wiring before removing.

(5) Remove relay mounting bracket bolts and

remove relay assembly.

INSTALLATION

(1) Install relay assembly to battery tray. Tighten

mounting bolts to 4.5 N´m (40 in. lbs.) torque.

(2) Connect eight electrical connectors to relays.

(3) Connect battery cables to both batteries.

INTAKE AIR TEMPERATURE

SENSOR/MAP SENSOR

DESCRIPTION

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP Sensor is installed into

the top of the intake manifold.

OPERATION

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP Sensor is installed into

the top of the intake manifold with the sensor ele-

ment extending into the air stream.

The IAT portion of the sensor provides an input

voltage to the Engine Control Module (ECM) indicat-

ing intake manifold air temperature. The MAP por-

tion of the sensor provides an input voltage to the

ECM indicating turbocharger boost pressure.

REMOVAL

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP (IAT/MAP) sensor is

installed into the top of the intake manifold (Fig. 30).

(1) Clean area around sensor.

(2) Disconnect electrical connector from IAT/MAP

sensor.

(3) Remove two T-15 Torx headed screws.

(4) Remove sensor from intake manifold.

(5) Check condition of sensor o-ring (Fig. 31).

INSTALLATION

(1) Check condition of sensor o-ring.

(2) Lubricate sensor o-ring with clean engine oil.

(3) Clean sensor mounting area at intake mani-

fold.

(4) Position sensor into intake manifold.

(5) Install and tighten 2 sensor mounting screws

to 1 N´m (9 in. lbs.) torque.

(6) Connect electrical connector to sensor.

Fig. 29 INTAKE MANIFOLD AIR HEATER RELAYS

1 - BATTERY

2 - CABLES TO INTAKE HEATERS

3 - RELAY TRIGGER WIRES

4 - INTAKE AIR HEATER RELAYS (2)

14 - 82 FUEL INJECTION - DIESELDR