steering DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1499 of 2627

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

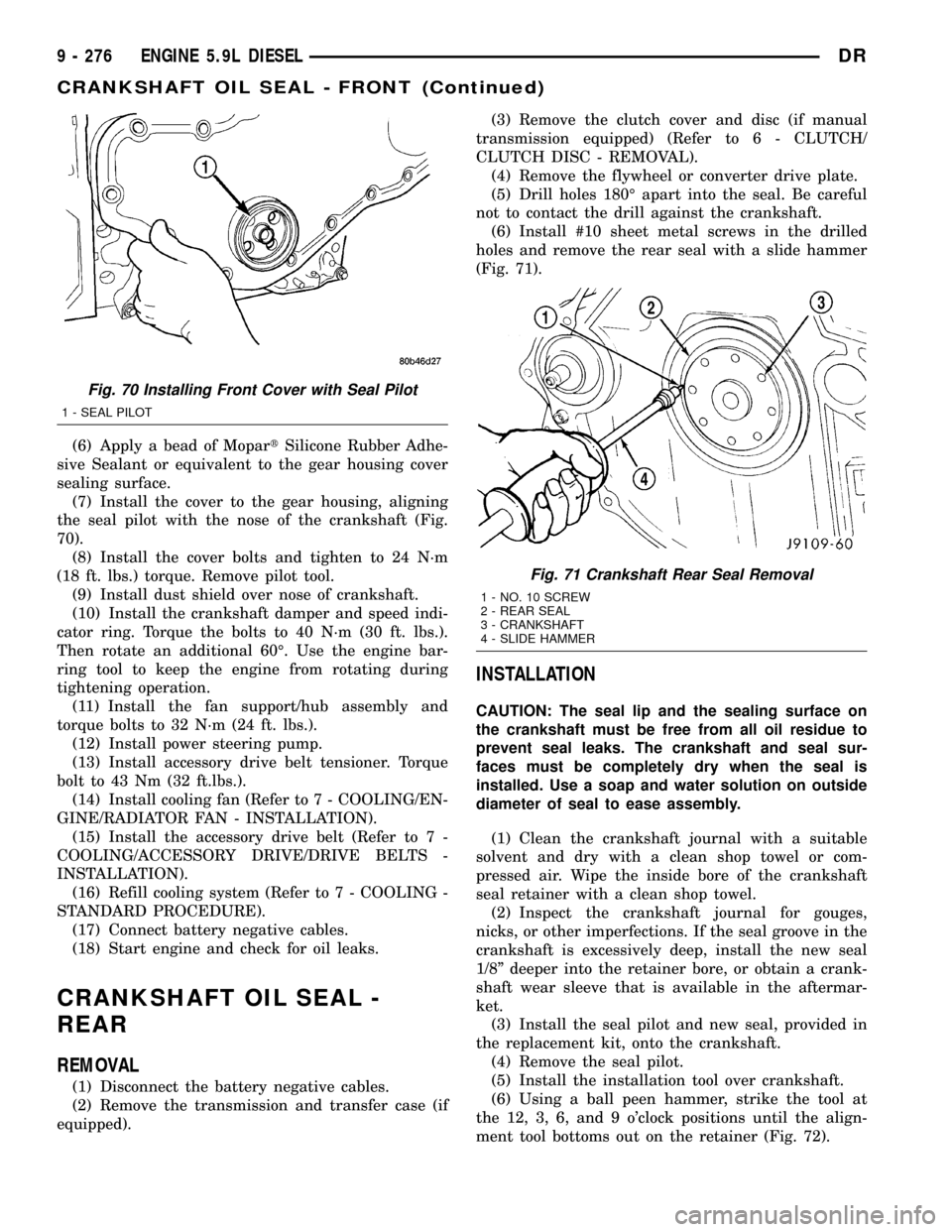

(7) Install the cover to the gear housing, aligning

the seal pilot with the nose of the crankshaft (Fig.

70).

(8) Install the cover bolts and tighten to 24 N´m

(18 ft. lbs.) torque. Remove pilot tool.

(9) Install dust shield over nose of crankshaft.

(10) Install the crankshaft damper and speed indi-

cator ring. Torque the bolts to 40 N´m (30 ft. lbs.).

Then rotate an additional 60É. Use the engine bar-

ring tool to keep the engine from rotating during

tightening operation.

(11) Install the fan support/hub assembly and

torque bolts to 32 N´m (24 ft. lbs.).

(12) Install power steering pump.

(13) Install accessory drive belt tensioner. Torque

bolt to 43 Nm (32 ft.lbs.).

(14) Install cooling fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(15) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(16) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(17) Connect battery negative cables.

(18) Start engine and check for oil leaks.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the transmission and transfer case (if

equipped).(3) Remove the clutch cover and disc (if manual

transmission equipped) (Refer to 6 - CLUTCH/

CLUTCH DISC - REMOVAL).

(4) Remove the flywheel or converter drive plate.

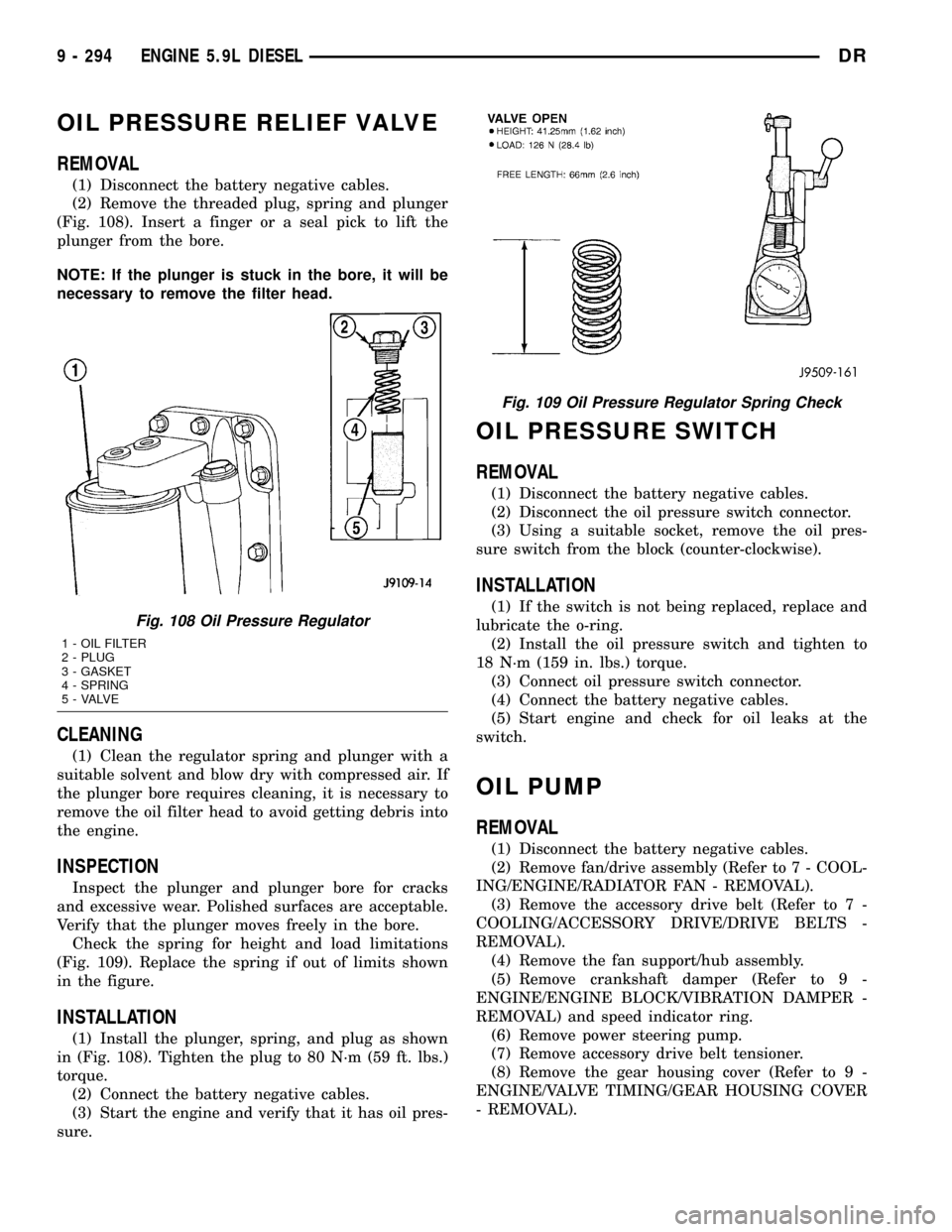

(5) Drill holes 180É apart into the seal. Be careful

not to contact the drill against the crankshaft.

(6) Install #10 sheet metal screws in the drilled

holes and remove the rear seal with a slide hammer

(Fig. 71).

INSTALLATION

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(1) Clean the crankshaft journal with a suitable

solvent and dry with a clean shop towel or com-

pressed air. Wipe the inside bore of the crankshaft

seal retainer with a clean shop towel.

(2) Inspect the crankshaft journal for gouges,

nicks, or other imperfections. If the seal groove in the

crankshaft is excessively deep, install the new seal

1/8º deeper into the retainer bore, or obtain a crank-

shaft wear sleeve that is available in the aftermar-

ket.

(3) Install the seal pilot and new seal, provided in

the replacement kit, onto the crankshaft.

(4) Remove the seal pilot.

(5) Install the installation tool over crankshaft.

(6) Using a ball peen hammer, strike the tool at

the 12, 3, 6, and 9 o'clock positions until the align-

ment tool bottoms out on the retainer (Fig. 72).

Fig. 70 Installing Front Cover with Seal Pilot

1 - SEAL PILOT

Fig. 71 Crankshaft Rear Seal Removal

1 - NO. 10 SCREW

2 - REAR SEAL

3 - CRANKSHAFT

4 - SLIDE HAMMER

9 - 276 ENGINE 5.9L DIESELDR

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1517 of 2627

OIL PRESSURE RELIEF VALVE

REMOVAL

(1) Disconnect the battery negative cables.

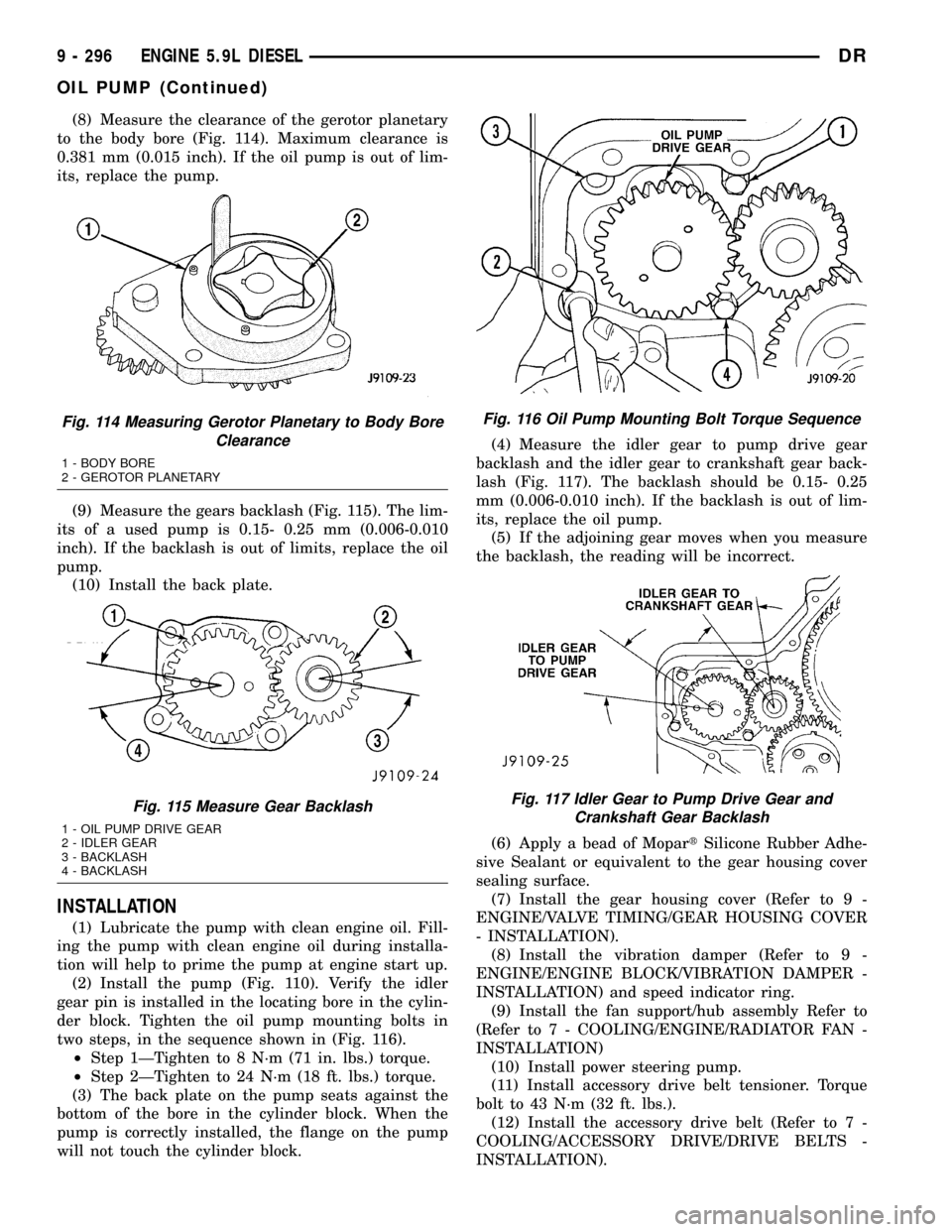

(2) Remove the threaded plug, spring and plunger

(Fig. 108). Insert a finger or a seal pick to lift the

plunger from the bore.

NOTE: If the plunger is stuck in the bore, it will be

necessary to remove the filter head.

CLEANING

(1) Clean the regulator spring and plunger with a

suitable solvent and blow dry with compressed air. If

the plunger bore requires cleaning, it is necessary to

remove the oil filter head to avoid getting debris into

the engine.

INSPECTION

Inspect the plunger and plunger bore for cracks

and excessive wear. Polished surfaces are acceptable.

Verify that the plunger moves freely in the bore.

Check the spring for height and load limitations

(Fig. 109). Replace the spring if out of limits shown

in the figure.

INSTALLATION

(1) Install the plunger, spring, and plug as shown

in (Fig. 108). Tighten the plug to 80 N´m (59 ft. lbs.)

torque.

(2) Connect the battery negative cables.

(3) Start the engine and verify that it has oil pres-

sure.

OIL PRESSURE SWITCH

REMOVAL

(1) Disconnect the battery negative cables.

(2) Disconnect the oil pressure switch connector.

(3) Using a suitable socket, remove the oil pres-

sure switch from the block (counter-clockwise).

INSTALLATION

(1) If the switch is not being replaced, replace and

lubricate the o-ring.

(2) Install the oil pressure switch and tighten to

18 N´m (159 in. lbs.) torque.

(3) Connect oil pressure switch connector.

(4) Connect the battery negative cables.

(5) Start engine and check for oil leaks at the

switch.

OIL PUMP

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove fan/drive assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove the fan support/hub assembly.

(5) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(6) Remove power steering pump.

(7) Remove accessory drive belt tensioner.

(8) Remove the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- REMOVAL).

Fig. 108 Oil Pressure Regulator

1 - OIL FILTER

2 - PLUG

3 - GASKET

4 - SPRING

5 - VALVE

Fig. 109 Oil Pressure Regulator Spring Check

9 - 294 ENGINE 5.9L DIESELDR

Page 1519 of 2627

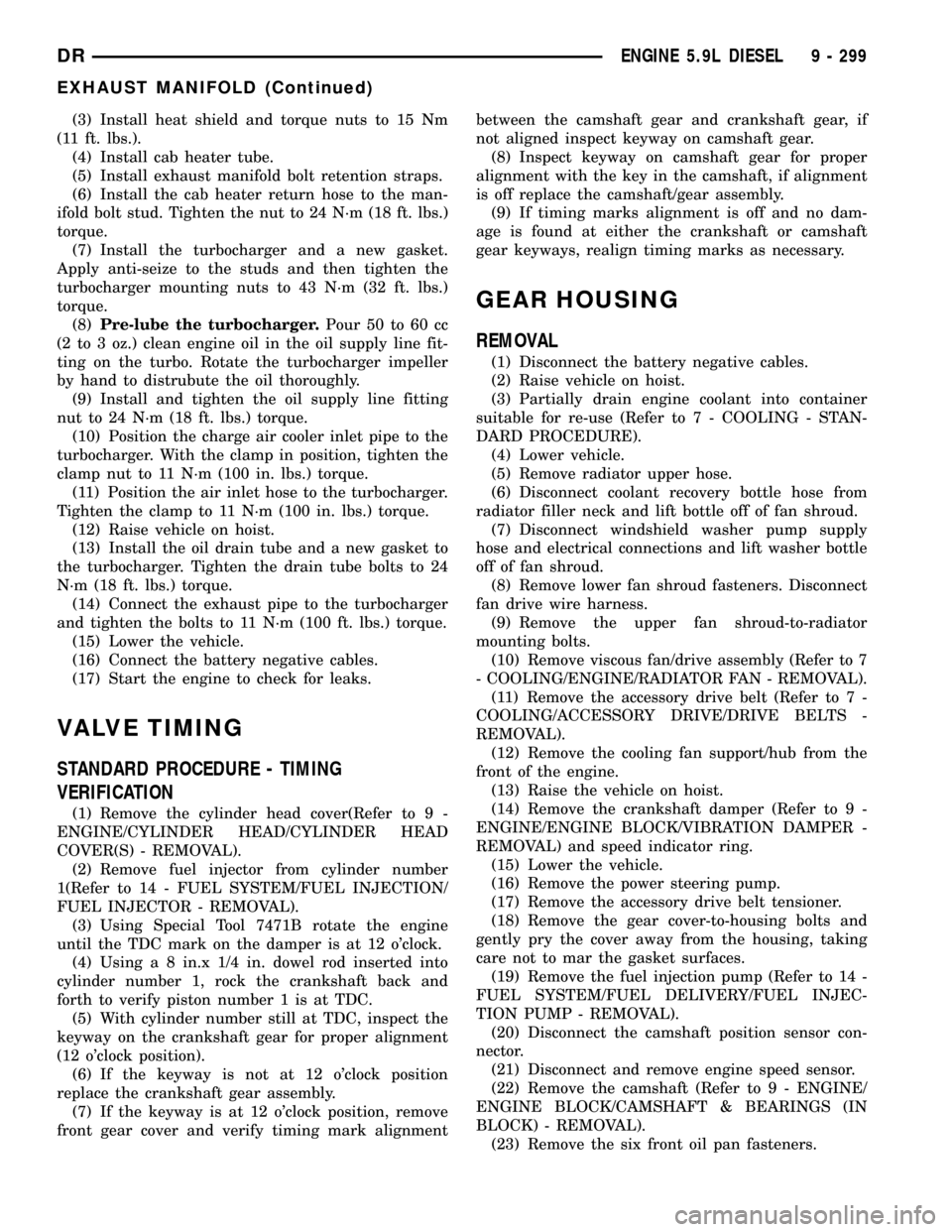

(8) Measure the clearance of the gerotor planetary

to the body bore (Fig. 114). Maximum clearance is

0.381 mm (0.015 inch). If the oil pump is out of lim-

its, replace the pump.

(9) Measure the gears backlash (Fig. 115). The lim-

its of a used pump is 0.15- 0.25 mm (0.006-0.010

inch). If the backlash is out of limits, replace the oil

pump.

(10) Install the back plate.

INSTALLATION

(1) Lubricate the pump with clean engine oil. Fill-

ing the pump with clean engine oil during installa-

tion will help to prime the pump at engine start up.

(2) Install the pump (Fig. 110). Verify the idler

gear pin is installed in the locating bore in the cylin-

der block. Tighten the oil pump mounting bolts in

two steps, in the sequence shown in (Fig. 116).

²Step 1ÐTighten to 8 N´m (71 in. lbs.) torque.

²Step 2ÐTighten to 24 N´m (18 ft. lbs.) torque.

(3) The back plate on the pump seats against the

bottom of the bore in the cylinder block. When the

pump is correctly installed, the flange on the pump

will not touch the cylinder block.(4) Measure the idler gear to pump drive gear

backlash and the idler gear to crankshaft gear back-

lash (Fig. 117). The backlash should be 0.15- 0.25

mm (0.006-0.010 inch). If the backlash is out of lim-

its, replace the oil pump.

(5) If the adjoining gear moves when you measure

the backlash, the reading will be incorrect.

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- INSTALLATION).

(8) Install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION) and speed indicator ring.

(9) Install the fan support/hub assembly Refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION)

(10) Install power steering pump.

(11) Install accessory drive belt tensioner. Torque

bolt to 43 N´m (32 ft. lbs.).

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Fig. 114 Measuring Gerotor Planetary to Body Bore

Clearance

1 - BODY BORE

2 - GEROTOR PLANETARY

Fig. 115 Measure Gear Backlash

1 - OIL PUMP DRIVE GEAR

2 - IDLER GEAR

3 - BACKLASH

4 - BACKLASH

Fig. 116 Oil Pump Mounting Bolt Torque Sequence

Fig. 117 Idler Gear to Pump Drive Gear and

Crankshaft Gear Backlash

9 - 296 ENGINE 5.9L DIESELDR

OIL PUMP (Continued)

Page 1522 of 2627

(3) Install heat shield and torque nuts to 15 Nm

(11 ft. lbs.).

(4) Install cab heater tube.

(5) Install exhaust manifold bolt retention straps.

(6) Install the cab heater return hose to the man-

ifold bolt stud. Tighten the nut to 24 N´m (18 ft. lbs.)

torque.

(7) Install the turbocharger and a new gasket.

Apply anti-seize to the studs and then tighten the

turbocharger mounting nuts to 43 N´m (32 ft. lbs.)

torque.

(8)Pre-lube the turbocharger.Pour 50 to 60 cc

(2 to 3 oz.) clean engine oil in the oil supply line fit-

ting on the turbo. Rotate the turbocharger impeller

by hand to distrubute the oil thoroughly.

(9) Install and tighten the oil supply line fitting

nut to 24 N´m (18 ft. lbs.) torque.

(10) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 11 N´m (100 in. lbs.) torque.

(11) Position the air inlet hose to the turbocharger.

Tighten the clamp to 11 N´m (100 in. lbs.) torque.

(12) Raise vehicle on hoist.

(13) Install the oil drain tube and a new gasket to

the turbocharger. Tighten the drain tube bolts to 24

N´m (18 ft. lbs.) torque.

(14) Connect the exhaust pipe to the turbocharger

and tighten the bolts to 11 N´m (100 ft. lbs.) torque.

(15) Lower the vehicle.

(16) Connect the battery negative cables.

(17) Start the engine to check for leaks.

VALVE TIMING

STANDARD PROCEDURE - TIMING

VERIFICATION

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Remove fuel injector from cylinder number

1(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

FUEL INJECTOR - REMOVAL).

(3) Using Special Tool 7471B rotate the engine

until the TDC mark on the damper is at 12 o'clock.

(4) Using a 8 in.x 1/4 in. dowel rod inserted into

cylinder number 1, rock the crankshaft back and

forth to verify piston number 1 is at TDC.

(5) With cylinder number still at TDC, inspect the

keyway on the crankshaft gear for proper alignment

(12 o'clock position).

(6) If the keyway is not at 12 o'clock position

replace the crankshaft gear assembly.

(7) If the keyway is at 12 o'clock position, remove

front gear cover and verify timing mark alignmentbetween the camshaft gear and crankshaft gear, if

not aligned inspect keyway on camshaft gear.

(8) Inspect keyway on camshaft gear for proper

alignment with the key in the camshaft, if alignment

is off replace the camshaft/gear assembly.

(9) If timing marks alignment is off and no dam-

age is found at either the crankshaft or camshaft

gear keyways, realign timing marks as necessary.

GEAR HOUSING

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove lower fan shroud fasteners. Disconnect

fan drive wire harness.

(9) Remove the upper fan shroud-to-radiator

mounting bolts.

(10) Remove viscous fan/drive assembly (Refer to 7

- COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(11) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(12) Remove the cooling fan support/hub from the

front of the engine.

(13) Raise the vehicle on hoist.

(14) Remove the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(15) Lower the vehicle.

(16) Remove the power steering pump.

(17) Remove the accessory drive belt tensioner.

(18) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

(19) Remove the fuel injection pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(20) Disconnect the camshaft position sensor con-

nector.

(21) Disconnect and remove engine speed sensor.

(22) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(23) Remove the six front oil pan fasteners.

DRENGINE 5.9L DIESEL 9 - 299

EXHAUST MANIFOLD (Continued)

Page 1523 of 2627

(24) Remove the gear housing fasteners.

NOTE: Use care when removing the gear housing,

to avoid damage to the oil pan gasket, as the gas-

ket will be reused if it is not damaged.

(25) Slide a feeler gauge between the gear housing

and oil pan gasket, to break the gasket seal.

(26) Remove the gear housing and gasket.

(27) Clean the gasket material from the cylinder

block and gear housing.

INSTALLATION

(1) Inspect oil pan gasket. If torn, gasket must be

replaced.

(2) Install a new gear housing gasket onto cylinder

block and trim any excesss gasket material flush to

oil pan rail.

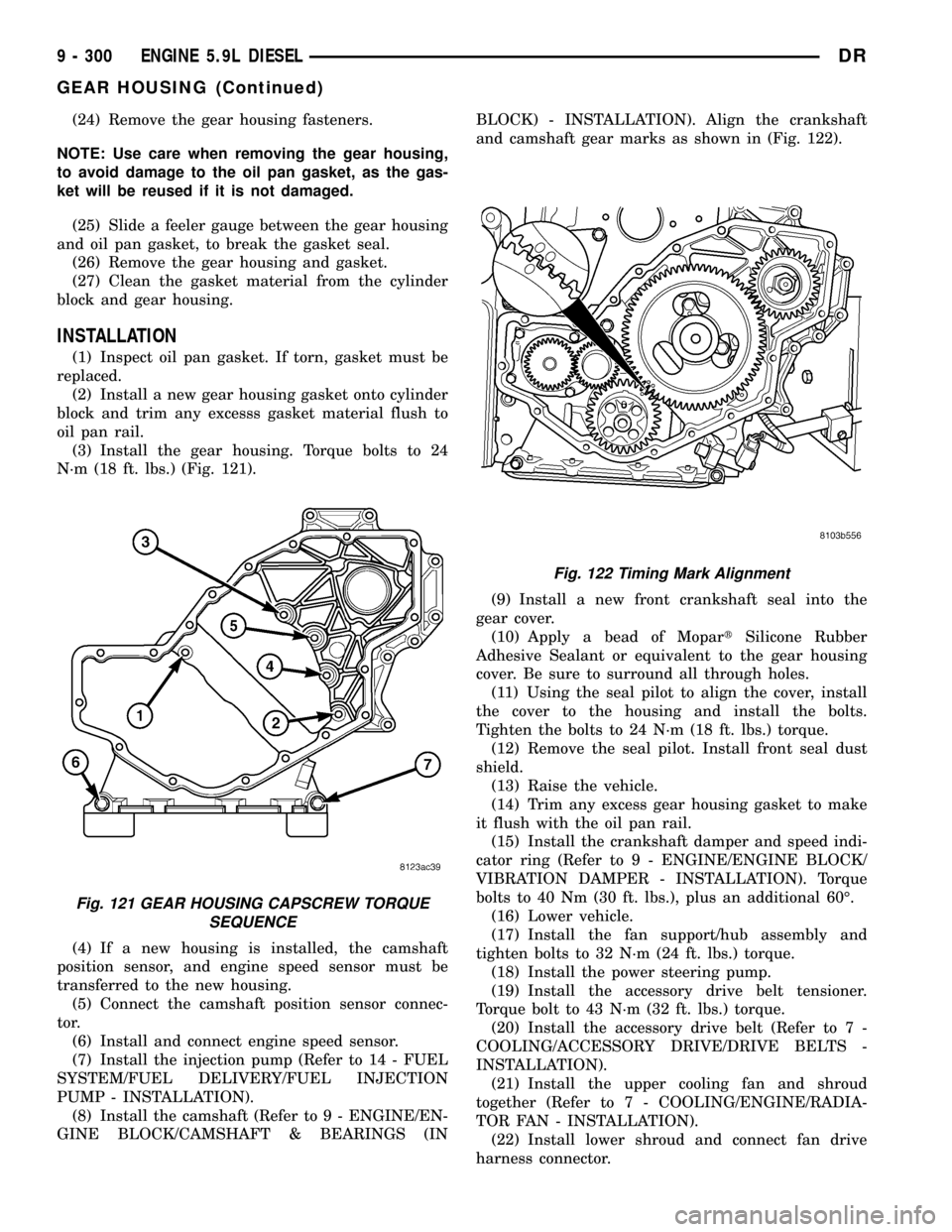

(3) Install the gear housing. Torque bolts to 24

N´m (18 ft. lbs.) (Fig. 121).

(4) If a new housing is installed, the camshaft

position sensor, and engine speed sensor must be

transferred to the new housing.

(5) Connect the camshaft position sensor connec-

tor.

(6) Install and connect engine speed sensor.

(7) Install the injection pump (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL INJECTION

PUMP - INSTALLATION).

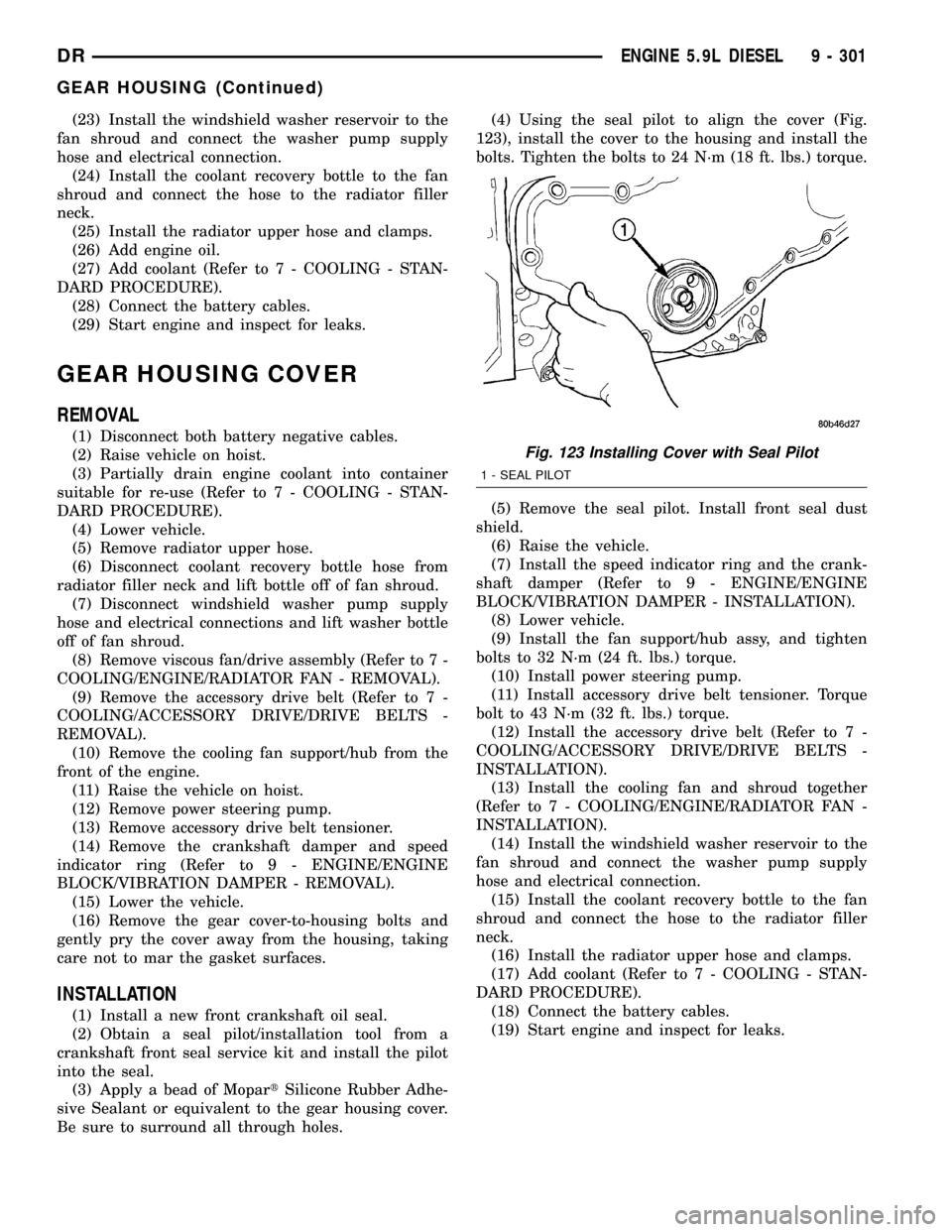

(8) Install the camshaft (Refer to 9 - ENGINE/EN-

GINE BLOCK/CAMSHAFT & BEARINGS (INBLOCK) - INSTALLATION). Align the crankshaft

and camshaft gear marks as shown in (Fig. 122).

(9) Install a new front crankshaft seal into the

gear cover.

(10) Apply a bead of MopartSilicone Rubber

Adhesive Sealant or equivalent to the gear housing

cover. Be sure to surround all through holes.

(11) Using the seal pilot to align the cover, install

the cover to the housing and install the bolts.

Tighten the bolts to 24 N´m (18 ft. lbs.) torque.

(12) Remove the seal pilot. Install front seal dust

shield.

(13) Raise the vehicle.

(14) Trim any excess gear housing gasket to make

it flush with the oil pan rail.

(15) Install the crankshaft damper and speed indi-

cator ring (Refer to 9 - ENGINE/ENGINE BLOCK/

VIBRATION DAMPER - INSTALLATION). Torque

bolts to 40 Nm (30 ft. lbs.), plus an additional 60É.

(16) Lower vehicle.

(17) Install the fan support/hub assembly and

tighten bolts to 32 N´m (24 ft. lbs.) torque.

(18) Install the power steering pump.

(19) Install the accessory drive belt tensioner.

Torque bolt to 43 N´m (32 ft. lbs.) torque.

(20) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(21) Install the upper cooling fan and shroud

together (Refer to 7 - COOLING/ENGINE/RADIA-

TOR FAN - INSTALLATION).

(22) Install lower shroud and connect fan drive

harness connector.

Fig. 121 GEAR HOUSING CAPSCREW TORQUE

SEQUENCE

Fig. 122 Timing Mark Alignment

9 - 300 ENGINE 5.9L DIESELDR

GEAR HOUSING (Continued)

Page 1524 of 2627

(23) Install the windshield washer reservoir to the

fan shroud and connect the washer pump supply

hose and electrical connection.

(24) Install the coolant recovery bottle to the fan

shroud and connect the hose to the radiator filler

neck.

(25) Install the radiator upper hose and clamps.

(26) Add engine oil.

(27) Add coolant (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(28) Connect the battery cables.

(29) Start engine and inspect for leaks.

GEAR HOUSING COVER

REMOVAL

(1) Disconnect both battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove viscous fan/drive assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(9) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(10) Remove the cooling fan support/hub from the

front of the engine.

(11) Raise the vehicle on hoist.

(12) Remove power steering pump.

(13) Remove accessory drive belt tensioner.

(14) Remove the crankshaft damper and speed

indicator ring (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - REMOVAL).

(15) Lower the vehicle.

(16) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

INSTALLATION

(1) Install a new front crankshaft oil seal.

(2) Obtain a seal pilot/installation tool from a

crankshaft front seal service kit and install the pilot

into the seal.

(3) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover.

Be sure to surround all through holes.(4) Using the seal pilot to align the cover (Fig.

123), install the cover to the housing and install the

bolts. Tighten the bolts to 24 N´m (18 ft. lbs.) torque.

(5) Remove the seal pilot. Install front seal dust

shield.

(6) Raise the vehicle.

(7) Install the speed indicator ring and the crank-

shaft damper (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - INSTALLATION).

(8) Lower vehicle.

(9) Install the fan support/hub assy, and tighten

bolts to 32 N´m (24 ft. lbs.) torque.

(10) Install power steering pump.

(11) Install accessory drive belt tensioner. Torque

bolt to 43 N´m (32 ft. lbs.) torque.

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install the cooling fan and shroud together

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(14) Install the windshield washer reservoir to the

fan shroud and connect the washer pump supply

hose and electrical connection.

(15) Install the coolant recovery bottle to the fan

shroud and connect the hose to the radiator filler

neck.

(16) Install the radiator upper hose and clamps.

(17) Add coolant (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(18) Connect the battery cables.

(19) Start engine and inspect for leaks.

Fig. 123 Installing Cover with Seal Pilot

1 - SEAL PILOT

DRENGINE 5.9L DIESEL 9 - 301

GEAR HOUSING (Continued)

Page 1573 of 2627

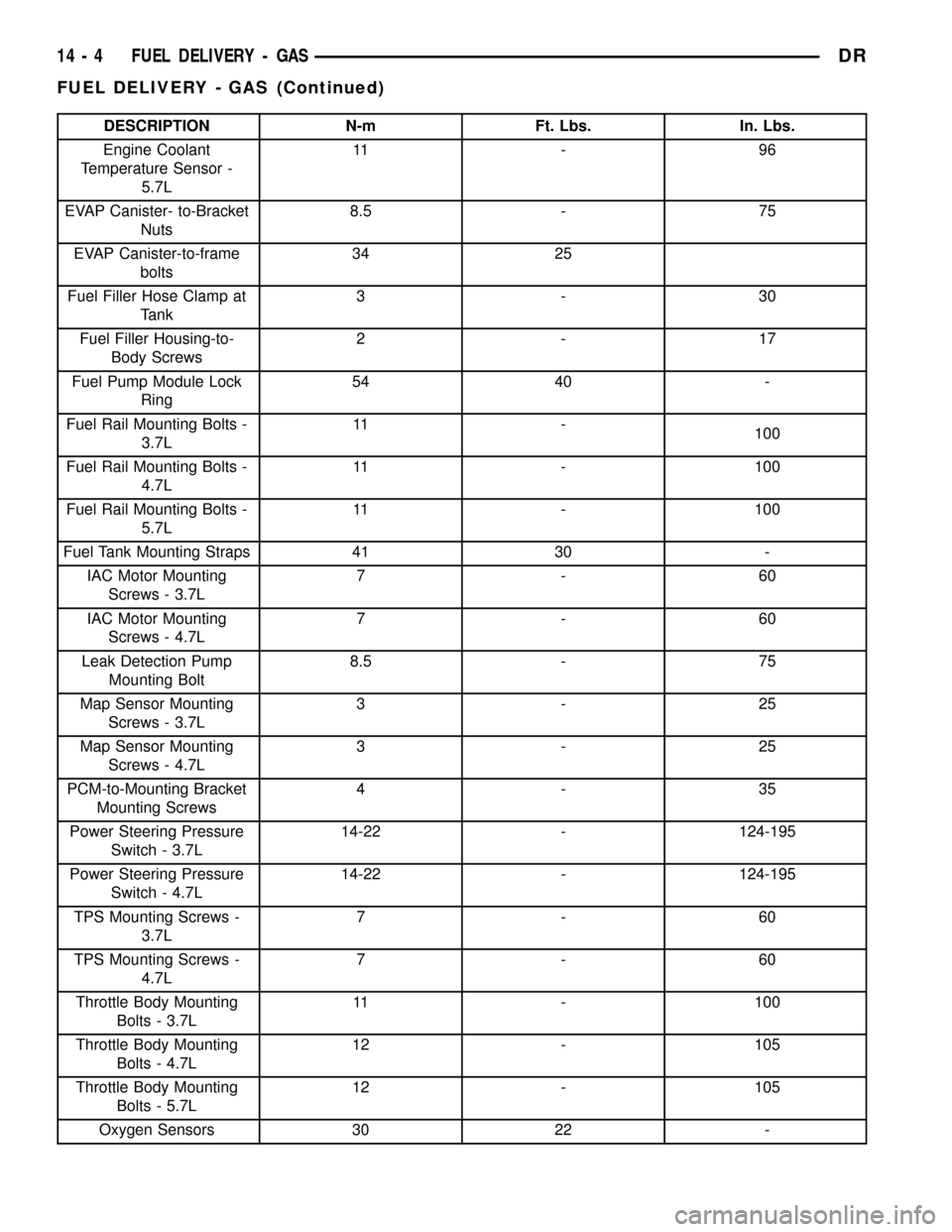

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Engine Coolant

Temperature Sensor -

5.7L11 - 9 6

EVAP Canister- to-Bracket

Nuts8.5 - 75

EVAP Canister-to-frame

bolts34 25

Fuel Filler Hose Clamp at

Tank3-30

Fuel Filler Housing-to-

Body Screws2-17

Fuel Pump Module Lock

Ring54 40 -

Fuel Rail Mounting Bolts -

3.7L11 -

100

Fuel Rail Mounting Bolts -

4.7L11 - 100

Fuel Rail Mounting Bolts -

5.7L11 - 100

Fuel Tank Mounting Straps 41 30 -

IAC Motor Mounting

Screws - 3.7L7-60

IAC Motor Mounting

Screws - 4.7L7-60

Leak Detection Pump

Mounting Bolt8.5 - 75

Map Sensor Mounting

Screws - 3.7L3-25

Map Sensor Mounting

Screws - 4.7L3-25

PCM-to-Mounting Bracket

Mounting Screws4-35

Power Steering Pressure

Switch - 3.7L14-22 - 124-195

Power Steering Pressure

Switch - 4.7L14-22 - 124-195

TPS Mounting Screws -

3.7L7-60

TPS Mounting Screws -

4.7L7-60

Throttle Body Mounting

Bolts - 3.7L11 - 100

Throttle Body Mounting

Bolts - 4.7L12 - 105

Throttle Body Mounting

Bolts - 5.7L12 - 105

Oxygen Sensors 30 22 -

14 - 4 FUEL DELIVERY - GASDR

FUEL DELIVERY - GAS (Continued)

Page 1597 of 2627

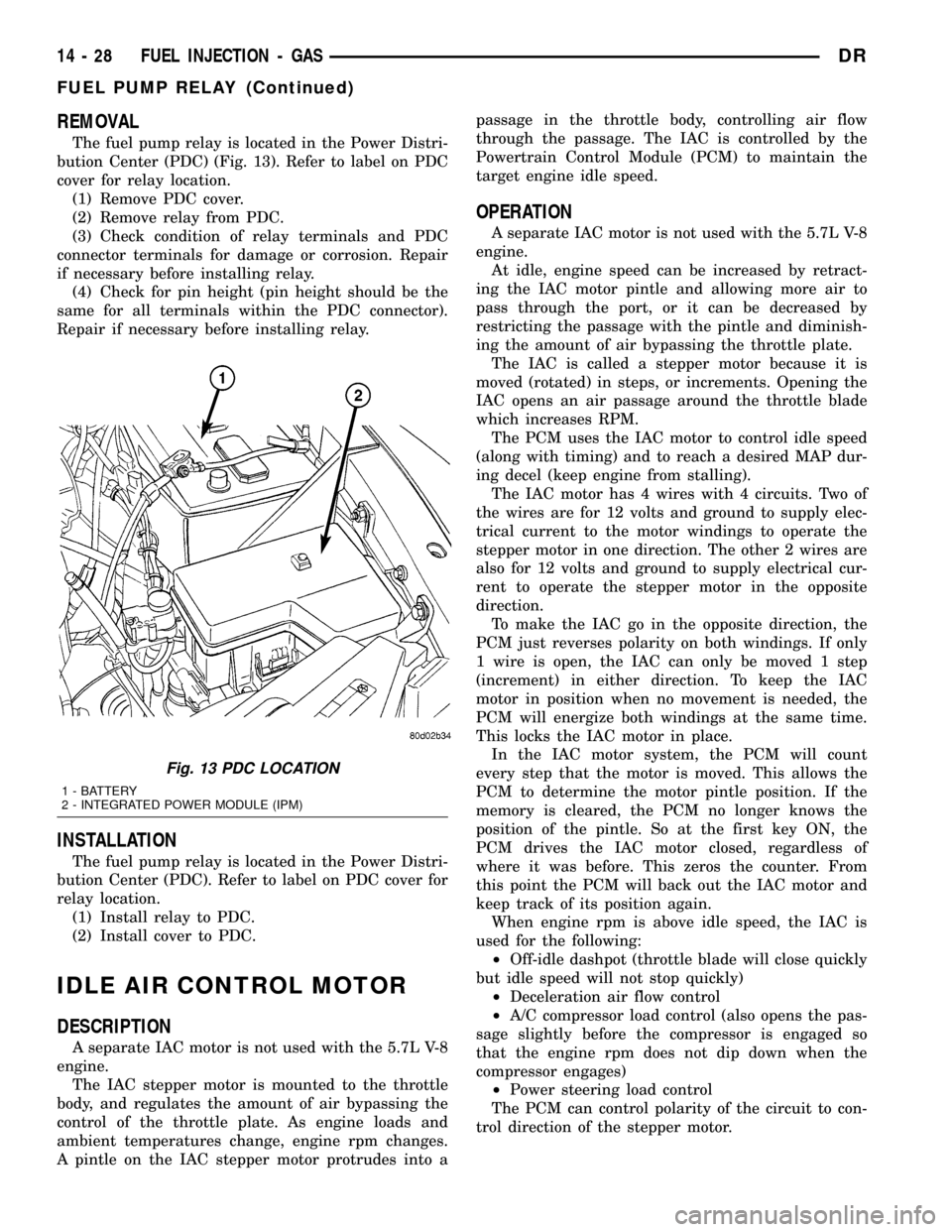

REMOVAL

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 13). Refer to label on PDC

cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel pump relay is located in the Power Distri-

bution Center (PDC). Refer to label on PDC cover for

relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

IDLE AIR CONTROL MOTOR

DESCRIPTION

A separate IAC motor is not used with the 5.7L V-8

engine.

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into apassage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

A separate IAC motor is not used with the 5.7L V-8

engine.

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply elec-

trical current to the motor windings to operate the

stepper motor in one direction. The other 2 wires are

also for 12 volts and ground to supply electrical cur-

rent to operate the stepper motor in the opposite

direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

Fig. 13 PDC LOCATION

1 - BATTERY

2 - INTEGRATED POWER MODULE (IPM)

14 - 28 FUEL INJECTION - GASDR

FUEL PUMP RELAY (Continued)

Page 1598 of 2627

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

REMOVAL

3.7L V-6

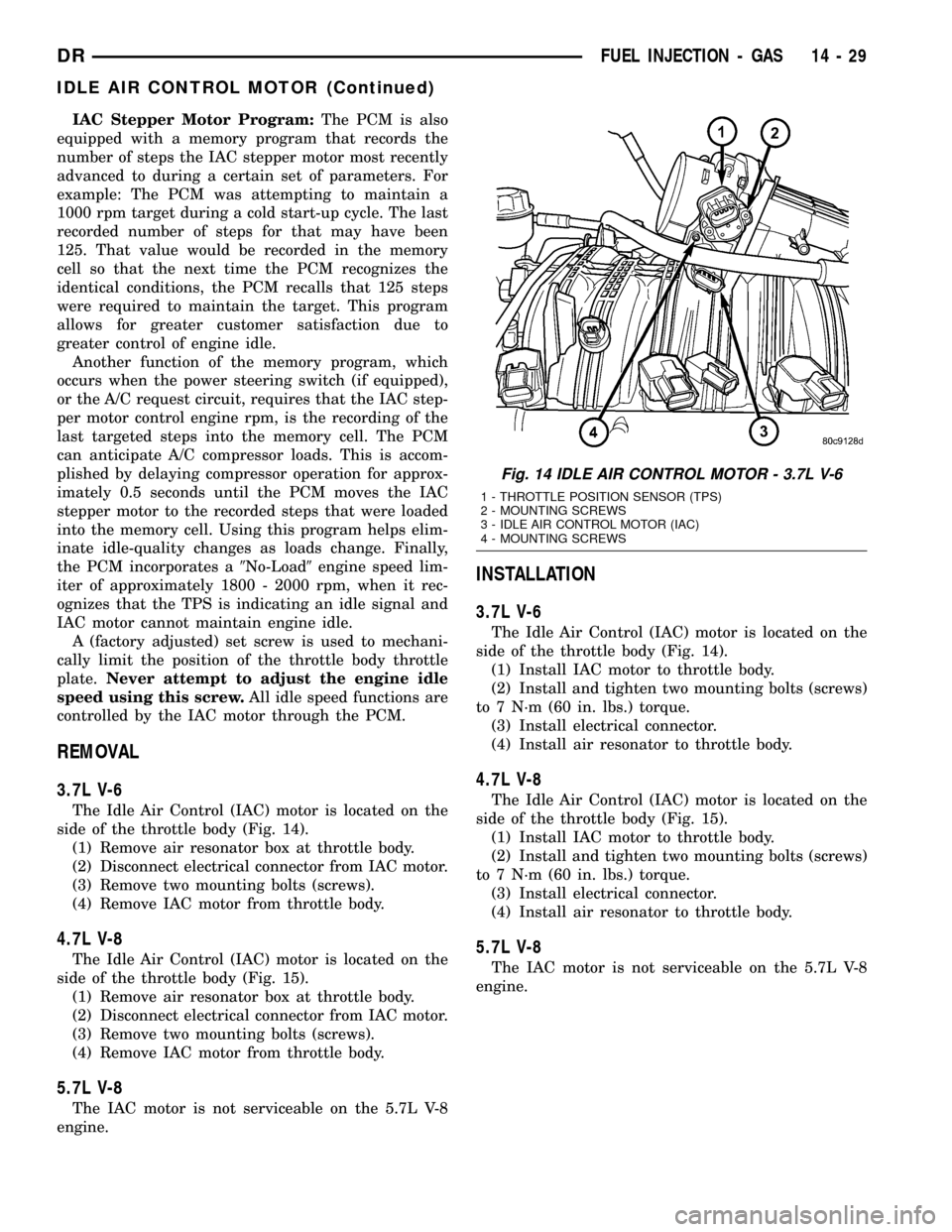

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 14).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 15).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

INSTALLATION

3.7L V-6

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 14).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 15).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

Fig. 14 IDLE AIR CONTROL MOTOR - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

DRFUEL INJECTION - GAS 14 - 29

IDLE AIR CONTROL MOTOR (Continued)

Page 1656 of 2627

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM....................2

DIAGNOSIS AND TESTING - POWER

STEERING FLOW AND PRESSURE........4

SPECIAL TOOLS

STEERING...........................5COLUMN...............................6

GEAR - INDEPENDENT FRONT SUSPENSION..17

GEAR - LINK/COIL.......................20

LINKAGE - INDEPENDENT FRONT

SUSPENSION...........................32

LINKAGE - LINK/COIL....................34

PUMP.................................39

STEERING

DESCRIPTION

CAUTION: MOPARTATF+4 is to be used in the

power steering system. No other power steering or

automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

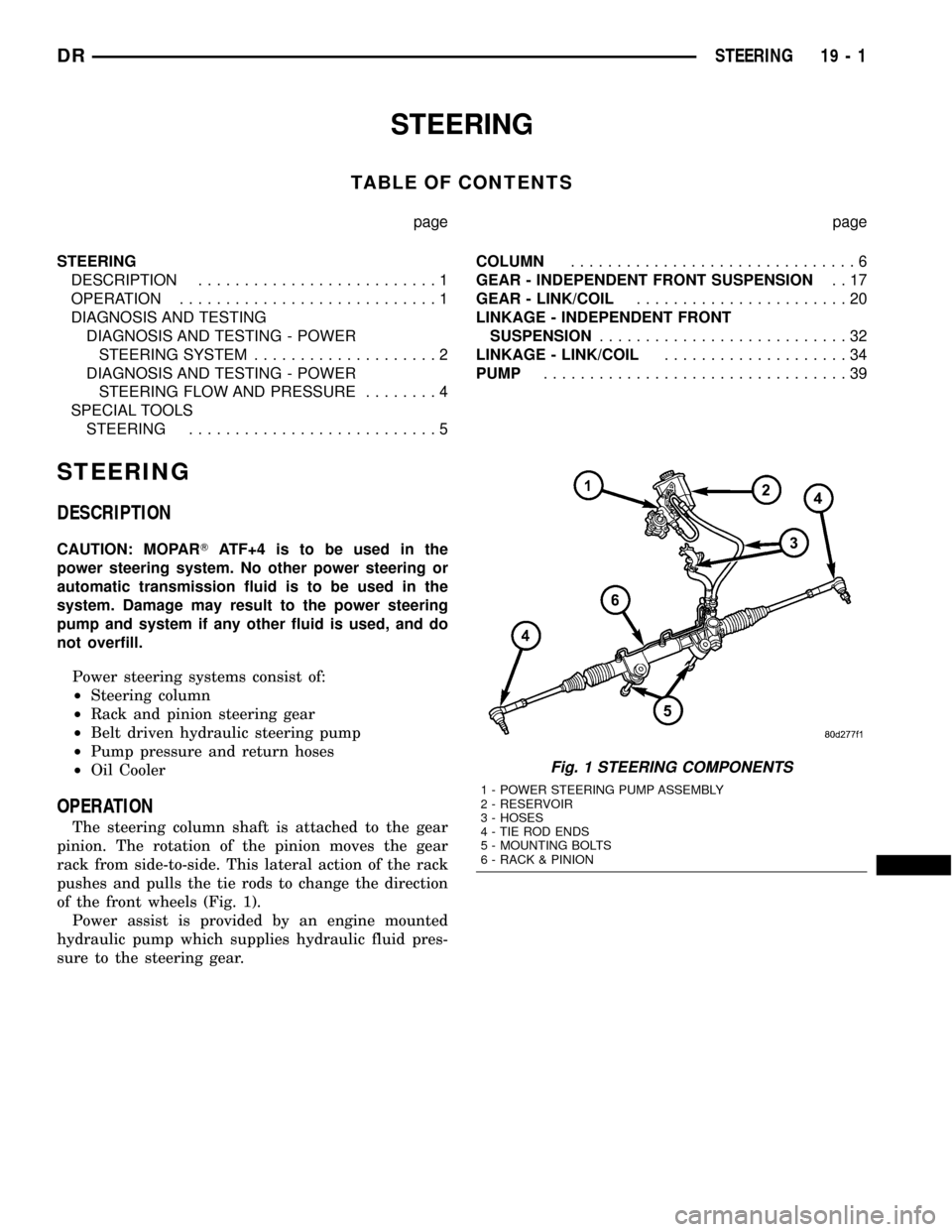

Power steering systems consist of:

²Steering column

²Rack and pinion steering gear

²Belt driven hydraulic steering pump

²Pump pressure and return hoses

²Oil Cooler

OPERATION

The steering column shaft is attached to the gear

pinion. The rotation of the pinion moves the gear

rack from side-to-side. This lateral action of the rack

pushes and pulls the tie rods to change the direction

of the front wheels (Fig. 1).

Power assist is provided by an engine mounted

hydraulic pump which supplies hydraulic fluid pres-

sure to the steering gear.

Fig. 1 STEERING COMPONENTS

1 - POWER STEERING PUMP ASSEMBLY

2 - RESERVOIR

3 - HOSES

4 - TIE ROD ENDS

5 - MOUNTING BOLTS

6 - RACK & PINION

DRSTEERING 19 - 1