steering DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1677 of 2627

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

(3) Hold the steering gear upside down over a

drain pan and rotate the input shaft back and forth

several times lock-to-lock to discharge the fluid from

the steering gear

(4) Rotate the input shaft to the left stop and then

back-off approximately 45 degrees. Using an inch-

pound torque wrench on the input shaft, record the

peak torque required to slowly and evenly rotate the

input shaft clockwise

1¤2turn (180 degrees) starting

from the 45 degree position. This peak torque read-

ing is the preload torque. The preload torque must be

within2-10in-lbs.

(5) Rotate the input shaft to its center of travel

(approximately 1.5 turns from either stop). Place the

torque wrench on the input shaft with the handle in

the vertical position. Rotate the torque wrench slowly

and evenly

1¤4turn (90 degrees) each side of center

and record the peak torque measure on or near cen-ter. This total on-center torque reading must be5-9

in-lbs higher than the previously measured preload

torque without exceeding a total of 17 in-lbs. The

value of the total on-center minus the preload torque

is defined as the meshload torque

(6) If required, adjust the on-center torque by loos-

ening the adjuster screw lock nut and turning the

adjuster screw until the total on-center and meshload

torque readings fall within the specified values. Turn

the adjuster screw clockwise to increase and counter-

clockwise to decrease the torque reading. While hold-

ing the adjuster screw in place, tighten the lock nut

to 31 N´m (23 ft. lbs.).

(7) Re-check the preload and on-center torque

readings.

(8) Install pitman arm on the steering gear (Refer

to 19 - STEERING/LINKAGE/PITMAN ARM -

INSTALLATION).

(9) Reinstall steering gear to the vehicle (Refer to

19 - STEERING/GEAR - INSTALLATION).

SPECIFICATIONS

POWER STEERING GEAR

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Steering Gear

TypeRecirculating Ball

Gear Code & Ratio 12.5:1

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Preload

Torque0.23-1.13 Ð 2-10

Meshload Torque 0.56-1.02 Ð 5-9

+ Preload (17 Max)

19 - 22 GEAR - LINK/COILDR

GEAR - LINK/COIL (Continued)

Page 1678 of 2627

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Gear Mounting

Frame Bolts196 145 Ð

Power Steering Line

Pressure32 23 Ð

Power Steering Line

Return71 52 Ð

Power Steering Line

Pressure Line To Pump37 27 Ð

Steering Gear

Adjustment Screw Locknut31 23 Ð

Steering Gear

Pitman Shaft Nut305 225 Ð

Steering Gear

Pitman Shaft Cover Bolts68 50 Ð

Steering Gear

Valve Housing to Gear

Bolts54 40 Ð

Steering Gear

Retainer Ring Screw2.26 Ð 20

Steering Gear

Retainer Ring97 72 Ð

SPECIAL TOOLS

POWER STEERING GEAR

HANDLE C-4171

INPUT SHAFT SEAL INSTALLER - 8987

PULLER, SLIDE HAMMER - C-3752

DRGEAR - LINK/COIL 19 - 23

GEAR - LINK/COIL (Continued)

Page 1680 of 2627

PITMAN SHAFT SEAL

REMOVAL

REMOVAL - GAS ENGINE

(1) Seperate the pitman arm from the gear box

(Refer to 19 - STEERING/LINKAGE/PITMAN ARM -

REMOVAL).

(2) Clean exposed end of pitman shaft and housing

with a wire brush.

(3) Rotate the steering wheel from stop to stop and

count the number of turns.

(4) Center the steering wheel by rotating it from

the stop back 1 1/2 turns to achieve center position.

(5) Remove the pitman shaft cover bolts.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(6) Remove the pitman shaft from the gear.

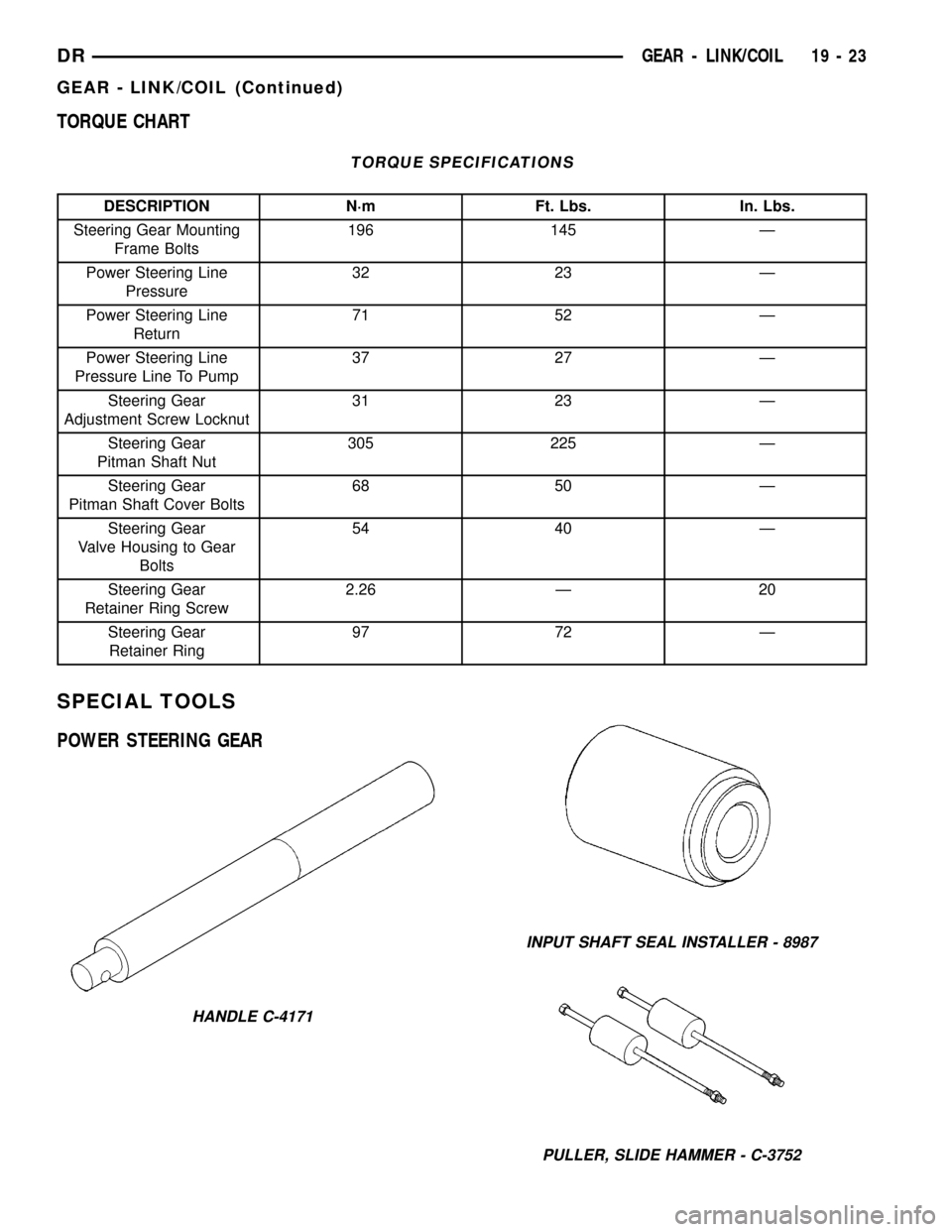

(7) Remove dust seal from the housing with a spe-

cial tool (Fig. 5).

CAUTION: Use care not to score the housing bore

when prying out seals and washer.

(8) Remove retaining ring with snap ring pliers.

(9) Remove washer from the housing.

NOTE: Tighten the slide hammer adapter 8990 into

the seal using wrenches, in order to make a tight fit

to pull the seal out. If this is not performed the seal

may tear on the removal making it difficult to

remove.(10) Remove oil seal from the housing with a spe-

cial tool 8990 with slide hammer C-3752.

REMOVAL - DIESEL

(1) Seperate the pitman arm from the gear box

(Refer to 19 - STEERING/LINKAGE/PITMAN ARM -

REMOVAL).

(2) Remove the steering gear box (Refer to 19 -

STEERING/GEAR - REMOVAL).

(3) Install the steering gear in a soft jawed bench

vise.

(4) Clean exposed end of pitman shaft and housing

with a wire brush.

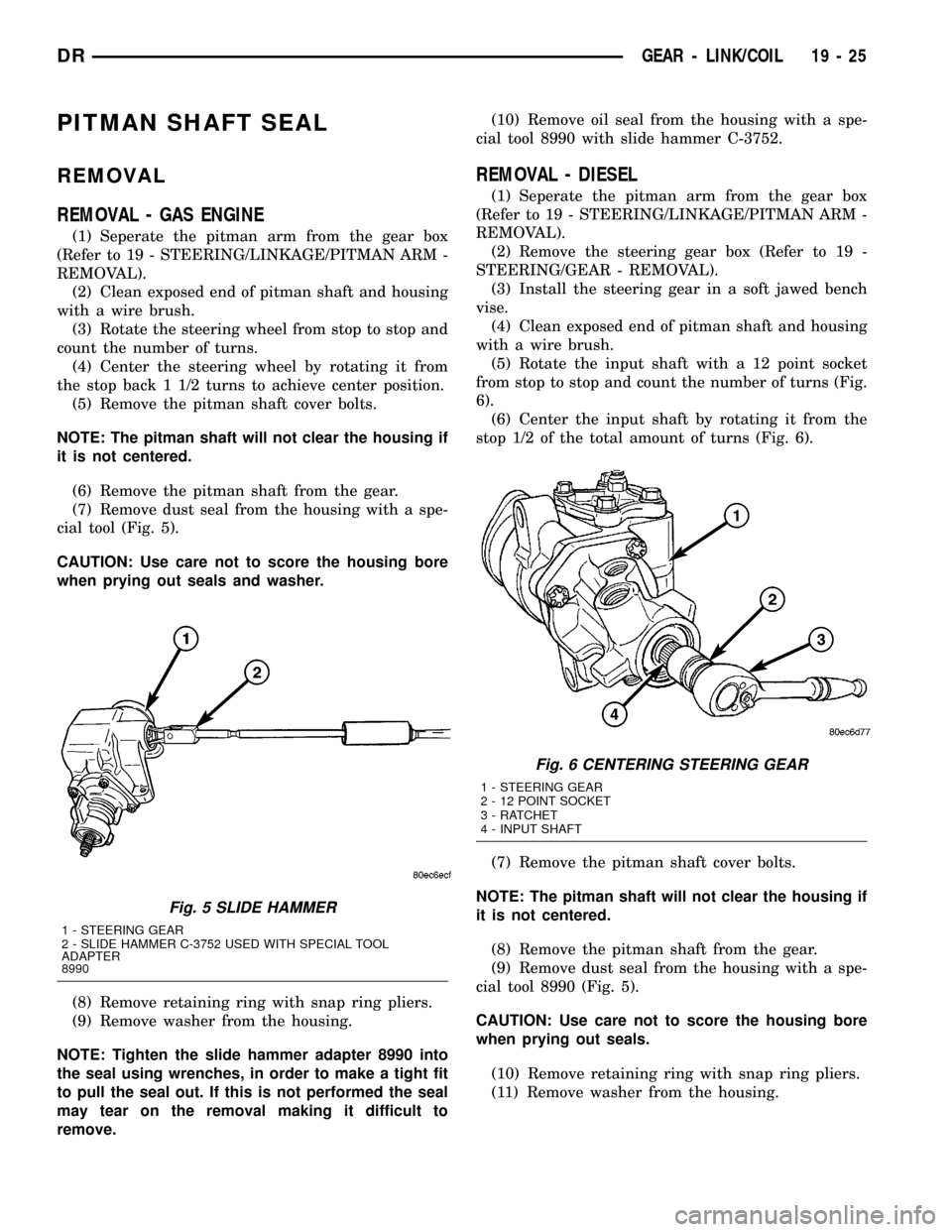

(5) Rotate the input shaft with a 12 point socket

from stop to stop and count the number of turns (Fig.

6).

(6) Center the input shaft by rotating it from the

stop 1/2 of the total amount of turns (Fig. 6).

(7) Remove the pitman shaft cover bolts.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(8) Remove the pitman shaft from the gear.

(9) Remove dust seal from the housing with a spe-

cial tool 8990 (Fig. 5).

CAUTION: Use care not to score the housing bore

when prying out seals.

(10) Remove retaining ring with snap ring pliers.

(11) Remove washer from the housing.

Fig. 5 SLIDE HAMMER

1 - STEERING GEAR

2 - SLIDE HAMMER C-3752 USED WITH SPECIAL TOOL

ADAPTER

8990

Fig. 6 CENTERING STEERING GEAR

1 - STEERING GEAR

2 - 12 POINT SOCKET

3 - RATCHET

4 - INPUT SHAFT

DRGEAR - LINK/COIL 19 - 25

Page 1681 of 2627

NOTE: Tighten the slide hammer adapter 8990 into

the seal using wrenches, in order to make a tight fit

to pull the seal out. If this is not performed the seal

may tear on the removal making it difficult to

remove.

(12) Remove oil seal from the housing with a spe-

cial tool 8990 with slide hammer C-3752. (Fig. 5).

INSTALLATION

INSTALLATION - GAS ENGINE

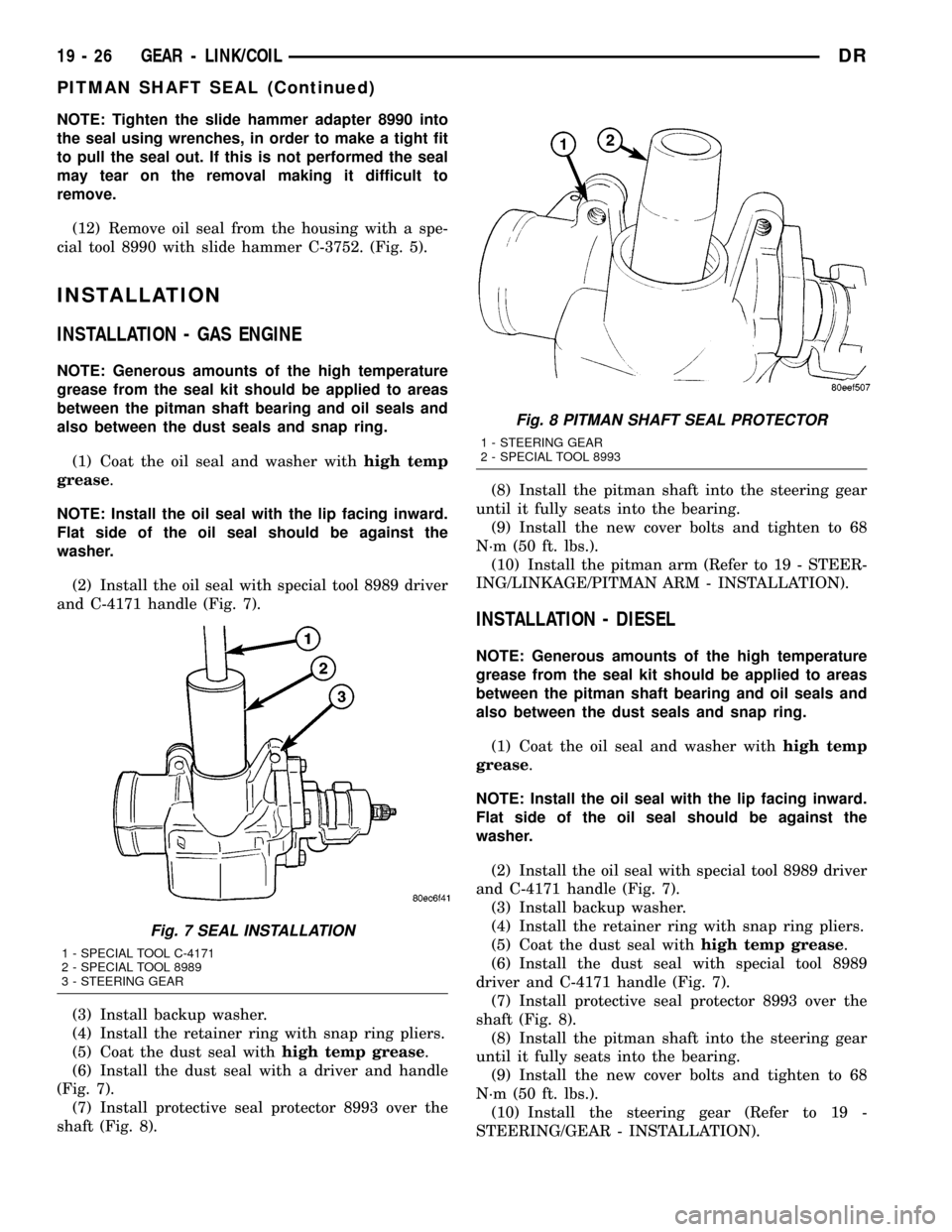

NOTE: Generous amounts of the high temperature

grease from the seal kit should be applied to areas

between the pitman shaft bearing and oil seals and

also between the dust seals and snap ring.

(1) Coat the oil seal and washer withhigh temp

grease.

NOTE: Install the oil seal with the lip facing inward.

Flat side of the oil seal should be against the

washer.

(2) Install the oil seal with special tool 8989 driver

and C-4171 handle (Fig. 7).

(3) Install backup washer.

(4) Install the retainer ring with snap ring pliers.

(5) Coat the dust seal withhigh temp grease.

(6) Install the dust seal with a driver and handle

(Fig. 7).

(7) Install protective seal protector 8993 over the

shaft (Fig. 8).(8) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(9) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(10) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

INSTALLATION - DIESEL

NOTE: Generous amounts of the high temperature

grease from the seal kit should be applied to areas

between the pitman shaft bearing and oil seals and

also between the dust seals and snap ring.

(1) Coat the oil seal and washer withhigh temp

grease.

NOTE: Install the oil seal with the lip facing inward.

Flat side of the oil seal should be against the

washer.

(2) Install the oil seal with special tool 8989 driver

and C-4171 handle (Fig. 7).

(3) Install backup washer.

(4) Install the retainer ring with snap ring pliers.

(5) Coat the dust seal withhigh temp grease.

(6) Install the dust seal with special tool 8989

driver and C-4171 handle (Fig. 7).

(7) Install protective seal protector 8993 over the

shaft (Fig. 8).

(8) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(9) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(10) Install the steering gear (Refer to 19 -

STEERING/GEAR - INSTALLATION).

Fig. 7 SEAL INSTALLATION

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL 8989

3 - STEERING GEAR

Fig. 8 PITMAN SHAFT SEAL PROTECTOR

1 - STEERING GEAR

2 - SPECIAL TOOL 8993

19 - 26 GEAR - LINK/COILDR

PITMAN SHAFT SEAL (Continued)

Page 1682 of 2627

(11) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(12) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

STEERING GEAR INPUT

SHAFT SEAL

REMOVAL

(1) Remove the steering gear from the vehicle

(Refer to 19 - STEERING/GEAR - REMOVAL).

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

(2) Mount the steering gear upside down over a

drain pan in a soft jawed vise.

(3) Place a drain pan under the gear and rotate

the input shaft back and forth several times lock-to-

lock to discharge the fluid from the steering gear

(4) Drain all the remaining fluid from the gear.

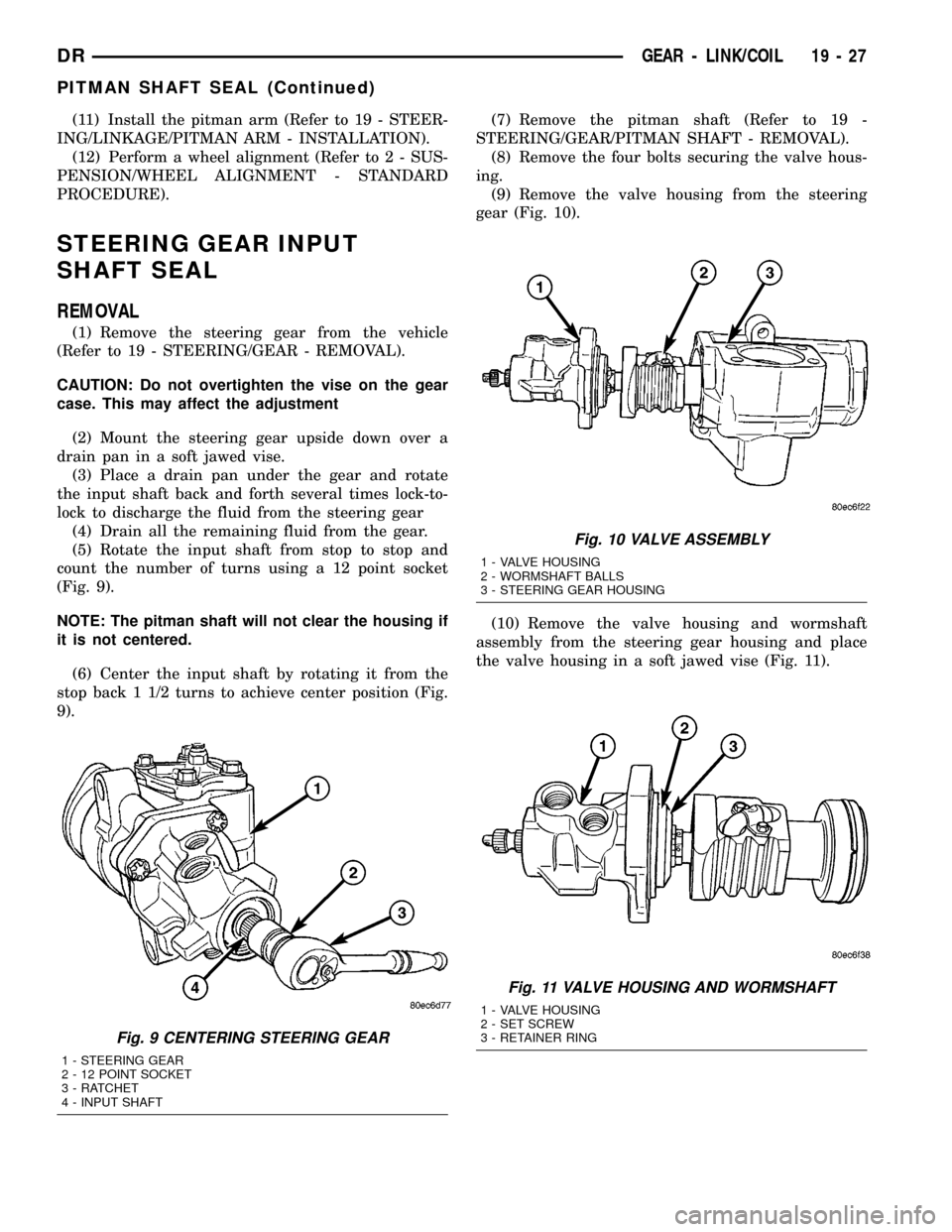

(5) Rotate the input shaft from stop to stop and

count the number of turns using a 12 point socket

(Fig. 9).

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(6) Center the input shaft by rotating it from the

stop back 1 1/2 turns to achieve center position (Fig.

9).(7) Remove the pitman shaft (Refer to 19 -

STEERING/GEAR/PITMAN SHAFT - REMOVAL).

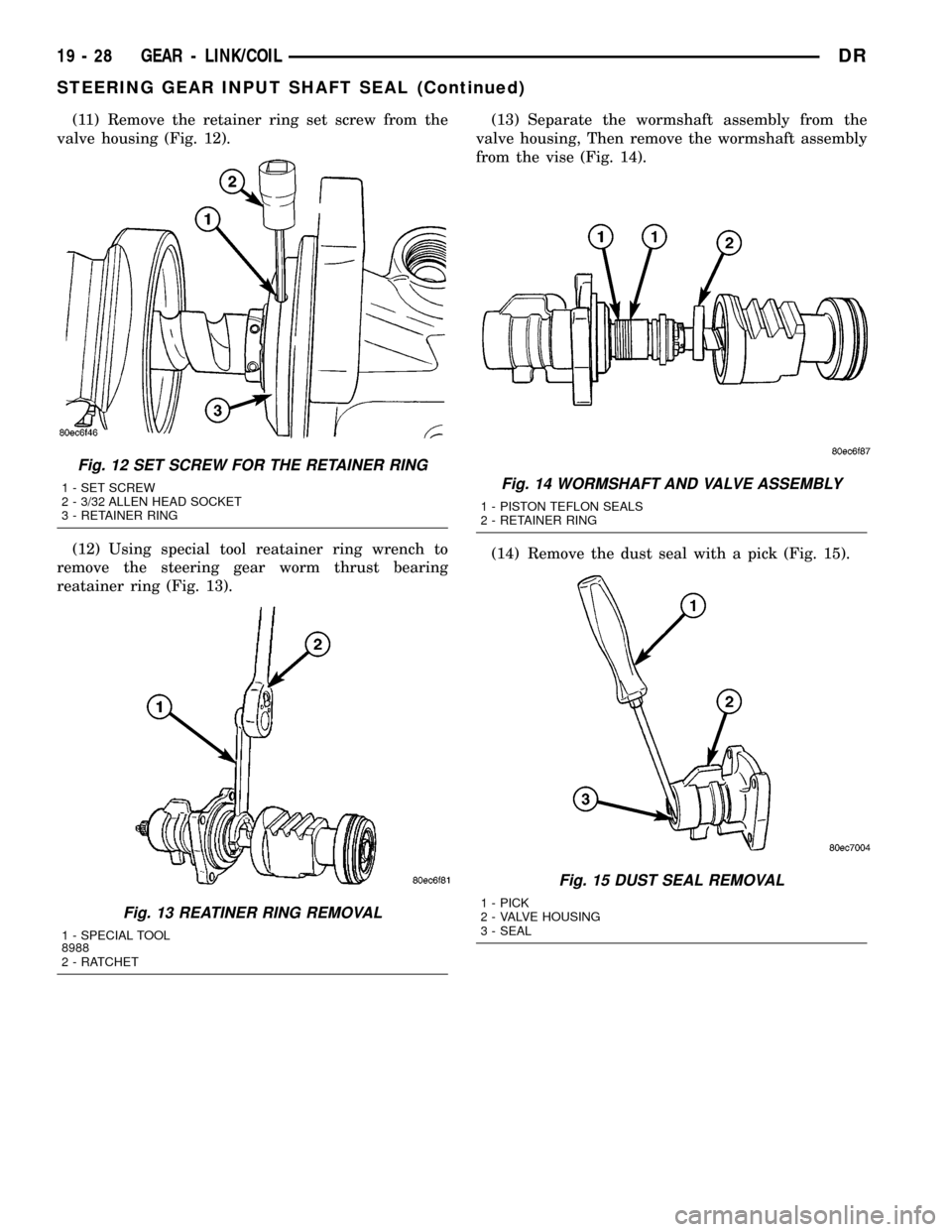

(8) Remove the four bolts securing the valve hous-

ing.

(9) Remove the valve housing from the steering

gear (Fig. 10).

(10) Remove the valve housing and wormshaft

assembly from the steering gear housing and place

the valve housing in a soft jawed vise (Fig. 11).

Fig. 9 CENTERING STEERING GEAR

1 - STEERING GEAR

2 - 12 POINT SOCKET

3 - RATCHET

4 - INPUT SHAFT

Fig. 10 VALVE ASSEMBLY

1 - VALVE HOUSING

2 - WORMSHAFT BALLS

3 - STEERING GEAR HOUSING

Fig. 11 VALVE HOUSING AND WORMSHAFT

1 - VALVE HOUSING

2 - SET SCREW

3 - RETAINER RING

DRGEAR - LINK/COIL 19 - 27

PITMAN SHAFT SEAL (Continued)

Page 1683 of 2627

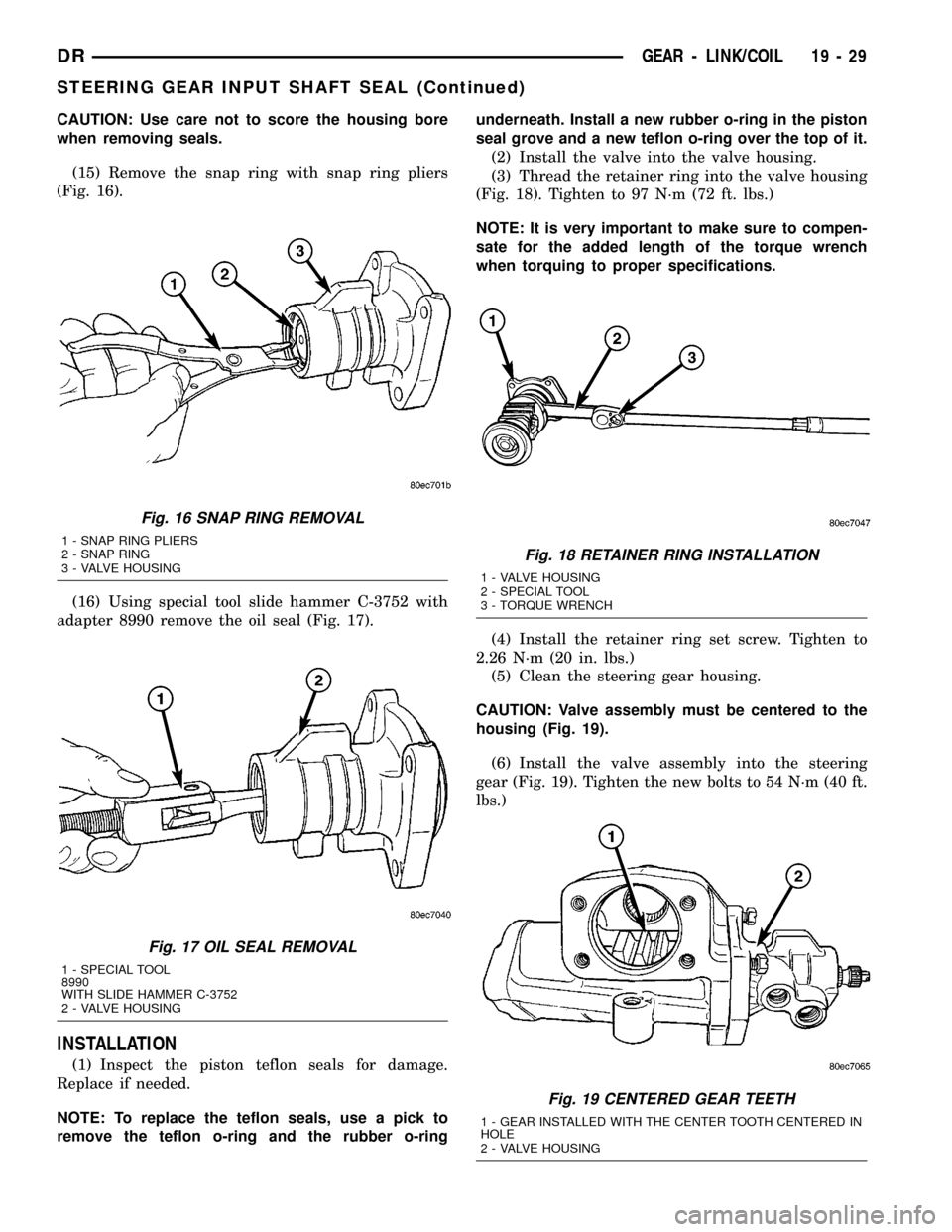

(11) Remove the retainer ring set screw from the

valve housing (Fig. 12).

(12) Using special tool reatainer ring wrench to

remove the steering gear worm thrust bearing

reatainer ring (Fig. 13).(13) Separate the wormshaft assembly from the

valve housing, Then remove the wormshaft assembly

from the vise (Fig. 14).

(14) Remove the dust seal with a pick (Fig. 15).

Fig. 12 SET SCREW FOR THE RETAINER RING

1 - SET SCREW

2 - 3/32 ALLEN HEAD SOCKET

3 - RETAINER RING

Fig. 13 REATINER RING REMOVAL

1 - SPECIAL TOOL

8988

2 - RATCHET

Fig. 14 WORMSHAFT AND VALVE ASSEMBLY

1 - PISTON TEFLON SEALS

2 - RETAINER RING

Fig. 15 DUST SEAL REMOVAL

1 - PICK

2 - VALVE HOUSING

3 - SEAL

19 - 28 GEAR - LINK/COILDR

STEERING GEAR INPUT SHAFT SEAL (Continued)

Page 1684 of 2627

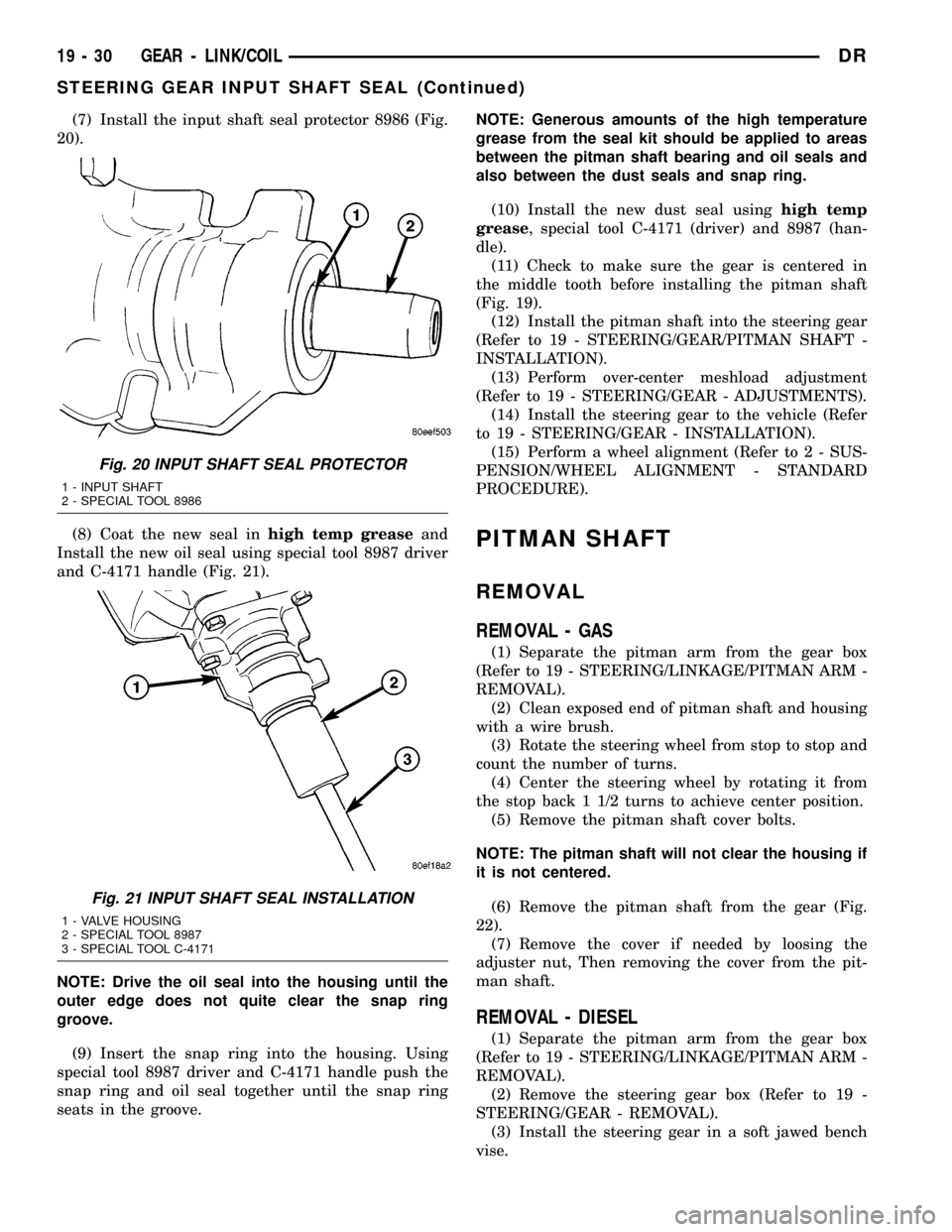

CAUTION: Use care not to score the housing bore

when removing seals.

(15) Remove the snap ring with snap ring pliers

(Fig. 16).

(16) Using special tool slide hammer C-3752 with

adapter 8990 remove the oil seal (Fig. 17).

INSTALLATION

(1) Inspect the piston teflon seals for damage.

Replace if needed.

NOTE: To replace the teflon seals, use a pick to

remove the teflon o-ring and the rubber o-ringunderneath. Install a new rubber o-ring in the piston

seal grove and a new teflon o-ring over the top of it.

(2) Install the valve into the valve housing.

(3) Thread the retainer ring into the valve housing

(Fig. 18). Tighten to 97 N´m (72 ft. lbs.)

NOTE: It is very important to make sure to compen-

sate for the added length of the torque wrench

when torquing to proper specifications.

(4) Install the retainer ring set screw. Tighten to

2.26 N´m (20 in. lbs.)

(5) Clean the steering gear housing.

CAUTION: Valve assembly must be centered to the

housing (Fig. 19).

(6) Install the valve assembly into the steering

gear (Fig. 19). Tighten the new bolts to 54 N´m (40 ft.

lbs.)

Fig. 16 SNAP RING REMOVAL

1 - SNAP RING PLIERS

2 - SNAP RING

3 - VALVE HOUSING

Fig. 17 OIL SEAL REMOVAL

1 - SPECIAL TOOL

8990

WITH SLIDE HAMMER C-3752

2 - VALVE HOUSING

Fig. 18 RETAINER RING INSTALLATION

1 - VALVE HOUSING

2 - SPECIAL TOOL

3 - TORQUE WRENCH

Fig. 19 CENTERED GEAR TEETH

1 - GEAR INSTALLED WITH THE CENTER TOOTH CENTERED IN

HOLE

2 - VALVE HOUSING

DRGEAR - LINK/COIL 19 - 29

STEERING GEAR INPUT SHAFT SEAL (Continued)

Page 1685 of 2627

(7) Install the input shaft seal protector 8986 (Fig.

20).

(8) Coat the new seal inhigh temp greaseand

Install the new oil seal using special tool 8987 driver

and C-4171 handle (Fig. 21).

NOTE: Drive the oil seal into the housing until the

outer edge does not quite clear the snap ring

groove.

(9) Insert the snap ring into the housing. Using

special tool 8987 driver and C-4171 handle push the

snap ring and oil seal together until the snap ring

seats in the groove.NOTE: Generous amounts of the high temperature

grease from the seal kit should be applied to areas

between the pitman shaft bearing and oil seals and

also between the dust seals and snap ring.

(10) Install the new dust seal usinghigh temp

grease, special tool C-4171 (driver) and 8987 (han-

dle).

(11) Check to make sure the gear is centered in

the middle tooth before installing the pitman shaft

(Fig. 19).

(12) Install the pitman shaft into the steering gear

(Refer to 19 - STEERING/GEAR/PITMAN SHAFT -

INSTALLATION).

(13) Perform over-center meshload adjustment

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

(14) Install the steering gear to the vehicle (Refer

to 19 - STEERING/GEAR - INSTALLATION).

(15) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

PITMAN SHAFT

REMOVAL

REMOVAL - GAS

(1) Separate the pitman arm from the gear box

(Refer to 19 - STEERING/LINKAGE/PITMAN ARM -

REMOVAL).

(2) Clean exposed end of pitman shaft and housing

with a wire brush.

(3) Rotate the steering wheel from stop to stop and

count the number of turns.

(4) Center the steering wheel by rotating it from

the stop back 1 1/2 turns to achieve center position.

(5) Remove the pitman shaft cover bolts.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(6) Remove the pitman shaft from the gear (Fig.

22).

(7) Remove the cover if needed by loosing the

adjuster nut, Then removing the cover from the pit-

man shaft.

REMOVAL - DIESEL

(1) Separate the pitman arm from the gear box

(Refer to 19 - STEERING/LINKAGE/PITMAN ARM -

REMOVAL).

(2) Remove the steering gear box (Refer to 19 -

STEERING/GEAR - REMOVAL).

(3) Install the steering gear in a soft jawed bench

vise.

Fig. 20 INPUT SHAFT SEAL PROTECTOR

1 - INPUT SHAFT

2 - SPECIAL TOOL 8986

Fig. 21 INPUT SHAFT SEAL INSTALLATION

1 - VALVE HOUSING

2 - SPECIAL TOOL 8987

3 - SPECIAL TOOL C-4171

19 - 30 GEAR - LINK/COILDR

STEERING GEAR INPUT SHAFT SEAL (Continued)

Page 1686 of 2627

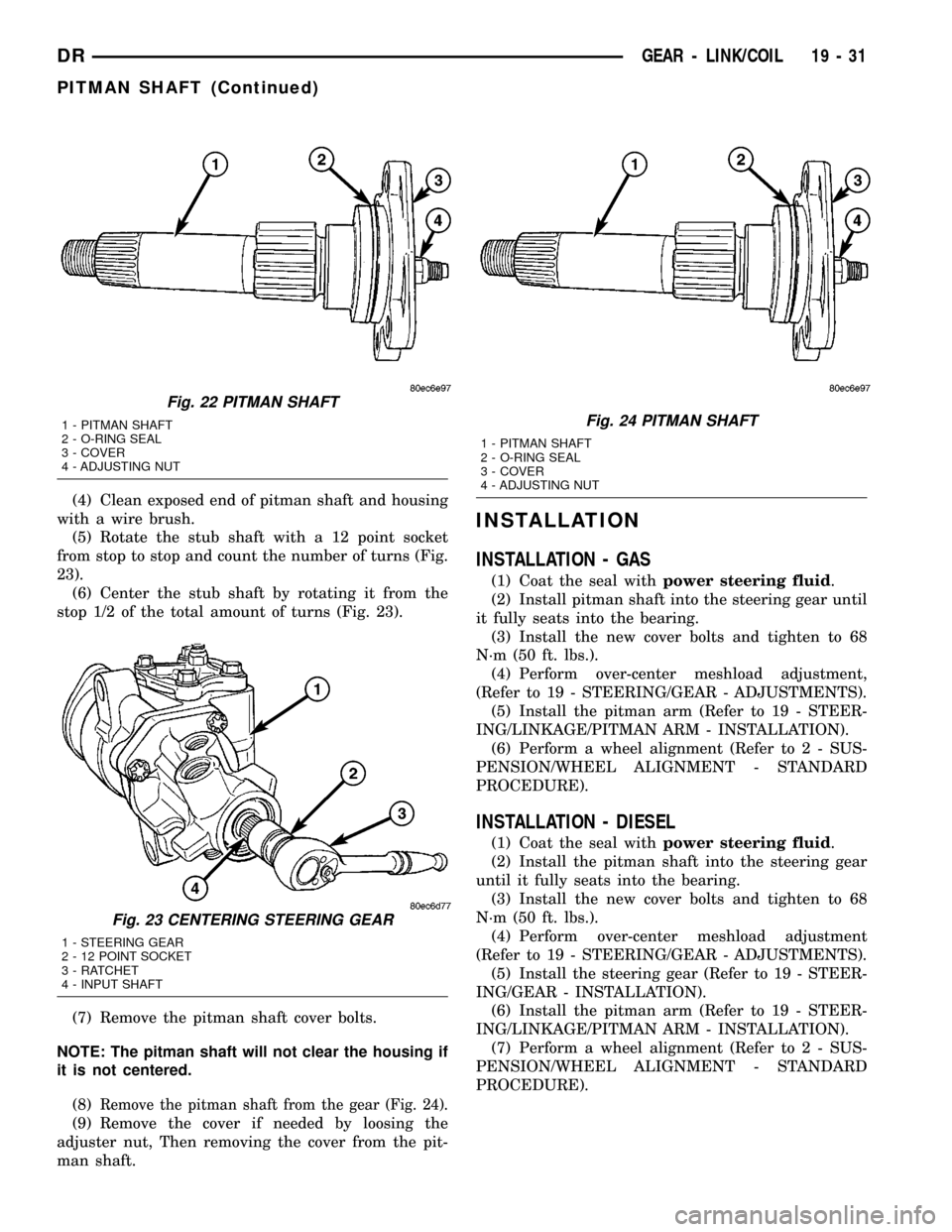

(4) Clean exposed end of pitman shaft and housing

with a wire brush.

(5) Rotate the stub shaft with a 12 point socket

from stop to stop and count the number of turns (Fig.

23).

(6) Center the stub shaft by rotating it from the

stop 1/2 of the total amount of turns (Fig. 23).

(7) Remove the pitman shaft cover bolts.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(8)

Remove the pitman shaft from the gear (Fig. 24).

(9) Remove the cover if needed by loosing the

adjuster nut, Then removing the cover from the pit-

man shaft.

INSTALLATION

INSTALLATION - GAS

(1) Coat the seal withpower steering fluid.

(2) Install pitman shaft into the steering gear until

it fully seats into the bearing.

(3) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(4) Perform over-center meshload adjustment,

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

(5) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(6) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

INSTALLATION - DIESEL

(1) Coat the seal withpower steering fluid.

(2) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(3) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(4) Perform over-center meshload adjustment

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

(5) Install the steering gear (Refer to 19 - STEER-

ING/GEAR - INSTALLATION).

(6) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(7) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 22 PITMAN SHAFT

1 - PITMAN SHAFT

2 - O-RING SEAL

3 - COVER

4 - ADJUSTING NUT

Fig. 23 CENTERING STEERING GEAR

1 - STEERING GEAR

2 - 12 POINT SOCKET

3 - RATCHET

4 - INPUT SHAFT

Fig. 24 PITMAN SHAFT

1 - PITMAN SHAFT

2 - O-RING SEAL

3 - COVER

4 - ADJUSTING NUT

DRGEAR - LINK/COIL 19 - 31

PITMAN SHAFT (Continued)

Page 1687 of 2627

LINKAGE - INDEPENDENT FRONT SUSPENSION

TABLE OF CONTENTS

page page

LINKAGE - INDEPENDENT FRONT

SUSPENSION

DIAGNOSIS AND TESTING - OUTER TIE ROD

END ................................32TIE ROD END

REMOVAL - OUTER TIE ROD END..........32

INSTALLATION - OUTER TIE ROD END......33

LINKAGE - INDEPENDENT

FRONT SUSPENSION

DIAGNOSIS AND TESTING - OUTER TIE ROD

END

NOTE: If the outer tie rod end is equipped with a

lubrication fitting, grease the joint then road test

the vehicle before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.

(3) Mount a dial indicator solidly to the vehicle

steering knuckle and then zero the dial indicator.

(4) Position indicator plunger on the topside of the

outer tie rod end.

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the outer tie rod

end.

(5) Position a pry bar in order to pry downwards

on the outer tie rod end.

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the outer tie rod end (Refer to 19 - STEERING/

LINKAGE/TIE ROD END - REMOVAL).

(7) If the outer tie rod end is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

TIE ROD END

REMOVAL - OUTER TIE ROD END

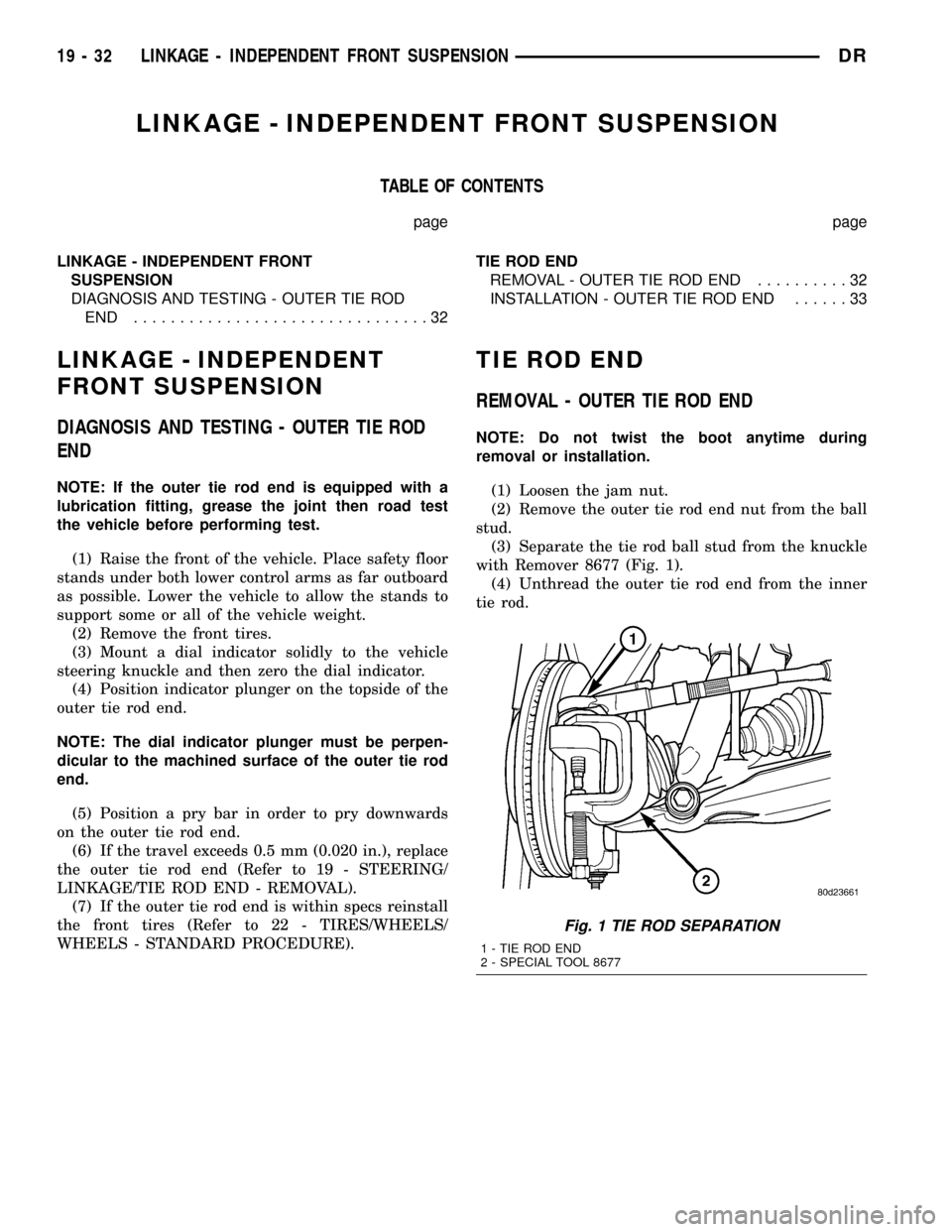

NOTE: Do not twist the boot anytime during

removal or installation.

(1) Loosen the jam nut.

(2) Remove the outer tie rod end nut from the ball

stud.

(3) Separate the tie rod ball stud from the knuckle

with Remover 8677 (Fig. 1).

(4) Unthread the outer tie rod end from the inner

tie rod.

Fig. 1 TIE ROD SEPARATION

1 - TIE ROD END

2 - SPECIAL TOOL 8677

19 - 32 LINKAGE - INDEPENDENT FRONT SUSPENSIONDR