air condition DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2164 of 2627

DRIVE CHAIN

Examine the drive chain and shaft bearings.

replace the chain if stretched, distorted, or if any of

the links bind. Replace the bearings if rough, or

noisy.

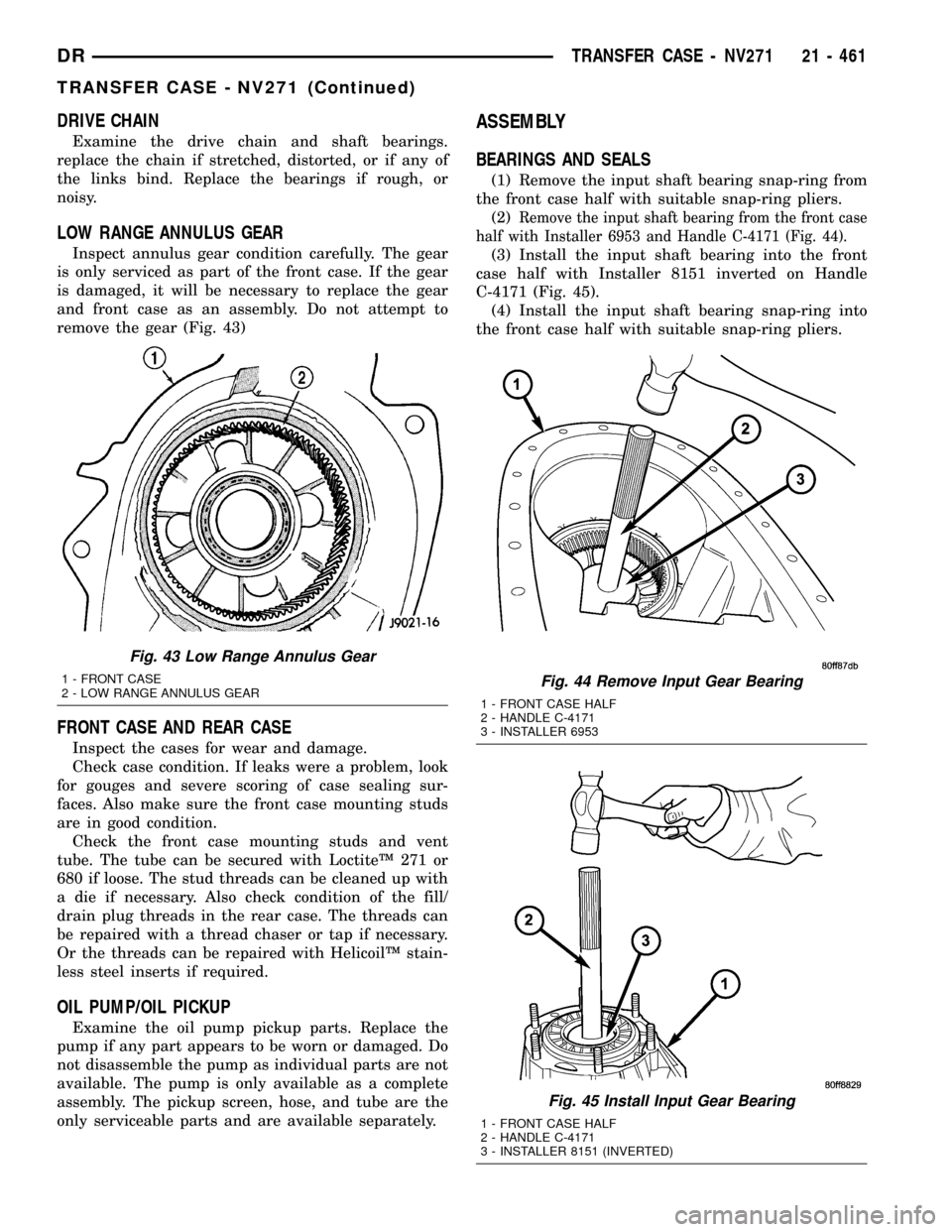

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 43)

FRONT CASE AND REAR CASE

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with HelicoilŸ stain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

(1) Remove the input shaft bearing snap-ring from

the front case half with suitable snap-ring pliers.

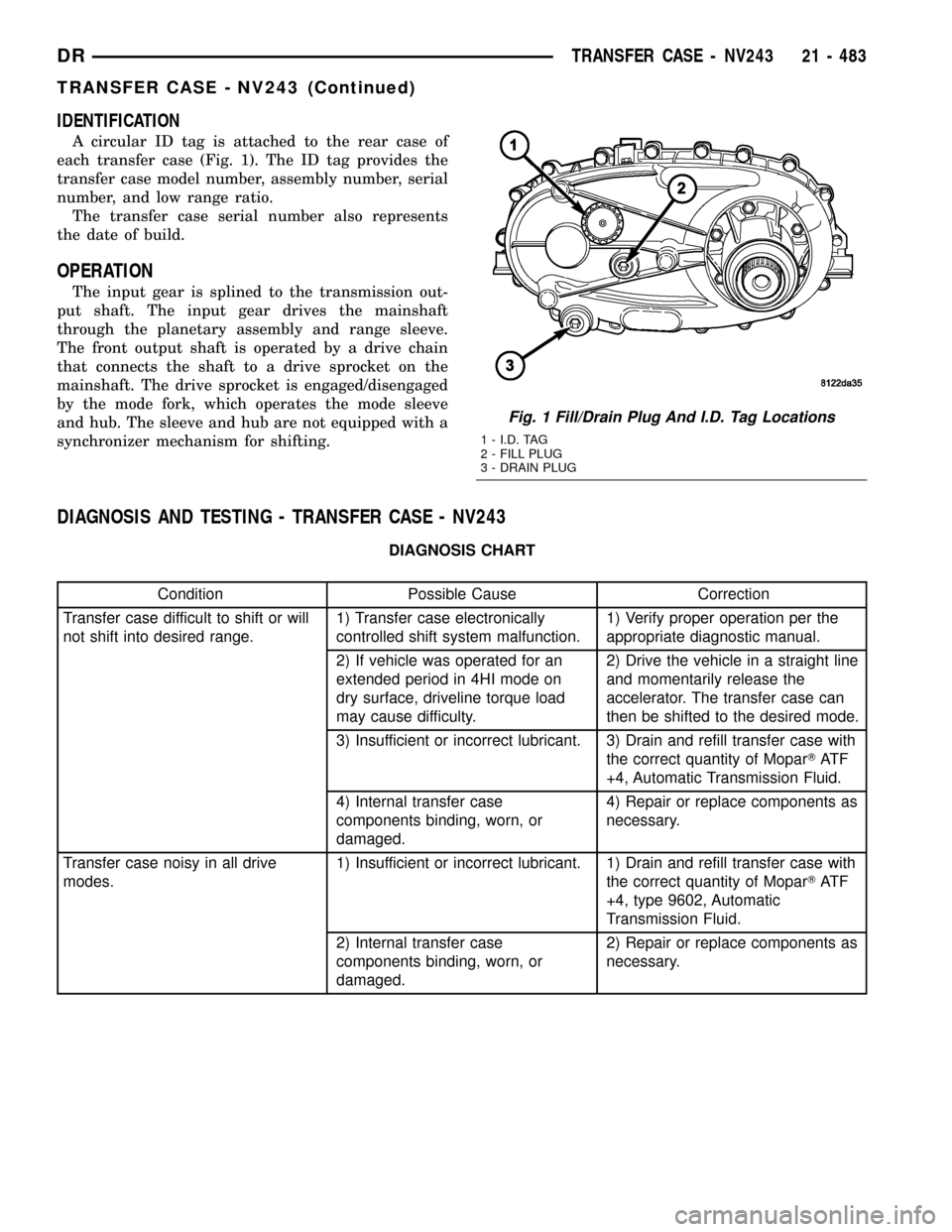

(2)

Remove the input shaft bearing from the front case

half with Installer 6953 and Handle C-4171 (Fig. 44).

(3) Install the input shaft bearing into the front

case half with Installer 8151 inverted on Handle

C-4171 (Fig. 45).

(4) Install the input shaft bearing snap-ring into

the front case half with suitable snap-ring pliers.

Fig. 43 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEARFig. 44 Remove Input Gear Bearing

1 - FRONT CASE HALF

2 - HANDLE C-4171

3 - INSTALLER 6953

Fig. 45 Install Input Gear Bearing

1 - FRONT CASE HALF

2 - HANDLE C-4171

3 - INSTALLER 8151 (INVERTED)

DRTRANSFER CASE - NV271 21 - 461

TRANSFER CASE - NV271 (Continued)

Page 2186 of 2627

IDENTIFICATION

A circular ID tag is attached to the rear case of

each transfer case (Fig. 1). The ID tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

The input gear is splined to the transmission out-

put shaft. The input gear drives the mainshaft

through the planetary assembly and range sleeve.

The front output shaft is operated by a drive chain

that connects the shaft to a drive sprocket on the

mainshaft. The drive sprocket is engaged/disengaged

by the mode fork, which operates the mode sleeve

and hub. The sleeve and hub are not equipped with a

synchronizer mechanism for shifting.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV243

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer case difficult to shift or will

not shift into desired range.1) Transfer case electronically

controlled shift system malfunction.1) Verify proper operation per the

appropriate diagnostic manual.

2) If vehicle was operated for an

extended period in 4HI mode on

dry surface, driveline torque load

may cause difficulty.2) Drive the vehicle in a straight line

and momentarily release the

accelerator. The transfer case can

then be shifted to the desired mode.

3) Insufficient or incorrect lubricant. 3) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, Automatic Transmission Fluid.

4) Internal transfer case

components binding, worn, or

damaged.4) Repair or replace components as

necessary.

Transfer case noisy in all drive

modes.1) Insufficient or incorrect lubricant. 1) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, type 9602, Automatic

Transmission Fluid.

2) Internal transfer case

components binding, worn, or

damaged.2) Repair or replace components as

necessary.

Fig. 1 Fill/Drain Plug And I.D. Tag Locations

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

DRTRANSFER CASE - NV243 21 - 483

TRANSFER CASE - NV243 (Continued)

Page 2187 of 2627

Condition Possible Cause Correction

Transfer case noisy while in, or

jumps out of, 4LO mode.1) Transfer case not completely

engaged in 4LO position.1) While rolling 2-3 MPH and the

transmission in NEUTRAL, or clutch

depressed on vehicles equipped

with a manual transmission, shift

transfer case to the 2WD or 4HI

position, and then back into the 4LO

position.

2) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.2) Repair or replace components as

necessary.

3) Low range gear worn or

damaged.3) Repair or replace components as

necessary.

Lubricant leaking from transfer case

seals or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Transfer case vent closed or

restricted.2) Clean or replace vent as

necessary.

3) Transfer case seals damaged or

installed incorrectly.3) Replace suspect seal.

Abnormal tire wear. 1) Extended operation in 4HI mode

on dry surfaces,1) Operate vehicle in 2WD mode on

dry surfaces.

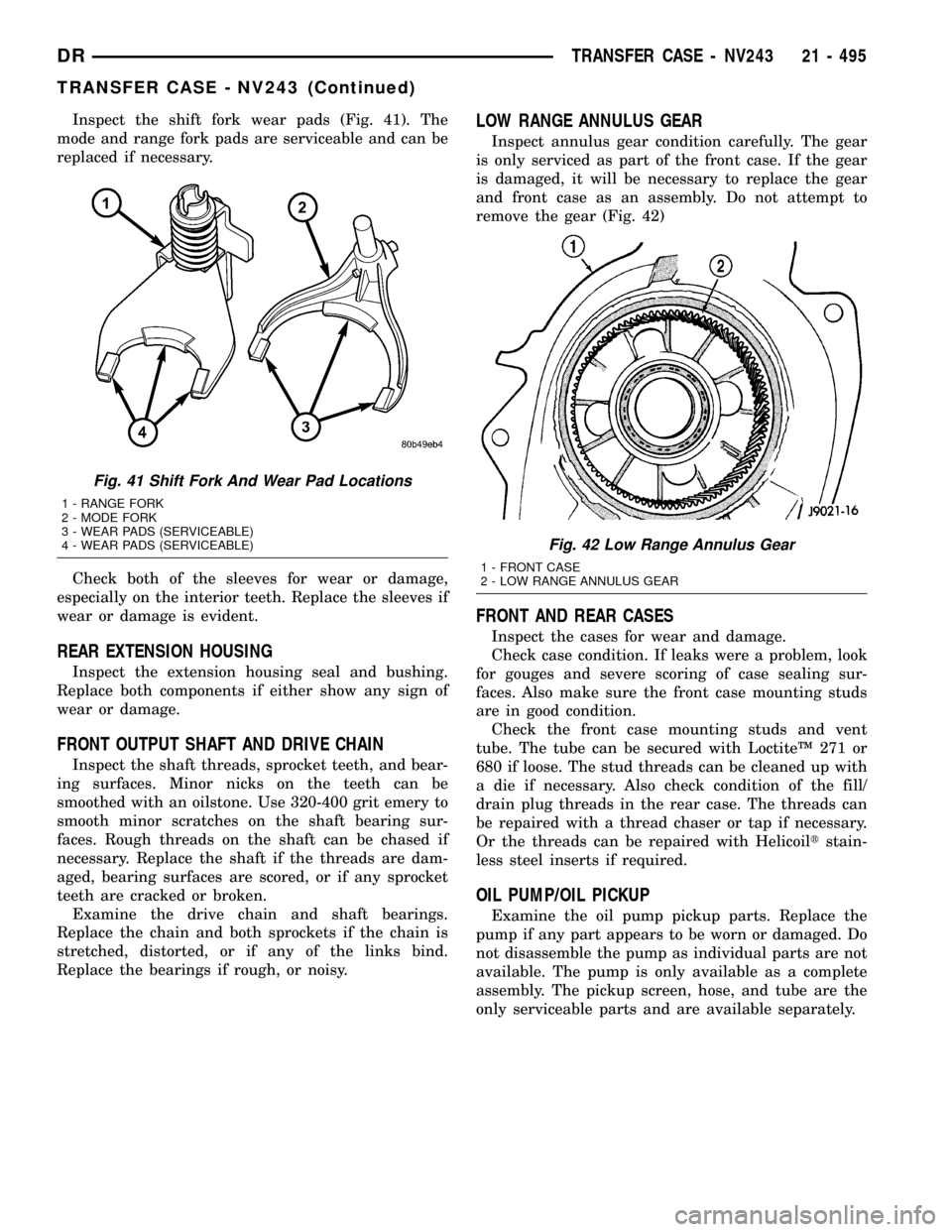

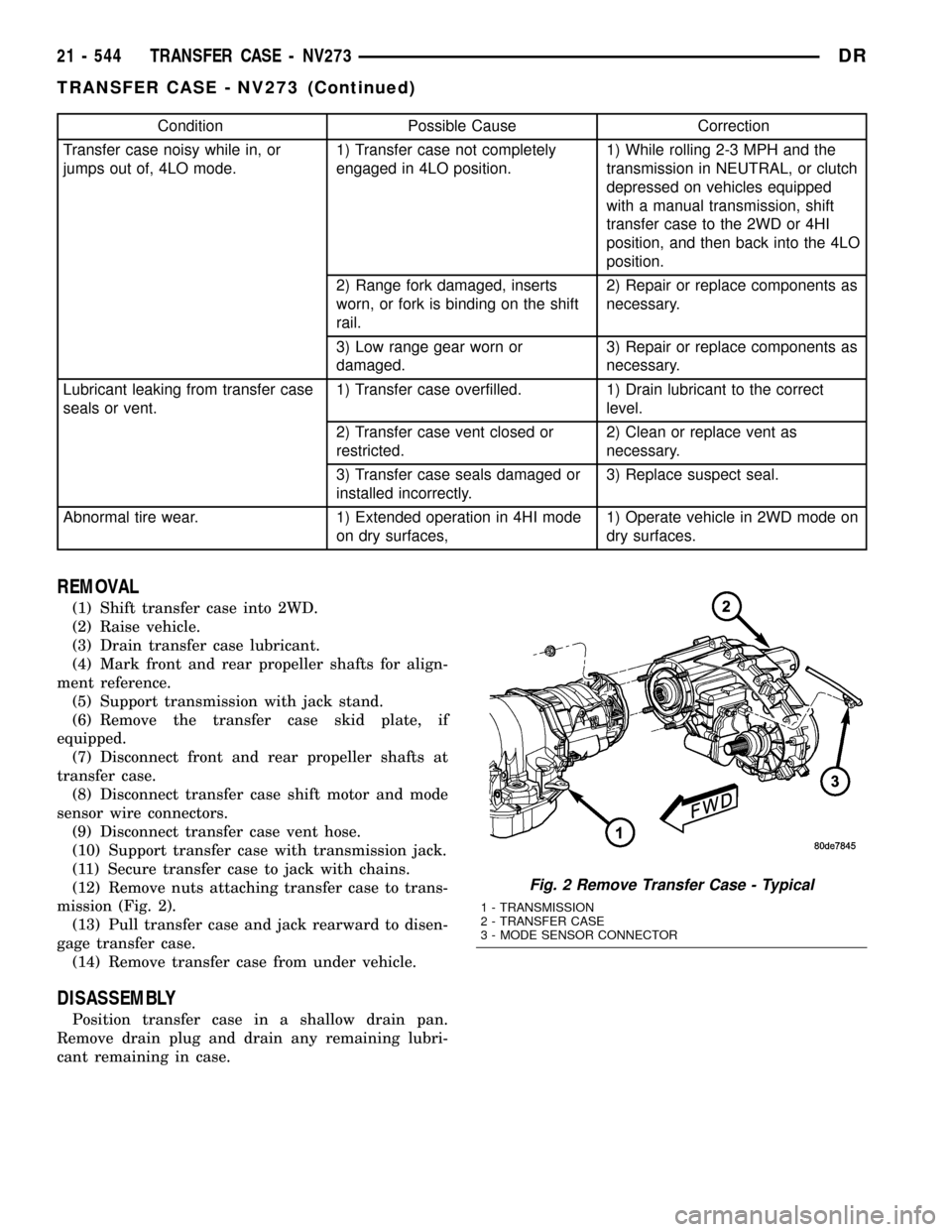

REMOVAL

(1) Shift transfer case into 2WD.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shafts for align-

ment reference.

(5) Support transmission with jack stand.

(6) Remove the transfer case skid plate, if

equipped.

(7) Disconnect front and rear propeller shafts at

transfer case.

(8) Disconnect transfer case shift motor and mode

sensor wire connectors.

(9) Disconnect transfer case vent hose.

(10) Support transfer case with transmission jack.

(11) Secure transfer case to jack with chains.

(12) Remove nuts attaching transfer case to trans-

mission (Fig. 2).

(13) Pull transfer case and jack rearward to disen-

gage transfer case.

(14) Remove transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

Fig. 2 Remove Transfer Case - Typical

1 - TRANSMISSION

2 - TRANSFER CASE

3 - MODE SENSOR CONNECTOR

21 - 484 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2198 of 2627

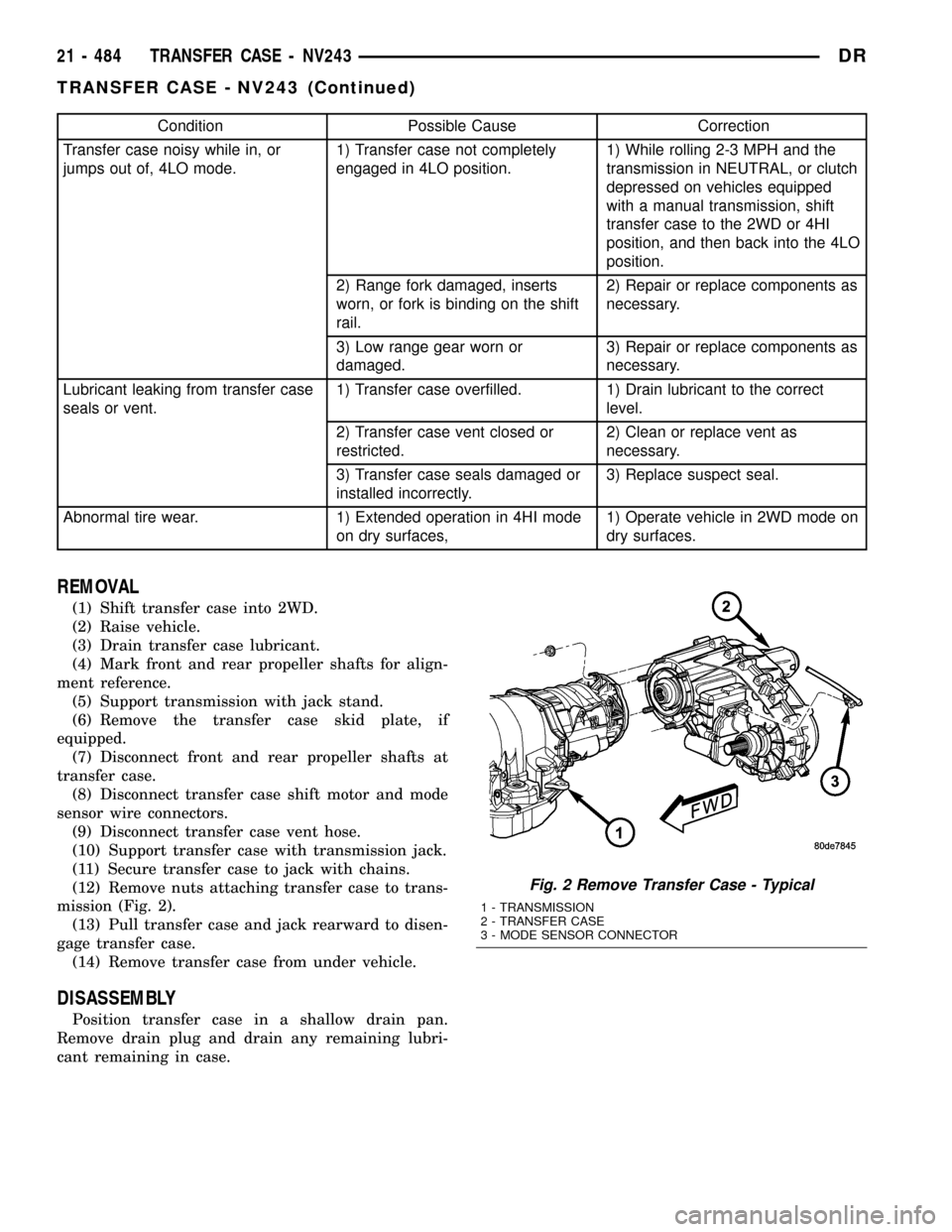

Inspect the shift fork wear pads (Fig. 41). The

mode and range fork pads are serviceable and can be

replaced if necessary.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

REAR EXTENSION HOUSING

Inspect the extension housing seal and bushing.

Replace both components if either show any sign of

wear or damage.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

Inspect the shaft threads, sprocket teeth, and bear-

ing surfaces. Minor nicks on the teeth can be

smoothed with an oilstone. Use 320-400 grit emery to

smooth minor scratches on the shaft bearing sur-

faces. Rough threads on the shaft can be chased if

necessary. Replace the shaft if the threads are dam-

aged, bearing surfaces are scored, or if any sprocket

teeth are cracked or broken.

Examine the drive chain and shaft bearings.

Replace the chain and both sprockets if the chain is

stretched, distorted, or if any of the links bind.

Replace the bearings if rough, or noisy.

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 42)

FRONT AND REAR CASES

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with Helicoiltstain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

Fig. 41 Shift Fork And Wear Pad Locations

1 - RANGE FORK

2 - MODE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

Fig. 42 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

DRTRANSFER CASE - NV243 21 - 495

TRANSFER CASE - NV243 (Continued)

Page 2216 of 2627

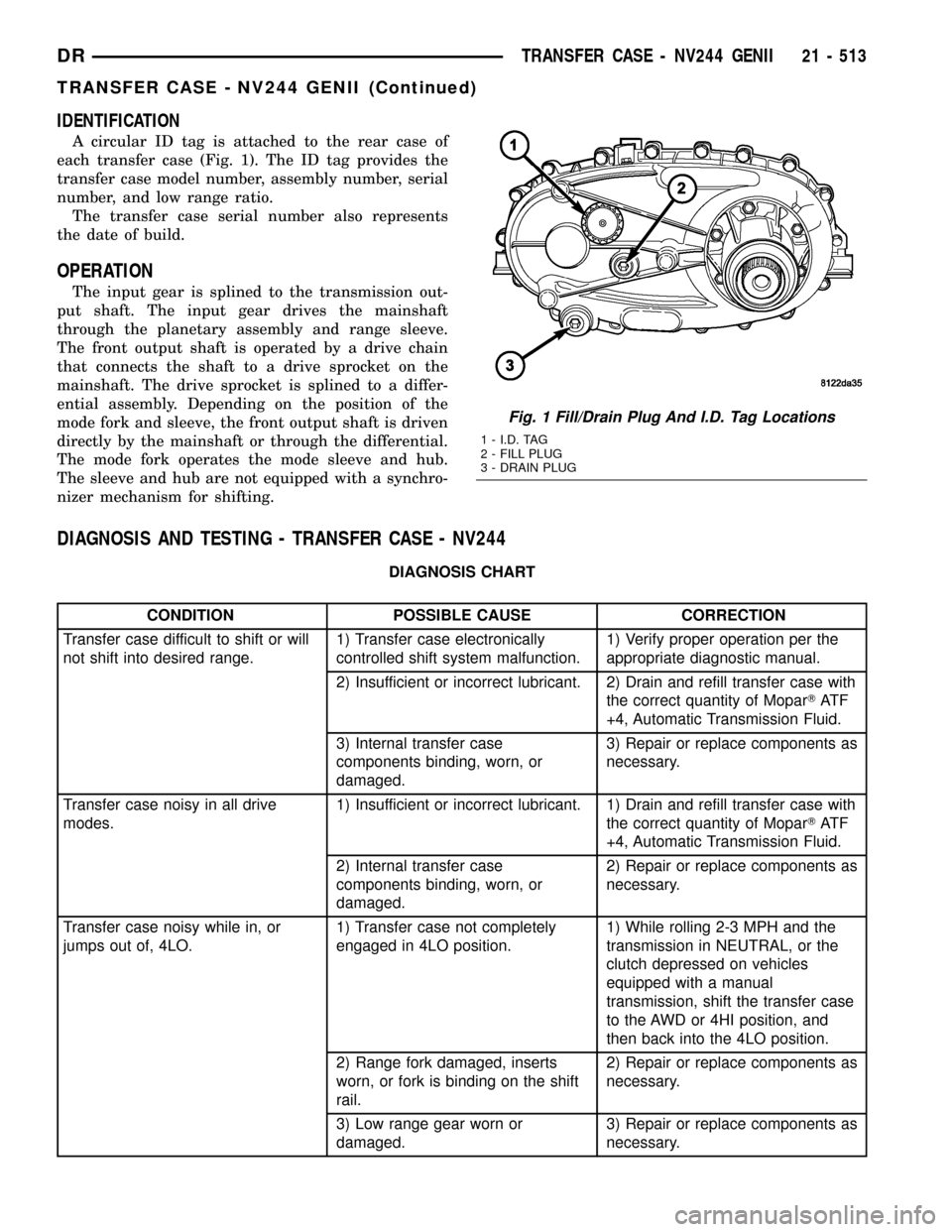

IDENTIFICATION

A circular ID tag is attached to the rear case of

each transfer case (Fig. 1). The ID tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

The input gear is splined to the transmission out-

put shaft. The input gear drives the mainshaft

through the planetary assembly and range sleeve.

The front output shaft is operated by a drive chain

that connects the shaft to a drive sprocket on the

mainshaft. The drive sprocket is splined to a differ-

ential assembly. Depending on the position of the

mode fork and sleeve, the front output shaft is driven

directly by the mainshaft or through the differential.

The mode fork operates the mode sleeve and hub.

The sleeve and hub are not equipped with a synchro-

nizer mechanism for shifting.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV244

DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

Transfer case difficult to shift or will

not shift into desired range.1) Transfer case electronically

controlled shift system malfunction.1) Verify proper operation per the

appropriate diagnostic manual.

2) Insufficient or incorrect lubricant. 2) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, Automatic Transmission Fluid.

3) Internal transfer case

components binding, worn, or

damaged.3) Repair or replace components as

necessary.

Transfer case noisy in all drive

modes.1) Insufficient or incorrect lubricant. 1) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, Automatic Transmission Fluid.

2) Internal transfer case

components binding, worn, or

damaged.2) Repair or replace components as

necessary.

Transfer case noisy while in, or

jumps out of, 4LO.1) Transfer case not completely

engaged in 4LO position.1) While rolling 2-3 MPH and the

transmission in NEUTRAL, or the

clutch depressed on vehicles

equipped with a manual

transmission, shift the transfer case

to the AWD or 4HI position, and

then back into the 4LO position.

2) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.2) Repair or replace components as

necessary.

3) Low range gear worn or

damaged.3) Repair or replace components as

necessary.

Fig. 1 Fill/Drain Plug And I.D. Tag Locations

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

DRTRANSFER CASE - NV244 GENII 21 - 513

TRANSFER CASE - NV244 GENII (Continued)

Page 2226 of 2627

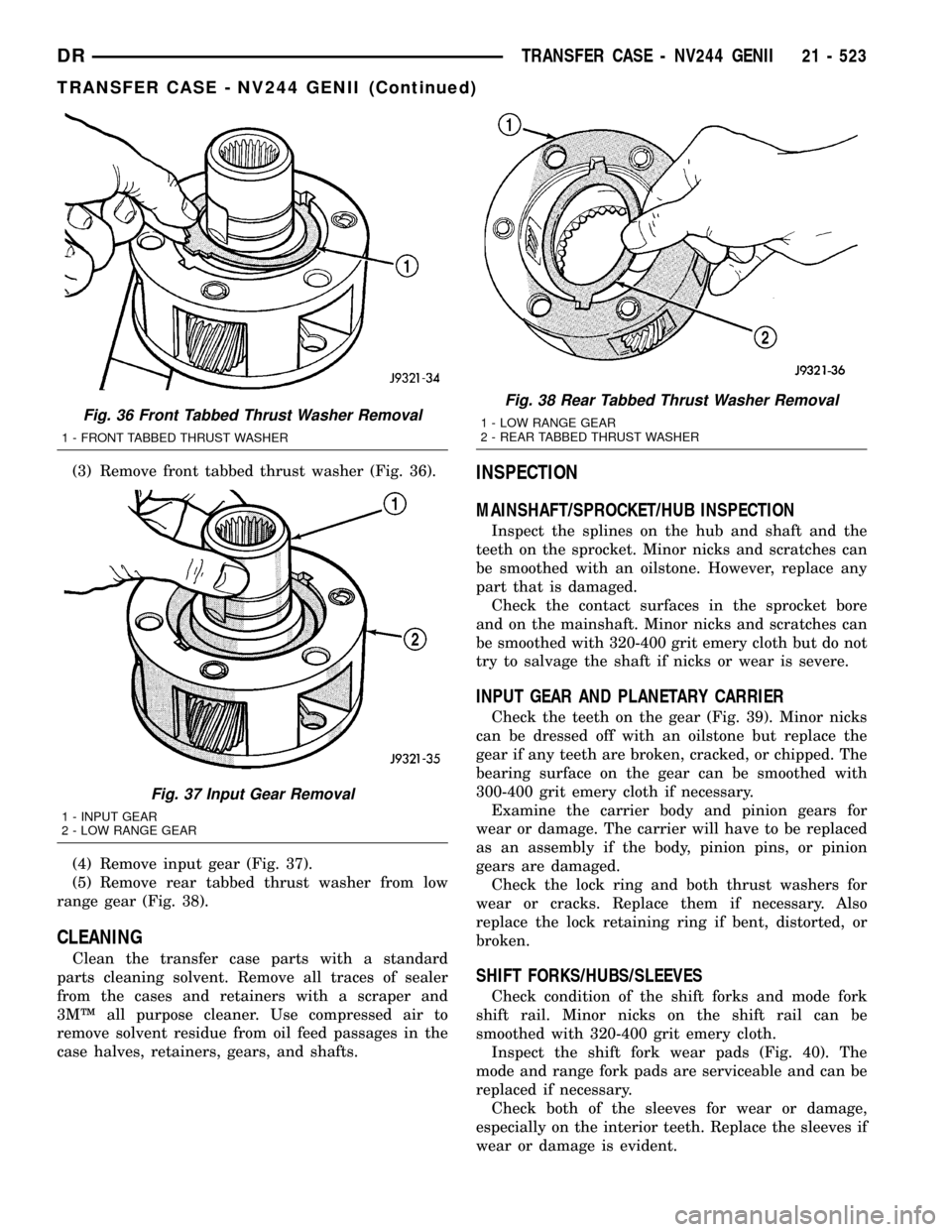

(3) Remove front tabbed thrust washer (Fig. 36).

(4) Remove input gear (Fig. 37).

(5) Remove rear tabbed thrust washer from low

range gear (Fig. 38).

CLEANING

Clean the transfer case parts with a standard

parts cleaning solvent. Remove all traces of sealer

from the cases and retainers with a scraper and

3MŸ all purpose cleaner. Use compressed air to

remove solvent residue from oil feed passages in the

case halves, retainers, gears, and shafts.

INSPECTION

MAINSHAFT/SPROCKET/HUB INSPECTION

Inspect the splines on the hub and shaft and the

teeth on the sprocket. Minor nicks and scratches can

be smoothed with an oilstone. However, replace any

part that is damaged.

Check the contact surfaces in the sprocket bore

and on the mainshaft. Minor nicks and scratches can

be smoothed with 320-400 grit emery cloth but do not

try to salvage the shaft if nicks or wear is severe.

INPUT GEAR AND PLANETARY CARRIER

Check the teeth on the gear (Fig. 39). Minor nicks

can be dressed off with an oilstone but replace the

gear if any teeth are broken, cracked, or chipped. The

bearing surface on the gear can be smoothed with

300-400 grit emery cloth if necessary.

Examine the carrier body and pinion gears for

wear or damage. The carrier will have to be replaced

as an assembly if the body, pinion pins, or pinion

gears are damaged.

Check the lock ring and both thrust washers for

wear or cracks. Replace them if necessary. Also

replace the lock retaining ring if bent, distorted, or

broken.

SHIFT FORKS/HUBS/SLEEVES

Check condition of the shift forks and mode fork

shift rail. Minor nicks on the shift rail can be

smoothed with 320-400 grit emery cloth.

Inspect the shift fork wear pads (Fig. 40). The

mode and range fork pads are serviceable and can be

replaced if necessary.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

Fig. 36 Front Tabbed Thrust Washer Removal

1 - FRONT TABBED THRUST WASHER

Fig. 37 Input Gear Removal

1 - INPUT GEAR

2 - LOW RANGE GEAR

Fig. 38 Rear Tabbed Thrust Washer Removal

1 - LOW RANGE GEAR

2 - REAR TABBED THRUST WASHER

DRTRANSFER CASE - NV244 GENII 21 - 523

TRANSFER CASE - NV244 GENII (Continued)

Page 2228 of 2627

FRONT AND REAR CASES

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with Helicoiltstain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

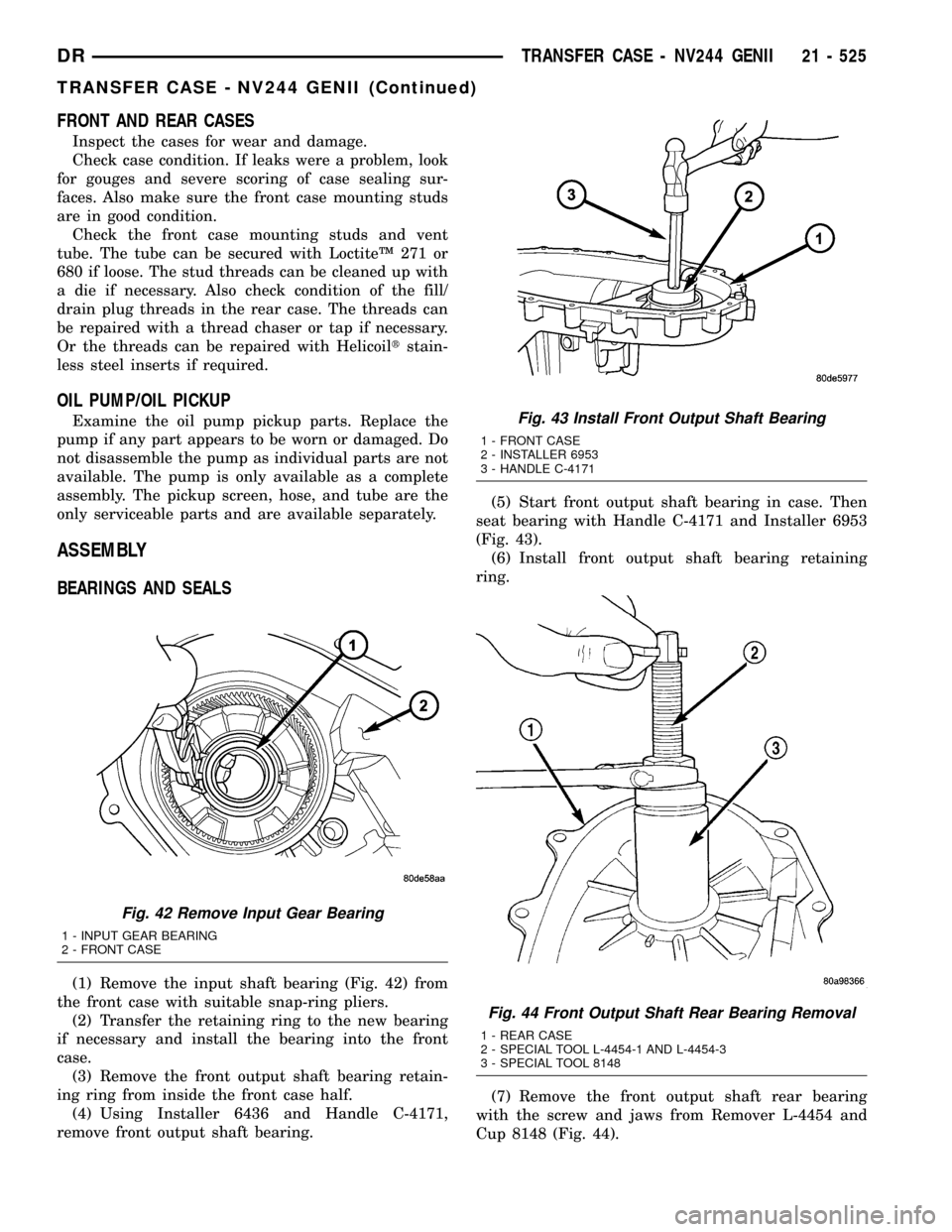

(1) Remove the input shaft bearing (Fig. 42) from

the front case with suitable snap-ring pliers.

(2) Transfer the retaining ring to the new bearing

if necessary and install the bearing into the front

case.

(3) Remove the front output shaft bearing retain-

ing ring from inside the front case half.

(4) Using Installer 6436 and Handle C-4171,

remove front output shaft bearing.(5) Start front output shaft bearing in case. Then

seat bearing with Handle C-4171 and Installer 6953

(Fig. 43).

(6) Install front output shaft bearing retaining

ring.

(7) Remove the front output shaft rear bearing

with the screw and jaws from Remover L-4454 and

Cup 8148 (Fig. 44).

Fig. 42 Remove Input Gear Bearing

1 - INPUT GEAR BEARING

2 - FRONT CASE

Fig. 43 Install Front Output Shaft Bearing

1 - FRONT CASE

2 - INSTALLER 6953

3 - HANDLE C-4171

Fig. 44 Front Output Shaft Rear Bearing Removal

1 - REAR CASE

2 - SPECIAL TOOL L-4454-1 AND L-4454-3

3 - SPECIAL TOOL 8148

DRTRANSFER CASE - NV244 GENII 21 - 525

TRANSFER CASE - NV244 GENII (Continued)

Page 2246 of 2627

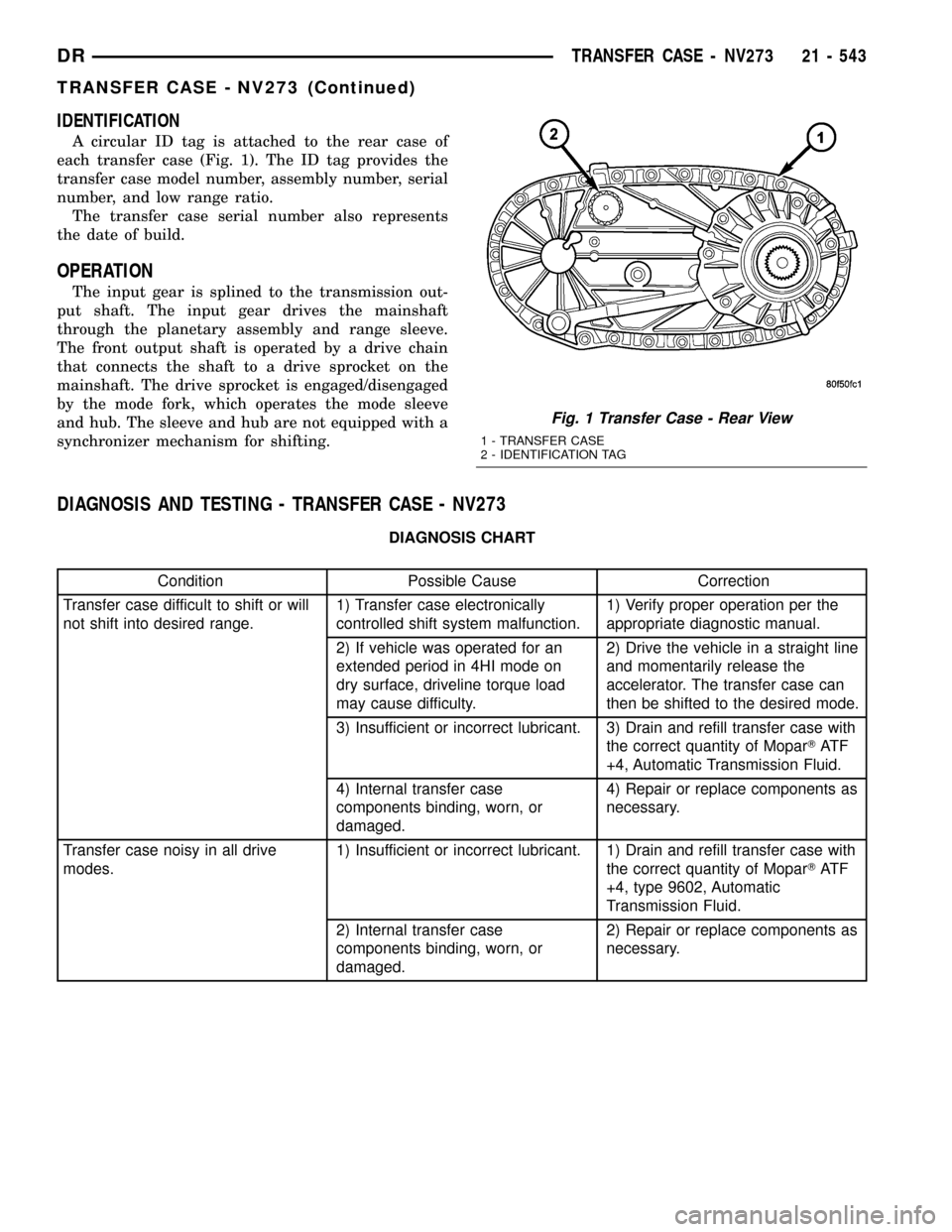

IDENTIFICATION

A circular ID tag is attached to the rear case of

each transfer case (Fig. 1). The ID tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

The input gear is splined to the transmission out-

put shaft. The input gear drives the mainshaft

through the planetary assembly and range sleeve.

The front output shaft is operated by a drive chain

that connects the shaft to a drive sprocket on the

mainshaft. The drive sprocket is engaged/disengaged

by the mode fork, which operates the mode sleeve

and hub. The sleeve and hub are not equipped with a

synchronizer mechanism for shifting.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV273

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer case difficult to shift or will

not shift into desired range.1) Transfer case electronically

controlled shift system malfunction.1) Verify proper operation per the

appropriate diagnostic manual.

2) If vehicle was operated for an

extended period in 4HI mode on

dry surface, driveline torque load

may cause difficulty.2) Drive the vehicle in a straight line

and momentarily release the

accelerator. The transfer case can

then be shifted to the desired mode.

3) Insufficient or incorrect lubricant. 3) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, Automatic Transmission Fluid.

4) Internal transfer case

components binding, worn, or

damaged.4) Repair or replace components as

necessary.

Transfer case noisy in all drive

modes.1) Insufficient or incorrect lubricant. 1) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, type 9602, Automatic

Transmission Fluid.

2) Internal transfer case

components binding, worn, or

damaged.2) Repair or replace components as

necessary.

Fig. 1 Transfer Case - Rear View

1 - TRANSFER CASE

2 - IDENTIFICATION TAG

DRTRANSFER CASE - NV273 21 - 543

TRANSFER CASE - NV273 (Continued)

Page 2247 of 2627

Condition Possible Cause Correction

Transfer case noisy while in, or

jumps out of, 4LO mode.1) Transfer case not completely

engaged in 4LO position.1) While rolling 2-3 MPH and the

transmission in NEUTRAL, or clutch

depressed on vehicles equipped

with a manual transmission, shift

transfer case to the 2WD or 4HI

position, and then back into the 4LO

position.

2) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.2) Repair or replace components as

necessary.

3) Low range gear worn or

damaged.3) Repair or replace components as

necessary.

Lubricant leaking from transfer case

seals or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Transfer case vent closed or

restricted.2) Clean or replace vent as

necessary.

3) Transfer case seals damaged or

installed incorrectly.3) Replace suspect seal.

Abnormal tire wear. 1) Extended operation in 4HI mode

on dry surfaces,1) Operate vehicle in 2WD mode on

dry surfaces.

REMOVAL

(1) Shift transfer case into 2WD.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shafts for align-

ment reference.

(5) Support transmission with jack stand.

(6) Remove the transfer case skid plate, if

equipped.

(7) Disconnect front and rear propeller shafts at

transfer case.

(8) Disconnect transfer case shift motor and mode

sensor wire connectors.

(9) Disconnect transfer case vent hose.

(10) Support transfer case with transmission jack.

(11) Secure transfer case to jack with chains.

(12) Remove nuts attaching transfer case to trans-

mission (Fig. 2).

(13) Pull transfer case and jack rearward to disen-

gage transfer case.

(14) Remove transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

Fig. 2 Remove Transfer Case - Typical

1 - TRANSMISSION

2 - TRANSFER CASE

3 - MODE SENSOR CONNECTOR

21 - 544 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2259 of 2627

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with Helicoiltstain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

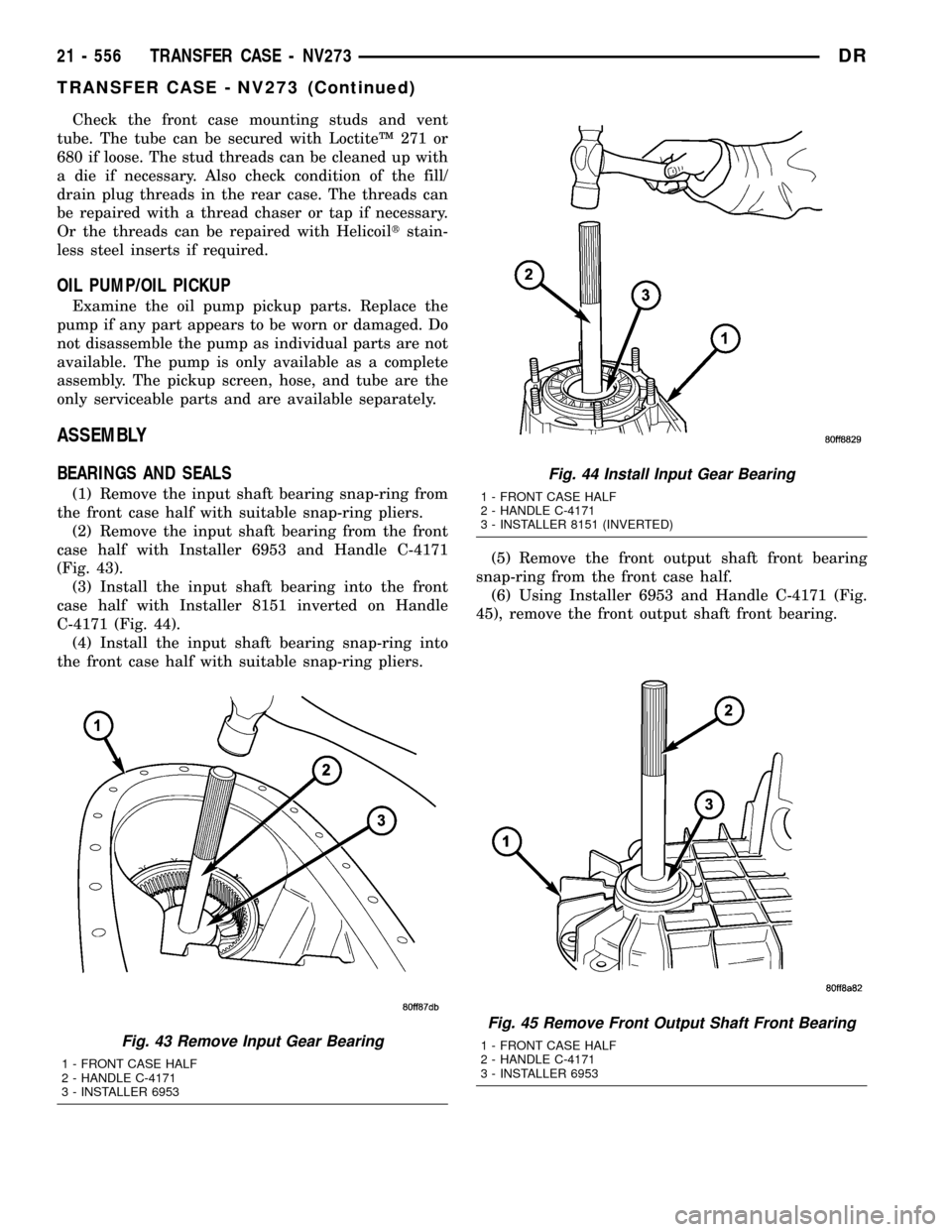

BEARINGS AND SEALS

(1) Remove the input shaft bearing snap-ring from

the front case half with suitable snap-ring pliers.

(2) Remove the input shaft bearing from the front

case half with Installer 6953 and Handle C-4171

(Fig. 43).

(3) Install the input shaft bearing into the front

case half with Installer 8151 inverted on Handle

C-4171 (Fig. 44).

(4) Install the input shaft bearing snap-ring into

the front case half with suitable snap-ring pliers.(5) Remove the front output shaft front bearing

snap-ring from the front case half.

(6) Using Installer 6953 and Handle C-4171 (Fig.

45), remove the front output shaft front bearing.

Fig. 45 Remove Front Output Shaft Front Bearing

1 - FRONT CASE HALF

2 - HANDLE C-4171

3 - INSTALLER 6953Fig. 43 Remove Input Gear Bearing

1 - FRONT CASE HALF

2 - HANDLE C-4171

3 - INSTALLER 6953

Fig. 44 Install Input Gear Bearing

1 - FRONT CASE HALF

2 - HANDLE C-4171

3 - INSTALLER 8151 (INVERTED)

21 - 556 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)