Egr DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1666 of 2627

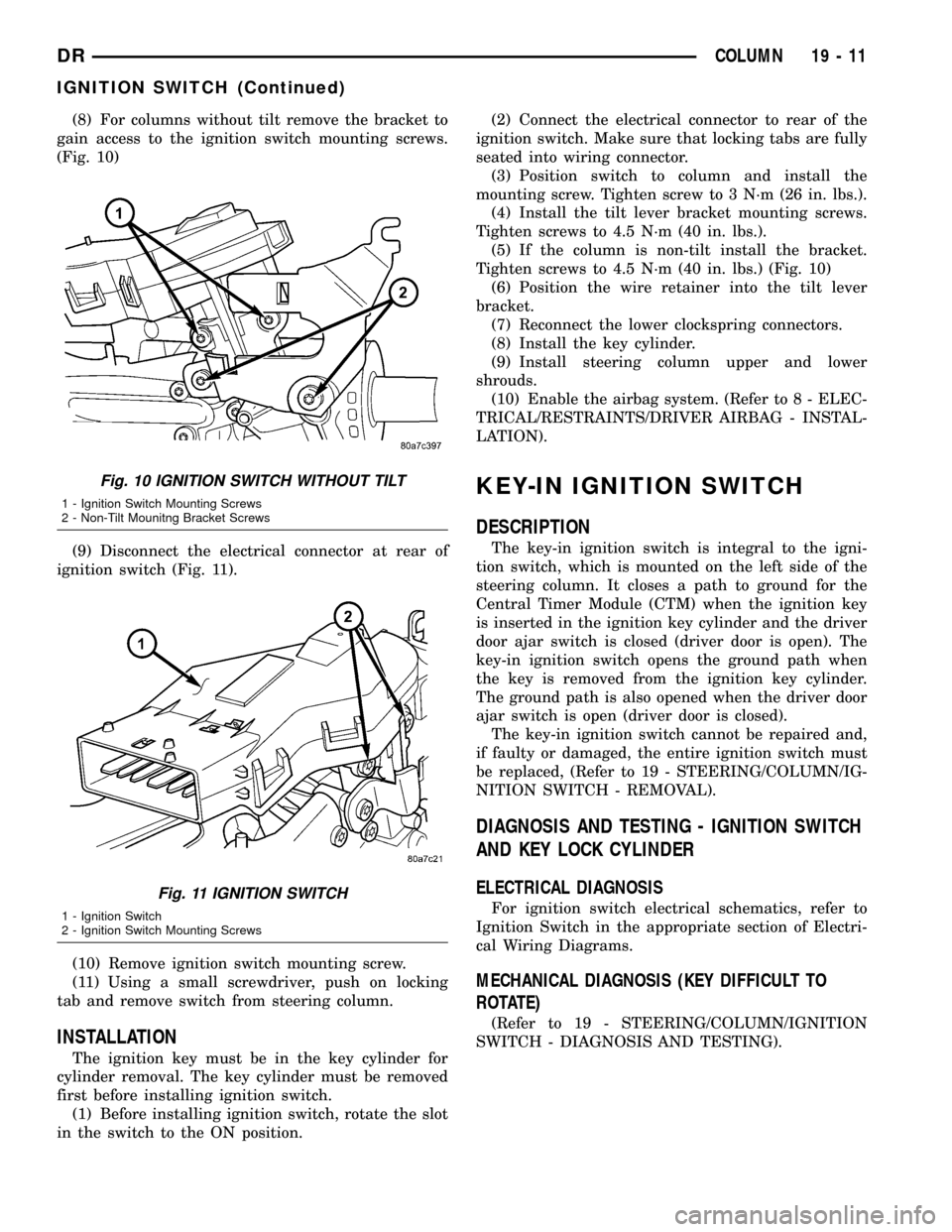

(8) For columns without tilt remove the bracket to

gain access to the ignition switch mounting screws.

(Fig. 10)

(9) Disconnect the electrical connector at rear of

ignition switch (Fig. 11).

(10) Remove ignition switch mounting screw.

(11) Using a small screwdriver, push on locking

tab and remove switch from steering column.

INSTALLATION

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before installing ignition switch.

(1) Before installing ignition switch, rotate the slot

in the switch to the ON position.(2) Connect the electrical connector to rear of the

ignition switch. Make sure that locking tabs are fully

seated into wiring connector.

(3) Position switch to column and install the

mounting screw. Tighten screw to 3 N´m (26 in. lbs.).

(4) Install the tilt lever bracket mounting screws.

Tighten screws to 4.5 N´m (40 in. lbs.).

(5) If the column is non-tilt install the bracket.

Tighten screws to 4.5 N´m (40 in. lbs.) (Fig. 10)

(6) Position the wire retainer into the tilt lever

bracket.

(7) Reconnect the lower clockspring connectors.

(8) Install the key cylinder.

(9) Install steering column upper and lower

shrouds.

(10) Enable the airbag system. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION).

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the left side of the

steering column. It closes a path to ground for the

Central Timer Module (CTM) when the ignition key

is inserted in the ignition key cylinder and the driver

door ajar switch is closed (driver door is open). The

key-in ignition switch opens the ground path when

the key is removed from the ignition key cylinder.

The ground path is also opened when the driver door

ajar switch is open (driver door is closed).

The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced, (Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

DIAGNOSIS AND TESTING - IGNITION SWITCH

AND KEY LOCK CYLINDER

ELECTRICAL DIAGNOSIS

For ignition switch electrical schematics, refer to

Ignition Switch in the appropriate section of Electri-

cal Wiring Diagrams.

MECHANICAL DIAGNOSIS (KEY DIFFICULT TO

ROTATE)

(Refer to 19 - STEERING/COLUMN/IGNITION

SWITCH - DIAGNOSIS AND TESTING).

Fig. 10 IGNITION SWITCH WITHOUT TILT

1 - Ignition Switch Mounting Screws

2 - Non-Tilt Mounitng Bracket Screws

Fig. 11 IGNITION SWITCH

1 - Ignition Switch

2 - Ignition Switch Mounting Screws

DRCOLUMN 19 - 11

IGNITION SWITCH (Continued)

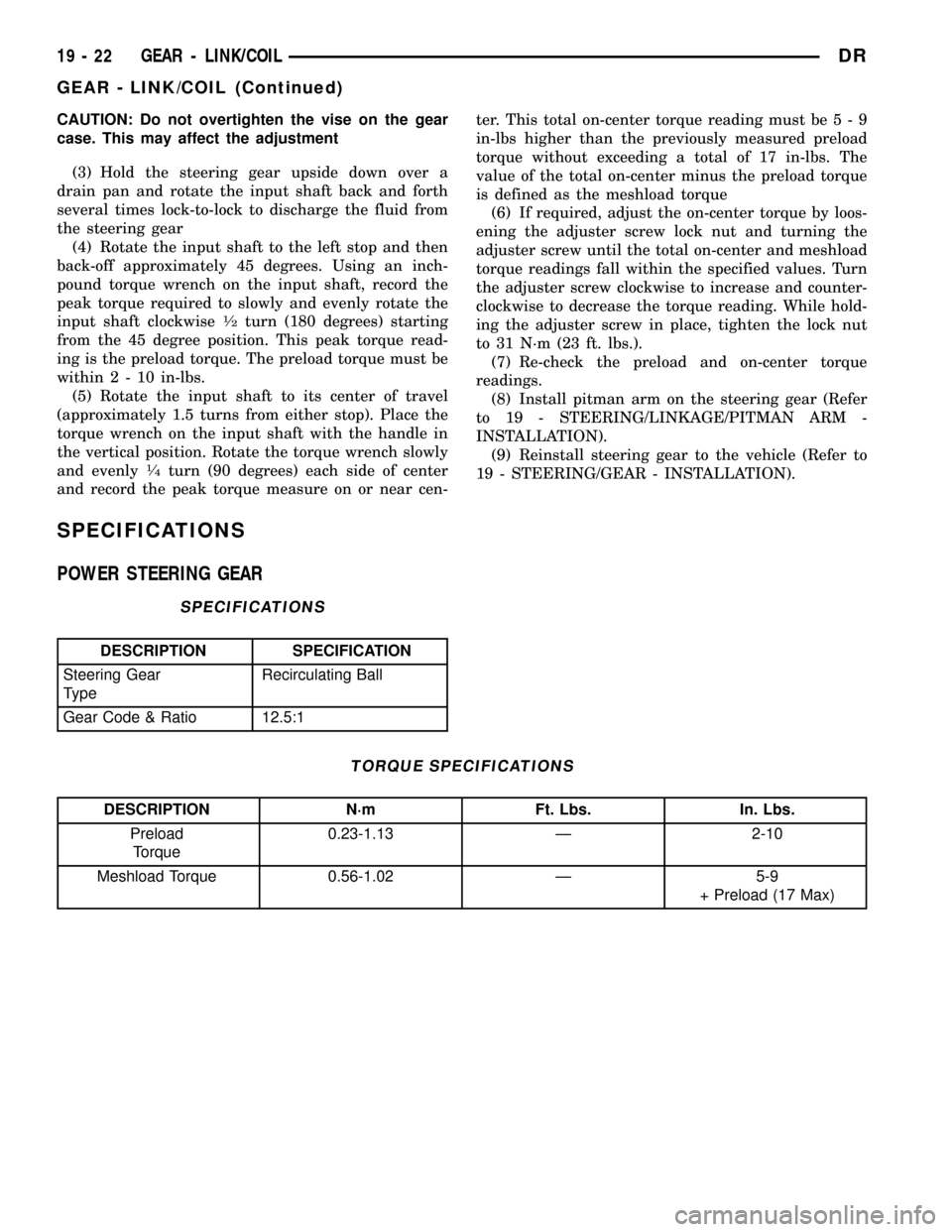

Page 1677 of 2627

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

(3) Hold the steering gear upside down over a

drain pan and rotate the input shaft back and forth

several times lock-to-lock to discharge the fluid from

the steering gear

(4) Rotate the input shaft to the left stop and then

back-off approximately 45 degrees. Using an inch-

pound torque wrench on the input shaft, record the

peak torque required to slowly and evenly rotate the

input shaft clockwise

1¤2turn (180 degrees) starting

from the 45 degree position. This peak torque read-

ing is the preload torque. The preload torque must be

within2-10in-lbs.

(5) Rotate the input shaft to its center of travel

(approximately 1.5 turns from either stop). Place the

torque wrench on the input shaft with the handle in

the vertical position. Rotate the torque wrench slowly

and evenly

1¤4turn (90 degrees) each side of center

and record the peak torque measure on or near cen-ter. This total on-center torque reading must be5-9

in-lbs higher than the previously measured preload

torque without exceeding a total of 17 in-lbs. The

value of the total on-center minus the preload torque

is defined as the meshload torque

(6) If required, adjust the on-center torque by loos-

ening the adjuster screw lock nut and turning the

adjuster screw until the total on-center and meshload

torque readings fall within the specified values. Turn

the adjuster screw clockwise to increase and counter-

clockwise to decrease the torque reading. While hold-

ing the adjuster screw in place, tighten the lock nut

to 31 N´m (23 ft. lbs.).

(7) Re-check the preload and on-center torque

readings.

(8) Install pitman arm on the steering gear (Refer

to 19 - STEERING/LINKAGE/PITMAN ARM -

INSTALLATION).

(9) Reinstall steering gear to the vehicle (Refer to

19 - STEERING/GEAR - INSTALLATION).

SPECIFICATIONS

POWER STEERING GEAR

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Steering Gear

TypeRecirculating Ball

Gear Code & Ratio 12.5:1

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Preload

Torque0.23-1.13 Ð 2-10

Meshload Torque 0.56-1.02 Ð 5-9

+ Preload (17 Max)

19 - 22 GEAR - LINK/COILDR

GEAR - LINK/COIL (Continued)

Page 1704 of 2627

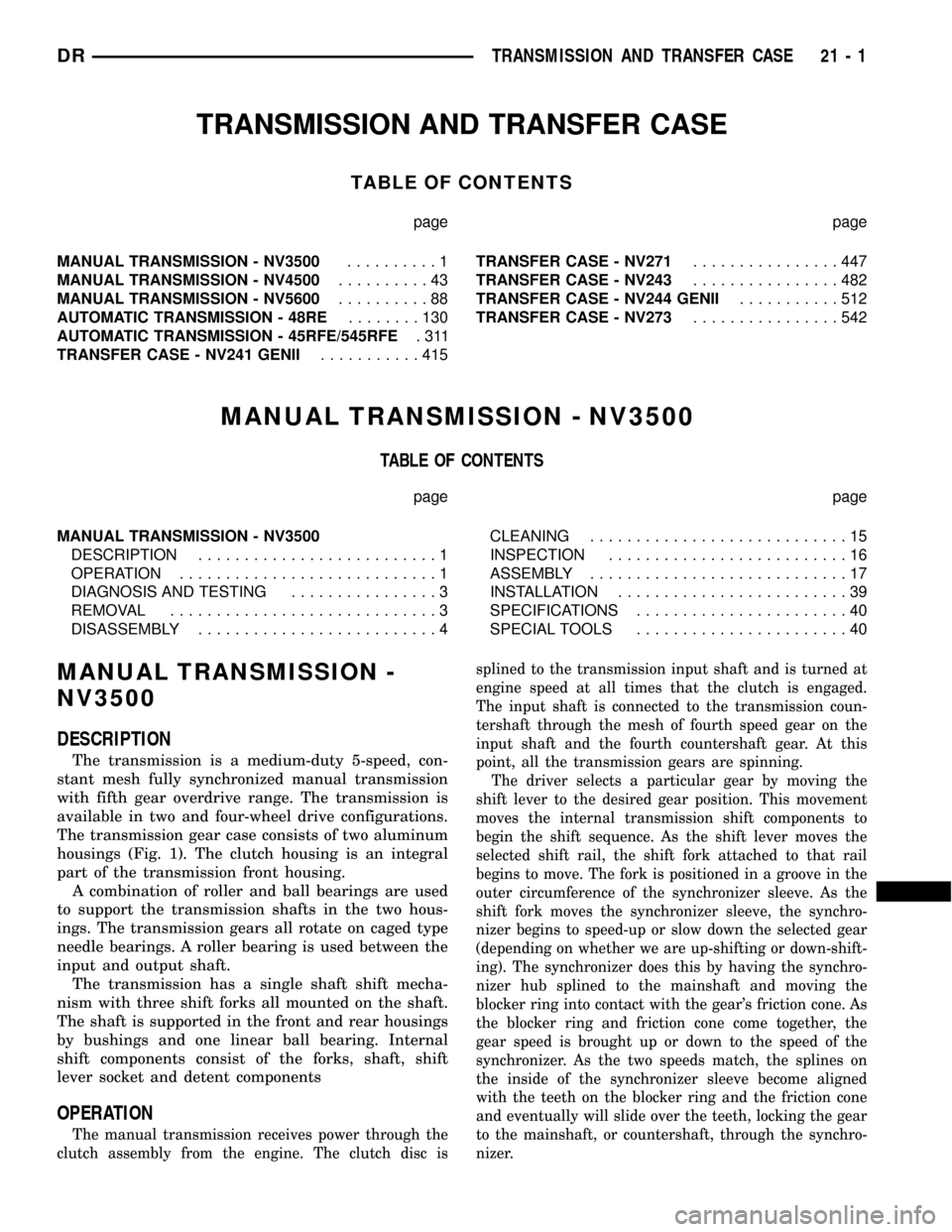

TRANSMISSION AND TRANSFER CASE

TABLE OF CONTENTS

page page

MANUAL TRANSMISSION - NV3500..........1

MANUAL TRANSMISSION - NV4500..........43

MANUAL TRANSMISSION - NV5600..........88

AUTOMATIC TRANSMISSION - 48RE........130

AUTOMATIC TRANSMISSION - 45RFE/545RFE.311

TRANSFER CASE - NV241 GENII...........415TRANSFER CASE - NV271................447

TRANSFER CASE - NV243................482

TRANSFER CASE - NV244 GENII...........512

TRANSFER CASE - NV273................542

MANUAL TRANSMISSION - NV3500

TABLE OF CONTENTS

page page

MANUAL TRANSMISSION - NV3500

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING................3

REMOVAL.............................3

DISASSEMBLY..........................4CLEANING............................15

INSPECTION..........................16

ASSEMBLY............................17

INSTALLATION.........................39

SPECIFICATIONS.......................40

SPECIAL TOOLS.......................40

MANUAL TRANSMISSION -

NV3500

DESCRIPTION

The transmission is a medium-duty 5-speed, con-

stant mesh fully synchronized manual transmission

with fifth gear overdrive range. The transmission is

available in two and four-wheel drive configurations.

The transmission gear case consists of two aluminum

housings (Fig. 1). The clutch housing is an integral

part of the transmission front housing.

A combination of roller and ball bearings are used

to support the transmission shafts in the two hous-

ings. The transmission gears all rotate on caged type

needle bearings. A roller bearing is used between the

input and output shaft.

The transmission has a single shaft shift mecha-

nism with three shift forks all mounted on the shaft.

The shaft is supported in the front and rear housings

by bushings and one linear ball bearing. Internal

shift components consist of the forks, shaft, shift

lever socket and detent components

OPERATION

The manual transmission receives power through the

clutch assembly from the engine. The clutch disc issplined to the transmission input shaft and is turned at

engine speed at all times that the clutch is engaged.

The input shaft is connected to the transmission coun-

tershaft through the mesh of fourth speed gear on the

input shaft and the fourth countershaft gear. At this

point, all the transmission gears are spinning.

The driver selects a particular gear by moving the

shift lever to the desired gear position. This movement

moves the internal transmission shift components to

begin the shift sequence. As the shift lever moves the

selected shift rail, the shift fork attached to that rail

begins to move. The fork is positioned in a groove in the

outer circumference of the synchronizer sleeve. As the

shift fork moves the synchronizer sleeve, the synchro-

nizer begins to speed-up or slow down the selected gear

(depending on whether we are up-shifting or down-shift-

ing). The synchronizer does this by having the synchro-

nizer hub splined to the mainshaft and moving the

blocker ring into contact with the gear's friction cone. As

the blocker ring and friction cone come together, the

gear speed is brought up or down to the speed of the

synchronizer. As the two speeds match, the splines on

the inside of the synchronizer sleeve become aligned

with the teeth on the blocker ring and the friction cone

and eventually will slide over the teeth, locking the gear

to the mainshaft, or countershaft, through the synchro-

nizer.

DRTRANSMISSION AND TRANSFER CASE 21 - 1

Page 1718 of 2627

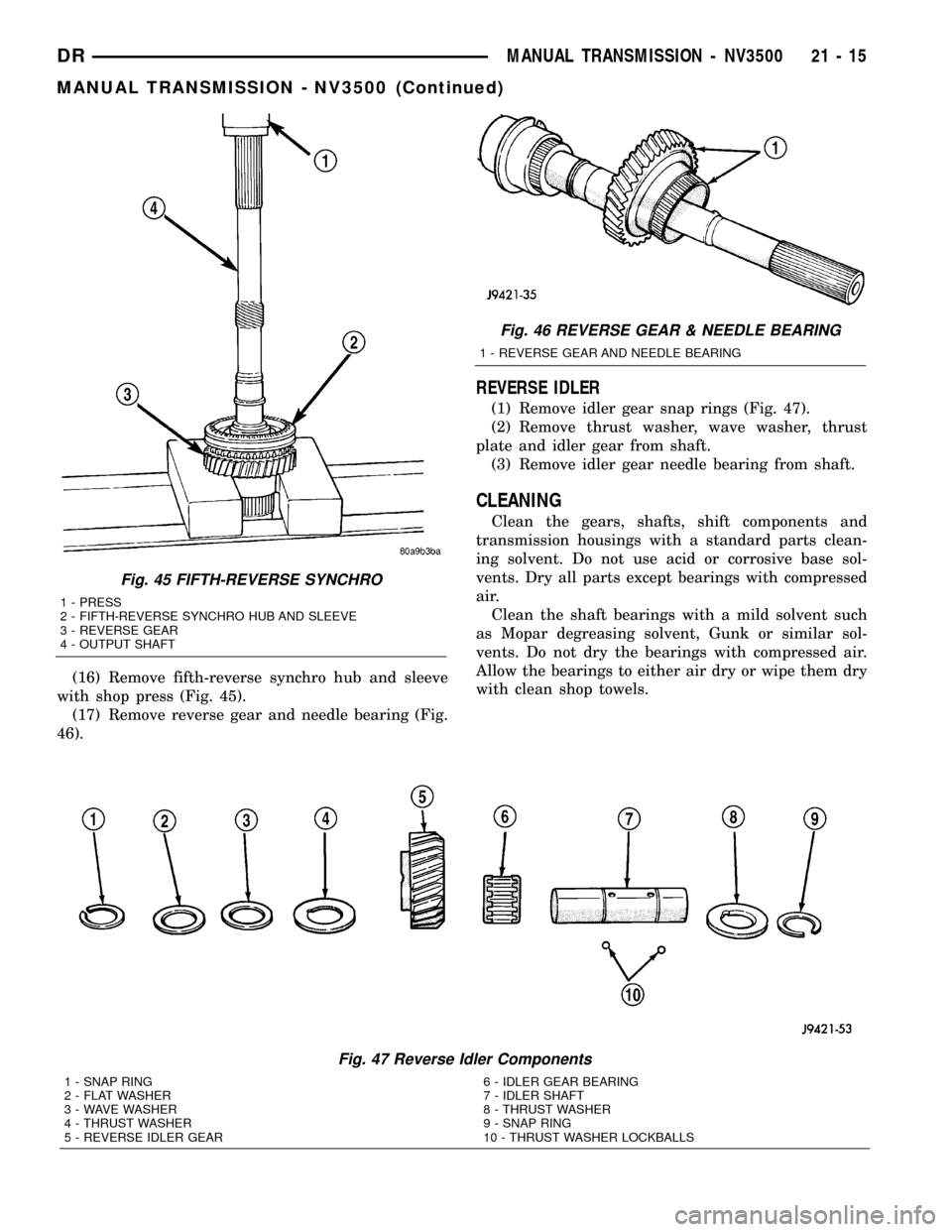

(16) Remove fifth-reverse synchro hub and sleeve

with shop press (Fig. 45).

(17) Remove reverse gear and needle bearing (Fig.

46).

REVERSE IDLER

(1) Remove idler gear snap rings (Fig. 47).

(2) Remove thrust washer, wave washer, thrust

plate and idler gear from shaft.

(3) Remove idler gear needle bearing from shaft.

CLEANING

Clean the gears, shafts, shift components and

transmission housings with a standard parts clean-

ing solvent. Do not use acid or corrosive base sol-

vents. Dry all parts except bearings with compressed

air.

Clean the shaft bearings with a mild solvent such

as Mopar degreasing solvent, Gunk or similar sol-

vents. Do not dry the bearings with compressed air.

Allow the bearings to either air dry or wipe them dry

with clean shop towels.

Fig. 45 FIFTH-REVERSE SYNCHRO

1 - PRESS

2 - FIFTH-REVERSE SYNCHRO HUB AND SLEEVE

3 - REVERSE GEAR

4 - OUTPUT SHAFT

Fig. 46 REVERSE GEAR & NEEDLE BEARING

1 - REVERSE GEAR AND NEEDLE BEARING

Fig. 47 Reverse Idler Components

1 - SNAP RING

2 - FLAT WASHER

3 - WAVE WASHER

4 - THRUST WASHER

5 - REVERSE IDLER GEAR6 - IDLER GEAR BEARING

7 - IDLER SHAFT

8 - THRUST WASHER

9 - SNAP RING

10 - THRUST WASHER LOCKBALLS

DRMANUAL TRANSMISSION - NV3500 21 - 15

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1765 of 2627

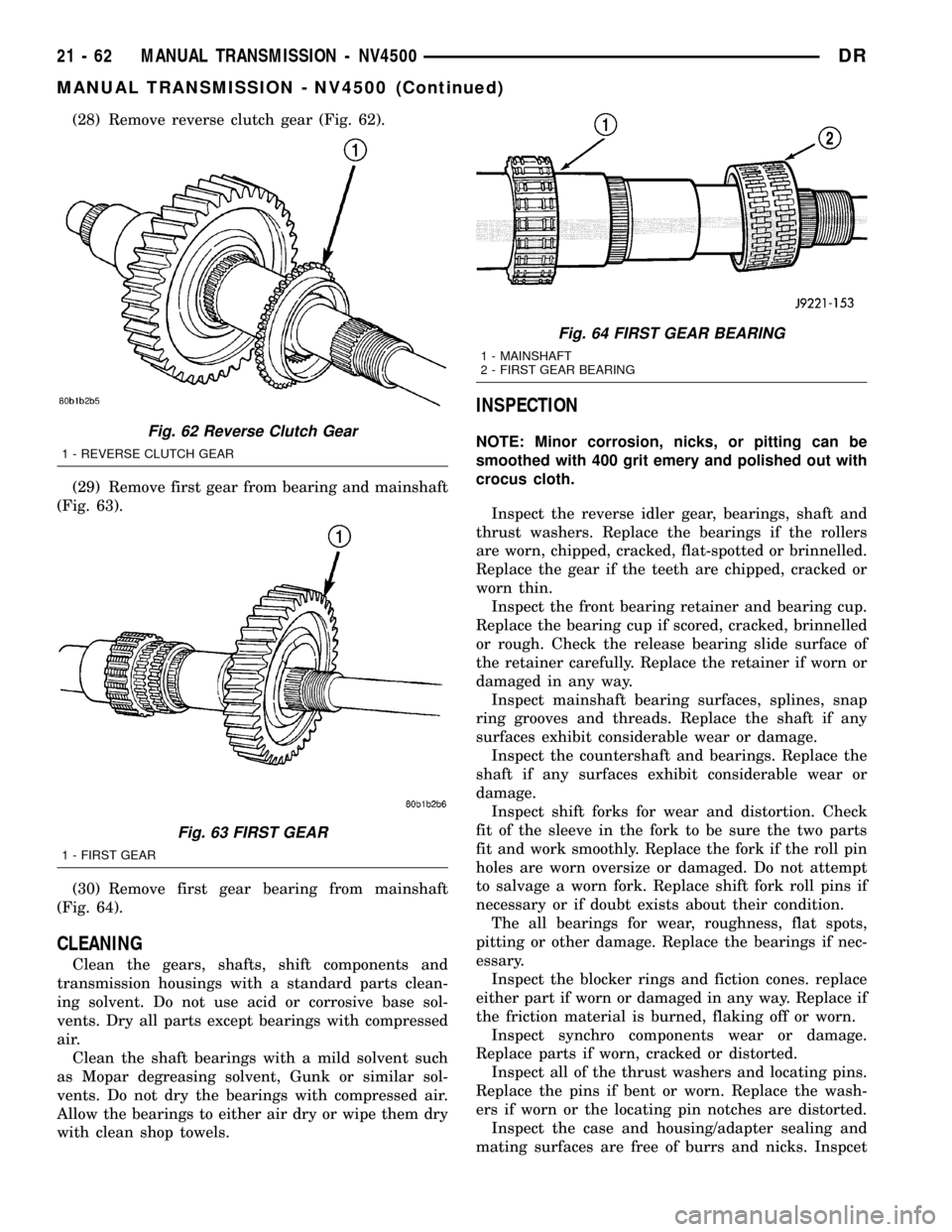

(28) Remove reverse clutch gear (Fig. 62).

(29) Remove first gear from bearing and mainshaft

(Fig. 63).

(30) Remove first gear bearing from mainshaft

(Fig. 64).

CLEANING

Clean the gears, shafts, shift components and

transmission housings with a standard parts clean-

ing solvent. Do not use acid or corrosive base sol-

vents. Dry all parts except bearings with compressed

air.

Clean the shaft bearings with a mild solvent such

as Mopar degreasing solvent, Gunk or similar sol-

vents. Do not dry the bearings with compressed air.

Allow the bearings to either air dry or wipe them dry

with clean shop towels.

INSPECTION

NOTE: Minor corrosion, nicks, or pitting can be

smoothed with 400 grit emery and polished out with

crocus cloth.

Inspect the reverse idler gear, bearings, shaft and

thrust washers. Replace the bearings if the rollers

are worn, chipped, cracked, flat-spotted or brinnelled.

Replace the gear if the teeth are chipped, cracked or

worn thin.

Inspect the front bearing retainer and bearing cup.

Replace the bearing cup if scored, cracked, brinnelled

or rough. Check the release bearing slide surface of

the retainer carefully. Replace the retainer if worn or

damaged in any way.

Inspect mainshaft bearing surfaces, splines, snap

ring grooves and threads. Replace the shaft if any

surfaces exhibit considerable wear or damage.

Inspect the countershaft and bearings. Replace the

shaft if any surfaces exhibit considerable wear or

damage.

Inspect shift forks for wear and distortion. Check

fit of the sleeve in the fork to be sure the two parts

fit and work smoothly. Replace the fork if the roll pin

holes are worn oversize or damaged. Do not attempt

to salvage a worn fork. Replace shift fork roll pins if

necessary or if doubt exists about their condition.

The all bearings for wear, roughness, flat spots,

pitting or other damage. Replace the bearings if nec-

essary.

Inspect the blocker rings and fiction cones. replace

either part if worn or damaged in any way. Replace if

the friction material is burned, flaking off or worn.

Inspect synchro components wear or damage.

Replace parts if worn, cracked or distorted.

Inspect all of the thrust washers and locating pins.

Replace the pins if bent or worn. Replace the wash-

ers if worn or the locating pin notches are distorted.

Inspect the case and housing/adapter sealing and

mating surfaces are free of burrs and nicks. InspcetFig. 62 Reverse Clutch Gear

1 - REVERSE CLUTCH GEAR

Fig. 63 FIRST GEAR

1 - FIRST GEAR

Fig. 64 FIRST GEAR BEARING

1 - MAINSHAFT

2 - FIRST GEAR BEARING

21 - 62 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1901 of 2627

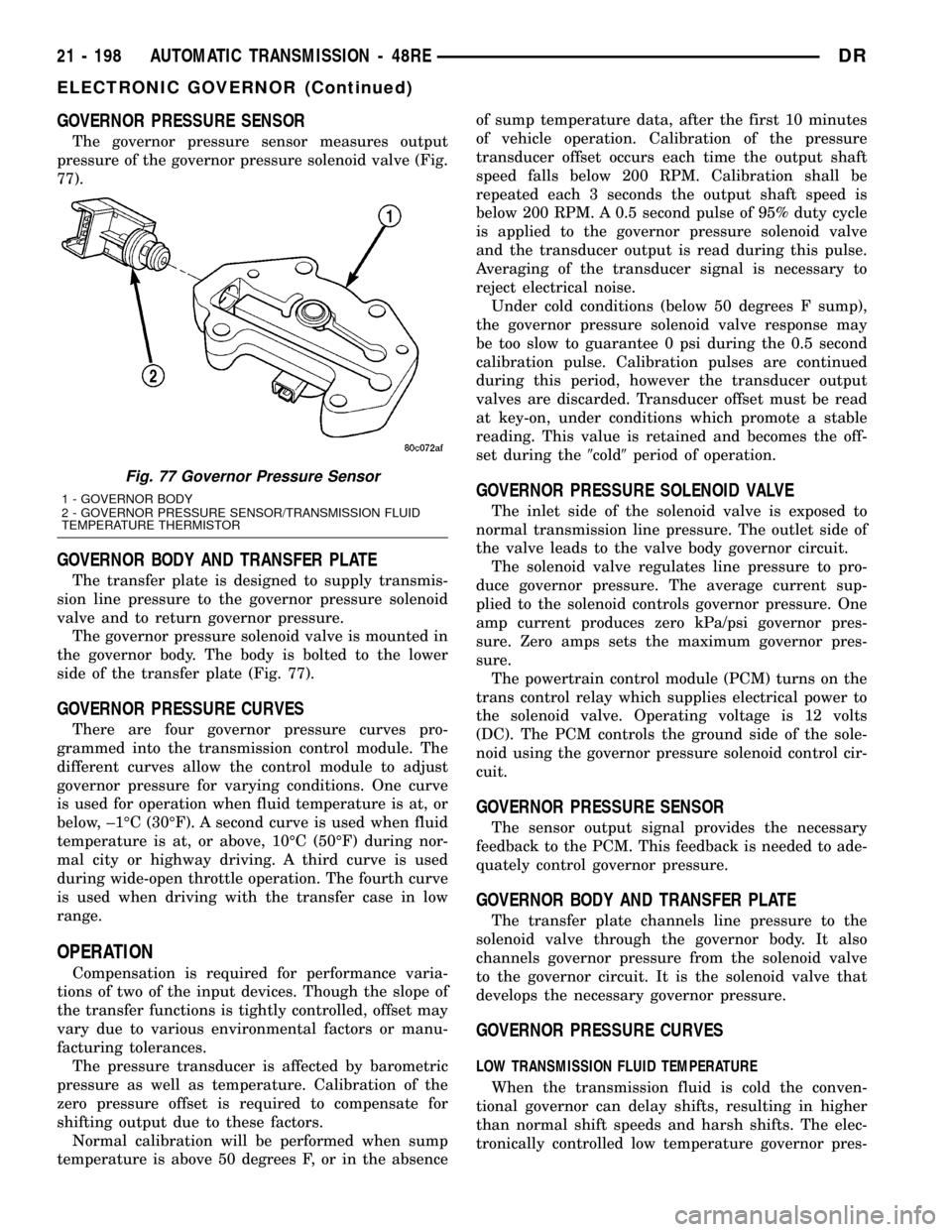

GOVERNOR PRESSURE SENSOR

The governor pressure sensor measures output

pressure of the governor pressure solenoid valve (Fig.

77).

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate is designed to supply transmis-

sion line pressure to the governor pressure solenoid

valve and to return governor pressure.

The governor pressure solenoid valve is mounted in

the governor body. The body is bolted to the lower

side of the transfer plate (Fig. 77).

GOVERNOR PRESSURE CURVES

There are four governor pressure curves pro-

grammed into the transmission control module. The

different curves allow the control module to adjust

governor pressure for varying conditions. One curve

is used for operation when fluid temperature is at, or

below, ±1ÉC (30ÉF). A second curve is used when fluid

temperature is at, or above, 10ÉC (50ÉF) during nor-

mal city or highway driving. A third curve is used

during wide-open throttle operation. The fourth curve

is used when driving with the transfer case in low

range.

OPERATION

Compensation is required for performance varia-

tions of two of the input devices. Though the slope of

the transfer functions is tightly controlled, offset may

vary due to various environmental factors or manu-

facturing tolerances.

The pressure transducer is affected by barometric

pressure as well as temperature. Calibration of the

zero pressure offset is required to compensate for

shifting output due to these factors.

Normal calibration will be performed when sump

temperature is above 50 degrees F, or in the absenceof sump temperature data, after the first 10 minutes

of vehicle operation. Calibration of the pressure

transducer offset occurs each time the output shaft

speed falls below 200 RPM. Calibration shall be

repeated each 3 seconds the output shaft speed is

below 200 RPM. A 0.5 second pulse of 95% duty cycle

is applied to the governor pressure solenoid valve

and the transducer output is read during this pulse.

Averaging of the transducer signal is necessary to

reject electrical noise.

Under cold conditions (below 50 degrees F sump),

the governor pressure solenoid valve response may

be too slow to guarantee 0 psi during the 0.5 second

calibration pulse. Calibration pulses are continued

during this period, however the transducer output

valves are discarded. Transducer offset must be read

at key-on, under conditions which promote a stable

reading. This value is retained and becomes the off-

set during the9cold9period of operation.

GOVERNOR PRESSURE SOLENOID VALVE

The inlet side of the solenoid valve is exposed to

normal transmission line pressure. The outlet side of

the valve leads to the valve body governor circuit.

The solenoid valve regulates line pressure to pro-

duce governor pressure. The average current sup-

plied to the solenoid controls governor pressure. One

amp current produces zero kPa/psi governor pres-

sure. Zero amps sets the maximum governor pres-

sure.

The powertrain control module (PCM) turns on the

trans control relay which supplies electrical power to

the solenoid valve. Operating voltage is 12 volts

(DC). The PCM controls the ground side of the sole-

noid using the governor pressure solenoid control cir-

cuit.

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary

feedback to the PCM. This feedback is needed to ade-

quately control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the

solenoid valve through the governor body. It also

channels governor pressure from the solenoid valve

to the governor circuit. It is the solenoid valve that

develops the necessary governor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conven-

tional governor can delay shifts, resulting in higher

than normal shift speeds and harsh shifts. The elec-

tronically controlled low temperature governor pres-

Fig. 77 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

21 - 198 AUTOMATIC TRANSMISSION - 48REDR

ELECTRONIC GOVERNOR (Continued)

Page 1959 of 2627

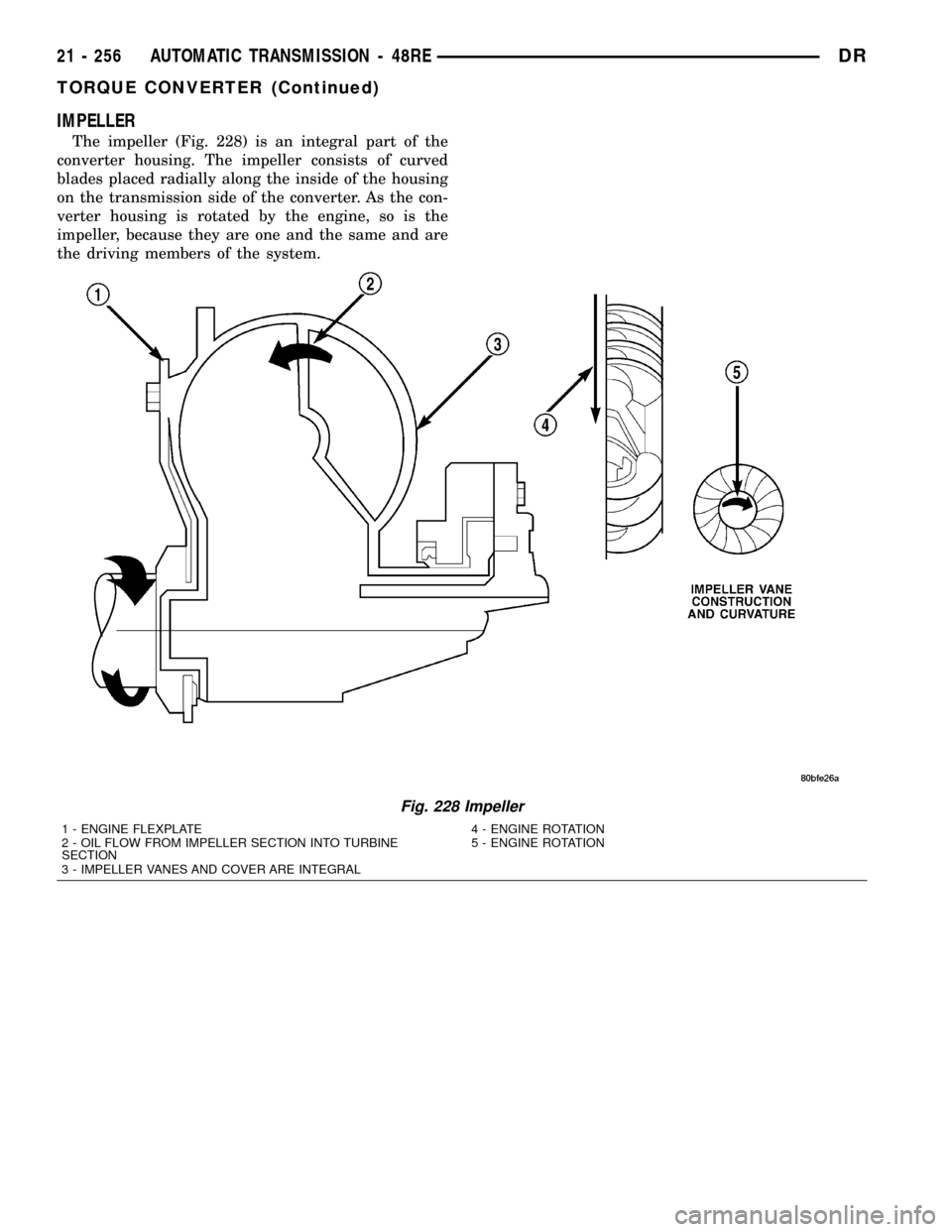

IMPELLER

The impeller (Fig. 228) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving members of the system.

Fig. 228 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

21 - 256 AUTOMATIC TRANSMISSION - 48REDR

TORQUE CONVERTER (Continued)

Page 1961 of 2627

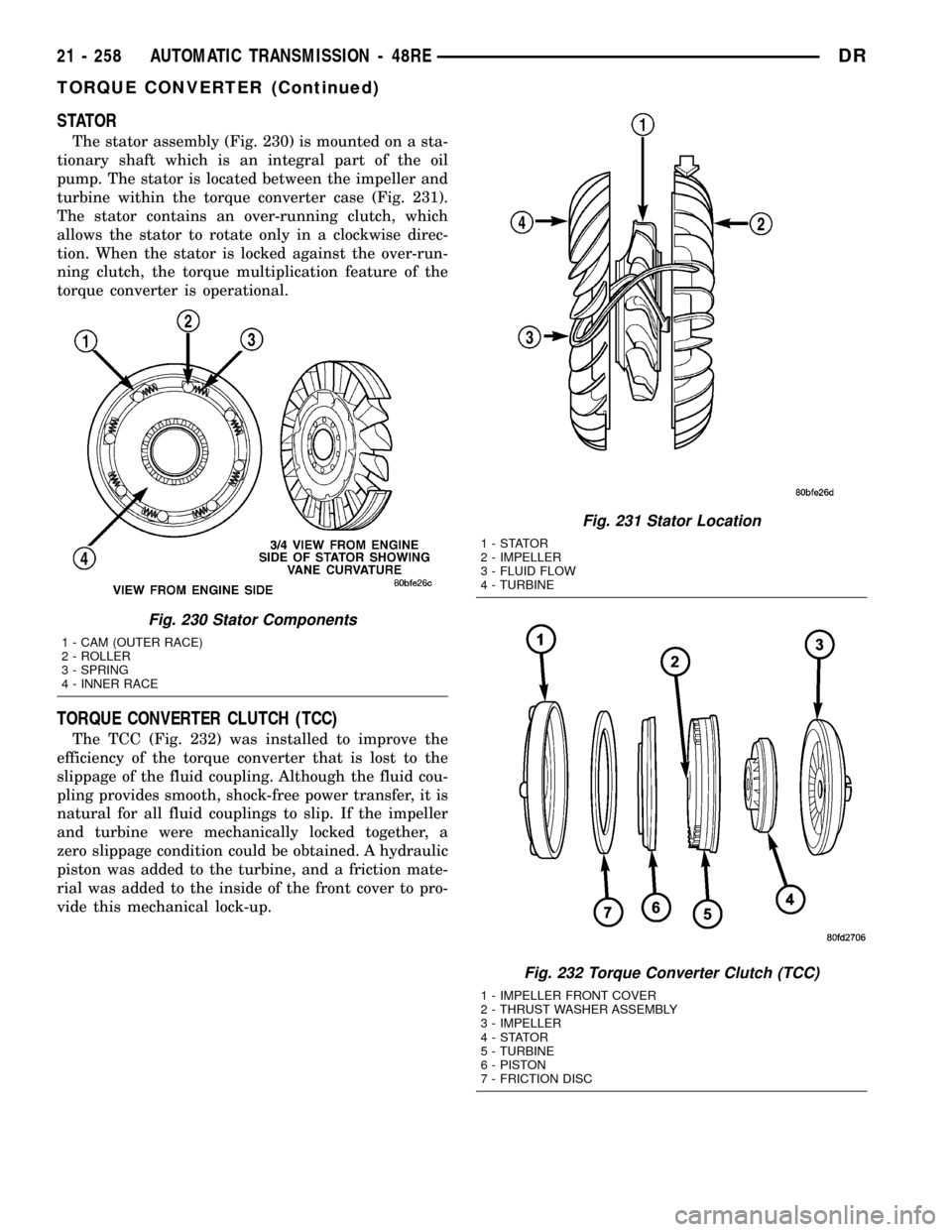

STATOR

The stator assembly (Fig. 230) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 231).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 232) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston was added to the turbine, and a friction mate-

rial was added to the inside of the front cover to pro-

vide this mechanical lock-up.

Fig. 230 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 231 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 232 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

21 - 258 AUTOMATIC TRANSMISSION - 48REDR

TORQUE CONVERTER (Continued)

Page 1962 of 2627

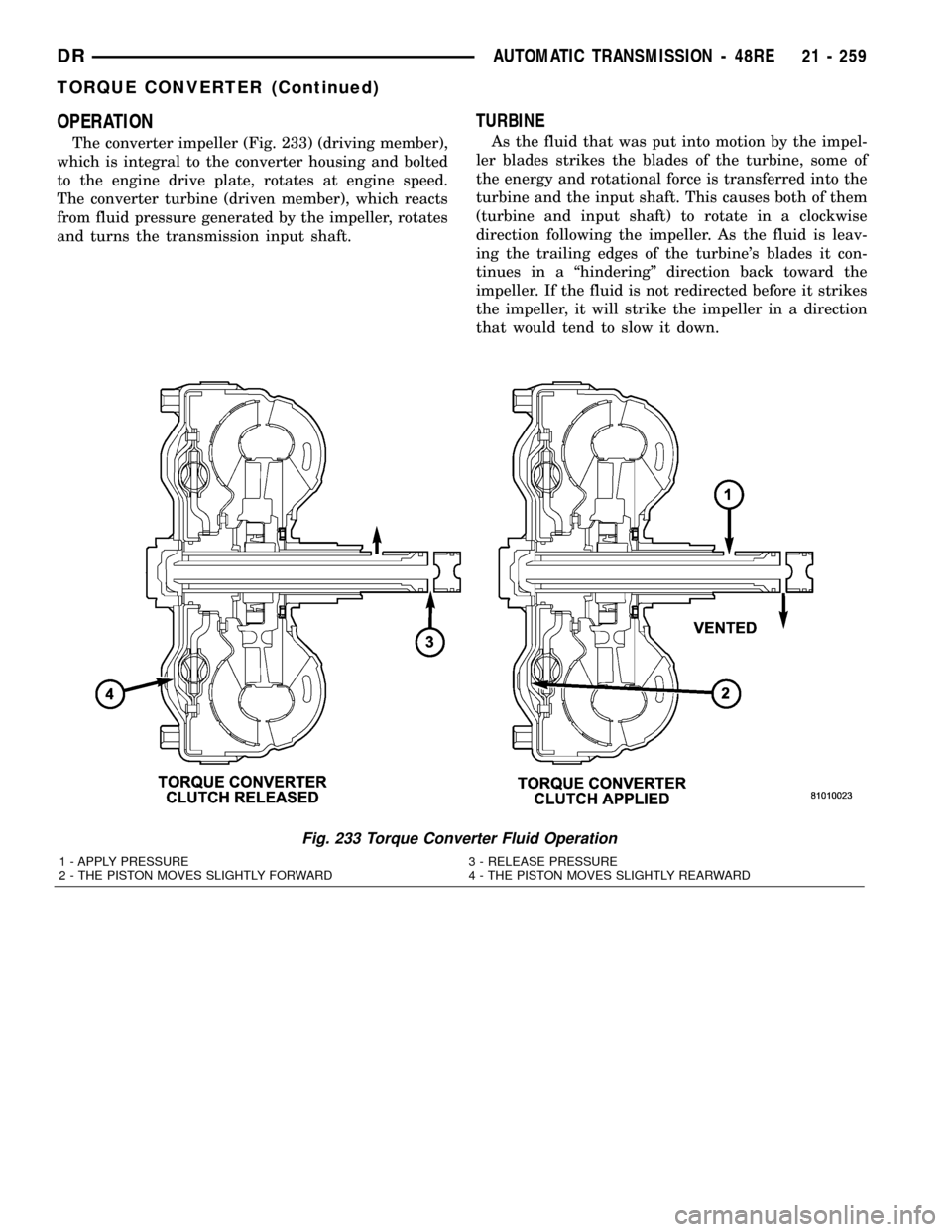

OPERATION

The converter impeller (Fig. 233) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in a direction

that would tend to slow it down.

Fig. 233 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

DRAUTOMATIC TRANSMISSION - 48RE 21 - 259

TORQUE CONVERTER (Continued)

Page 2103 of 2627

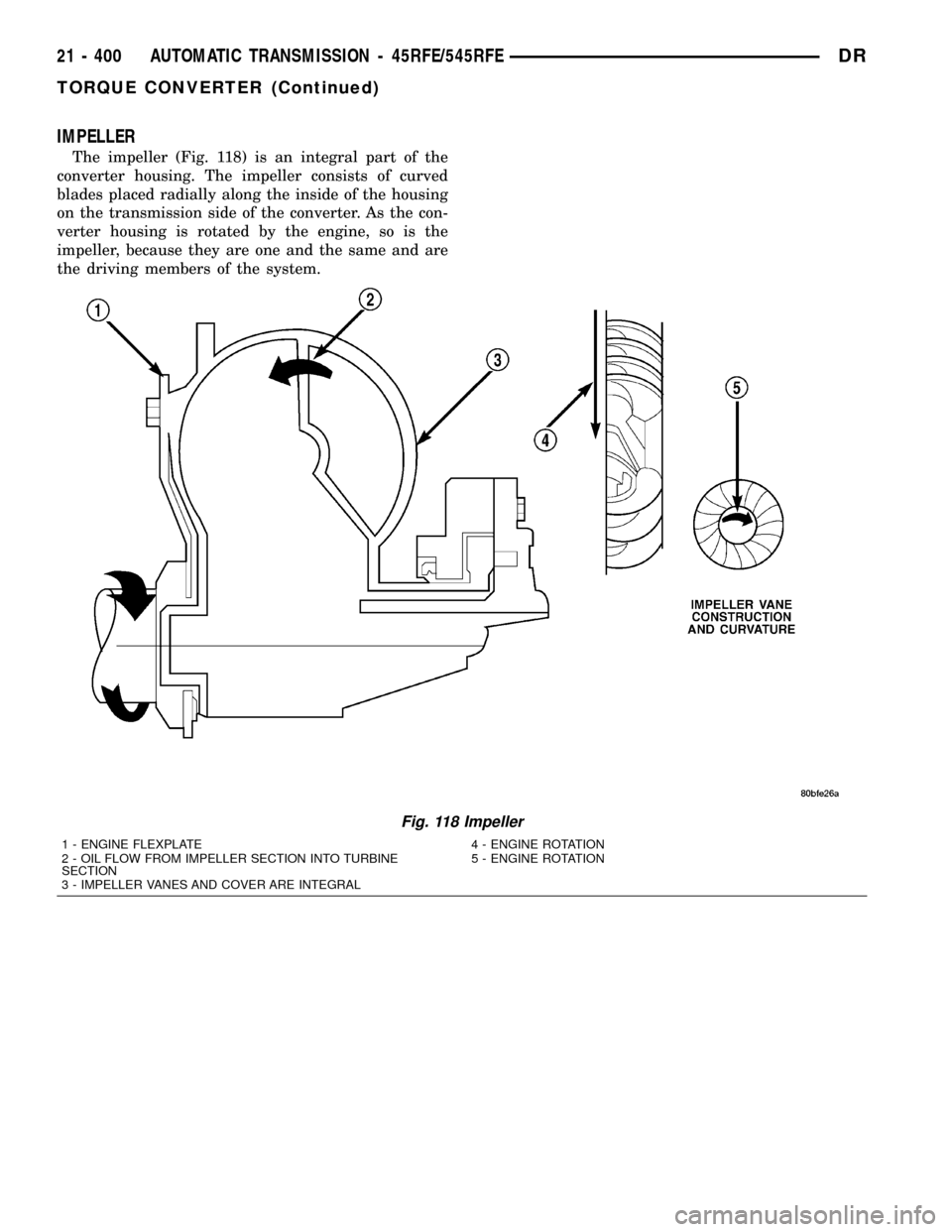

IMPELLER

The impeller (Fig. 118) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving members of the system.

Fig. 118 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

21 - 400 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TORQUE CONVERTER (Continued)