Egr DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2531 of 2627

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS

WARNING: R-134a SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. MIXTURE OF AIR and R-134a CAN BE COM-

BUSTIBLE AT ELEVATED PRESSURES. THESE MIX-

TURES ARE POTENTIALLY DANGEROUS AND MAY

RESULT IN FIRE OR EXPLOSION CAUSING INJURY

OR PROPERTY DAMAGE.

AVOID BREATHING A/C REFRIGERANT AND LUBRI-

CANT VAPOR OR MIST. EXPOSURE MAY IRRITATE

EYES, NOSE AND THROAT. USE ONLY APPROVED

SERVICE EQUIPMENT MEETING SAE REQUIRE-

MENTS TO DISCHARGE R-134a SYSTEM. IF ACCI-

DENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

NOTE: The refrigerant system does come from the

factory with a yellow tracer dye already installed to

aid in detection of leaks.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a system

Charge Level-Check or Fill. If while performing this

test A/C liquid line pressure is less than 345 kPa (50

psi) proceed to System Empty procedure. If liquid

line pressure is greater than 345 kPa (50 psi) proceed

to System Low procedure. If the refrigerant system is

empty or low in refrigerant charge, a leak at any line

fitting or component seal is likely. A review of the fit-

tings, lines and components for oily residue is an

indication of the leak location. To detect a leak in the

refrigerant system, perform one of the following pro-

cedures as indicated by the symptoms.

SYSTEM EMPTY

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approx. 28 in Hg.). Deter-

mine if the system holds a vacuum for 15 minutes. If

vacuum is held, a leak is probably not present. If sys-

tem will not maintain vacuum level, proceed with

this procedure.(2) Prepare a 0.284 Kg. (10 oz.) refrigerant charge

to be injected into the system.

(3) Connect and dispense 0.284 Kg. (10 oz.) of

refrigerant into the evacuated refrigerant system.

(4) Proceed to Step 2 of System Low procedure.

SYSTEM LOW

(1) Determine if there is any (R-134a) refrigerant

in the system.

(2) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

²Transmission in Park or Neutral with parking

brake set

²Engine idling at 700 rpm

²A/C controls set in 100 percent outside air

²Blower switch in the high A/C position

²A/C in the ON position

²Open all windows

CAUTION: A leak detector designed for R-12 refrig-

erant (only) will not detect leaks in a R-134a refrig-

erant system.

(4) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the drain tube opening or a heat

duct. A R-134a dye is available to aid in leak detec-

tion, use only DaimlerChrysler approved refrigerant

dye.

24 - 44 PLUMBINGDR

PLUMBING (Continued)

Page 2548 of 2627

DIAGNOSIS AND TESTING - A/C ORIFICE TUBE

WARNING: THE LIQUID LINE BETWEEN THE CON-

DENSER OUTLET AND THE A/C ORIFICE TUBE

CAN BECOME HOT ENOUGH TO BURN THE SKIN.

USE EXTREME CAUTION WHEN PERFORMING THE

FOLLOWING TEST.

NOTE: The A/C orifice tube can be checked for

proper operation using the following procedure.

However, the A/C orifice tube is only serviced as a

part of the liquid line. If the results of this test indi-

cate that the A/C orifice tube is obstructed or miss-

ing, the liquid line must be replaced.

(1) Confirm that the refrigerant system is properly

charged. (Refer to 24 - HEATING & AIR CONDI-

TIONING - DIAGNOSIS AND TESTING - A/C PER-

FORMANCE)

(2) Start the engine. Turn on the air conditioning

system and confirm that the compressor clutch is

engaged.

(3) Allow the air conditioning system to operate for

five minutes.

(4) Lightly and cautiously touch the liquid line

near the condenser outlet at the front of the engine

compartment. The liquid line should be hot to the

touch.

(5) Touch the liquid line near the evaporator inlet

at the rear of the engine compartment. The liquid

line should be cold to the touch.

(6) If there is a distinct temperature differential

between the two ends of the liquid line, the A/C ori-

fice tube is in good condition. If there is little or no

detectable temperature differential between the two

ends of the liquid line, the A/C orifice tube is

obstructed or missing and the liquid line must be

replaced.

ACCUMULATOR

DESCRIPTION

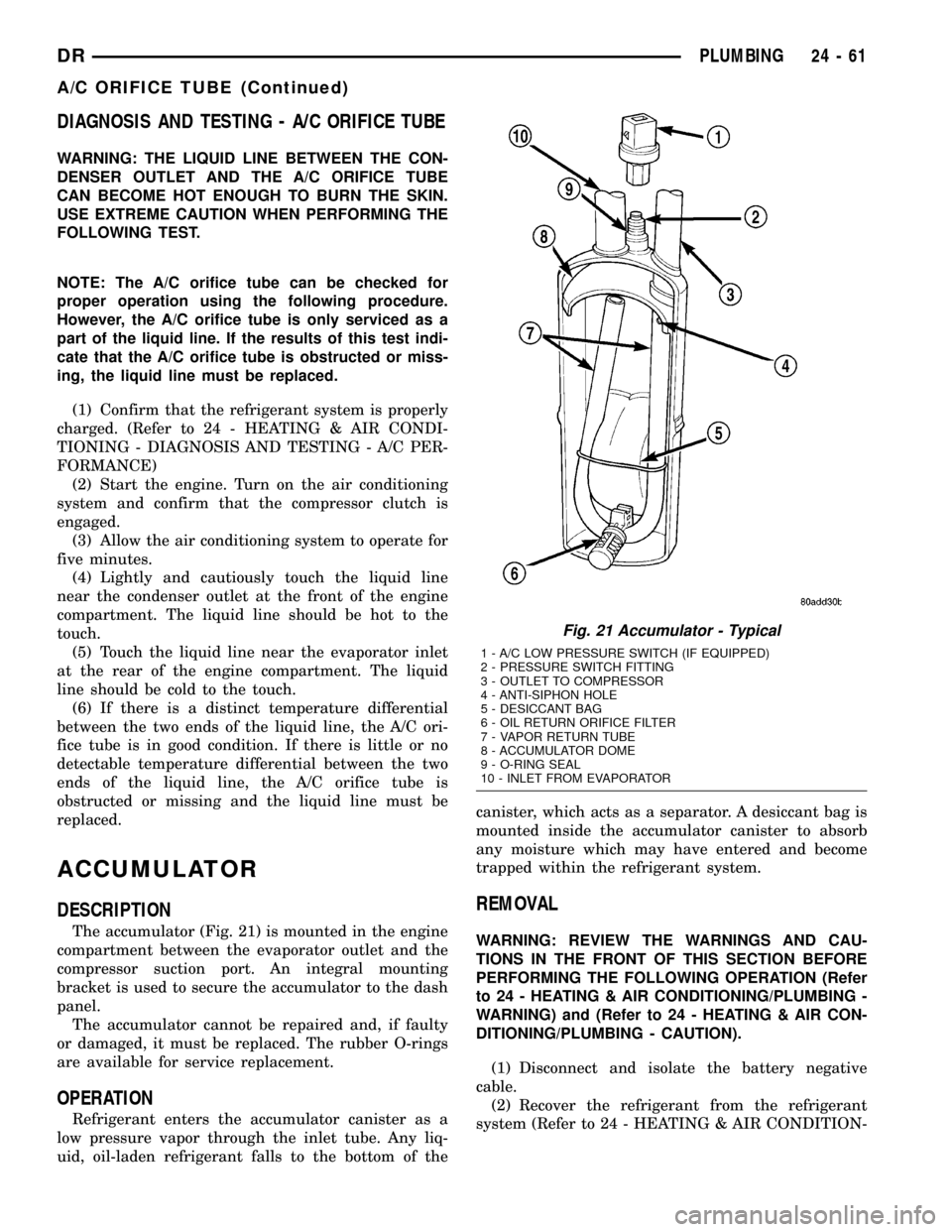

The accumulator (Fig. 21) is mounted in the engine

compartment between the evaporator outlet and the

compressor suction port. An integral mounting

bracket is used to secure the accumulator to the dash

panel.

The accumulator cannot be repaired and, if faulty

or damaged, it must be replaced. The rubber O-rings

are available for service replacement.

OPERATION

Refrigerant enters the accumulator canister as a

low pressure vapor through the inlet tube. Any liq-

uid, oil-laden refrigerant falls to the bottom of thecanister, which acts as a separator. A desiccant bag is

mounted inside the accumulator canister to absorb

any moisture which may have entered and become

trapped within the refrigerant system.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

Fig. 21 Accumulator - Typical

1 - A/C LOW PRESSURE SWITCH (IF EQUIPPED)

2 - PRESSURE SWITCH FITTING

3 - OUTLET TO COMPRESSOR

4 - ANTI-SIPHON HOLE

5 - DESICCANT BAG

6 - OIL RETURN ORIFICE FILTER

7 - VAPOR RETURN TUBE

8 - ACCUMULATOR DOME

9 - O-RING SEAL

10 - INLET FROM EVAPORATOR

DRPLUMBING 24 - 61

A/C ORIFICE TUBE (Continued)

Page 2565 of 2627

O2S is used to detect the amount of oxygen in the

exhaust gas before the gas enters the catalytic con-

verter. The PCM calculates the A/F mixture from the

output of the O2S. A low voltage indicates high oxy-

gen content (lean mixture). A high voltage indicates a

low content of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL will be illu-

minated.

DESCRIPTION - TRIP DEFINITION

The term ªTripº has different meanings depending

on what the circumstances are. If the MIL (Malfunc-

tion Indicator Lamp) is OFF, a Trip is defined as

when the Oxygen Sensor Monitor and the Catalyst

Monitor have been completed in the same drive cycle.

When any Emission DTC is set, the MIL on the

dash is turned ON. When the MIL is ON, it takes 3

good trips to turn the MIL OFF. In this case, it

depends on what type of DTC is set to know what a

ªTripº is.

For the Fuel Monitor or Mis-Fire Monitor (contin-

uous monitor), the vehicle must be operated in the

ªSimilar Condition Windowº for a specified amount of

time to be considered a Good Trip.If a Non-Contiuous OBDII Monitor fails twice in a

row and turns ON the MIL, re-running that monitor

which previously failed, on the next start-up and

passing the monitor, is considered to be a Good Trip.

These will include the following:

²Oxygen Sensor

²Catalyst Monitor

²Purge Flow Monitor

²Leak Detection Pump Monitor (if equipped)

²EGR Monitor (if equipped)

²Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII

Monitor), a Good Trip is considered to be when the

Oxygen Sensor Monitor and Catalyst Monitor have

been completed; or 2 Minutes of engine run time if

the Oxygen Sensor Monitor or Catalyst Monitor have

been stopped from running.

It can take up to 2 Failures in a row to turn on the

MIL. After the MIL is ON, it takes 3 Good Trips to

turn the MIL OFF. After the MIL is OFF, the PCM

will self-erase the DTC after 40 Warm-up cycles. A

Warm-up cycle is counted when the ECT (Engine

Coolant Temperature Sensor) has crossed 160ÉF and

has risen by at least 40ÉF since the engine has been

started.

DESCRIPTION - COMPONENT MONITORS

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (MIL) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater,

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum if

the TPS indicates a small throttle opening.

All open/short circuit checks, or any component

that has an associated limp-in, will set a fault after 1

trip with the malfunction present. Components with-

out an associated limp-in will take two trips to illu-

minate the MIL.

25 - 4 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2567 of 2627

For example, when the MIL is illuminated for an

Oxygen Sensor fault, the Task Manager does not run

the Catalyst Monitor until the Oxygen Sensor fault is

remedied. Since the Catalyst Monitor is based on sig-

nals from the Oxygen Sensor, running the test would

produce inaccurate results.

²Conflict

There are situations when the Task Manager does

not run a test if another monitor is in progress. In

these situations, the effects of another monitor run-

ning could result in an erroneous failure. If thiscon-

flictis present, the monitor is not run until the

conflicting condition passes. Most likely the monitor

will run later after the conflicting monitor has

passed.

For example, if the Fuel System Monitor is in

progress, the Task Manager does not run the EGR

Monitor. Since both tests monitor changes in air/fuel

ratio and adaptive fuel compensation, the monitors

will conflict with each other.

²Suspend

Occasionally the Task Manager may not allow a two

trip fault to mature. The Task Manager willsus-

pendthe maturing of a fault if a condition exists

that may induce an erroneous failure. This prevents

illuminating the MIL for the wrong fault and allows

more precis diagnosis.

For example, if the PCM is storing a one trip fault

for the Oxygen Sensor and the EGR monitor, the

Task Manager may still run the EGR Monitor but

will suspend the results until the Oxygen Sensor

Monitor either passes or fails. At that point the Task

Manager can determine if the EGR system is actu-

ally failing or if an Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

25 - 6 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2568 of 2627

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.

²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

²If the MIL is ON and any other emissions DTC

was set (not an OBD II monitor), a good trip occurs

when the Oxygen Sensor Monitor and Catalyst Mon-

itor have been completed, or two minutes of engine

run time if the Oxygen Sensor Monitor and Catalyst

Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfireWarm-Up Cycles

Once the MIL has been extinguished by the Good

Trip Counter, the PCM automatically switches to a

Warm-Up Cycle Counter that can be viewed on the

DRB III. Warm-Up Cycles are used to erase DTCs

and Freeze Frames. Forty Warm-Up cycles must

occur in order for the PCM to self-erase a DTC and

Freeze Frame. A Warm-Up Cycle is defined as fol-

lows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

can determine under what vehicle operating condi-

tions the failure occurred.

The data stored in Freeze Frame is usually

recorded when a system fails the first time for two

trip faults. Freeze Frame data will only be overwrit-

ten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or

by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays informa-

tion about engine operation during a monitor. Abso-

lute MAP (engine load) and Engine RPM are stored

in this window when a failure occurs. There are two

different Similar conditions Windows: Fuel System

and Misfire.

FUEL SYSTEM

²Fuel System Similar Conditions WindowÐ

An indicator that 'Absolute MAP When Fuel Sys Fail'

and 'RPM When Fuel Sys Failed' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Fuel Sys FailÐ The

stored MAP reading at the time of failure. Informs

the user at what engine load the failure occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Fuel Sys FailÐ The stored RPM

reading at the time of failure. Informs the user at

what engine RPM the failure occurred.

DREMISSIONS CONTROL 25 - 7

EMISSIONS CONTROL (Continued)

Page 2569 of 2627

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²Upstream O2S VoltsÐ A live reading of the

Oxygen Sensor to indicate its performance. For

example, stuck lean, stuck rich, etc.

²SCW Time in Window (Similar Conditions

Window Time in Window)Ð A timer used by the

PCM that indicates that, after all Similar Conditions

have been met, if there has been enough good engine

running time in the SCW without failure detected.

This timer is used to increment a Good Trip.

²Fuel System Good Trip CounterÐATrip

Counter used to turn OFF the MIL for Fuel System

DTCs. To increment a Fuel System Good Trip, the

engine must be in the Similar Conditions Window,

Adaptive Memory Factor must be less than cali-

brated threshold and the Adaptive Memory Factor

must stay below that threshold for a calibrated

amount of time.

²Test Done This TripÐ Indicates that the

monitor has already been run and completed during

the current trip.

MISFIRE

²Same Misfire Warm-Up StateÐ Indicates if

the misfire occurred when the engine was warmed up

(above 160É F).

²In Similar Misfire WindowÐ An indicator

that 'Absolute MAP When Misfire Occurred' and

'RPM When Misfire Occurred' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Misfire OccurredÐ

The stored MAP reading at the time of failure.

Informs the user at what engine load the failure

occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Misfire OccurredÐ The stored

RPM reading at the time of failure. Informs the user

at what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²200 Rev CounterÐ Counts 0±100 720 degree

cycles.²SCW Cat 200 Rev CounterÐ Counts when in

similar conditions.

²SCW FTP 1000 Rev CounterÐ Counts 0±4

when in similar conditions.

²Misfire Good Trip CounterÐ Counts up to

three to turn OFF the MIL.

²Misfire DataÐ Data collected during test.

²Test Done This TripÐ Indicates YES when the

test is done.

OPERATION - NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

causing driveability problems. The PCM might not

store diagnostic trouble codes for these conditions.

However, problems with these systems may cause the

PCM to store diagnostic trouble codes for other sys-

tems or components.EXAMPLE:a fuel pressure

problem will not register a fault directly, but could

cause a rich/lean condition or misfire. This could

cause the PCM to store an oxygen sensor or misfire

diagnostic trouble code

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system, although it may set a fuel

system fault.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

25 - 8 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2582 of 2627

REMOVAL

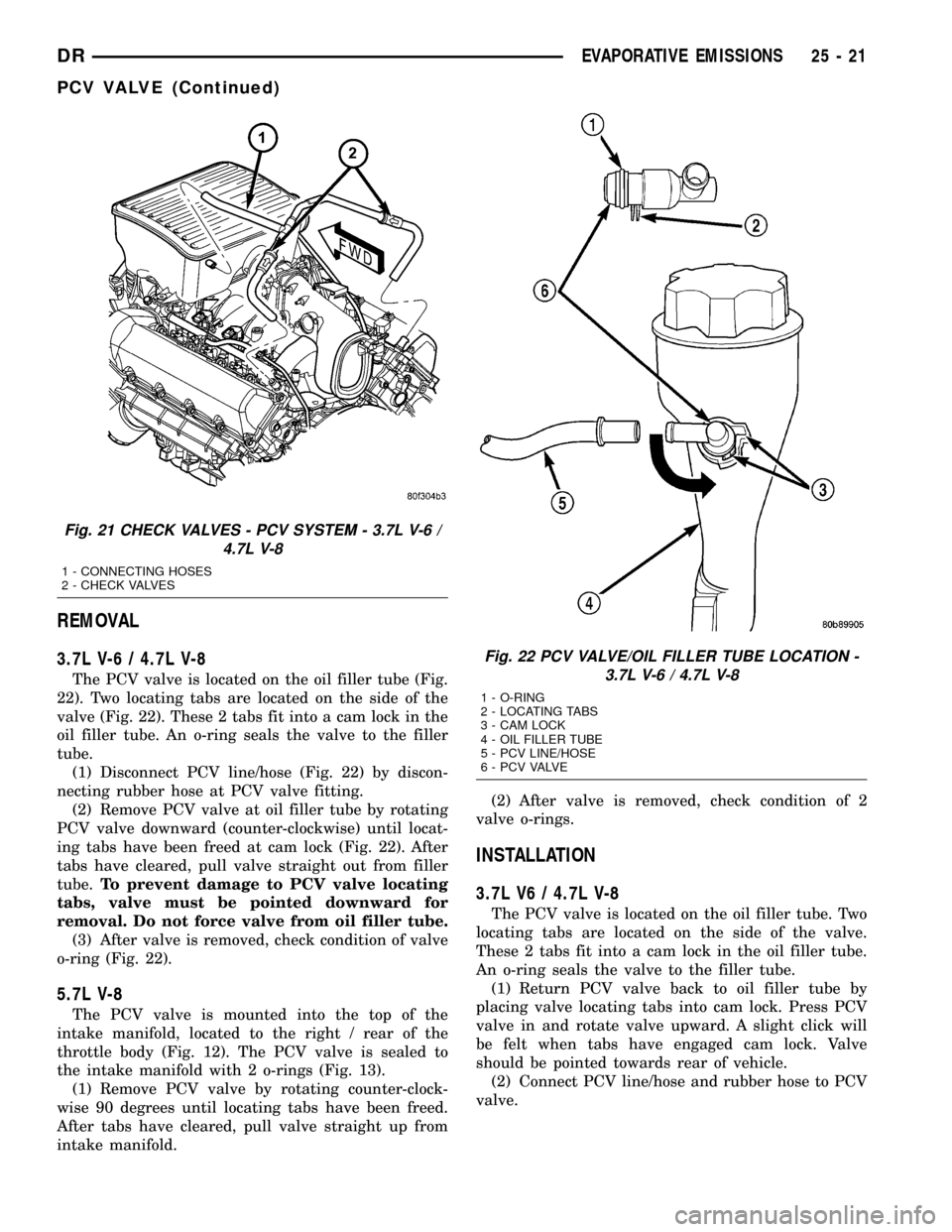

3.7L V-6 / 4.7L V-8

The PCV valve is located on the oil filler tube (Fig.

22). Two locating tabs are located on the side of the

valve (Fig. 22). These 2 tabs fit into a cam lock in the

oil filler tube. An o-ring seals the valve to the filler

tube.

(1) Disconnect PCV line/hose (Fig. 22) by discon-

necting rubber hose at PCV valve fitting.

(2) Remove PCV valve at oil filler tube by rotating

PCV valve downward (counter-clockwise) until locat-

ing tabs have been freed at cam lock (Fig. 22). After

tabs have cleared, pull valve straight out from filler

tube.To prevent damage to PCV valve locating

tabs, valve must be pointed downward for

removal. Do not force valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 22).

5.7L V-8

The PCV valve is mounted into the top of the

intake manifold, located to the right / rear of the

throttle body (Fig. 12). The PCV valve is sealed to

the intake manifold with 2 o-rings (Fig. 13).

(1) Remove PCV valve by rotating counter-clock-

wise 90 degrees until locating tabs have been freed.

After tabs have cleared, pull valve straight up from

intake manifold.(2) After valve is removed, check condition of 2

valve o-rings.

INSTALLATION

3.7L V6 / 4.7L V-8

The PCV valve is located on the oil filler tube. Two

locating tabs are located on the side of the valve.

These 2 tabs fit into a cam lock in the oil filler tube.

An o-ring seals the valve to the filler tube.

(1) Return PCV valve back to oil filler tube by

placing valve locating tabs into cam lock. Press PCV

valve in and rotate valve upward. A slight click will

be felt when tabs have engaged cam lock. Valve

should be pointed towards rear of vehicle.

(2) Connect PCV line/hose and rubber hose to PCV

valve.

Fig. 21 CHECK VALVES - PCV SYSTEM - 3.7L V-6 /

4.7L V-8

1 - CONNECTING HOSES

2 - CHECK VALVES

Fig. 22 PCV VALVE/OIL FILLER TUBE LOCATION -

3.7L V-6 / 4.7L V-8

1 - O-RING

2 - LOCATING TABS

3 - CAM LOCK

4 - OIL FILLER TUBE

5 - PCV LINE/HOSE

6 - P C V VA LV E

DREVAPORATIVE EMISSIONS 25 - 21

PCV VALVE (Continued)

Page 2583 of 2627

5.7L V-8

(1) Clean out intake manifold opening.

(2) Check condition of 2 o-rings on PCV valve.

(3) Apply engine oil to 2 o-rings.

(4) Place PCV valve into intake manifold and

rotate 90 degrees clockwise for installation.

VACUUM LINES

DESCRIPTION

A vacuum schematic for emission related items can

be found on the vehicles VECI label. Refer to Vehicle

Emission Control Information (VECI) Label for label

location.

VAPOR CANISTER

DESCRIPTION

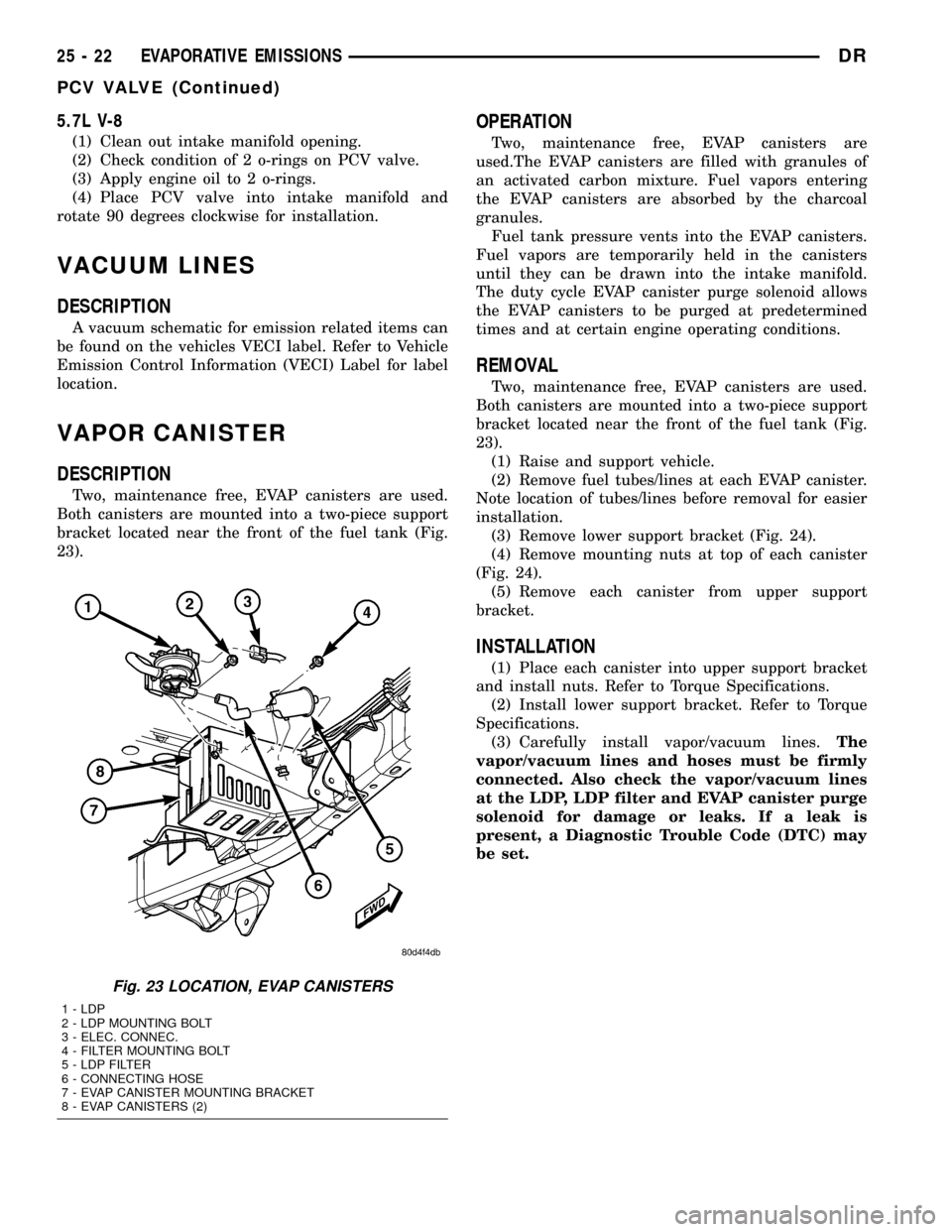

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

23).

OPERATION

Two, maintenance free, EVAP canisters are

used.The EVAP canisters are filled with granules of

an activated carbon mixture. Fuel vapors entering

the EVAP canisters are absorbed by the charcoal

granules.

Fuel tank pressure vents into the EVAP canisters.

Fuel vapors are temporarily held in the canisters

until they can be drawn into the intake manifold.

The duty cycle EVAP canister purge solenoid allows

the EVAP canisters to be purged at predetermined

times and at certain engine operating conditions.

REMOVAL

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

23).

(1) Raise and support vehicle.

(2) Remove fuel tubes/lines at each EVAP canister.

Note location of tubes/lines before removal for easier

installation.

(3) Remove lower support bracket (Fig. 24).

(4) Remove mounting nuts at top of each canister

(Fig. 24).

(5) Remove each canister from upper support

bracket.

INSTALLATION

(1) Place each canister into upper support bracket

and install nuts. Refer to Torque Specifications.

(2) Install lower support bracket. Refer to Torque

Specifications.

(3) Carefully install vapor/vacuum lines.The

vapor/vacuum lines and hoses must be firmly

connected. Also check the vapor/vacuum lines

at the LDP, LDP filter and EVAP canister purge

solenoid for damage or leaks. If a leak is

present, a Diagnostic Trouble Code (DTC) may

be set.

Fig. 23 LOCATION, EVAP CANISTERS

1 - LDP

2 - LDP MOUNTING BOLT

3 - ELEC. CONNEC.

4 - FILTER MOUNTING BOLT

5 - LDP FILTER

6 - CONNECTING HOSE

7 - EVAP CANISTER MOUNTING BRACKET

8 - EVAP CANISTERS (2)

25 - 22 EVAPORATIVE EMISSIONSDR

PCV VALVE (Continued)

Page 2605 of 2627

INTAKE AIR HEATER - OPERATION.......14-80

INTAKE AIR HEATER - REMOVAL........14-80

INTAKE AIR HEATER RELAY -

DESCRIPTION.......................14-82

INTAKE AIR HEATER RELAY -

INSTALLATION.......................14-82

INTAKE AIR HEATER RELAY -

OPERATION.........................14-82

INTAKE AIR HEATER RELAY - REMOVAL . . 14-82

INTAKE AIR TEMPERATURE SENSOR -

DESCRIPTION.......................14-30

INTAKE AIR TEMPERATURE SENSOR -

INSTALLATION.......................14-31

INTAKE AIR TEMPERATURE SENSOR -

OPERATION.........................14-30

INTAKE AIR TEMPERATURE SENSOR -

REMOVAL..........................14-30

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - DESCRIPTION..........14-82

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - INSTALLATION..........14-82

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - OPERATION............14-82

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - REMOVAL.............14-82

INTAKE MANIFOLD - CLEANING....9-160,9-226,

9-297

INTAKE MANIFOLD - DESCRIPTION . 9-159,9-225,

9-72

INTAKE MANIFOLD - INSPECTION . . 9-160,9-226,

9-297

INTAKE MANIFOLD - INSTALLATION.....9-160,

9-226,9-298,9-73

INTAKE MANIFOLD - REMOVAL....9-159,9-226,

9-297,9-73

INTAKE MANIFOLD LEAKAGE -

DIAGNOSIS AND TESTING........9-159,9-225

INTAKE MANIFOLD LEAKS - DIAGNOSIS

AND TESTING........................9-72

INTAKE SYSTEM - INSTALLATION, AIR....9-199

INTAKE SYSTEM - REMOVAL, AIR.......9-199

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION..............9-123,9-256,9-28

INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION...................9-124,9-30

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL......................9-124,9-29

INTEGRATED POWER MODULE -

DESCRIPTION.....................8W-97-3

INTEGRATED POWER MODULE -

INSTALLATION....................8W-97-4

INTEGRATED POWER MODULE -

OPERATION.......................8W-97-3

INTEGRATED POWER MODULE -

REMOVAL........................8W-97-3

INTERIOR - CAUTION.................23-62

INTERLOCK - ADJUSTMENTS, BRAKE

TRANSMISSION SHIFT.........21-196,21-365

INTERLOCK - DIAGNOSIS AND TESTING,

BRAKE TRANSMISSION SHIFT . . . 21-196,21-364

INTERLOCK SYSTEM - DESCRIPTION,

BRAKE TRANSMISSION SHIFT . . . 21-196,21-364

INTERLOCK SYSTEM - OPERATION,

BRAKE TRANSMISSION SHIFT . . . 21-196,21-364

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-5

INVERTED FLARING - STANDARD

PROCEDURE, DOUBLE.................5-10

IOD FUSE - DESCRIPTION...........8W-97-6

IOD FUSE - INSTALLATION...........8W-97-7

IOD FUSE - OPERATION.............8W-97-6

IOD FUSE - REMOVAL..............8W-97-7

ISO FLARING - STANDARD PROCEDURE

. . . 5-11

ISOLATORS - INSTALLATION, BODY

......23-37

ISOLATORS - REMOVAL, BODY

.........23-36

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL

....................2-19,2-34

JOINT - DIAGNOSIS AND TESTING,

UPPER BALL

.....................2-27,2-36

JOINT - INSTALLATION, LOWER BALL

. 2-20,2-35

JOINT - INSTALLATION, UPPER BALL

.....2-36

JOINT - REMOVAL, LOWER BALL

.....2-19,2-35

JOINT - REMOVAL, UPPER BALL

.........2-36

JOINT-INNER - INSTALLATION, CV

........3-25

JOINT-INNER - REMOVAL, CV

............3-25

JOINT-OUTER - INSTALLATION, CV

........3-23

JOINT-OUTER - REMOVAL, CV

...........3-22JOINTS - ASSEMBLY, DOUBLE CARDAN

UNIVERSAL..........................3-17

JOINTS - DISASSEMBLY, DOUBLE

CARDAN UNIVERSAL..................3-16

JOUNCE BUMPER - INSTALLATION.......2-43

JOUNCE BUMPER - REMOVAL...........2-43

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-272

JUMP STARTING - STANDARD

PROCEDURE.........................0-19

JUNCTION BLOCK - INSTALLATION,

BRAKE..............................5-24

JUNCTION BLOCK - REMOVAL, BRAKE....5-24

KEY CYLINDER - INSTALLATION.........19-12

KEY CYLINDER - REMOVAL............19-12

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-13

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY...............8E-15

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY.................8E-13

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY............................8E-15

KEY IMMOBILIZER MODULE (SKIM) -

DESCRIPTION, SENTRY................8Q-1

KEY IMMOBILIZER MODULE (SKIM) -

OPERATION, SENTRY..................8Q-2

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY..........8Q-5

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY...........8Q-5

KEY IMMOBILIZER SYSTEM

INITIALIZATION, STANDARD

PROCEDURE - SENTRY................8Q-3

KEY IMMOBILIZER SYSTEM (SKIS) -

DESCRIPTION, SENTRY................8Q-1

KEY IMMOBILIZER SYSTEM (SKIS) -

OPERATION, SENTRY..................8Q-2

KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE - SENTRY.......8Q-4

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH............19-11

KEY-IN IGNITION SWITCH -

DESCRIPTION.......................19-11

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE................8N-7

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE...............8N-8

KEYLESS ENTRY MODULE - OPERATION,

REMOTE............................8N-7

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE............................8N-7

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE..............8N-9

KNOB RELEASE - INSTALLATION, TILT

LEVER.............................19-16

KNOB RELEASE - REMOVAL, TILT LEVER . . 19-16

KNOCK SENSOR - DESCRIPTION.........8I-14

KNOCK SENSOR - INSTALLATION........8I-15

KNOCK SENSOR - OPERATION..........8I-14

KNOCK SENSOR - REMOVAL............8I-15

KNUCKLE - DESCRIPTION...............2-18

KNUCKLE - INSTALLATION..........2-19,2-37

KNUCKLE - OPERATION................2-18

KNUCKLE - REMOVAL..............2-18,2-37

LABEL - DESCRIPTION, VEHICLE

CERTIFICATION....................Intro.-11

LAMP - DESCRIPTION, DOME...........8L-26

LAMP - DESCRIPTION, READING........8L-28

LAMP - DESCRIPTION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - INSTALLATION, CAB CLEARANCE . 8L-12

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP - INSTALLATION, DOME..........8L-26

LAMP - INSTALLATION, FENDER

MARKER

...........................8L-18

LAMP - INSTALLATION, FOG

............8L-12

LAMP - INSTALLATION, LICENSE PLATE

. . 8L-17

LAMP - INSTALLATION, PARK/TURN

SIGNAL

............................8L-21

LAMP - INSTALLATION, READING

........8L-29LAMP - INSTALLATION, TAILGATE

MARKER...........................8L-18

LAMP - INSTALLATION, UNDERHOOD....8L-25

LAMP - OPERATION, DOME............8L-26

LAMP - OPERATION, READING..........8L-28

LAMP - OPERATION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - REMOVAL, CAB CLEARANCE.....8L-11

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP - REMOVAL, DOME..............8L-26

LAMP - REMOVAL, FENDER MARKER....8L-17

LAMP - REMOVAL, FOG...............8L-12

LAMP - REMOVAL, LICENSE PLATE......8L-17

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-21

LAMP - REMOVAL, READING...........8L-28

LAMP - REMOVAL, TAILGATE MARKER . . . 8L-18

LAMP - REMOVAL, UNDERHOOD........8L-25

LAMP INDICATOR - DESCRIPTION,

CARGO.............................8J-20

LAMP INDICATOR - OPERATION, CARGO . . 8J-20

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-31

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR.............8J-31

LAMP OUT INDICATOR - DESCRIPTION . . . 8J-29

LAMP OUT INDICATOR - OPERATION.....8J-29

LAMP RELAY - DESCRIPTION, FOG......8L-12

LAMP RELAY - DESCRIPTION, PARK.....8L-20

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-20

LAMP RELAY - INSTALLATION, FOG......8L-13

LAMP RELAY - INSTALLATION, PARK.....8L-21

LAMP RELAY - OPERATION, FOG........8L-13

LAMP RELAY - OPERATION, PARK.......8L-20

LAMP RELAY - REMOVAL, FOG.........8L-13

LAMP RELAY - REMOVAL, PARK........8L-21

LAMP REPLACEMENT - STANDARD

PROCEDURE, MODULE................8M-3

LAMP REPLACEMENT - STANDARD

PROCEDURE, READING/COURTESY.......8M-3

LAMP SWITCH - DESCRIPTION, BACKUP . . . 8L-8

LAMP SWITCH - DESCRIPTION, BRAKE....8L-9

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP.....................8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE.....................8L-10

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-11

LAMP SWITCH - OPERATION, BACKUP....8L-8

LAMP SWITCH - OPERATION, BRAKE......8L-9

LAMP SWITCH - REMOVAL, BRAKE......8L-10

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-11

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-17

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-25

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-17

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-25

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-7

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-3

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-2

LAMP/SWITCH - INSTALLATION, GLOVE

BOX ...............................8L-28

LAMP/SWITCH - REMOVAL, GLOVE BOX . . 8L-27

LASH ADJUSTER - DIAGNOSIS AND

TESTING, HYDRAULIC.............9-125,9-32

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE.......9-259

LATCH - INSTALLATION.....23-16,23-23,23-32,

23-47

LATCH - INSTALLATION, GLOVE BOX.....23-52

LATCH - INSTALLATION, UNDER SEAT

STORAGE BIN.......................23-80

LATCH - REMOVAL

....23-16,23-23,23-32,23-47

LATCH - REMOVAL, GLOVE BOX

.........23-52

LATCH - REMOVAL, UNDER SEAT

STORAGE BIN

.......................23-80

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - INSTALLATION

............23-47

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - REMOVAL

................23-47

18 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2607 of 2627

LUBRICATION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS.......9-187,9-7

LUBRICATION - OPERATION . . . 9-150,9-289,9-61

LUBRICATION - STANDARD PROCEDURE . . 19-34

LUBRICATION - STANDARD PROCEDURE,

BODY...............................23-3

LUMBAR CONTROL SWITCH -

DESCRIPTION.......................8N-17

LUMBAR CONTROL SWITCH -

OPERATION.........................8N-18

LUMBAR CONTROL SWITCH - REMOVAL . 8N-18

LUMBAR MOTOR - DESCRIPTION.......8N-18

LUMBAR MOTOR - DIAGNOSIS AND

TESTING...........................8N-18

LUMBAR MOTOR - OPERATION.........8N-18

LUMBAR SUPPORT HANDLE/BEZEL -

INSTALLATION.......................23-82

LUMBAR SUPPORT HANDLE/BEZEL -

REMOVAL..........................23-82

MAIN BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT.......9-134,9-207

MAIN BEARING CLEARANCE -

STANDARD PROCEDURE...............9-274

MAIN BEARING FITTING, STANDARD

PROCEDURE.........................9-44

MAIN BEARINGS - INSPECTION,

CRANKSHAFT..................9-135,9-208

MAINTENANCE SCHEDULES, 24-VALVE

CUMMINS TURBO DIESEL..............0-12

MALFUNCTION INDICATOR LAMP (MIL) -

DESCRIPTION.......................8J-31

MALFUNCTION INDICATOR LAMP (MIL) -

OPERATION.........................8J-31

MANAGER - DESCRIPTION, TASK.........25-1

MANAGER - OPERATION, TASK..........25-5

MANIFOLD - CLEANING, EXHAUST . 9-163,9-226,

9-298

MANIFOLD - CLEANING, INTAKE . . . 9-160,9-226,

9-297

MANIFOLD - DESCRIPTION, EXHAUST . . . 9-161,

9-226,9-74

MANIFOLD - DESCRIPTION, INTAKE.....9-159,

9-225,9-72

MANIFOLD - INSPECTION, EXHAUST.....9-163,

9-227,9-298

MANIFOLD - INSPECTION, INTAKE . 9-160,9-226,

9-297

MANIFOLD - INSTALLATION, EXHAUST . . . 9-164,

9-227,9-298,9-74

MANIFOLD - INSTALLATION, INTAKE.....9-160,

9-226,9-298,9-73

MANIFOLD - OPERATION, EXHAUST......9-226

MANIFOLD - REMOVAL, EXHAUST . . 9-161,9-226,

9-298,9-74

MANIFOLD - REMOVAL, INTAKE . . . 9-159,9-226,

9-297,9-73

MANIFOLD LEAKAGE - DIAGNOSIS AND

TESTING, INTAKE...............9-159,9-225

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE.....................9-72

MANUAL - INSTALLATION, WINDOW

REGULATOR...................23-27,23-35

MANUAL - REMOVAL, WINDOW

REGULATOR...................23-26,23-35

MANUAL BLEEDING - STANDARD

PROCEDURE..........................5-5

MANUAL TRANSMISSION -

DESCRIPTION.........................0-4

MANUAL TRANSMISSION - NV3500 -

ASSEMBLY..........................21-17

MANUAL TRANSMISSION - NV3500 -

CLEANING..........................21-15

MANUAL TRANSMISSION - NV3500 -

DESCRIPTION........................21-1

MANUAL TRANSMISSION - NV3500 -

DIAGNOSIS AND TESTING..............21-3

MANUAL TRANSMISSION - NV3500 -

DISASSEMBLY........................21-4

MANUAL TRANSMISSION - NV3500 -

INSPECTION

........................21-16

MANUAL TRANSMISSION - NV3500 -

INSTALLATION

.......................21-39

MANUAL TRANSMISSION - NV3500 -

OPERATION

..........................21-1

MANUAL TRANSMISSION - NV3500 -

REMOVAL

...........................21-3

MANUAL TRANSMISSION - NV3500 -

SPECIAL TOOLS

.....................21-40MANUAL TRANSMISSION - NV3500 -

SPECIFICATIONS.....................21-40

MANUAL TRANSMISSION - NV4500 -

ASSEMBLY..........................21-63

MANUAL TRANSMISSION - NV4500 -

CLEANING..........................21-62

MANUAL TRANSMISSION - NV4500 -

DESCRIPTION.......................21-43

MANUAL TRANSMISSION - NV4500 -

DIAGNOSIS AND TESTING.............21-44

MANUAL TRANSMISSION - NV4500 -

DISASSEMBLY.......................21-46

MANUAL TRANSMISSION - NV4500 -

INSPECTION........................21-62

MANUAL TRANSMISSION - NV4500 -

INSTALLATION.......................21-80

MANUAL TRANSMISSION - NV4500 -

OPERATION.........................21-43

MANUAL TRANSMISSION - NV4500 -

REMOVAL..........................21-44

MANUAL TRANSMISSION - NV4500 -

SPECIAL TOOLS.....................21-81

MANUAL TRANSMISSION - NV4500 -

SPECIFICATIONS.....................21-81

MANUAL TRANSMISSION - NV5600 -

ASSEMBLY.........................21-106

MANUAL TRANSMISSION - NV5600 -

DESCRIPTION.......................21-88

MANUAL TRANSMISSION - NV5600 -

DIAGNOSIS AND TESTING.............21-90

MANUAL TRANSMISSION - NV5600 -

DISASSEMBLY.......................21-91

MANUAL TRANSMISSION - NV5600 -

INSPECTION.........................21-106

MANUAL TRANSMISSION - NV5600 -

INSTALLATION......................21-121

MANUAL TRANSMISSION - NV5600 -

OPERATION.........................21-90

MANUAL TRANSMISSION - NV5600 -

REMOVAL..........................21-90

MANUAL TRANSMISSION - NV5600 -

SPECIAL TOOLS....................21-123

MAP SENSOR - DESCRIPTION.....14-32,14-83

MAP SENSOR - INSTALLATION..........14-34

MAP SENSOR - OPERATION............14-32

MAP SENSOR - REMOVAL.............14-33

MARKER LAMP - INSTALLATION,

FENDER............................8L-18

MARKER LAMP - INSTALLATION,

TAILGATE...........................8L-18

MARKER LAMP - REMOVAL, FENDER....8L-17

MARKER LAMP - REMOVAL, TAILGATE . . . 8L-18

MASTER CYLINDER - DESCRIPTION......5-24

MASTER CYLINDER - OPERATION........5-25

MASTER CYLINDER BLEEDING -

STANDARD PROCEDURE................5-26

MASTER CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING..............5-25

MATCH MOUNTING - STANDARD

PROCEDURE.........................22-3

MATCHING TIRE - DESCRIPTION, FULL

SIZE, SPARE WHEEL WITH.............22-15

MATS - INSTALLATION, CARPETS AND

FLOOR.............................23-65

MATS - REMOVAL, CARPETS AND

FLOOR.............................23-65

MEASUREMENT - 4WD (LD) -

STANDARD PROCEDURE, HEIGHT.........2-3

MEASURING TIMING CHAIN WEAR -

STANDARD PROCEDURE...............9-167

MEASURING TIMING CHAIN WEAR,

STANDARD PROCEDURE................9-77

MECHANICAL - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS.....9-185,9-188,

9-233,9-6,9-92

MECHANISM - DESCRIPTION, SHIFT....21-252,

21-398

MECHANISM - INSTALLATION, SHIFT.....21-87

MECHANISM - OPERATION, SHIFT......21-252,

21-398

MECHANISM - REMOVAL, SHIFT

........21-86

METRIC SYSTEM - DESCRIPTION

......Intro.-8

MICRO 420 BATTERY TESTER -

STANDARD PROCEDURE, USING

........8F-12

MILE, SPECIFICATIONS - TIRE

REVOLUTIONS PER

...................22-10

MINI-TRIP COMPUTER - DIAGNOSIS

AND TESTING, COMPASS

..............8M-6MIRROR - DESCRIPTION, AUTOMATIC

DAY / NIGHT........................8N-11

MIRROR - DIAGNOSIS AND TESTING,

AUTOMATIC DAY / NIGHT..............8N-11

MIRROR - INSTALLATION, SIDE VIEW....23-42

MIRROR - OPERATION, AUTOMATIC DAY

/ NIGHT............................8N-11

MIRROR - REMOVAL, AUTOMATIC DAY /

NIGHT.............................8N-12

MIRROR - REMOVAL, REAR VIEW.......23-69

MIRROR - REMOVAL, SIDE VIEW........23-41

MIRROR - REMOVAL, SIDEVIEW........8N-12

MIRROR FLAG - INSTALLATION, SIDE

VIEW..............................23-27

MIRROR FLAG - REMOVAL, SIDE VIEW . . . 23-27

MIRROR GLASS - INSTALLATION, SIDE

VIEW..............................23-43

MIRROR GLASS - REMOVAL, SIDE VIEW . . 23-42

MIRROR SUPPORT BRACKET -

INSTALLATION, REAR VIEW............23-70

MIRROR SWITCH - DIAGNOSIS AND

TESTING, POWER....................8N-12

MIRROR SWITCH - REMOVAL, POWER . . . 8N-12

MIRRORS - DESCRIPTION, HEATED.......8G-6

MIRRORS - DESCRIPTION, POWER......8N-10

MIRRORS - DIAGNOSIS AND TESTING,

POWER............................8N-10

MIRRORS - OPERATION, HEATED........8G-6

MIRRORS - OPERATION, POWER........8N-10

MODE - DESCRIPTION, CIRCUIT

ACTUATION TEST.....................25-1

MODE - DESCRIPTION, STATE DISPLAY

TEST...............................25-1

MODE DOOR - INSTALLATION..........24-38

MODE DOOR - REMOVAL..............24-38

MODE DOOR ACTUATOR - DESCRIPTION . . 24-23

MODE DOOR ACTUATOR -

INSTALLATION.......................24-23

MODE DOOR ACTUATOR - OPERATION . . . 24-23

MODE DOOR ACTUATOR - REMOVAL.....24-23

MODE SENSOR - DESCRIPTION . . 21-509,21-538,

21-573

MODE SENSOR - OPERATION . . . 21-509,21-539,

21-573

MODES OF OPERATION - DESCRIPTION....8E-7

MODES, STANDARD PROCEDURE -

CONFIGURING A NEW MODULE /

SWITCH OPERATING...................8Q-3

MODULE - DESCRIPTION, AIRBAG

CONTROL..........................8O-11

MODULE - DESCRIPTION, DRIVER DOOR . . 8N-5

MODULE - DESCRIPTION, FRONT

CONTROL........................8W-97-5

MODULE - DESCRIPTION, FRONT

CONTROL...........................8E-5

MODULE - DESCRIPTION, FUEL PUMP....14-11

MODULE - DESCRIPTION, FUEL TANK....14-63

MODULE - DESCRIPTION, HEATED SEAT . . . 8E-6

MODULE - DESCRIPTION, HEATED SEAT . . 8G-13

MODULE - DESCRIPTION, INTEGRATED

POWER..........................8W-97-3

MODULE - DESCRIPTION, REMOTE

KEYLESS ENTRY......................8N-7

MODULE - DESCRIPTION, SENTRY KEY

IMMOBILIZER.......................8E-13

MODULE - DESCRIPTION, TRANSFER

CASE CONTROL......................8E-16

MODULE - DESCRIPTION,

TRANSMISSION CONTROL.............8E-20

MODULE - DESCRIPTION, WIPER.......8R-22

MODULE - DIAGNOSIS AND TESTING,

DRIVER DOOR.......................8N-6

MODULE - DIAGNOSIS AND TESTING,

FRONT CONTROL..................8W-97-5

MODULE - DIAGNOSIS AND TESTING,

FRONT CONTROL.....................8E-5

MODULE - DIAGNOSIS AND TESTING,

HEATED SEAT ........................8E-6

MODULE - DIAGNOSIS AND TESTING,

HEATED SEAT

.......................8G-14

MODULE - DIAGNOSIS AND TESTING,

REMOTE KEYLESS ENTRY

..............8N-7

MODULE - INSTALLATION, AIRBAG

CONTROL

..........................8O-13

MODULE - INSTALLATION, DRIVER

DOOR

..............................8N-7

MODULE - INSTALLATION, ENGINE

CONTROL

...........................8E-4

20 INDEXDR

Description Group-Page Description Group-Page Description Group-Page