Transfer case DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2248 of 2627

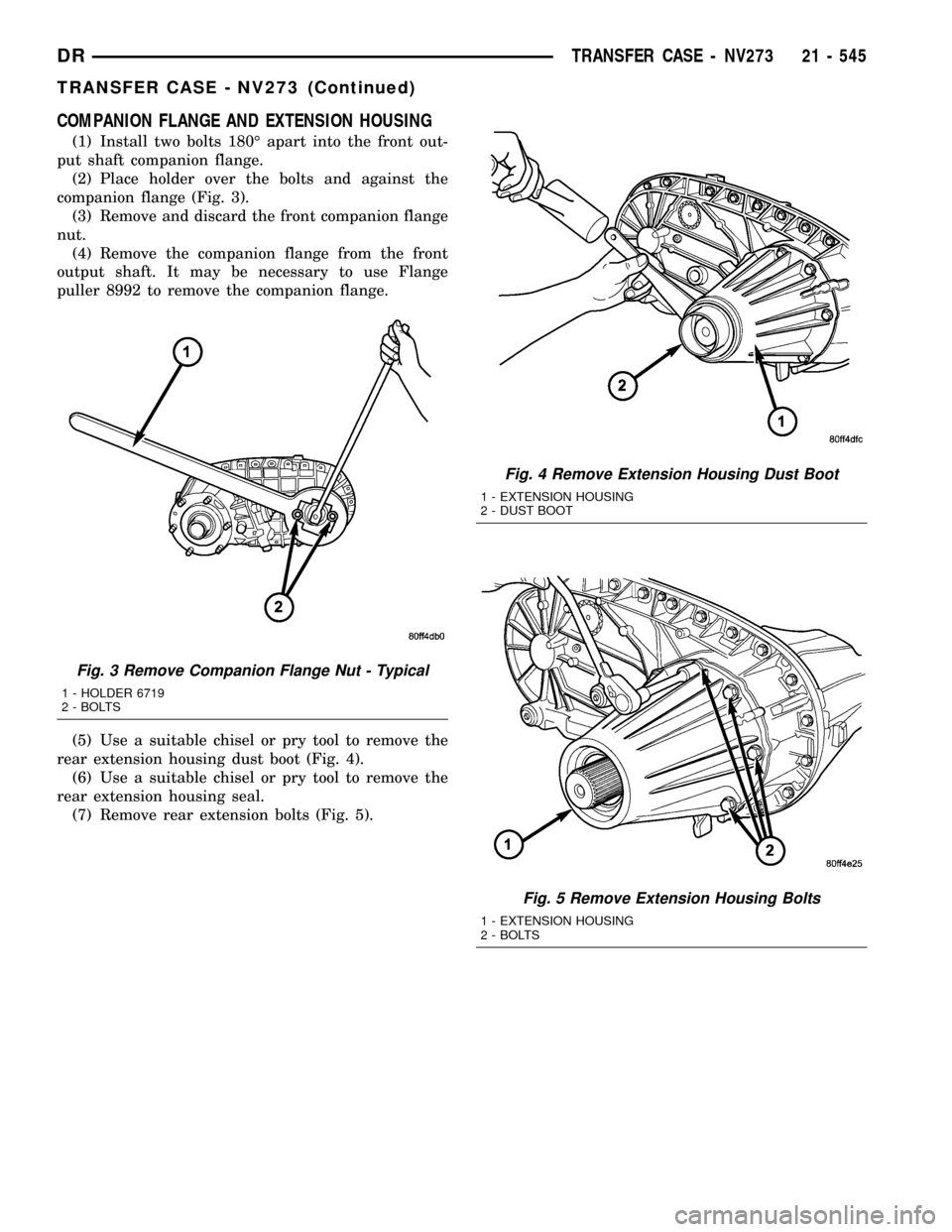

COMPANION FLANGE AND EXTENSION HOUSING

(1) Install two bolts 180É apart into the front out-

put shaft companion flange.

(2) Place holder over the bolts and against the

companion flange (Fig. 3).

(3) Remove and discard the front companion flange

nut.

(4) Remove the companion flange from the front

output shaft. It may be necessary to use Flange

puller 8992 to remove the companion flange.

(5) Use a suitable chisel or pry tool to remove the

rear extension housing dust boot (Fig. 4).

(6) Use a suitable chisel or pry tool to remove the

rear extension housing seal.

(7) Remove rear extension bolts (Fig. 5).

Fig. 3 Remove Companion Flange Nut - Typical

1 - HOLDER 6719

2 - BOLTS

Fig. 4 Remove Extension Housing Dust Boot

1 - EXTENSION HOUSING

2 - DUST BOOT

Fig. 5 Remove Extension Housing Bolts

1 - EXTENSION HOUSING

2 - BOLTS

DRTRANSFER CASE - NV273 21 - 545

TRANSFER CASE - NV273 (Continued)

Page 2249 of 2627

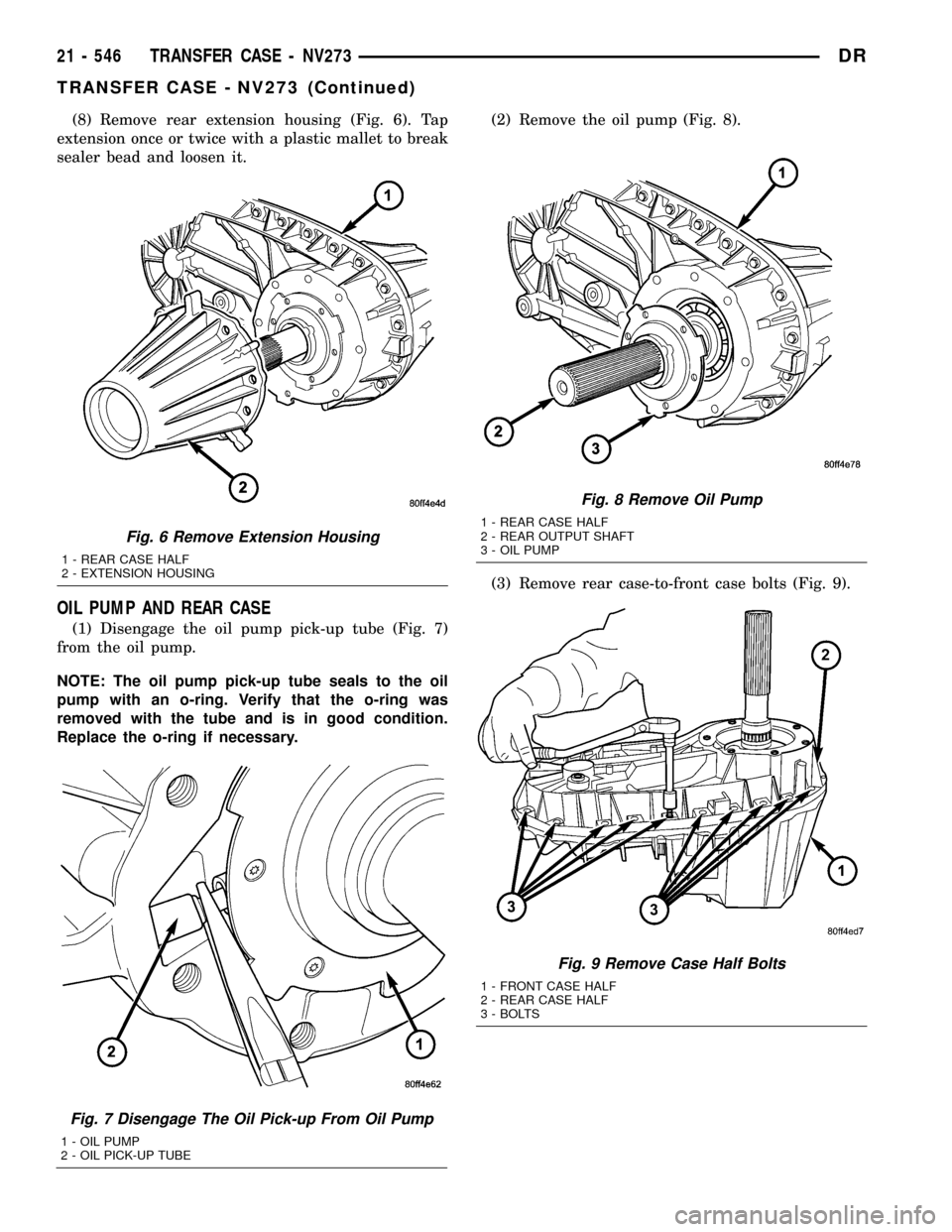

(8) Remove rear extension housing (Fig. 6). Tap

extension once or twice with a plastic mallet to break

sealer bead and loosen it.

OIL PUMP AND REAR CASE

(1) Disengage the oil pump pick-up tube (Fig. 7)

from the oil pump.

NOTE: The oil pump pick-up tube seals to the oil

pump with an o-ring. Verify that the o-ring was

removed with the tube and is in good condition.

Replace the o-ring if necessary.(2) Remove the oil pump (Fig. 8).

(3) Remove rear case-to-front case bolts (Fig. 9).

Fig. 7 Disengage The Oil Pick-up From Oil Pump

1 - OIL PUMP

2 - OIL PICK-UP TUBE

Fig. 6 Remove Extension Housing

1 - REAR CASE HALF

2 - EXTENSION HOUSING

Fig. 8 Remove Oil Pump

1 - REAR CASE HALF

2 - REAR OUTPUT SHAFT

3 - OIL PUMP

Fig. 9 Remove Case Half Bolts

1 - FRONT CASE HALF

2 - REAR CASE HALF

3 - BOLTS

21 - 546 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2250 of 2627

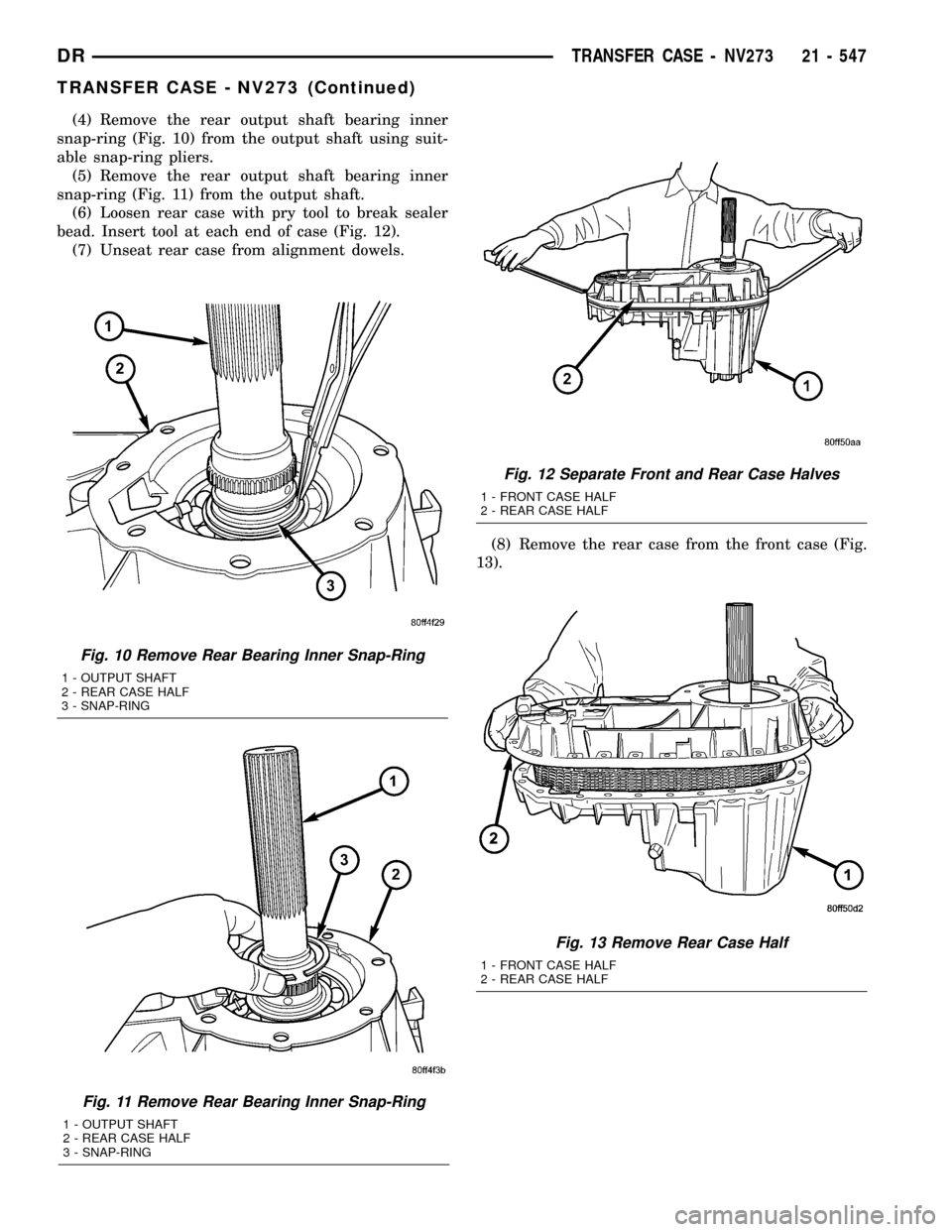

(4) Remove the rear output shaft bearing inner

snap-ring (Fig. 10) from the output shaft using suit-

able snap-ring pliers.

(5) Remove the rear output shaft bearing inner

snap-ring (Fig. 11) from the output shaft.

(6) Loosen rear case with pry tool to break sealer

bead. Insert tool at each end of case (Fig. 12).

(7) Unseat rear case from alignment dowels.

(8) Remove the rear case from the front case (Fig.

13).

Fig. 10 Remove Rear Bearing Inner Snap-Ring

1 - OUTPUT SHAFT

2 - REAR CASE HALF

3 - SNAP-RING

Fig. 11 Remove Rear Bearing Inner Snap-Ring

1 - OUTPUT SHAFT

2 - REAR CASE HALF

3 - SNAP-RING

Fig. 12 Separate Front and Rear Case Halves

1 - FRONT CASE HALF

2 - REAR CASE HALF

Fig. 13 Remove Rear Case Half

1 - FRONT CASE HALF

2 - REAR CASE HALF

DRTRANSFER CASE - NV273 21 - 547

TRANSFER CASE - NV273 (Continued)

Page 2251 of 2627

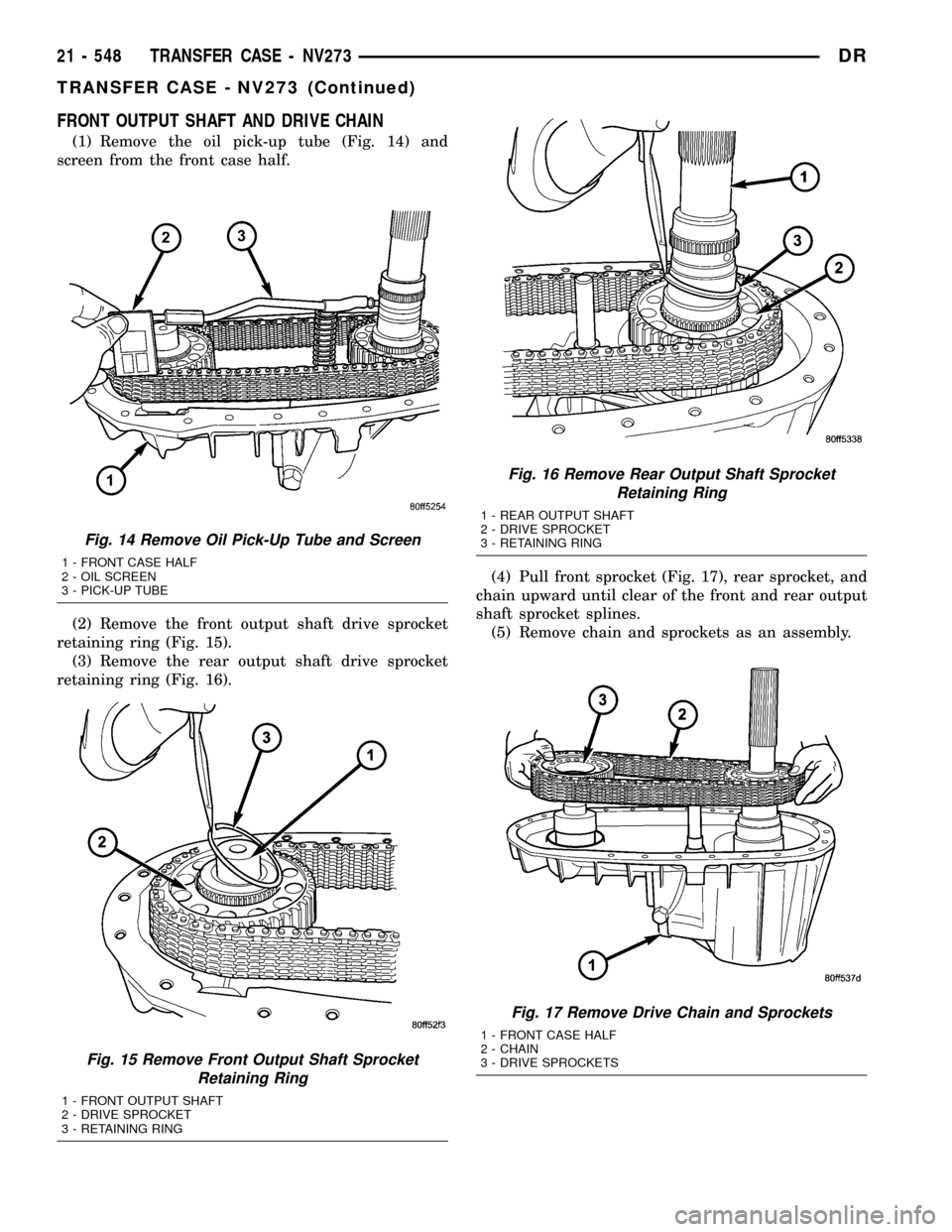

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Remove the oil pick-up tube (Fig. 14) and

screen from the front case half.

(2) Remove the front output shaft drive sprocket

retaining ring (Fig. 15).

(3) Remove the rear output shaft drive sprocket

retaining ring (Fig. 16).(4) Pull front sprocket (Fig. 17), rear sprocket, and

chain upward until clear of the front and rear output

shaft sprocket splines.

(5) Remove chain and sprockets as an assembly.

Fig. 14 Remove Oil Pick-Up Tube and Screen

1 - FRONT CASE HALF

2 - OIL SCREEN

3 - PICK-UP TUBE

Fig. 15 Remove Front Output Shaft Sprocket

Retaining Ring

1 - FRONT OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 16 Remove Rear Output Shaft Sprocket

Retaining Ring

1 - REAR OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 17 Remove Drive Chain and Sprockets

1 - FRONT CASE HALF

2 - CHAIN

3 - DRIVE SPROCKETS

21 - 548 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2252 of 2627

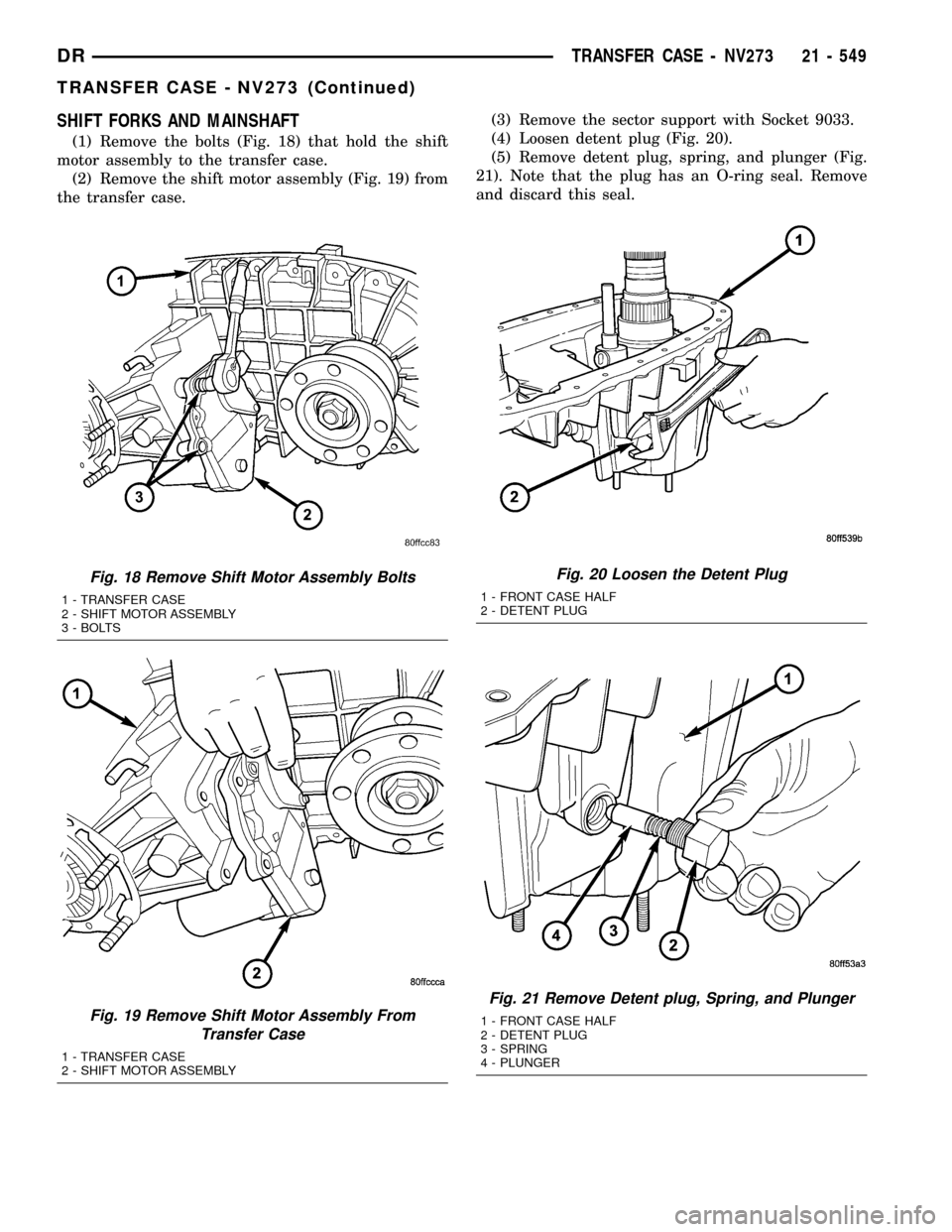

SHIFT FORKS AND MAINSHAFT

(1) Remove the bolts (Fig. 18) that hold the shift

motor assembly to the transfer case.

(2) Remove the shift motor assembly (Fig. 19) from

the transfer case.(3) Remove the sector support with Socket 9033.

(4) Loosen detent plug (Fig. 20).

(5) Remove detent plug, spring, and plunger (Fig.

21). Note that the plug has an O-ring seal. Remove

and discard this seal.

Fig. 18 Remove Shift Motor Assembly Bolts

1 - TRANSFER CASE

2 - SHIFT MOTOR ASSEMBLY

3 - BOLTS

Fig. 19 Remove Shift Motor Assembly From

Transfer Case

1 - TRANSFER CASE

2 - SHIFT MOTOR ASSEMBLY

Fig. 20 Loosen the Detent Plug

1 - FRONT CASE HALF

2 - DETENT PLUG

Fig. 21 Remove Detent plug, Spring, and Plunger

1 - FRONT CASE HALF

2 - DETENT PLUG

3 - SPRING

4 - PLUNGER

DRTRANSFER CASE - NV273 21 - 549

TRANSFER CASE - NV273 (Continued)

Page 2253 of 2627

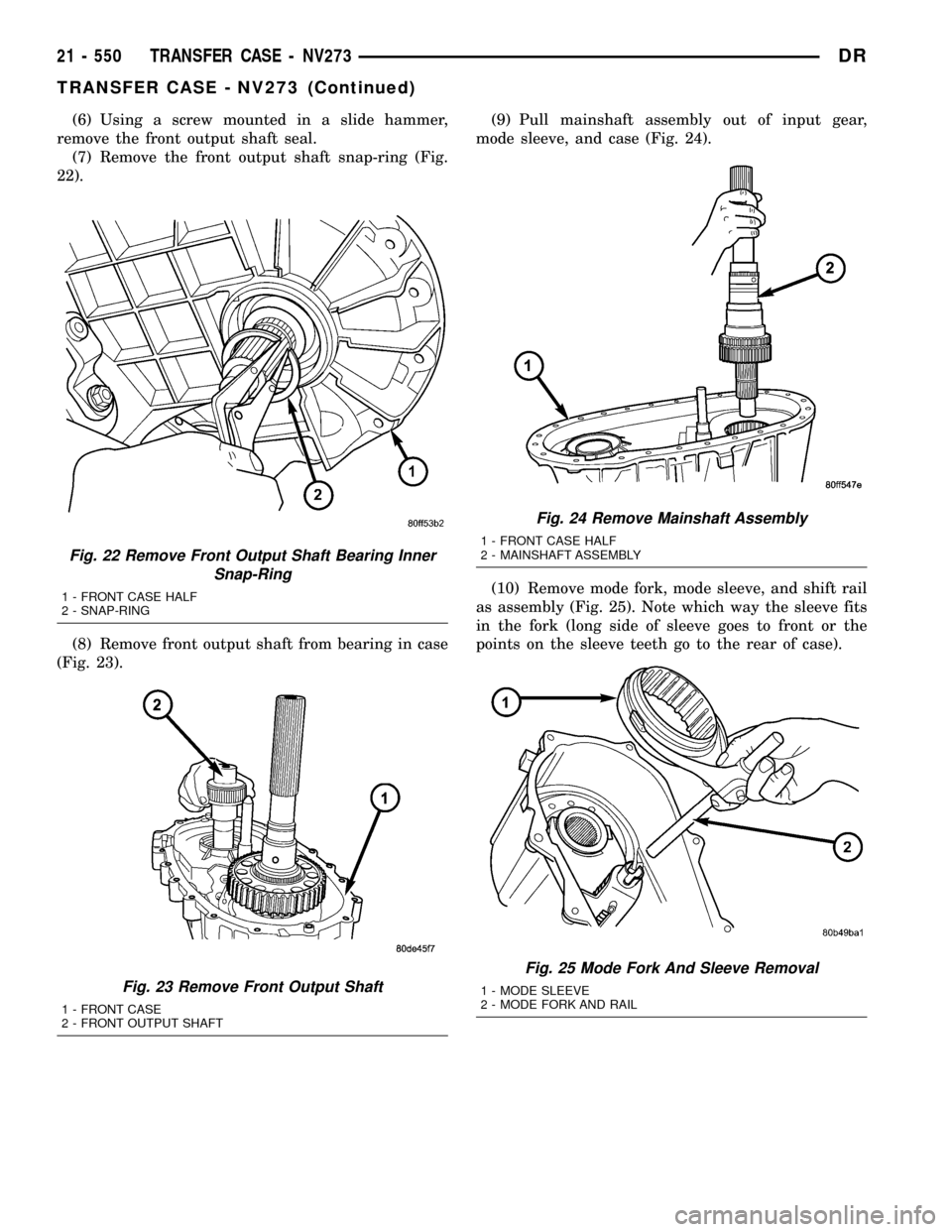

(6) Using a screw mounted in a slide hammer,

remove the front output shaft seal.

(7) Remove the front output shaft snap-ring (Fig.

22).

(8) Remove front output shaft from bearing in case

(Fig. 23).(9) Pull mainshaft assembly out of input gear,

mode sleeve, and case (Fig. 24).

(10) Remove mode fork, mode sleeve, and shift rail

as assembly (Fig. 25). Note which way the sleeve fits

in the fork (long side of sleeve goes to front or the

points on the sleeve teeth go to the rear of case).

Fig. 22 Remove Front Output Shaft Bearing Inner

Snap-Ring

1 - FRONT CASE HALF

2 - SNAP-RING

Fig. 23 Remove Front Output Shaft

1 - FRONT CASE

2 - FRONT OUTPUT SHAFT

Fig. 24 Remove Mainshaft Assembly

1 - FRONT CASE HALF

2 - MAINSHAFT ASSEMBLY

Fig. 25 Mode Fork And Sleeve Removal

1 - MODE SLEEVE

2 - MODE FORK AND RAIL

21 - 550 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2254 of 2627

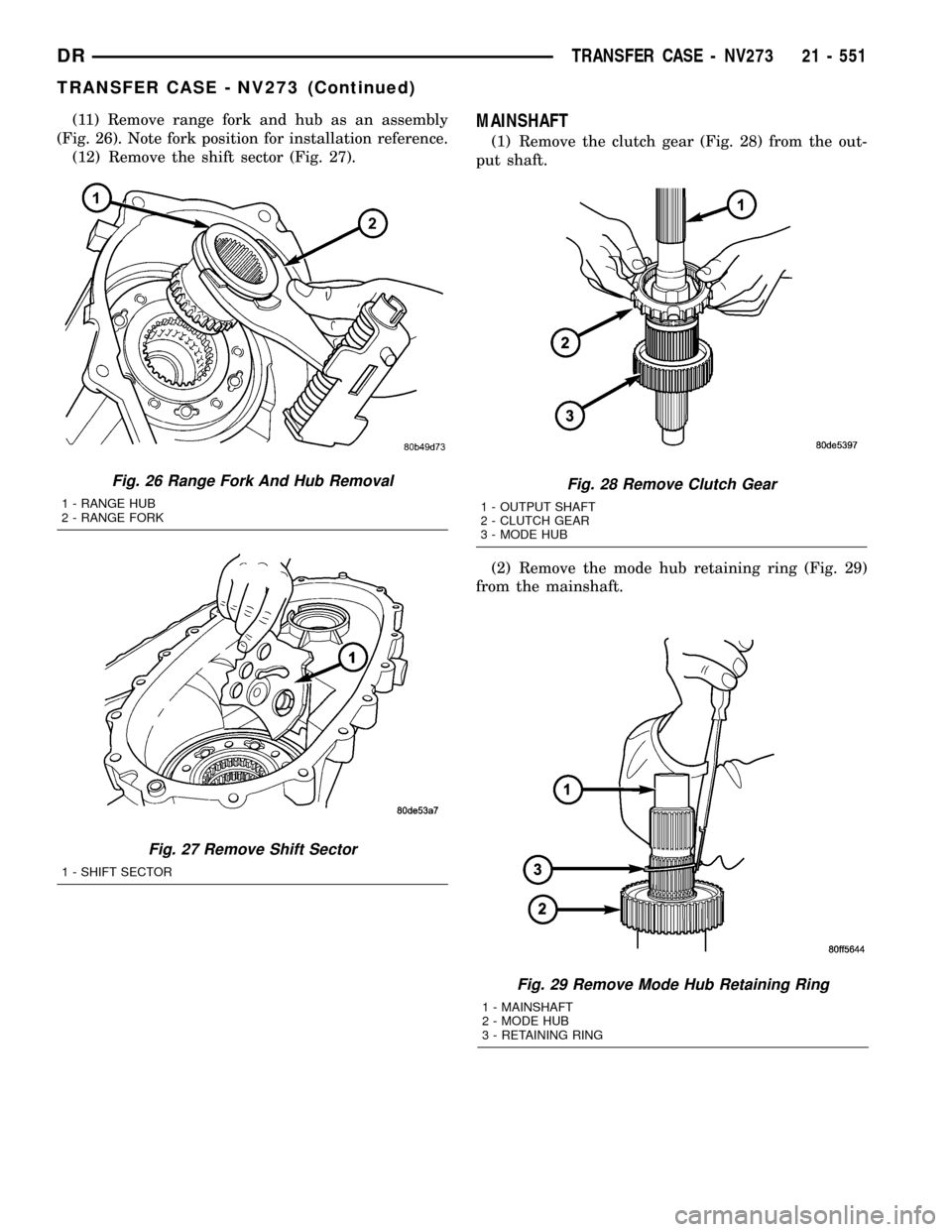

(11) Remove range fork and hub as an assembly

(Fig. 26). Note fork position for installation reference.

(12) Remove the shift sector (Fig. 27).MAINSHAFT

(1) Remove the clutch gear (Fig. 28) from the out-

put shaft.

(2) Remove the mode hub retaining ring (Fig. 29)

from the mainshaft.

Fig. 29 Remove Mode Hub Retaining Ring

1 - MAINSHAFT

2 - MODE HUB

3 - RETAINING RING

Fig. 26 Range Fork And Hub Removal

1 - RANGE HUB

2 - RANGE FORK

Fig. 27 Remove Shift Sector

1 - SHIFT SECTOR

Fig. 28 Remove Clutch Gear

1 - OUTPUT SHAFT

2 - CLUTCH GEAR

3 - MODE HUB

DRTRANSFER CASE - NV273 21 - 551

TRANSFER CASE - NV273 (Continued)

Page 2255 of 2627

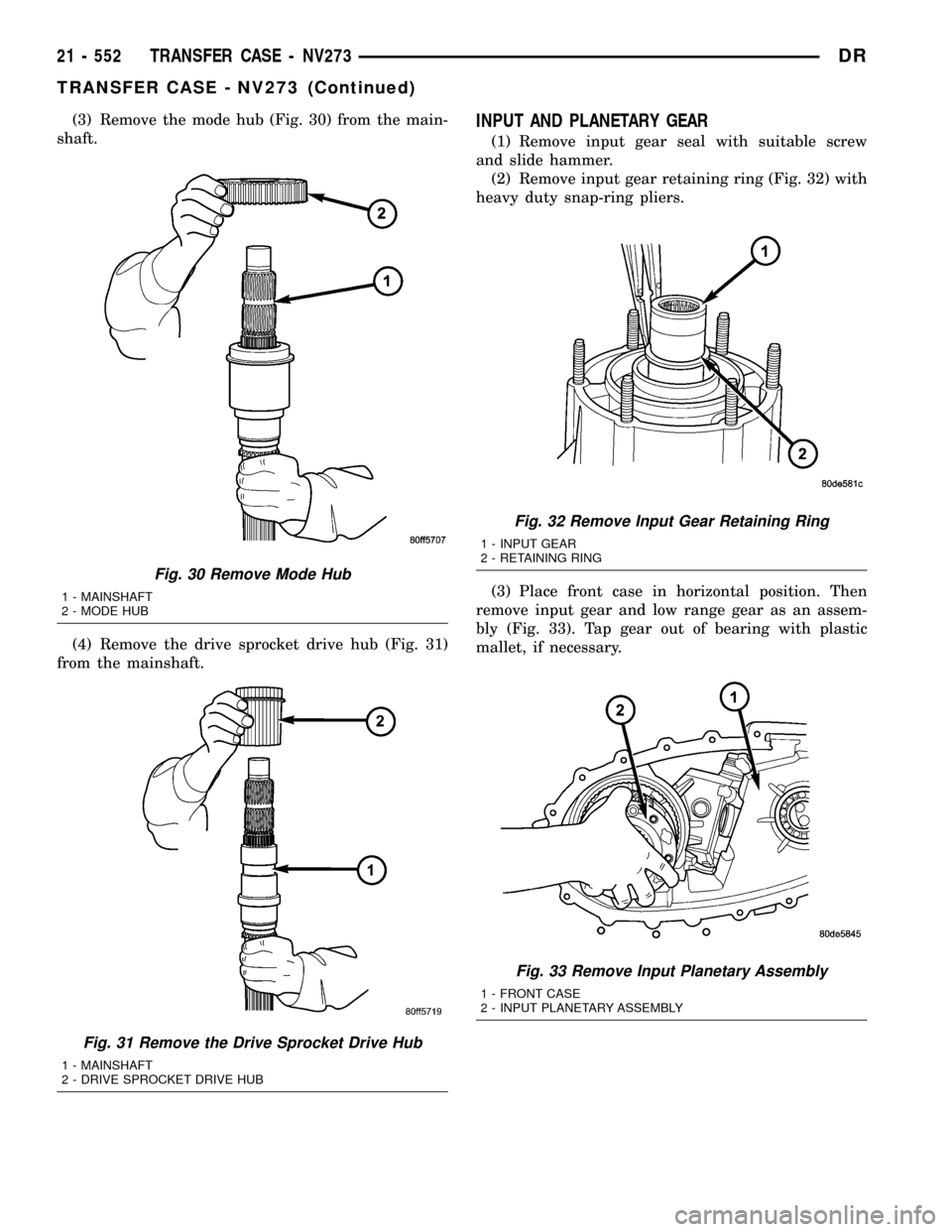

(3) Remove the mode hub (Fig. 30) from the main-

shaft.

(4) Remove the drive sprocket drive hub (Fig. 31)

from the mainshaft.INPUT AND PLANETARY GEAR

(1) Remove input gear seal with suitable screw

and slide hammer.

(2) Remove input gear retaining ring (Fig. 32) with

heavy duty snap-ring pliers.

(3) Place front case in horizontal position. Then

remove input gear and low range gear as an assem-

bly (Fig. 33). Tap gear out of bearing with plastic

mallet, if necessary.

Fig. 30 Remove Mode Hub

1 - MAINSHAFT

2 - MODE HUB

Fig. 31 Remove the Drive Sprocket Drive Hub

1 - MAINSHAFT

2 - DRIVE SPROCKET DRIVE HUB

Fig. 32 Remove Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 33 Remove Input Planetary Assembly

1 - FRONT CASE

2 - INPUT PLANETARY ASSEMBLY

21 - 552 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2256 of 2627

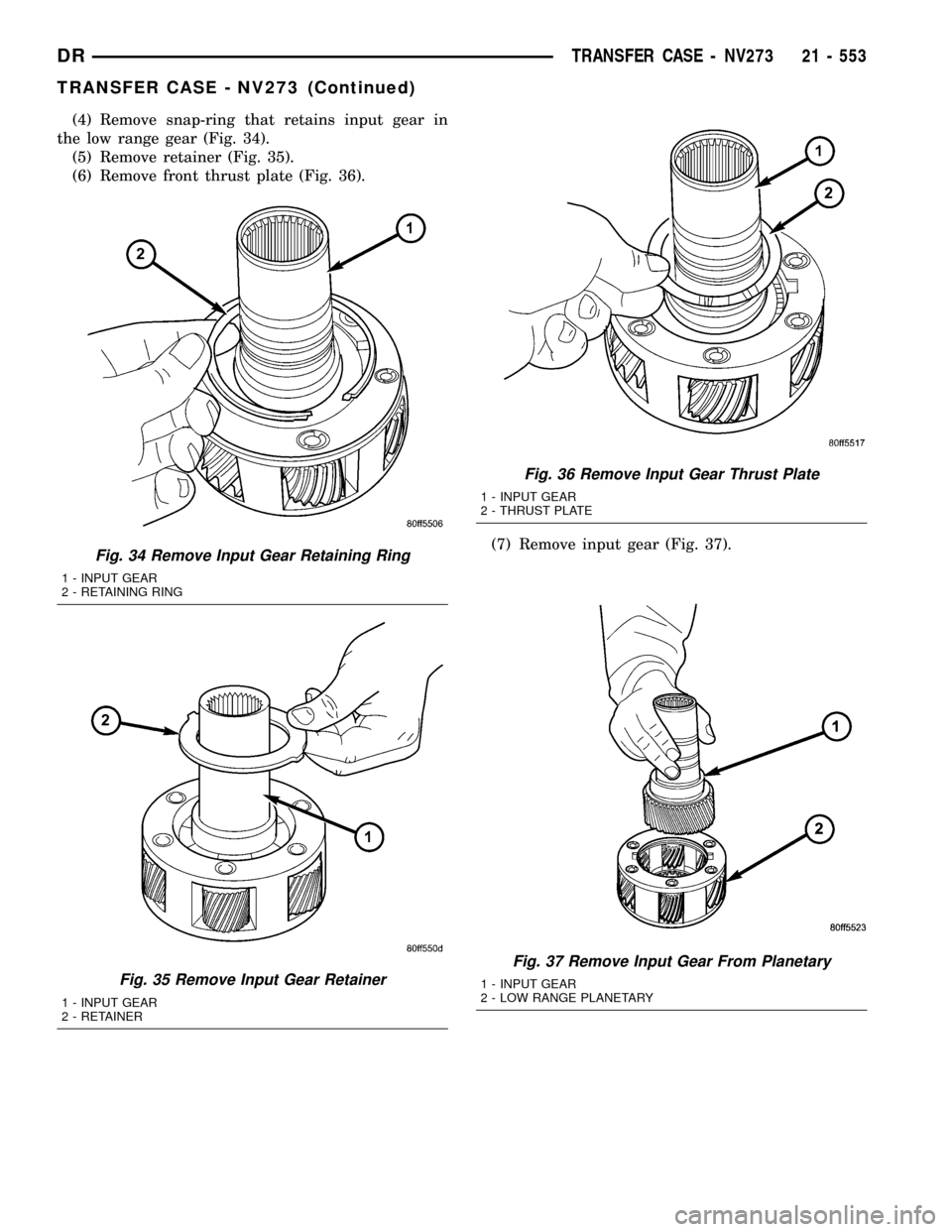

(4) Remove snap-ring that retains input gear in

the low range gear (Fig. 34).

(5) Remove retainer (Fig. 35).

(6) Remove front thrust plate (Fig. 36).

(7) Remove input gear (Fig. 37).

Fig. 37 Remove Input Gear From Planetary

1 - INPUT GEAR

2 - LOW RANGE PLANETARY

Fig. 34 Remove Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 35 Remove Input Gear Retainer

1 - INPUT GEAR

2 - RETAINER

Fig. 36 Remove Input Gear Thrust Plate

1 - INPUT GEAR

2 - THRUST PLATE

DRTRANSFER CASE - NV273 21 - 553

TRANSFER CASE - NV273 (Continued)

Page 2257 of 2627

(8) Remove bottom tabbed thrust washer from low

range planetary (Fig. 38).

CLEANING

Clean the transfer case parts with a standard

parts cleaning solvent. Remove all traces of sealer

from the cases and retainers with a scraper and

3MŸ all purpose cleaner. Use compressed air to

remove solvent residue from oil feed passages in the

case halves, retainers, gears, and shafts.

INSPECTION

MAINSHAFT/SPROCKET/HUB INSPECTION

Inspect the splines on the hub and shaft and the

teeth on the sprocket. Minor nicks and scratches can

be smoothed with an oilstone. However, replace any

part that is damaged.

Check the contact surfaces in the sprocket bore

and on the mainshaft. Minor nicks and scratches can

be smoothed with 320-400 grit emery cloth but do not

try to salvage the shaft if nicks or wear is severe.

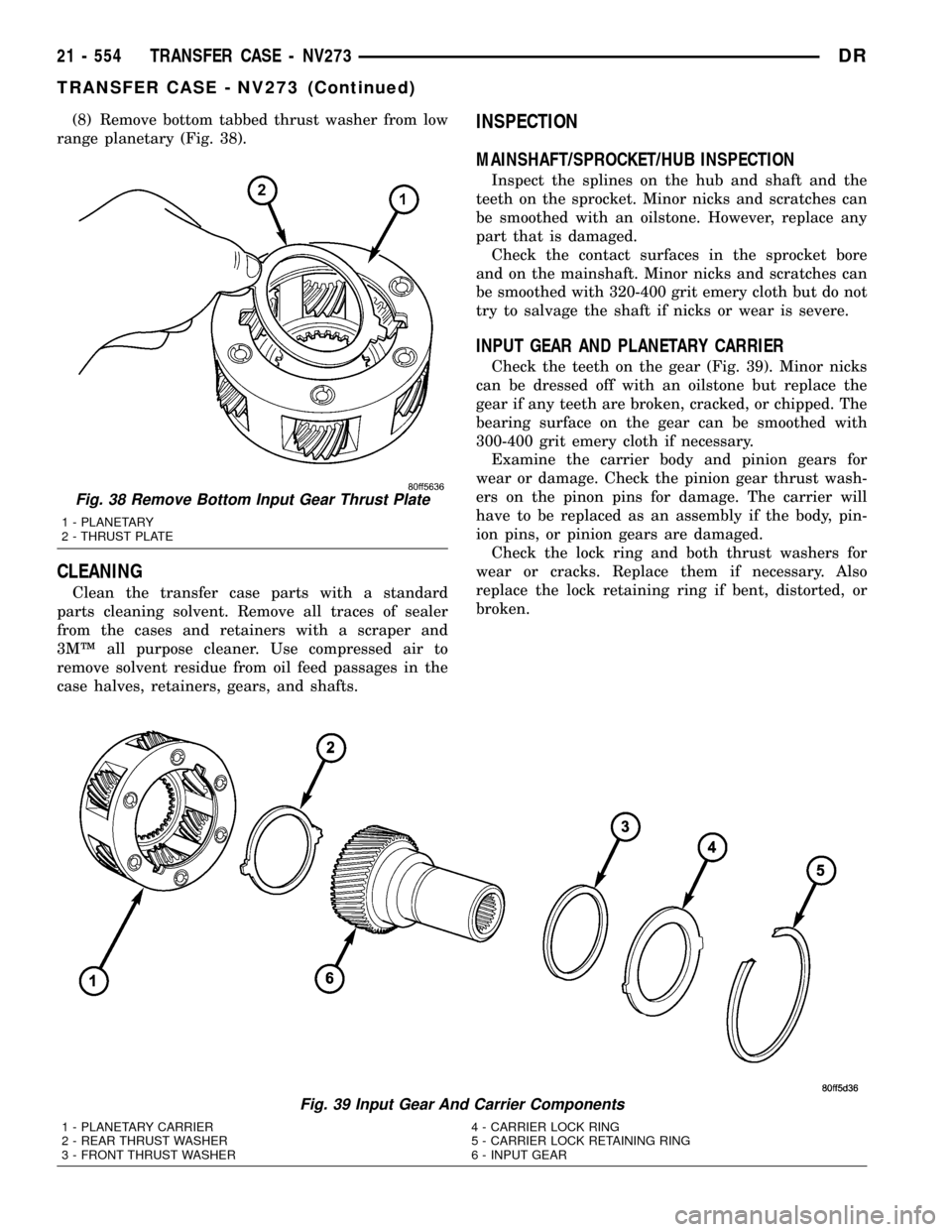

INPUT GEAR AND PLANETARY CARRIER

Check the teeth on the gear (Fig. 39). Minor nicks

can be dressed off with an oilstone but replace the

gear if any teeth are broken, cracked, or chipped. The

bearing surface on the gear can be smoothed with

300-400 grit emery cloth if necessary.

Examine the carrier body and pinion gears for

wear or damage. Check the pinion gear thrust wash-

ers on the pinon pins for damage. The carrier will

have to be replaced as an assembly if the body, pin-

ion pins, or pinion gears are damaged.

Check the lock ring and both thrust washers for

wear or cracks. Replace them if necessary. Also

replace the lock retaining ring if bent, distorted, or

broken.

Fig. 39 Input Gear And Carrier Components

1 - PLANETARY CARRIER 4 - CARRIER LOCK RING

2 - REAR THRUST WASHER 5 - CARRIER LOCK RETAINING RING

3 - FRONT THRUST WASHER 6 - INPUT GEAR

Fig. 38 Remove Bottom Input Gear Thrust Plate

1 - PLANETARY

2 - THRUST PLATE

21 - 554 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)