clock DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 39 of 2627

To adjust the vehicle height turn the torsion bar

adjustment bolt CLOCKWISE to raise the vehicle

and COUNTER CLOCKWISE to lower the vehicle.

CAUTION: ALWAYS raise the vehicle to the correct

suspension height, NEVER lower the vehicle to

obtain the correct suspension height. If the vehicle

suspension height is too high, lower the vehicle

below the height specification. Then raise the vehi-

cle to the correct suspension height specification.

This will insure the vehicle maintains the proper

suspension height.

NOTE: If a height adjustment has been made, per-

form height measurement again on both sides of

the vehicle.

STANDARD PROCEDURE - CAMBER AND

CASTER ADJUSTMENT

NOTE: 4X4 (LD) SUSPENSION HEIGHT MEASURE-

MENT MUST BE PERFORMED BEFORE AN ALIGN-

MENT.

NOTE: When the upper control arm pivot bolts are

loosened the upper control arm will normally go

inwards toward the frame automatically with the

weight of the vehicle.

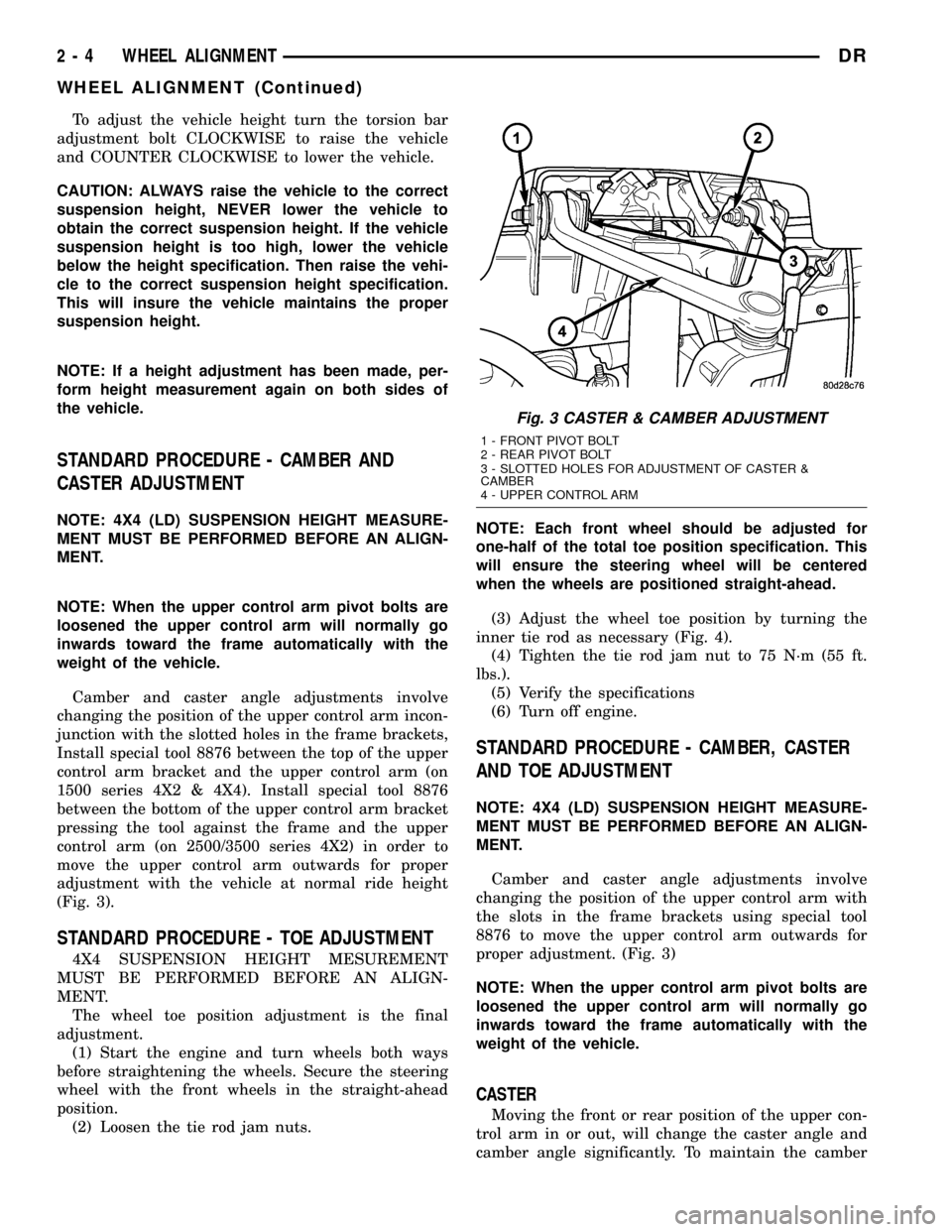

Camber and caster angle adjustments involve

changing the position of the upper control arm incon-

junction with the slotted holes in the frame brackets,

Install special tool 8876 between the top of the upper

control arm bracket and the upper control arm (on

1500 series 4X2 & 4X4). Install special tool 8876

between the bottom of the upper control arm bracket

pressing the tool against the frame and the upper

control arm (on 2500/3500 series 4X2) in order to

move the upper control arm outwards for proper

adjustment with the vehicle at normal ride height

(Fig. 3).

STANDARD PROCEDURE - TOE ADJUSTMENT

4X4 SUSPENSION HEIGHT MESUREMENT

MUST BE PERFORMED BEFORE AN ALIGN-

MENT.

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.

(2) Loosen the tie rod jam nuts.NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the

inner tie rod as necessary (Fig. 4).

(4) Tighten the tie rod jam nut to 75 N´m (55 ft.

lbs.).

(5) Verify the specifications

(6) Turn off engine.

STANDARD PROCEDURE - CAMBER, CASTER

AND TOE ADJUSTMENT

NOTE: 4X4 (LD) SUSPENSION HEIGHT MEASURE-

MENT MUST BE PERFORMED BEFORE AN ALIGN-

MENT.

Camber and caster angle adjustments involve

changing the position of the upper control arm with

the slots in the frame brackets using special tool

8876 to move the upper control arm outwards for

proper adjustment. (Fig. 3)

NOTE: When the upper control arm pivot bolts are

loosened the upper control arm will normally go

inwards toward the frame automatically with the

weight of the vehicle.

CASTER

Moving the front or rear position of the upper con-

trol arm in or out, will change the caster angle and

camber angle significantly. To maintain the camber

Fig. 3 CASTER & CAMBER ADJUSTMENT

1 - FRONT PIVOT BOLT

2 - REAR PIVOT BOLT

3 - SLOTTED HOLES FOR ADJUSTMENT OF CASTER &

CAMBER

4 - UPPER CONTROL ARM

2 - 4 WHEEL ALIGNMENTDR

WHEEL ALIGNMENT (Continued)

Page 61 of 2627

INSTALLATION

INSTALLATION - 4X4

(1) Install the stabilizer link to the vehicle.

(2) Install the lower nut and Tighten to 102 N´m

(75 ft. lbs.).

(3) Install the retainers, grommets and upper nut

and Tighten to 38 N´m (27 ft. lbs.).

(4) Remove the support and lower the vehicle.

INSTALLATION - 4X2

(1) Install the stabilizer link to the vehicle (Fig.

29).

(2) Install the lower nut and Tighten to 102 N´m

(75 ft. lbs.).

(3) Install the retainers, grommets and upper nut

and Tighten to 38 N´m (27 ft. lbs.).

(4) Remove the support and lower the vehicle.

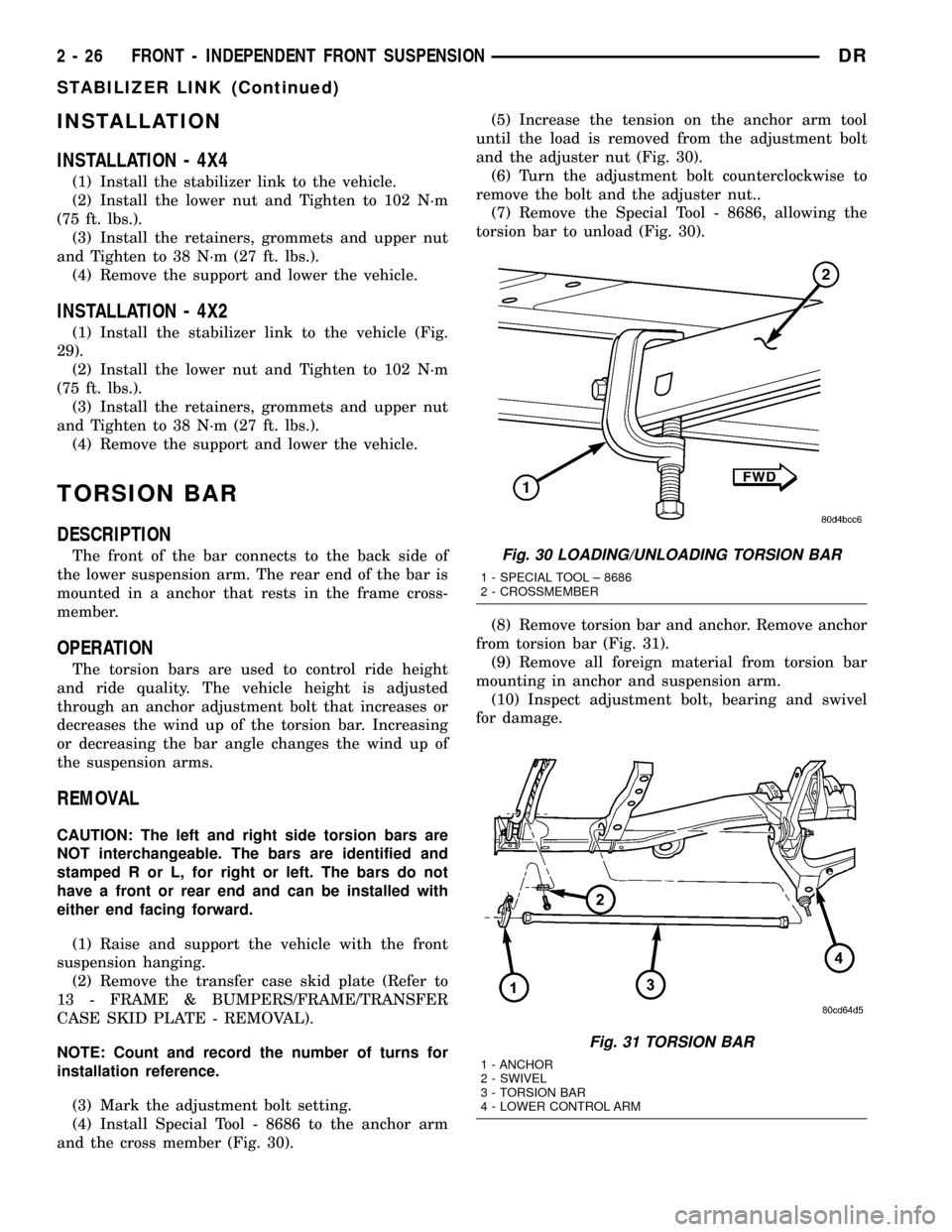

TORSION BAR

DESCRIPTION

The front of the bar connects to the back side of

the lower suspension arm. The rear end of the bar is

mounted in a anchor that rests in the frame cross-

member.

OPERATION

The torsion bars are used to control ride height

and ride quality. The vehicle height is adjusted

through an anchor adjustment bolt that increases or

decreases the wind up of the torsion bar. Increasing

or decreasing the bar angle changes the wind up of

the suspension arms.

REMOVAL

CAUTION: The left and right side torsion bars are

NOT interchangeable. The bars are identified and

stamped R or L, for right or left. The bars do not

have a front or rear end and can be installed with

either end facing forward.

(1) Raise and support the vehicle with the front

suspension hanging.

(2) Remove the transfer case skid plate (Refer to

13 - FRAME & BUMPERS/FRAME/TRANSFER

CASE SKID PLATE - REMOVAL).

NOTE: Count and record the number of turns for

installation reference.

(3) Mark the adjustment bolt setting.

(4) Install Special Tool - 8686 to the anchor arm

and the cross member (Fig. 30).(5) Increase the tension on the anchor arm tool

until the load is removed from the adjustment bolt

and the adjuster nut (Fig. 30).

(6) Turn the adjustment bolt counterclockwise to

remove the bolt and the adjuster nut..

(7) Remove the Special Tool - 8686, allowing the

torsion bar to unload (Fig. 30).

(8) Remove torsion bar and anchor. Remove anchor

from torsion bar (Fig. 31).

(9) Remove all foreign material from torsion bar

mounting in anchor and suspension arm.

(10) Inspect adjustment bolt, bearing and swivel

for damage.

Fig. 30 LOADING/UNLOADING TORSION BAR

1 - SPECIAL TOOL ± 8686

2 - CROSSMEMBER

Fig. 31 TORSION BAR

1 - ANCHOR

2 - SWIVEL

3 - TORSION BAR

4 - LOWER CONTROL ARM

2 - 26 FRONT - INDEPENDENT FRONT SUSPENSIONDR

STABILIZER LINK (Continued)

Page 62 of 2627

INSTALLATION

CAUTION: The left and right side torsion bars are

NOT interchangeable. The bars are identified and

stamped R or L, for right or left. The bars do not

have a front or rear end and can be installed with

either end facing forward.

(1) Insert torsion bar ends into anchor and suspen-

sion arm.

(2) Position the anchor in the frame crossmember.

(3) Install Special Tool - 8686 to the anchor and

the crossmember (Fig. 30).

(4) Increase the tension on the anchor in order to

load the torsion bar.

(5) Install the adjustment bolt and the adjuster

nut.

(6) Turn adjustment bolt clockwise the recorded

amount of turns.

(7) Remove tool - 8686 from the torsion bar cross-

member (Fig. 30).

(8) Install the transfer case skid plate (Refer to 13

- FRAME & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION).

(9) Lower vehicle and adjust the front suspension

height (Refer to 2 - SUSPENSION/WHEEL ALIGN-

MENT - STANDARD PROCEDURE).

(10) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

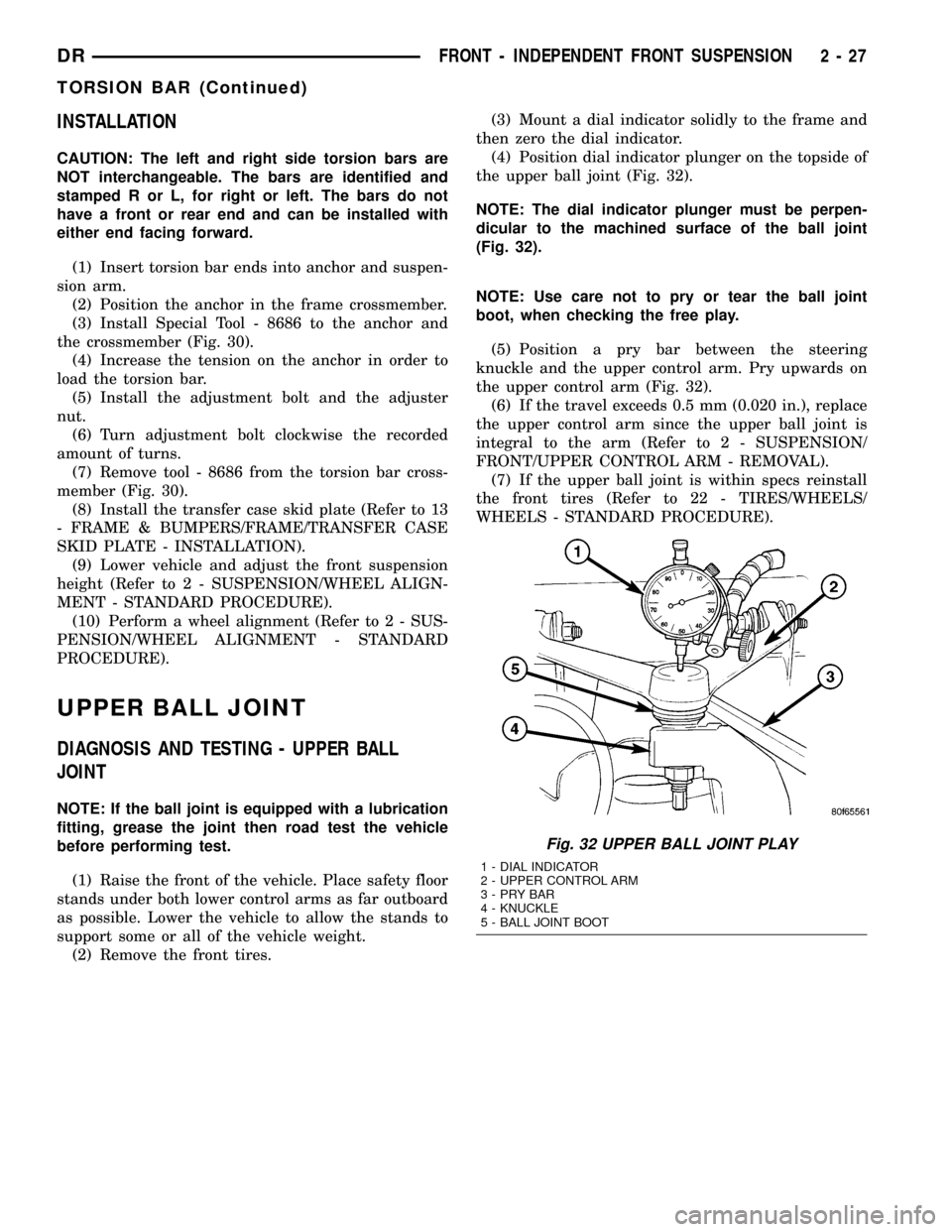

UPPER BALL JOINT

DIAGNOSIS AND TESTING - UPPER BALL

JOINT

NOTE: If the ball joint is equipped with a lubrication

fitting, grease the joint then road test the vehicle

before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.(3) Mount a dial indicator solidly to the frame and

then zero the dial indicator.

(4) Position dial indicator plunger on the topside of

the upper ball joint (Fig. 32).

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the ball joint

(Fig. 32).

NOTE: Use care not to pry or tear the ball joint

boot, when checking the free play.

(5) Position a pry bar between the steering

knuckle and the upper control arm. Pry upwards on

the upper control arm (Fig. 32).

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the upper control arm since the upper ball joint is

integral to the arm (Refer to 2 - SUSPENSION/

FRONT/UPPER CONTROL ARM - REMOVAL).

(7) If the upper ball joint is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

Fig. 32 UPPER BALL JOINT PLAY

1 - DIAL INDICATOR

2 - UPPER CONTROL ARM

3-PRYBAR

4 - KNUCKLE

5 - BALL JOINT BOOT

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 27

TORSION BAR (Continued)

Page 309 of 2627

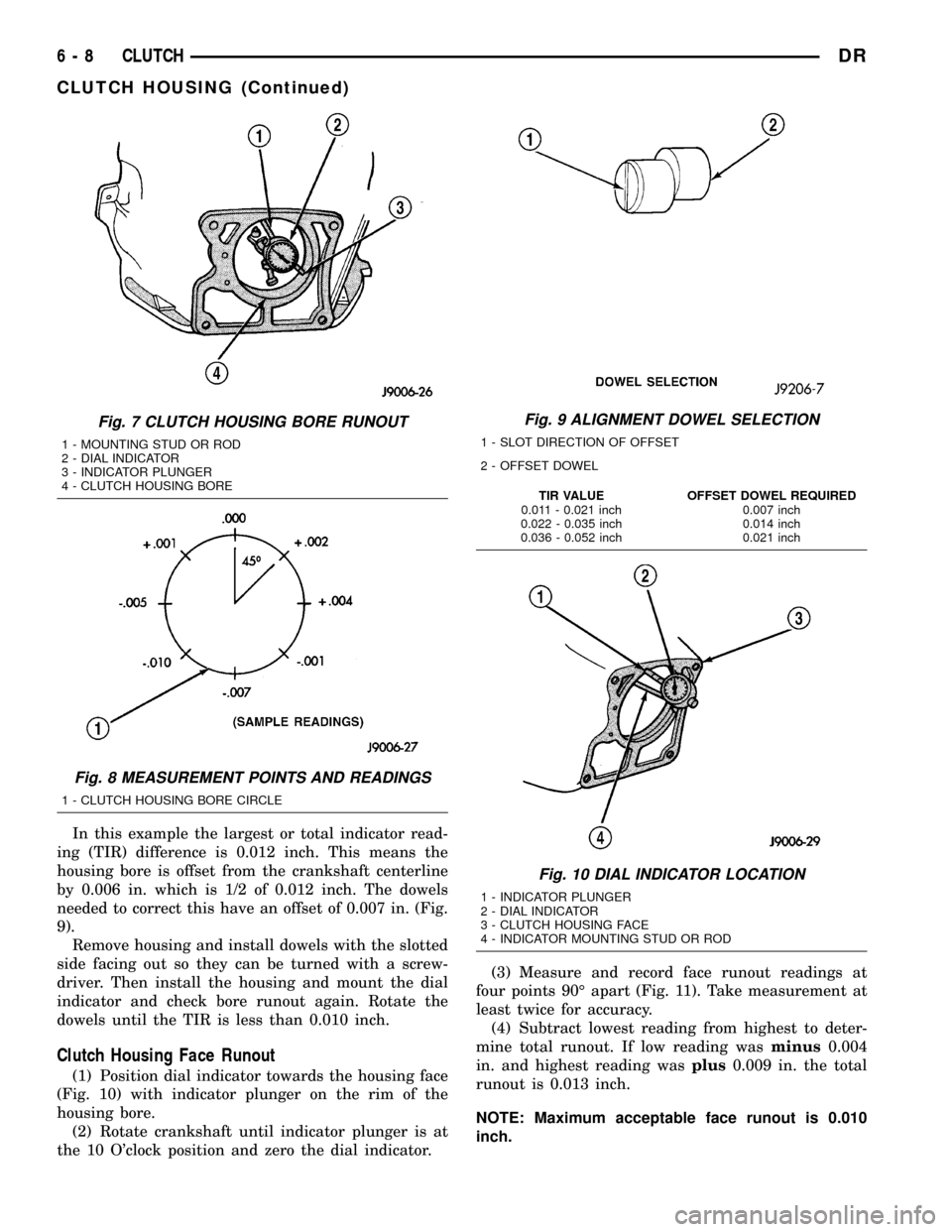

In this example the largest or total indicator read-

ing (TIR) difference is 0.012 inch. This means the

housing bore is offset from the crankshaft centerline

by 0.006 in. which is 1/2 of 0.012 inch. The dowels

needed to correct this have an offset of 0.007 in. (Fig.

9).

Remove housing and install dowels with the slotted

side facing out so they can be turned with a screw-

driver. Then install the housing and mount the dial

indicator and check bore runout again. Rotate the

dowels until the TIR is less than 0.010 inch.

Clutch Housing Face Runout

(1) Position dial indicator towards the housing face

(Fig. 10) with indicator plunger on the rim of the

housing bore.

(2) Rotate crankshaft until indicator plunger is at

the 10 O'clock position and zero the dial indicator.(3) Measure and record face runout readings at

four points 90É apart (Fig. 11). Take measurement at

least twice for accuracy.

(4) Subtract lowest reading from highest to deter-

mine total runout. If low reading wasminus0.004

in. and highest reading wasplus0.009 in. the total

runout is 0.013 inch.

NOTE: Maximum acceptable face runout is 0.010

inch.

Fig. 7 CLUTCH HOUSING BORE RUNOUT

1 - MOUNTING STUD OR ROD

2 - DIAL INDICATOR

3 - INDICATOR PLUNGER

4 - CLUTCH HOUSING BORE

Fig. 8 MEASUREMENT POINTS AND READINGS

1 - CLUTCH HOUSING BORE CIRCLE

Fig. 9 ALIGNMENT DOWEL SELECTION

1 - SLOT DIRECTION OF OFFSET

2 - OFFSET DOWEL

TIR VALUE OFFSET DOWEL REQUIRED

0.011 - 0.021 inch 0.007 inch

0.022 - 0.035 inch 0.014 inch

0.036 - 0.052 inch 0.021 inch

Fig. 10 DIAL INDICATOR LOCATION

1 - INDICATOR PLUNGER

2 - DIAL INDICATOR

3 - CLUTCH HOUSING FACE

4 - INDICATOR MOUNTING STUD OR ROD

6 - 8 CLUTCHDR

CLUTCH HOUSING (Continued)

Page 344 of 2627

REMOVAL

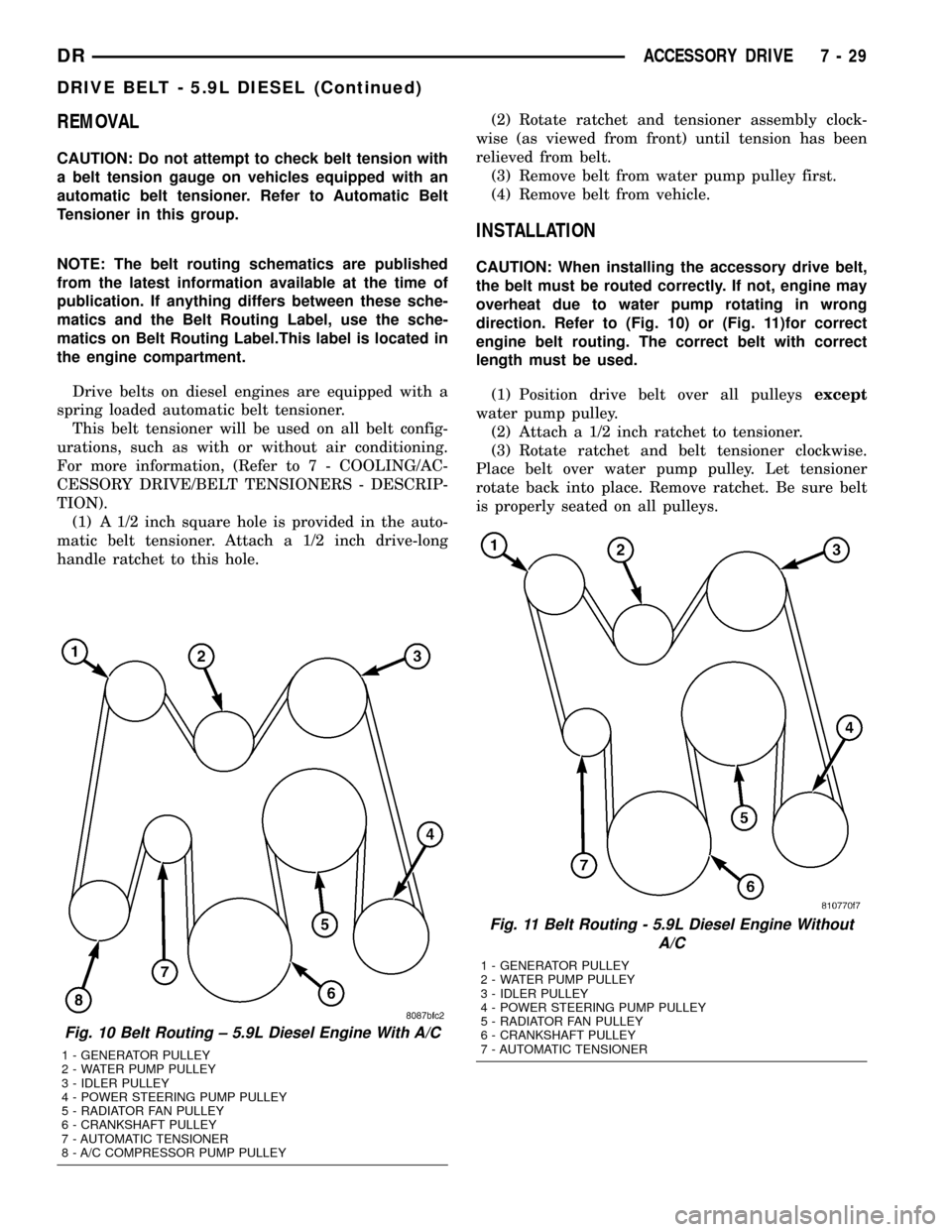

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner.

This belt tensioner will be used on all belt config-

urations, such as with or without air conditioning.

For more information, (Refer to 7 - COOLING/AC-

CESSORY DRIVE/BELT TENSIONERS - DESCRIP-

TION).

(1) A 1/2 inch square hole is provided in the auto-

matic belt tensioner. Attach a 1/2 inch drive-long

handle ratchet to this hole.(2) Rotate ratchet and tensioner assembly clock-

wise (as viewed from front) until tension has been

relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 10) or (Fig. 11)for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleysexcept

water pump pulley.

(2) Attach a 1/2 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner clockwise.

Place belt over water pump pulley. Let tensioner

rotate back into place. Remove ratchet. Be sure belt

is properly seated on all pulleys.

Fig. 10 Belt Routing ± 5.9L Diesel Engine With A/C

1 - GENERATOR PULLEY

2 - WATER PUMP PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AUTOMATIC TENSIONER

8 - A/C COMPRESSOR PUMP PULLEY

Fig. 11 Belt Routing - 5.9L Diesel Engine Without

A/C

1 - GENERATOR PULLEY

2 - WATER PUMP PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AUTOMATIC TENSIONER

DRACCESSORY DRIVE 7 - 29

DRIVE BELT - 5.9L DIESEL (Continued)

Page 348 of 2627

OPERATION

Coolant flows through the engine block absorbing

the heat from the engine, then flows to the radiator

where the cooling fins in the radiator transfers the

heat from the coolant to the atmosphere. During cold

weather the ethylene-glycol or propylene-glycol cool-

ant prevents water present in the cooling system

from freezing within temperatures indicated by mix-

ture ratio of coolant to water.

COOLANT RECOVERY

CONTAINER- GAS ENGINES

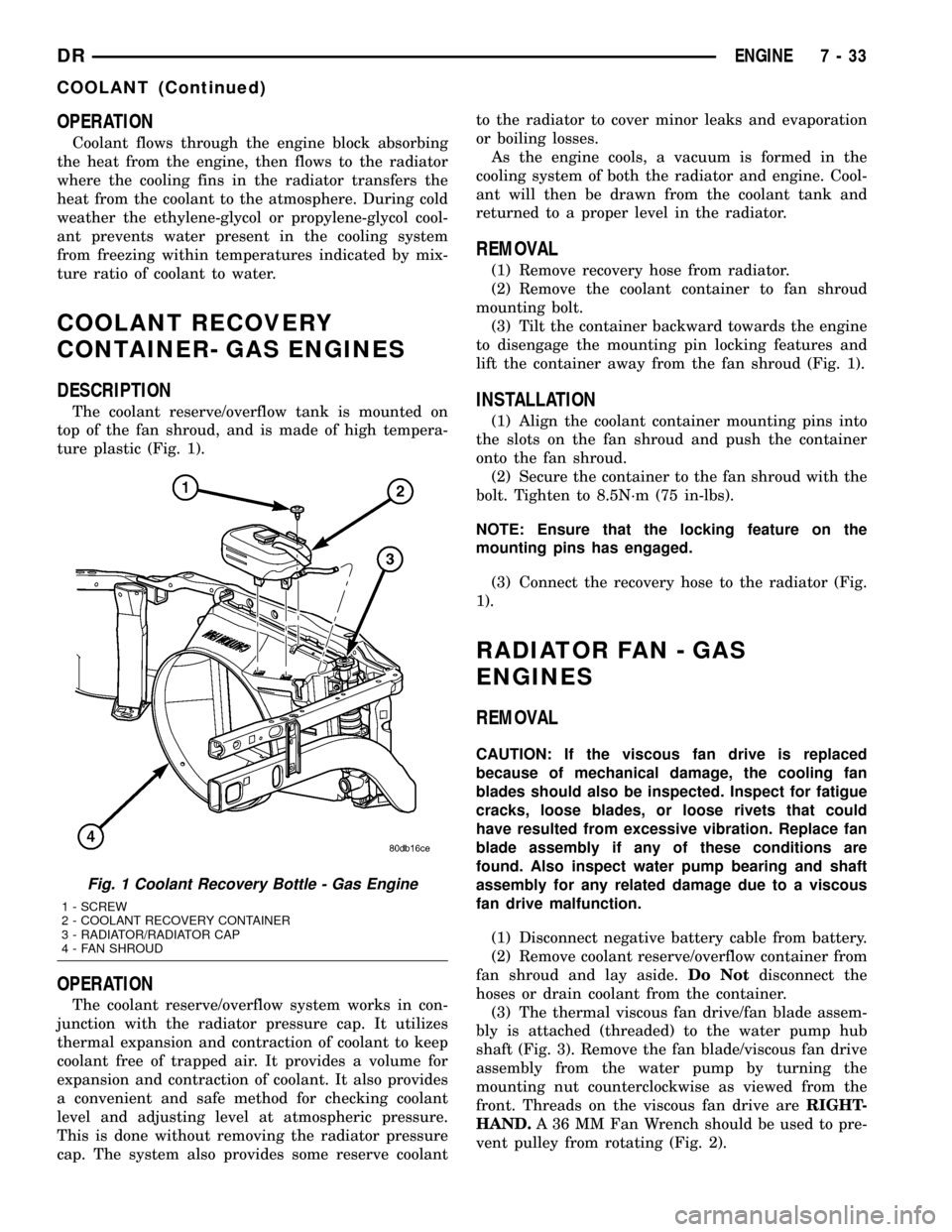

DESCRIPTION

The coolant reserve/overflow tank is mounted on

top of the fan shroud, and is made of high tempera-

ture plastic (Fig. 1).

OPERATION

The coolant reserve/overflow system works in con-

junction with the radiator pressure cap. It utilizes

thermal expansion and contraction of coolant to keep

coolant free of trapped air. It provides a volume for

expansion and contraction of coolant. It also provides

a convenient and safe method for checking coolant

level and adjusting level at atmospheric pressure.

This is done without removing the radiator pressure

cap. The system also provides some reserve coolantto the radiator to cover minor leaks and evaporation

or boiling losses.

As the engine cools, a vacuum is formed in the

cooling system of both the radiator and engine. Cool-

ant will then be drawn from the coolant tank and

returned to a proper level in the radiator.

REMOVAL

(1) Remove recovery hose from radiator.

(2) Remove the coolant container to fan shroud

mounting bolt.

(3) Tilt the container backward towards the engine

to disengage the mounting pin locking features and

lift the container away from the fan shroud (Fig. 1).

INSTALLATION

(1) Align the coolant container mounting pins into

the slots on the fan shroud and push the container

onto the fan shroud.

(2) Secure the container to the fan shroud with the

bolt. Tighten to 8.5N´m (75 in-lbs).

NOTE: Ensure that the locking feature on the

mounting pins has engaged.

(3) Connect the recovery hose to the radiator (Fig.

1).

RADIATOR FAN - GAS

ENGINES

REMOVAL

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks, loose blades, or loose rivets that could

have resulted from excessive vibration. Replace fan

blade assembly if any of these conditions are

found. Also inspect water pump bearing and shaft

assembly for any related damage due to a viscous

fan drive malfunction.

(1) Disconnect negative battery cable from battery.

(2) Remove coolant reserve/overflow container from

fan shroud and lay aside.Do Notdisconnect the

hoses or drain coolant from the container.

(3) The thermal viscous fan drive/fan blade assem-

bly is attached (threaded) to the water pump hub

shaft (Fig. 3). Remove the fan blade/viscous fan drive

assembly from the water pump by turning the

mounting nut counterclockwise as viewed from the

front. Threads on the viscous fan drive areRIGHT-

HAND.A 36 MM Fan Wrench should be used to pre-

vent pulley from rotating (Fig. 2).

Fig. 1 Coolant Recovery Bottle - Gas Engine

1 - SCREW

2 - COOLANT RECOVERY CONTAINER

3 - RADIATOR/RADIATOR CAP

4 - FAN SHROUD

DRENGINE 7 - 33

COOLANT (Continued)

Page 350 of 2627

(4) Install the fan blade/viscous fan drive assembly

to the water pump shaft (Fig. 3). Tighten mounting

nut to 50 N´m (37 ft. lbs.).

(5) Install the coolant reserve/overflow container

to the fan shroud.

(6) Connect the negative battery cable.

NOTE:

Viscous Fan Drive Fluid Pump Out Requirement:

After installing a new viscous fan drive, bring the

engine speed up to approximately 2000 rpm and

hold for approximately two minutes. This will

ensure proper fluid distribution within the drive.

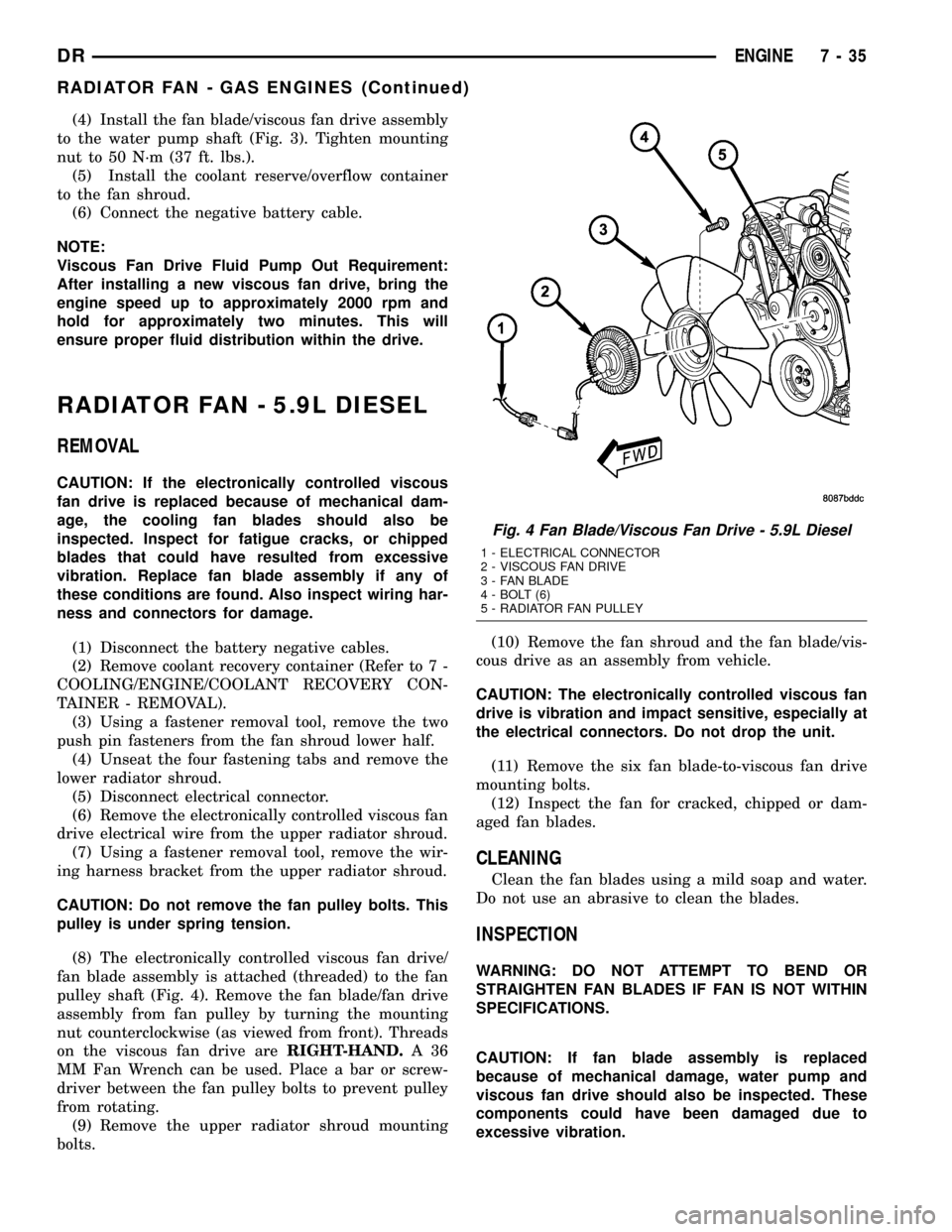

RADIATOR FAN - 5.9L DIESEL

REMOVAL

CAUTION: If the electronically controlled viscous

fan drive is replaced because of mechanical dam-

age, the cooling fan blades should also be

inspected. Inspect for fatigue cracks, or chipped

blades that could have resulted from excessive

vibration. Replace fan blade assembly if any of

these conditions are found. Also inspect wiring har-

ness and connectors for damage.

(1) Disconnect the battery negative cables.

(2) Remove coolant recovery container (Refer to 7 -

COOLING/ENGINE/COOLANT RECOVERY CON-

TAINER - REMOVAL).

(3) Using a fastener removal tool, remove the two

push pin fasteners from the fan shroud lower half.

(4) Unseat the four fastening tabs and remove the

lower radiator shroud.

(5) Disconnect electrical connector.

(6) Remove the electronically controlled viscous fan

drive electrical wire from the upper radiator shroud.

(7) Using a fastener removal tool, remove the wir-

ing harness bracket from the upper radiator shroud.

CAUTION: Do not remove the fan pulley bolts. This

pulley is under spring tension.

(8) The electronically controlled viscous fan drive/

fan blade assembly is attached (threaded) to the fan

pulley shaft (Fig. 4). Remove the fan blade/fan drive

assembly from fan pulley by turning the mounting

nut counterclockwise (as viewed from front). Threads

on the viscous fan drive areRIGHT-HAND.A36

MM Fan Wrench can be used. Place a bar or screw-

driver between the fan pulley bolts to prevent pulley

from rotating.

(9) Remove the upper radiator shroud mounting

bolts.(10) Remove the fan shroud and the fan blade/vis-

cous drive as an assembly from vehicle.

CAUTION: The electronically controlled viscous fan

drive is vibration and impact sensitive, especially at

the electrical connectors. Do not drop the unit.

(11) Remove the six fan blade-to-viscous fan drive

mounting bolts.

(12) Inspect the fan for cracked, chipped or dam-

aged fan blades.

CLEANING

Clean the fan blades using a mild soap and water.

Do not use an abrasive to clean the blades.

INSPECTION

WARNING: DO NOT ATTEMPT TO BEND OR

STRAIGHTEN FAN BLADES IF FAN IS NOT WITHIN

SPECIFICATIONS.

CAUTION: If fan blade assembly is replaced

because of mechanical damage, water pump and

viscous fan drive should also be inspected. These

components could have been damaged due to

excessive vibration.

Fig. 4 Fan Blade/Viscous Fan Drive - 5.9L Diesel

1 - ELECTRICAL CONNECTOR

2 - VISCOUS FAN DRIVE

3 - FAN BLADE

4 - BOLT (6)

5 - RADIATOR FAN PULLEY

DRENGINE 7 - 35

RADIATOR FAN - GAS ENGINES (Continued)

Page 373 of 2627

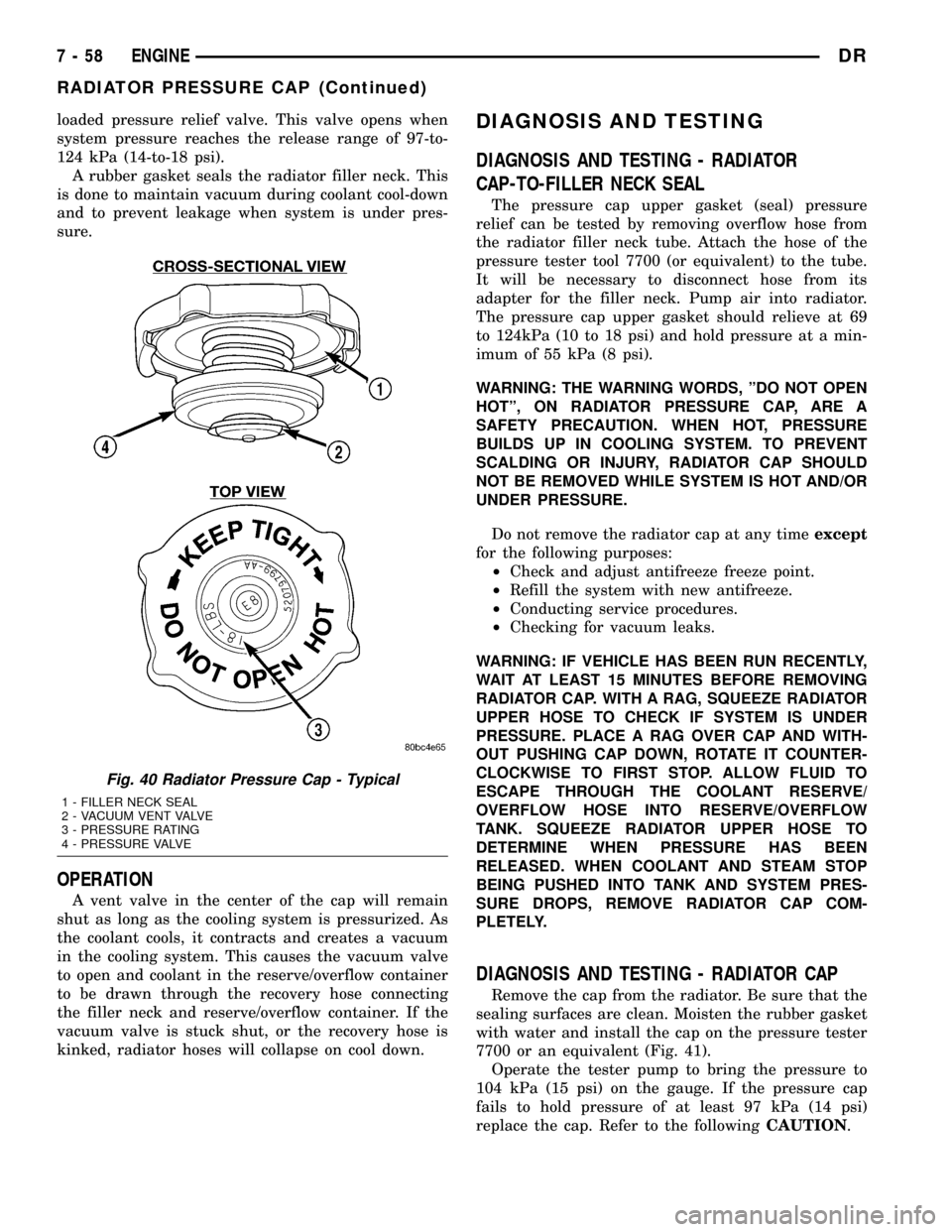

loaded pressure relief valve. This valve opens when

system pressure reaches the release range of 97-to-

124 kPa (14-to-18 psi).

A rubber gasket seals the radiator filler neck. This

is done to maintain vacuum during coolant cool-down

and to prevent leakage when system is under pres-

sure.

OPERATION

A vent valve in the center of the cap will remain

shut as long as the cooling system is pressurized. As

the coolant cools, it contracts and creates a vacuum

in the cooling system. This causes the vacuum valve

to open and coolant in the reserve/overflow container

to be drawn through the recovery hose connecting

the filler neck and reserve/overflow container. If the

vacuum valve is stuck shut, or the recovery hose is

kinked, radiator hoses will collapse on cool down.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - RADIATOR

CAP-TO-FILLER NECK SEAL

The pressure cap upper gasket (seal) pressure

relief can be tested by removing overflow hose from

the radiator filler neck tube. Attach the hose of the

pressure tester tool 7700 (or equivalent) to the tube.

It will be necessary to disconnect hose from its

adapter for the filler neck. Pump air into radiator.

The pressure cap upper gasket should relieve at 69

to 124kPa (10 to 18 psi) and hold pressure at a min-

imum of 55 kPa (8 psi).

WARNING: THE WARNING WORDS, ºDO NOT OPEN

HOTº, ON RADIATOR PRESSURE CAP, ARE A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, RADIATOR CAP SHOULD

NOT BE REMOVED WHILE SYSTEM IS HOT AND/OR

UNDER PRESSURE.

Do not remove the radiator cap at any timeexcept

for the following purposes:

²Check and adjust antifreeze freeze point.

²Refill the system with new antifreeze.

²Conducting service procedures.

²Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT AT LEAST 15 MINUTES BEFORE REMOVING

RADIATOR CAP. WITH A RAG, SQUEEZE RADIATOR

UPPER HOSE TO CHECK IF SYSTEM IS UNDER

PRESSURE. PLACE A RAG OVER CAP AND WITH-

OUT PUSHING CAP DOWN, ROTATE IT COUNTER-

CLOCKWISE TO FIRST STOP. ALLOW FLUID TO

ESCAPE THROUGH THE COOLANT RESERVE/

OVERFLOW HOSE INTO RESERVE/OVERFLOW

TANK. SQUEEZE RADIATOR UPPER HOSE TO

DETERMINE WHEN PRESSURE HAS BEEN

RELEASED. WHEN COOLANT AND STEAM STOP

BEING PUSHED INTO TANK AND SYSTEM PRES-

SURE DROPS, REMOVE RADIATOR CAP COM-

PLETELY.

DIAGNOSIS AND TESTING - RADIATOR CAP

Remove the cap from the radiator. Be sure that the

sealing surfaces are clean. Moisten the rubber gasket

with water and install the cap on the pressure tester

7700 or an equivalent (Fig. 41).

Operate the tester pump to bring the pressure to

104 kPa (15 psi) on the gauge. If the pressure cap

fails to hold pressure of at least 97 kPa (14 psi)

replace the cap. Refer to the followingCAUTION.

Fig. 40 Radiator Pressure Cap - Typical

1 - FILLER NECK SEAL

2 - VACUUM VENT VALVE

3 - PRESSURE RATING

4 - PRESSURE VALVE

7 - 58 ENGINEDR

RADIATOR PRESSURE CAP (Continued)

Page 379 of 2627

REMOVAL

NOTE:

The water pump on all models can be removed

without discharging the air conditioning system (if

equipped).

The water pump on all gas powered engines is

bolted directly to the engine timing chain case/

cover.

On the 8.0L V-10 engine, a rubber o-ring (instead of

a gasket) is used as a seal between the water pump

and timing chain case/cover.

If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for

fatigue cracks, loose blades or loose rivets that could

have resulted from excessive vibration. Replace fan if

any of these conditions are found. Also check condi-

tion of the thermal viscous fan drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - DIAGNOSIS AND TESTING).

(1) Disconnect negative battery cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

(3) Remove windshield washer reservoir tank from

radiator fan shroud.

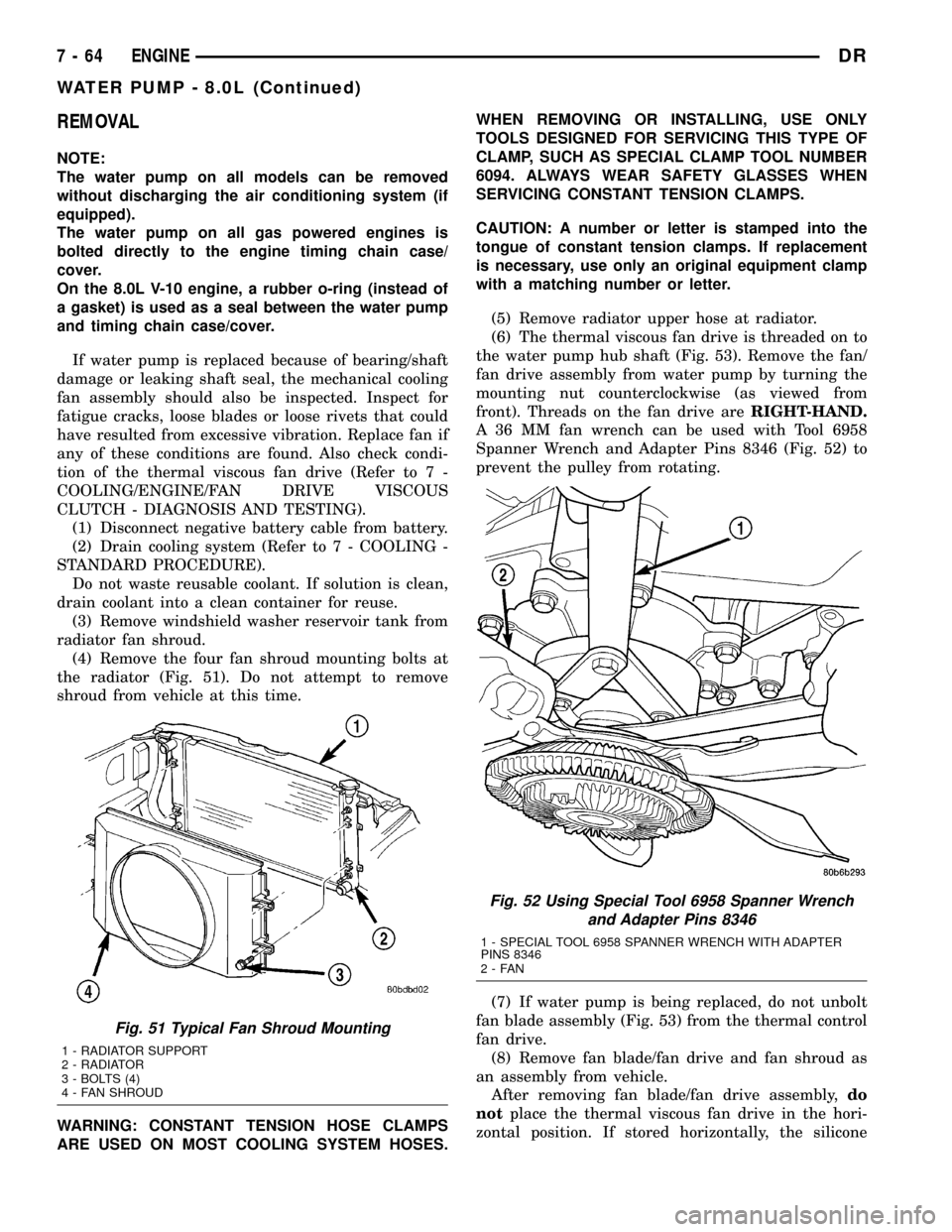

(4) Remove the four fan shroud mounting bolts at

the radiator (Fig. 51). Do not attempt to remove

shroud from vehicle at this time.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL NUMBER

6094. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(5) Remove radiator upper hose at radiator.

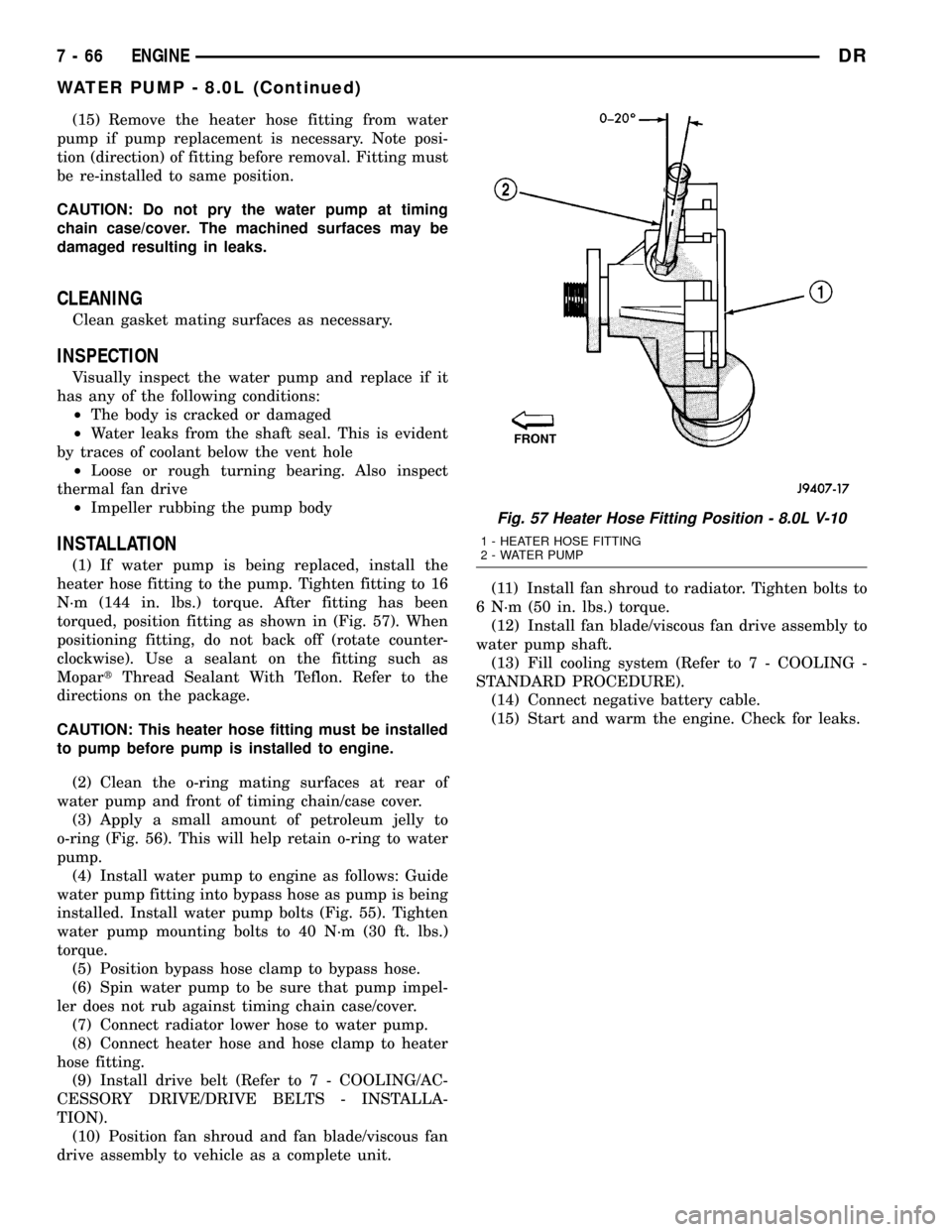

(6) The thermal viscous fan drive is threaded on to

the water pump hub shaft (Fig. 53). Remove the fan/

fan drive assembly from water pump by turning the

mounting nut counterclockwise (as viewed from

front). Threads on the fan drive areRIGHT-HAND.

A 36 MM fan wrench can be used with Tool 6958

Spanner Wrench and Adapter Pins 8346 (Fig. 52) to

prevent the pulley from rotating.

(7) If water pump is being replaced, do not unbolt

fan blade assembly (Fig. 53) from the thermal control

fan drive.

(8) Remove fan blade/fan drive and fan shroud as

an assembly from vehicle.

After removing fan blade/fan drive assembly,do

notplace the thermal viscous fan drive in the hori-

zontal position. If stored horizontally, the silicone

Fig. 51 Typical Fan Shroud Mounting

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

Fig. 52 Using Special Tool 6958 Spanner Wrench

and Adapter Pins 8346

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

7 - 64 ENGINEDR

WATER PUMP - 8.0L (Continued)

Page 381 of 2627

(15) Remove the heater hose fitting from water

pump if pump replacement is necessary. Note posi-

tion (direction) of fitting before removal. Fitting must

be re-installed to same position.

CAUTION: Do not pry the water pump at timing

chain case/cover. The machined surfaces may be

damaged resulting in leaks.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing. Also inspect

thermal fan drive

²Impeller rubbing the pump body

INSTALLATION

(1) If water pump is being replaced, install the

heater hose fitting to the pump. Tighten fitting to 16

N´m (144 in. lbs.) torque. After fitting has been

torqued, position fitting as shown in (Fig. 57). When

positioning fitting, do not back off (rotate counter-

clockwise). Use a sealant on the fitting such as

MopartThread Sealant With Teflon. Refer to the

directions on the package.

CAUTION: This heater hose fitting must be installed

to pump before pump is installed to engine.

(2) Clean the o-ring mating surfaces at rear of

water pump and front of timing chain/case cover.

(3) Apply a small amount of petroleum jelly to

o-ring (Fig. 56). This will help retain o-ring to water

pump.

(4) Install water pump to engine as follows: Guide

water pump fitting into bypass hose as pump is being

installed. Install water pump bolts (Fig. 55). Tighten

water pump mounting bolts to 40 N´m (30 ft. lbs.)

torque.

(5) Position bypass hose clamp to bypass hose.

(6) Spin water pump to be sure that pump impel-

ler does not rub against timing chain case/cover.

(7) Connect radiator lower hose to water pump.

(8) Connect heater hose and hose clamp to heater

hose fitting.

(9) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(10) Position fan shroud and fan blade/viscous fan

drive assembly to vehicle as a complete unit.(11) Install fan shroud to radiator. Tighten bolts to

6 N´m (50 in. lbs.) torque.

(12) Install fan blade/viscous fan drive assembly to

water pump shaft.

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect negative battery cable.

(15) Start and warm the engine. Check for leaks.

Fig. 57 Heater Hose Fitting Position - 8.0L V-10

1 - HEATER HOSE FITTING

2 - WATER PUMP

7 - 66 ENGINEDR

WATER PUMP - 8.0L (Continued)