transfer DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2215 of 2627

TRANSFER CASE - NV244 GENII

TABLE OF CONTENTS

page page

TRANSFER CASE - NV244 GENII

DESCRIPTION........................512

OPERATION..........................513

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV244.......................513

REMOVAL............................514

DISASSEMBLY........................514

CLEANING...........................523

INSPECTION.........................523

ASSEMBLY...........................525

INSTALLATION........................534

SPECIFICATIONS

TRANSFER CASE - NV244 GENII........535

SPECIAL TOOLS

TRANSFER CASE - NV244 GENII........535

EXTENSION HOUSING SEAL

REMOVAL............................536

INSTALLATION........................536FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................537

FRONT OUTPUT SHAFT SEAL

REMOVAL............................537

INSTALLATION........................538

MODE SENSOR

DESCRIPTION........................538

OPERATION..........................539

SELECTOR SWITCH

DESCRIPTION........................539

OPERATION..........................540

SHIFT MOTOR

DESCRIPTION........................541

OPERATION..........................541

REMOVAL............................541

INSTALLATION........................541

TRANSFER CASE - NV244

GENII

DESCRIPTION

The NV244 GENII is an electronically controlled

full and part-time transfer case with no two wheel

drive operation.

A differential in the transfer case is used to control

torque transfer to the front and rear axles. A low

range gear reduction system provides increased low

speed torque capability for off road operation. The

low range provides a 2.72:1 reduction ratio.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum retainer

housings bolted to the case halves.

OPERATING RANGES

NV244 GENII operating ranges are:

²AWD(All-Wheel Drive)

²4HI (Part-time)

²4LO

²NEUTRAL

The AWD mode can be used at any time and on

any road surface.The 4HI (Part-time) and 4LO ranges are for off

road use only. The only time these ranges can be

used is when the road surface is covered with snow,

ice, or other loose slippery material.

SHIFT MECHANISM

Operating ranges are selected with a dash

mounted shift selector switch. The shift selector

switch provides a input to the Transfer Case Control

Module (TCCM) to indicate the driver's desire to

change operating ranges. The TCCM uses this input,

along with the input from the transfer case mounted

mode sensor and information from the vehicle's bus,

to determine if a shift is permitted. If the TCCM

decides the shift is permitted, the TCCM controls the

shift motor, mounted to the exterior of the transfer

case, to perform the shift.

21 - 512 TRANSFER CASE - NV244 GENIIDR

Page 2216 of 2627

IDENTIFICATION

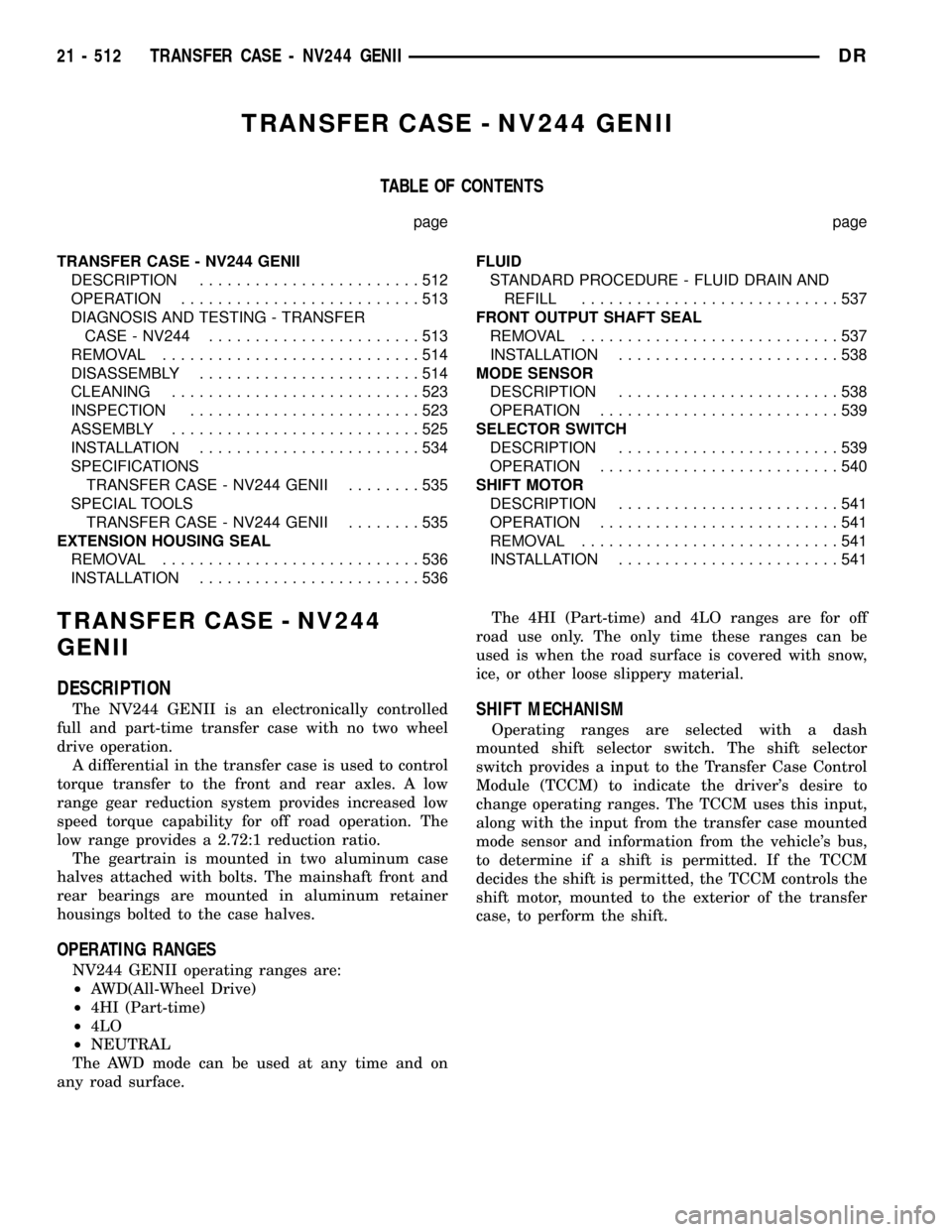

A circular ID tag is attached to the rear case of

each transfer case (Fig. 1). The ID tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

The input gear is splined to the transmission out-

put shaft. The input gear drives the mainshaft

through the planetary assembly and range sleeve.

The front output shaft is operated by a drive chain

that connects the shaft to a drive sprocket on the

mainshaft. The drive sprocket is splined to a differ-

ential assembly. Depending on the position of the

mode fork and sleeve, the front output shaft is driven

directly by the mainshaft or through the differential.

The mode fork operates the mode sleeve and hub.

The sleeve and hub are not equipped with a synchro-

nizer mechanism for shifting.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV244

DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

Transfer case difficult to shift or will

not shift into desired range.1) Transfer case electronically

controlled shift system malfunction.1) Verify proper operation per the

appropriate diagnostic manual.

2) Insufficient or incorrect lubricant. 2) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, Automatic Transmission Fluid.

3) Internal transfer case

components binding, worn, or

damaged.3) Repair or replace components as

necessary.

Transfer case noisy in all drive

modes.1) Insufficient or incorrect lubricant. 1) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, Automatic Transmission Fluid.

2) Internal transfer case

components binding, worn, or

damaged.2) Repair or replace components as

necessary.

Transfer case noisy while in, or

jumps out of, 4LO.1) Transfer case not completely

engaged in 4LO position.1) While rolling 2-3 MPH and the

transmission in NEUTRAL, or the

clutch depressed on vehicles

equipped with a manual

transmission, shift the transfer case

to the AWD or 4HI position, and

then back into the 4LO position.

2) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.2) Repair or replace components as

necessary.

3) Low range gear worn or

damaged.3) Repair or replace components as

necessary.

Fig. 1 Fill/Drain Plug And I.D. Tag Locations

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

DRTRANSFER CASE - NV244 GENII 21 - 513

TRANSFER CASE - NV244 GENII (Continued)

Page 2217 of 2627

CONDITION POSSIBLE CAUSE CORRECTION

Lubricant leaking from transfer case

seals or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Transfer case vent closed or

restricted.2) Clean or replace vent as

necessary.

3) Transfer case seals damaged or

installed incorrectly.3) Replace suspect seal.

Transfer case will not shift through

4HI (Part-time) range.1) Incomplete shift due to drivetrain

torque load.1) Drive in a straight line and

momentarily release the accelerator

pedal to complete the shift.

2) Incorrect tire pressure. 2) Correct tire pressure as

necessary.

3) Excessive tire wear. 3) Correct tire condition as

necessary.

4) Excessive vehicle loading. 4) Correct as necessary.

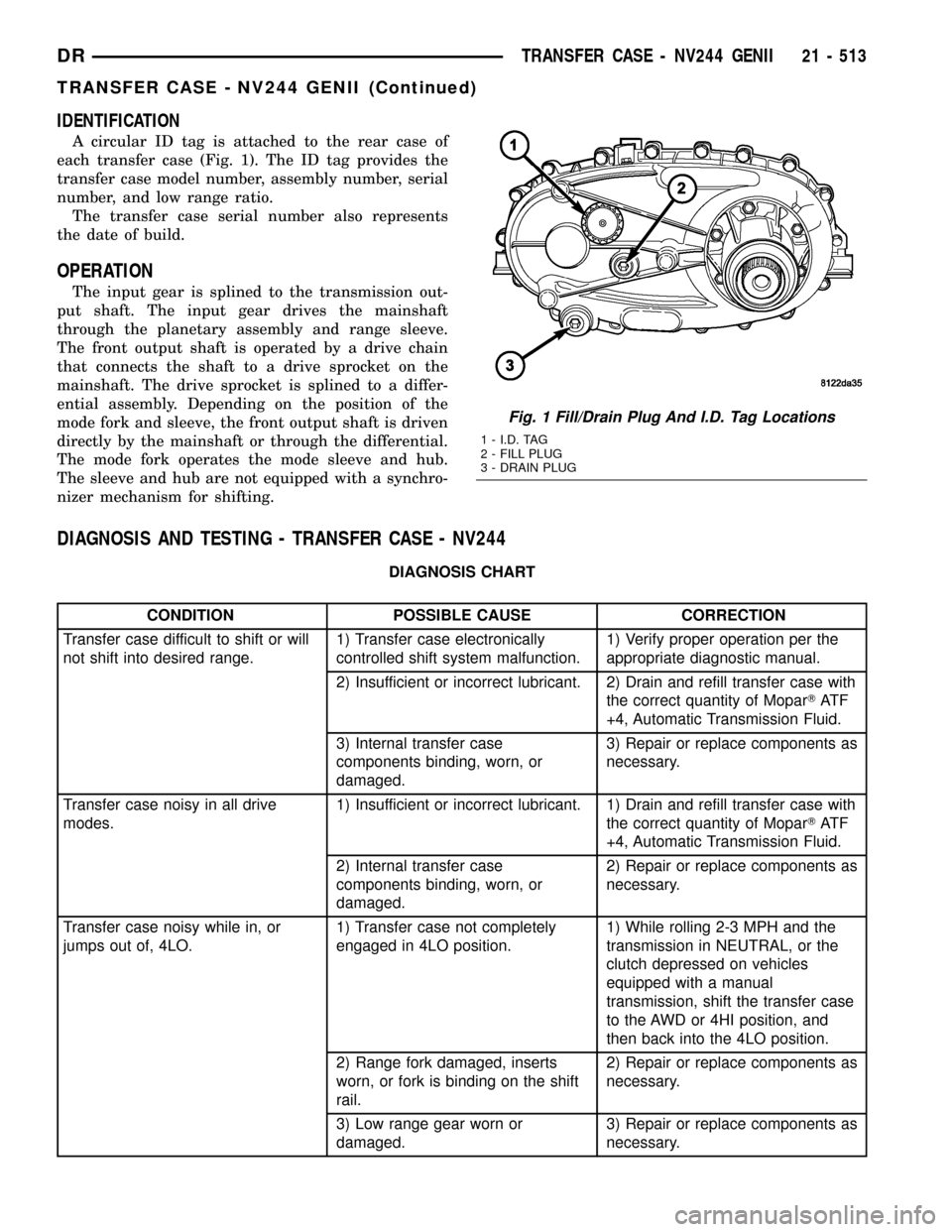

REMOVAL

(1) Shift transfer case into AWD.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shafts for align-

ment reference.

(5) Support transmission with jack stand.

(6)

Remove the transfer case skid plate, if equipped.

(7) Disconnect front and rear propeller shafts at

transfer case.

(8) Disconnect transfer case shift motor and mode

sensor wire connectors.

(9) Disconnect transfer case vent hose.

(10) Support transfer case with transmission jack.

(11) Secure transfer case to jack with chains.

(12) Remove nuts attaching transfer case to trans-

mission (Fig. 2).(13) Pull transfer case and jack rearward to disen-

gage transfer case.

(14) Remove transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

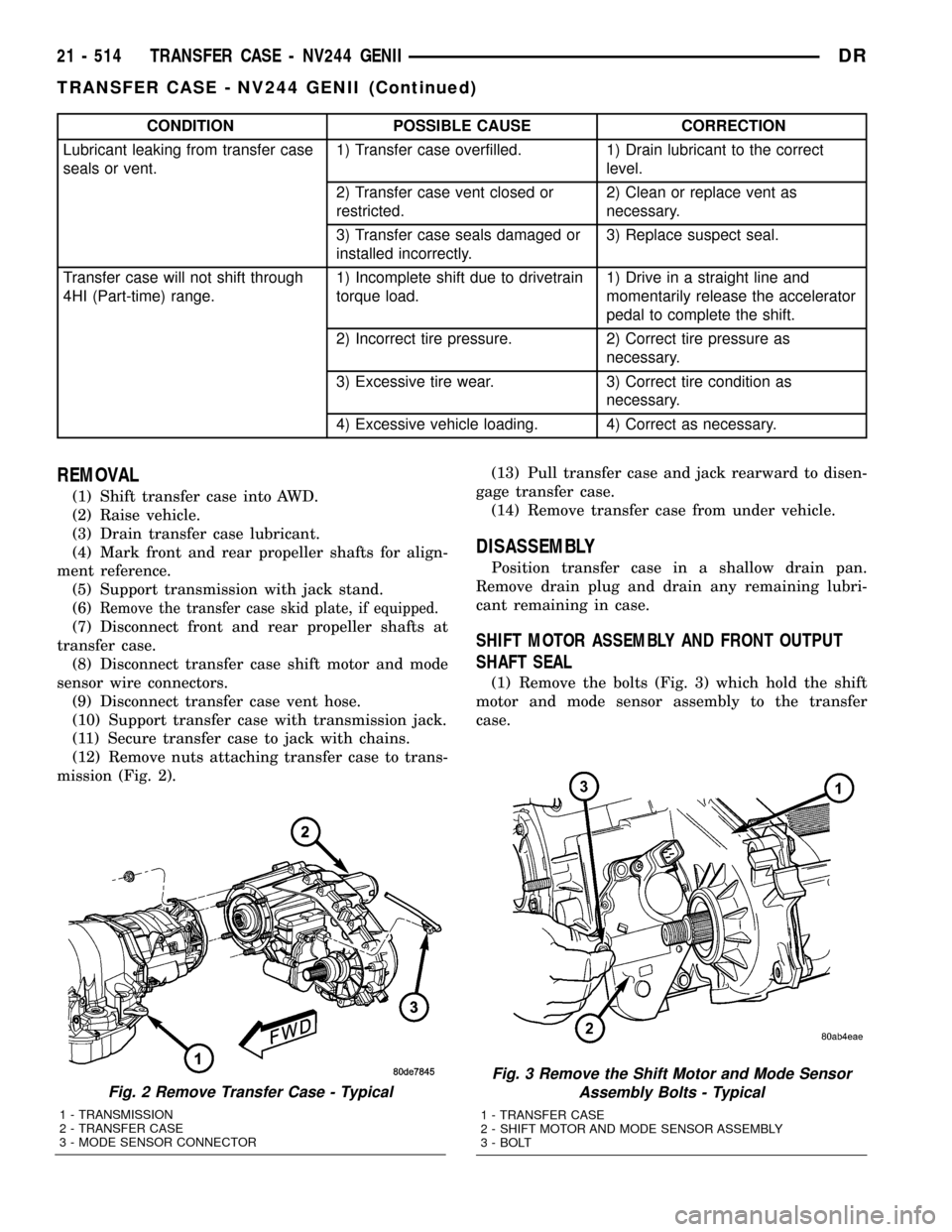

SHIFT MOTOR ASSEMBLY AND FRONT OUTPUT

SHAFT SEAL

(1) Remove the bolts (Fig. 3) which hold the shift

motor and mode sensor assembly to the transfer

case.

Fig. 2 Remove Transfer Case - Typical

1 - TRANSMISSION

2 - TRANSFER CASE

3 - MODE SENSOR CONNECTOR

Fig. 3 Remove the Shift Motor and Mode Sensor

Assembly Bolts - Typical

1 - TRANSFER CASE

2 - SHIFT MOTOR AND MODE SENSOR ASSEMBLY

3 - BOLT

21 - 514 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2218 of 2627

(2) Remove the shift motor and mode sensor

assembly from the transfer case.

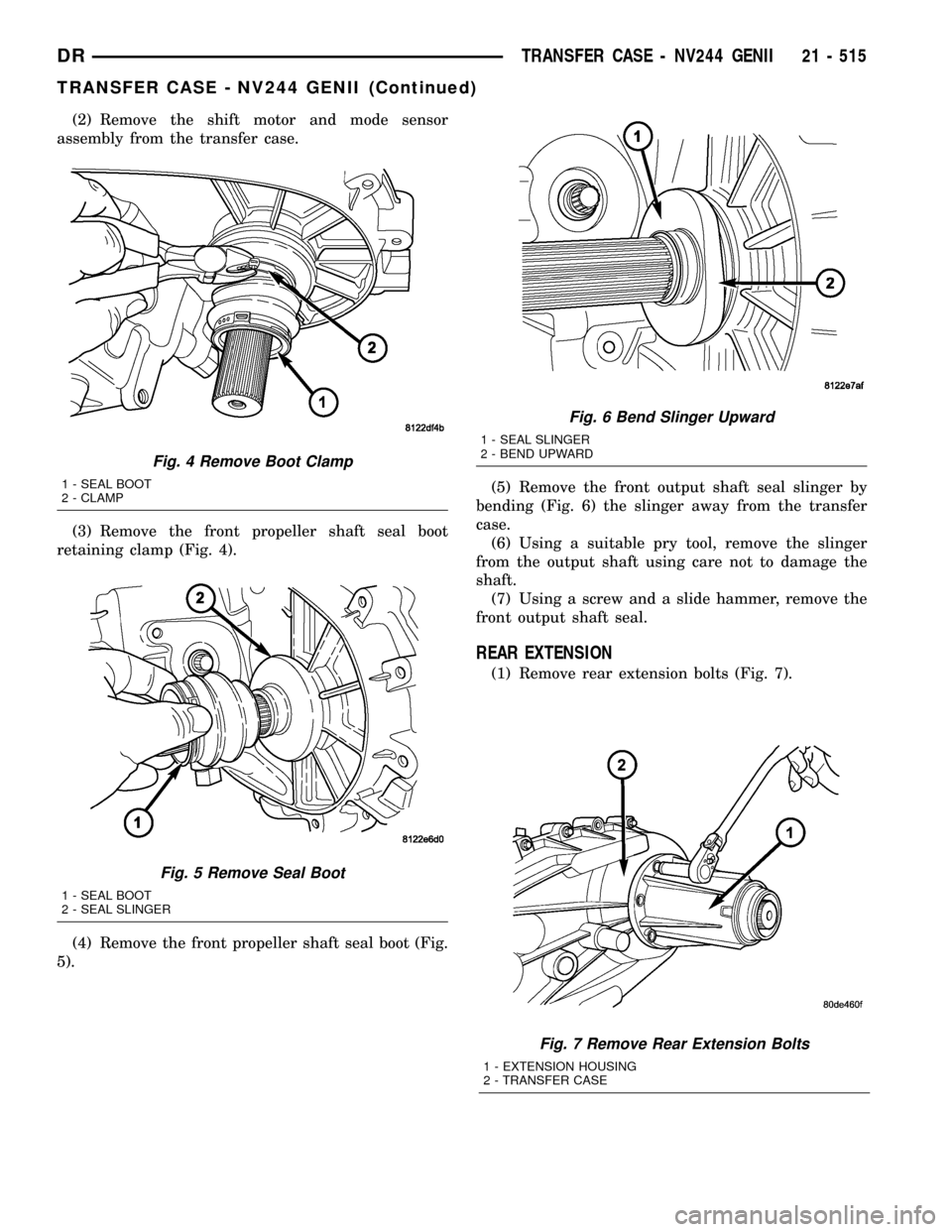

(3) Remove the front propeller shaft seal boot

retaining clamp (Fig. 4).

(4) Remove the front propeller shaft seal boot (Fig.

5).(5) Remove the front output shaft seal slinger by

bending (Fig. 6) the slinger away from the transfer

case.

(6) Using a suitable pry tool, remove the slinger

from the output shaft using care not to damage the

shaft.

(7) Using a screw and a slide hammer, remove the

front output shaft seal.

REAR EXTENSION

(1) Remove rear extension bolts (Fig. 7).

Fig. 7 Remove Rear Extension Bolts

1 - EXTENSION HOUSING

2 - TRANSFER CASE

Fig. 4 Remove Boot Clamp

1 - SEAL BOOT

2 - CLAMP

Fig. 5 Remove Seal Boot

1 - SEAL BOOT

2 - SEAL SLINGER

Fig. 6 Bend Slinger Upward

1 - SEAL SLINGER

2 - BEND UPWARD

DRTRANSFER CASE - NV244 GENII 21 - 515

TRANSFER CASE - NV244 GENII (Continued)

Page 2219 of 2627

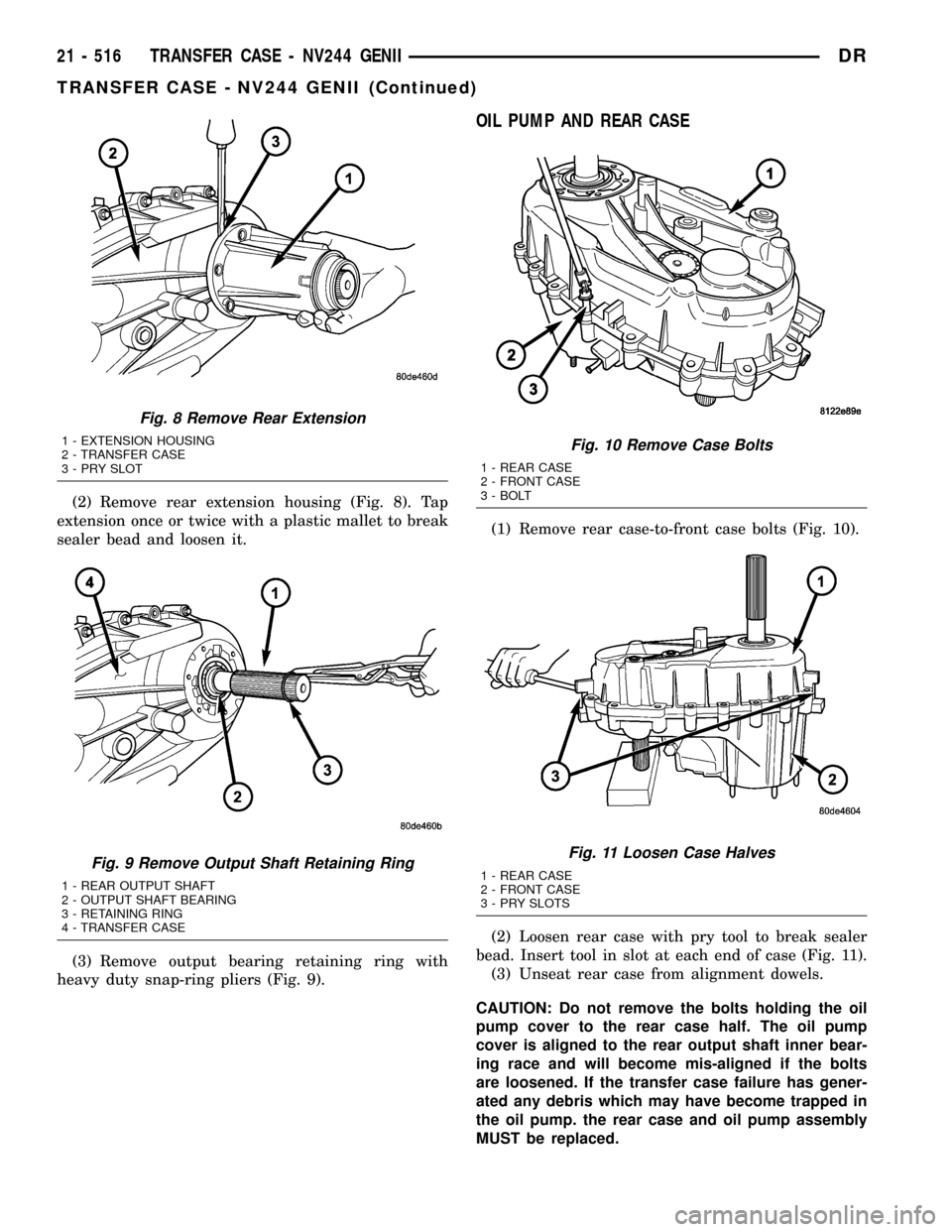

(2) Remove rear extension housing (Fig. 8). Tap

extension once or twice with a plastic mallet to break

sealer bead and loosen it.

(3) Remove output bearing retaining ring with

heavy duty snap-ring pliers (Fig. 9).

OIL PUMP AND REAR CASE

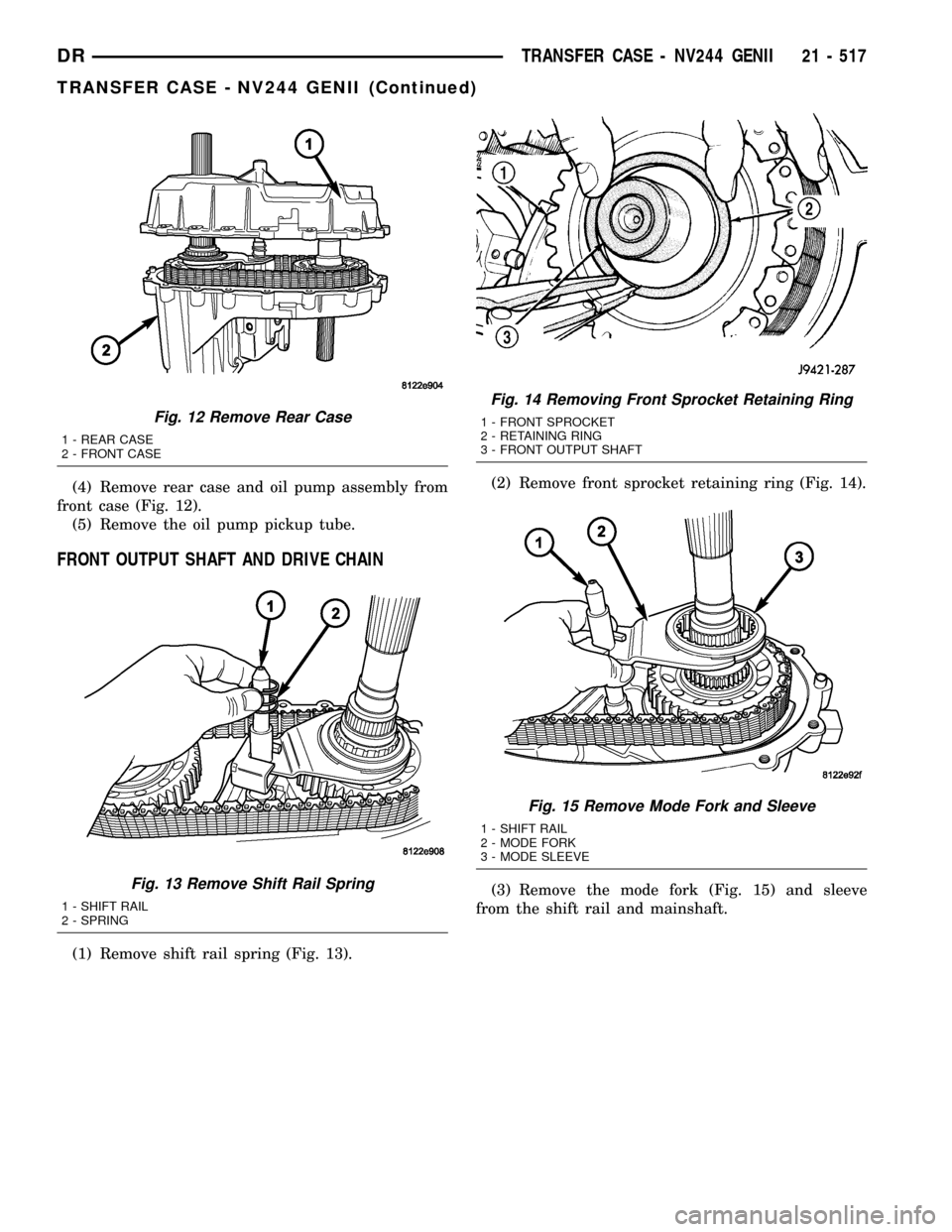

(1) Remove rear case-to-front case bolts (Fig. 10).

(2) Loosen rear case with pry tool to break sealer

bead. Insert tool in slot at each end of case (Fig. 11).

(3) Unseat rear case from alignment dowels.

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner bear-

ing race and will become mis-aligned if the bolts

are loosened. If the transfer case failure has gener-

ated any debris which may have become trapped in

the oil pump. the rear case and oil pump assembly

MUST be replaced.

Fig. 8 Remove Rear Extension

1 - EXTENSION HOUSING

2 - TRANSFER CASE

3 - PRY SLOT

Fig. 9 Remove Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - OUTPUT SHAFT BEARING

3 - RETAINING RING

4 - TRANSFER CASE

Fig. 10 Remove Case Bolts

1 - REAR CASE

2 - FRONT CASE

3 - BOLT

Fig. 11 Loosen Case Halves

1 - REAR CASE

2 - FRONT CASE

3 - PRY SLOTS

21 - 516 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2220 of 2627

(4) Remove rear case and oil pump assembly from

front case (Fig. 12).

(5) Remove the oil pump pickup tube.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Remove shift rail spring (Fig. 13).(2) Remove front sprocket retaining ring (Fig. 14).

(3) Remove the mode fork (Fig. 15) and sleeve

from the shift rail and mainshaft.

Fig. 12 Remove Rear Case

1 - REAR CASE

2 - FRONT CASE

Fig. 13 Remove Shift Rail Spring

1 - SHIFT RAIL

2 - SPRING

Fig. 14 Removing Front Sprocket Retaining Ring

1 - FRONT SPROCKET

2 - RETAINING RING

3 - FRONT OUTPUT SHAFT

Fig. 15 Remove Mode Fork and Sleeve

1 - SHIFT RAIL

2 - MODE FORK

3 - MODE SLEEVE

DRTRANSFER CASE - NV244 GENII 21 - 517

TRANSFER CASE - NV244 GENII (Continued)

Page 2221 of 2627

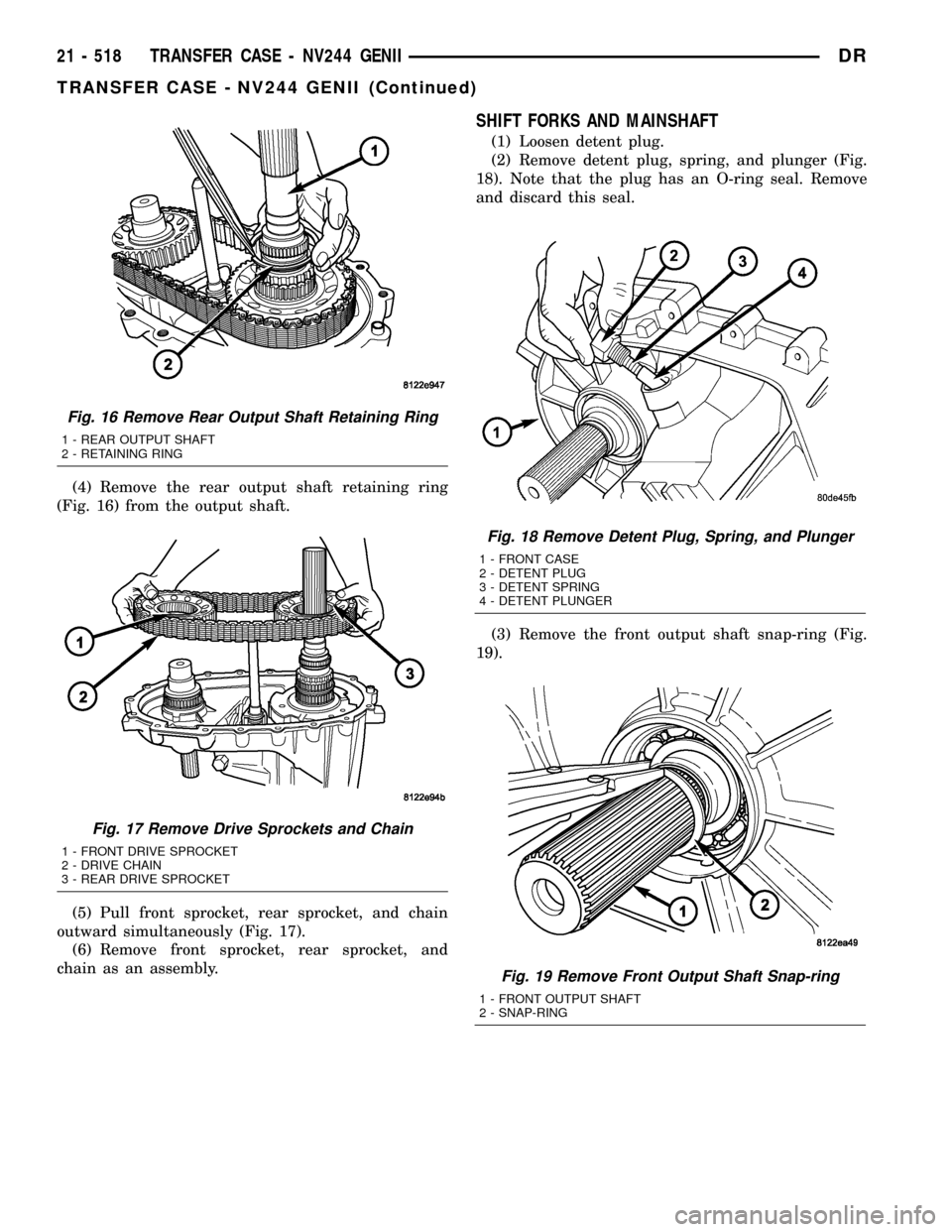

(4) Remove the rear output shaft retaining ring

(Fig. 16) from the output shaft.

(5) Pull front sprocket, rear sprocket, and chain

outward simultaneously (Fig. 17).

(6) Remove front sprocket, rear sprocket, and

chain as an assembly.

SHIFT FORKS AND MAINSHAFT

(1) Loosen detent plug.

(2) Remove detent plug, spring, and plunger (Fig.

18). Note that the plug has an O-ring seal. Remove

and discard this seal.

(3) Remove the front output shaft snap-ring (Fig.

19).

Fig. 18 Remove Detent Plug, Spring, and Plunger

1 - FRONT CASE

2 - DETENT PLUG

3 - DETENT SPRING

4 - DETENT PLUNGER

Fig. 19 Remove Front Output Shaft Snap-ring

1 - FRONT OUTPUT SHAFT

2 - SNAP-RING

Fig. 16 Remove Rear Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - RETAINING RING

Fig. 17 Remove Drive Sprockets and Chain

1 - FRONT DRIVE SPROCKET

2 - DRIVE CHAIN

3 - REAR DRIVE SPROCKET

21 - 518 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2222 of 2627

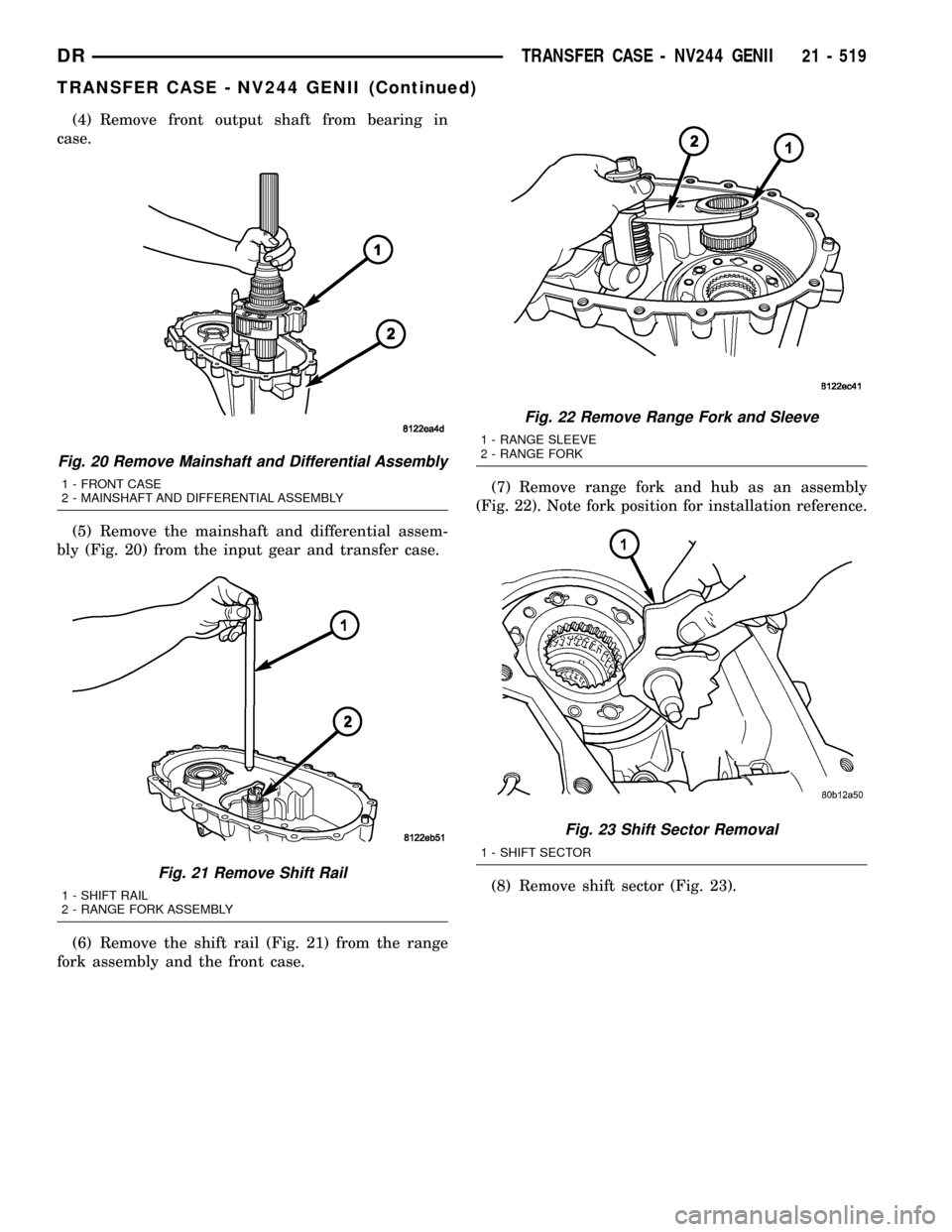

(4) Remove front output shaft from bearing in

case.

(5) Remove the mainshaft and differential assem-

bly (Fig. 20) from the input gear and transfer case.

(6) Remove the shift rail (Fig. 21) from the range

fork assembly and the front case.(7) Remove range fork and hub as an assembly

(Fig. 22). Note fork position for installation reference.

(8) Remove shift sector (Fig. 23).

Fig. 20 Remove Mainshaft and Differential Assembly

1 - FRONT CASE

2 - MAINSHAFT AND DIFFERENTIAL ASSEMBLY

Fig. 21 Remove Shift Rail

1 - SHIFT RAIL

2 - RANGE FORK ASSEMBLY

Fig. 22 Remove Range Fork and Sleeve

1 - RANGE SLEEVE

2 - RANGE FORK

Fig. 23 Shift Sector Removal

1 - SHIFT SECTOR

DRTRANSFER CASE - NV244 GENII 21 - 519

TRANSFER CASE - NV244 GENII (Continued)

Page 2223 of 2627

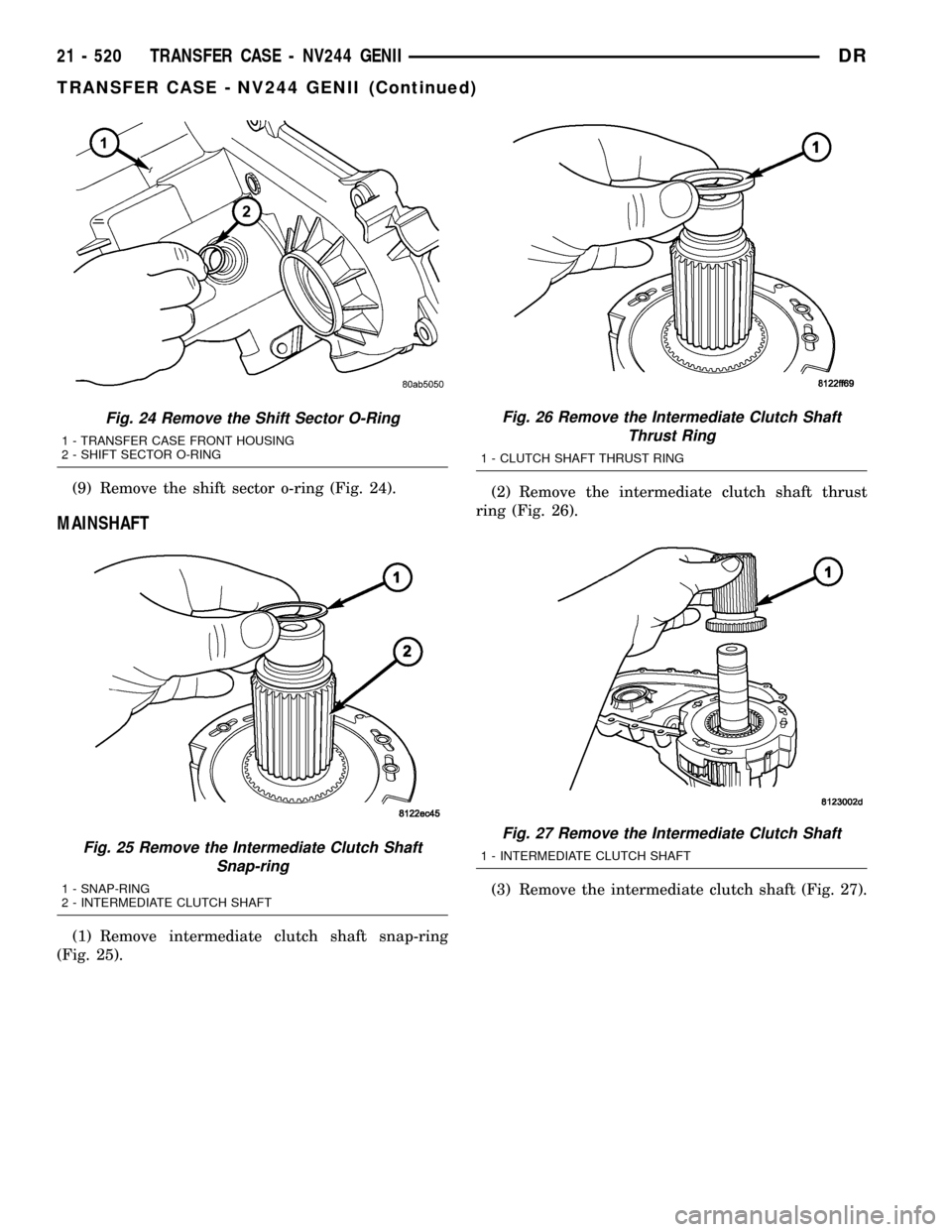

(9) Remove the shift sector o-ring (Fig. 24).

MAINSHAFT

(1) Remove intermediate clutch shaft snap-ring

(Fig. 25).(2) Remove the intermediate clutch shaft thrust

ring (Fig. 26).

(3) Remove the intermediate clutch shaft (Fig. 27).

Fig. 24 Remove the Shift Sector O-Ring

1 - TRANSFER CASE FRONT HOUSING

2 - SHIFT SECTOR O-RING

Fig. 25 Remove the Intermediate Clutch Shaft

Snap-ring

1 - SNAP-RING

2 - INTERMEDIATE CLUTCH SHAFT

Fig. 26 Remove the Intermediate Clutch Shaft

Thrust Ring

1 - CLUTCH SHAFT THRUST RING

Fig. 27 Remove the Intermediate Clutch Shaft

1 - INTERMEDIATE CLUTCH SHAFT

21 - 520 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2224 of 2627

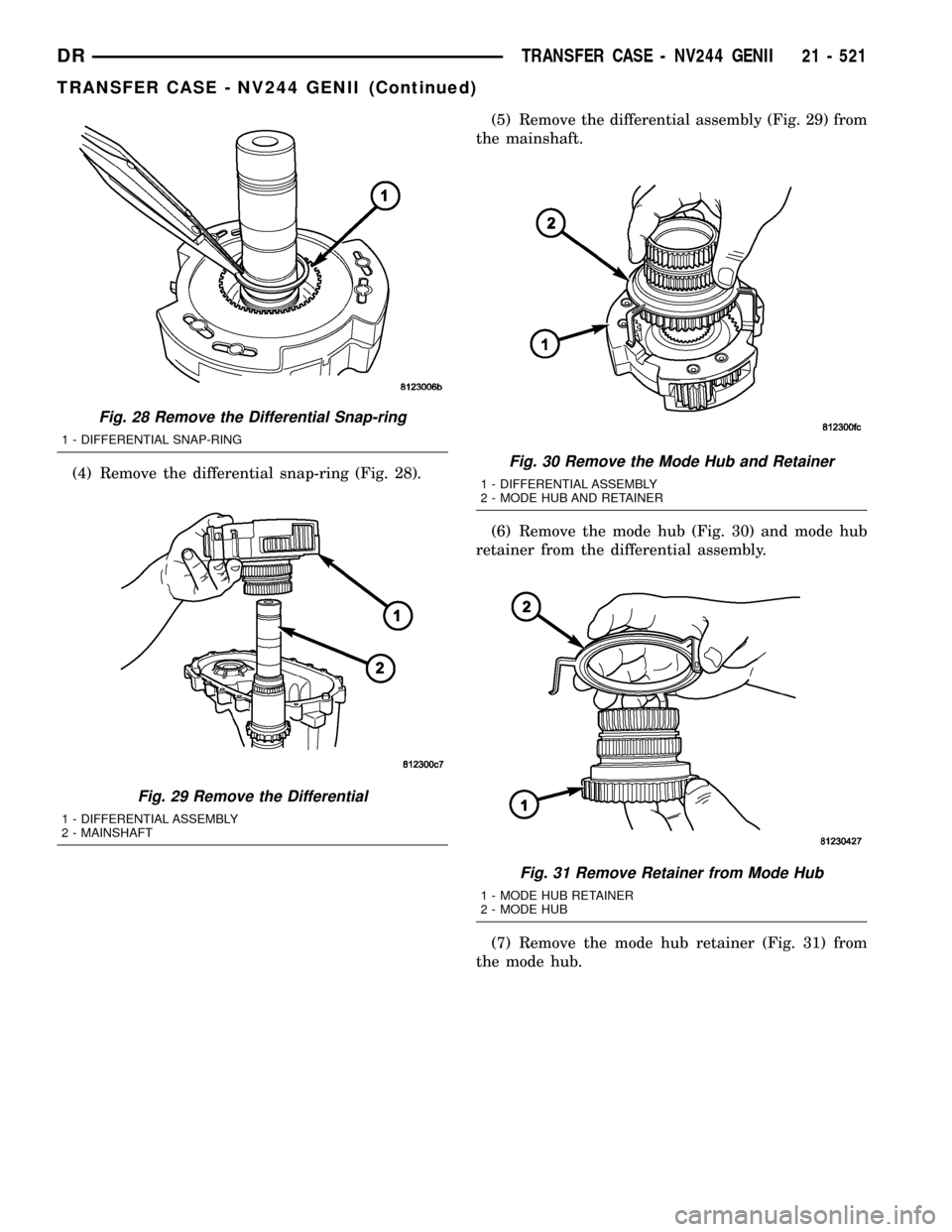

(4) Remove the differential snap-ring (Fig. 28).(5) Remove the differential assembly (Fig. 29) from

the mainshaft.

(6) Remove the mode hub (Fig. 30) and mode hub

retainer from the differential assembly.

(7) Remove the mode hub retainer (Fig. 31) from

the mode hub.

Fig. 28 Remove the Differential Snap-ring

1 - DIFFERENTIAL SNAP-RING

Fig. 29 Remove the Differential

1 - DIFFERENTIAL ASSEMBLY

2 - MAINSHAFT

Fig. 30 Remove the Mode Hub and Retainer

1 - DIFFERENTIAL ASSEMBLY

2 - MODE HUB AND RETAINER

Fig. 31 Remove Retainer from Mode Hub

1 - MODE HUB RETAINER

2 - MODE HUB

DRTRANSFER CASE - NV244 GENII 21 - 521

TRANSFER CASE - NV244 GENII (Continued)