gear DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1729 of 2627

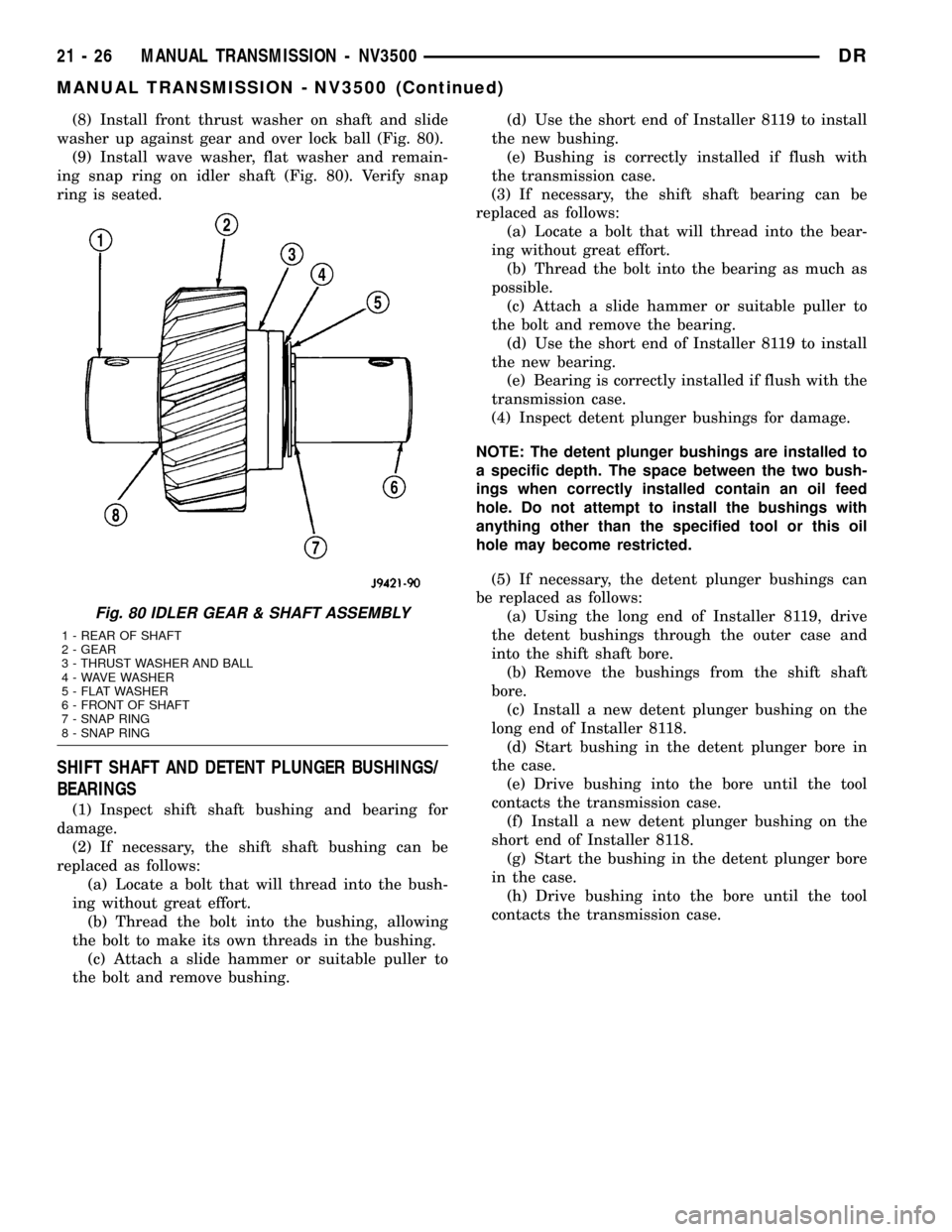

(8) Install front thrust washer on shaft and slide

washer up against gear and over lock ball (Fig. 80).

(9) Install wave washer, flat washer and remain-

ing snap ring on idler shaft (Fig. 80). Verify snap

ring is seated.

SHIFT SHAFT AND DETENT PLUNGER BUSHINGS/

BEARINGS

(1) Inspect shift shaft bushing and bearing for

damage.

(2) If necessary, the shift shaft bushing can be

replaced as follows:

(a) Locate a bolt that will thread into the bush-

ing without great effort.

(b) Thread the bolt into the bushing, allowing

the bolt to make its own threads in the bushing.

(c) Attach a slide hammer or suitable puller to

the bolt and remove bushing.(d) Use the short end of Installer 8119 to install

the new bushing.

(e) Bushing is correctly installed if flush with

the transmission case.

(3) If necessary, the shift shaft bearing can be

replaced as follows:

(a) Locate a bolt that will thread into the bear-

ing without great effort.

(b) Thread the bolt into the bearing as much as

possible.

(c) Attach a slide hammer or suitable puller to

the bolt and remove the bearing.

(d) Use the short end of Installer 8119 to install

the new bearing.

(e) Bearing is correctly installed if flush with the

transmission case.

(4) Inspect detent plunger bushings for damage.

NOTE: The detent plunger bushings are installed to

a specific depth. The space between the two bush-

ings when correctly installed contain an oil feed

hole. Do not attempt to install the bushings with

anything other than the specified tool or this oil

hole may become restricted.

(5) If necessary, the detent plunger bushings can

be replaced as follows:

(a) Using the long end of Installer 8119, drive

the detent bushings through the outer case and

into the shift shaft bore.

(b) Remove the bushings from the shift shaft

bore.

(c) Install a new detent plunger bushing on the

long end of Installer 8118.

(d) Start bushing in the detent plunger bore in

the case.

(e) Drive bushing into the bore until the tool

contacts the transmission case.

(f) Install a new detent plunger bushing on the

short end of Installer 8118.

(g) Start the bushing in the detent plunger bore

in the case.

(h) Drive bushing into the bore until the tool

contacts the transmission case.

Fig. 80 IDLER GEAR & SHAFT ASSEMBLY

1 - REAR OF SHAFT

2 - GEAR

3 - THRUST WASHER AND BALL

4 - WAVE WASHER

5 - FLAT WASHER

6 - FRONT OF SHAFT

7 - SNAP RING

8 - SNAP RING

21 - 26 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1730 of 2627

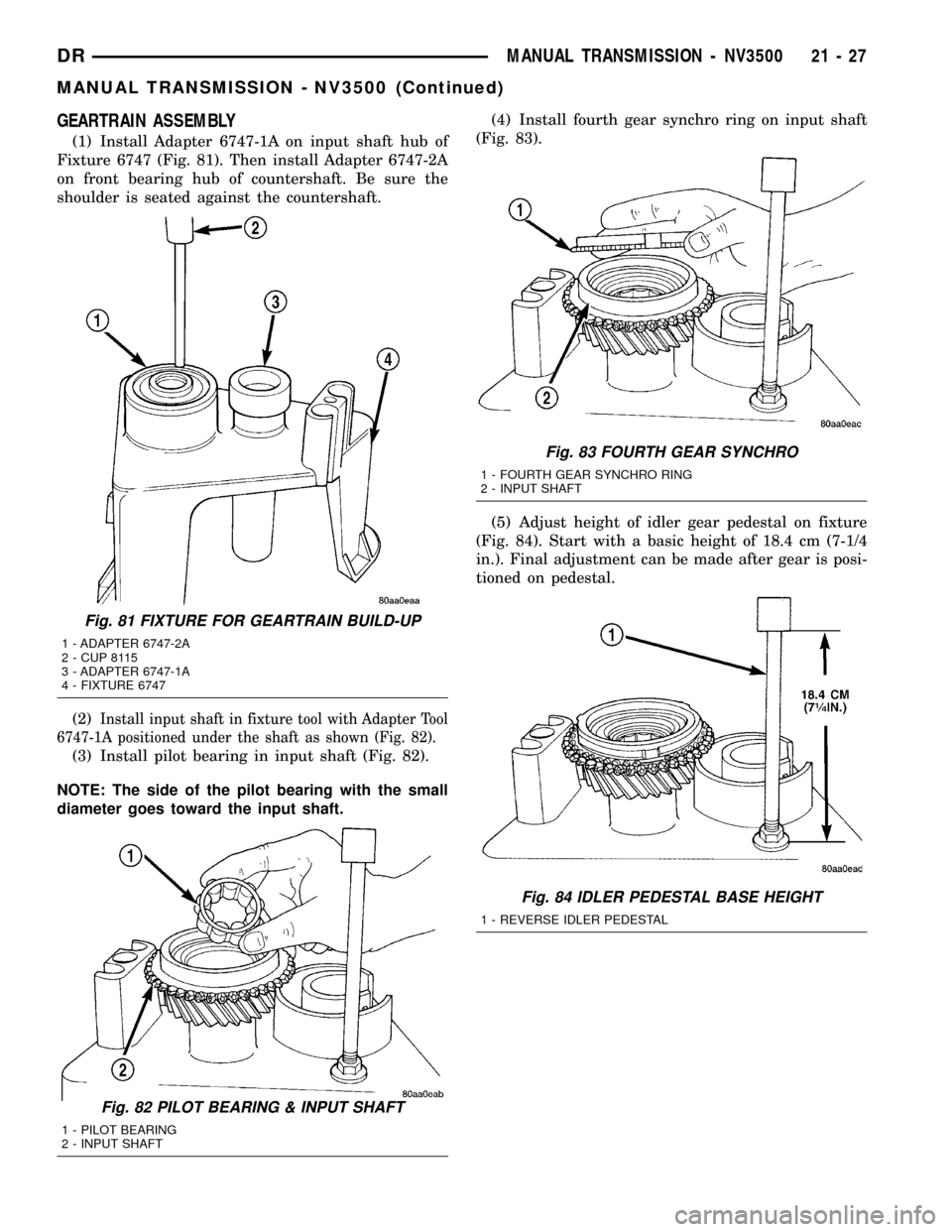

GEARTRAIN ASSEMBLY

(1) Install Adapter 6747-1A on input shaft hub of

Fixture 6747 (Fig. 81). Then install Adapter 6747-2A

on front bearing hub of countershaft. Be sure the

shoulder is seated against the countershaft.

(2)

Install input shaft in fixture tool with Adapter Tool

6747-1A positioned under the shaft as shown (Fig. 82).

(3) Install pilot bearing in input shaft (Fig. 82).

NOTE: The side of the pilot bearing with the small

diameter goes toward the input shaft.(4) Install fourth gear synchro ring on input shaft

(Fig. 83).

(5) Adjust height of idler gear pedestal on fixture

(Fig. 84). Start with a basic height of 18.4 cm (7-1/4

in.). Final adjustment can be made after gear is posi-

tioned on pedestal.

Fig. 81 FIXTURE FOR GEARTRAIN BUILD-UP

1 - ADAPTER 6747-2A

2 - CUP 8115

3 - ADAPTER 6747-1A

4 - FIXTURE 6747

Fig. 82 PILOT BEARING & INPUT SHAFT

1 - PILOT BEARING

2 - INPUT SHAFT

Fig. 83 FOURTH GEAR SYNCHRO

1 - FOURTH GEAR SYNCHRO RING

2 - INPUT SHAFT

Fig. 84 IDLER PEDESTAL BASE HEIGHT

1 - REVERSE IDLER PEDESTAL

DRMANUAL TRANSMISSION - NV3500 21 - 27

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1731 of 2627

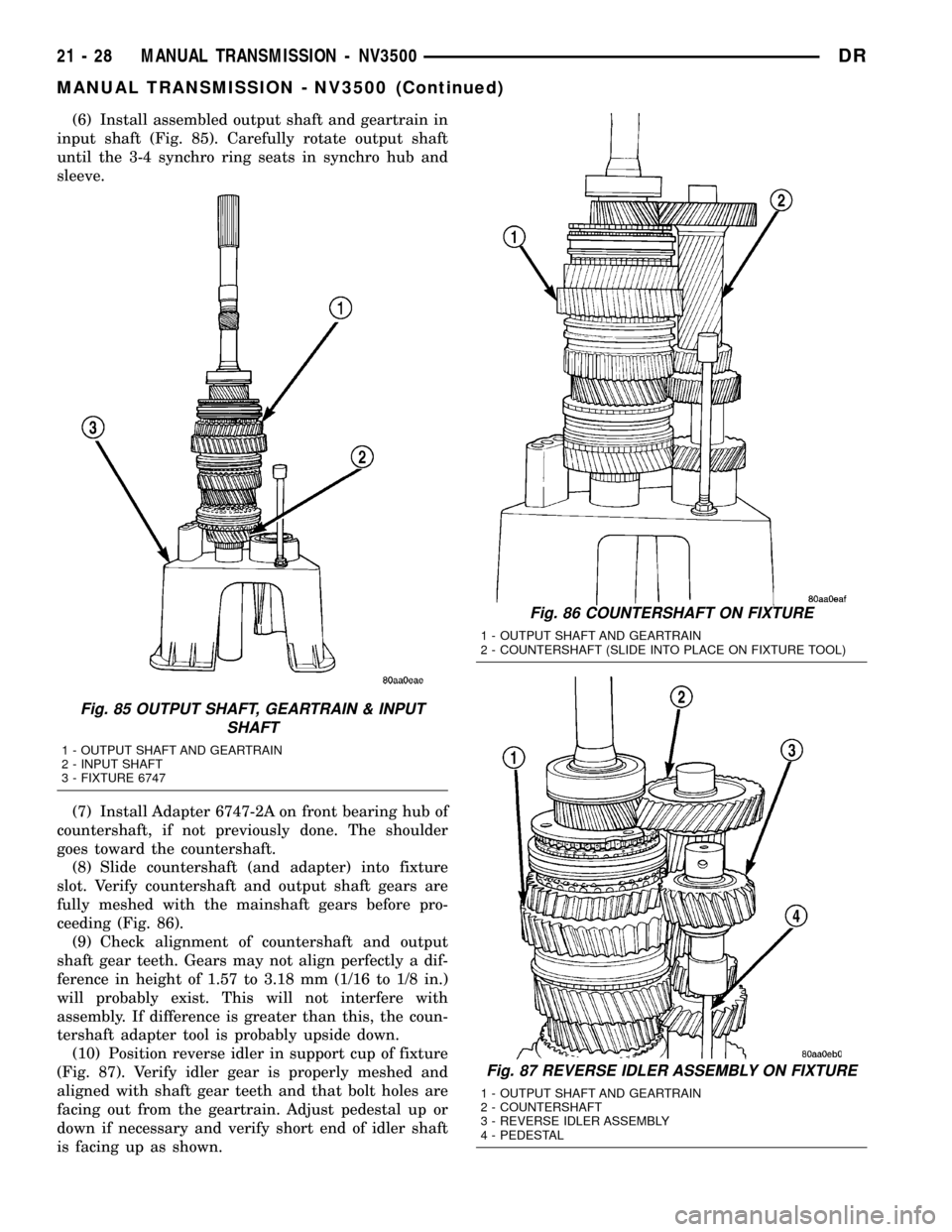

(6) Install assembled output shaft and geartrain in

input shaft (Fig. 85). Carefully rotate output shaft

until the 3-4 synchro ring seats in synchro hub and

sleeve.

(7) Install Adapter 6747-2A on front bearing hub of

countershaft, if not previously done. The shoulder

goes toward the countershaft.

(8) Slide countershaft (and adapter) into fixture

slot. Verify countershaft and output shaft gears are

fully meshed with the mainshaft gears before pro-

ceeding (Fig. 86).

(9) Check alignment of countershaft and output

shaft gear teeth. Gears may not align perfectly a dif-

ference in height of 1.57 to 3.18 mm (1/16 to 1/8 in.)

will probably exist. This will not interfere with

assembly. If difference is greater than this, the coun-

tershaft adapter tool is probably upside down.

(10) Position reverse idler in support cup of fixture

(Fig. 87). Verify idler gear is properly meshed and

aligned with shaft gear teeth and that bolt holes are

facing out from the geartrain. Adjust pedestal up or

down if necessary and verify short end of idler shaft

is facing up as shown.

Fig. 85 OUTPUT SHAFT, GEARTRAIN & INPUT

SHAFT

1 - OUTPUT SHAFT AND GEARTRAIN

2 - INPUT SHAFT

3 - FIXTURE 6747

Fig. 86 COUNTERSHAFT ON FIXTURE

1 - OUTPUT SHAFT AND GEARTRAIN

2 - COUNTERSHAFT (SLIDE INTO PLACE ON FIXTURE TOOL)

Fig. 87 REVERSE IDLER ASSEMBLY ON FIXTURE

1 - OUTPUT SHAFT AND GEARTRAIN

2 - COUNTERSHAFT

3 - REVERSE IDLER ASSEMBLY

4 - PEDESTAL

21 - 28 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1732 of 2627

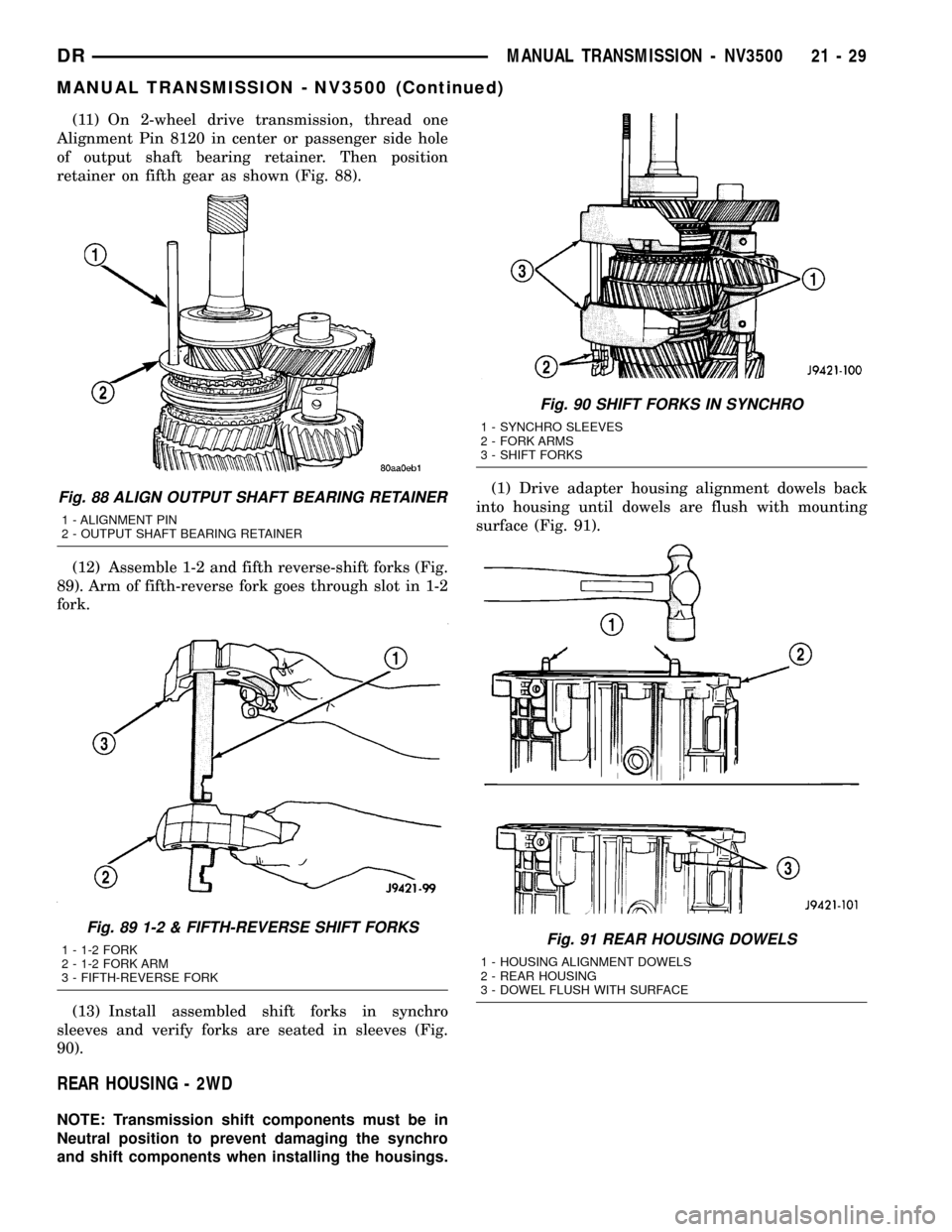

(11) On 2-wheel drive transmission, thread one

Alignment Pin 8120 in center or passenger side hole

of output shaft bearing retainer. Then position

retainer on fifth gear as shown (Fig. 88).

(12) Assemble 1-2 and fifth reverse-shift forks (Fig.

89). Arm of fifth-reverse fork goes through slot in 1-2

fork.

(13) Install assembled shift forks in synchro

sleeves and verify forks are seated in sleeves (Fig.

90).

REAR HOUSING - 2WD

NOTE: Transmission shift components must be in

Neutral position to prevent damaging the synchro

and shift components when installing the housings.(1) Drive adapter housing alignment dowels back

into housing until dowels are flush with mounting

surface (Fig. 91).

Fig. 88 ALIGN OUTPUT SHAFT BEARING RETAINER

1 - ALIGNMENT PIN

2 - OUTPUT SHAFT BEARING RETAINER

Fig. 89 1-2 & FIFTH-REVERSE SHIFT FORKS

1 - 1-2 FORK

2 - 1-2 FORK ARM

3 - FIFTH-REVERSE FORK

Fig. 90 SHIFT FORKS IN SYNCHRO

1 - SYNCHRO SLEEVES

2 - FORK ARMS

3 - SHIFT FORKS

Fig. 91 REAR HOUSING DOWELS

1 - HOUSING ALIGNMENT DOWELS

2 - REAR HOUSING

3 - DOWEL FLUSH WITH SURFACE

DRMANUAL TRANSMISSION - NV3500 21 - 29

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1733 of 2627

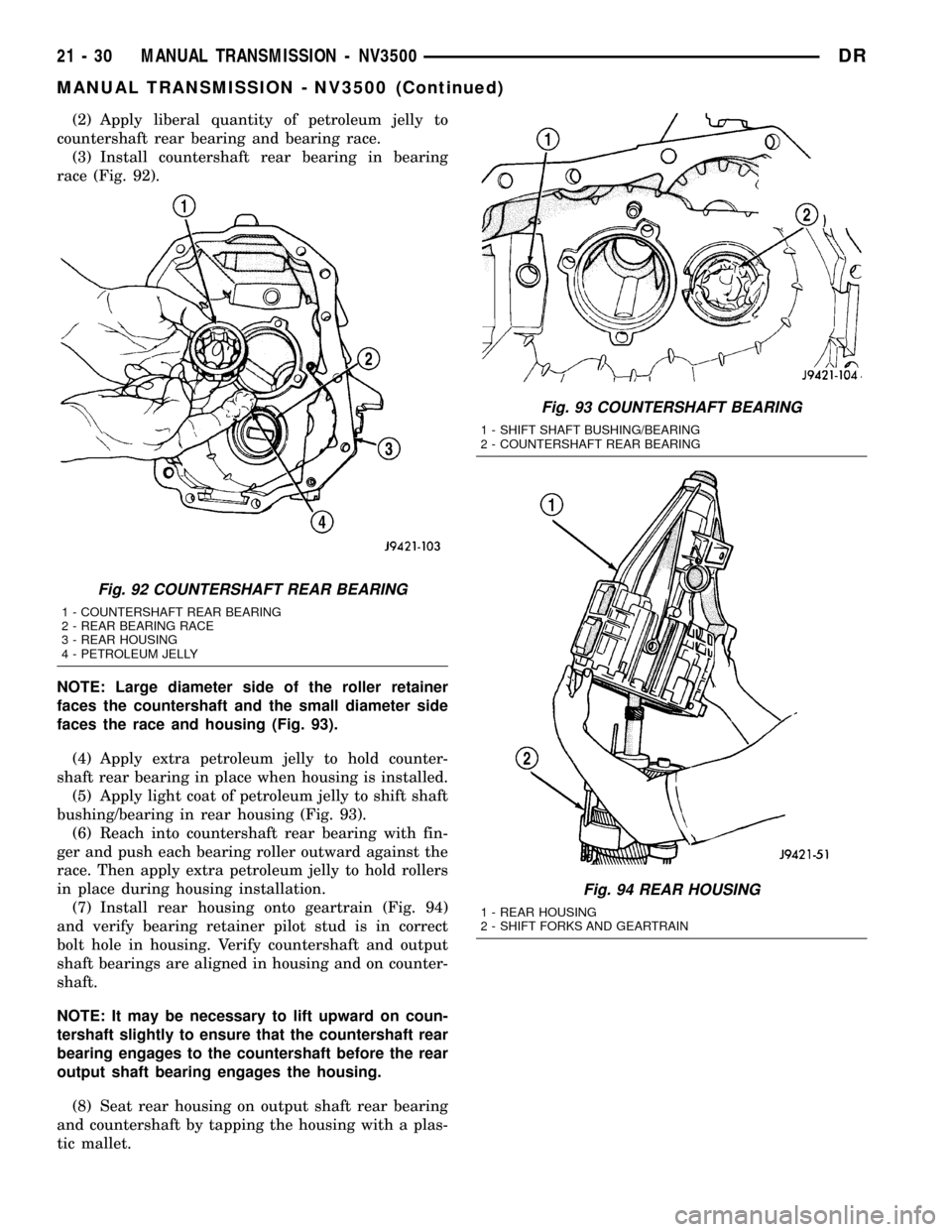

(2) Apply liberal quantity of petroleum jelly to

countershaft rear bearing and bearing race.

(3) Install countershaft rear bearing in bearing

race (Fig. 92).

NOTE: Large diameter side of the roller retainer

faces the countershaft and the small diameter side

faces the race and housing (Fig. 93).

(4) Apply extra petroleum jelly to hold counter-

shaft rear bearing in place when housing is installed.

(5) Apply light coat of petroleum jelly to shift shaft

bushing/bearing in rear housing (Fig. 93).

(6) Reach into countershaft rear bearing with fin-

ger and push each bearing roller outward against the

race. Then apply extra petroleum jelly to hold rollers

in place during housing installation.

(7) Install rear housing onto geartrain (Fig. 94)

and verify bearing retainer pilot stud is in correct

bolt hole in housing. Verify countershaft and output

shaft bearings are aligned in housing and on counter-

shaft.

NOTE: It may be necessary to lift upward on coun-

tershaft slightly to ensure that the countershaft rear

bearing engages to the countershaft before the rear

output shaft bearing engages the housing.

(8) Seat rear housing on output shaft rear bearing

and countershaft by tapping the housing with a plas-

tic mallet.

Fig. 92 COUNTERSHAFT REAR BEARING

1 - COUNTERSHAFT REAR BEARING

2 - REAR BEARING RACE

3 - REAR HOUSING

4 - PETROLEUM JELLY

Fig. 93 COUNTERSHAFT BEARING

1 - SHIFT SHAFT BUSHING/BEARING

2 - COUNTERSHAFT REAR BEARING

Fig. 94 REAR HOUSING

1 - REAR HOUSING

2 - SHIFT FORKS AND GEARTRAIN

21 - 30 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1734 of 2627

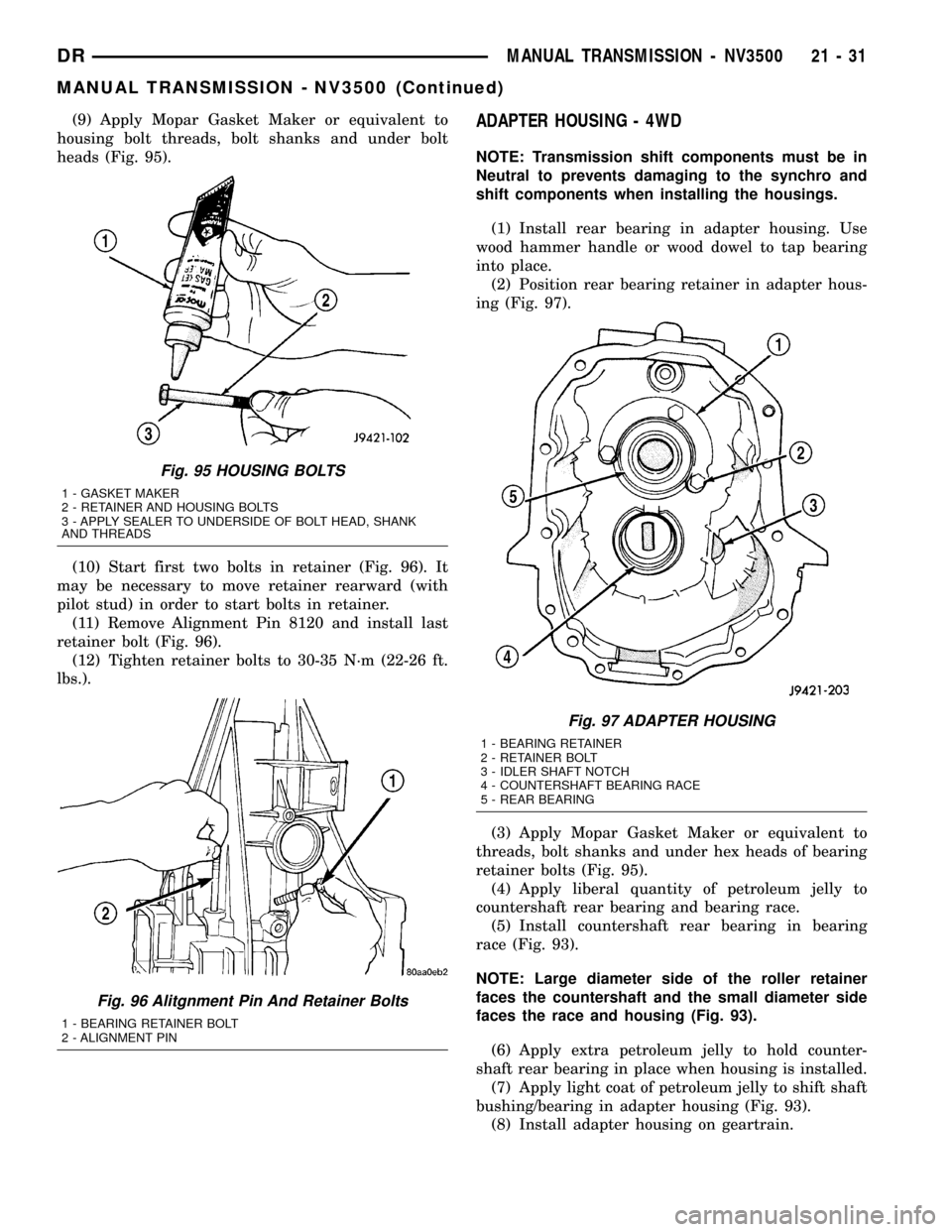

(9) Apply Mopar Gasket Maker or equivalent to

housing bolt threads, bolt shanks and under bolt

heads (Fig. 95).

(10) Start first two bolts in retainer (Fig. 96). It

may be necessary to move retainer rearward (with

pilot stud) in order to start bolts in retainer.

(11) Remove Alignment Pin 8120 and install last

retainer bolt (Fig. 96).

(12) Tighten retainer bolts to 30-35 N´m (22-26 ft.

lbs.).ADAPTER HOUSING - 4WD

NOTE: Transmission shift components must be in

Neutral to prevents damaging to the synchro and

shift components when installing the housings.

(1) Install rear bearing in adapter housing. Use

wood hammer handle or wood dowel to tap bearing

into place.

(2) Position rear bearing retainer in adapter hous-

ing (Fig. 97).

(3) Apply Mopar Gasket Maker or equivalent to

threads, bolt shanks and under hex heads of bearing

retainer bolts (Fig. 95).

(4) Apply liberal quantity of petroleum jelly to

countershaft rear bearing and bearing race.

(5) Install countershaft rear bearing in bearing

race (Fig. 93).

NOTE: Large diameter side of the roller retainer

faces the countershaft and the small diameter side

faces the race and housing (Fig. 93).

(6) Apply extra petroleum jelly to hold counter-

shaft rear bearing in place when housing is installed.

(7) Apply light coat of petroleum jelly to shift shaft

bushing/bearing in adapter housing (Fig. 93).

(8) Install adapter housing on geartrain.

Fig. 95 HOUSING BOLTS

1 - GASKET MAKER

2 - RETAINER AND HOUSING BOLTS

3 - APPLY SEALER TO UNDERSIDE OF BOLT HEAD, SHANK

AND THREADS

Fig. 96 Alitgnment Pin And Retainer Bolts

1 - BEARING RETAINER BOLT

2 - ALIGNMENT PIN

Fig. 97 ADAPTER HOUSING

1 - BEARING RETAINER

2 - RETAINER BOLT

3 - IDLER SHAFT NOTCH

4 - COUNTERSHAFT BEARING RACE

5 - REAR BEARING

DRMANUAL TRANSMISSION - NV3500 21 - 31

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1735 of 2627

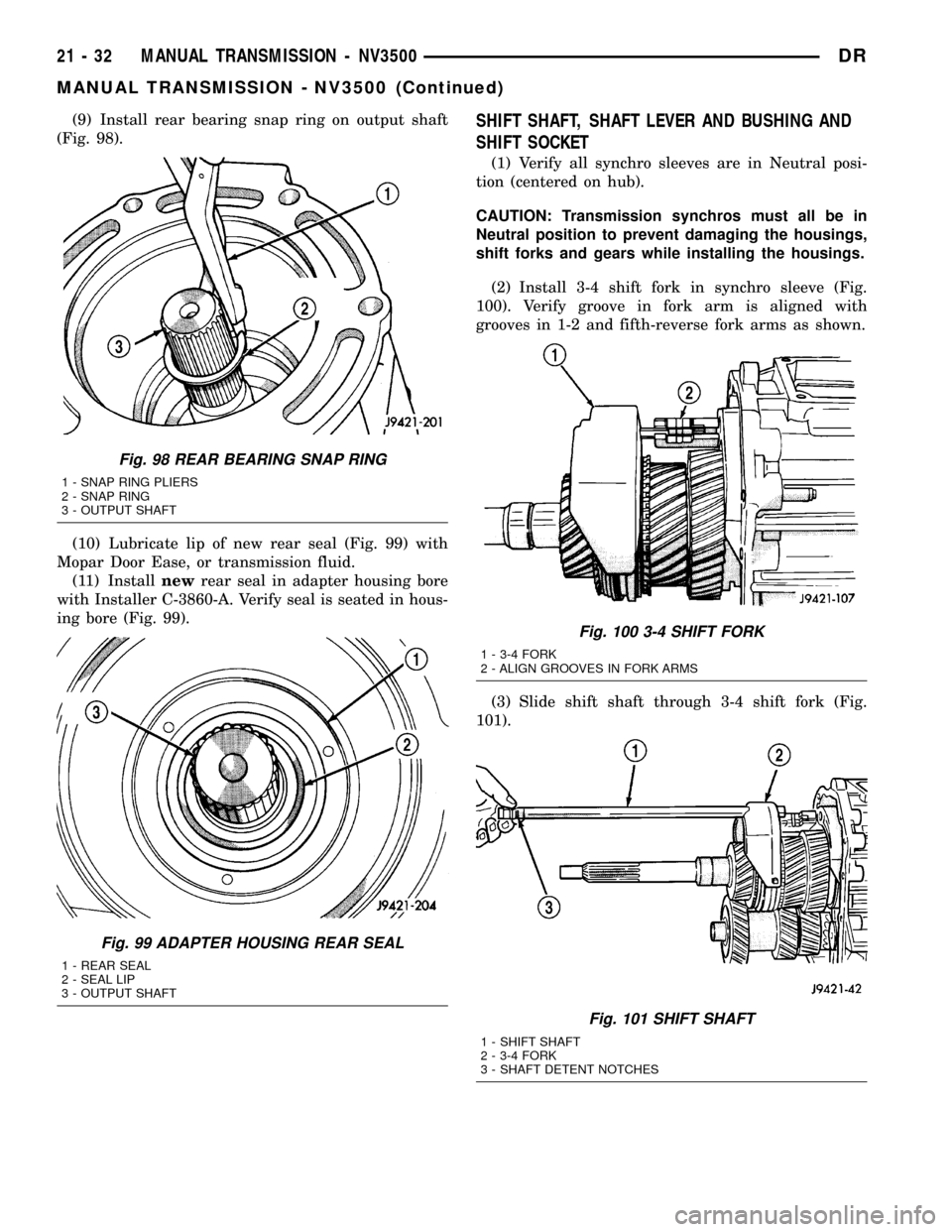

(9) Install rear bearing snap ring on output shaft

(Fig. 98).

(10) Lubricate lip of new rear seal (Fig. 99) with

Mopar Door Ease, or transmission fluid.

(11) Installnewrear seal in adapter housing bore

with Installer C-3860-A. Verify seal is seated in hous-

ing bore (Fig. 99).SHIFT SHAFT, SHAFT LEVER AND BUSHING AND

SHIFT SOCKET

(1) Verify all synchro sleeves are in Neutral posi-

tion (centered on hub).

CAUTION: Transmission synchros must all be in

Neutral position to prevent damaging the housings,

shift forks and gears while installing the housings.

(2) Install 3-4 shift fork in synchro sleeve (Fig.

100). Verify groove in fork arm is aligned with

grooves in 1-2 and fifth-reverse fork arms as shown.

(3) Slide shift shaft through 3-4 shift fork (Fig.

101).

Fig. 98 REAR BEARING SNAP RING

1 - SNAP RING PLIERS

2 - SNAP RING

3 - OUTPUT SHAFT

Fig. 99 ADAPTER HOUSING REAR SEAL

1 - REAR SEAL

2 - SEAL LIP

3 - OUTPUT SHAFT

Fig. 100 3-4 SHIFT FORK

1 - 3-4 FORK

2 - ALIGN GROOVES IN FORK ARMS

Fig. 101 SHIFT SHAFT

1 - SHIFT SHAFT

2 - 3-4 FORK

3 - SHAFT DETENT NOTCHES

21 - 32 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1739 of 2627

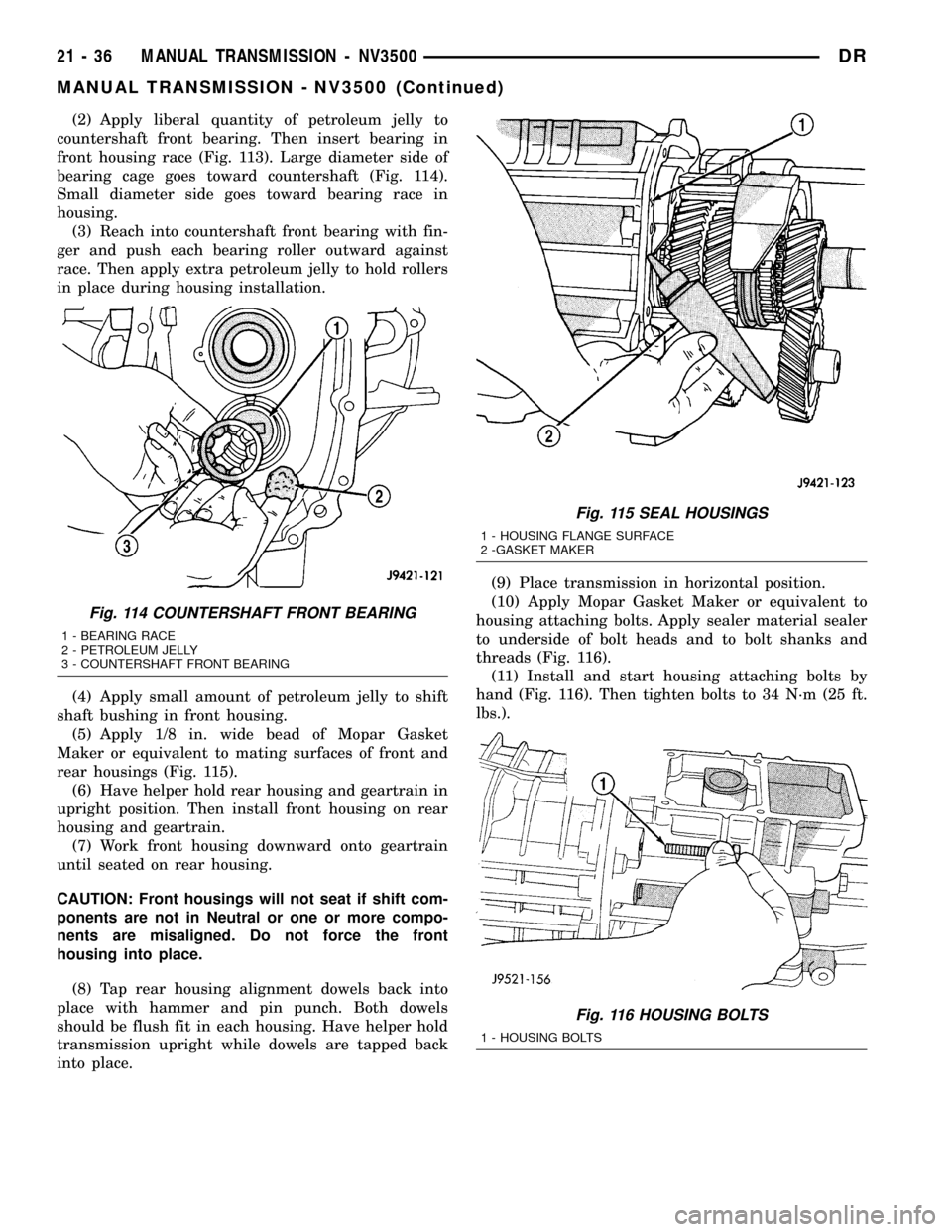

(2) Apply liberal quantity of petroleum jelly to

countershaft front bearing. Then insert bearing in

front housing race (Fig. 113). Large diameter side of

bearing cage goes toward countershaft (Fig. 114).

Small diameter side goes toward bearing race in

housing.

(3) Reach into countershaft front bearing with fin-

ger and push each bearing roller outward against

race. Then apply extra petroleum jelly to hold rollers

in place during housing installation.

(4) Apply small amount of petroleum jelly to shift

shaft bushing in front housing.

(5) Apply 1/8 in. wide bead of Mopar Gasket

Maker or equivalent to mating surfaces of front and

rear housings (Fig. 115).

(6) Have helper hold rear housing and geartrain in

upright position. Then install front housing on rear

housing and geartrain.

(7) Work front housing downward onto geartrain

until seated on rear housing.

CAUTION: Front housings will not seat if shift com-

ponents are not in Neutral or one or more compo-

nents are misaligned. Do not force the front

housing into place.

(8) Tap rear housing alignment dowels back into

place with hammer and pin punch. Both dowels

should be flush fit in each housing. Have helper hold

transmission upright while dowels are tapped back

into place.(9) Place transmission in horizontal position.

(10) Apply Mopar Gasket Maker or equivalent to

housing attaching bolts. Apply sealer material sealer

to underside of bolt heads and to bolt shanks and

threads (Fig. 116).

(11) Install and start housing attaching bolts by

hand (Fig. 116). Then tighten bolts to 34 N´m (25 ft.

lbs.).

Fig. 114 COUNTERSHAFT FRONT BEARING

1 - BEARING RACE

2 - PETROLEUM JELLY

3 - COUNTERSHAFT FRONT BEARING

Fig. 115 SEAL HOUSINGS

1 - HOUSING FLANGE SURFACE

2 -GASKET MAKER

Fig. 116 HOUSING BOLTS

1 - HOUSING BOLTS

21 - 36 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1741 of 2627

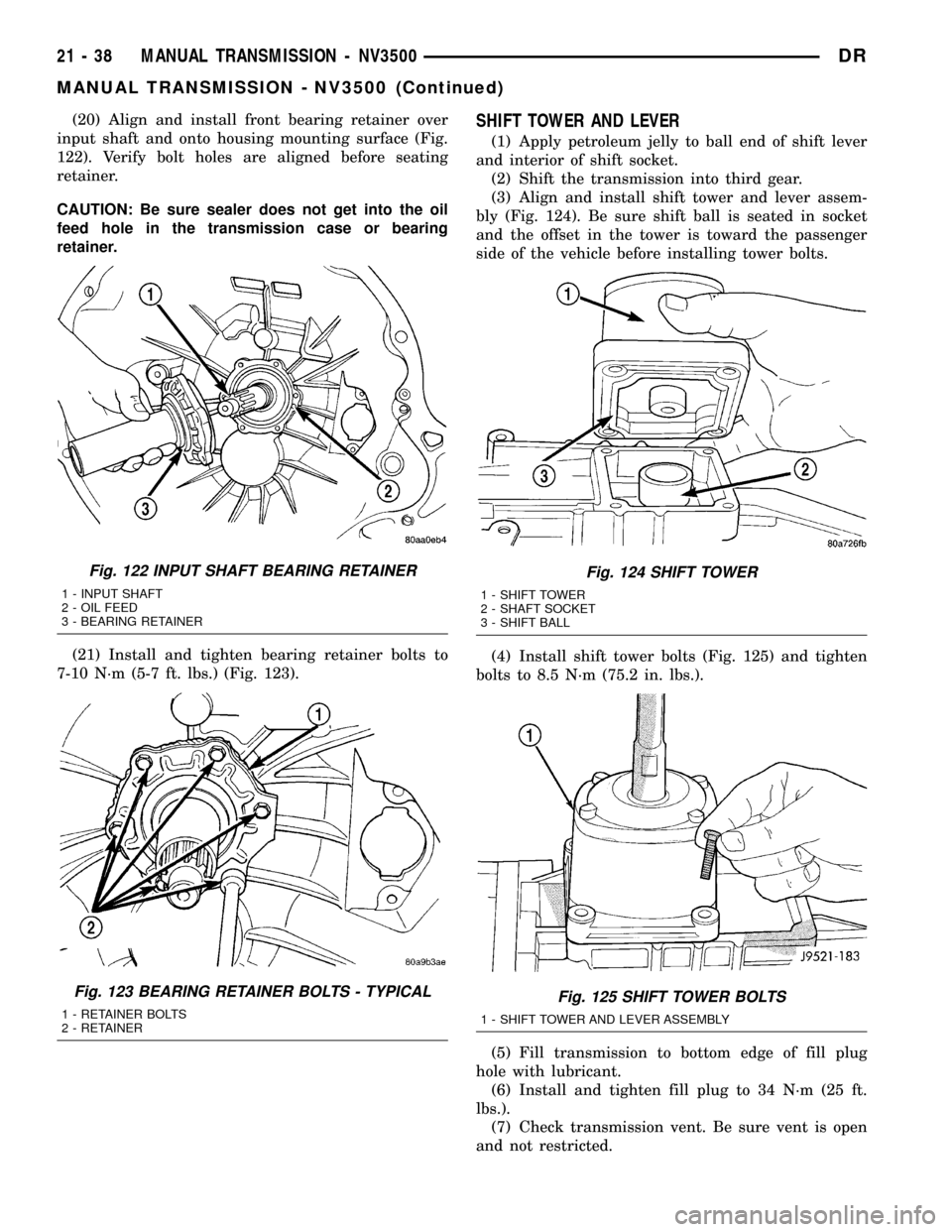

(20) Align and install front bearing retainer over

input shaft and onto housing mounting surface (Fig.

122). Verify bolt holes are aligned before seating

retainer.

CAUTION: Be sure sealer does not get into the oil

feed hole in the transmission case or bearing

retainer.

(21) Install and tighten bearing retainer bolts to

7-10 N´m (5-7 ft. lbs.) (Fig. 123).SHIFT TOWER AND LEVER

(1) Apply petroleum jelly to ball end of shift lever

and interior of shift socket.

(2) Shift the transmission into third gear.

(3) Align and install shift tower and lever assem-

bly (Fig. 124). Be sure shift ball is seated in socket

and the offset in the tower is toward the passenger

side of the vehicle before installing tower bolts.

(4) Install shift tower bolts (Fig. 125) and tighten

bolts to 8.5 N´m (75.2 in. lbs.).

(5) Fill transmission to bottom edge of fill plug

hole with lubricant.

(6) Install and tighten fill plug to 34 N´m (25 ft.

lbs.).

(7) Check transmission vent. Be sure vent is open

and not restricted.

Fig. 122 INPUT SHAFT BEARING RETAINER

1 - INPUT SHAFT

2 - OIL FEED

3 - BEARING RETAINER

Fig. 123 BEARING RETAINER BOLTS - TYPICAL

1 - RETAINER BOLTS

2 - RETAINER

Fig. 124 SHIFT TOWER

1 - SHIFT TOWER

2 - SHAFT SOCKET

3 - SHIFT BALL

Fig. 125 SHIFT TOWER BOLTS

1 - SHIFT TOWER AND LEVER ASSEMBLY

21 - 38 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1746 of 2627

MANUAL TRANSMISSION - NV4500

TABLE OF CONTENTS

page page

MANUAL TRANSMISSION - NV4500

DESCRIPTION.........................43

OPERATION...........................43

DIAGNOSIS AND TESTING................44

REMOVAL.............................44

DISASSEMBLY.........................46

CLEANING............................62

INSPECTION..........................62

ASSEMBLY............................63

INSTALLATION.........................80

SPECIFICATIONS.......................81

SPECIAL TOOLS.......................81ADAPTER HOUSING SEAL

REMOVAL.............................85

INSTALLATION.........................85

EXTENSION HOUSING SEAL

REMOVAL.............................85

INSTALLATION.........................85

SHIFT MECHANISM

REMOVAL.............................86

INSTALLATION.........................87

SHIFT COVER

REMOVAL.............................87

INSTALLATION.........................87

MANUAL TRANSMISSION -

NV4500

DESCRIPTION

The NV4500 is a five speed constant mesh manual

transmission. All gear ranges including reverse are

synchronized. Fifth gear is an overdrive range. The

transmission has a cast iron gear case and aluminum

shift cover.

Two versions are used, a standard duty for 5.7L

applications and a heavy duty for V10 and Cummins

diesel applications. Main difference is a larger diam-

eter input shaft, for the heavy duty model.

Tapered roller bearings support the drive gear,

mainshaft and countershaft in the gear case. Roller

bearings in the drive gear support the forward end of

the mainshaft. The mainshaft gears are all supported

on caged type roller bearings. Drive gear thrust reac-

tion is controlled by a needle type thrust bearing.

The bearing is located at the forward end of the

mainshaft.

The transmission is a top loader style. The shift

lever is located in a shifter tower which is bolted to

the shift cover and operates the shift forks and rails

directly. The shift forks and rails are all located

within the aluminum cover which is bolted to the top

of the gear case.

IDENTIFICATION

The transmission identification tag is attached to

the driver side PTO cover (Fig. 1).

The tag provides the transmission model number,

build date and part number. Be sure to reinstall the

I.D. tag if removed during service. The information

on the tag is essential to correct parts ordering.

OPERATION

The manual transmission receives power through

the clutch assembly from the engine. The clutch disc

is splined to the transmission input shaft and is

turned at engine speed at all times that the clutch is

engaged. The input shaft is connected to the trans-

mission countershaft through the mesh of fourth

speed gear on the input shaft and the fourth counter-

shaft gear. At this point all the transmission gears

are spinning.

Fig. 1 IDENTIFICATION TAG LOCATION

1 - PTO COVER

2 - I.D. TAG

DRMANUAL TRANSMISSION - NV4500 21 - 43