system DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 680 of 2627

(5) Pull the side impact sensor out through the

large hole in the B-pillar far enough to access and

disconnect the body wire harness connector for the

sensor from the sensor connector receptacle.

(6) Remove the side impact sensor from the B-pil-

lar.

INSTALLATION

INSTALLATION - STANDARD CAB

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.WARNING: TO AVOID PERSONAL INJURY OR

DEATH, NEVER STRIKE OR DROP THE SIDE

IMPACT SENSOR, AS IT CAN DAMAGE THE IMPACT

SENSOR OR AFFECT ITS CALIBRATION. THE SIDE

IMPACT SENSOR ENABLES THE SYSTEM TO

DEPLOY THE SIDE CURTAIN AIRBAGS. IF AN

IMPACT SENSOR IS ACCIDENTALLY DROPPED

DURING SERVICE, THE MODULE MUST BE

SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER SUPPLEMENTAL RESTRAINT DEPLOY-

MENT.

(1) Position the side impact sensor to the retractor

mounting hole in the inner B-pillar (Fig. 55).

(2) Reconnect the body wire harness connector for

the side impact sensor to the sensor connector recep-

tacle.

(3) Reach through the retractor mounting hole in

the inner B-pillar to position and engage the locating

pin and the stud on the side impact sensor to the

locating slot and mounting hole from the inside of

the B-pillar.

(4) Install and tighten the nut that secures the

side impact sensor stud to the inner B-pillar. Tighten

the nut to 8 N´m (70 in. lbs.).

(5) Reinstall the front outboard seat belt and

retractor to the inside of the B-pillar. (Refer to 8 -

ELECTRICAL/RESTRAINTS/FRONT OUTBOARD

SEAT BELT & RETRACTOR - INSTALLATION -

STANDARD CAB).

(6) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

INSTALLATION - QUAD CAB

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

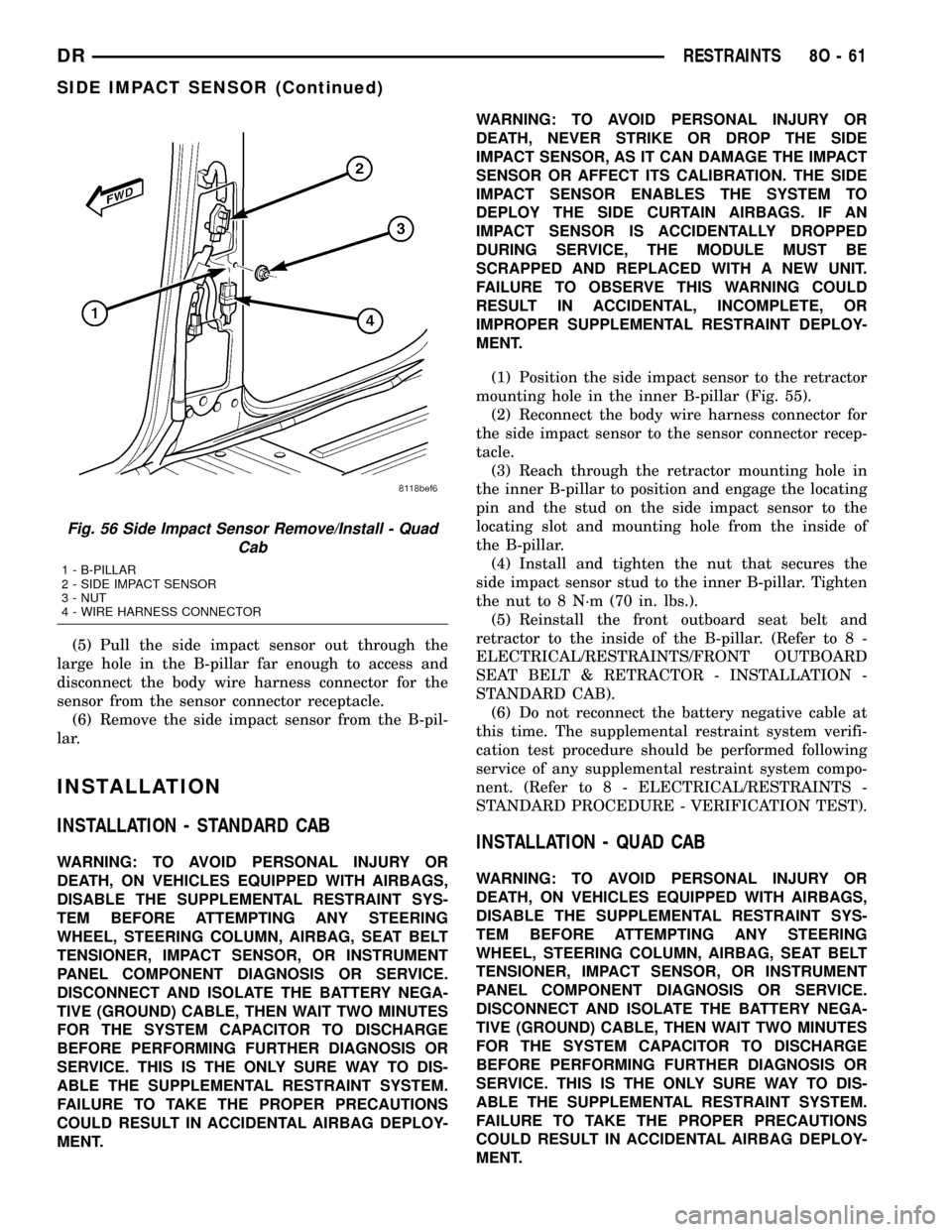

Fig. 56 Side Impact Sensor Remove/Install - Quad

Cab

1 - B-PILLAR

2 - SIDE IMPACT SENSOR

3 - NUT

4 - WIRE HARNESS CONNECTOR

DRRESTRAINTS 8O - 61

SIDE IMPACT SENSOR (Continued)

Page 681 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, NEVER STRIKE OR DROP THE SIDE

IMPACT SENSOR, AS IT CAN DAMAGE THE IMPACT

SENSOR OR AFFECT ITS CALIBRATION. THE SIDE

IMPACT SENSOR ENABLES THE SYSTEM TO

DEPLOY THE SIDE CURTAIN AIRBAGS. IF AN

IMPACT SENSOR IS ACCIDENTALLY DROPPED

DURING SERVICE, THE MODULE MUST BE

SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER SUPPLEMENTAL RESTRAINT DEPLOY-

MENT.

(1) Position the side impact sensor to the large

hole above the retractor mounting hole in the inner

B-pillar (Fig. 56).

(2) Reconnect the body wire harness connector for

the side impact sensor to the sensor connector recep-

tacle.(3) Reach through the large hole above the retrac-

tor mounting hole in the inner B-pillar to position

and engage the locating pin and the stud on the side

impact sensor to the locating slot and mounting hole

from the inside of the B-pillar.

(4) Install and tighten the nut that secures the

side impact sensor stud to the inner B-pillar. Tighten

the nut to 8 N´m (70 in. lbs.).

(5) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

8O - 62 RESTRAINTSDR

SIDE IMPACT SENSOR (Continued)

Page 682 of 2627

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - VACUUM

SUPPLY TEST.........................2

DIAGNOSIS AND TESTING - ROAD TEST....3

SPECIFICATIONS

TORQUE - SPEED CONTROL.............3

CABLE

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................5

SERVO

DESCRIPTION..........................6OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

SWITCH

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................8

INSTALLATION..........................8

VACUUM RESERVOIR

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - VACUUM

RESERVOIR..........................9

REMOVAL.............................9

INSTALLATION.........................10

SPEED CONTROL

DESCRIPTION

All 3.7L/4.7LGas Engines and/or Diesel With

Automatic Trans.

The speed control system is operated by the use of

a cable and a vacuum controlled servo. On all

engines except diesels, electronic control of the speed

control system is integrated into the Powertrain Con-

trol Module (PCM). If equipped with a diesel engine,

electronic control of the speed control system is inte-

grated into the Engine Control Module (ECM). The

controls consist of two steering wheel mounted

switches. The switches are labeled: ON/OFF, RES/

ACCEL, SET, COAST, and CANCEL.

The system is designed to operate at speeds above

30 mph (50 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

5.7L Gas

The speed control system is fully electronically con-

trolled by the Powertrain Control Module (PCM).A

cable and a vacuum controlled servo are not

used. This is a servo-less system.The controls

consist of two steering wheel mounted switches. The

switches are labeled: ON/OFF, RES/ACCEL, SET,

COAST, and CANCEL.

The system is designed to operate at speeds above

30 mph (50 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

DRSPEED CONTROL 8P - 1

Page 683 of 2627

5.9L Diesel With Manual Trans.

The speed control system is fully electronically con-

trolled by the Engine Control Module (ECM).A

cable and a vacuum controlled servo are not

used if the vehicle is equipped with a manual

transmission and a diesel engine. This is a ser-

vo-less system.The controls consist of two steering

wheel mounted switches. The switches are labeled:

ON/OFF, RES/ACCEL, SET, COAST, and CANCEL.

The system is designed to operate at speeds above

30 mph (50 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

When speed control is selected by depressing the

ON switch, the PCM (the ECM with a diesel engine)

allows a set speed to be stored in its RAM for speed

control. To store a set speed, depress the SET switch

while the vehicle is moving at a speed between 35

and 85 mph. In order for the speed control to engage,

the brakes cannot be applied, nor can the gear selec-

tor be indicating the transmission is in Park or Neu-

tral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal (if equipped).

NOTE: Depressing the OFF switch or turning off the

ignition switch will erase the set speed stored in

the PCM (the ECM with a diesel engine).

For added safety, the speed control system is pro-

grammed to disengage for any of the following condi-

tions:

²An indication of Park or Neutral

²A rapid increase rpm (indicates that the clutch

has been disengaged)

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The speed signal increases at a rate of 10 mph

per second (indicates that the coefficient of friction

between the road surface and tires is extremely low)

²The speed signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)Once the speed control has been disengaged,

depressing the RES/ACCEL switch (when speed is

greater than 30 mph) restores the vehicle to the tar-

get speed that was stored in the PCM (the ECM with

a diesel engine).

While the speed control is engaged, the driver can

increase the vehicle speed by depressing the RES/AC-

CEL switch. The new target speed is stored in the

PCM (the ECM with a diesel engine) when the RES/

ACCEL is released. The PCM (the ECM with a diesel

engine) also has a9tap-up9feature in which vehicle

speed increases at a rate of approximately 2 mph for

each momentary switch activation of the RES/AC-

CEL switch.

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - VACUUM SUPPLY

TEST

3.7L / 4.7L Gas Powered Engines

3.7L/4.7L gas powered engines: actual engine vac-

uum, a vacuum reservoir, a one-way check valve and

vacuum lines are used to supply vacuum to the speed

control servo.

(1) Disconnect vacuum hose at speed control servo

and install a vacuum gauge into the disconnected

hose.

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury.

(3) If vacuum is less than ten inches of mercury,

determine source of leak. Check vacuum line to

engine for leaks. Also check actual engine intake

manifold vacuum. If manifold vacuum does not meet

this requirement, check for poor engine performance

and repair as necessary.

(4) If vacuum line to engine is not leaking, check

for leak at vacuum reservoir. To locate and gain

access to reservoir, refer to Vacuum Reservoir Remov-

al/Installation in this group. Disconnect vacuum line

at reservoir and connect a hand-operated vacuum

pump to reservoir fitting. Apply vacuum. Reservoir

vacuum should not bleed off. If vacuum is being lost,

replace reservoir.

8P - 2 SPEED CONTROLDR

SPEED CONTROL (Continued)

Page 684 of 2627

(5) Verify operation of one-way check valve and

check it for leaks.

(a) Locate one-way check valve. The valve is

located in vacuum line between vacuum reservoir

and engine vacuum source. Disconnect vacuum

hoses (lines) at each end of valve.

(b) Connect a hand-operated vacuum pump to

reservoir end of check valve. Apply vacuum. Vac-

uum should not bleed off. If vacuum is being lost,

replace one-way check valve.

(c) Connect a hand-operated vacuum pump to

vacuum source end of check valve. Apply vacuum.

Vacuum should flow through valve. If vacuum is

not flowing, replace one-way check valve. Seal the

fitting at opposite end of valve with a finger and

apply vacuum. If vacuum will not hold, diaphragm

within check valve has ruptured. Replace valve.

5.7 Gas

Vacuum is not used for any part of the speed con-

trol system if equipped with a 5.7L V-8 engine.

5.9L Diesel Engine With Manual Trans.

Vacuum is not used for any part of the speed con-

trol system if equipped with a diesel engine and a

manual transmission.

5.9L Diesel Engines With Automatic Trans.

If equipped with a diesel powered engine and an

automatic transmission, an electric vacuum pump

and vacuum lines are used to supply vacuum to the

speed control servo. A vacuum reservoir is not used.

DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road test

should include attention to the speedometer. Speed-ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Instrument

Cluster for speedometer diagnosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose, damaged or corroded electrical connec-

tions at the servo (if used). Corrosion should be

removed from electrical terminals and a light coating

of Mopar MultiPurpose Grease, or equivalent,

applied.

²Leaking vacuum reservoir (if used).

²Loose or leaking vacuum hoses or connections (if

used).

²Defective one-way vacuum check valve (if used).

²Secure attachment of both ends of the speed con-

trol servo cable (if used).

²Smooth operation of throttle linkage (if used)

and throttle body air valve.

²Failed speed control servo (if used). Do the servo

vacuum test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SPECIFICATIONS

TORQUE - SPEED CONTROL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Servo Mounting Bracket-

to-Servo Nuts7-60

Servo Mounting Bracket-

to-Battery Tray Screws4-30

Speed Control Switch

Mounting Screws1.7 - 15

Vacuum Reservoir

Mounting Nuts3-20

DRSPEED CONTROL 8P - 3

SPEED CONTROL (Continued)

Page 688 of 2627

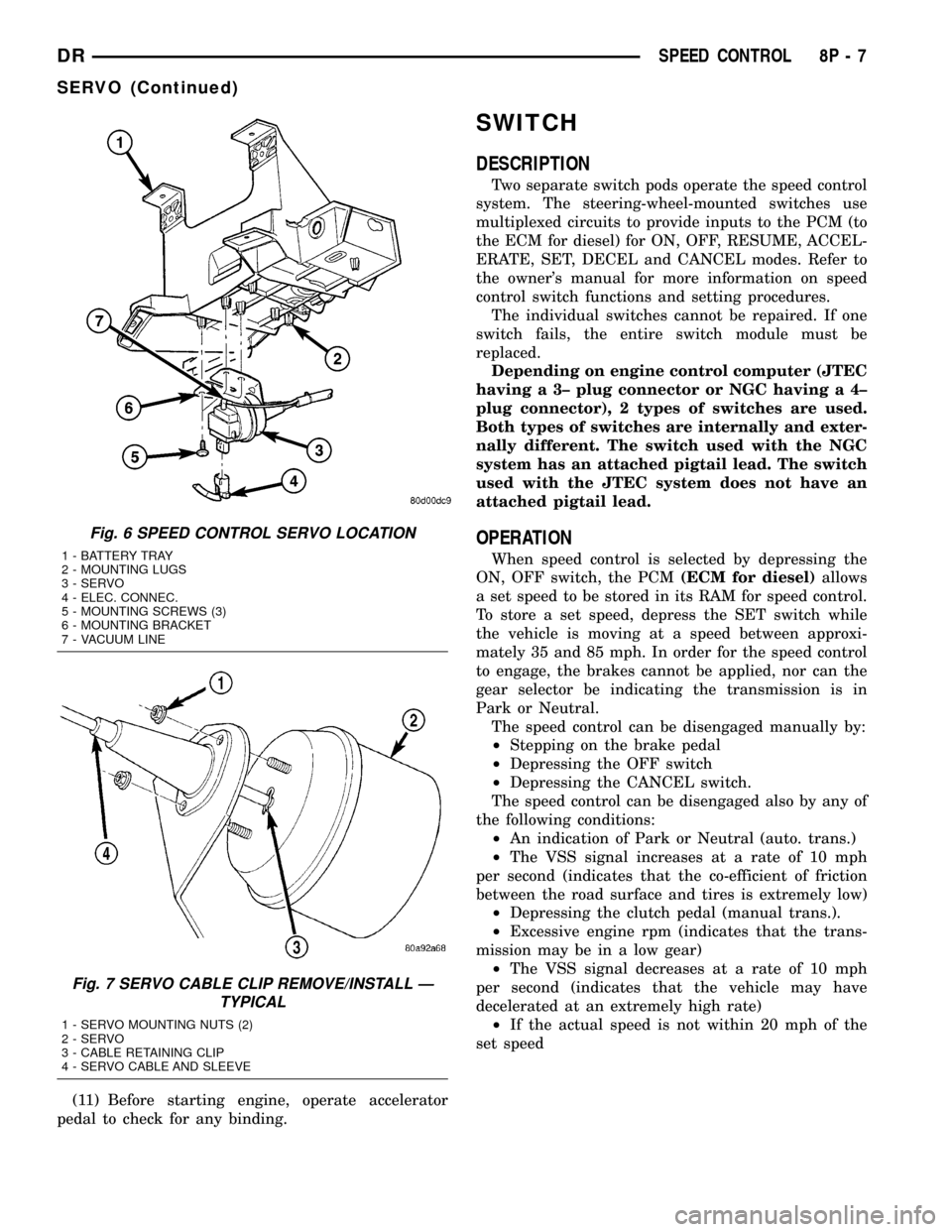

(11) Before starting engine, operate accelerator

pedal to check for any binding.

SWITCH

DESCRIPTION

Two separate switch pods operate the speed control

system. The steering-wheel-mounted switches use

multiplexed circuits to provide inputs to the PCM (to

the ECM for diesel) for ON, OFF, RESUME, ACCEL-

ERATE, SET, DECEL and CANCEL modes. Refer to

the owner's manual for more information on speed

control switch functions and setting procedures.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

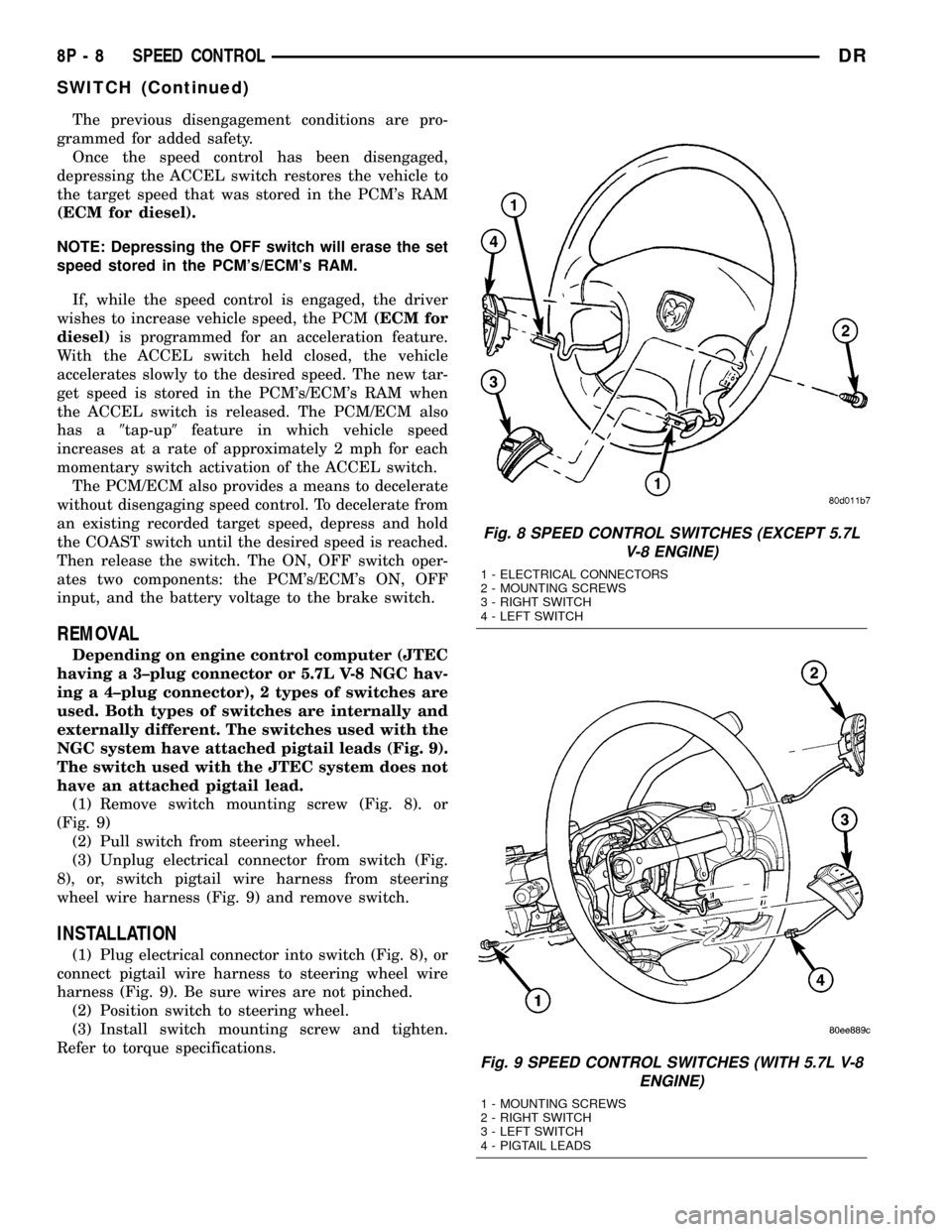

Depending on engine control computer (JTEC

having a 3± plug connector or NGC having a 4±

plug connector), 2 types of switches are used.

Both types of switches are internally and exter-

nally different. The switch used with the NGC

system has an attached pigtail lead. The switch

used with the JTEC system does not have an

attached pigtail lead.

OPERATION

When speed control is selected by depressing the

ON, OFF switch, the PCM(ECM for diesel)allows

a set speed to be stored in its RAM for speed control.

To store a set speed, depress the SET switch while

the vehicle is moving at a speed between approxi-

mately 35 and 85 mph. In order for the speed control

to engage, the brakes cannot be applied, nor can the

gear selector be indicating the transmission is in

Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

The speed control can be disengaged also by any of

the following conditions:

²An indication of Park or Neutral (auto. trans.)

²The VSS signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²Depressing the clutch pedal (manual trans.).

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The VSS signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

²If the actual speed is not within 20 mph of the

set speed

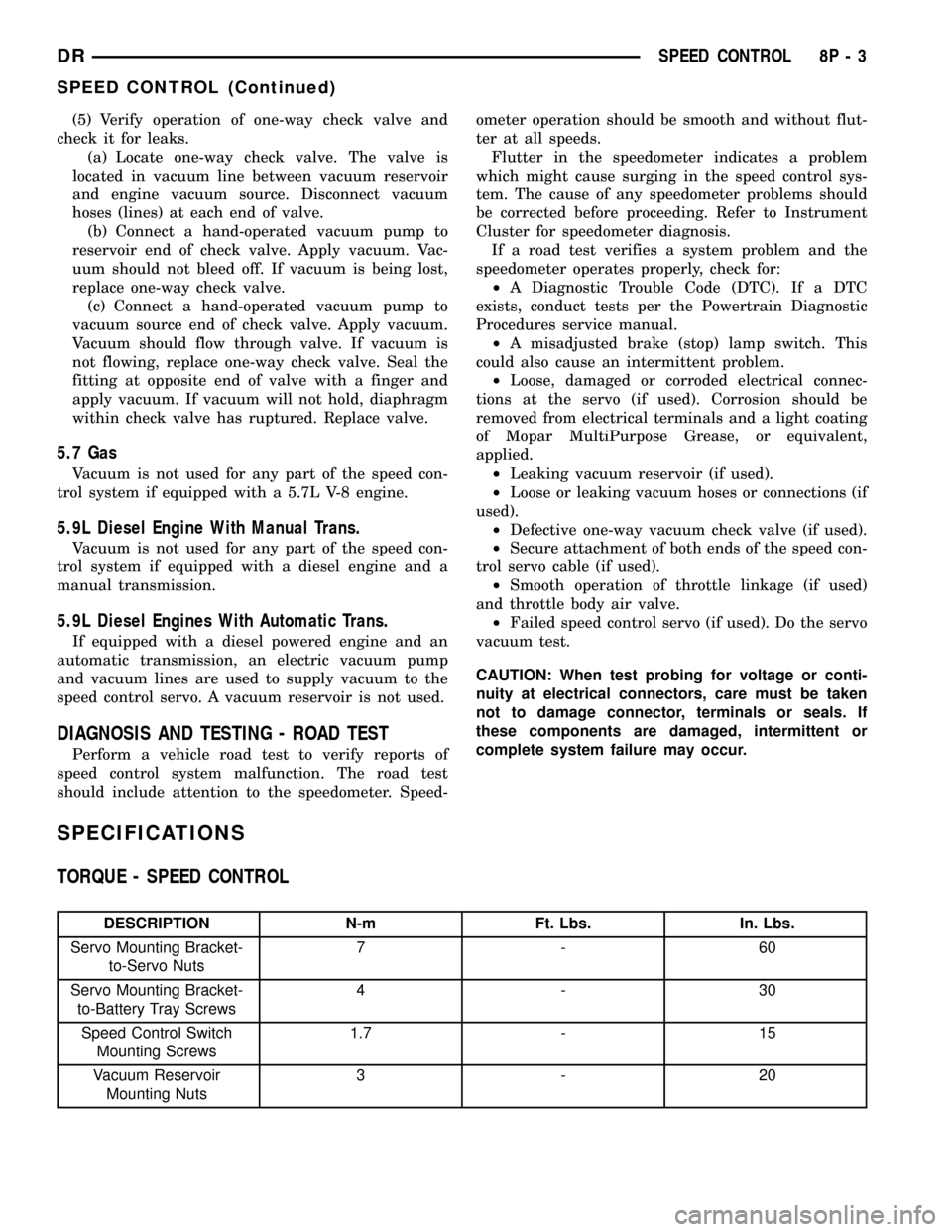

Fig. 6 SPEED CONTROL SERVO LOCATION

1 - BATTERY TRAY

2 - MOUNTING LUGS

3 - SERVO

4 - ELEC. CONNEC.

5 - MOUNTING SCREWS (3)

6 - MOUNTING BRACKET

7 - VACUUM LINE

Fig. 7 SERVO CABLE CLIP REMOVE/INSTALL Ð

TYPICAL

1 - SERVO MOUNTING NUTS (2)

2 - SERVO

3 - CABLE RETAINING CLIP

4 - SERVO CABLE AND SLEEVE

DRSPEED CONTROL 8P - 7

SERVO (Continued)

Page 689 of 2627

The previous disengagement conditions are pro-

grammed for added safety.

Once the speed control has been disengaged,

depressing the ACCEL switch restores the vehicle to

the target speed that was stored in the PCM's RAM

(ECM for diesel).

NOTE: Depressing the OFF switch will erase the set

speed stored in the PCM's/ECM's RAM.

If, while the speed control is engaged, the driver

wishes to increase vehicle speed, the PCM(ECM for

diesel)is programmed for an acceleration feature.

With the ACCEL switch held closed, the vehicle

accelerates slowly to the desired speed. The new tar-

get speed is stored in the PCM's/ECM's RAM when

the ACCEL switch is released. The PCM/ECM also

has a9tap-up9feature in which vehicle speed

increases at a rate of approximately 2 mph for each

momentary switch activation of the ACCEL switch.

The PCM/ECM also provides a means to decelerate

without disengaging speed control. To decelerate from

an existing recorded target speed, depress and hold

the COAST switch until the desired speed is reached.

Then release the switch. The ON, OFF switch oper-

ates two components: the PCM's/ECM's ON, OFF

input, and the battery voltage to the brake switch.

REMOVAL

Depending on engine control computer (JTEC

having a 3±plug connector or 5.7L V-8 NGC hav-

ing a 4±plug connector), 2 types of switches are

used. Both types of switches are internally and

externally different. The switches used with the

NGC system have attached pigtail leads (Fig. 9).

The switch used with the JTEC system does not

have an attached pigtail lead.

(1) Remove switch mounting screw (Fig. 8). or

(Fig. 9)

(2) Pull switch from steering wheel.

(3) Unplug electrical connector from switch (Fig.

8), or, switch pigtail wire harness from steering

wheel wire harness (Fig. 9) and remove switch.

INSTALLATION

(1) Plug electrical connector into switch (Fig. 8), or

connect pigtail wire harness to steering wheel wire

harness (Fig. 9). Be sure wires are not pinched.

(2) Position switch to steering wheel.

(3) Install switch mounting screw and tighten.

Refer to torque specifications.

Fig. 8 SPEED CONTROL SWITCHES (EXCEPT 5.7L

V-8 ENGINE)

1 - ELECTRICAL CONNECTORS

2 - MOUNTING SCREWS

3 - RIGHT SWITCH

4 - LEFT SWITCH

Fig. 9 SPEED CONTROL SWITCHES (WITH 5.7L V-8

ENGINE)

1 - MOUNTING SCREWS

2 - RIGHT SWITCH

3 - LEFT SWITCH

4 - PIGTAIL LEADS

8P - 8 SPEED CONTROLDR

SWITCH (Continued)

Page 690 of 2627

VACUUM RESERVOIR

DESCRIPTION

The vacuum reservoir is a plastic storage tank con-

nected to an engine vacuum source by vacuum lines.

A vacuum reservoir is not used with diesel engines or

the 5.7L gas powered engine.

OPERATION

The vacuum reservoir is used to supply the vac-

uum needed to maintain proper speed control opera-

tion when engine vacuum drops, such as in climbing

a grade while driving. A one-way check valve is used

in the vacuum line between the reservoir and the

vacuum source. This check valve is used to trap

engine vacuum in the reservoir. On certain vehicle

applications, this reservoir is shared with the heat-

ing/air-conditioning system. The vacuum reservoir

cannot be repaired and must be replaced if faulty.

DIAGNOSIS AND TESTING - VACUUM

RESERVOIR

(1) Disconnect vacuum hose at speed control servo

and install a vacuum gauge into the disconnected

hose.

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury.

(3) If vacuum is less than ten inches of mercury,

determine source of leak. Check vacuum line to

engine for leaks. Also check actual engine intake

manifold vacuum. If manifold vacuum does not meet

this requirement, check for poor engine performance

and repair as necessary.

(4) If vacuum line to engine is not leaking, check

for leak at vacuum reservoir. To locate and gain

access to reservoir, refer to Vacuum Reservoir Remov-

al/Installation in this group. Disconnect vacuum line

at reservoir and connect a hand-operated vacuum

pump to reservoir fitting. Apply vacuum. Reservoir

vacuum should not bleed off. If vacuum is being lost,

replace reservoir.

(5) Verify operation of one-way check valve and

check it for leaks.Certain models may be

equipped with 2 check-valves.

(a) Locate one-way check valve. The valve is

located in vacuum line between vacuum reservoir

and engine vacuum source. Disconnect vacuum

hoses (lines) at each end of valve.(b) Connect a hand-operated vacuum pump to

reservoir end of check valve. Apply vacuum. Vac-

uum should not bleed off. If vacuum is being lost,

replace one-way check valve.

(c) Connect a hand-operated vacuum pump to

vacuum source end of check valve. Apply vacuum.

Vacuum should flow through valve. If vacuum is

not flowing, replace one-way check valve. Seal the

fitting at opposite end of valve with a finger and

apply vacuum. If vacuum will not hold, diaphragm

within check valve has ruptured. Replace valve.

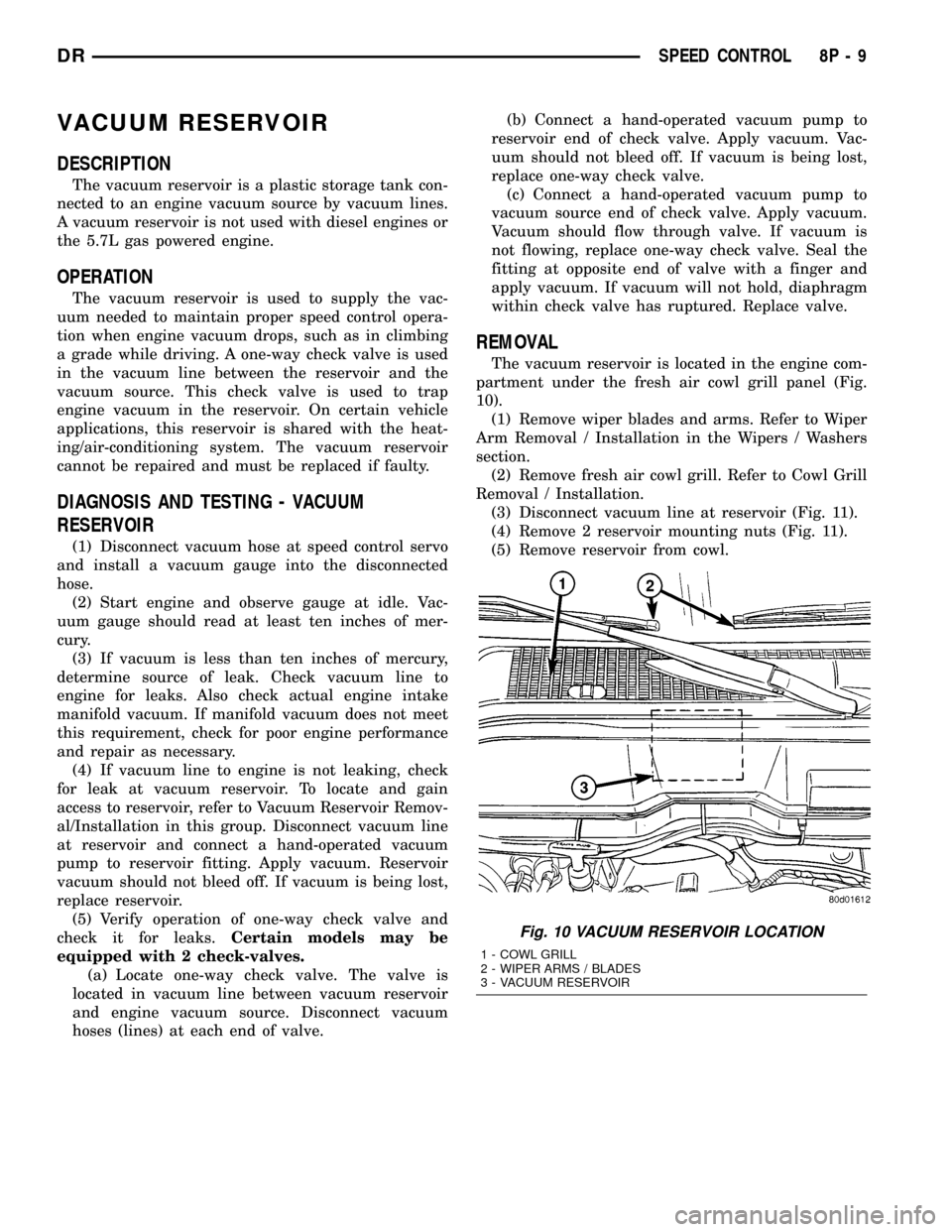

REMOVAL

The vacuum reservoir is located in the engine com-

partment under the fresh air cowl grill panel (Fig.

10).

(1) Remove wiper blades and arms. Refer to Wiper

Arm Removal / Installation in the Wipers / Washers

section.

(2) Remove fresh air cowl grill. Refer to Cowl Grill

Removal / Installation.

(3) Disconnect vacuum line at reservoir (Fig. 11).

(4) Remove 2 reservoir mounting nuts (Fig. 11).

(5) Remove reservoir from cowl.

Fig. 10 VACUUM RESERVOIR LOCATION

1 - COWL GRILL

2 - WIPER ARMS / BLADES

3 - VACUUM RESERVOIR

DRSPEED CONTROL 8P - 9

Page 692 of 2627

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION

DESCRIPTION - VEHICLE THEFT/

SECURITY SYSTEM....................1

DESCRIPTION - SENTRY KEY

IMMOBILIZER SYSTEM (SKIS)............1

DESCRIPTION ± SENTRY KEY

IMMOBILIZER MODULE (SKIM)............1

OPERATION

OPERATION - VEHICLE THEFT/SECURITY

SYSTEM.............................1

OPERATION - SENTRY KEY IMMOBILIZER

SYSTEM (SKIS)........................2

OPERATION ± SENTRY KEY IMMOBILIZER

MODULE (SKIM).......................2DIAGNOSIS AND TESTING

VEHICLE THEFT SECURITY SYSTEM......3

STANDARD PROCEDURE

CONFIGURING A NEW MODULE / SWITCH

OPERATING MODES....................3

SENTRY KEY IMMOBILIZER SYSTEM

INITIALIZATION........................3

SENTRY KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING..........4

SENTRY KEY IMMOBILIZER SYSTEM

INDICATOR LAMP

DESCRIPTION..........................5

OPERATION............................5

VEHICLE THEFT SECURITY

DESCRIPTION

DESCRIPTION - VEHICLE THEFT/SECURITY

SYSTEM

The Vehicle Theft/Security System (VTSS) is

designed to protect against whole vehicle theft. The

system monitors the vehicle doors and ignition for

unauthorized operation.

The VTSS activates:

²Sounding of the horn

²Flashing of the park lamps

²Flashing of the head lamps

The Remote Keyless Entry (RKE) has 1 mode of

operation,CUSTOMER USAGEmode. The cus-

tomer usage mode provides full functionality of the

module and is the mode in which the RKE module

should be operating when used by the customer.

DESCRIPTION - SENTRY KEY IMMOBILIZER

SYSTEM (SKIS)

The Sentry Key Immobilizer System (SKIS) is

designed to provide passive protection against unau-

thorized vehicle use by preventing the engine from

operating while the system is armed. The primary

components of this system are the Sentry Key Immo-

bilizer Module (SKIM), the Sentry Key transponder,

the Vehicle Theft/Security System (VTSS) indicator

LED, and the Powertrain Control Module (PCM).The SKIM is installed on the steering column near

the ignition lock cylinder. The transponder is located

under the molded rubber cap on the head of the igni-

tion key. The VTSS indicator LED is located in the

instrument cluster.

DESCRIPTION ± SENTRY KEY IMMOBILIZER

MODULE (SKIM)

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a cen-

tral processing unit, which includes the Sentry Key

Immobilizer System (SKIS) program logic. The SKIS

programming enables the SKIM to program and

retain in memory the codes of at least two, but no

more than eight electronically coded Sentry Key

transponders. The SKIS programming also enables

the SKIM to communicate over the Programmable

Communication Interface (PCI) bus network with the

Powertrain Control Module (PCM), and/or the

DRBIIItscan tool.

OPERATION

OPERATION - VEHICLE THEFT/SECURITY

SYSTEM

When in theCustomer Usagemode of operation,

the system is armed when the vehicle is locked using

the:

²Power Door Lock Switches

²Remote Keyless Entry (RKE) Transmitter

²Key Cylinder Switches

DRVEHICLE THEFT SECURITY 8Q - 1

Page 693 of 2627

After the vehicle is locked and the last door is

closed, the VTSS indicator in the instrument cluster

will flash quickly for 16 seconds, indicating that the

arming is in process. After 16 seconds, the LED will

continue to flash at a slower rate indicating that the

system is armed.

VTSS disarming occurs upon normal vehicle entry

by unlocking either door via the key cylinder or RKE

transmitter, or by starting the vehicle with a valid

Sentry Key. This disarming will also halt the alarm

once it has been activated.

A tamper alert exists to notify the driver that the

system has been activated. This alert consists of 3

horn pulses and the security telltale flashing for 30

seconds when the vehicle is disarmed. The tamper

alert will not occur if disarmed while alarming.

The VTSS will not arm by mechanically locking the

vehicle doors. This will manually override the sys-

tem.

OPERATION - SENTRY KEY IMMOBILIZER

SYSTEM (SKIS)

The SKIS includes two valid Sentry Key transpon-

ders from the factory. These two Sentry Keys can be

used to program additional non-coded blank Sentry

Keys. These blank keys can be cut to match a valid

ignition key, but the engine will not start unless the

key transponder is also programmed to the vehicle.

The SKIS will recognize no more than eight valid

Sentry Key transponders at any one time.

The SKIS performs a self-test each time the igni-

tion switch is turned to the ON position, and will

store Diagnostic Trouble Codes (DTC's) if a system

malfunction is detected. The SKIS can be diagnosed,

and any stored DTC can be retrieved using a

DRBIIItscan tool as described in the proper Power-

train Diagnostic Procedures manual.

OPERATION ± SENTRY KEY IMMOBILIZER

MODULE (SKIM)

The SKIM transmits and receives RF signals

through a tuned antenna enclosed within a molded

plastic ring formation that is integral to the SKIM

housing. When the SKIM is properly installed on the

steering column, the antenna ring is oriented around

the circumference of the ignition lock cylinder hous-

ing. This antenna ring must be located within eight

millimeters (0.31 inches) of the Sentry Key in order

to ensure proper RF communication between the

SKIM and the Sentry Key transponder.

For added system security, each SKIM is pro-

grammed with a unique ªSecret Keyº code and a

security code. The SKIM keeps the ªSecret Keyº code

in memory. The SKIM also sends the ªSecret Keyº

code to each of the programmed Sentry Key tran-

sponders. The security code is used by the assemblyplant to access the SKIS for initialization, or by the

dealer technician to access the system for service.

The SKIM also stores in its memory the Vehicle

Identification Number (VIN), which it learns through

a PCI bus message from the PCM during initializa-

tion.

The SKIM and the PCM both use software that

includes a rolling code algorithm strategy, which

helps to reduce the possibility of unauthorized SKIS

disarming. The rolling code algorithm ensures secu-

rity by preventing an override of the SKIS through

the unauthorized substitution of the SKIM or the

PCM. However, the use of this strategy also means

that replacement of either the SKIM or the PCM

units will require a system initialization procedure to

restore system operation.

When the ignition switch is turned to the ON or

START positions, the SKIM transmits an RF signal

to excite the Sentry Key transponder. The SKIM then

listens for a return RF signal from the transponder

of the Sentry Key that is inserted in the ignition lock

cylinder. If the SKIM receives an RF signal with

valid ªSecret Keyº and transponder identification

codes, the SKIM sends a ªvalid keyº message to the

PCM over the PCI bus. If the SKIM receives an

invalid RF signal or no response, it sends ªinvalid

keyº messages to the PCM. The PCM will enable or

disable engine operation based upon the status of the

SKIM messages.

The SKIM also sends messages to the Instrument

Cluster which controls the VTSS indicator. The

SKIM sends messages to the Instrument Cluster to

turn the indicator on for about three seconds when

the ignition switch is turned to the ON position as a

ªbulbº test. After completion of the ªbulbº test, the

SKIM sends bus messages to keep the indicator off

for a duration of about one second. Then the SKIM

sends messages to turn the indicator on or off based

upon the results of the SKIS self-tests. If the VTSS

indicator comes on and stays on after the ªbulb testº,

it indicates that the SKIM has detected a system

malfunction and/or that the SKIS has become inoper-

ative.

If the SKIM detects an invalid key when the igni-

tion switch is turned to the ON position, it sends

messages to flash the VTSS indicator. The SKIM can

also send messages to flash the indicator to serve as

an indication to the customer that the SKIS has been

placed in its ªCustomer Learnº programming mode.

See Sentry Key Immobilizer System Transponder

Programming in this section for more information on

the ªCustomer Learnº programming mode.

For diagnosis or initialization of the SKIM and the

PCM, a DRBIIItscan tool and the proper Powertrain

Diagnostic Procedures manual are required. The

8Q - 2 VEHICLE THEFT SECURITYDR

VEHICLE THEFT SECURITY (Continued)