system DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 705 of 2627

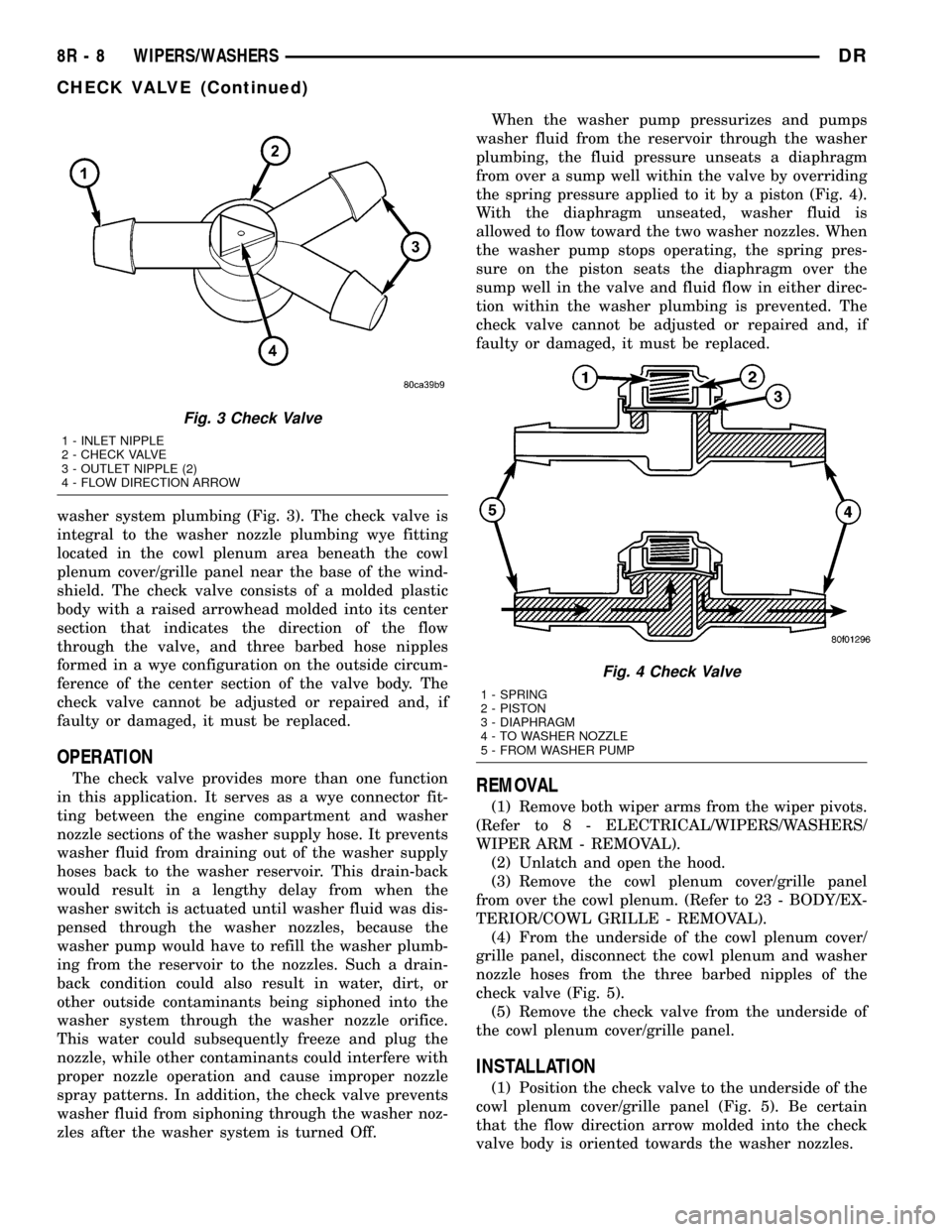

washer system plumbing (Fig. 3). The check valve is

integral to the washer nozzle plumbing wye fitting

located in the cowl plenum area beneath the cowl

plenum cover/grille panel near the base of the wind-

shield. The check valve consists of a molded plastic

body with a raised arrowhead molded into its center

section that indicates the direction of the flow

through the valve, and three barbed hose nipples

formed in a wye configuration on the outside circum-

ference of the center section of the valve body. The

check valve cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.

OPERATION

The check valve provides more than one function

in this application. It serves as a wye connector fit-

ting between the engine compartment and washer

nozzle sections of the washer supply hose. It prevents

washer fluid from draining out of the washer supply

hoses back to the washer reservoir. This drain-back

would result in a lengthy delay from when the

washer switch is actuated until washer fluid was dis-

pensed through the washer nozzles, because the

washer pump would have to refill the washer plumb-

ing from the reservoir to the nozzles. Such a drain-

back condition could also result in water, dirt, or

other outside contaminants being siphoned into the

washer system through the washer nozzle orifice.

This water could subsequently freeze and plug the

nozzle, while other contaminants could interfere with

proper nozzle operation and cause improper nozzle

spray patterns. In addition, the check valve prevents

washer fluid from siphoning through the washer noz-

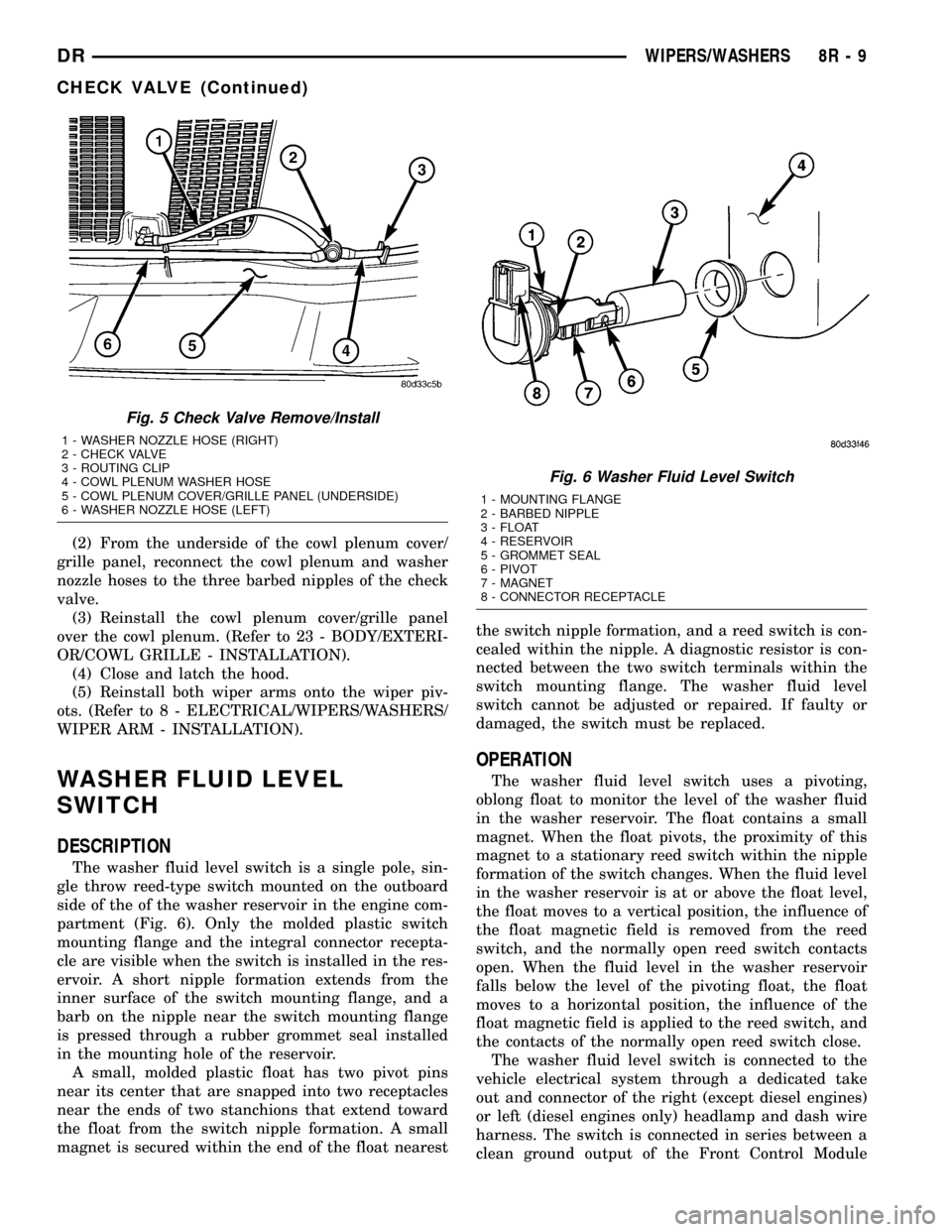

zles after the washer system is turned Off.When the washer pump pressurizes and pumps

washer fluid from the reservoir through the washer

plumbing, the fluid pressure unseats a diaphragm

from over a sump well within the valve by overriding

the spring pressure applied to it by a piston (Fig. 4).

With the diaphragm unseated, washer fluid is

allowed to flow toward the two washer nozzles. When

the washer pump stops operating, the spring pres-

sure on the piston seats the diaphragm over the

sump well in the valve and fluid flow in either direc-

tion within the washer plumbing is prevented. The

check valve cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.REMOVAL

(1) Remove both wiper arms from the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - REMOVAL).

(2) Unlatch and open the hood.

(3) Remove the cowl plenum cover/grille panel

from over the cowl plenum. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - REMOVAL).

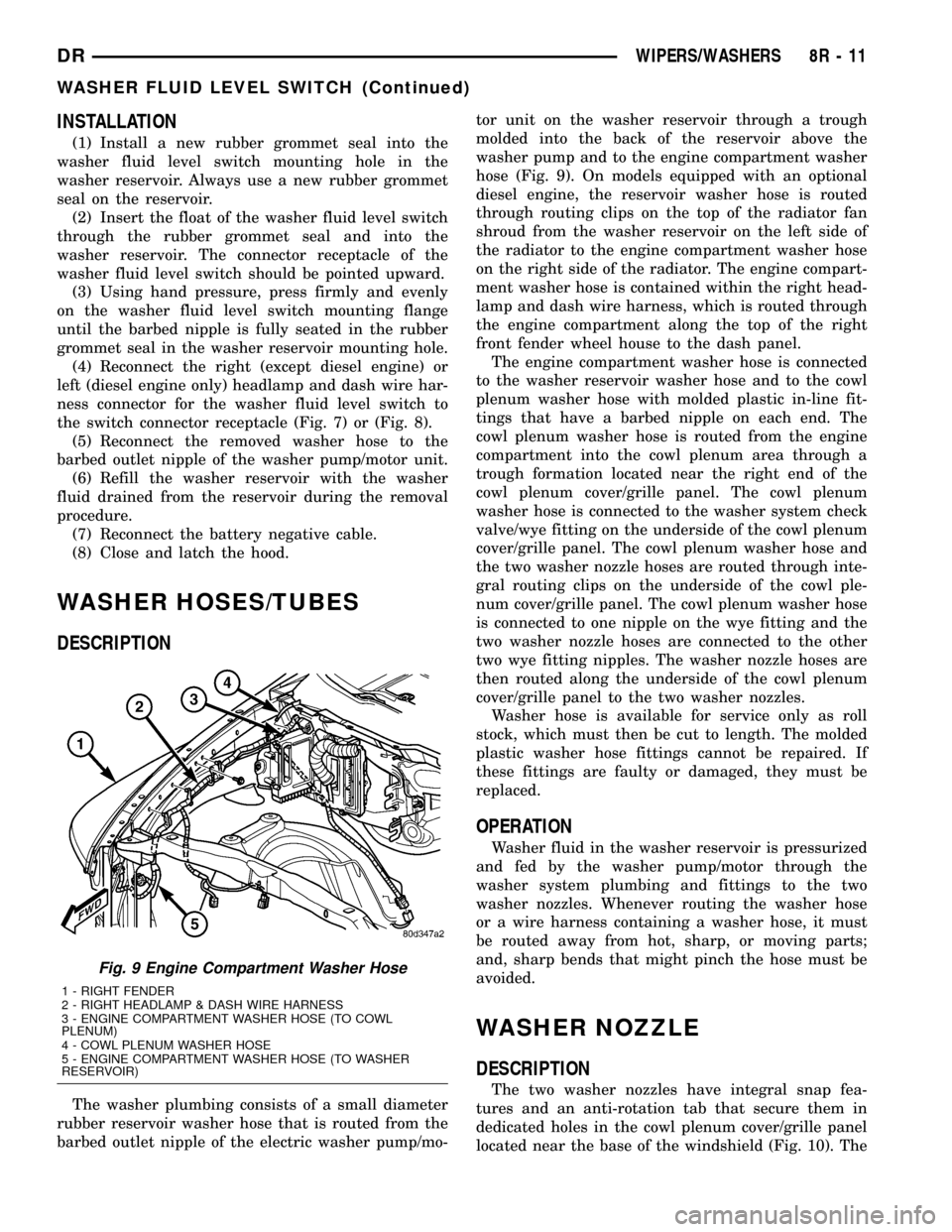

(4) From the underside of the cowl plenum cover/

grille panel, disconnect the cowl plenum and washer

nozzle hoses from the three barbed nipples of the

check valve (Fig. 5).

(5) Remove the check valve from the underside of

the cowl plenum cover/grille panel.

INSTALLATION

(1) Position the check valve to the underside of the

cowl plenum cover/grille panel (Fig. 5). Be certain

that the flow direction arrow molded into the check

valve body is oriented towards the washer nozzles.

Fig. 3 Check Valve

1 - INLET NIPPLE

2 - CHECK VALVE

3 - OUTLET NIPPLE (2)

4 - FLOW DIRECTION ARROW

Fig. 4 Check Valve

1 - SPRING

2 - PISTON

3 - DIAPHRAGM

4 - TO WASHER NOZZLE

5 - FROM WASHER PUMP

8R - 8 WIPERS/WASHERSDR

CHECK VALVE (Continued)

Page 706 of 2627

(2) From the underside of the cowl plenum cover/

grille panel, reconnect the cowl plenum and washer

nozzle hoses to the three barbed nipples of the check

valve.

(3) Reinstall the cowl plenum cover/grille panel

over the cowl plenum. (Refer to 23 - BODY/EXTERI-

OR/COWL GRILLE - INSTALLATION).

(4) Close and latch the hood.

(5) Reinstall both wiper arms onto the wiper piv-

ots. (Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - INSTALLATION).

WASHER FLUID LEVEL

SWITCH

DESCRIPTION

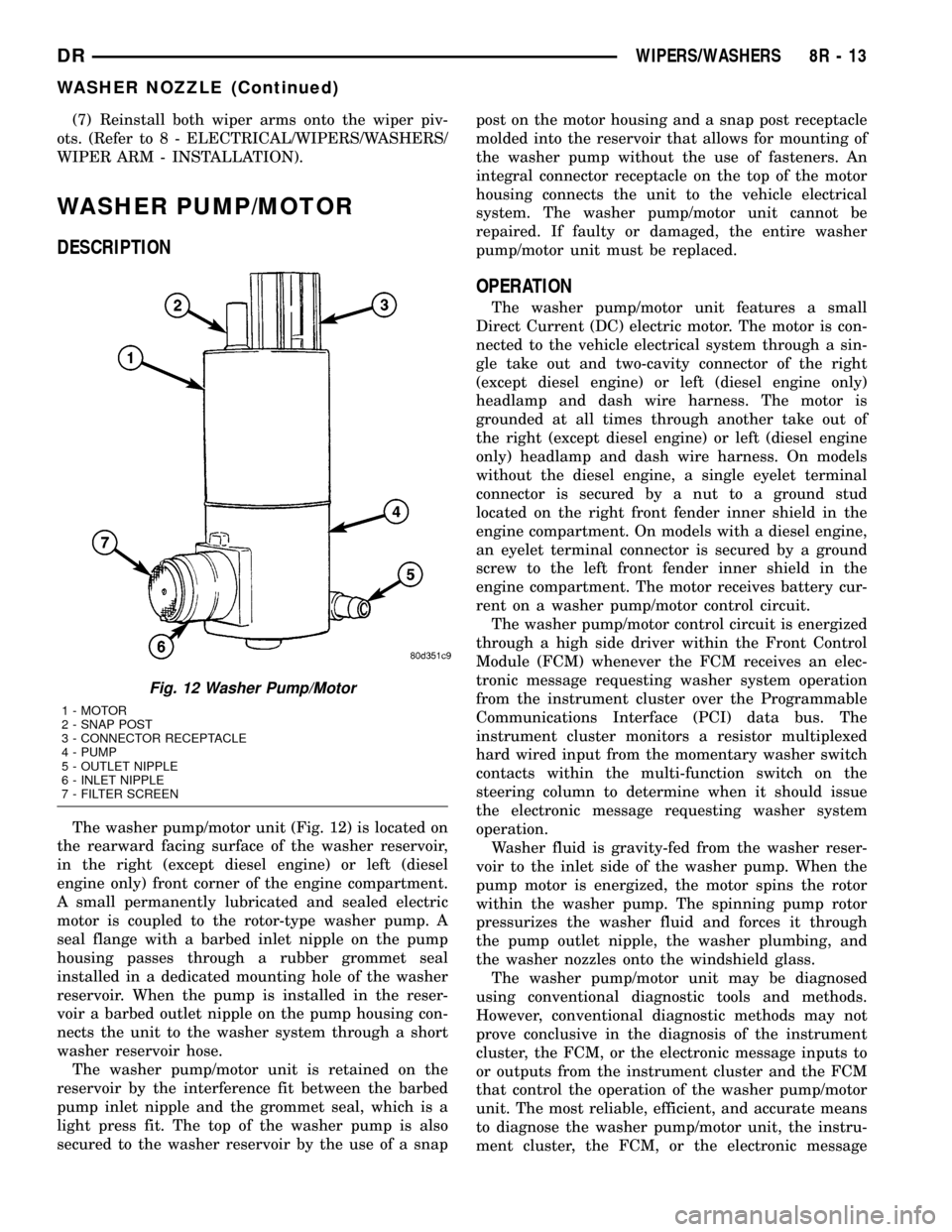

The washer fluid level switch is a single pole, sin-

gle throw reed-type switch mounted on the outboard

side of the of the washer reservoir in the engine com-

partment (Fig. 6). Only the molded plastic switch

mounting flange and the integral connector recepta-

cle are visible when the switch is installed in the res-

ervoir. A short nipple formation extends from the

inner surface of the switch mounting flange, and a

barb on the nipple near the switch mounting flange

is pressed through a rubber grommet seal installed

in the mounting hole of the reservoir.

A small, molded plastic float has two pivot pins

near its center that are snapped into two receptacles

near the ends of two stanchions that extend toward

the float from the switch nipple formation. A small

magnet is secured within the end of the float nearestthe switch nipple formation, and a reed switch is con-

cealed within the nipple. A diagnostic resistor is con-

nected between the two switch terminals within the

switch mounting flange. The washer fluid level

switch cannot be adjusted or repaired. If faulty or

damaged, the switch must be replaced.

OPERATION

The washer fluid level switch uses a pivoting,

oblong float to monitor the level of the washer fluid

in the washer reservoir. The float contains a small

magnet. When the float pivots, the proximity of this

magnet to a stationary reed switch within the nipple

formation of the switch changes. When the fluid level

in the washer reservoir is at or above the float level,

the float moves to a vertical position, the influence of

the float magnetic field is removed from the reed

switch, and the normally open reed switch contacts

open. When the fluid level in the washer reservoir

falls below the level of the pivoting float, the float

moves to a horizontal position, the influence of the

float magnetic field is applied to the reed switch, and

the contacts of the normally open reed switch close.

The washer fluid level switch is connected to the

vehicle electrical system through a dedicated take

out and connector of the right (except diesel engines)

or left (diesel engines only) headlamp and dash wire

harness. The switch is connected in series between a

clean ground output of the Front Control Module

Fig. 5 Check Valve Remove/Install

1 - WASHER NOZZLE HOSE (RIGHT)

2 - CHECK VALVE

3 - ROUTING CLIP

4 - COWL PLENUM WASHER HOSE

5 - COWL PLENUM COVER/GRILLE PANEL (UNDERSIDE)

6 - WASHER NOZZLE HOSE (LEFT)

Fig. 6 Washer Fluid Level Switch

1 - MOUNTING FLANGE

2 - BARBED NIPPLE

3 - FLOAT

4 - RESERVOIR

5 - GROMMET SEAL

6 - PIVOT

7 - MAGNET

8 - CONNECTOR RECEPTACLE

DRWIPERS/WASHERS 8R - 9

CHECK VALVE (Continued)

Page 708 of 2627

INSTALLATION

(1) Install a new rubber grommet seal into the

washer fluid level switch mounting hole in the

washer reservoir. Always use a new rubber grommet

seal on the reservoir.

(2) Insert the float of the washer fluid level switch

through the rubber grommet seal and into the

washer reservoir. The connector receptacle of the

washer fluid level switch should be pointed upward.

(3) Using hand pressure, press firmly and evenly

on the washer fluid level switch mounting flange

until the barbed nipple is fully seated in the rubber

grommet seal in the washer reservoir mounting hole.

(4) Reconnect the right (except diesel engine) or

left (diesel engine only) headlamp and dash wire har-

ness connector for the washer fluid level switch to

the switch connector receptacle (Fig. 7) or (Fig. 8).

(5) Reconnect the removed washer hose to the

barbed outlet nipple of the washer pump/motor unit.

(6) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(7) Reconnect the battery negative cable.

(8) Close and latch the hood.

WASHER HOSES/TUBES

DESCRIPTION

The washer plumbing consists of a small diameter

rubber reservoir washer hose that is routed from the

barbed outlet nipple of the electric washer pump/mo-tor unit on the washer reservoir through a trough

molded into the back of the reservoir above the

washer pump and to the engine compartment washer

hose (Fig. 9). On models equipped with an optional

diesel engine, the reservoir washer hose is routed

through routing clips on the top of the radiator fan

shroud from the washer reservoir on the left side of

the radiator to the engine compartment washer hose

on the right side of the radiator. The engine compart-

ment washer hose is contained within the right head-

lamp and dash wire harness, which is routed through

the engine compartment along the top of the right

front fender wheel house to the dash panel.

The engine compartment washer hose is connected

to the washer reservoir washer hose and to the cowl

plenum washer hose with molded plastic in-line fit-

tings that have a barbed nipple on each end. The

cowl plenum washer hose is routed from the engine

compartment into the cowl plenum area through a

trough formation located near the right end of the

cowl plenum cover/grille panel. The cowl plenum

washer hose is connected to the washer system check

valve/wye fitting on the underside of the cowl plenum

cover/grille panel. The cowl plenum washer hose and

the two washer nozzle hoses are routed through inte-

gral routing clips on the underside of the cowl ple-

num cover/grille panel. The cowl plenum washer hose

is connected to one nipple on the wye fitting and the

two washer nozzle hoses are connected to the other

two wye fitting nipples. The washer nozzle hoses are

then routed along the underside of the cowl plenum

cover/grille panel to the two washer nozzles.

Washer hose is available for service only as roll

stock, which must then be cut to length. The molded

plastic washer hose fittings cannot be repaired. If

these fittings are faulty or damaged, they must be

replaced.

OPERATION

Washer fluid in the washer reservoir is pressurized

and fed by the washer pump/motor through the

washer system plumbing and fittings to the two

washer nozzles. Whenever routing the washer hose

or a wire harness containing a washer hose, it must

be routed away from hot, sharp, or moving parts;

and, sharp bends that might pinch the hose must be

avoided.

WASHER NOZZLE

DESCRIPTION

The two washer nozzles have integral snap fea-

tures and an anti-rotation tab that secure them in

dedicated holes in the cowl plenum cover/grille panel

located near the base of the windshield (Fig. 10). The

Fig. 9 Engine Compartment Washer Hose

1 - RIGHT FENDER

2 - RIGHT HEADLAMP & DASH WIRE HARNESS

3 - ENGINE COMPARTMENT WASHER HOSE (TO COWL

PLENUM)

4 - COWL PLENUM WASHER HOSE

5 - ENGINE COMPARTMENT WASHER HOSE (TO WASHER

RESERVOIR)

DRWIPERS/WASHERS 8R - 11

WASHER FLUID LEVEL SWITCH (Continued)

Page 710 of 2627

(7) Reinstall both wiper arms onto the wiper piv-

ots. (Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - INSTALLATION).

WASHER PUMP/MOTOR

DESCRIPTION

The washer pump/motor unit (Fig. 12) is located on

the rearward facing surface of the washer reservoir,

in the right (except diesel engine) or left (diesel

engine only) front corner of the engine compartment.

A small permanently lubricated and sealed electric

motor is coupled to the rotor-type washer pump. A

seal flange with a barbed inlet nipple on the pump

housing passes through a rubber grommet seal

installed in a dedicated mounting hole of the washer

reservoir. When the pump is installed in the reser-

voir a barbed outlet nipple on the pump housing con-

nects the unit to the washer system through a short

washer reservoir hose.

The washer pump/motor unit is retained on the

reservoir by the interference fit between the barbed

pump inlet nipple and the grommet seal, which is a

light press fit. The top of the washer pump is also

secured to the washer reservoir by the use of a snappost on the motor housing and a snap post receptacle

molded into the reservoir that allows for mounting of

the washer pump without the use of fasteners. An

integral connector receptacle on the top of the motor

housing connects the unit to the vehicle electrical

system. The washer pump/motor unit cannot be

repaired. If faulty or damaged, the entire washer

pump/motor unit must be replaced.

OPERATION

The washer pump/motor unit features a small

Direct Current (DC) electric motor. The motor is con-

nected to the vehicle electrical system through a sin-

gle take out and two-cavity connector of the right

(except diesel engine) or left (diesel engine only)

headlamp and dash wire harness. The motor is

grounded at all times through another take out of

the right (except diesel engine) or left (diesel engine

only) headlamp and dash wire harness. On models

without the diesel engine, a single eyelet terminal

connector is secured by a nut to a ground stud

located on the right front fender inner shield in the

engine compartment. On models with a diesel engine,

an eyelet terminal connector is secured by a ground

screw to the left front fender inner shield in the

engine compartment. The motor receives battery cur-

rent on a washer pump/motor control circuit.

The washer pump/motor control circuit is energized

through a high side driver within the Front Control

Module (FCM) whenever the FCM receives an elec-

tronic message requesting washer system operation

from the instrument cluster over the Programmable

Communications Interface (PCI) data bus. The

instrument cluster monitors a resistor multiplexed

hard wired input from the momentary washer switch

contacts within the multi-function switch on the

steering column to determine when it should issue

the electronic message requesting washer system

operation.

Washer fluid is gravity-fed from the washer reser-

voir to the inlet side of the washer pump. When the

pump motor is energized, the motor spins the rotor

within the washer pump. The spinning pump rotor

pressurizes the washer fluid and forces it through

the pump outlet nipple, the washer plumbing, and

the washer nozzles onto the windshield glass.

The washer pump/motor unit may be diagnosed

using conventional diagnostic tools and methods.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the instrument

cluster, the FCM, or the electronic message inputs to

or outputs from the instrument cluster and the FCM

that control the operation of the washer pump/motor

unit. The most reliable, efficient, and accurate means

to diagnose the washer pump/motor unit, the instru-

ment cluster, the FCM, or the electronic message

Fig. 12 Washer Pump/Motor

1 - MOTOR

2 - SNAP POST

3 - CONNECTOR RECEPTACLE

4 - PUMP

5 - OUTLET NIPPLE

6 - INLET NIPPLE

7 - FILTER SCREEN

DRWIPERS/WASHERS 8R - 13

WASHER NOZZLE (Continued)

Page 712 of 2627

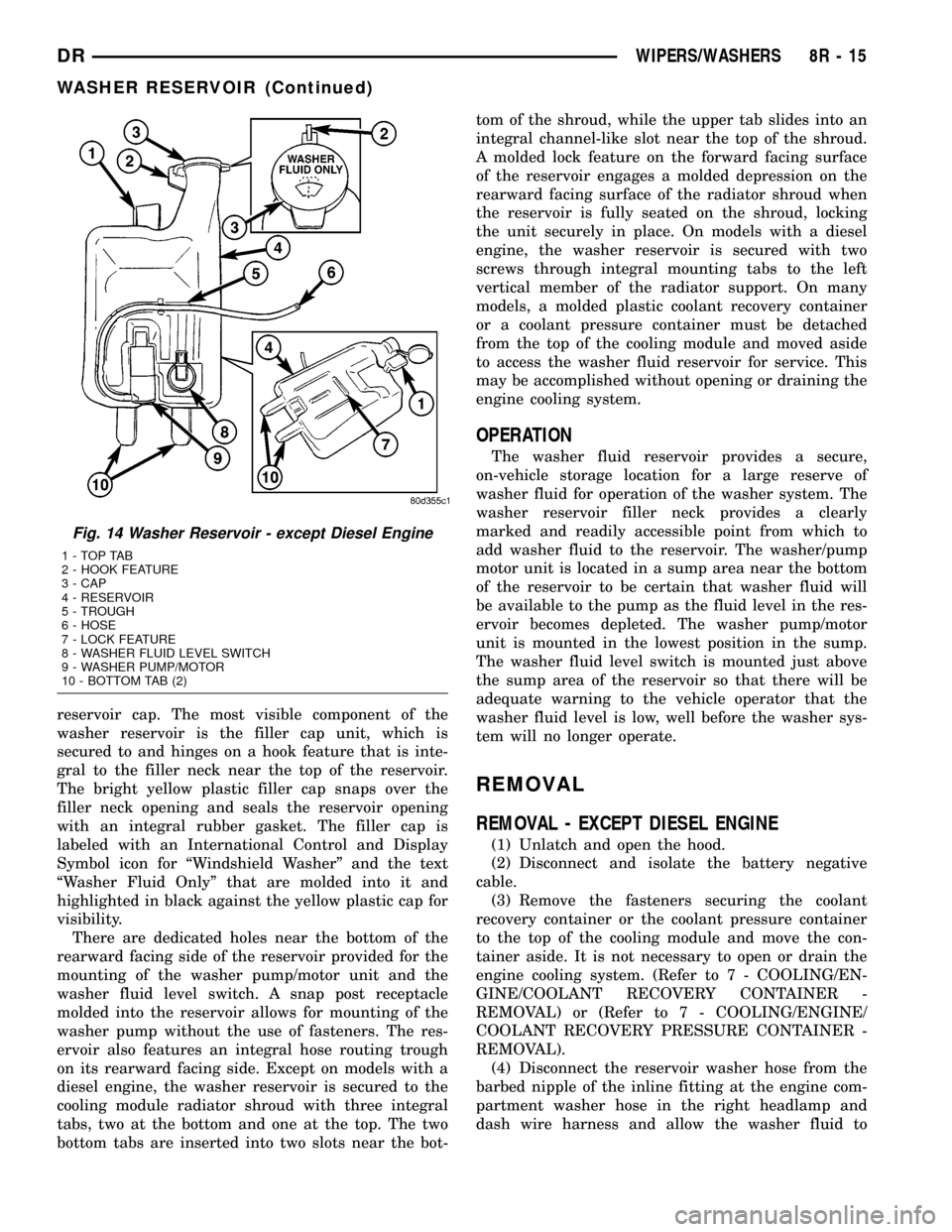

reservoir cap. The most visible component of the

washer reservoir is the filler cap unit, which is

secured to and hinges on a hook feature that is inte-

gral to the filler neck near the top of the reservoir.

The bright yellow plastic filler cap snaps over the

filler neck opening and seals the reservoir opening

with an integral rubber gasket. The filler cap is

labeled with an International Control and Display

Symbol icon for ªWindshield Washerº and the text

ªWasher Fluid Onlyº that are molded into it and

highlighted in black against the yellow plastic cap for

visibility.

There are dedicated holes near the bottom of the

rearward facing side of the reservoir provided for the

mounting of the washer pump/motor unit and the

washer fluid level switch. A snap post receptacle

molded into the reservoir allows for mounting of the

washer pump without the use of fasteners. The res-

ervoir also features an integral hose routing trough

on its rearward facing side. Except on models with a

diesel engine, the washer reservoir is secured to the

cooling module radiator shroud with three integral

tabs, two at the bottom and one at the top. The two

bottom tabs are inserted into two slots near the bot-tom of the shroud, while the upper tab slides into an

integral channel-like slot near the top of the shroud.

A molded lock feature on the forward facing surface

of the reservoir engages a molded depression on the

rearward facing surface of the radiator shroud when

the reservoir is fully seated on the shroud, locking

the unit securely in place. On models with a diesel

engine, the washer reservoir is secured with two

screws through integral mounting tabs to the left

vertical member of the radiator support. On many

models, a molded plastic coolant recovery container

or a coolant pressure container must be detached

from the top of the cooling module and moved aside

to access the washer fluid reservoir for service. This

may be accomplished without opening or draining the

engine cooling system.

OPERATION

The washer fluid reservoir provides a secure,

on-vehicle storage location for a large reserve of

washer fluid for operation of the washer system. The

washer reservoir filler neck provides a clearly

marked and readily accessible point from which to

add washer fluid to the reservoir. The washer/pump

motor unit is located in a sump area near the bottom

of the reservoir to be certain that washer fluid will

be available to the pump as the fluid level in the res-

ervoir becomes depleted. The washer pump/motor

unit is mounted in the lowest position in the sump.

The washer fluid level switch is mounted just above

the sump area of the reservoir so that there will be

adequate warning to the vehicle operator that the

washer fluid level is low, well before the washer sys-

tem will no longer operate.

REMOVAL

REMOVAL - EXCEPT DIESEL ENGINE

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the fasteners securing the coolant

recovery container or the coolant pressure container

to the top of the cooling module and move the con-

tainer aside. It is not necessary to open or drain the

engine cooling system. (Refer to 7 - COOLING/EN-

GINE/COOLANT RECOVERY CONTAINER -

REMOVAL) or (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESSURE CONTAINER -

REMOVAL).

(4) Disconnect the reservoir washer hose from the

barbed nipple of the inline fitting at the engine com-

partment washer hose in the right headlamp and

dash wire harness and allow the washer fluid to

Fig. 14 Washer Reservoir - except Diesel Engine

1-TOPTAB

2 - HOOK FEATURE

3 - CAP

4 - RESERVOIR

5 - TROUGH

6 - HOSE

7 - LOCK FEATURE

8 - WASHER FLUID LEVEL SWITCH

9 - WASHER PUMP/MOTOR

10 - BOTTOM TAB (2)

DRWIPERS/WASHERS 8R - 15

WASHER RESERVOIR (Continued)

Page 717 of 2627

INSTALLATION

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper pivot.

(1) Lift the wiper arm off of the windshield glass,

until the wiper arm hinge is in its over-center posi-

tion.

(2) Position the wiper blade near the hook forma-

tion on the tip of the arm with the notched end of the

wiper element flexor oriented towards the end of the

wiper arm that is nearest to the wiper pivot.

(3) Insert the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure ahead of the wiper blade pivot block/

latch unit far enough to engage the pivot block into

the hook (Fig. 21).

(4) Slide the wiper blade pivot block/latch up into

the hook formation on the tip of the wiper arm until

the latch release tab snaps into its locked position.

Latch engagement will be accompanied by an audible

click.

(5) Gently lower the wiper blade onto the glass.

WIPER HIGH/LOW RELAY

DESCRIPTION

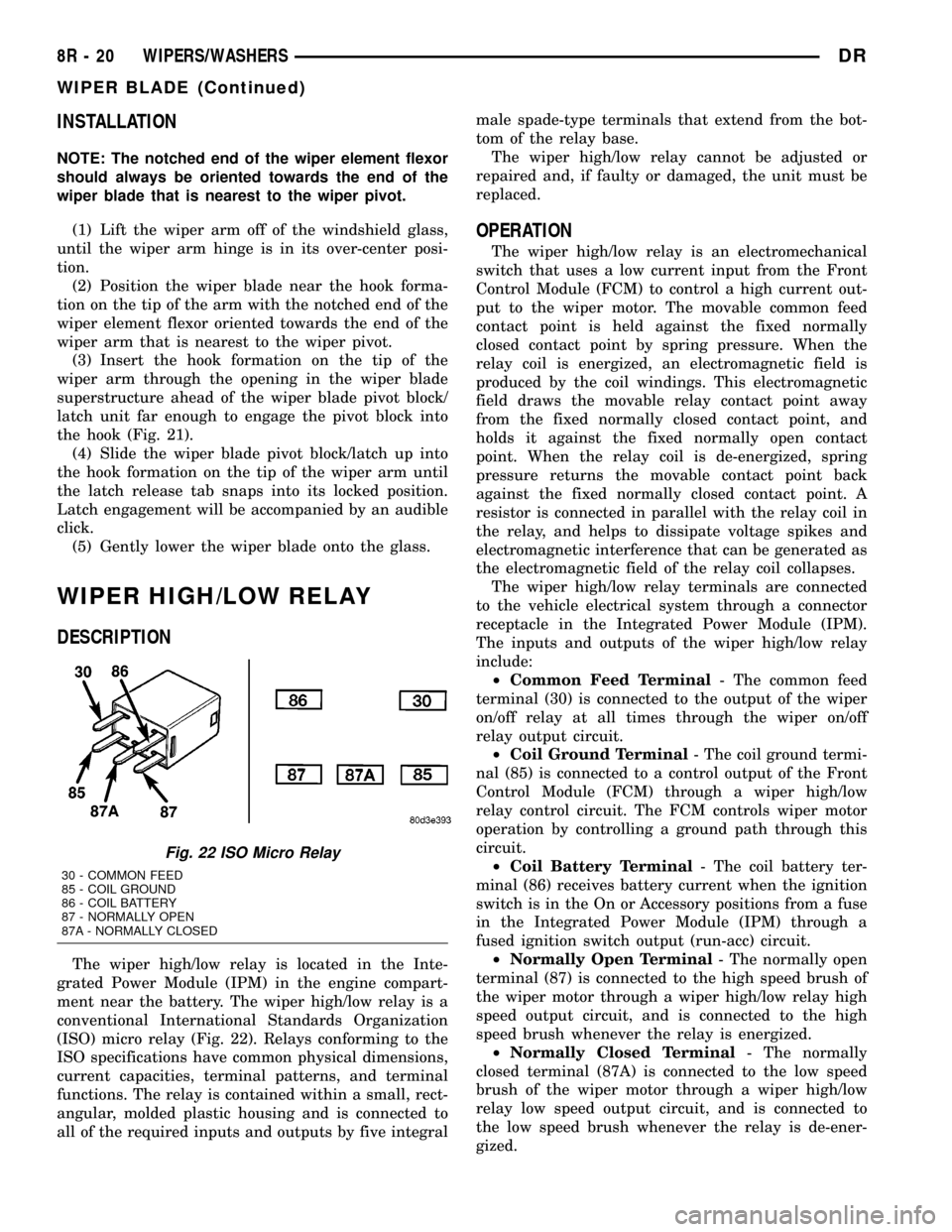

The wiper high/low relay is located in the Inte-

grated Power Module (IPM) in the engine compart-

ment near the battery. The wiper high/low relay is a

conventional International Standards Organization

(ISO) micro relay (Fig. 22). Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The relay is contained within a small, rect-

angular, molded plastic housing and is connected to

all of the required inputs and outputs by five integralmale spade-type terminals that extend from the bot-

tom of the relay base.

The wiper high/low relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper high/low relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control a high current out-

put to the wiper motor. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper high/low relay terminals are connected

to the vehicle electrical system through a connector

receptacle in the Integrated Power Module (IPM).

The inputs and outputs of the wiper high/low relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the output of the wiper

on/off relay at all times through the wiper on/off

relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Front

Control Module (FCM) through a wiper high/low

relay control circuit. The FCM controls wiper motor

operation by controlling a ground path through this

circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current when the ignition

switch is in the On or Accessory positions from a fuse

in the Integrated Power Module (IPM) through a

fused ignition switch output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the high speed brush of

the wiper motor through a wiper high/low relay high

speed output circuit, and is connected to the high

speed brush whenever the relay is energized.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to the low speed

brush of the wiper motor through a wiper high/low

relay low speed output circuit, and is connected to

the low speed brush whenever the relay is de-ener-

gized.

Fig. 22 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

8R - 20 WIPERS/WASHERSDR

WIPER BLADE (Continued)

Page 722 of 2627

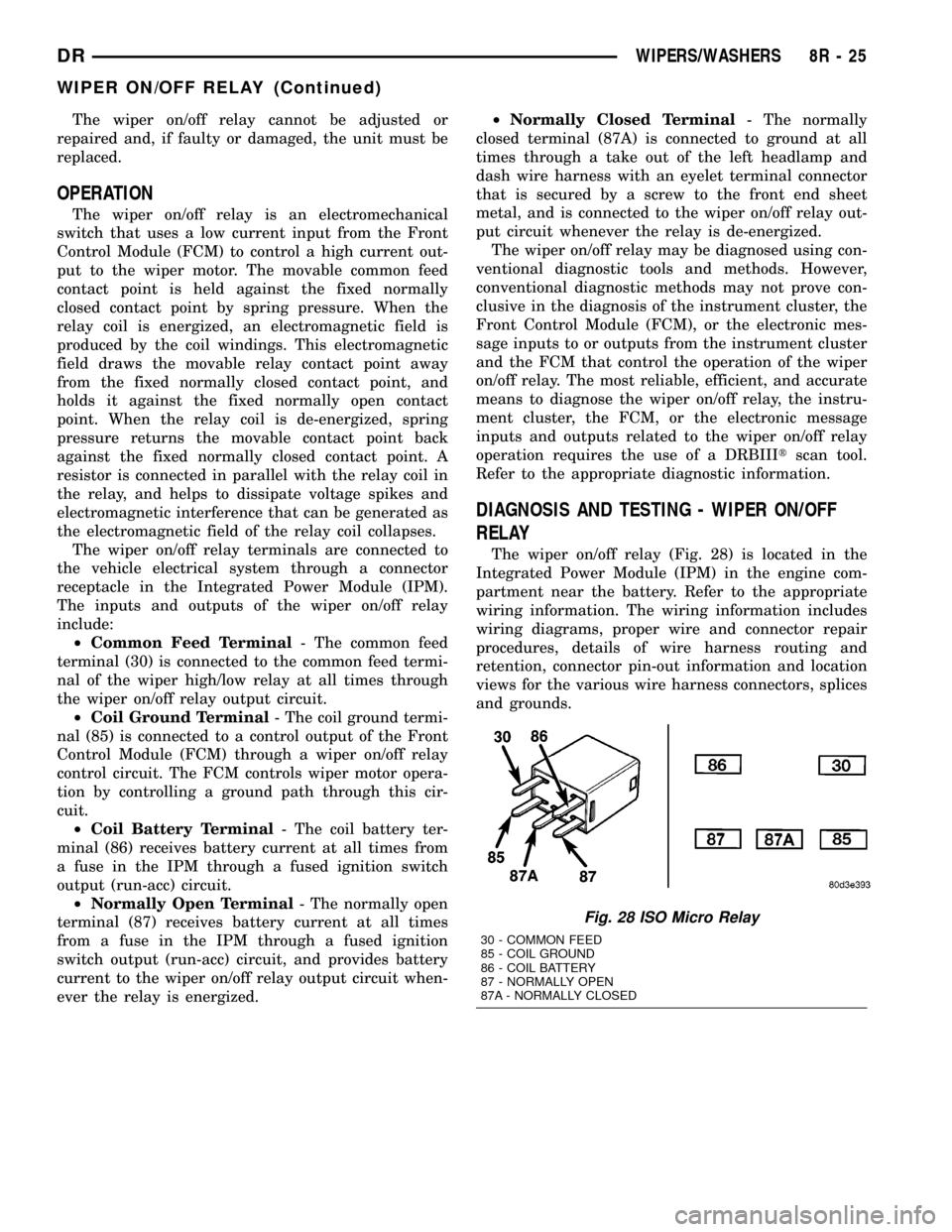

The wiper on/off relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper on/off relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control a high current out-

put to the wiper motor. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper on/off relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Integrated Power Module (IPM).

The inputs and outputs of the wiper on/off relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the common feed termi-

nal of the wiper high/low relay at all times through

the wiper on/off relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Front

Control Module (FCM) through a wiper on/off relay

control circuit. The FCM controls wiper motor opera-

tion by controlling a ground path through this cir-

cuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a fuse in the IPM through a fused ignition switch

output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) receives battery current at all times

from a fuse in the IPM through a fused ignition

switch output (run-acc) circuit, and provides battery

current to the wiper on/off relay output circuit when-

ever the relay is energized.²Normally Closed Terminal- The normally

closed terminal (87A) is connected to ground at all

times through a take out of the left headlamp and

dash wire harness with an eyelet terminal connector

that is secured by a screw to the front end sheet

metal, and is connected to the wiper on/off relay out-

put circuit whenever the relay is de-energized.

The wiper on/off relay may be diagnosed using con-

ventional diagnostic tools and methods. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the instrument cluster, the

Front Control Module (FCM), or the electronic mes-

sage inputs to or outputs from the instrument cluster

and the FCM that control the operation of the wiper

on/off relay. The most reliable, efficient, and accurate

means to diagnose the wiper on/off relay, the instru-

ment cluster, the FCM, or the electronic message

inputs and outputs related to the wiper on/off relay

operation requires the use of a DRBIIItscan tool.

Refer to the appropriate diagnostic information.

DIAGNOSIS AND TESTING - WIPER ON/OFF

RELAY

The wiper on/off relay (Fig. 28) is located in the

Integrated Power Module (IPM) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

Fig. 28 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DRWIPERS/WASHERS 8R - 25

WIPER ON/OFF RELAY (Continued)

Page 724 of 2627

NAVIGATION/TELECOMMUNICATION

TABLE OF CONTENTS

page page

NAVIGATION/TELECOMMUNICATION

DESCRIPTION..........................1

OPERATION............................1HANDS FREE MODULE

REMOVAL.............................2

INSTALLATION..........................2

NAVIGATION/

TELECOMMUNICATION

DESCRIPTION

TELECOMMUNICATIONS

The hands-free cellular system on this vehicle uses

BluetoothŸ technology to provide wireless communi-

cation between the operator's compatible cellular

telephone and the vehicle's on-board receiver.

The system uses voice recognition technology to

control operation. The incoming voice is broadcast

through the vehicle's radio speakers, automatically

overriding any other audio signals on the front

speakers when the hands-free system is in use. A

microphone in the rearview mirror picks up vehicle

occupant's voices. If a call is in progress when the

ignition is switched off, the hands-free system will

continue to operate for up to 45 seconds as part of

the Accessory Relay Delay function. Thereafter, the

call can continue on the hand-held telephone.

The system will communicate with a telephone

that is anywhere within the vehicle. However, cover-

ing the hand held phone or the hands-free phone

module with a metal object may block the signal. The

system will recognize up to seven telephones, each of

which is given a spoken identification by the user

during the setup process. The system includes Span-

ish and French voice recognition in addition to

English.

Two buttons on the rearview mirror, identified with

ISO icons, control the system: A9phone9button turns

the system on and off; a9voice recognition9(or voice

command) button prompts the hands-free system to

listen for a voice command.

OPERATION

TELECOMMUNICATION

Two buttons on the rearview mirror, identified with

ISO icons, control the system: A9phone9button turns

the system on and off; a9voice recognition9(or voice

command) button prompts the hands-free system to

listen for a voice command. The system includes the

following features:

²Phone book - Stores telephone numbers for later

recall by name or other verbal identification, called a

voice tag, and memory location.

²Four memory locations - Home, Work, Cellular

and Pager. A maximum of 32 unique names or voice

tags may be stored at the same time, with a different

number in each of the four memory locations.

²Voice tag dialing - Dials the number associated

with a voice tag and memory location.

²Digit dialing - Dials the telephone number by

recognizing the names of the digits as they are spo-

ken.

²Receiving calls - A voice prompt notifies the user

of an incoming call. A voice response accepts or

rejects the call without manual intervention.

²Privacy Mode - Switches the call to the hand-

held telephone and the hands-free system and back

again using the ªvoice recognitionº (or ªvoice com-

mandº) button and a voice command, if desired.

DRNAVIGATION/TELECOMMUNICATION 8T - 1

Page 726 of 2627

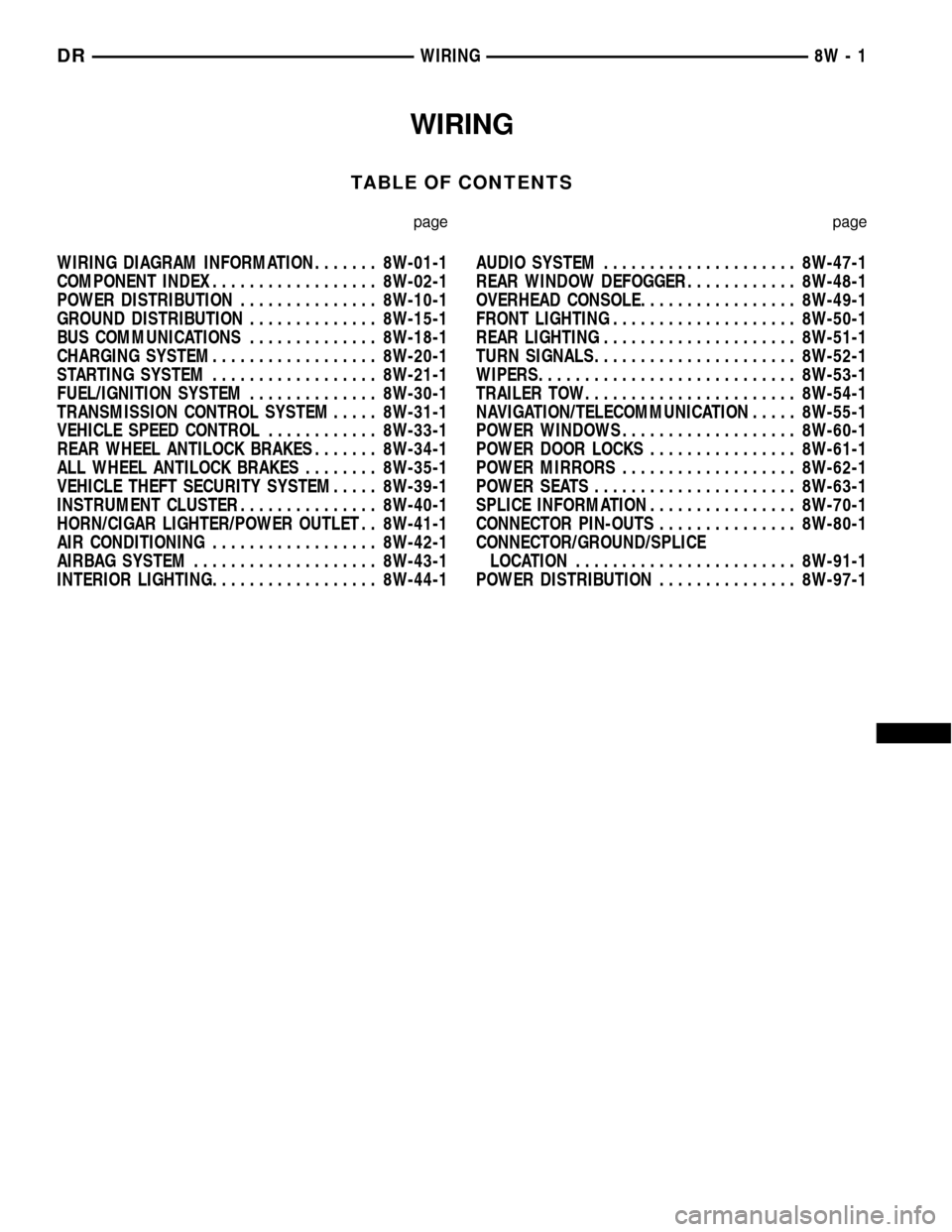

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

REAR WHEEL ANTILOCK BRAKES....... 8W-34-1

ALL WHEEL ANTILOCK BRAKES........ 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING.................. 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATION..... 8W-55-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 DRWIRING 8W - 1

Page 733 of 2627

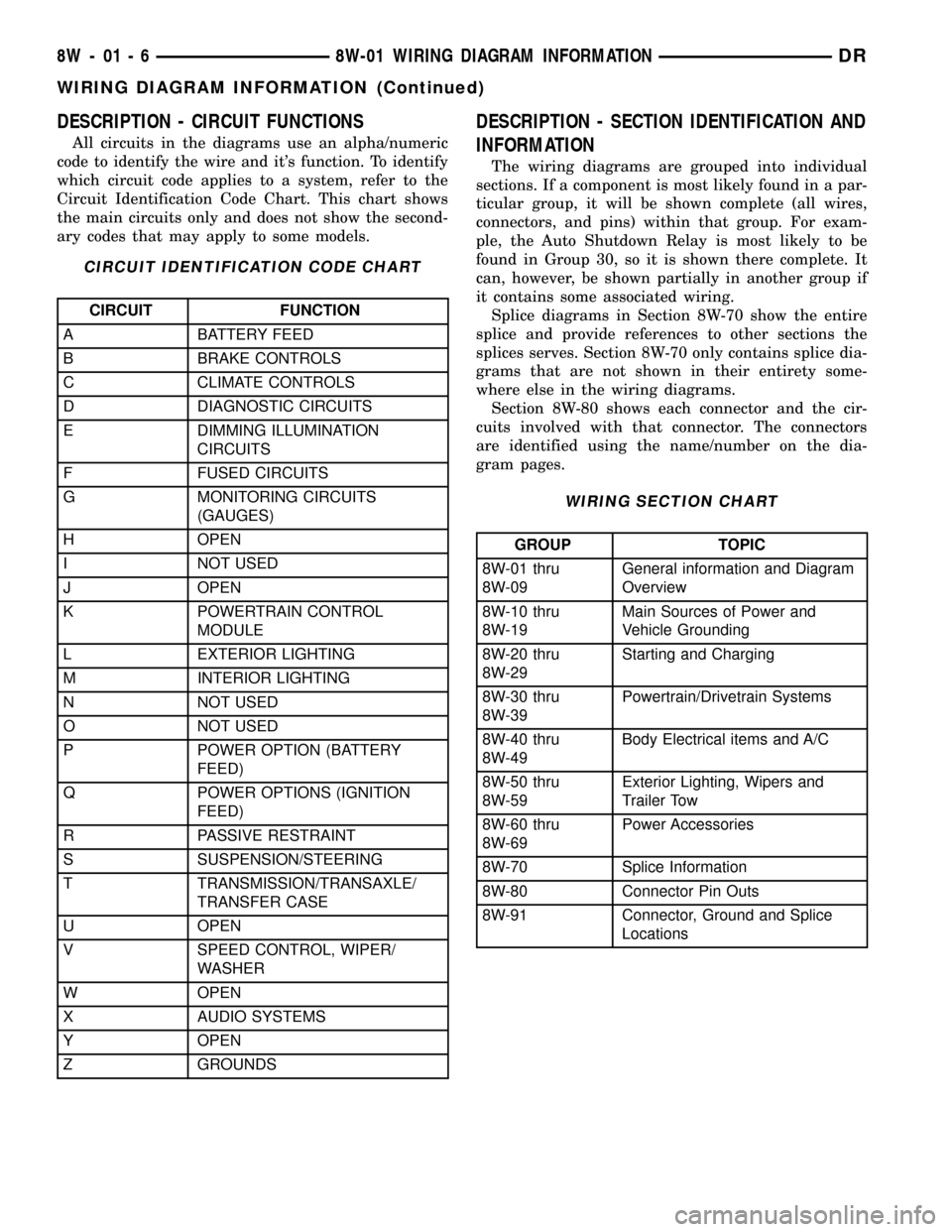

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONDR

WIRING DIAGRAM INFORMATION (Continued)