Starter solenoid DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1616 of 2627

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER DRAINING

AT FUEL FILTER

Refer to Fuel Filter/Water Separator removal/in-

stallation for procedures.

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM PARTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

STANDARD PROCEDURE - FUEL SYSTEM

PRIMING

A certain amount of air becomes trapped in the

fuel system when fuel system components on the

supply and/or high-pressure side are serviced or

replaced. Fuel system priming is accomplished using

the electric fuel transfer (lift) pump.

Servicing or replacing fuel system components will

not require fuel system priming.

The fuel transfer (lift) pump is self-priming: When

the key is first turned on (without cranking engine),

the pump operates for approximately 1 to 2 second

and then shuts off. The pump will also operate for up

to 25 seconds after the starter is quickly engaged,

and then disengaged without allowing the engine to

start. The pump shuts off immediately if the key is

on and the engine stops running.

(1) Turn key to CRANK position and quickly

release key to ON position before engine starts. This

will operate fuel transfer pump for approximately 25

seconds.

(2) Crank engine. If the engine does not start after

25 seconds, turn key OFF. Repeat previous step until

engine starts.

(3) Fuel system priming is now completed.

(4) Attempt to start engine. If engine will not

start, proceed to following steps.When engine does

start, it may run erratically and be noisy for a

few minutes. This is a normal condition.

CAUTION: Do not engage the starter motor for more

than 30 seconds at a time. Allow two minutes

between cranking intervals.

(5) Perform previous fuel priming procedure steps

using fuel transfer pump. Be sure fuel is present at

fuel tank.

(6) Crank the engine for 30 seconds at a time to

allow fuel system to prime.

WARNING: THE FUEL INJECTION PUMP SUPPLIES

EXTREMELY HIGH FUEL PRESSURE TO EACH INDI-

VIDUAL INJECTOR THROUGH THE HIGH-PRES-

SURE LINES. FUEL UNDER THIS AMOUNT OF

PRESSURE CAN PENETRATE THE SKIN AND

CAUSE PERSONAL INJURY. WEAR SAFETY GOG-

GLES AND ADEQUATE PROTECTIVE CLOTHING.

DO NOT LOOSEN FUEL FITTINGS WHILE ENGINE

IS RUNNING.

WARNING: ENGINE MAY START WHILE CRANKING

STARTER MOTOR.

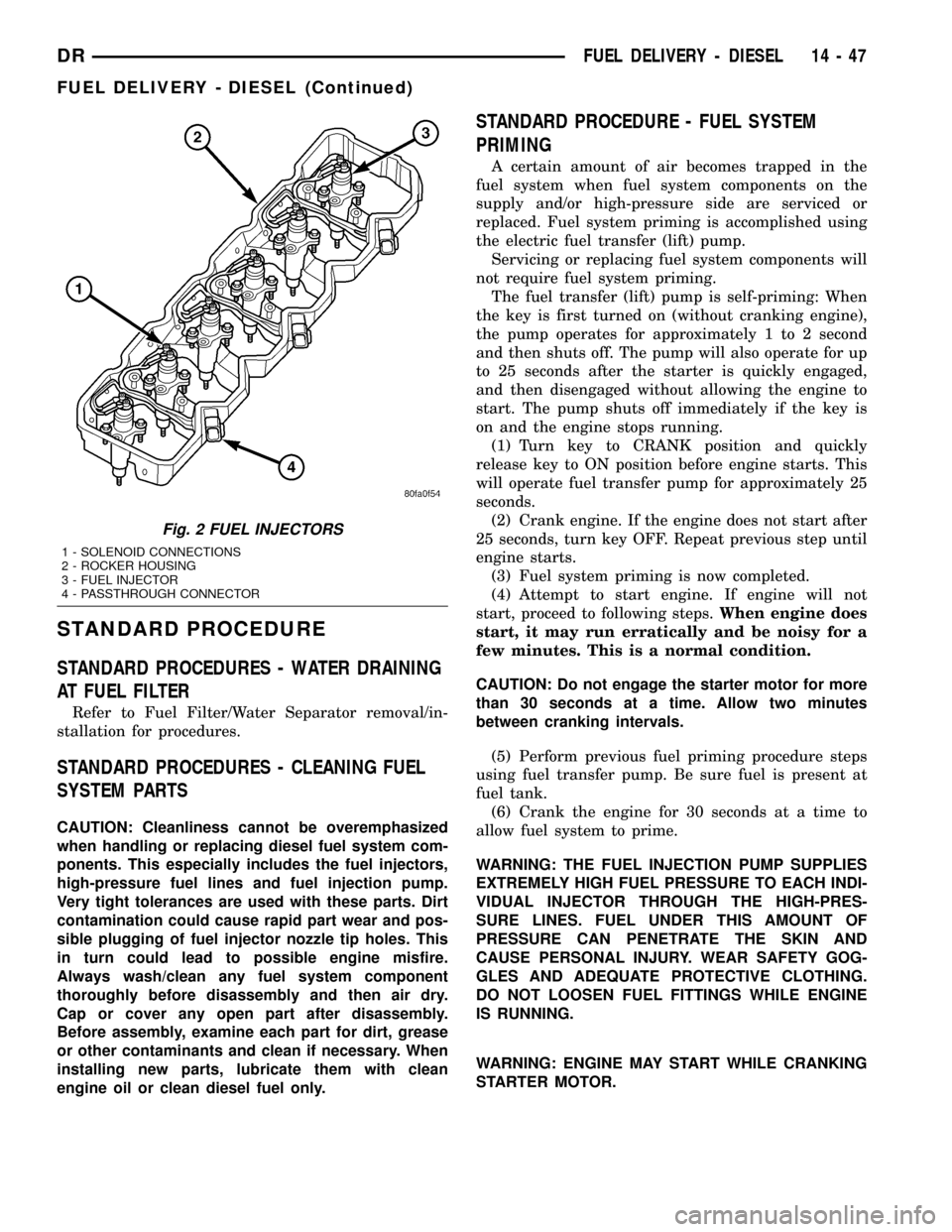

Fig. 2 FUEL INJECTORS

1 - SOLENOID CONNECTIONS

2 - ROCKER HOUSING

3 - FUEL INJECTOR

4 - PASSTHROUGH CONNECTOR

DRFUEL DELIVERY - DIESEL 14 - 47

FUEL DELIVERY - DIESEL (Continued)

Page 1861 of 2627

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

NOTE: The overdrive unit can be removed and ser-

viced separately. It is not necessary to remove the

entire transmission assembly to perform overdrive

unit repairs.

(1) Disconnect battery negative cable.

(2) Raise vehicle.

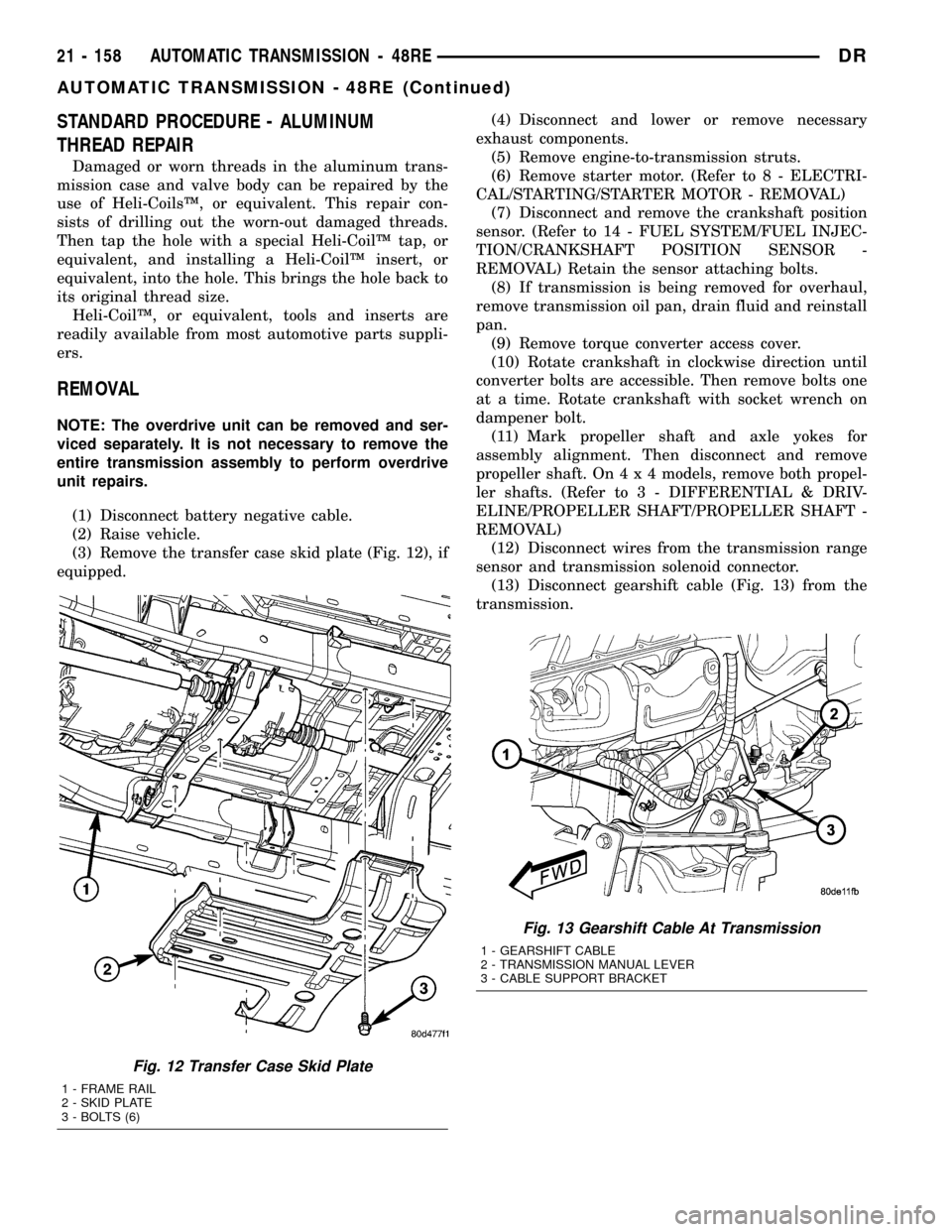

(3) Remove the transfer case skid plate (Fig. 12), if

equipped.(4) Disconnect and lower or remove necessary

exhaust components.

(5) Remove engine-to-transmission struts.

(6) Remove starter motor. (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

(7) Disconnect and remove the crankshaft position

sensor. (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/CRANKSHAFT POSITION SENSOR -

REMOVAL) Retain the sensor attaching bolts.

(8) If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and reinstall

pan.

(9) Remove torque converter access cover.

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propel-

ler shafts. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(12) Disconnect wires from the transmission range

sensor and transmission solenoid connector.

(13) Disconnect gearshift cable (Fig. 13) from the

transmission.

Fig. 12 Transfer Case Skid Plate

1 - FRAME RAIL

2 - SKID PLATE

3 - BOLTS (6)

Fig. 13 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

21 - 158 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1878 of 2627

(13) Install bolts attaching converter housing to

engine.

(14) Install rear support.

(15) Install the rear transmission crossmember.

(16) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member.

(17) Remove engine support fixture.

(18) Install the transfer case, if equipped.

(19) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

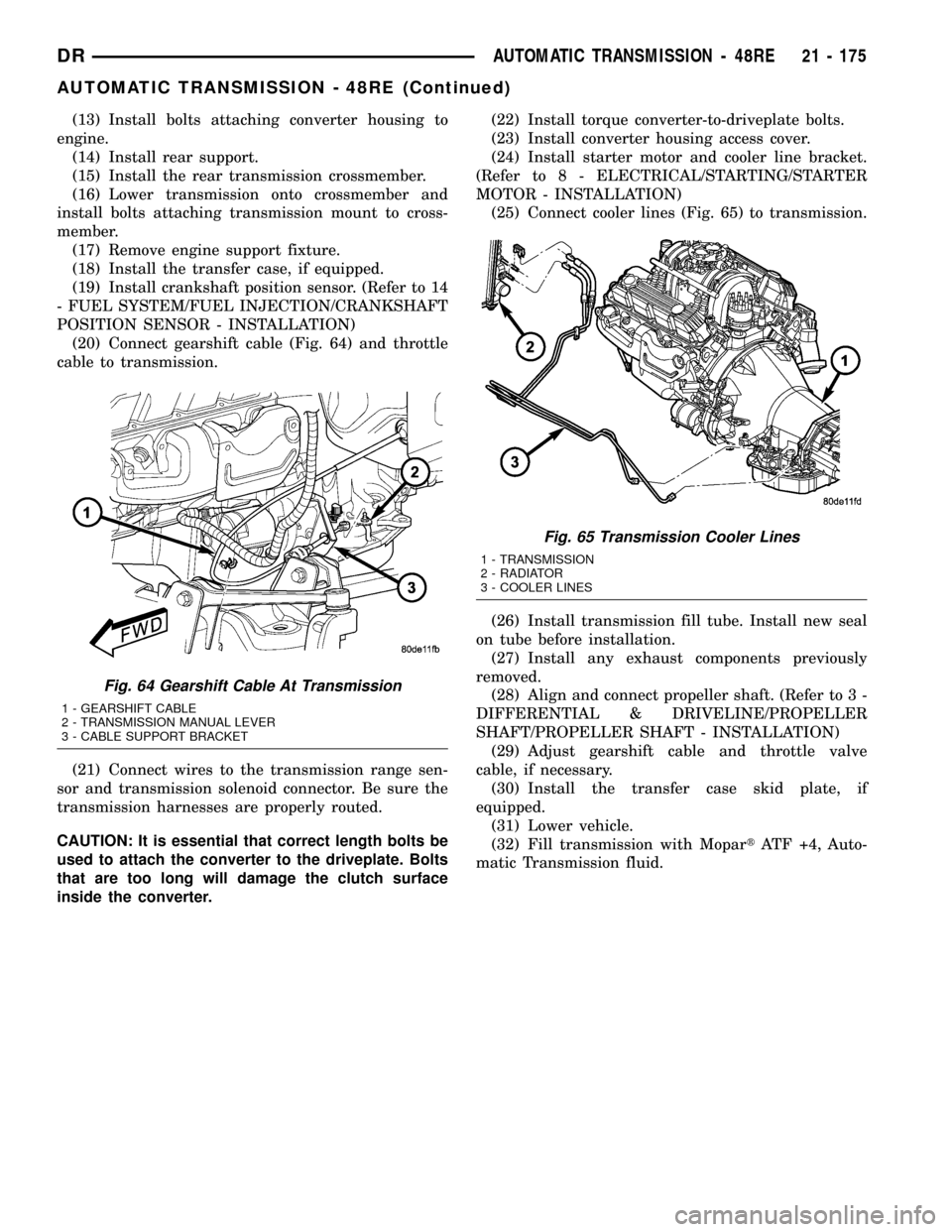

(20) Connect gearshift cable (Fig. 64) and throttle

cable to transmission.

(21) Connect wires to the transmission range sen-

sor and transmission solenoid connector. Be sure the

transmission harnesses are properly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.(22) Install torque converter-to-driveplate bolts.

(23) Install converter housing access cover.

(24) Install starter motor and cooler line bracket.

(Refer to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION)

(25) Connect cooler lines (Fig. 65) to transmission.

(26) Install transmission fill tube. Install new seal

on tube before installation.

(27) Install any exhaust components previously

removed.

(28) Align and connect propeller shaft. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(29) Adjust gearshift cable and throttle valve

cable, if necessary.

(30) Install the transfer case skid plate, if

equipped.

(31) Lower vehicle.

(32) Fill transmission with MopartATF +4, Auto-

matic Transmission fluid.

Fig. 64 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

Fig. 65 Transmission Cooler Lines

1 - TRANSMISSION

2 - RADIATOR

3 - COOLER LINES

DRAUTOMATIC TRANSMISSION - 48RE 21 - 175

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2022 of 2627

(10) Remove the starter motor.

(11) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(12) Disengage the output speed sensor connector

from the output speed sensor (Fig. 9).

(13) Disengage the input speed sensor connector

from the input speed sensor (Fig. 10).(14) Disengage the transmission solenoid/TRS

assembly connector from the transmission solenoid/

TRS assembly (Fig. 11).

(15) Disengage the line pressure sensor connector

from the line pressure sensor (Fig. 12).

Fig. 9 Disconnect Output Speed Sensor

1 - TRANSMISSION

2 - OUTPUT SPEED SENSOR

Fig. 10 Disconnect Input Speed Sensor

1 - TRANSMISSION

2 - INPUT SPEED SENSOR

Fig. 11 Disconnect Transmission Solenoid/TRS

Assembly

1 - TRANSMISSION

2 - TRANSMISSION SOLENOID/TRS ASSEMBLY

Fig. 12 Disconnect Line Pressure Sensor

1 - TRANSMISSION

2 - LINE PRESSURE SENSOR

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 319

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2108 of 2627

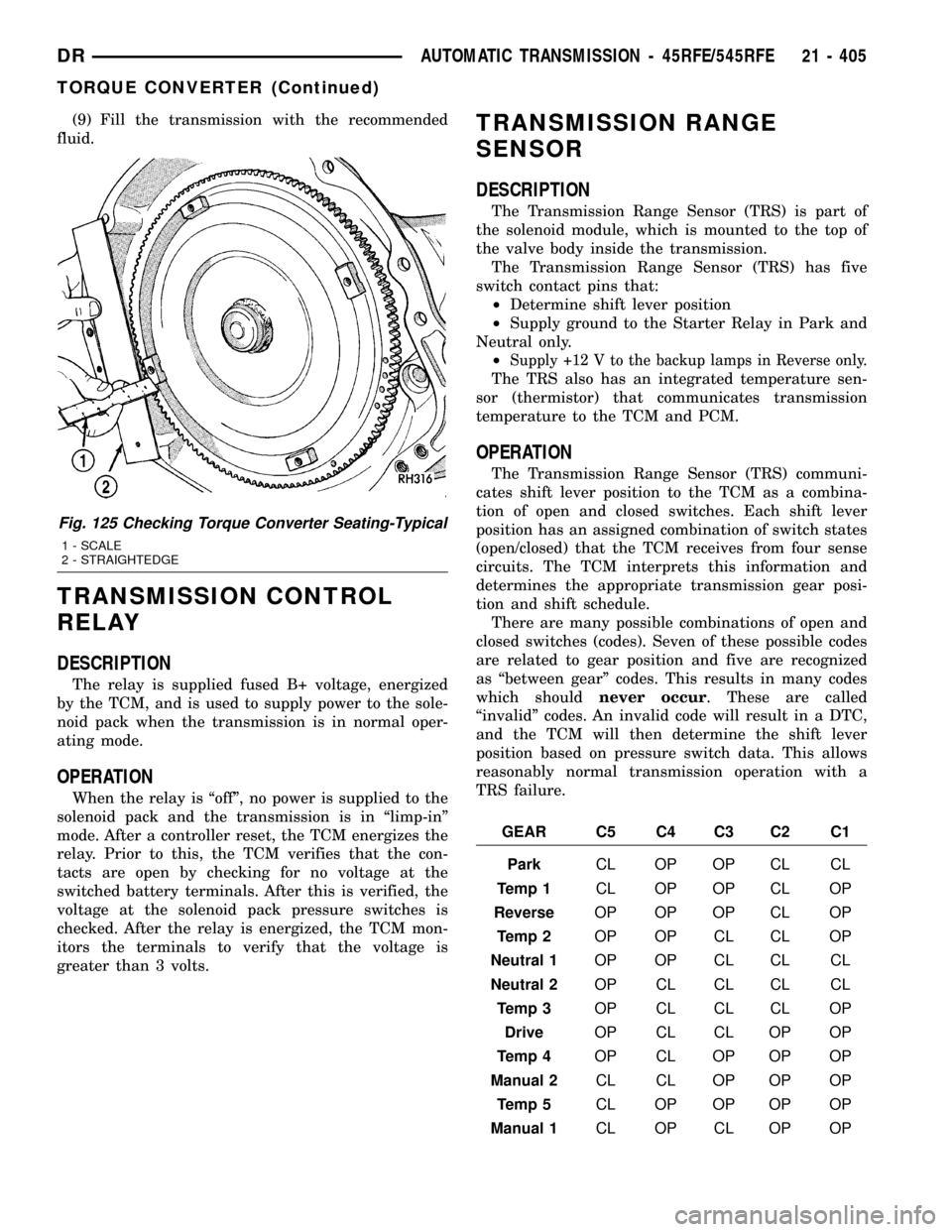

(9) Fill the transmission with the recommended

fluid.

TRANSMISSION CONTROL

RELAY

DESCRIPTION

The relay is supplied fused B+ voltage, energized

by the TCM, and is used to supply power to the sole-

noid pack when the transmission is in normal oper-

ating mode.

OPERATION

When the relay is ªoffº, no power is supplied to the

solenoid pack and the transmission is in ªlimp-inº

mode. After a controller reset, the TCM energizes the

relay. Prior to this, the TCM verifies that the con-

tacts are open by checking for no voltage at the

switched battery terminals. After this is verified, the

voltage at the solenoid pack pressure switches is

checked. After the relay is energized, the TCM mon-

itors the terminals to verify that the voltage is

greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is part of

the solenoid module, which is mounted to the top of

the valve body inside the transmission.

The Transmission Range Sensor (TRS) has five

switch contact pins that:

²Determine shift lever position

²Supply ground to the Starter Relay in Park and

Neutral only.

²

Supply +12 V to the backup lamps in Reverse only.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transmission

temperature to the TCM and PCM.

OPERATION

The Transmission Range Sensor (TRS) communi-

cates shift lever position to the TCM as a combina-

tion of open and closed switches. Each shift lever

position has an assigned combination of switch states

(open/closed) that the TCM receives from four sense

circuits. The TCM interprets this information and

determines the appropriate transmission gear posi-

tion and shift schedule.

There are many possible combinations of open and

closed switches (codes). Seven of these possible codes

are related to gear position and five are recognized

as ªbetween gearº codes. This results in many codes

which shouldnever occur. These are called

ªinvalidº codes. An invalid code will result in a DTC,

and the TCM will then determine the shift lever

position based on pressure switch data. This allows

reasonably normal transmission operation with a

TRS failure.

GEAR C5 C4 C3 C2 C1

ParkCL OP OP CL CL

Temp 1CL OP OP CL OP

ReverseOP OP OP CL OP

Temp 2OP OP CL CL OP

Neutral 1OP OP CL CL CL

Neutral 2OP CL CL CL CL

Temp 3OP CL CL CL OP

DriveOP CL CL OP OP

Temp 4OP CL OP OP OP

Manual 2CL CL OP OP OP

Temp 5CL OP OP OP OP

Manual 1CL OP CL OP OP

Fig. 125 Checking Torque Converter Seating-Typical

1 - SCALE

2 - STRAIGHTEDGE

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 405

TORQUE CONVERTER (Continued)

Page 2618 of 2627

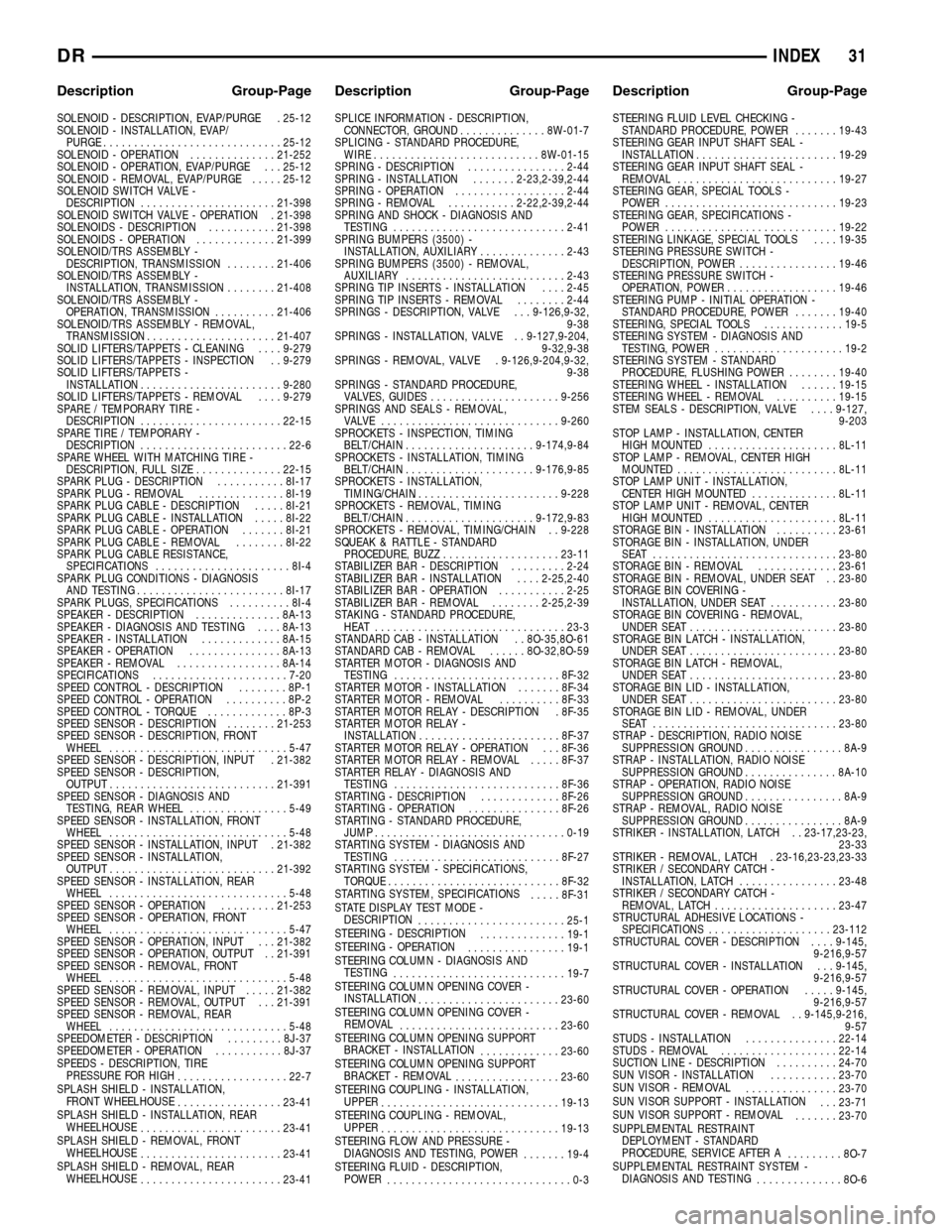

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-12

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-12

SOLENOID - OPERATION..............21-252

SOLENOID - OPERATION, EVAP/PURGE . . . 25-12

SOLENOID - REMOVAL, EVAP/PURGE.....25-12

SOLENOID SWITCH VALVE -

DESCRIPTION......................21-398

SOLENOID SWITCH VALVE - OPERATION . 21-398

SOLENOIDS - DESCRIPTION...........21-398

SOLENOIDS - OPERATION.............21-399

SOLENOID/TRS ASSEMBLY -

DESCRIPTION, TRANSMISSION........21-406

SOLENOID/TRS ASSEMBLY -

INSTALLATION, TRANSMISSION........21-408

SOLENOID/TRS ASSEMBLY -

OPERATION, TRANSMISSION..........21-406

SOLENOID/TRS ASSEMBLY - REMOVAL,

TRANSMISSION.....................21-407

SOLID LIFTERS/TAPPETS - CLEANING....9-279

SOLID LIFTERS/TAPPETS - INSPECTION . . 9-279

SOLID LIFTERS/TAPPETS -

INSTALLATION.......................9-280

SOLID LIFTERS/TAPPETS - REMOVAL....9-279

SPARE / TEMPORARY TIRE -

DESCRIPTION.......................22-15

SPARE TIRE / TEMPORARY -

DESCRIPTION........................22-6

SPARE WHEEL WITH MATCHING TIRE -

DESCRIPTION, FULL SIZE..............22-15

SPARK PLUG - DESCRIPTION...........8I-17

SPARK PLUG - REMOVAL..............8I-19

SPARK PLUG CABLE - DESCRIPTION.....8I-21

SPARK PLUG CABLE - INSTALLATION.....8I-22

SPARK PLUG CABLE - OPERATION.......8I-21

SPARK PLUG CABLE - REMOVAL........8I-22

SPARK PLUG CABLE RESISTANCE,

SPECIFICATIONS......................8I-4

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-17

SPARK PLUGS, SPECIFICATIONS..........8I-4

SPEAKER - DESCRIPTION..............8A-13

SPEAKER - DIAGNOSIS AND TESTING....8A-13

SPEAKER - INSTALLATION.............8A-15

SPEAKER - OPERATION...............8A-13

SPEAKER - REMOVAL.................8A-14

SPECIFICATIONS......................7-20

SPEED CONTROL - DESCRIPTION........8P-1

SPEED CONTROL - OPERATION..........8P-2

SPEED CONTROL - TORQUE.............8P-3

SPEED SENSOR - DESCRIPTION........21-253

SPEED SENSOR - DESCRIPTION, FRONT

WHEEL.............................5-47

SPEED SENSOR - DESCRIPTION, INPUT . 21-382

SPEED SENSOR - DESCRIPTION,

OUTPUT...........................21-391

SPEED SENSOR - DIAGNOSIS AND

TESTING, REAR WHEEL................5-49

SPEED SENSOR - INSTALLATION, FRONT

WHEEL.............................5-48

SPEED SENSOR - INSTALLATION, INPUT . 21-382

SPEED SENSOR - INSTALLATION,

OUTPUT...........................21-392

SPEED SENSOR - INSTALLATION, REAR

WHEEL.............................5-48

SPEED SENSOR - OPERATION.........21-253

SPEED SENSOR - OPERATION, FRONT

WHEEL.............................5-47

SPEED SENSOR - OPERATION, INPUT . . . 21-382

SPEED SENSOR - OPERATION, OUTPUT . . 21-391

SPEED SENSOR - REMOVAL, FRONT

WHEEL.............................5-48

SPEED SENSOR - REMOVAL, INPUT.....21-382

SPEED SENSOR - REMOVAL, OUTPUT . . . 21-391

SPEED SENSOR - REMOVAL, REAR

WHEEL.............................5-48

SPEEDOMETER - DESCRIPTION.........8J-37

SPEEDOMETER - OPERATION...........8J-37

SPEEDS - DESCRIPTION, TIRE

PRESSURE FOR HIGH

..................22-7

SPLASH SHIELD - INSTALLATION,

FRONT WHEELHOUSE

.................23-41

SPLASH SHIELD - INSTALLATION, REAR

WHEELHOUSE

.......................23-41

SPLASH SHIELD - REMOVAL, FRONT

WHEELHOUSE

.......................23-41

SPLASH SHIELD - REMOVAL, REAR

WHEELHOUSE

.......................23-41SPLICE INFORMATION - DESCRIPTION,

CONNECTOR, GROUND..............8W-01-7

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-15

SPRING - DESCRIPTION................2-44

SPRING - INSTALLATION.......2-23,2-39,2-44

SPRING - OPERATION..................2-44

SPRING - REMOVAL...........2-22,2-39,2-44

SPRING AND SHOCK - DIAGNOSIS AND

TESTING............................2-41

SPRING BUMPERS (3500) -

INSTALLATION, AUXILIARY..............2-43

SPRING BUMPERS (3500) - REMOVAL,

AUXILIARY..........................2-43

SPRING TIP INSERTS - INSTALLATION....2-45

SPRING TIP INSERTS - REMOVAL........2-44

SPRINGS - DESCRIPTION, VALVE . . . 9-126,9-32,

9-38

SPRINGS - INSTALLATION, VALVE . . 9-127,9-204,

9-32,9-38

SPRINGS - REMOVAL, VALVE . 9-126,9-204,9-32,

9-38

SPRINGS - STANDARD PROCEDURE,

VALVES, GUIDES.....................9-256

SPRINGS AND SEALS - REMOVAL,

VALVE .............................9-260

SPROCKETS - INSPECTION, TIMING

BELT/CHAIN.....................9-174,9-84

SPROCKETS - INSTALLATION, TIMING

BELT/CHAIN.....................9-176,9-85

SPROCKETS - INSTALLATION,

TIMING/CHAIN........................9-228

SPROCKETS - REMOVAL, TIMING

BELT/CHAIN.....................9-172,9-83

SPROCKETS - REMOVAL, TIMING/CHAIN . . 9-228

SQUEAK & RATTLE - STANDARD

PROCEDURE, BUZZ...................23-11

STABILIZER BAR - DESCRIPTION.........2-24

STABILIZER BAR - INSTALLATION....2-25,2-40

STABILIZER BAR - OPERATION...........2-25

STABILIZER BAR - REMOVAL........2-25,2-39

STAKING - STANDARD PROCEDURE,

HEAT ...............................23-3

STANDARD CAB - INSTALLATION . . 8O-35,8O-61

STANDARD CAB - REMOVAL......8O-32,8O-59

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-32

STARTER MOTOR - INSTALLATION.......8F-34

STARTER MOTOR - REMOVAL..........8F-33

STARTER MOTOR RELAY - DESCRIPTION . 8F-35

STARTER MOTOR RELAY -

INSTALLATION.......................8F-37

STARTER MOTOR RELAY - OPERATION . . . 8F-36

STARTER MOTOR RELAY - REMOVAL.....8F-37

STARTER RELAY - DIAGNOSIS AND

TESTING...........................8F-36

STARTING - DESCRIPTION.............8F-26

STARTING - OPERATION...............8F-26

STARTING - STANDARD PROCEDURE,

JUMP...............................0-19

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-27

STARTING SYSTEM - SPECIFICATIONS,

TORQUE............................8F-32

STARTING SYSTEM, SPECIFICATIONS

.....8F-31

STATE DISPLAY TEST MODE -

DESCRIPTION

........................25-1

STEERING - DESCRIPTION

..............19-1

STEERING - OPERATION

................19-1

STEERING COLUMN - DIAGNOSIS AND

TESTING

............................19-7

STEERING COLUMN OPENING COVER -

INSTALLATION

.......................23-60

STEERING COLUMN OPENING COVER -

REMOVAL

..........................23-60

STEERING COLUMN OPENING SUPPORT

BRACKET - INSTALLATION

.............23-60

STEERING COLUMN OPENING SUPPORT

BRACKET - REMOVAL

.................23-60

STEERING COUPLING - INSTALLATION,

UPPER

.............................19-13

STEERING COUPLING - REMOVAL,

UPPER

.............................19-13

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER

.......19-4

STEERING FLUID - DESCRIPTION,

POWER

..............................0-3STEERING FLUID LEVEL CHECKING -

STANDARD PROCEDURE, POWER.......19-43

STEERING GEAR INPUT SHAFT SEAL -

INSTALLATION.......................19-29

STEERING GEAR INPUT SHAFT SEAL -

REMOVAL..........................19-27

STEERING GEAR, SPECIAL TOOLS -

POWER............................19-23

STEERING GEAR, SPECIFICATIONS -

POWER............................19-22

STEERING LINKAGE, SPECIAL TOOLS....19-35

STEERING PRESSURE SWITCH -

DESCRIPTION, POWER................19-46

STEERING PRESSURE SWITCH -

OPERATION, POWER..................19-46

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-40

STEERING, SPECIAL TOOLS.............19-5

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-2

STEERING SYSTEM - STANDARD

PROCEDURE, FLUSHING POWER........19-40

STEERING WHEEL - INSTALLATION......19-15

STEERING WHEEL - REMOVAL..........19-15

STEM SEALS - DESCRIPTION, VALVE....9-127,

9-203

STOP LAMP - INSTALLATION, CENTER

HIGH MOUNTED.....................8L-11

STOP LAMP - REMOVAL, CENTER HIGH

MOUNTED..........................8L-11

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED..............8L-11

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED.....................8L-11

STORAGE BIN - INSTALLATION..........23-61

STORAGE BIN - INSTALLATION, UNDER

SEAT ..............................23-80

STORAGE BIN - REMOVAL.............23-61

STORAGE BIN - REMOVAL, UNDER SEAT . . 23-80

STORAGE BIN COVERING -

INSTALLATION, UNDER SEAT...........23-80

STORAGE BIN COVERING - REMOVAL,

UNDER SEAT........................23-80

STORAGE BIN LATCH - INSTALLATION,

UNDER SEAT........................23-80

STORAGE BIN LATCH - REMOVAL,

UNDER SEAT........................23-80

STORAGE BIN LID - INSTALLATION,

UNDER SEAT........................23-80

STORAGE BIN LID - REMOVAL, UNDER

SEAT ..............................23-80

STRAP - DESCRIPTION, RADIO NOISE

SUPPRESSION GROUND................8A-9

STRAP - INSTALLATION, RADIO NOISE

SUPPRESSION GROUND...............8A-10

STRAP - OPERATION, RADIO NOISE

SUPPRESSION GROUND................8A-9

STRAP - REMOVAL, RADIO NOISE

SUPPRESSION GROUND................8A-9

STRIKER - INSTALLATION, LATCH . . 23-17,23-23,

23-33

STRIKER - REMOVAL, LATCH . 23-16,23-23,23-33

STRIKER / SECONDARY CATCH -

INSTALLATION, LATCH................23-48

STRIKER / SECONDARY CATCH -

REMOVAL, LATCH....................23-47

STRUCTURAL ADHESIVE LOCATIONS -

SPECIFICATIONS....................23-112

STRUCTURAL COVER - DESCRIPTION....9-145,

9-216,9-57

STRUCTURAL COVER - INSTALLATION . . . 9-145,

9-216,9-57

STRUCTURAL COVER - OPERATION.....9-145,

9-216,9-57

STRUCTURAL COVER - REMOVAL . . 9-145,9-216,

9-57

STUDS - INSTALLATION...............22-14

STUDS - REMOVAL...................22-14

SUCTION LINE - DESCRIPTION..........24-70

SUN VISOR - INSTALLATION...........23-70

SUN VISOR - REMOVAL

...............23-70

SUN VISOR SUPPORT - INSTALLATION

. . . 23-71

SUN VISOR SUPPORT - REMOVAL

.......23-70

SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

.........8O-7

SUPPLEMENTAL RESTRAINT SYSTEM -

DIAGNOSIS AND TESTING

..............8O-6

DRINDEX 31

Description Group-Page Description Group-Page Description Group-Page