rear axle DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 83 of 2627

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign

material on shaft.1) Clean exterior of shaft and wash

with solvent.

2) Loose U-joint clamp screws. 2) Install new clamps and screws

and tighten to proper torque.

3) Loose or bent U-joint yoke or

excessive runout.3) Install new yoke.

4) Incorrect driveline angularity. 4) Measure and correct driveline

angles.

5) Rear spring center bolt not in

seat.5) Loosen spring u-bolts and seat

center bolt.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out

of balance.7) Installl new propeller shaft.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.9) Re-index propeller shaft, test,

and evaluate.

10) Excessive drive pinion gear

shaft runout.10) Re-index propeller shaft and

evaluate.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if

necessary.

12) Excessive transfer case runout. 12) Inspect and repair as necessary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws

and tighten to proper torque.

2) Lack of lubrication. 2) Replace as U-joints as

necessary.

PROPELLER SHAFT BALANCE

If propeller shaft is suspected of being out of bal-

ance, use the following procedure.

NOTE: Indexing propeller shaft 180É relative to the

yoke may eliminate some vibrations.

(1) Raise and support vehicle.

(2) Clean all foreign material from the propeller

shaft and universal joints.

(3) Inspect propeller shaft for missing balance

weights, broken welds and bent areas.If propeller

shaft is bent, it must be replaced.

(4) Inspect universal joints for wear and properly

installed.

(5) Check propeller shaft bolt torques.

(6) Remove wheels and install lug nuts to retain

brake rotors.

(7) Mark and number the shaft six inches from the

pinion yoke end at four positions 90É apart.

(8) Run and accelerate vehicle until vibration

occurs. Note the intensity and speed the vibration

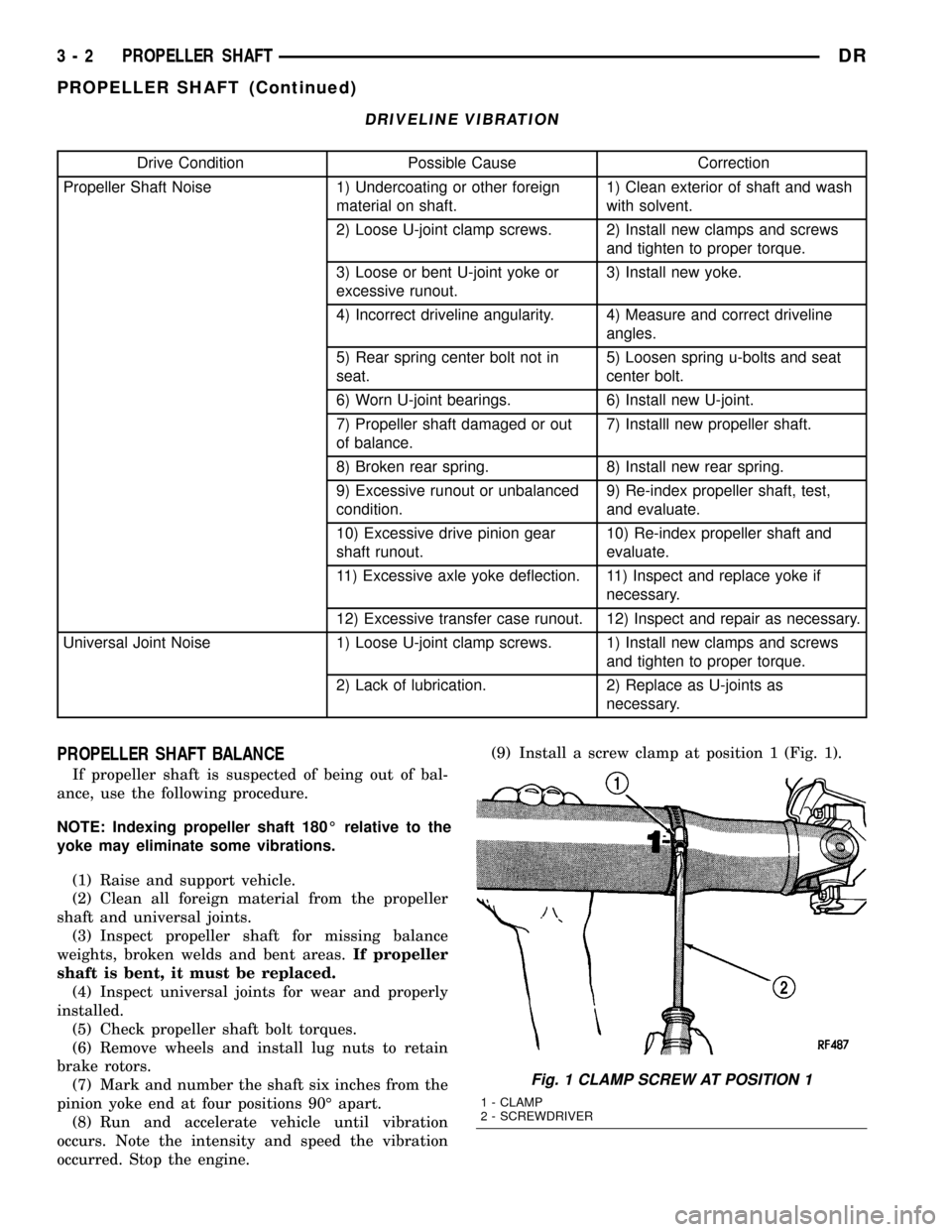

occurred. Stop the engine.(9) Install a screw clamp at position 1 (Fig. 1).

Fig. 1 CLAMP SCREW AT POSITION 1

1 - CLAMP

2 - SCREWDRIVER

3 - 2 PROPELLER SHAFTDR

PROPELLER SHAFT (Continued)

Page 84 of 2627

(10) Start engine and check vibration. If there is

little or no change move the clamp to the next posi-

tions. Repeat the vibration test.

NOTE: If there is no difference in vibration at this

positions, the vibration may not be the propeller

shaft.

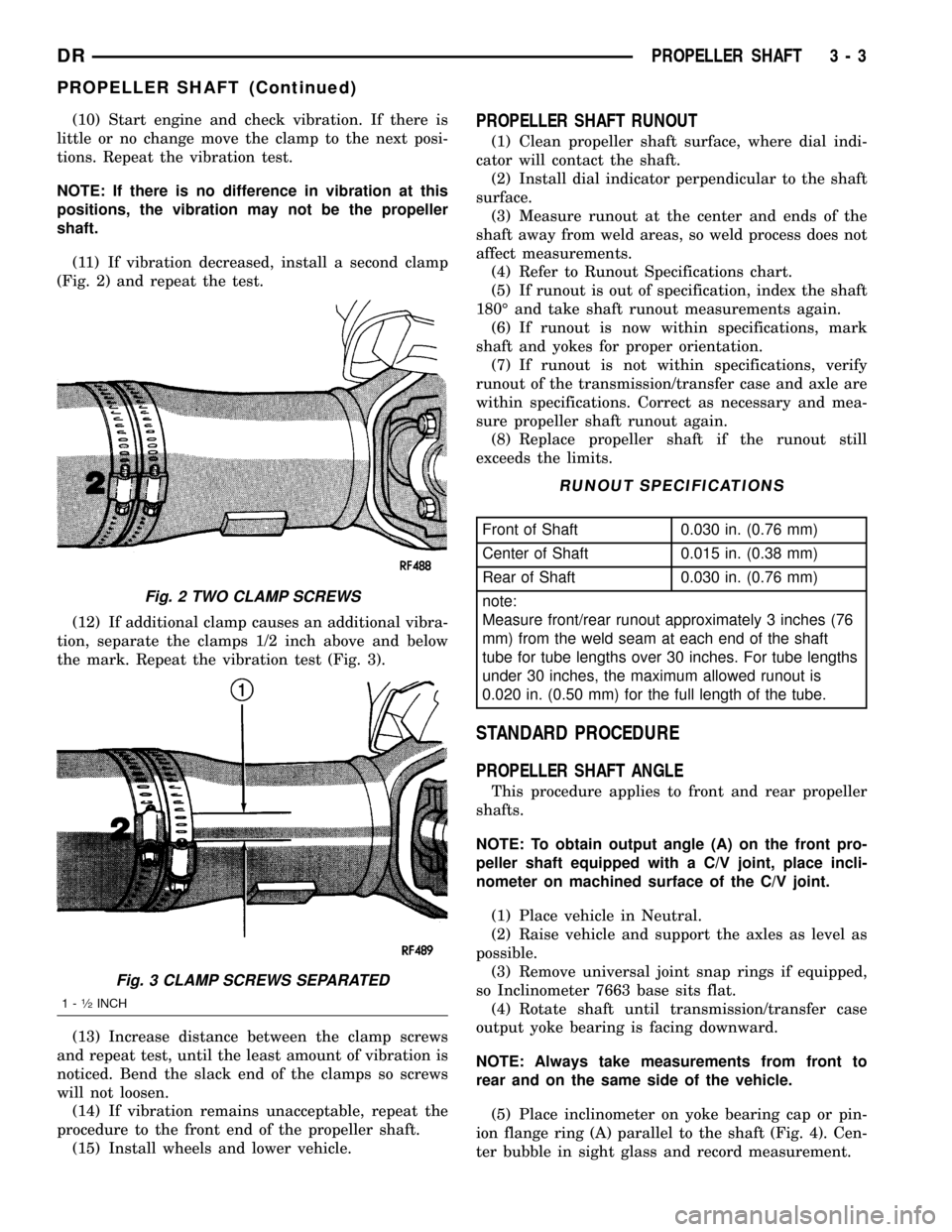

(11) If vibration decreased, install a second clamp

(Fig. 2) and repeat the test.

(12) If additional clamp causes an additional vibra-

tion, separate the clamps 1/2 inch above and below

the mark. Repeat the vibration test (Fig. 3).

(13) Increase distance between the clamp screws

and repeat test, until the least amount of vibration is

noticed. Bend the slack end of the clamps so screws

will not loosen.

(14) If vibration remains unacceptable, repeat the

procedure to the front end of the propeller shaft.

(15) Install wheels and lower vehicle.PROPELLER SHAFT RUNOUT

(1) Clean propeller shaft surface, where dial indi-

cator will contact the shaft.

(2) Install dial indicator perpendicular to the shaft

surface.

(3) Measure runout at the center and ends of the

shaft away from weld areas, so weld process does not

affect measurements.

(4) Refer to Runout Specifications chart.

(5) If runout is out of specification, index the shaft

180É and take shaft runout measurements again.

(6) If runout is now within specifications, mark

shaft and yokes for proper orientation.

(7) If runout is not within specifications, verify

runout of the transmission/transfer case and axle are

within specifications. Correct as necessary and mea-

sure propeller shaft runout again.

(8) Replace propeller shaft if the runout still

exceeds the limits.

RUNOUT SPECIFICATIONS

Front of Shaft 0.030 in. (0.76 mm)

Center of Shaft 0.015 in. (0.38 mm)

Rear of Shaft 0.030 in. (0.76 mm)

note:

Measure front/rear runout approximately 3 inches (76

mm) from the weld seam at each end of the shaft

tube for tube lengths over 30 inches. For tube lengths

under 30 inches, the maximum allowed runout is

0.020 in. (0.50 mm) for the full length of the tube.

STANDARD PROCEDURE

PROPELLER SHAFT ANGLE

This procedure applies to front and rear propeller

shafts.

NOTE: To obtain output angle (A) on the front pro-

peller shaft equipped with a C/V joint, place incli-

nometer on machined surface of the C/V joint.

(1) Place vehicle in Neutral.

(2) Raise vehicle and support the axles as level as

possible.

(3) Remove universal joint snap rings if equipped,

so Inclinometer 7663 base sits flat.

(4) Rotate shaft until transmission/transfer case

output yoke bearing is facing downward.

NOTE: Always take measurements from front to

rear and on the same side of the vehicle.

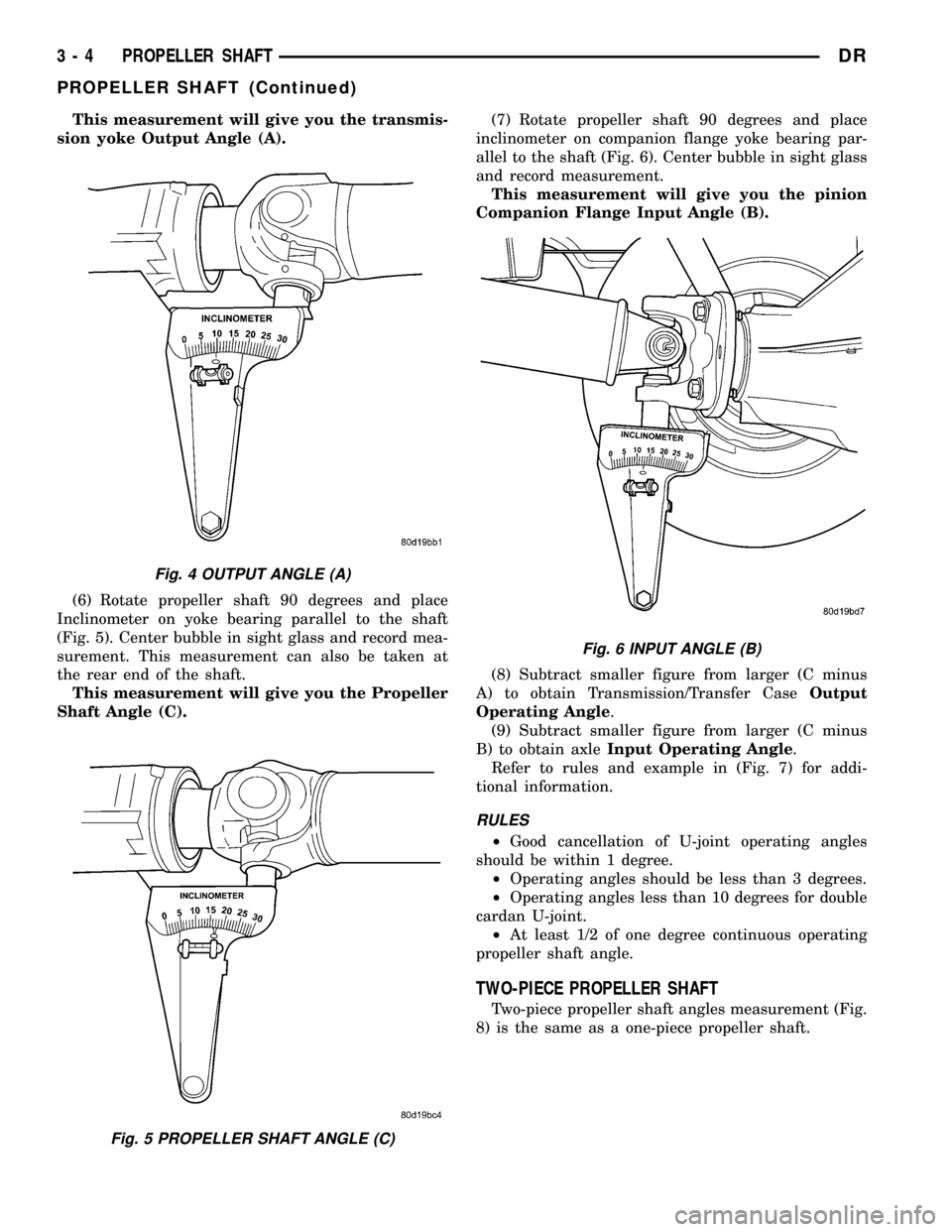

(5) Place inclinometer on yoke bearing cap or pin-

ion flange ring (A) parallel to the shaft (Fig. 4). Cen-

ter bubble in sight glass and record measurement.

Fig. 2 TWO CLAMP SCREWS

Fig. 3 CLAMP SCREWS SEPARATED

1-1¤2INCH

DRPROPELLER SHAFT 3 - 3

PROPELLER SHAFT (Continued)

Page 85 of 2627

This measurement will give you the transmis-

sion yoke Output Angle (A).

(6) Rotate propeller shaft 90 degrees and place

Inclinometer on yoke bearing parallel to the shaft

(Fig. 5). Center bubble in sight glass and record mea-

surement. This measurement can also be taken at

the rear end of the shaft.

This measurement will give you the Propeller

Shaft Angle (C).(7) Rotate propeller shaft 90 degrees and place

inclinometer on companion flange yoke bearing par-

allel to the shaft (Fig. 6). Center bubble in sight glass

and record measurement.

This measurement will give you the pinion

Companion Flange Input Angle (B).

(8) Subtract smaller figure from larger (C minus

A) to obtain Transmission/Transfer CaseOutput

Operating Angle.

(9) Subtract smaller figure from larger (C minus

B) to obtain axleInput Operating Angle.

Refer to rules and example in (Fig. 7) for addi-

tional information.

RULES

²Good cancellation of U-joint operating angles

should be within 1 degree.

²Operating angles should be less than 3 degrees.

²Operating angles less than 10 degrees for double

cardan U-joint.

²At least 1/2 of one degree continuous operating

propeller shaft angle.

TWO-PIECE PROPELLER SHAFT

Two-piece propeller shaft angles measurement (Fig.

8) is the same as a one-piece propeller shaft.

Fig. 4 OUTPUT ANGLE (A)

Fig. 5 PROPELLER SHAFT ANGLE (C)

Fig. 6 INPUT ANGLE (B)

3 - 4 PROPELLER SHAFTDR

PROPELLER SHAFT (Continued)

Page 87 of 2627

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Center Bearing Bolts 54 40 -

Transfer Case Flange

Bolts88 65 -

LD - Front Pinion Flange

Bolts11 5 8 5 -

HD - Front Pinion Flange

Bolts28 21 -

Rear Pinion Flange Bolts 115 85 -

Rear Pinion Yoke Bolts 29 22 -

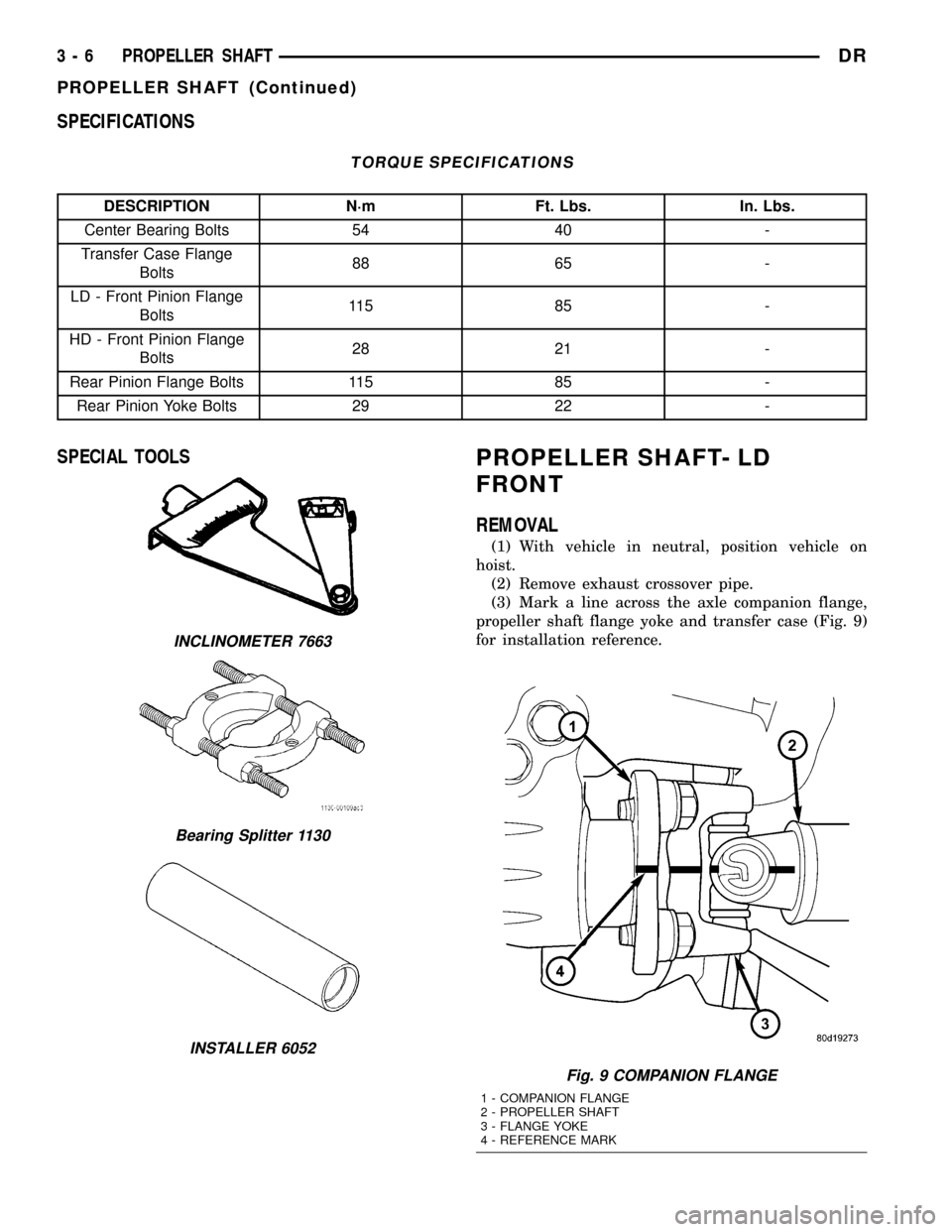

SPECIAL TOOLSPROPELLER SHAFT- LD

FRONT

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove exhaust crossover pipe.

(3) Mark a line across the axle companion flange,

propeller shaft flange yoke and transfer case (Fig. 9)

for installation reference.

INCLINOMETER 7663

Bearing Splitter 1130

INSTALLER 6052

Fig. 9 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

3 - FLANGE YOKE

4 - REFERENCE MARK

3 - 6 PROPELLER SHAFTDR

PROPELLER SHAFT (Continued)

Page 108 of 2627

FRONT AXLE - C205F

TABLE OF CONTENTS

page page

FRONT AXLE - C205F

DIAGNOSIS AND TESTING................27

REMOVAL.............................31

INSTALLATION.........................31

ADJUSTMENTS........................32

SPECIFICATIONS.......................39

SPECIAL TOOLS.......................40

AXLE SHAFTS

REMOVAL.............................43

INSTALLATION.........................43

AXLE SHAFT SEALS

REMOVAL.............................43

INSTALLATION.........................43

AXLE BEARINGS

REMOVAL.............................43INSTALLATION.........................44

PINION SEAL

REMOVAL.............................44

INSTALLATION.........................45

DIFFERENTIAL

REMOVAL.............................46

DISASSEMBLY.........................47

ASSEMBLY............................47

INSTALLATION.........................48

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................48

INSTALLATION.........................48

PINION GEAR/RING GEAR

REMOVAL.............................49

INSTALLATION.........................51

FRONT AXLE - C205F

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, tooth contact, worn/damaged

gears or the carrier housing not having the proper

offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly check for:

²Insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. The side gears are loaded dur-

ing turns. They usually do not cause noise during

straight-ahead driving when the gears are unloaded.

A worn pinion mate shaft can also cause a snapping

or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearingshave a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Differential bearingsusually produce a low pitch

noise. Differential bearing noise is similar to pinion

bearing noise. The pitch of differential bearing noise

is also constant and varies only with vehicle speed.

Axle shaft bearingsproduce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 m.p.h.

LOW SPEED KNOCK

Low speed knock is generally caused by:

²Worn U-joints/CV joint.

²Worn side-gear thrust washers.

²Worn pinion shaft bore.

DRFRONT AXLE - C205F 3 - 27

Page 109 of 2627

VIBRATION

Vibration at the rear of the vehicle is usually

caused by:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out of balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear end

vibration. Do not overlook engine accessories, brack-

ets and drive belts.

All driveline components should be examined

before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged) can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints/CV joint.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear and lis-

ten for the noise. A mechanics stethoscope is helpful

in isolating the source of a noise.

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

3. End-play in pinion bearings. 3. Refer to pinion pre-load

information and correct as

necessary.

4. Excessive gear backlash

between the ring gear and pinion.4. Check adjustment of the ring

gear and pinion backlash. Correct

as necessary.

5. Improper adjustment of pinion

gear bearings.5. Adjust the pinion bearings

pre-load.

6. Loose pinion yoke nut. 6. Tighten the pinion yoke nut.

7. Scuffed gear tooth contact

surfaces.7. Inspect and replace as

necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

3 - 28 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 113 of 2627

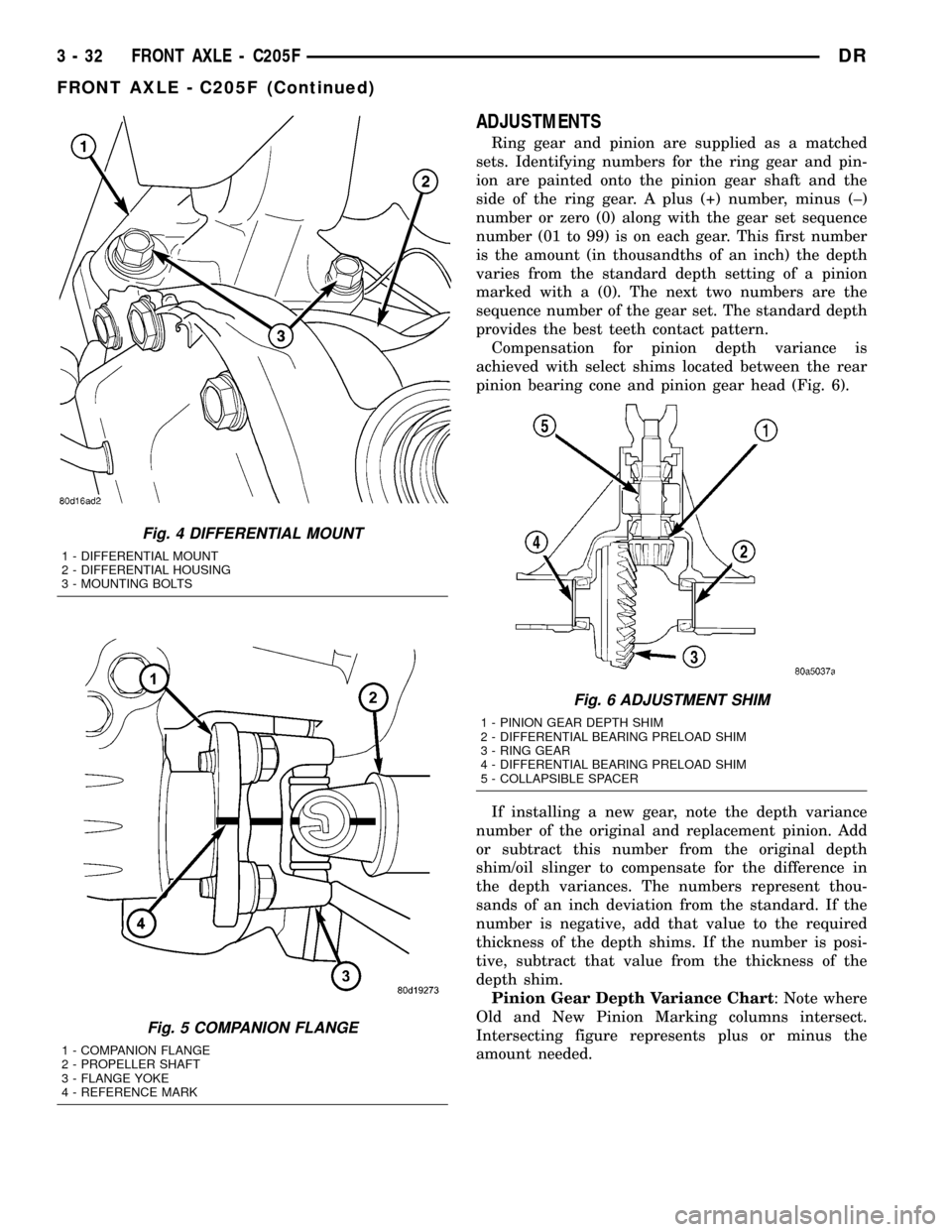

ADJUSTMENTS

Ring gear and pinion are supplied as a matched

sets. Identifying numbers for the ring gear and pin-

ion are painted onto the pinion gear shaft and the

side of the ring gear. A plus (+) number, minus (±)

number or zero (0) along with the gear set sequence

number (01 to 99) is on each gear. This first number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

marked with a (0). The next two numbers are the

sequence number of the gear set. The standard depth

provides the best teeth contact pattern.

Compensation for pinion depth variance is

achieved with select shims located between the rear

pinion bearing cone and pinion gear head (Fig. 6).

If installing a new gear, note the depth variance

number of the original and replacement pinion. Add

or subtract this number from the original depth

shim/oil slinger to compensate for the difference in

the depth variances. The numbers represent thou-

sands of an inch deviation from the standard. If the

number is negative, add that value to the required

thickness of the depth shims. If the number is posi-

tive, subtract that value from the thickness of the

depth shim.

Pinion Gear Depth Variance Chart: Note where

Old and New Pinion Marking columns intersect.

Intersecting figure represents plus or minus the

amount needed.

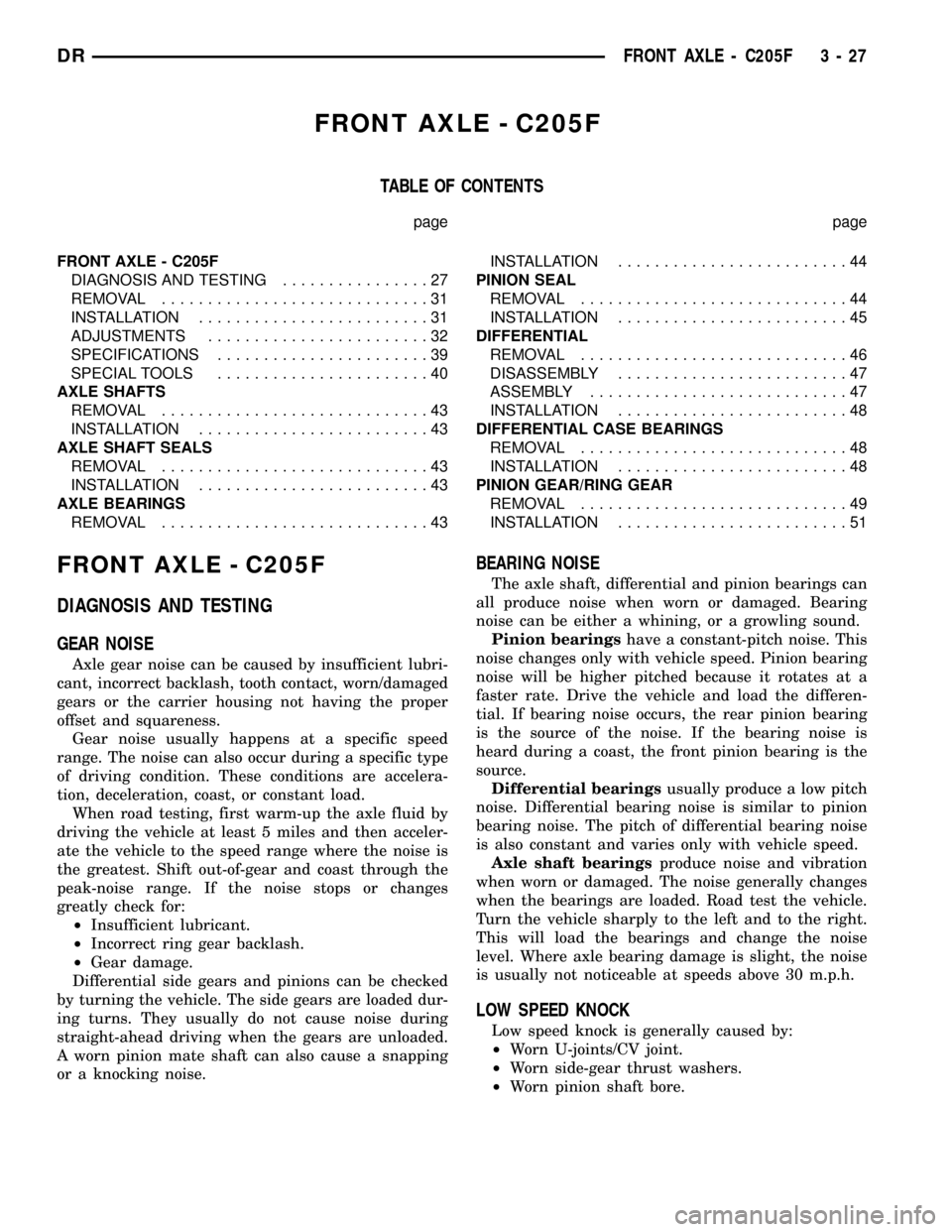

Fig. 4 DIFFERENTIAL MOUNT

1 - DIFFERENTIAL MOUNT

2 - DIFFERENTIAL HOUSING

3 - MOUNTING BOLTS

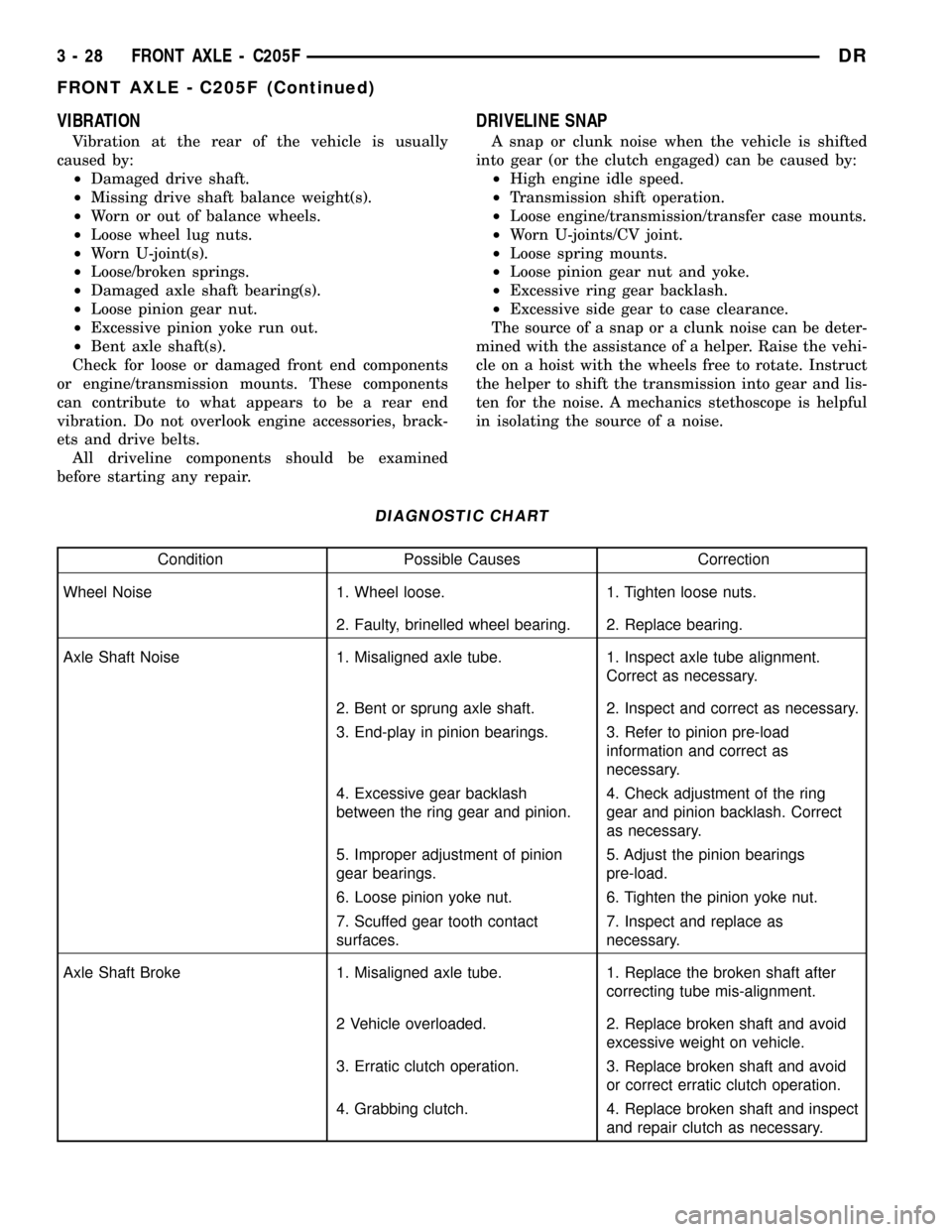

Fig. 5 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

3 - FLANGE YOKE

4 - REFERENCE MARK

Fig. 6 ADJUSTMENT SHIM

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING PRELOAD SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING PRELOAD SHIM

5 - COLLAPSIBLE SPACER

3 - 32 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 114 of 2627

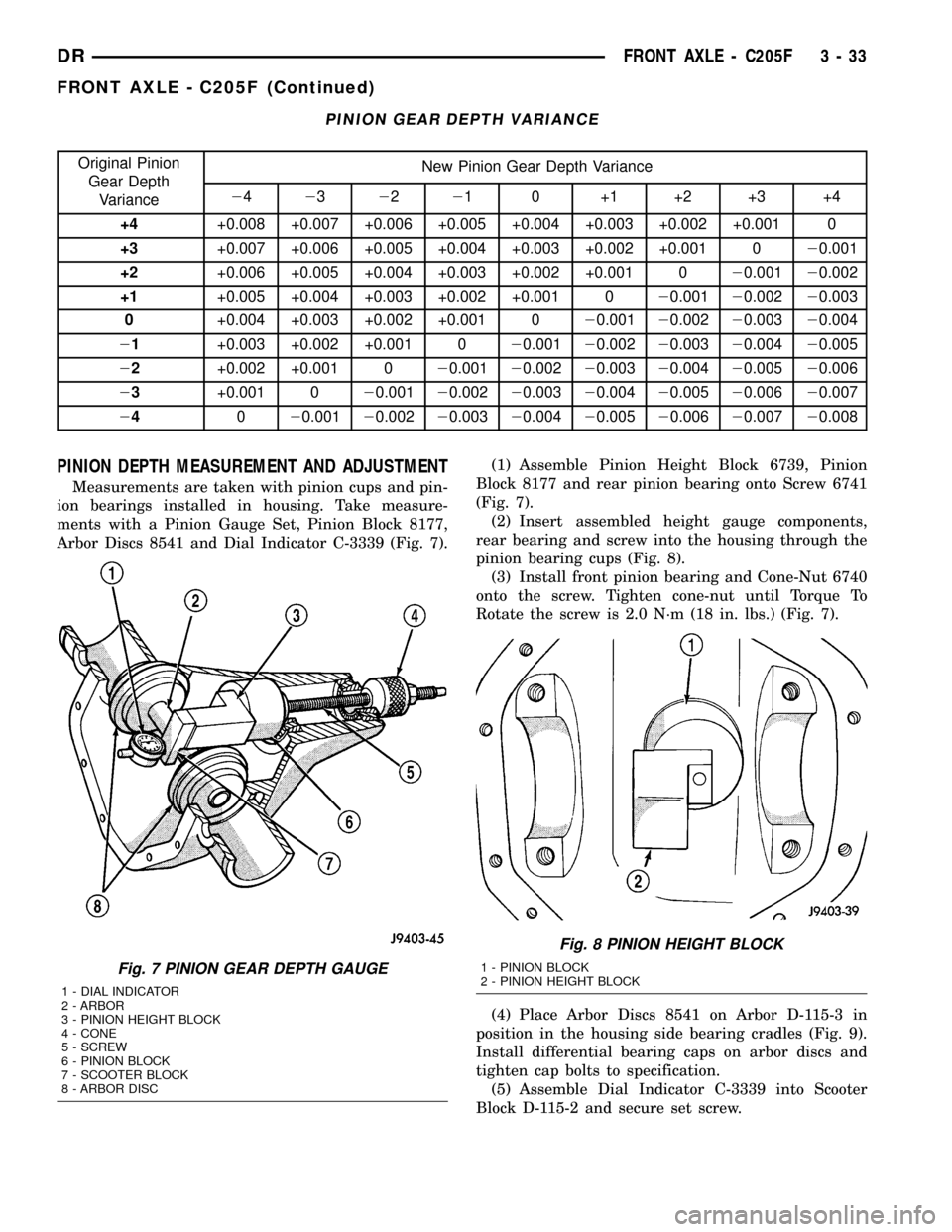

PINION GEAR DEPTH VARIANCE

Original Pinion

Gear Depth

VarianceNew Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion cups and pin-

ion bearings installed in housing. Take measure-

ments with a Pinion Gauge Set, Pinion Block 8177,

Arbor Discs 8541 and Dial Indicator C-3339 (Fig. 7).(1) Assemble Pinion Height Block 6739, Pinion

Block 8177 and rear pinion bearing onto Screw 6741

(Fig. 7).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through the

pinion bearing cups (Fig. 8).

(3) Install front pinion bearing and Cone-Nut 6740

onto the screw. Tighten cone-nut until Torque To

Rotate the screw is 2.0 N´m (18 in. lbs.) (Fig. 7).

(4) Place Arbor Discs 8541 on Arbor D-115-3 in

position in the housing side bearing cradles (Fig. 9).

Install differential bearing caps on arbor discs and

tighten cap bolts to specification.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

Fig. 7 PINION GEAR DEPTH GAUGE

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 8 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

DRFRONT AXLE - C205F 3 - 33

FRONT AXLE - C205F (Continued)

Page 131 of 2627

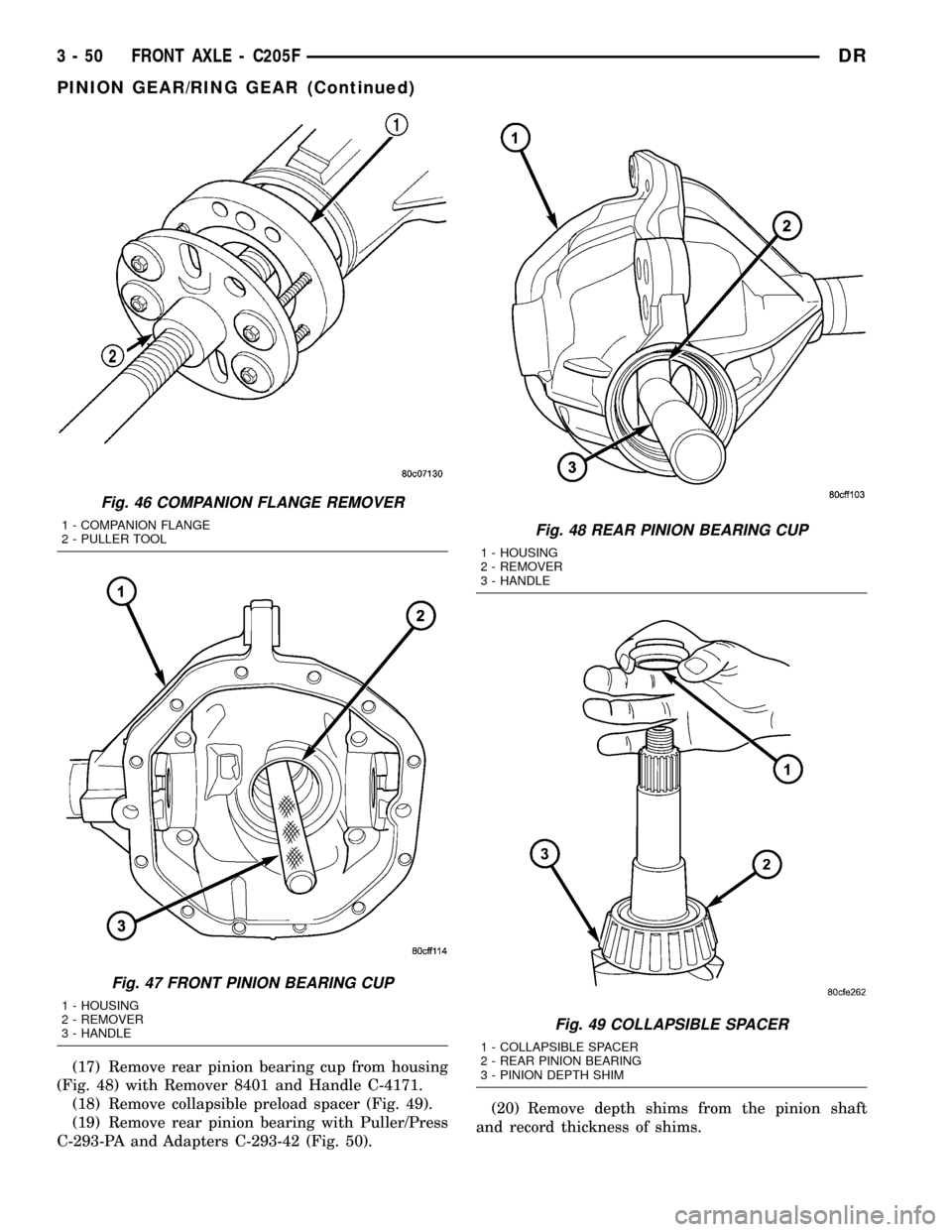

(17) Remove rear pinion bearing cup from housing

(Fig. 48) with Remover 8401 and Handle C-4171.

(18) Remove collapsible preload spacer (Fig. 49).

(19) Remove rear pinion bearing with Puller/Press

C-293-PA and Adapters C-293-42 (Fig. 50).(20) Remove depth shims from the pinion shaft

and record thickness of shims.

Fig. 46 COMPANION FLANGE REMOVER

1 - COMPANION FLANGE

2 - PULLER TOOL

Fig. 47 FRONT PINION BEARING CUP

1 - HOUSING

2 - REMOVER

3 - HANDLE

Fig. 48 REAR PINION BEARING CUP

1 - HOUSING

2 - REMOVER

3 - HANDLE

Fig. 49 COLLAPSIBLE SPACER

1 - COLLAPSIBLE SPACER

2 - REAR PINION BEARING

3 - PINION DEPTH SHIM

3 - 50 FRONT AXLE - C205FDR

PINION GEAR/RING GEAR (Continued)

Page 132 of 2627

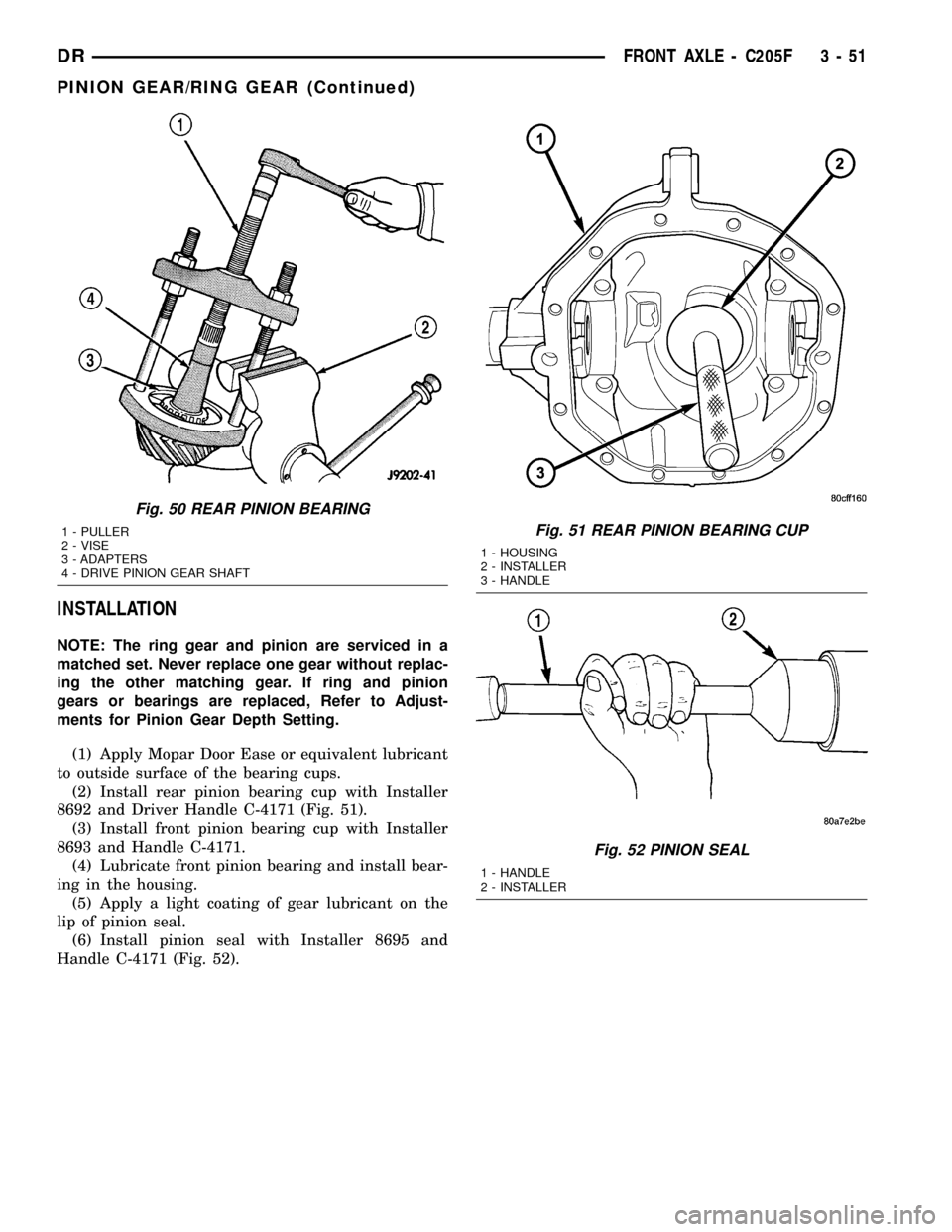

INSTALLATION

NOTE: The ring gear and pinion are serviced in a

matched set. Never replace one gear without replac-

ing the other matching gear. If ring and pinion

gears or bearings are replaced, Refer to Adjust-

ments for Pinion Gear Depth Setting.

(1) Apply Mopar Door Ease or equivalent lubricant

to outside surface of the bearing cups.

(2) Install rear pinion bearing cup with Installer

8692 and Driver Handle C-4171 (Fig. 51).

(3) Install front pinion bearing cup with Installer

8693 and Handle C-4171.

(4) Lubricate front pinion bearing and install bear-

ing in the housing.

(5) Apply a light coating of gear lubricant on the

lip of pinion seal.

(6) Install pinion seal with Installer 8695 and

Handle C-4171 (Fig. 52).

Fig. 50 REAR PINION BEARING

1 - PULLER

2 - VISE

3 - ADAPTERS

4 - DRIVE PINION GEAR SHAFTFig. 51 REAR PINION BEARING CUP

1 - HOUSING

2 - INSTALLER

3 - HANDLE

Fig. 52 PINION SEAL

1 - HANDLE

2 - INSTALLER

DRFRONT AXLE - C205F 3 - 51

PINION GEAR/RING GEAR (Continued)