set clock DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1507 of 2627

(10)For fractured/split type connecting rods,

the long end of the rod must be installed towards the

intake side of the engine.

(a) The connecting rod split/face must face

toward the same side as the piston notch feature

on the skirt. The split face will face toward the

exhaust side of the engine if properly installed.

(11) Install the rod cap and bolts to the connecting

rod. Tighten the connecting rod bolts evenly in 3

steps.

²Tighten the bolts to 30 N´m (22 ft. lbs.) torque.

²Tighten the bolts to 60 N´m (44 ft. lbs.) torque.

²Rotate 60É clockwise.

(12) The crankshaft must rotate freely. Check for

freedom of rotation as the caps are installed. If the

crankshaft does not rotate freely, check the installa-

tion of the rod bearing and the bearing size.

(13) Measure the side clearance between the con-

necting rod and the crankshaft. DO NOT measure

the clearance between the cap and crankshaft.

(14) Install J-jet piston cooling nozzles if equipped.

(15) Install block stiffener. Torque to 43 N´m (32 ft.

lbs.).

(16) Install the suction tube and oil pan (Refer to 9

- ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(17) Install the cylinder head onto the engine

(Refer to 9 - ENGINE/CYLINDER HEAD - INSTAL-

LATION).

(18) Install a new filter and fill the crankcase with

new engine oil.Prefill the filter with clean oil.

(19) Connect the battery negative cables and start

engine.

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING

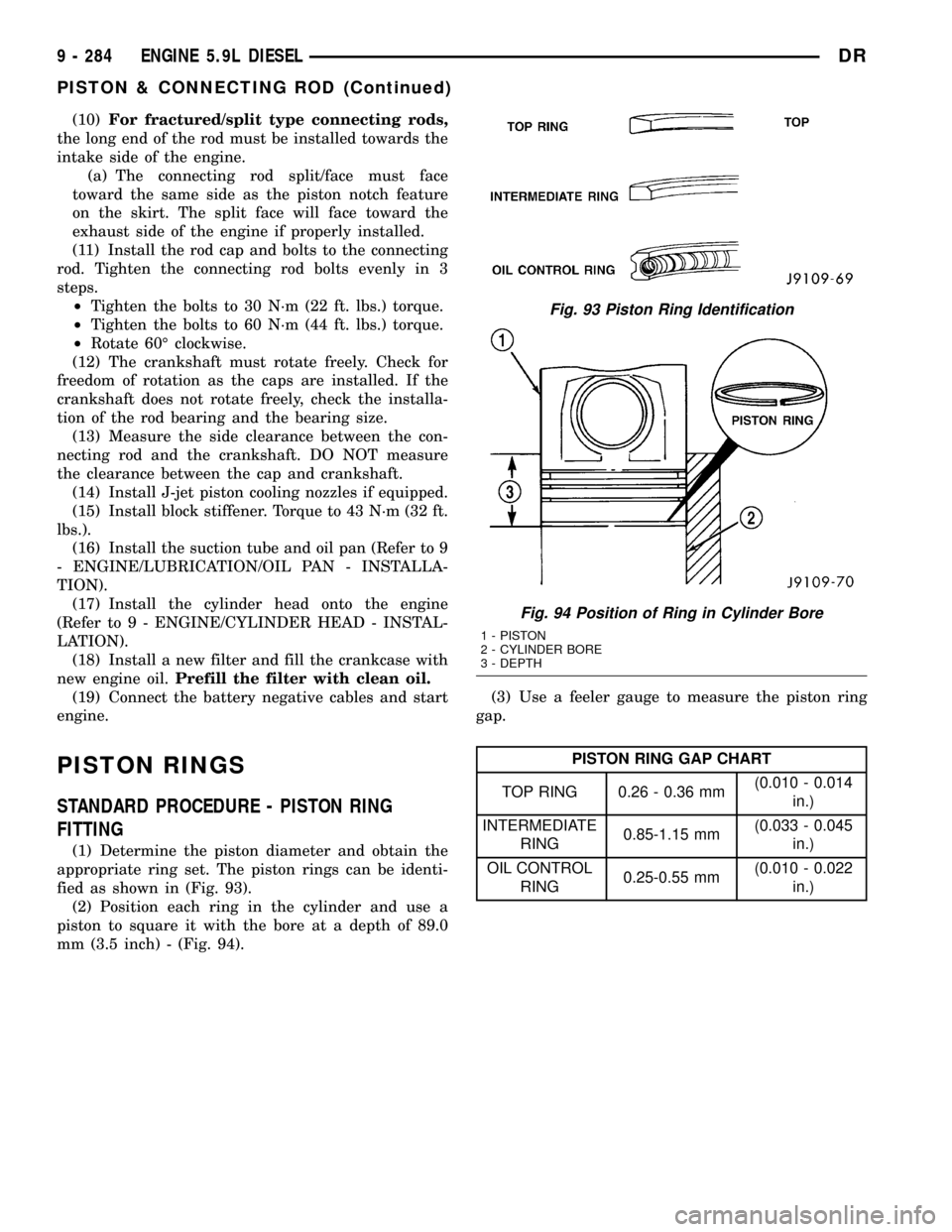

(1) Determine the piston diameter and obtain the

appropriate ring set. The piston rings can be identi-

fied as shown in (Fig. 93).

(2) Position each ring in the cylinder and use a

piston to square it with the bore at a depth of 89.0

mm (3.5 inch) - (Fig. 94).(3) Use a feeler gauge to measure the piston ring

gap.

PISTON RING GAP CHART

TOP RING 0.26 - 0.36 mm(0.010 - 0.014

in.)

INTERMEDIATE

RING0.85-1.15 mm(0.033 - 0.045

in.)

OIL CONTROL

RING0.25-0.55 mm(0.010 - 0.022

in.)

Fig. 93 Piston Ring Identification

Fig. 94 Position of Ring in Cylinder Bore

1 - PISTON

2 - CYLINDER BORE

3 - DEPTH

9 - 284 ENGINE 5.9L DIESELDR

PISTON & CONNECTING ROD (Continued)

Page 1839 of 2627

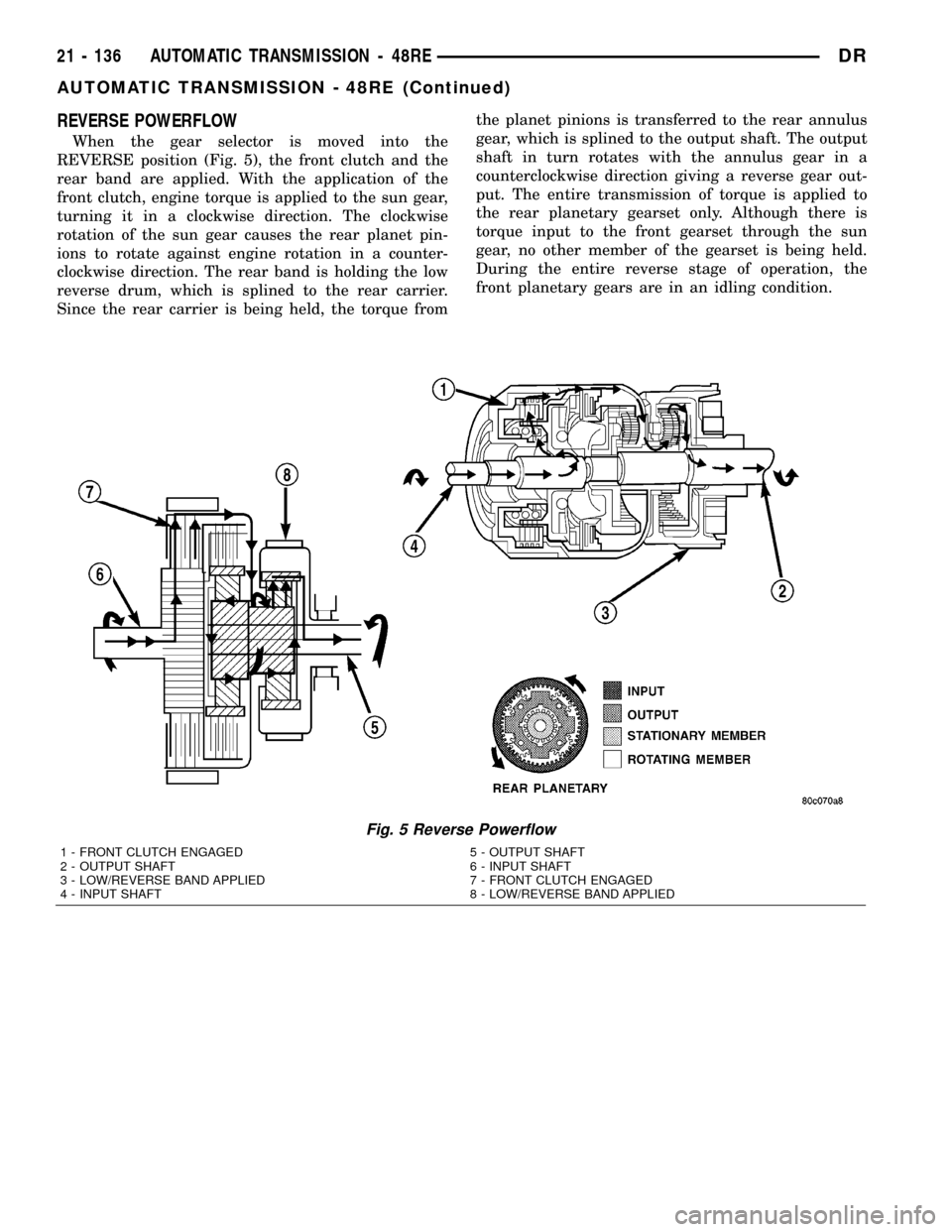

REVERSE POWERFLOW

When the gear selector is moved into the

REVERSE position (Fig. 5), the front clutch and the

rear band are applied. With the application of the

front clutch, engine torque is applied to the sun gear,

turning it in a clockwise direction. The clockwise

rotation of the sun gear causes the rear planet pin-

ions to rotate against engine rotation in a counter-

clockwise direction. The rear band is holding the low

reverse drum, which is splined to the rear carrier.

Since the rear carrier is being held, the torque fromthe planet pinions is transferred to the rear annulus

gear, which is splined to the output shaft. The output

shaft in turn rotates with the annulus gear in a

counterclockwise direction giving a reverse gear out-

put. The entire transmission of torque is applied to

the rear planetary gearset only. Although there is

torque input to the front gearset through the sun

gear, no other member of the gearset is being held.

During the entire reverse stage of operation, the

front planetary gears are in an idling condition.

Fig. 5 Reverse Powerflow

1 - FRONT CLUTCH ENGAGED 5 - OUTPUT SHAFT

2 - OUTPUT SHAFT 6 - INPUT SHAFT

3 - LOW/REVERSE BAND APPLIED 7 - FRONT CLUTCH ENGAGED

4 - INPUT SHAFT 8 - LOW/REVERSE BAND APPLIED

21 - 136 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1841 of 2627

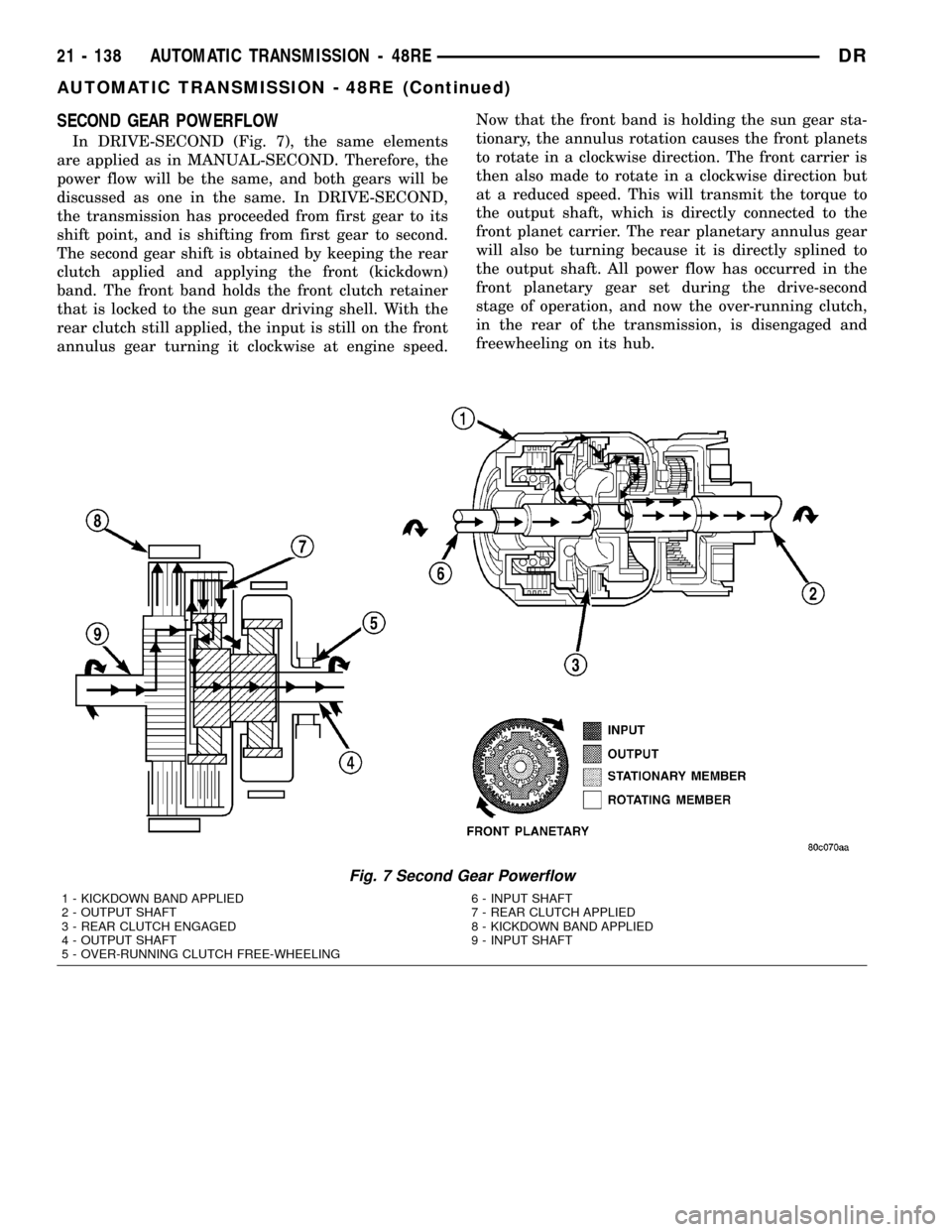

SECOND GEAR POWERFLOW

In DRIVE-SECOND (Fig. 7), the same elements

are applied as in MANUAL-SECOND. Therefore, the

power flow will be the same, and both gears will be

discussed as one in the same. In DRIVE-SECOND,

the transmission has proceeded from first gear to its

shift point, and is shifting from first gear to second.

The second gear shift is obtained by keeping the rear

clutch applied and applying the front (kickdown)

band. The front band holds the front clutch retainer

that is locked to the sun gear driving shell. With the

rear clutch still applied, the input is still on the front

annulus gear turning it clockwise at engine speed.Now that the front band is holding the sun gear sta-

tionary, the annulus rotation causes the front planets

to rotate in a clockwise direction. The front carrier is

then also made to rotate in a clockwise direction but

at a reduced speed. This will transmit the torque to

the output shaft, which is directly connected to the

front planet carrier. The rear planetary annulus gear

will also be turning because it is directly splined to

the output shaft. All power flow has occurred in the

front planetary gear set during the drive-second

stage of operation, and now the over-running clutch,

in the rear of the transmission, is disengaged and

freewheeling on its hub.

Fig. 7 Second Gear Powerflow

1 - KICKDOWN BAND APPLIED 6 - INPUT SHAFT

2 - OUTPUT SHAFT 7 - REAR CLUTCH APPLIED

3 - REAR CLUTCH ENGAGED 8 - KICKDOWN BAND APPLIED

4 - OUTPUT SHAFT 9 - INPUT SHAFT

5 - OVER-RUNNING CLUTCH FREE-WHEELING

21 - 138 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1842 of 2627

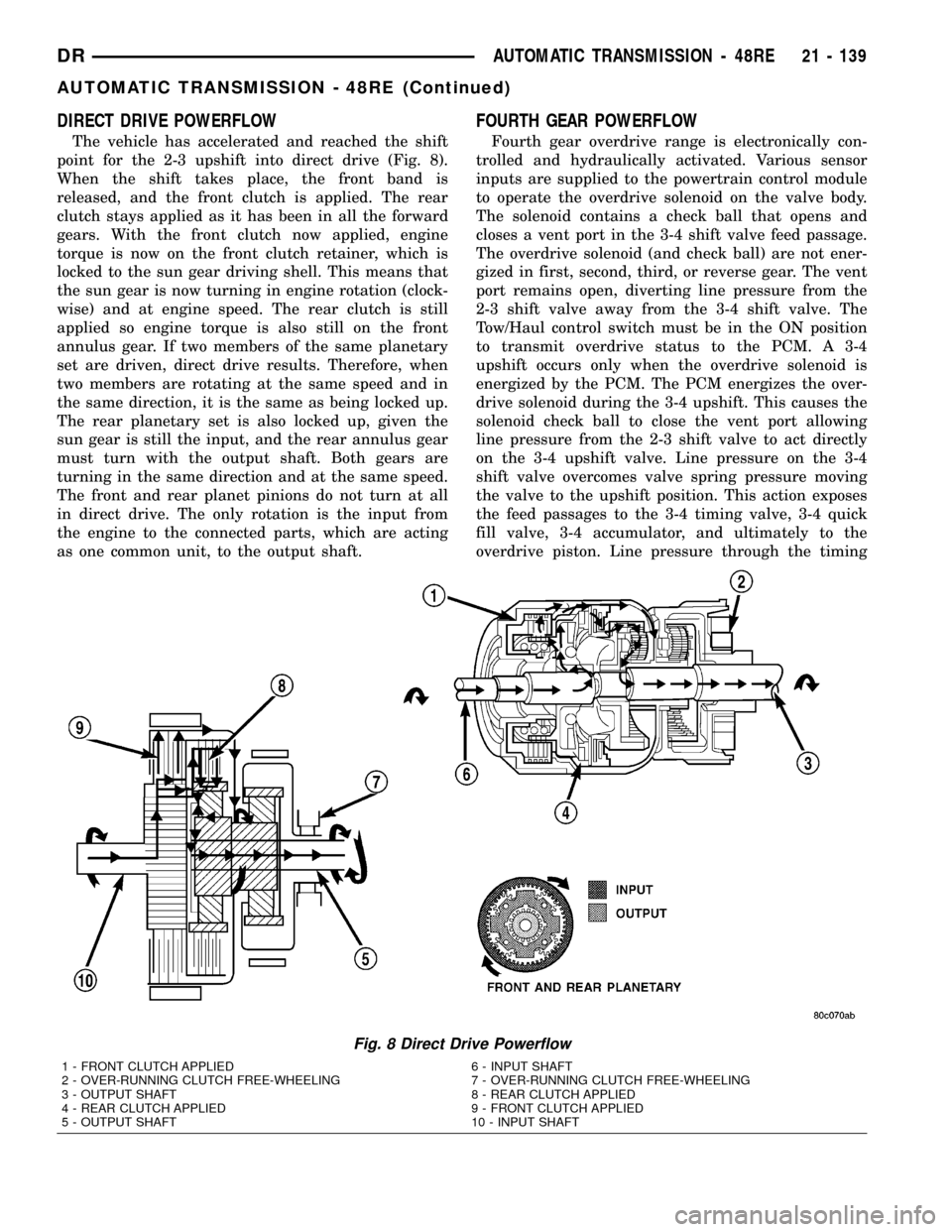

DIRECT DRIVE POWERFLOW

The vehicle has accelerated and reached the shift

point for the 2-3 upshift into direct drive (Fig. 8).

When the shift takes place, the front band is

released, and the front clutch is applied. The rear

clutch stays applied as it has been in all the forward

gears. With the front clutch now applied, engine

torque is now on the front clutch retainer, which is

locked to the sun gear driving shell. This means that

the sun gear is now turning in engine rotation (clock-

wise) and at engine speed. The rear clutch is still

applied so engine torque is also still on the front

annulus gear. If two members of the same planetary

set are driven, direct drive results. Therefore, when

two members are rotating at the same speed and in

the same direction, it is the same as being locked up.

The rear planetary set is also locked up, given the

sun gear is still the input, and the rear annulus gear

must turn with the output shaft. Both gears are

turning in the same direction and at the same speed.

The front and rear planet pinions do not turn at all

in direct drive. The only rotation is the input from

the engine to the connected parts, which are acting

as one common unit, to the output shaft.

FOURTH GEAR POWERFLOW

Fourth gear overdrive range is electronically con-

trolled and hydraulically activated. Various sensor

inputs are supplied to the powertrain control module

to operate the overdrive solenoid on the valve body.

The solenoid contains a check ball that opens and

closes a vent port in the 3-4 shift valve feed passage.

The overdrive solenoid (and check ball) are not ener-

gized in first, second, third, or reverse gear. The vent

port remains open, diverting line pressure from the

2-3 shift valve away from the 3-4 shift valve. The

Tow/Haul control switch must be in the ON position

to transmit overdrive status to the PCM. A 3-4

upshift occurs only when the overdrive solenoid is

energized by the PCM. The PCM energizes the over-

drive solenoid during the 3-4 upshift. This causes the

solenoid check ball to close the vent port allowing

line pressure from the 2-3 shift valve to act directly

on the 3-4 upshift valve. Line pressure on the 3-4

shift valve overcomes valve spring pressure moving

the valve to the upshift position. This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston. Line pressure through the timing

Fig. 8 Direct Drive Powerflow

1 - FRONT CLUTCH APPLIED 6 - INPUT SHAFT

2 - OVER-RUNNING CLUTCH FREE-WHEELING 7 - OVER-RUNNING CLUTCH FREE-WHEELING

3 - OUTPUT SHAFT 8 - REAR CLUTCH APPLIED

4 - REAR CLUTCH APPLIED 9 - FRONT CLUTCH APPLIED

5 - OUTPUT SHAFT 10 - INPUT SHAFT

DRAUTOMATIC TRANSMISSION - 48RE 21 - 139

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2013 of 2627

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

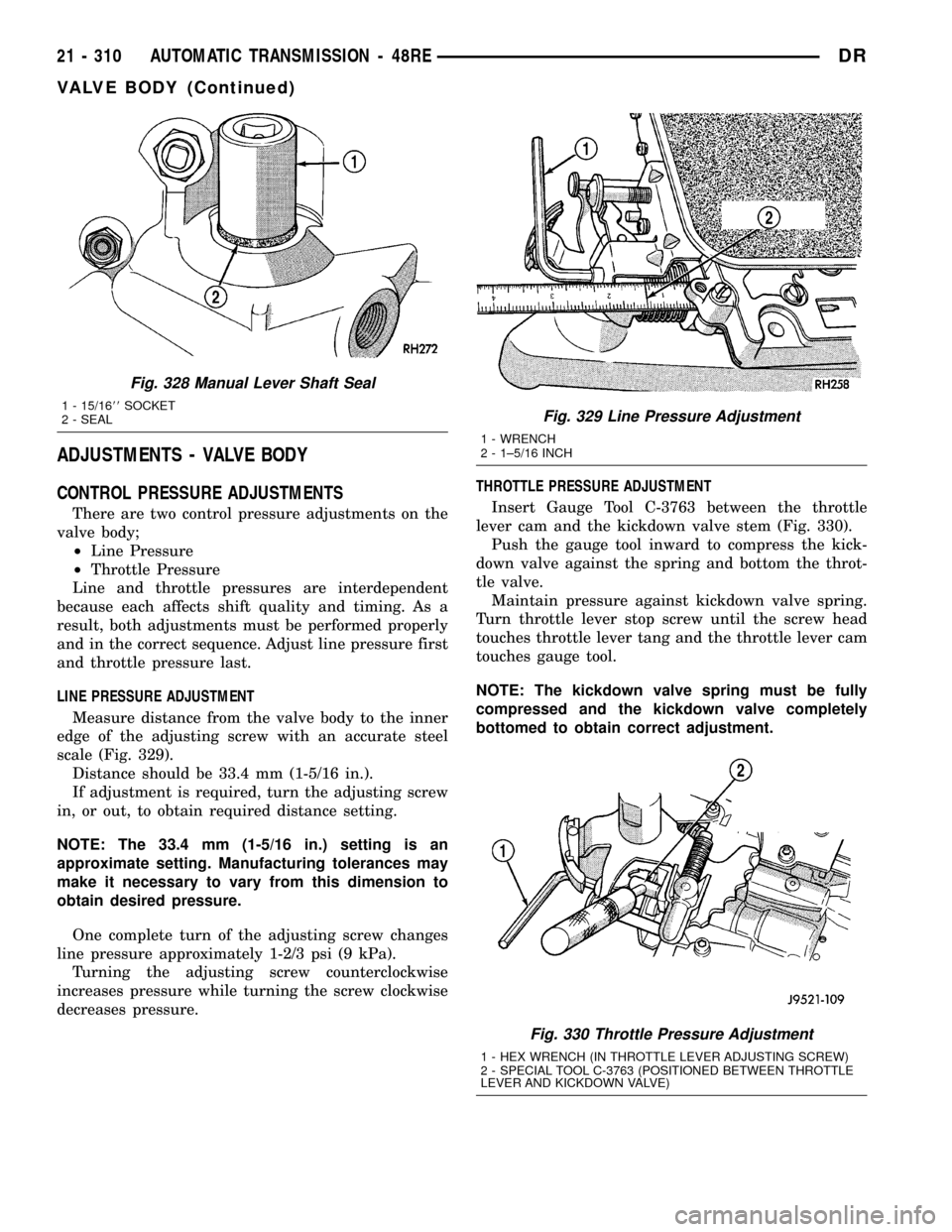

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 329).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 330).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 328 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEALFig. 329 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 330 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

21 - 310 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2533 of 2627

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT

WARNING: EYE PROTECTION MUST BE WORN

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED

BEFORE CONNECTING TO, OR DISCONNECTING

FROM THE REFRIGERANT SYSTEM. FAILURE TO

OBSERVE THESE WARNINGS MAY RESULT IN PER-

SONAL INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

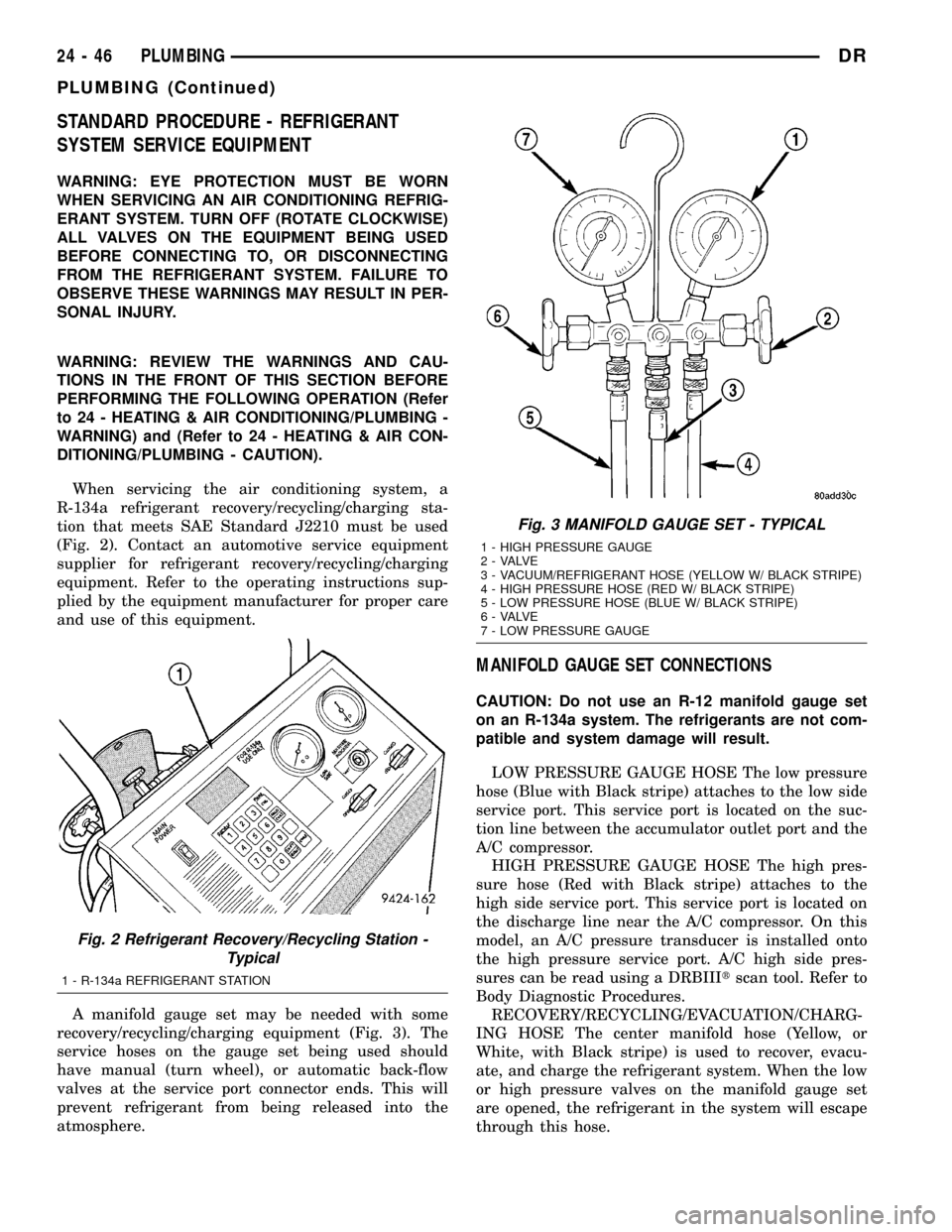

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 must be used

(Fig. 2). Contact an automotive service equipment

supplier for refrigerant recovery/recycling/charging

equipment. Refer to the operating instructions sup-

plied by the equipment manufacturer for proper care

and use of this equipment.

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 3). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

LOW PRESSURE GAUGE HOSE The low pressure

hose (Blue with Black stripe) attaches to the low side

service port. This service port is located on the suc-

tion line between the accumulator outlet port and the

A/C compressor.

HIGH PRESSURE GAUGE HOSE The high pres-

sure hose (Red with Black stripe) attaches to the

high side service port. This service port is located on

the discharge line near the A/C compressor. On this

model, an A/C pressure transducer is installed onto

the high pressure service port. A/C high side pres-

sures can be read using a DRBIIItscan tool. Refer to

Body Diagnostic Procedures.

RECOVERY/RECYCLING/EVACUATION/CHARG-

ING HOSE The center manifold hose (Yellow, or

White, with Black stripe) is used to recover, evacu-

ate, and charge the refrigerant system. When the low

or high pressure valves on the manifold gauge set

are opened, the refrigerant in the system will escape

through this hose.

Fig. 2 Refrigerant Recovery/Recycling Station -

Typical

1 - R-134a REFRIGERANT STATION

Fig. 3 MANIFOLD GAUGE SET - TYPICAL

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/ BLACK STRIPE)

4 - HIGH PRESSURE HOSE (RED W/ BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/ BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

24 - 46 PLUMBINGDR

PLUMBING (Continued)

Page 2564 of 2627

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode: The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode: The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º H20.

The cycle rate of pump strokes is quite rapid as the

system begins to pump up to this pressure. As the

pressure increases, the cycle rate starts to drop off. If

there is no leak in the system, the pump would even-

tually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at .040º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

After passing the leak detection phase of the test,

system pressure is maintained by turning on the

LDP's solenoid until the purge system is activated.

Purge activation in effect creates a leak. The cycle

rate is again interrogated and when it increases due

to the flow through the purge system, the leak check

portion of the diagnostic is complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

Evaporative system functionality will be verified by

using the stricter evap purge flow monitor. At an

appropriate warm idle the LDP will be energized to

seal the canister vent. The purge flow will be clocked

up from some small value in an attempt to see a

shift in the 02 control system. If fuel vapor, indicatedby a shift in the 02 control, is present the test is

passed. If not, it is assumed that the purge system is

not functioning in some respect. The LDP is again

turned off and the test is ended.

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

FUEL SYSTEM MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide. The catalyst works best

when the Air Fuel (A/F) ratio is at or near the opti-

mum of 14.7 to 1.

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S sensor output. The programmed

memory acts as a self calibration tool that the engine

controller uses to compensate for variations in engine

specifications, sensor tolerances and engine fatigue

over the life span of the engine. By monitoring the

actual fuel-air ratio with the O2S sensor (short term)

and multiplying that with the program long-term

(adaptive) memory and comparing that to the limit,

it can be determined whether it will pass an emis-

sions test. If a malfunction occurs such that the PCM

cannot maintain the optimum A/F ratio, then the

MIL will be illuminated.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. This can increase vehicle emissions

and deteriorate engine performance, driveability and

fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S's sensor strategy is based on the fact that

as a catalyst deteriorates, its oxygen storage capacity

and its efficiency are both reduced. By monitoring

the oxygen storage capacity of a catalyst, its effi-

ciency can be indirectly calculated. The upstream

DREMISSIONS CONTROL 25 - 3

EMISSIONS CONTROL (Continued)

Page 2583 of 2627

5.7L V-8

(1) Clean out intake manifold opening.

(2) Check condition of 2 o-rings on PCV valve.

(3) Apply engine oil to 2 o-rings.

(4) Place PCV valve into intake manifold and

rotate 90 degrees clockwise for installation.

VACUUM LINES

DESCRIPTION

A vacuum schematic for emission related items can

be found on the vehicles VECI label. Refer to Vehicle

Emission Control Information (VECI) Label for label

location.

VAPOR CANISTER

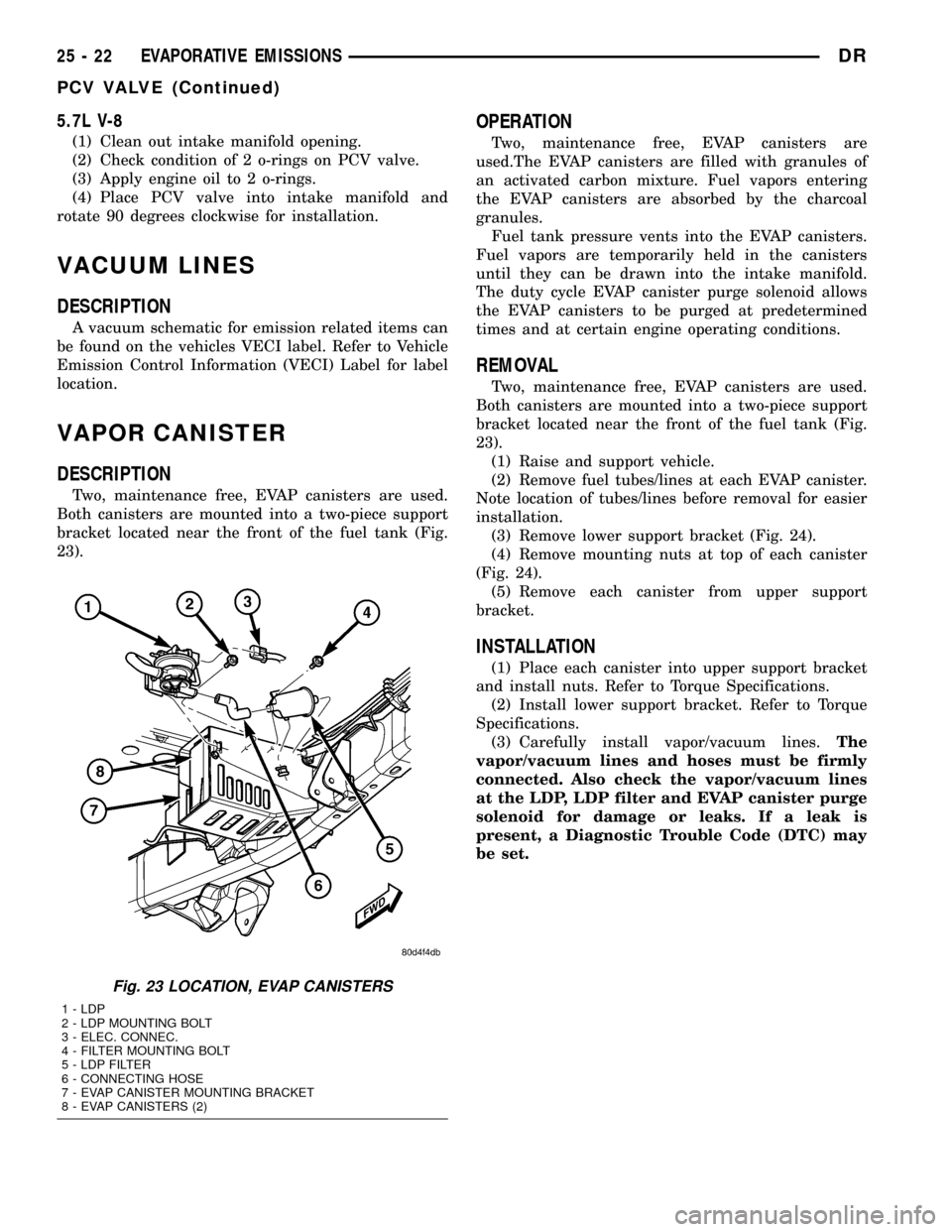

DESCRIPTION

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

23).

OPERATION

Two, maintenance free, EVAP canisters are

used.The EVAP canisters are filled with granules of

an activated carbon mixture. Fuel vapors entering

the EVAP canisters are absorbed by the charcoal

granules.

Fuel tank pressure vents into the EVAP canisters.

Fuel vapors are temporarily held in the canisters

until they can be drawn into the intake manifold.

The duty cycle EVAP canister purge solenoid allows

the EVAP canisters to be purged at predetermined

times and at certain engine operating conditions.

REMOVAL

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

23).

(1) Raise and support vehicle.

(2) Remove fuel tubes/lines at each EVAP canister.

Note location of tubes/lines before removal for easier

installation.

(3) Remove lower support bracket (Fig. 24).

(4) Remove mounting nuts at top of each canister

(Fig. 24).

(5) Remove each canister from upper support

bracket.

INSTALLATION

(1) Place each canister into upper support bracket

and install nuts. Refer to Torque Specifications.

(2) Install lower support bracket. Refer to Torque

Specifications.

(3) Carefully install vapor/vacuum lines.The

vapor/vacuum lines and hoses must be firmly

connected. Also check the vapor/vacuum lines

at the LDP, LDP filter and EVAP canister purge

solenoid for damage or leaks. If a leak is

present, a Diagnostic Trouble Code (DTC) may

be set.

Fig. 23 LOCATION, EVAP CANISTERS

1 - LDP

2 - LDP MOUNTING BOLT

3 - ELEC. CONNEC.

4 - FILTER MOUNTING BOLT

5 - LDP FILTER

6 - CONNECTING HOSE

7 - EVAP CANISTER MOUNTING BRACKET

8 - EVAP CANISTERS (2)

25 - 22 EVAPORATIVE EMISSIONSDR

PCV VALVE (Continued)