steering wheel adjustment DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1686 of 2627

(4) Clean exposed end of pitman shaft and housing

with a wire brush.

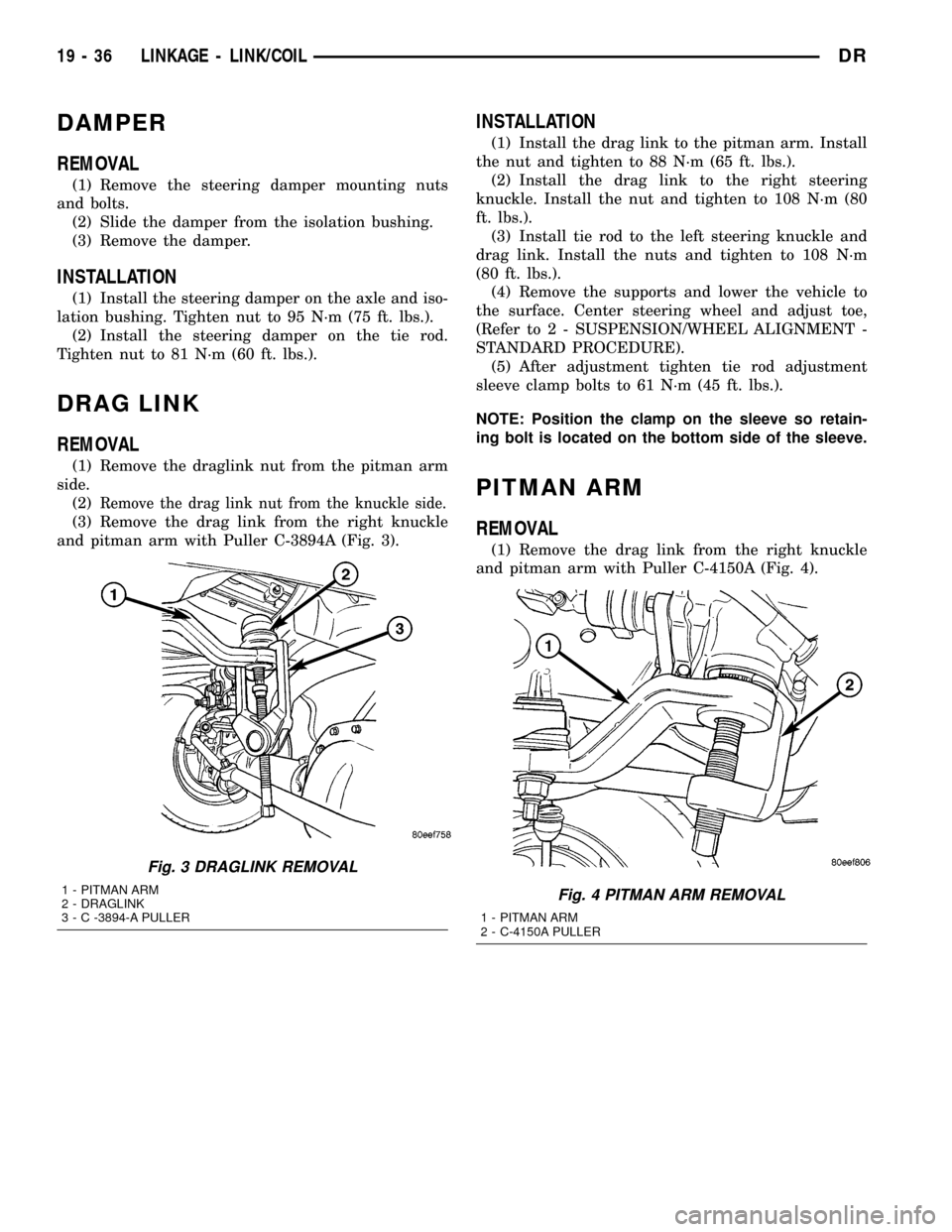

(5) Rotate the stub shaft with a 12 point socket

from stop to stop and count the number of turns (Fig.

23).

(6) Center the stub shaft by rotating it from the

stop 1/2 of the total amount of turns (Fig. 23).

(7) Remove the pitman shaft cover bolts.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

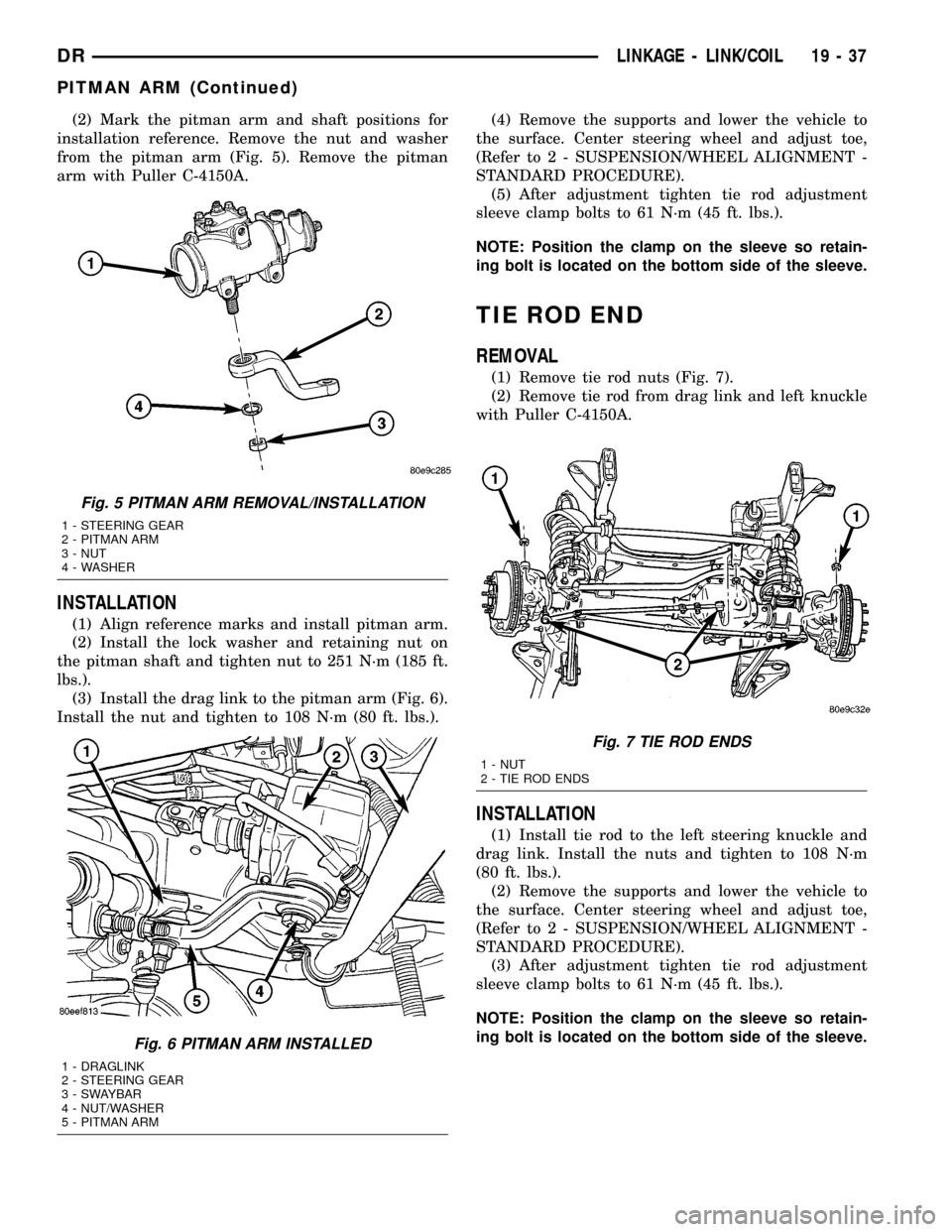

(8)

Remove the pitman shaft from the gear (Fig. 24).

(9) Remove the cover if needed by loosing the

adjuster nut, Then removing the cover from the pit-

man shaft.

INSTALLATION

INSTALLATION - GAS

(1) Coat the seal withpower steering fluid.

(2) Install pitman shaft into the steering gear until

it fully seats into the bearing.

(3) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(4) Perform over-center meshload adjustment,

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

(5) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(6) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

INSTALLATION - DIESEL

(1) Coat the seal withpower steering fluid.

(2) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(3) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(4) Perform over-center meshload adjustment

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

(5) Install the steering gear (Refer to 19 - STEER-

ING/GEAR - INSTALLATION).

(6) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(7) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

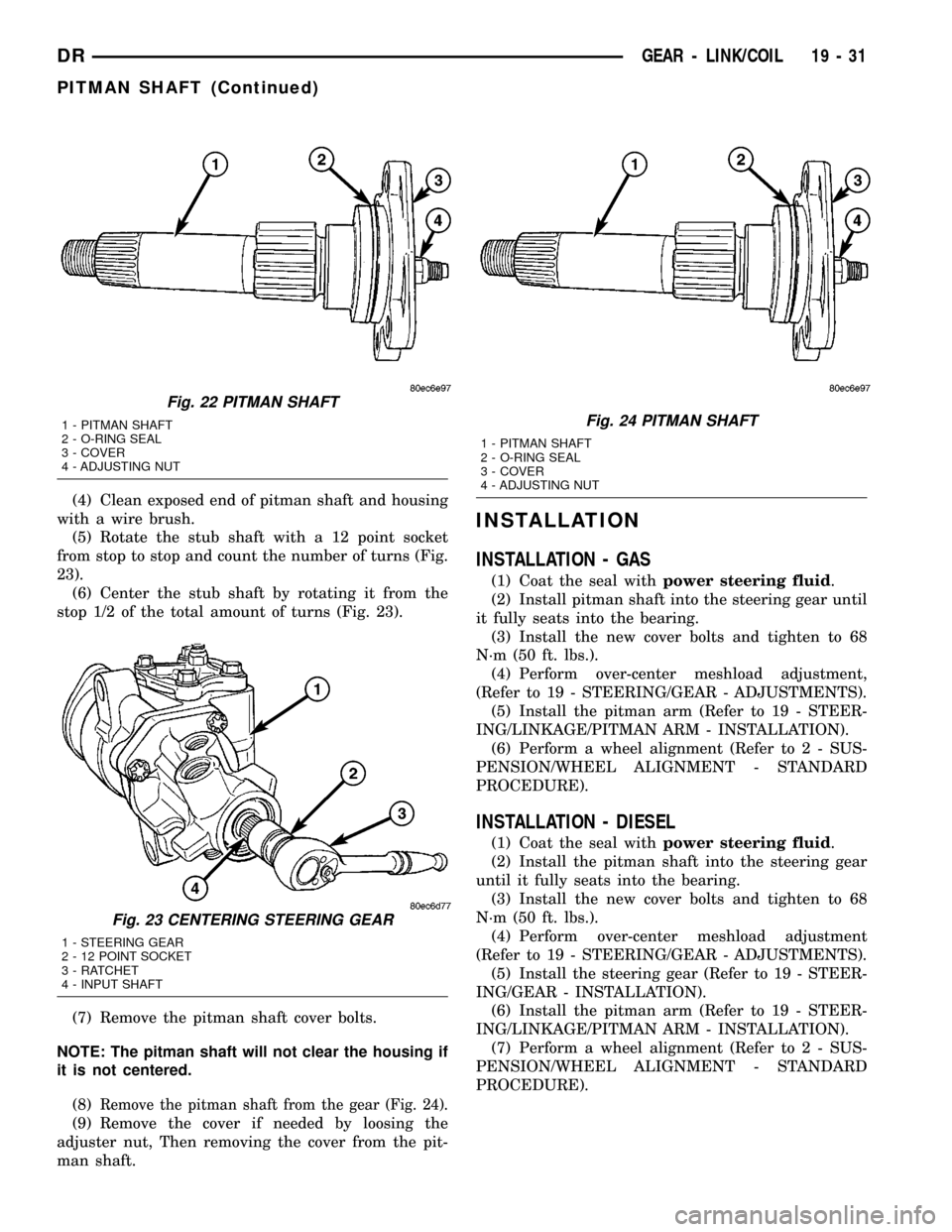

Fig. 22 PITMAN SHAFT

1 - PITMAN SHAFT

2 - O-RING SEAL

3 - COVER

4 - ADJUSTING NUT

Fig. 23 CENTERING STEERING GEAR

1 - STEERING GEAR

2 - 12 POINT SOCKET

3 - RATCHET

4 - INPUT SHAFT

Fig. 24 PITMAN SHAFT

1 - PITMAN SHAFT

2 - O-RING SEAL

3 - COVER

4 - ADJUSTING NUT

DRGEAR - LINK/COIL 19 - 31

PITMAN SHAFT (Continued)

Page 1691 of 2627

DAMPER

REMOVAL

(1) Remove the steering damper mounting nuts

and bolts.

(2) Slide the damper from the isolation bushing.

(3) Remove the damper.

INSTALLATION

(1) Install the steering damper on the axle and iso-

lation bushing. Tighten nut to 95 N´m (75 ft. lbs.).

(2) Install the steering damper on the tie rod.

Tighten nut to 81 N´m (60 ft. lbs.).

DRAG LINK

REMOVAL

(1) Remove the draglink nut from the pitman arm

side.

(2)

Remove the drag link nut from the knuckle side.

(3) Remove the drag link from the right knuckle

and pitman arm with Puller C-3894A (Fig. 3).

INSTALLATION

(1) Install the drag link to the pitman arm. Install

the nut and tighten to 88 N´m (65 ft. lbs.).

(2) Install the drag link to the right steering

knuckle. Install the nut and tighten to 108 N´m (80

ft. lbs.).

(3) Install tie rod to the left steering knuckle and

drag link. Install the nuts and tighten to 108 N´m

(80 ft. lbs.).

(4) Remove the supports and lower the vehicle to

the surface. Center steering wheel and adjust toe,

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

(5) After adjustment tighten tie rod adjustment

sleeve clamp bolts to 61 N´m (45 ft. lbs.).

NOTE: Position the clamp on the sleeve so retain-

ing bolt is located on the bottom side of the sleeve.

PITMAN ARM

REMOVAL

(1) Remove the drag link from the right knuckle

and pitman arm with Puller C-4150A (Fig. 4).

Fig. 3 DRAGLINK REMOVAL

1 - PITMAN ARM

2 - DRAGLINK

3 - C -3894-A PULLERFig. 4 PITMAN ARM REMOVAL

1 - PITMAN ARM

2 - C-4150A PULLER

19 - 36 LINKAGE - LINK/COILDR

Page 1692 of 2627

(2) Mark the pitman arm and shaft positions for

installation reference. Remove the nut and washer

from the pitman arm (Fig. 5). Remove the pitman

arm with Puller C-4150A.

INSTALLATION

(1) Align reference marks and install pitman arm.

(2) Install the lock washer and retaining nut on

the pitman shaft and tighten nut to 251 N´m (185 ft.

lbs.).

(3) Install the drag link to the pitman arm (Fig. 6).

Install the nut and tighten to 108 N´m (80 ft. lbs.).(4) Remove the supports and lower the vehicle to

the surface. Center steering wheel and adjust toe,

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

(5) After adjustment tighten tie rod adjustment

sleeve clamp bolts to 61 N´m (45 ft. lbs.).

NOTE: Position the clamp on the sleeve so retain-

ing bolt is located on the bottom side of the sleeve.

TIE ROD END

REMOVAL

(1) Remove tie rod nuts (Fig. 7).

(2) Remove tie rod from drag link and left knuckle

with Puller C-4150A.

INSTALLATION

(1) Install tie rod to the left steering knuckle and

drag link. Install the nuts and tighten to 108 N´m

(80 ft. lbs.).

(2) Remove the supports and lower the vehicle to

the surface. Center steering wheel and adjust toe,

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

(3) After adjustment tighten tie rod adjustment

sleeve clamp bolts to 61 N´m (45 ft. lbs.).

NOTE: Position the clamp on the sleeve so retain-

ing bolt is located on the bottom side of the sleeve.

Fig. 5 PITMAN ARM REMOVAL/INSTALLATION

1 - STEERING GEAR

2 - PITMAN ARM

3 - NUT

4 - WASHER

Fig. 6 PITMAN ARM INSTALLED

1 - DRAGLINK

2 - STEERING GEAR

3 - SWAYBAR

4 - NUT/WASHER

5 - PITMAN ARM

Fig. 7 TIE ROD ENDS

1 - NUT

2 - TIE ROD ENDS

DRLINKAGE - LINK/COIL 19 - 37

PITMAN ARM (Continued)

Page 2600 of 2627

FIRING ORDER / CABLE ROUTING, 5.7L

V-8 ENGINE..........................8I-4

FIRING ORDER, 3.7L V-6 - ENGINE........8I-4

FIRING ORDER, 4.7L V-8 - ENGINE........8I-4

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-48

FITTING - DESCRIPTION, QUICK

CONNECT............................14-8

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING...........9-129

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING.....9-134,9-207

FITTING - STANDARD PROCEDURE,

PISTON...................9-139,9-211,9-51

FITTING - STANDARD PROCEDURE,

PISTON RING.........9-142,9-213,9-284,9-53

FITTING, STANDARD PROCEDURE -

CONNECTING ROD BEARING............9-49

FITTING, STANDARD PROCEDURE -

MAIN BEARING.......................9-44

FITTINGS - STANDARD PROCEDURE,

HANDLING TUBING...................24-45

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT......................14-8

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-27

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-27

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED....................5-10

FLARING - STANDARD PROCEDURE, ISO . . . 5-11

FLEX PLATE - INSTALLATION . . 9-138,9-210,9-48

FLEX PLATE - REMOVAL.......9-138,9-210,9-48

FLOOR - INSTALLATION, LOAD..........23-72

FLOOR - REMOVAL, LOAD.............23-71

FLOOR CONSOLE - INSTALLATION.......23-67

FLOOR CONSOLE - REMOVAL...........23-67

FLOOR DISTRIBUTION DUCT -

INSTALLATION.......................24-34

FLOOR DISTRIBUTION DUCT - REMOVAL . 24-33

FLOOR MATS - INSTALLATION, CARPETS . 23-65

FLOOR MATS - REMOVAL, CARPETS.....23-65

FLOOR SHIFT BOOT - INSTALLATION,

4WD ..............................23-62

FLOOR SHIFT BOOT - REMOVAL, 4WD....23-62

FLOOR SUPPORT CYLINDER -

INSTALLATION, LOAD.................23-72

FLOOR SUPPORT CYLINDER -

REMOVAL, LOAD.....................23-72

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-3

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..............7-54,7-56

FLOW 3.7L/4.7L/5.7L ENGINE -

DESCRIPTION, COOLING SYSTEM.........7-1

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION................19-43

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-4

FLUID - DESCRIPTION, POWER

STEERING............................0-3

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT............21-201,21-366

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE........21-203,21-367

FLUID CAPACITIES, SPECIFICATIONS.......0-5

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING................21-202,21-366

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-23

FLUID COOLER - INSTALLATION.........19-43

FLUID COOLER - REMOVAL............19-43

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE.....21-441,21-476,21-507,21-537,

21-571

FLUID INDICATOR - DESCRIPTION,

WASHER

...........................8J-44

FLUID INDICATOR - OPERATION,

WASHER

...........................8J-44

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING

.........21-144,21-318

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT

.....21-201,

21-366

FLUID LEVEL - STANDARD PROCEDURE,

BRAKE

..............................5-23FLUID LEVEL CHECK - STANDARD

PROCEDURE.................21-202,21-366

FLUID LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING........19-43

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER............................8R-9

FLUID LEVEL SWITCH - INSTALLATION,

WASHER...........................8R-11

FLUID LEVEL SWITCH - OPERATION,

WASHER............................8R-9

FLUID LEVEL SWITCH - REMOVAL,

WASHER...........................8R-10

FLUID RESERVOIR - INSTALLATION.......5-24

FLUID RESERVOIR - REMOVAL..........5-23

FLUID, SPECIFICATIONS - BRAKE.........5-23

FLUSH - SPECIFICATIONS, GAP.........23-95

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM CLEANING/

REVERSE............................7-17

FLUSHING POWER STEERING SYSTEM -

STANDARD PROCEDURE...............19-40

FLYWHEEL - ASSEMBLY................6-11

FLYWHEEL - DIAGNOSIS AND TESTING....6-10

FLYWHEEL - DISASSEMBLY.............6-11

FLYWHEEL - INSTALLATION.............6-11

FLYWHEEL - REMOVAL.................6-11

FOG LAMP - INSTALLATION............8L-12

FOG LAMP - REMOVAL................8L-12

FOG LAMP RELAY - DESCRIPTION.......8L-12

FOG LAMP RELAY - INSTALLATION........8L-13

FOG LAMP RELAY - OPERATION.........8L-13

FOG LAMP RELAY - REMOVAL..........8L-13

FOOTMANS LOOP BRACKETS -

INSTALLATION, SEAT BACK REAR.......23-85

FOOTMANS LOOP BRACKETS -

REMOVAL, SEAT BACK REAR...........23-85

FORM-IN-PLACE GASKETS AND

SEALERS - STANDARD PROCEDURE . . 9-239,9-9,

9-94

FRAME - INSTALLATION, GRILLE........23-40

FRAME - REAR - INSTALLATION, SEAT

CUSHION...........................23-85

FRAME - REAR - REMOVAL, SEAT

CUSHION...........................23-85

FRAME - REMOVAL, GRILLE............23-40

FRAME DIMENSIONS - SPECIFICATIONS . . 13-16

FRAME H-SECTION REPLACEMENT -

STANDARD PROCEDURE, REAR.........13-13

FRAME RAIL TIP REPLACEMENT -

STANDARD PROCEDURE, LIGHT DUTY

FRONT..............................13-4

FREE MODULE - INSTALLATION, HANDS . . . 8T-2

FREE MODULE - REMOVAL, HANDS.......8T-2

FRONT - INSTALLATION....5-16,5-21,5-22,5-34

FRONT - INSTALLATION...............22-14

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL.............9-136,9-208,9-275,9-46

FRONT - INSTALLATION, PROPELLER

SHAFT - HD...........................3-7

FRONT - INSTALLATION, PROPELLER

SHAFT- LD............................3-7

FRONT - INSTALLATION, SEAT..........23-81

FRONT - INSTALLATION, SEAT BACK

CUSHION / COVER...................23-82

FRONT - INSTALLATION, SEAT CUSHION

/ COVER............................23-83

FRONT - REMOVAL........5-13,5-17,5-21,5-33

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL................9-135,9-208,9-275,9-46

FRONT - REMOVAL, PROPELLER SHAFT

- HD ................................3-7

FRONT - REMOVAL, PROPELLER SHAFT-

LD ..................................3-6

FRONT - REMOVAL, SEAT..............23-81

FRONT - REMOVAL, SEAT BACK

CUSHION / COVER...................23-82

FRONT - REMOVAL, SEAT CUSHION /

COVER.............................23-83

FRONT AIR DAM - INSTALLATION........13-2

FRONT AIR DAM - REMOVAL............13-2

FRONT AXLE - 9 1/4 AA -

ADJUSTMENTS

.......................3-59

FRONT AXLE - 9 1/4 AA - DIAGNOSIS

AND TESTING

........................3-54

FRONT AXLE - 9 1/4 AA - INSTALLATION

. . . 3-58

FRONT AXLE - 9 1/4 AA - REMOVAL

......3-57

FRONT AXLE - 9 1/4 AA - SPECIAL

TOOLS

..............................3-64FRONT AXLE - 9 1/4 AA -

SPECIFICATIONS......................3-63

FRONT AXLE - C205F - ADJUSTMENTS....3-32

FRONT AXLE - C205F - DIAGNOSIS AND

TESTING............................3-27

FRONT AXLE - C205F - INSTALLATION.....3-31

FRONT AXLE - C205F - REMOVAL........3-31

FRONT AXLE - C205F - SPECIAL TOOLS . . . 3-40

FRONT AXLE - C205F - SPECIFICATIONS . . . 3-39

FRONT BEARING - INSTALLATION,

OUTPUT SHAFT.....................21-216

FRONT BEARING - REMOVAL, OUTPUT

SHAFT............................21-216

FRONT BRAKE HOSE - INSTALLATION.....5-13

FRONT BUMPER - INSTALLATION.........13-2

FRONT BUMPER - REMOVAL............13-2

FRONT CENTER SEAT BELT -

INSTALLATION......................8O-31

FRONT CENTER SEAT BELT - REMOVAL . . 8O-30

FRONT CENTER SEAT BELT &

RETRACTOR - INSTALLATION...........8O-29

FRONT CENTER SEAT BELT &

RETRACTOR - REMOVAL..............8O-29

FRONT CLUTCH - ASSEMBLY..........21-207

FRONT CLUTCH - DESCRIPTION........21-205

FRONT CLUTCH - DISASSEMBLY.......21-205

FRONT CLUTCH - INSPECTION.........21-206

FRONT CLUTCH - OPERATION.........21-205

FRONT CONTROL MODULE -

DESCRIPTION.....................8W-97-5

FRONT CONTROL MODULE -

DESCRIPTION........................8E-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING.....................8W-97-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING........................8E-5

FRONT CONTROL MODULE -

INSTALLATION....................8W-97-6

FRONT CONTROL MODULE -

INSTALLATION........................8E-5

FRONT CONTROL MODULE - OPERATION . 8W-97-5

FRONT CONTROL MODULE - OPERATION . . 8E-5

FRONT CONTROL MODULE - REMOVAL . 8W-97-6

FRONT CONTROL MODULE - REMOVAL....8E-5

FRONT CROSSMEMBER - INSTALLATION . . 13-22

FRONT CROSSMEMBER - REMOVAL.....13-22

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION........23-92

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL............23-92

FRONT DOOR INNER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR INNER BELT MOLDING -

REMOVAL..........................23-93

FRONT DOOR OUTER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR OUTER BELT MOLDING -

REMOVAL..........................23-92

FRONT FASCIA - INSTALLATION..........13-3

FRONT FASCIA - REMOVAL..............13-2

FRONT FENDER - INSTALLATION........23-39

FRONT FENDER - REMOVAL............23-39

FRONT FRAME RAIL TIP REPLACEMENT

- STANDARD PROCEDURE, LIGHT

DUTY...............................13-4

FRONT HOSE - REMOVAL...............5-12

FRONT MOUNT - INSTALLATION . . . 9-147,9-218,

9-287,9-59

FRONT MOUNT - REMOVAL . . 9-146,9-217,9-286,

9-58

FRONT OUTBOARD SEAT BELT BUCKLE -

INSTALLATION......................8O-38

FRONT OUTBOARD SEAT BELT BUCKLE -

REMOVAL..........................8O-37

FRONT OUTPUT SHAFT SEAL -

INSTALLATION . . . 21-442,21-477,21-508,21-538,

21-572

FRONT OUTPUT SHAFT SEAL -

REMOVAL . 21-441,21-477,21-507,21-537,21-572

FRONT PARKING BRAKE CABLE -

INSTALLATION........................5-38

FRONT PARKING BRAKE CABLE -

REMOVAL

...........................5-36

FRONT SEAL - INSTALLATION, OIL

PUMP

............................21-391

FRONT SEAL - REMOVAL, OIL PUMP

....21-391

FRONT SERVO - ASSEMBLY

...........21-209

FRONT SERVO - CLEANING

...........21-209

DRINDEX 13

Description Group-Page Description Group-Page Description Group-Page

Page 2617 of 2627

SENSOR - REMOVAL, LINE PRESSURE

(LP)..............................21-383

SENSOR - REMOVAL, MAP.............14-33

SENSOR - REMOVAL, OUTPUT SPEED . . . 21-391

SENSOR - REMOVAL, OXYGEN..........14-35

SENSOR - REMOVAL, POSITION . . 21-443,21-478

SENSOR - REMOVAL, REAR WHEEL

SPEED..............................5-48

SENSOR - REMOVAL, THROTTLE

POSITION..........................14-41

SENSOR - REMOVAL, TRANSMISSION

RANGE............................21-265

SENSOR - REMOVAL, WATER IN FUEL....14-66

SENSOR CIRCUIT - DIAGNOSIS AND

TESTING, AMBIENT TEMPERATURE......8M-10

SENSOR RETURN - DESCRIPTION.......8E-10

SENSOR (TRS) - DIAGNOSIS AND

TESTING, TRANSMISSION RANGE......21-264

SENSOR/MAP SENSOR - DESCRIPTION,

INTAKE AIR TEMPERATURE............14-82

SENSOR/MAP SENSOR - INSTALLATION,

INTAKE AIR TEMPERATURE............14-82

SENSOR/MAP SENSOR - OPERATION,

INTAKE AIR TEMPERATURE............14-82

SENSOR/MAP SENSOR - REMOVAL,

INTAKE AIR TEMPERATURE............14-82

SENSOR/PRESSURE SENSOR -

DESCRIPTION, INLET AIR

TEMPERATURE......................14-79

SENSOR/PRESSURE SENSOR -

INSTALLATION, INLET AIR

TEMPERATURE......................14-79

SENSOR/PRESSURE SENSOR -

OPERATION, INLET AIR TEMPERATURE . . . 14-79

SENSOR/PRESSURE SENSOR -

REMOVAL, INLET AIR TEMPERATURE....14-79

SENSOR/SWITCH - DESCRIPTION, OIL

PRESSURE..........................9-67

SENSOR/SWITCH - INSTALLATION, OIL

PRESSURE..........................9-67

SENSOR/SWITCH - OPERATION, OIL

PRESSURE..........................9-67

SENSOR/SWITCH - REMOVAL, OIL

PRESSURE..........................9-67

SENTRY KEY IMMOBILIZER MODULE -

DESCRIPTION.......................8E-13

SENTRY KEY IMMOBILIZER MODULE -

INSTALLATION.......................8E-15

SENTRY KEY IMMOBILIZER MODULE -

OPERATION.........................8E-13

SENTRY KEY IMMOBILIZER MODULE -

REMOVAL..........................8E-15

SENTRY KEY IMMOBILIZER MODULE

(SKIM) - DESCRIPTION................8Q-1

SENTRY KEY IMMOBILIZER MODULE

(SKIM) - OPERATION..................8Q-2

SENTRY KEY IMMOBILIZER SYSTEM

INDICATOR LAMP - DESCRIPTION........8Q-5

SENTRY KEY IMMOBILIZER SYSTEM

INDICATOR LAMP - OPERATION..........8Q-5

SENTRY KEY IMMOBILIZER SYSTEM

INITIALIZATION, STANDARD

PROCEDURE.........................8Q-3

SENTRY KEY IMMOBILIZER SYSTEM

(SKIS) - DESCRIPTION.................8Q-1

SENTRY KEY IMMOBILIZER SYSTEM

(SKIS) - OPERATION...................8Q-2

SENTRY KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE...............8Q-4

SEPARATOR - DESCRIPTION, FUEL

FILTER / WATER .....................14-50

SEPARATOR - INSTALLATION, FUEL

FILTER / WATER .....................14-50

SEPARATOR - OPERATION, FUEL FILTER

/ WATER ...........................14-50

SEPARATOR - REMOVAL, FUEL FILTER /

WATER.............................14-50

SERVO - ASSEMBLY, FRONT...........21-209

SERVO - ASSEMBLY, REAR............21-251

SERVO - CLEANING, FRONT...........21-209

SERVO - CLEANING, REAR............21-251

SERVO - DESCRIPTION.................8P-6

SERVO - DESCRIPTION, FRONT

........21-208

SERVO - DESCRIPTION, REAR

.........21-251

SERVO - DISASSEMBLY, FRONT

........21-209

SERVO - DISASSEMBLY, REAR

.........21-251

SERVO - INSPECTION, FRONT

.........21-209SERVO - INSTALLATION................8P-6

SERVO - OPERATION..................8P-6

SERVO - OPERATION, FRONT..........21-208

SERVO - OPERATION, REAR...........21-251

SERVO - REMOVAL....................8P-6

SETTING TRANSMITTER CODES -

STANDARD PROCEDURE..............8M-12

SHAFT - ASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT.................21-244

SHAFT - CAUTION, HALF................3-20

SHAFT - DESCRIPTION, PLANETARY

GEARTRAIN/OUTPUT.................21-241

SHAFT - DIAGNOSIS AND TESTING,

HALF...............................3-20

SHAFT - DIAGNOSIS AND TESTING,

PROPELLER...........................3-1

SHAFT - DISASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT.................21-242

SHAFT - HD FRONT - INSTALLATION,

PROPELLER...........................3-7

SHAFT - HD FRONT - REMOVAL,

PROPELLER...........................3-7

SHAFT - INSPECTION, PLANETARY

GEARTRAIN/OUTPUT.................21-243

SHAFT - INSTALLATION, BALANCE........9-80

SHAFT - INSTALLATION, HALF...........3-21

SHAFT - INSTALLATION, IDLER.....9-179,9-81

SHAFT - INSTALLATION, REAR

PROPELLER...........................3-8

SHAFT - OPERATION, PLANETARY

GEARTRAIN/OUTPUT..................21-241

SHAFT - REMOVAL, BALANCE...........9-80

SHAFT - REMOVAL, HALF...............3-20

SHAFT - REMOVAL, IDLER.........9-179,9-81

SHAFT - REMOVAL, REAR PROPELLER.....3-8

SHAFT - SPECIAL TOOLS, HALF..........3-21

SHAFT - SPECIAL TOOLS, PROPELLER.....3-6

SHAFT - SPECIFICATIONS, HALF..........3-21

SHAFT - SPECIFICATIONS, PROPELLER.....3-6

SHAFT - STANDARD PROCEDURE,

PROPELLER...........................3-3

SHAFT FRONT BEARING -

INSTALLATION, OUTPUT..............21-216

SHAFT FRONT BEARING - REMOVAL,

OUTPUT...........................21-216

SHAFT- LD FRONT - INSTALLATION,

PROPELLER...........................3-7

SHAFT- LD FRONT - REMOVAL,

PROPELLER...........................3-6

SHAFT REAR BEARING - INSTALLATION,

OUTPUT...........................21-217

SHAFT REAR BEARING - REMOVAL,

OUTPUT...........................21-216

SHAFT SEAL - INSTALLATION, FRONT

OUTPUT . . . 21-442,21-477,21-508,21-538,21-572

SHAFT SEAL - INSTALLATION, STEERING

GEAR INPUT........................19-29

SHAFT SEAL - REMOVAL, FRONT

OUTPUT . . . 21-441,21-477,21-507,21-537,21-572

SHAFT SEAL - REMOVAL, STEERING

GEAR INPUT........................19-27

SHAFT SEALS - INSTALLATION, AXLE . 3-43,3-70,

3-94

SHAFT SEALS - REMOVAL, AXLE . 3-43,3-69,3-94

SHAFTS - ASSEMBLY, AXLE.............3-69

SHAFTS - DISASSEMBLY, AXLE..........3-68

SHAFTS - INSTALLATION, AXLE....3-124,3-152,

3-43,3-69,3-94

SHAFTS - REMOVAL, AXLE . . . 3-124,3-152,3-43,

3-67,3-93

SHIELD - INSTALLATION, FRONT

WHEELHOUSE SPLASH................23-41

SHIELD - INSTALLATION, REAR

WHEELHOUSE SPLASH................23-41

SHIELD - REMOVAL, FRONT

WHEELHOUSE SPLASH................23-41

SHIELD - REMOVAL, REAR

WHEELHOUSE SPLASH................23-41

SHIELDS - DESCRIPTION, HEAT..........11-8

SHIELDS - INSTALLATION, HEAT.........11-8

SHIELDS - REMOVAL, HEAT.............11-8

SHIFT BOOT - INSTALLATION, 4WD

FLOOR

.............................23-62

SHIFT BOOT - REMOVAL, 4WD FLOOR

....23-62

SHIFT COVER - INSTALLATION

....21-129,21-87

SHIFT COVER - REMOVAL

.......21-129,21-87

SHIFT INTERLOCK - ADJUSTMENTS,

BRAKE TRANSMISSION

........21-196,21-365SHIFT INTERLOCK - DIAGNOSIS AND

TESTING, BRAKE TRANSMISSION......21-196,

21-364

SHIFT INTERLOCK SYSTEM -

DESCRIPTION, BRAKE TRANSMISSION . . 21-196,

21-364

SHIFT INTERLOCK SYSTEM -

OPERATION, BRAKE TRANSMISSION....21-196,

21-364

SHIFT LEVER - ADJUSTMENT....21-446,21-481

SHIFT LEVER - INSTALLATION . . . 21-445,21-480

SHIFT LEVER - INSTALLATION, GEAR.....19-12

SHIFT LEVER - REMOVAL.......21-444,21-479

SHIFT LEVER - REMOVAL, GEAR........19-12

SHIFT MECHANISM - DESCRIPTION....21-252,

21-398

SHIFT MECHANISM - INSTALLATION.....21-87

SHIFT MECHANISM - OPERATION......21-252,

21-398

SHIFT MECHANISM - REMOVAL.........21-86

SHIFT MOTOR - DESCRIPTION . . 21-511,21-541,

21-575

SHIFT MOTOR - INSTALLATION . . 21-511,21-541,

21-575

SHIFT MOTOR - OPERATION....21-511,21-541,

21-575

SHIFT MOTOR - REMOVAL.....21-511,21-541,

21-575

SHOCK - DIAGNOSIS AND TESTING . . . 2-24,2-38

SHOCK - DIAGNOSIS AND TESTING,

SPRING.............................2-41

SHOCK - INSTALLATION.............2-38,2-43

SHOCK - REMOVAL................2-38,2-43

SHOES - ADJUSTMENT, PARKING BRAKE . . 5-41

SHOES - INSTALLATION................5-40

SHOES - REMOVAL....................5-39

SIDE - INSTALLATION, LEFT............9-123

SIDE - INSTALLATION, RIGHT...........9-123

SIDE - REMOVAL, LEFT................9-122

SIDE - REMOVAL, RIGHT..............9-122

SIDE BEZEL - INSTALLATION,

INSTRUMENT PANEL DRIVER...........23-58

SIDE BEZEL - REMOVAL, INSTRUMENT

PANEL DRIVER......................23-58

SIDE CURTAIN AIRBAG - DESCRIPTION . . . 8O-56

SIDE CURTAIN AIRBAG - INSTALLATION . . 8O-58

SIDE CURTAIN AIRBAG - OPERATION....8O-56

SIDE CURTAIN AIRBAG - REMOVAL......8O-57

SIDE IMPACT SENSOR - DESCRIPTION . . . 8O-59

SIDE IMPACT SENSOR - OPERATION.....8O-59

SIDE MOLDINGS - INSTALLATION, BODY . . 23-36

SIDE MOLDINGS - REMOVAL, BODY.....23-36

SIDE VIEW MIRROR - INSTALLATION.....23-42

SIDE VIEW MIRROR - REMOVAL........23-41

SIDE VIEW MIRROR FLAG -

INSTALLATION.......................23-27

SIDE VIEW MIRROR FLAG - REMOVAL . . . 23-27

SIDE VIEW MIRROR GLASS -

INSTALLATION.......................23-43

SIDE VIEW MIRROR GLASS - REMOVAL . . 23-42

SIDEVIEW MIRROR - REMOVAL.........8N-12

SIGNAL INDICATOR - DESCRIPTION,

TURN..............................8J-40

SIGNAL INDICATOR - OPERATION, TURN . . 8J-41

SIGNAL LAMP - INSTALLATION,

PARK/TURN.........................8L-21

SIGNAL LAMP - REMOVAL, PARK/TURN . . 8L-21

SIGNAL SYSTEM - DESCRIPTION, TURN . . 8L-18

SIGNAL SYSTEM - OPERATION, TURN....8L-18

SILL TRIM COVER - INSTALLATION,

REAR DOOR........................23-71

SILL TRIM COVER - REMOVAL, REAR

DOOR.............................23-71

SIZE, SPARE WHEEL WITH MATCHING

TIRE - DESCRIPTION, FULL............22-15

SKID PLATE - INSTALLATION, FRONT.....13-23

SKID PLATE - INSTALLATION, TRANSFER

CASE..............................13-26

SKID PLATE - REMOVAL, FRONT........13-23

SKID PLATE - REMOVAL, TRANSFER

CASE..............................13-26

SLEEVE - INSTALLATION, HEADREST.....23-81

SLEEVE - REMOVAL, HEADREST

........23-81

SMOKE DIAGNOSIS CHARTS -

DIAGNOSIS AND TESTING

.............9-236

SNAP RINGS - ASSEMBLY, WITH

.........3-12

SNAP RINGS - DISASSEMBLY, WITH

......3-10

SOLENOID - DESCRIPTION

............21-252

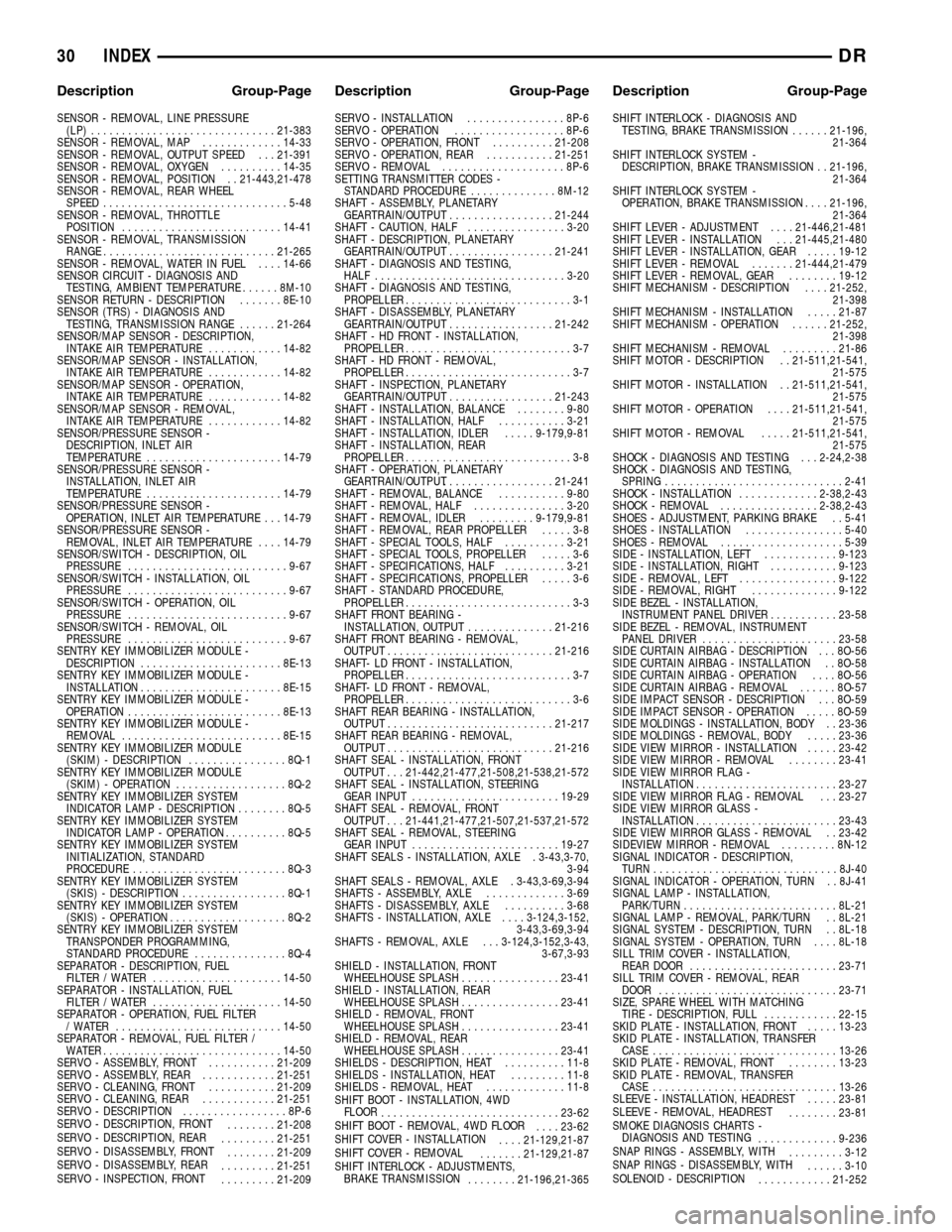

30 INDEXDR

Description Group-Page Description Group-Page Description Group-Page