system DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 260 of 2627

(9) Tighten tool handle until plug gauge is

squarely seated on jaws of flaring tool. This will start

the inverted flare.

(10) Remove the plug gauge and complete the

inverted flare.

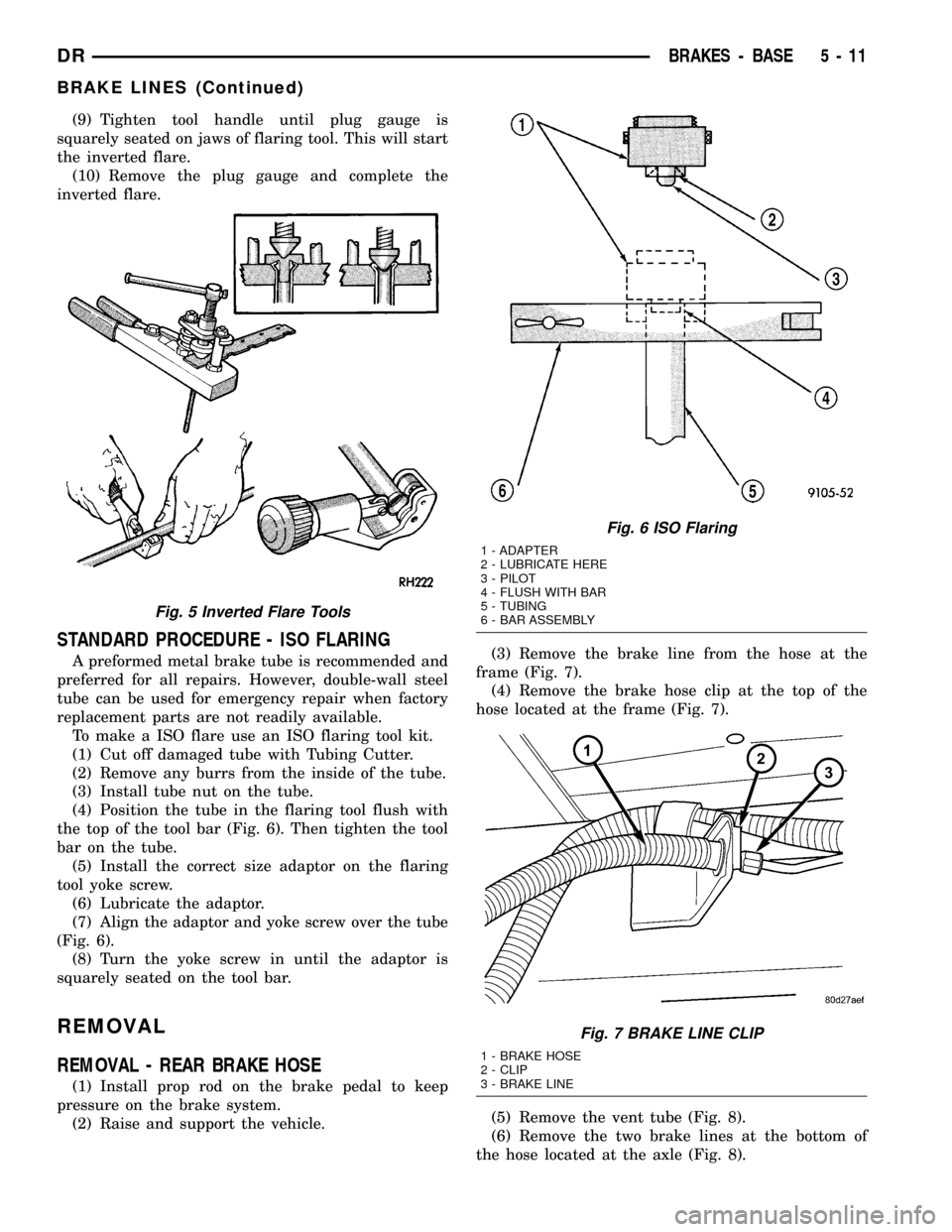

STANDARD PROCEDURE - ISO FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

To make a ISO flare use an ISO flaring tool kit.

(1) Cut off damaged tube with Tubing Cutter.

(2) Remove any burrs from the inside of the tube.

(3) Install tube nut on the tube.

(4) Position the tube in the flaring tool flush with

the top of the tool bar (Fig. 6). Then tighten the tool

bar on the tube.

(5) Install the correct size adaptor on the flaring

tool yoke screw.

(6) Lubricate the adaptor.

(7) Align the adaptor and yoke screw over the tube

(Fig. 6).

(8) Turn the yoke screw in until the adaptor is

squarely seated on the tool bar.

REMOVAL

REMOVAL - REAR BRAKE HOSE

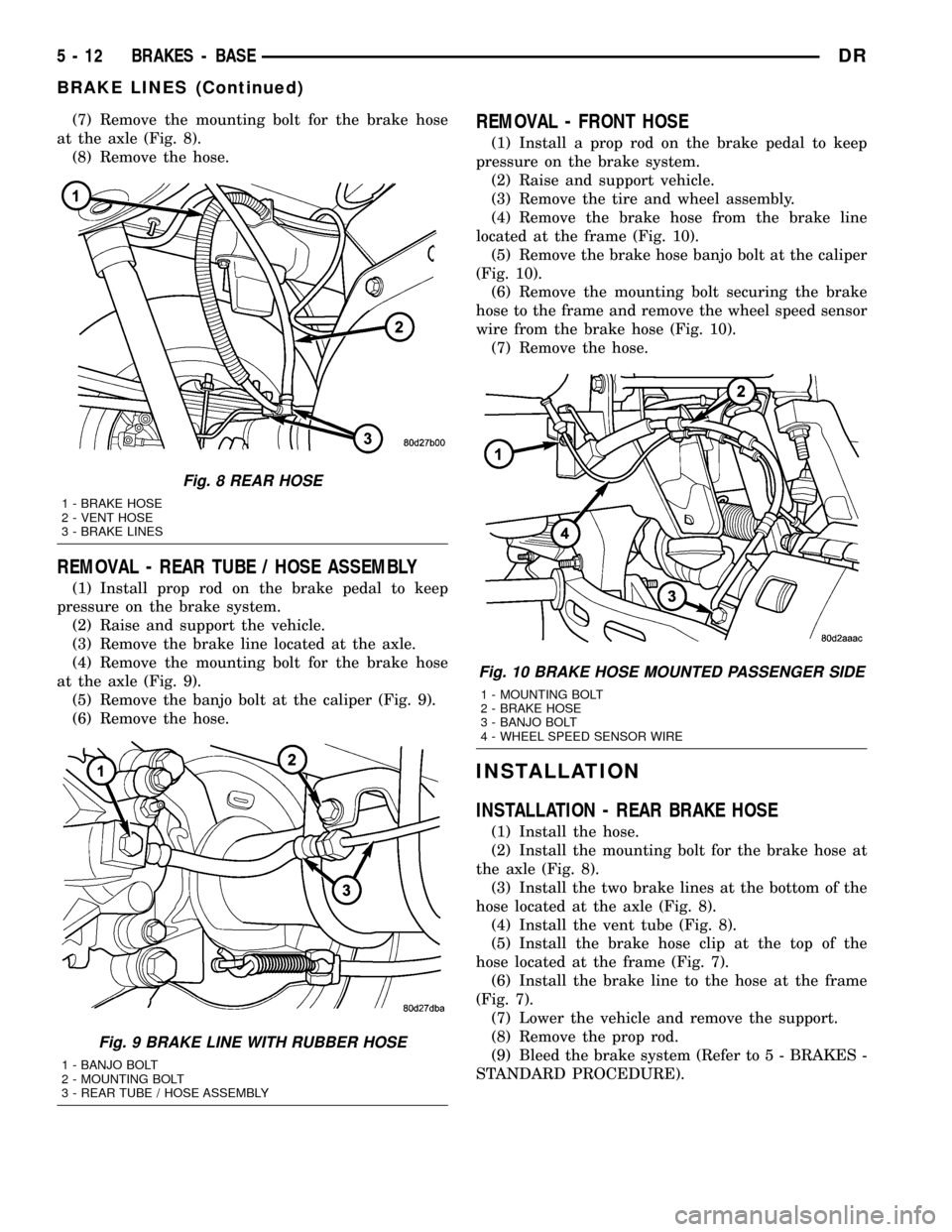

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support the vehicle.(3) Remove the brake line from the hose at the

frame (Fig. 7).

(4) Remove the brake hose clip at the top of the

hose located at the frame (Fig. 7).

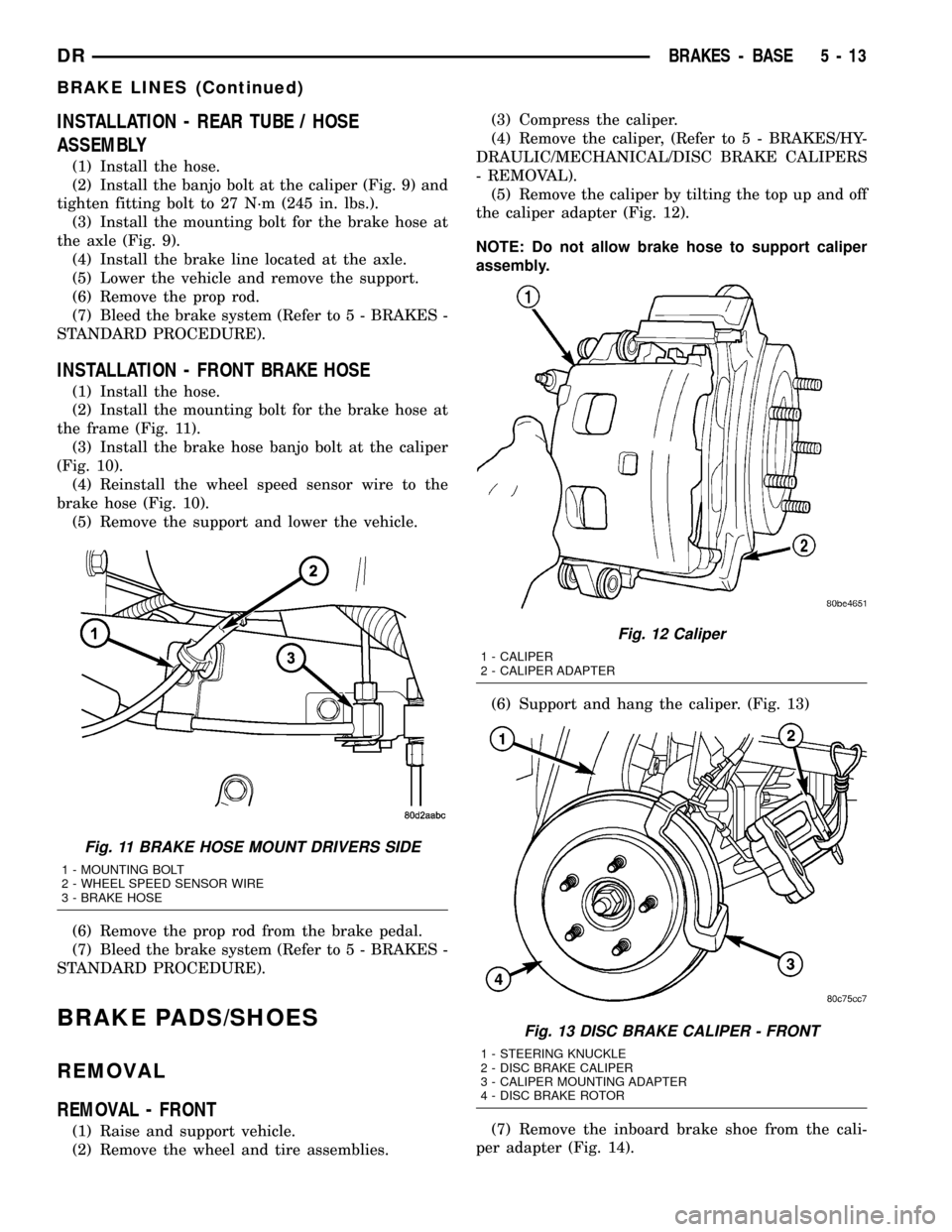

(5) Remove the vent tube (Fig. 8).

(6) Remove the two brake lines at the bottom of

the hose located at the axle (Fig. 8).

Fig. 5 Inverted Flare Tools

Fig. 6 ISO Flaring

1 - ADAPTER

2 - LUBRICATE HERE

3 - PILOT

4 - FLUSH WITH BAR

5 - TUBING

6 - BAR ASSEMBLY

Fig. 7 BRAKE LINE CLIP

1 - BRAKE HOSE

2 - CLIP

3 - BRAKE LINE

DRBRAKES - BASE 5 - 11

BRAKE LINES (Continued)

Page 261 of 2627

(7) Remove the mounting bolt for the brake hose

at the axle (Fig. 8).

(8) Remove the hose.

REMOVAL - REAR TUBE / HOSE ASSEMBLY

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support the vehicle.

(3) Remove the brake line located at the axle.

(4) Remove the mounting bolt for the brake hose

at the axle (Fig. 9).

(5) Remove the banjo bolt at the caliper (Fig. 9).

(6) Remove the hose.

REMOVAL - FRONT HOSE

(1) Install a prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support vehicle.

(3) Remove the tire and wheel assembly.

(4) Remove the brake hose from the brake line

located at the frame (Fig. 10).

(5) Remove the brake hose banjo bolt at the caliper

(Fig. 10).

(6) Remove the mounting bolt securing the brake

hose to the frame and remove the wheel speed sensor

wire from the brake hose (Fig. 10).

(7) Remove the hose.

INSTALLATION

INSTALLATION - REAR BRAKE HOSE

(1) Install the hose.

(2) Install the mounting bolt for the brake hose at

the axle (Fig. 8).

(3) Install the two brake lines at the bottom of the

hose located at the axle (Fig. 8).

(4) Install the vent tube (Fig. 8).

(5) Install the brake hose clip at the top of the

hose located at the frame (Fig. 7).

(6) Install the brake line to the hose at the frame

(Fig. 7).

(7) Lower the vehicle and remove the support.

(8) Remove the prop rod.

(9) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

Fig. 8 REAR HOSE

1 - BRAKE HOSE

2 - VENT HOSE

3 - BRAKE LINES

Fig. 9 BRAKE LINE WITH RUBBER HOSE

1 - BANJO BOLT

2 - MOUNTING BOLT

3 - REAR TUBE / HOSE ASSEMBLY

Fig. 10 BRAKE HOSE MOUNTED PASSENGER SIDE

1 - MOUNTING BOLT

2 - BRAKE HOSE

3 - BANJO BOLT

4 - WHEEL SPEED SENSOR WIRE

5 - 12 BRAKES - BASEDR

BRAKE LINES (Continued)

Page 262 of 2627

INSTALLATION - REAR TUBE / HOSE

ASSEMBLY

(1) Install the hose.

(2) Install the banjo bolt at the caliper (Fig. 9) and

tighten fitting bolt to 27 N´m (245 in. lbs.).

(3) Install the mounting bolt for the brake hose at

the axle (Fig. 9).

(4) Install the brake line located at the axle.

(5) Lower the vehicle and remove the support.

(6) Remove the prop rod.

(7) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

INSTALLATION - FRONT BRAKE HOSE

(1) Install the hose.

(2) Install the mounting bolt for the brake hose at

the frame (Fig. 11).

(3) Install the brake hose banjo bolt at the caliper

(Fig. 10).

(4) Reinstall the wheel speed sensor wire to the

brake hose (Fig. 10).

(5) Remove the support and lower the vehicle.

(6) Remove the prop rod from the brake pedal.

(7) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

BRAKE PADS/SHOES

REMOVAL

REMOVAL - FRONT

(1) Raise and support vehicle.

(2) Remove the wheel and tire assemblies.(3) Compress the caliper.

(4) Remove the caliper, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- REMOVAL).

(5) Remove the caliper by tilting the top up and off

the caliper adapter (Fig. 12).

NOTE: Do not allow brake hose to support caliper

assembly.

(6) Support and hang the caliper. (Fig. 13)

(7) Remove the inboard brake shoe from the cali-

per adapter (Fig. 14).

Fig. 11 BRAKE HOSE MOUNT DRIVERS SIDE

1 - MOUNTING BOLT

2 - WHEEL SPEED SENSOR WIRE

3 - BRAKE HOSE

Fig. 12 Caliper

1 - CALIPER

2 - CALIPER ADAPTER

Fig. 13 DISC BRAKE CALIPER - FRONT

1 - STEERING KNUCKLE

2 - DISC BRAKE CALIPER

3 - CALIPER MOUNTING ADAPTER

4 - DISC BRAKE ROTOR

DRBRAKES - BASE 5 - 13

BRAKE LINES (Continued)

Page 266 of 2627

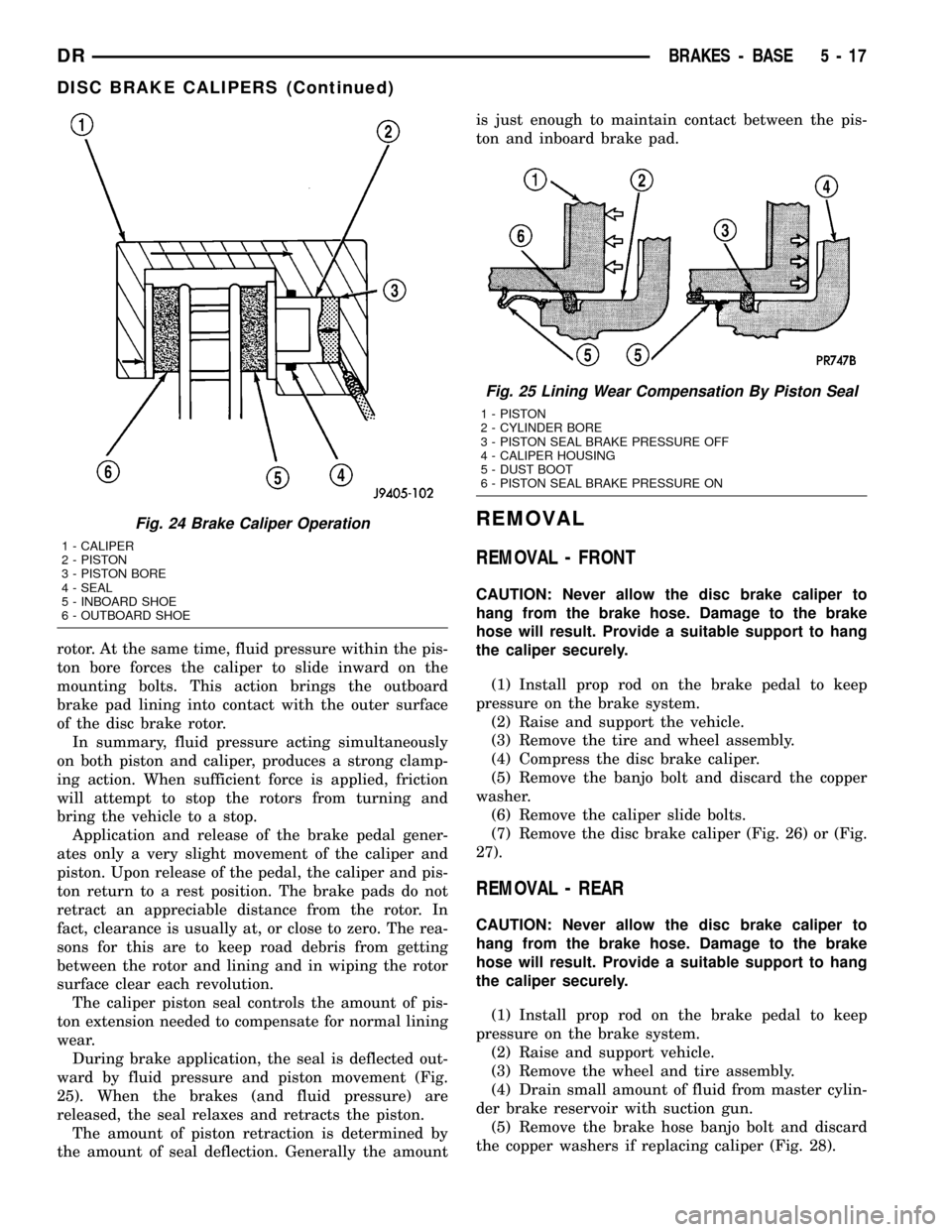

rotor. At the same time, fluid pressure within the pis-

ton bore forces the caliper to slide inward on the

mounting bolts. This action brings the outboard

brake pad lining into contact with the outer surface

of the disc brake rotor.

In summary, fluid pressure acting simultaneously

on both piston and caliper, produces a strong clamp-

ing action. When sufficient force is applied, friction

will attempt to stop the rotors from turning and

bring the vehicle to a stop.

Application and release of the brake pedal gener-

ates only a very slight movement of the caliper and

piston. Upon release of the pedal, the caliper and pis-

ton return to a rest position. The brake pads do not

retract an appreciable distance from the rotor. In

fact, clearance is usually at, or close to zero. The rea-

sons for this are to keep road debris from getting

between the rotor and lining and in wiping the rotor

surface clear each revolution.

The caliper piston seal controls the amount of pis-

ton extension needed to compensate for normal lining

wear.

During brake application, the seal is deflected out-

ward by fluid pressure and piston movement (Fig.

25). When the brakes (and fluid pressure) are

released, the seal relaxes and retracts the piston.

The amount of piston retraction is determined by

the amount of seal deflection. Generally the amountis just enough to maintain contact between the pis-

ton and inboard brake pad.

REMOVAL

REMOVAL - FRONT

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support the vehicle.

(3) Remove the tire and wheel assembly.

(4) Compress the disc brake caliper.

(5) Remove the banjo bolt and discard the copper

washer.

(6) Remove the caliper slide bolts.

(7) Remove the disc brake caliper (Fig. 26) or (Fig.

27).

REMOVAL - REAR

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support vehicle.

(3) Remove the wheel and tire assembly.

(4) Drain small amount of fluid from master cylin-

der brake reservoir with suction gun.

(5) Remove the brake hose banjo bolt and discard

the copper washers if replacing caliper (Fig. 28).

Fig. 24 Brake Caliper Operation

1 - CALIPER

2 - PISTON

3 - PISTON BORE

4 - SEAL

5 - INBOARD SHOE

6 - OUTBOARD SHOE

Fig. 25 Lining Wear Compensation By Piston Seal

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

DRBRAKES - BASE 5 - 17

DISC BRAKE CALIPERS (Continued)

Page 270 of 2627

INSTALLATION

INSTALLATION - FRONT

NOTE: Install a new copper washers on the banjo

bolt when installing

(1) Install the disc brake caliper (Fig. 26) or (Fig.

27).

CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(2) Install the banjo bolt with new copper washers

to the caliper. Tighten to 27 N´m (20 ft. lbs.)

(3) Install the caliper slide pin bolts. tighten to 32

N´m (24 ft. lbs.)

(4) Remove the prop rod.

(5) Bleed the base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(6) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(7) Lower the vehicle.

INSTALLATION - REAR

(1) Install caliper to the caliper adapter.

(2) Coat the caliper mounting slide pin bolts with

silicone grease. Then install and tighten the bolts to

15 N´m (11 ft. lbs.).

(3) Install the brake hose banjo bolt if removed.

(4) Install the brake hose to the caliper withnew

seal washersand tighten fitting bolt to 27 N´m (245

in. lbs.).CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(5) Remove the prop rod from the vehicle.

(6) Bleed the base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(7) Install the wheel and tire assemblies (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(8) Remove the supports and lower the vehicle.

(9) Verify a firm pedal before moving the vehicle.

DISC BRAKE CALIPER

ADAPTER

REMOVAL

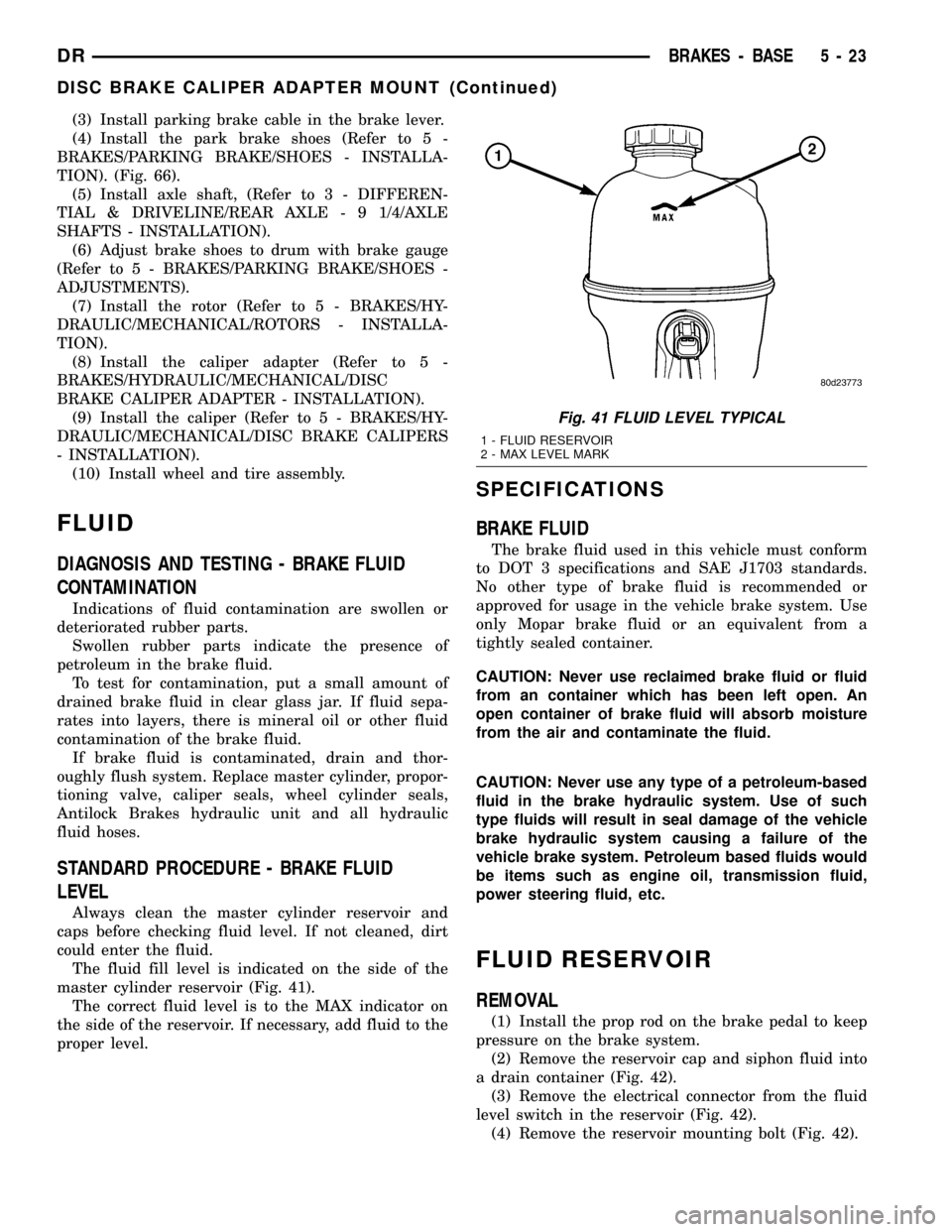

REMOVAL - FRONT

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the bolts securing the caliper adapter

to the steering knuckle (Fig. 38)

(5) Remove the caliper adapter.

REMOVAL - REAR

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Drain a small amount of fluid from master cyl-

inder brake reservoir with acleansuction gun.

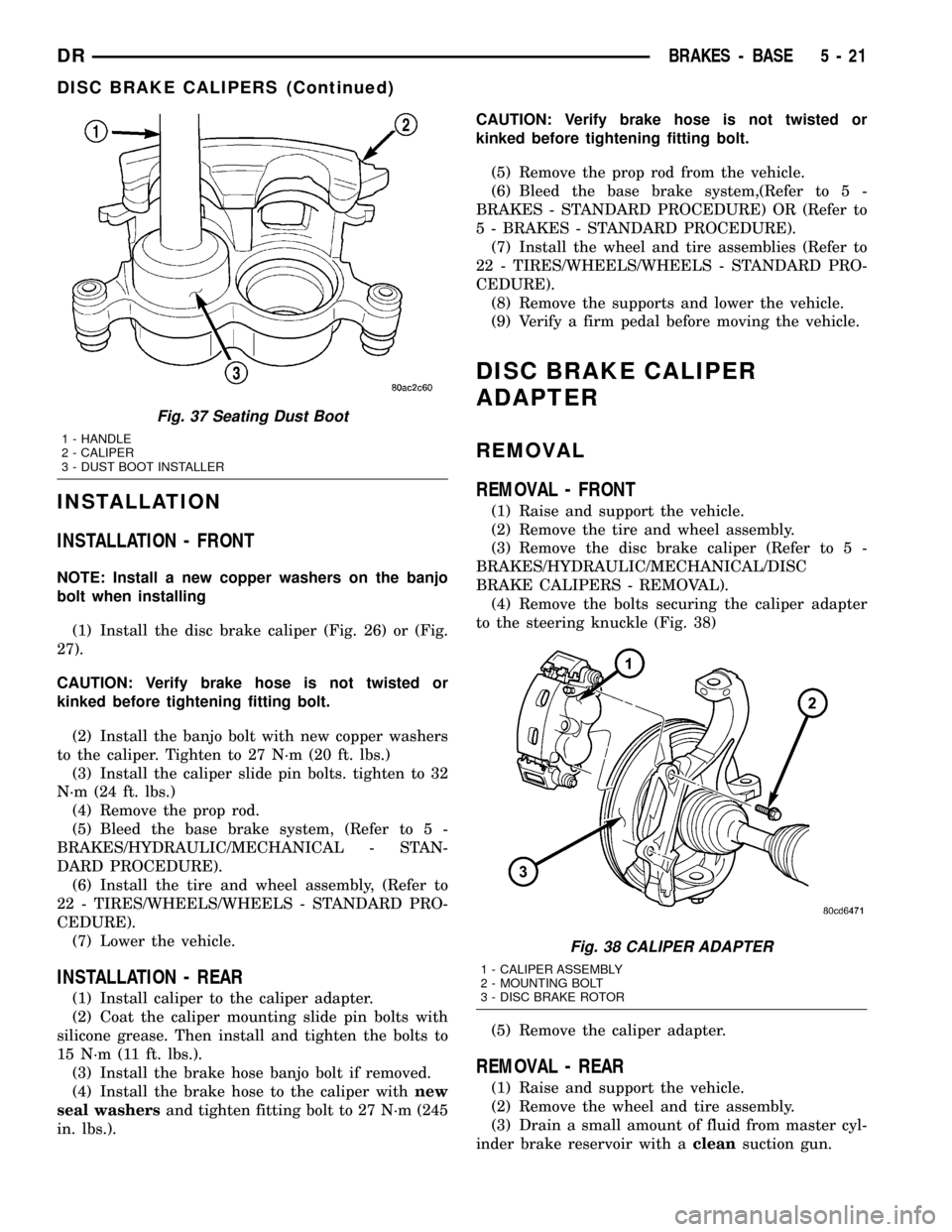

Fig. 37 Seating Dust Boot

1 - HANDLE

2 - CALIPER

3 - DUST BOOT INSTALLER

Fig. 38 CALIPER ADAPTER

1 - CALIPER ASSEMBLY

2 - MOUNTING BOLT

3 - DISC BRAKE ROTOR

DRBRAKES - BASE 5 - 21

DISC BRAKE CALIPERS (Continued)

Page 272 of 2627

(3) Install parking brake cable in the brake lever.

(4) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 66).

(5) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

(6) Adjust brake shoes to drum with brake gauge

(Refer to 5 - BRAKES/PARKING BRAKE/SHOES -

ADJUSTMENTS).

(7) Install the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION).

(8) Install the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(9) Install the caliper (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(10) Install wheel and tire assembly.

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

STANDARD PROCEDURE - BRAKE FLUID

LEVEL

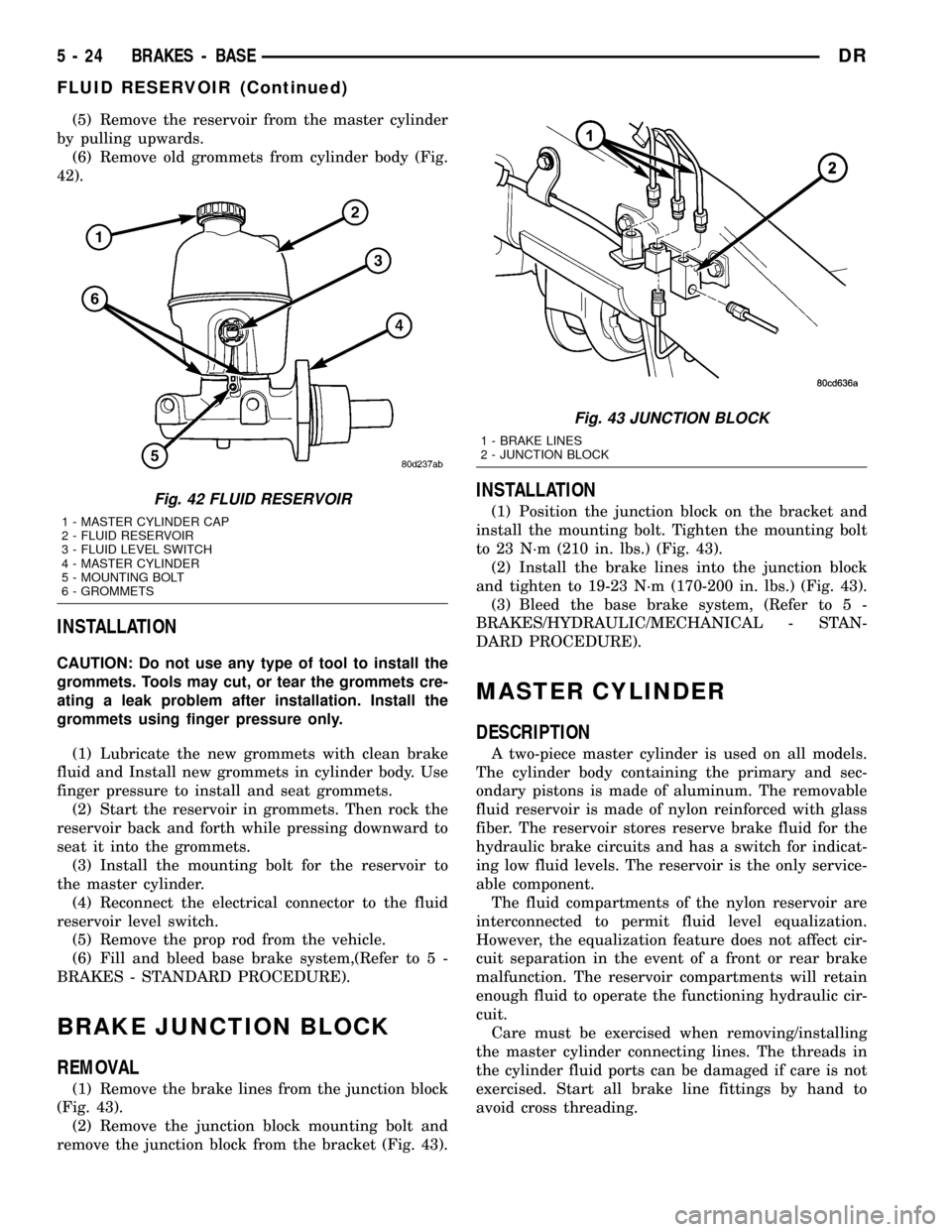

Always clean the master cylinder reservoir and

caps before checking fluid level. If not cleaned, dirt

could enter the fluid.

The fluid fill level is indicated on the side of the

master cylinder reservoir (Fig. 41).

The correct fluid level is to the MAX indicator on

the side of the reservoir. If necessary, add fluid to the

proper level.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

FLUID RESERVOIR

REMOVAL

(1) Install the prop rod on the brake pedal to keep

pressure on the brake system.

(2) Remove the reservoir cap and siphon fluid into

a drain container (Fig. 42).

(3) Remove the electrical connector from the fluid

level switch in the reservoir (Fig. 42).

(4) Remove the reservoir mounting bolt (Fig. 42).

Fig. 41 FLUID LEVEL TYPICAL

1 - FLUID RESERVOIR

2 - MAX LEVEL MARK

DRBRAKES - BASE 5 - 23

DISC BRAKE CALIPER ADAPTER MOUNT (Continued)

Page 273 of 2627

(5) Remove the reservoir from the master cylinder

by pulling upwards.

(6) Remove old grommets from cylinder body (Fig.

42).

INSTALLATION

CAUTION: Do not use any type of tool to install the

grommets. Tools may cut, or tear the grommets cre-

ating a leak problem after installation. Install the

grommets using finger pressure only.

(1) Lubricate the new grommets with clean brake

fluid and Install new grommets in cylinder body. Use

finger pressure to install and seat grommets.

(2) Start the reservoir in grommets. Then rock the

reservoir back and forth while pressing downward to

seat it into the grommets.

(3) Install the mounting bolt for the reservoir to

the master cylinder.

(4) Reconnect the electrical connector to the fluid

reservoir level switch.

(5) Remove the prop rod from the vehicle.

(6) Fill and bleed base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE).

BRAKE JUNCTION BLOCK

REMOVAL

(1) Remove the brake lines from the junction block

(Fig. 43).

(2) Remove the junction block mounting bolt and

remove the junction block from the bracket (Fig. 43).

INSTALLATION

(1) Position the junction block on the bracket and

install the mounting bolt. Tighten the mounting bolt

to 23 N´m (210 in. lbs.) (Fig. 43).

(2) Install the brake lines into the junction block

and tighten to 19-23 N´m (170-200 in. lbs.) (Fig. 43).

(3) Bleed the base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

MASTER CYLINDER

DESCRIPTION

A two-piece master cylinder is used on all models.

The cylinder body containing the primary and sec-

ondary pistons is made of aluminum. The removable

fluid reservoir is made of nylon reinforced with glass

fiber. The reservoir stores reserve brake fluid for the

hydraulic brake circuits and has a switch for indicat-

ing low fluid levels. The reservoir is the only service-

able component.

The fluid compartments of the nylon reservoir are

interconnected to permit fluid level equalization.

However, the equalization feature does not affect cir-

cuit separation in the event of a front or rear brake

malfunction. The reservoir compartments will retain

enough fluid to operate the functioning hydraulic cir-

cuit.

Care must be exercised when removing/installing

the master cylinder connecting lines. The threads in

the cylinder fluid ports can be damaged if care is not

exercised. Start all brake line fittings by hand to

avoid cross threading.

Fig. 42 FLUID RESERVOIR

1 - MASTER CYLINDER CAP

2 - FLUID RESERVOIR

3 - FLUID LEVEL SWITCH

4 - MASTER CYLINDER

5 - MOUNTING BOLT

6 - GROMMETS

Fig. 43 JUNCTION BLOCK

1 - BRAKE LINES

2 - JUNCTION BLOCK

5 - 24 BRAKES - BASEDR

FLUID RESERVOIR (Continued)

Page 276 of 2627

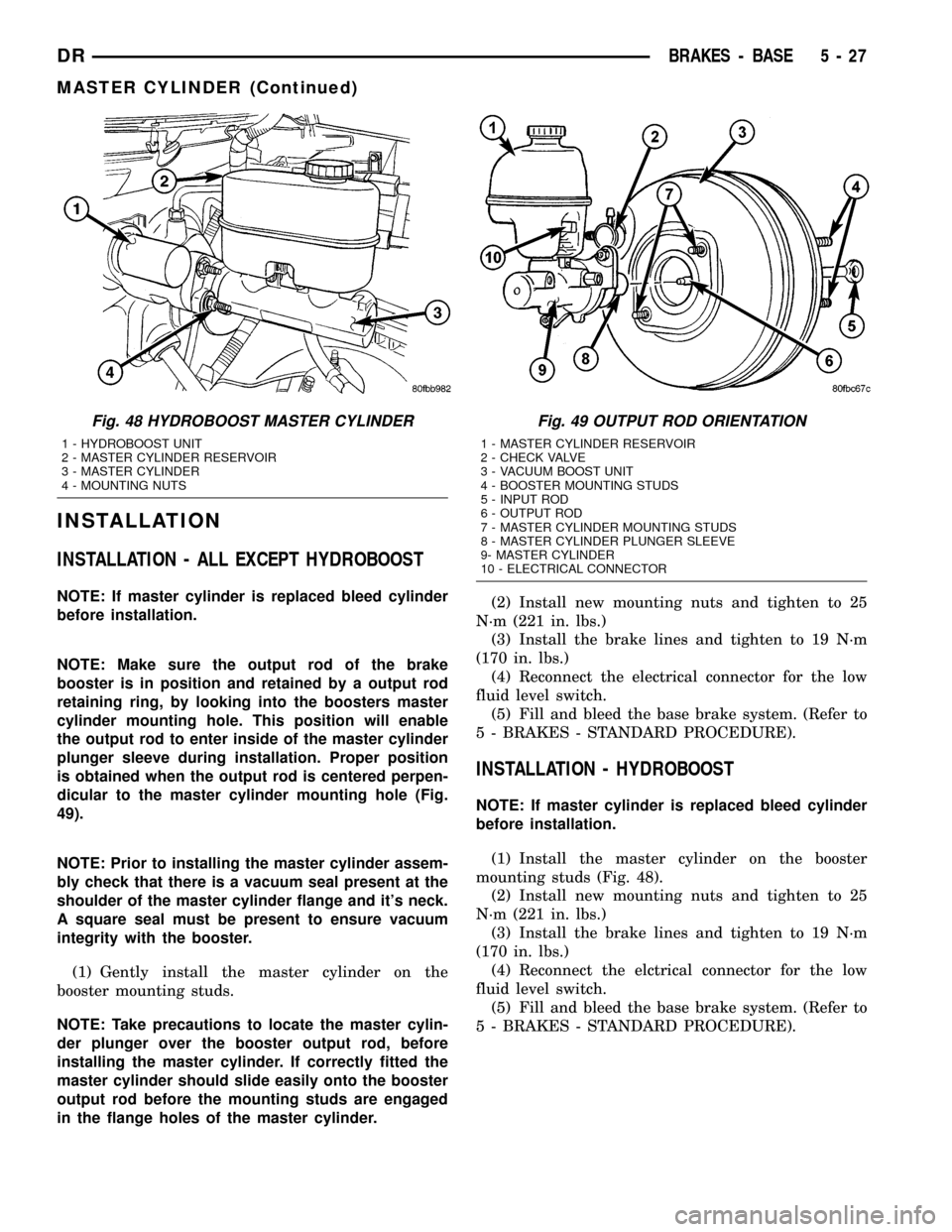

INSTALLATION

INSTALLATION - ALL EXCEPT HYDROBOOST

NOTE: If master cylinder is replaced bleed cylinder

before installation.

NOTE: Make sure the output rod of the brake

booster is in position and retained by a output rod

retaining ring, by looking into the boosters master

cylinder mounting hole. This position will enable

the output rod to enter inside of the master cylinder

plunger sleeve during installation. Proper position

is obtained when the output rod is centered perpen-

dicular to the master cylinder mounting hole (Fig.

49).

NOTE: Prior to installing the master cylinder assem-

bly check that there is a vacuum seal present at the

shoulder of the master cylinder flange and it's neck.

A square seal must be present to ensure vacuum

integrity with the booster.

(1) Gently install the master cylinder on the

booster mounting studs.

NOTE: Take precautions to locate the master cylin-

der plunger over the booster output rod, before

installing the master cylinder. If correctly fitted the

master cylinder should slide easily onto the booster

output rod before the mounting studs are engaged

in the flange holes of the master cylinder.(2) Install new mounting nuts and tighten to 25

N´m (221 in. lbs.)

(3) Install the brake lines and tighten to 19 N´m

(170 in. lbs.)

(4) Reconnect the electrical connector for the low

fluid level switch.

(5) Fill and bleed the base brake system. (Refer to

5 - BRAKES - STANDARD PROCEDURE).

INSTALLATION - HYDROBOOST

NOTE: If master cylinder is replaced bleed cylinder

before installation.

(1) Install the master cylinder on the booster

mounting studs (Fig. 48).

(2) Install new mounting nuts and tighten to 25

N´m (221 in. lbs.)

(3) Install the brake lines and tighten to 19 N´m

(170 in. lbs.)

(4) Reconnect the elctrical connector for the low

fluid level switch.

(5) Fill and bleed the base brake system. (Refer to

5 - BRAKES - STANDARD PROCEDURE).

Fig. 48 HYDROBOOST MASTER CYLINDER

1 - HYDROBOOST UNIT

2 - MASTER CYLINDER RESERVOIR

3 - MASTER CYLINDER

4 - MOUNTING NUTS

Fig. 49 OUTPUT ROD ORIENTATION

1 - MASTER CYLINDER RESERVOIR

2 - CHECK VALVE

3 - VACUUM BOOST UNIT

4 - BOOSTER MOUNTING STUDS

5 - INPUT ROD

6 - OUTPUT ROD

7 - MASTER CYLINDER MOUNTING STUDS

8 - MASTER CYLINDER PLUNGER SLEEVE

9- MASTER CYLINDER

10 - ELECTRICAL CONNECTOR

DRBRAKES - BASE 5 - 27

MASTER CYLINDER (Continued)

Page 278 of 2627

(9)On vehicles equipped with adjustable

brake pedal.Reconnect the electrical connector to

the motor and the adjuster cable at the pedal.

(10) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(11) Reconnect the negative battery cable.

POWER BRAKE BOOSTER

DESCRIPTION

All models use a tandem diaphragm, power brake

booster.

NOTE: The power brake booster is not a repairable

component. The booster must be replaced as an

assembly if diagnosis indicates a malfunction has

occurred.

OPERATION

The booster unit consists of a single housing

divided into two by a tandem diaphragm. The outer

edge of the diaphragm is secured to the housing. The

booster push rod, which connects the booster to the

brake pedal and master cylinder, is attached to the

center of the diaphragm. A check valve is used in the

booster outlet connected to the engine intake mani-

fold. Power assist is generated by utilizing a combi-

nation of vacuum and atmospheric pressure to boost

brake assist.

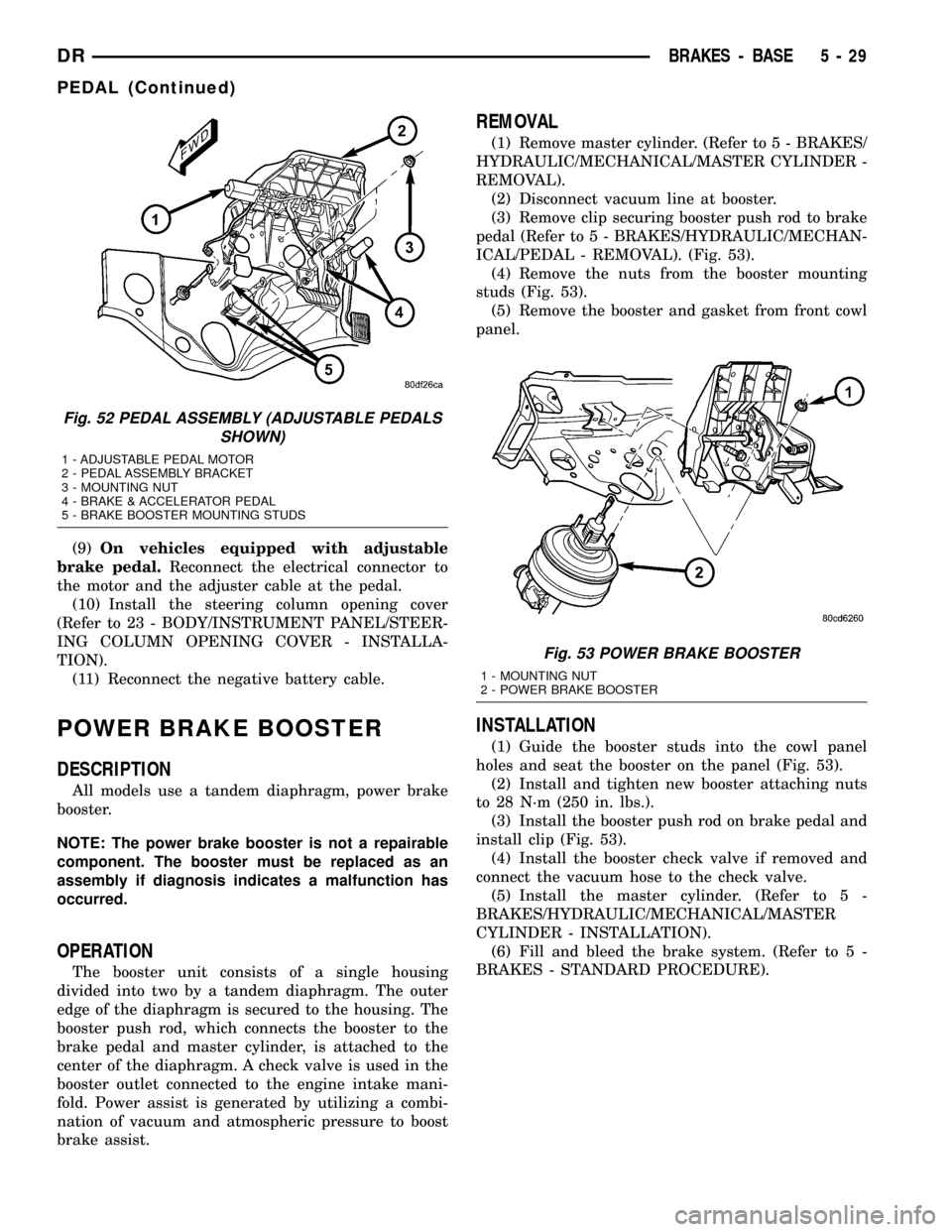

REMOVAL

(1) Remove master cylinder. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/MASTER CYLINDER -

REMOVAL).

(2) Disconnect vacuum line at booster.

(3) Remove clip securing booster push rod to brake

pedal (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/PEDAL - REMOVAL). (Fig. 53).

(4) Remove the nuts from the booster mounting

studs (Fig. 53).

(5) Remove the booster and gasket from front cowl

panel.

INSTALLATION

(1) Guide the booster studs into the cowl panel

holes and seat the booster on the panel (Fig. 53).

(2) Install and tighten new booster attaching nuts

to 28 N´m (250 in. lbs.).

(3) Install the booster push rod on brake pedal and

install clip (Fig. 53).

(4) Install the booster check valve if removed and

connect the vacuum hose to the check valve.

(5) Install the master cylinder. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/MASTER

CYLINDER - INSTALLATION).

(6) Fill and bleed the brake system. (Refer to 5 -

BRAKES - STANDARD PROCEDURE).

Fig. 52 PEDAL ASSEMBLY (ADJUSTABLE PEDALS

SHOWN)

1 - ADJUSTABLE PEDAL MOTOR

2 - PEDAL ASSEMBLY BRACKET

3 - MOUNTING NUT

4 - BRAKE & ACCELERATOR PEDAL

5 - BRAKE BOOSTER MOUNTING STUDS

Fig. 53 POWER BRAKE BOOSTER

1 - MOUNTING NUT

2 - POWER BRAKE BOOSTER

DRBRAKES - BASE 5 - 29

PEDAL (Continued)

Page 279 of 2627

HYDRO-BOOST BRAKE

BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER

The hydraulic booster uses hydraulic pressure from

the power steering pump. Before diagnosing a

booster problem, first verify the power steering pump

is operating properly. Perform the following checks.

²Check the power steering fluid level.

²Check the brake fluid level.

²Check all power steering hoses and lines for

leaks and restrictions.

²Check power steering pump pressure.

NOISES

The hydraulic booster unit will produce certain

characteristic booster noises. The noises may occur

when the brake pedal is used in a manner not asso-

ciated with normal braking or driving habits.

HISSING

A hissing noise may be noticed when above normal

brake pedal pressure is applied, 40 lbs. or above. The

noise will be more noticeable if the vehicle is not

moving. The noise will increase with the brake pedal

pressure and an increase of system operating temper-

ature.

CLUNK-CHATTER-CLICKING

A clunk-chatter-clicking may be noticed when the

brake pedal is released quickly, after above normal

brake pedal pressure is applied 50-100 lbs..

BOOSTER FUNCTION TEST

With the engine off depress the brake pedal several

times to discharge the accumulator. Then depress the

brake pedal using 40 lbs. of force and start the

engine. The brake pedal should fall and then push

back against your foot. This indicates the booster is

operating properly.

ACCUMULATOR LEAKDOWN

(1) Start the engine, apply the brakes and turn the

steering wheel from lock to lock. This will ensure the

accumulator is charged. Turn off the engine and let

the vehicle sit for one hour. After one hour thereshould be at least two power assisted brake applica-

tion with the engine off. If the system does not retain

a charge the booster must be replaced.

(2) With the engine off depress the brake pedal

several times to discharge the accumulator. Grasp

the accumulator and see if it wobbles or turns. If it

does the accumulator has lost a gas charge and the

booster must be replaced.

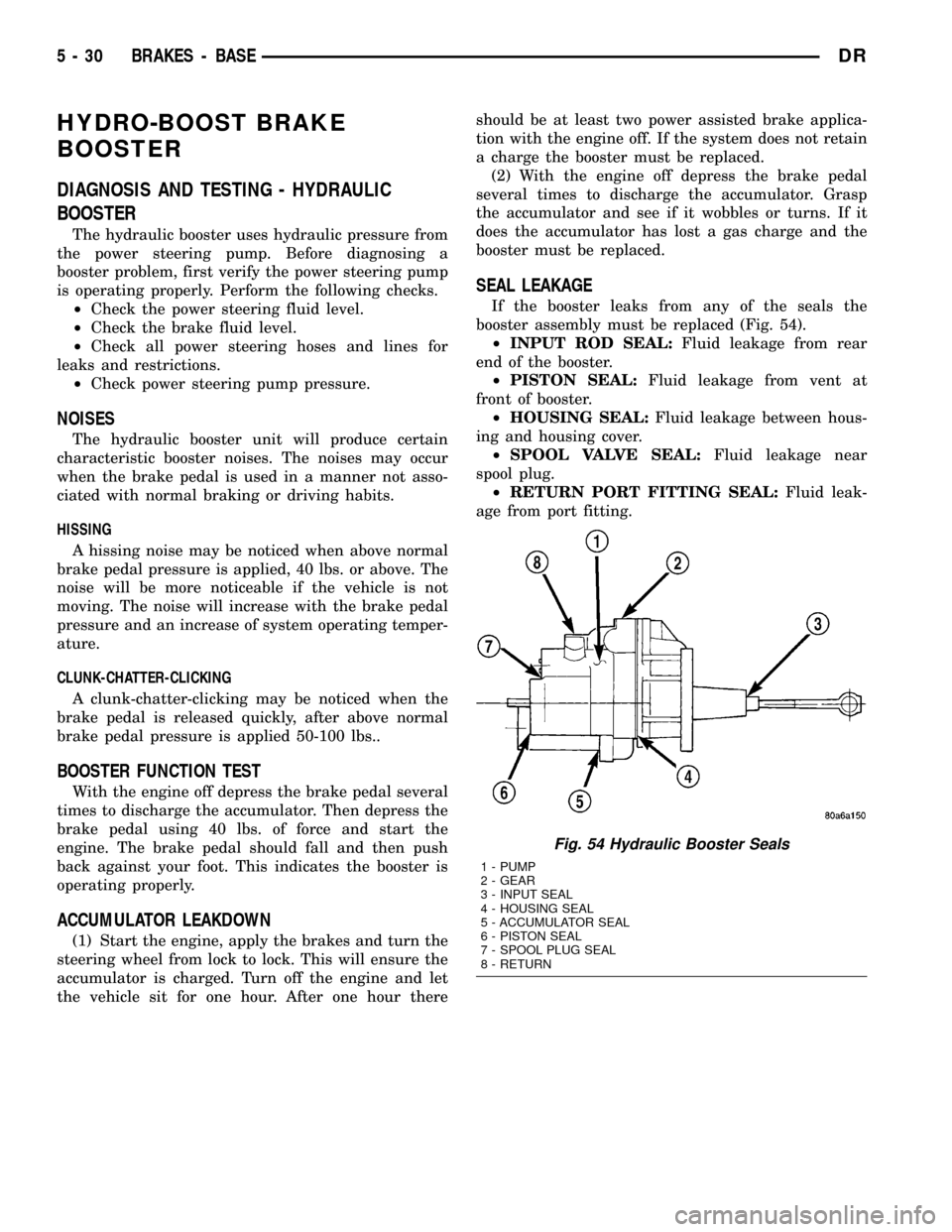

SEAL LEAKAGE

If the booster leaks from any of the seals the

booster assembly must be replaced (Fig. 54).

²INPUT ROD SEAL:Fluid leakage from rear

end of the booster.

²PISTON SEAL:Fluid leakage from vent at

front of booster.

²HOUSING SEAL:Fluid leakage between hous-

ing and housing cover.

²SPOOL VALVE SEAL:Fluid leakage near

spool plug.

²RETURN PORT FITTING SEAL:Fluid leak-

age from port fitting.

Fig. 54 Hydraulic Booster Seals

1 - PUMP

2 - GEAR

3 - INPUT SEAL

4 - HOUSING SEAL

5 - ACCUMULATOR SEAL

6 - PISTON SEAL

7 - SPOOL PLUG SEAL

8 - RETURN

5 - 30 BRAKES - BASEDR