Engine Installation DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1609 of 2627

(3) Remove APPS. Refer to Accelerator Pedal Posi-

tion Sensor (APPS) Removal / Installation.

(4) From inside vehicle, remove cable clip (Fig. 1).

(5) Remove cable housing from dash panel and

pull cable into engine compartment.

(6) Remove cable housing at APPS bracket by

pressing on release tab with a small screwdriver.To

prevent cable housing breakage, press on tab

only enough to release cable from APPS

bracket.

INSTALLATION

3.7L V-6

(1) Slide accelerator cable plastic mount into throt-

tle body mounting bracket. Continue sliding until

release tab (Fig. 34) is aligned to hole in mounting

bracket.

(2) Hold throttle in wide open position. While held

in this position, slide throttle cable pin (Fig. 33) into

throttle body bellcrank.

(3) Push cable housing into rubber grommet and

through opening in dash panel.

(4) From inside vehicle, install metal clip holding

cable to dashpanel (Fig. 1).(5) From inside vehicle, slide throttle cable core

wire into opening (slot) in top of pedal arm.

(6) Push plastic cable retainer (clip) into pedal arm

opening until it snaps in place.

(7) Install air resonator tube to throttle body.

(8) Before starting engine, operate accelerator

pedal to check for any binding.

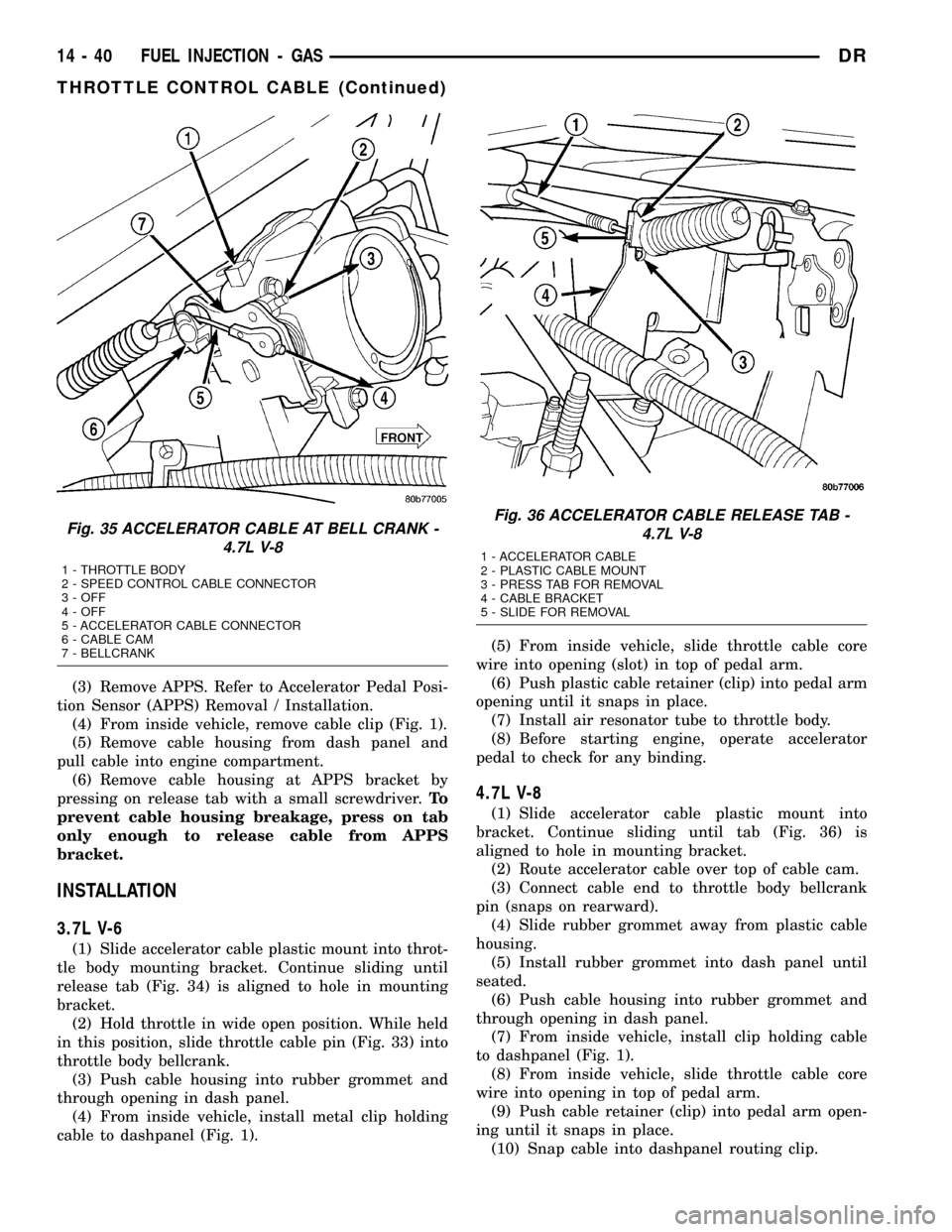

4.7L V-8

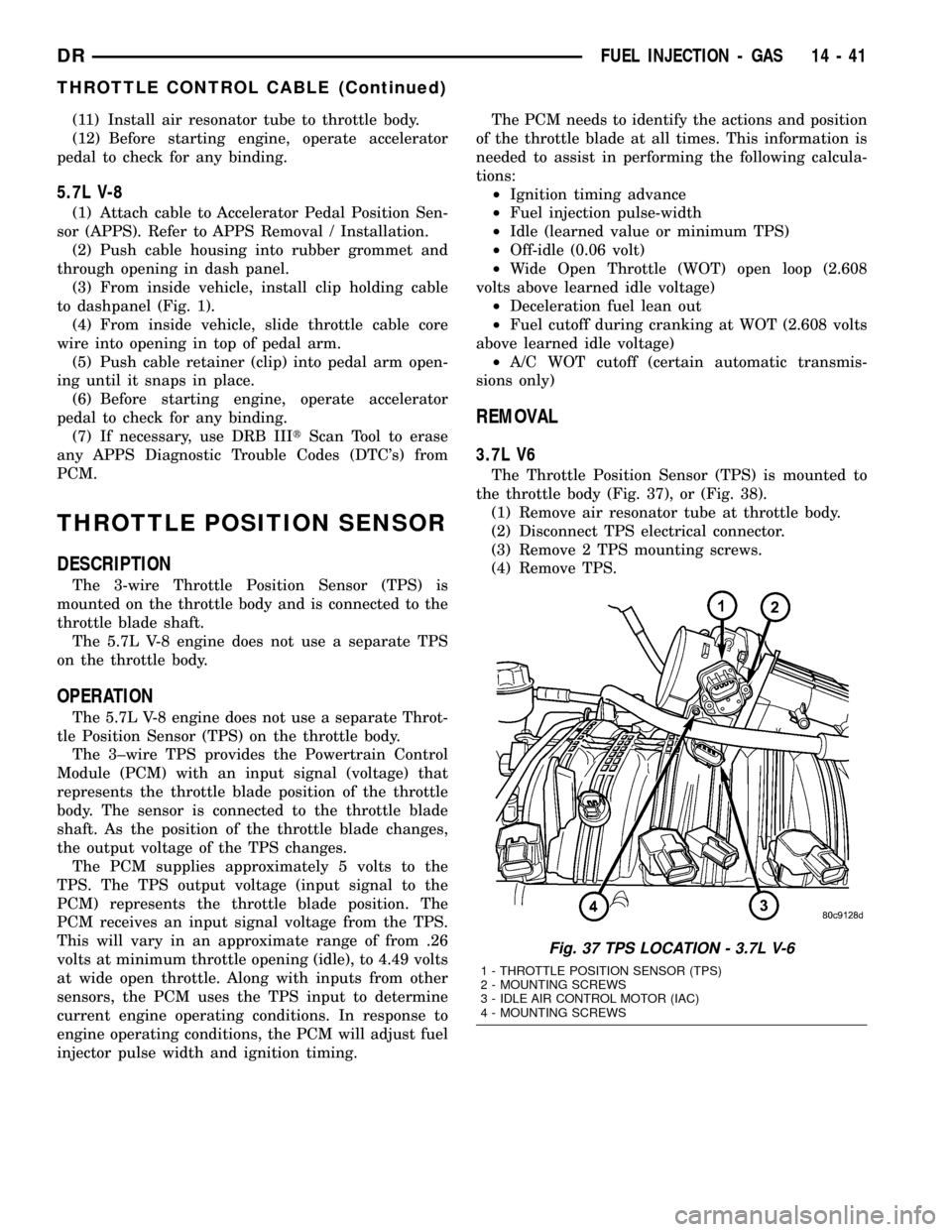

(1) Slide accelerator cable plastic mount into

bracket. Continue sliding until tab (Fig. 36) is

aligned to hole in mounting bracket.

(2) Route accelerator cable over top of cable cam.

(3) Connect cable end to throttle body bellcrank

pin (snaps on rearward).

(4) Slide rubber grommet away from plastic cable

housing.

(5) Install rubber grommet into dash panel until

seated.

(6) Push cable housing into rubber grommet and

through opening in dash panel.

(7) From inside vehicle, install clip holding cable

to dashpanel (Fig. 1).

(8) From inside vehicle, slide throttle cable core

wire into opening in top of pedal arm.

(9) Push cable retainer (clip) into pedal arm open-

ing until it snaps in place.

(10) Snap cable into dashpanel routing clip.

Fig. 35 ACCELERATOR CABLE AT BELL CRANK -

4.7L V-8

1 - THROTTLE BODY

2 - SPEED CONTROL CABLE CONNECTOR

3 - OFF

4 - OFF

5 - ACCELERATOR CABLE CONNECTOR

6 - CABLE CAM

7 - BELLCRANK

Fig. 36 ACCELERATOR CABLE RELEASE TAB -

4.7L V-8

1 - ACCELERATOR CABLE

2 - PLASTIC CABLE MOUNT

3 - PRESS TAB FOR REMOVAL

4 - CABLE BRACKET

5 - SLIDE FOR REMOVAL

14 - 40 FUEL INJECTION - GASDR

THROTTLE CONTROL CABLE (Continued)

Page 1610 of 2627

(11) Install air resonator tube to throttle body.

(12) Before starting engine, operate accelerator

pedal to check for any binding.

5.7L V-8

(1) Attach cable to Accelerator Pedal Position Sen-

sor (APPS). Refer to APPS Removal / Installation.

(2) Push cable housing into rubber grommet and

through opening in dash panel.

(3) From inside vehicle, install clip holding cable

to dashpanel (Fig. 1).

(4) From inside vehicle, slide throttle cable core

wire into opening in top of pedal arm.

(5) Push cable retainer (clip) into pedal arm open-

ing until it snaps in place.

(6) Before starting engine, operate accelerator

pedal to check for any binding.

(7) If necessary, use DRB IIItScan Tool to erase

any APPS Diagnostic Trouble Codes (DTC's) from

PCM.

THROTTLE POSITION SENSOR

DESCRIPTION

The 3-wire Throttle Position Sensor (TPS) is

mounted on the throttle body and is connected to the

throttle blade shaft.

The 5.7L V-8 engine does not use a separate TPS

on the throttle body.

OPERATION

The 5.7L V-8 engine does not use a separate Throt-

tle Position Sensor (TPS) on the throttle body.

The 3±wire TPS provides the Powertrain Control

Module (PCM) with an input signal (voltage) that

represents the throttle blade position of the throttle

body. The sensor is connected to the throttle blade

shaft. As the position of the throttle blade changes,

the output voltage of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS.

This will vary in an approximate range of from .26

volts at minimum throttle opening (idle), to 4.49 volts

at wide open throttle. Along with inputs from other

sensors, the PCM uses the TPS input to determine

current engine operating conditions. In response to

engine operating conditions, the PCM will adjust fuel

injector pulse width and ignition timing.The PCM needs to identify the actions and position

of the throttle blade at all times. This information is

needed to assist in performing the following calcula-

tions:

²Ignition timing advance

²Fuel injection pulse-width

²Idle (learned value or minimum TPS)

²Off-idle (0.06 volt)

²Wide Open Throttle (WOT) open loop (2.608

volts above learned idle voltage)

²Deceleration fuel lean out

²Fuel cutoff during cranking at WOT (2.608 volts

above learned idle voltage)

²A/C WOT cutoff (certain automatic transmis-

sions only)

REMOVAL

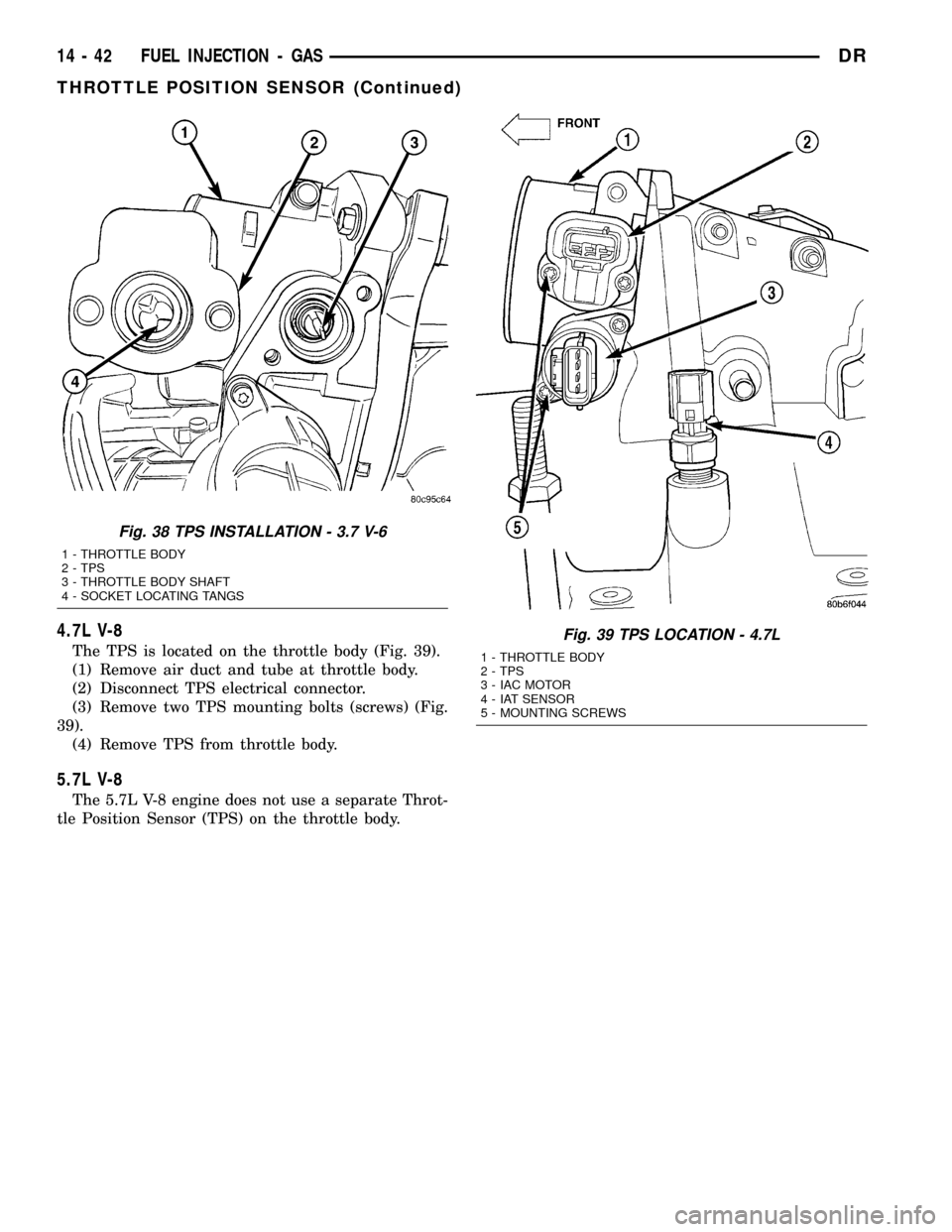

3.7L V6

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 37), or (Fig. 38).

(1) Remove air resonator tube at throttle body.

(2) Disconnect TPS electrical connector.

(3) Remove 2 TPS mounting screws.

(4) Remove TPS.

Fig. 37 TPS LOCATION - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

DRFUEL INJECTION - GAS 14 - 41

THROTTLE CONTROL CABLE (Continued)

Page 1611 of 2627

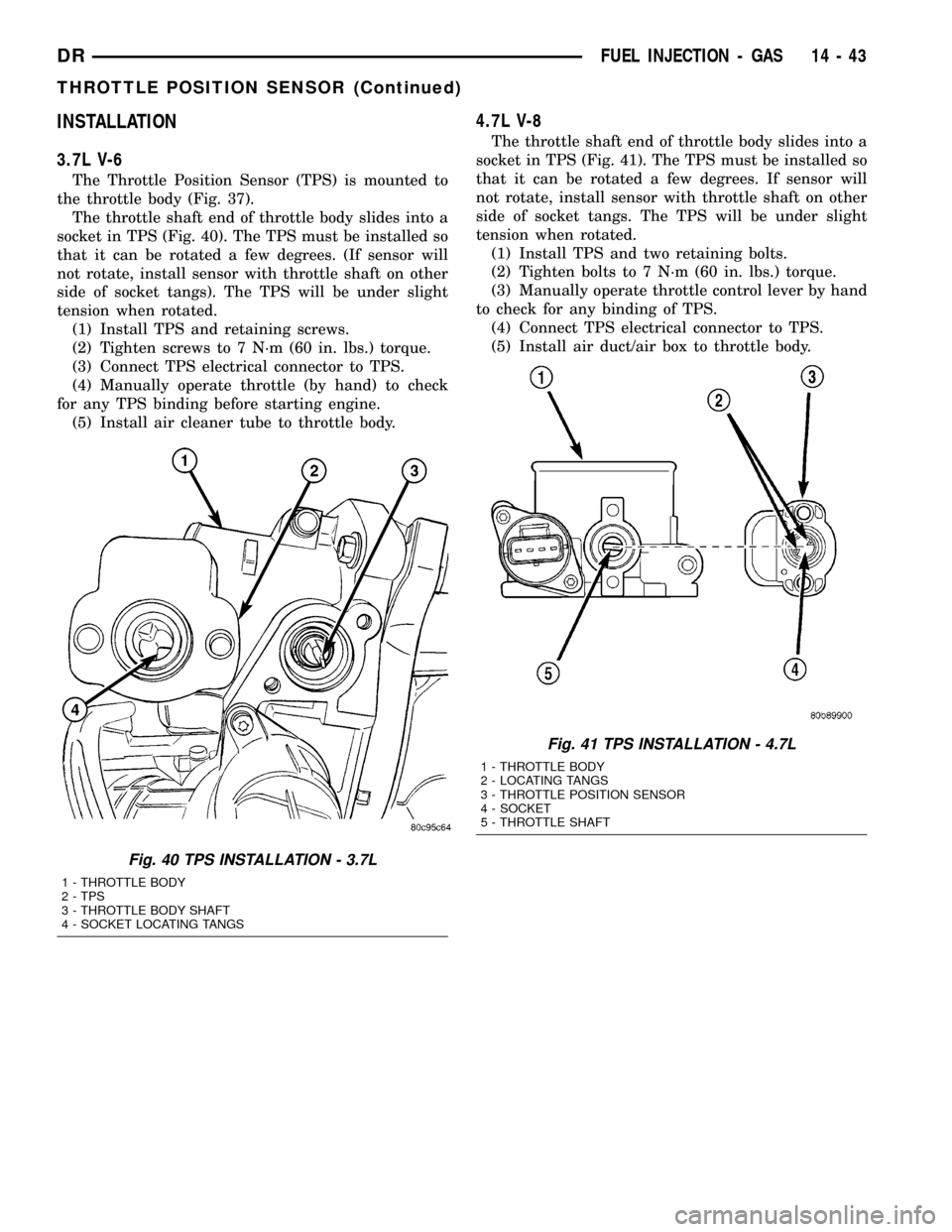

4.7L V-8

The TPS is located on the throttle body (Fig. 39).

(1) Remove air duct and tube at throttle body.

(2) Disconnect TPS electrical connector.

(3) Remove two TPS mounting bolts (screws) (Fig.

39).

(4) Remove TPS from throttle body.

5.7L V-8

The 5.7L V-8 engine does not use a separate Throt-

tle Position Sensor (TPS) on the throttle body.

Fig. 38 TPS INSTALLATION - 3.7 V-6

1 - THROTTLE BODY

2 - TPS

3 - THROTTLE BODY SHAFT

4 - SOCKET LOCATING TANGS

Fig. 39 TPS LOCATION - 4.7L

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR

5 - MOUNTING SCREWS

14 - 42 FUEL INJECTION - GASDR

THROTTLE POSITION SENSOR (Continued)

Page 1612 of 2627

INSTALLATION

3.7L V-6

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 37).

The throttle shaft end of throttle body slides into a

socket in TPS (Fig. 40). The TPS must be installed so

that it can be rotated a few degrees. (If sensor will

not rotate, install sensor with throttle shaft on other

side of socket tangs). The TPS will be under slight

tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.

(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

(5) Install air cleaner tube to throttle body.

4.7L V-8

The throttle shaft end of throttle body slides into a

socket in TPS (Fig. 41). The TPS must be installed so

that it can be rotated a few degrees. If sensor will

not rotate, install sensor with throttle shaft on other

side of socket tangs. The TPS will be under slight

tension when rotated.

(1) Install TPS and two retaining bolts.

(2) Tighten bolts to 7 N´m (60 in. lbs.) torque.

(3) Manually operate throttle control lever by hand

to check for any binding of TPS.

(4) Connect TPS electrical connector to TPS.

(5) Install air duct/air box to throttle body.

Fig. 40 TPS INSTALLATION - 3.7L

1 - THROTTLE BODY

2 - TPS

3 - THROTTLE BODY SHAFT

4 - SOCKET LOCATING TANGS

Fig. 41 TPS INSTALLATION - 4.7L

1 - THROTTLE BODY

2 - LOCATING TANGS

3 - THROTTLE POSITION SENSOR

4 - SOCKET

5 - THROTTLE SHAFT

DRFUEL INJECTION - GAS 14 - 43

THROTTLE POSITION SENSOR (Continued)

Page 1613 of 2627

FUEL DELIVERY - DIESEL

TABLE OF CONTENTS

page page

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM.....45

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER

DRAINING AT FUEL FILTER..............47

STANDARD PROCEDURES - CLEANING

FUEL SYSTEM PARTS.................47

STANDARD PROCEDURE - FUEL SYSTEM

PRIMING............................47

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL . 48

TORQUE - FUEL SYSTEM - DIESEL

ENGINE.............................48

SPECIAL TOOLS

DIESEL FUEL SYSTEM.................49

FUEL FILTER / WATER SEPARATOR

DESCRIPTION.........................50

OPERATION...........................50

REMOVAL.............................50

INSTALLATION.........................50

FUEL HEATER

DESCRIPTION.........................51

OPERATION...........................51

DIAGNOSIS AND TESTING - FUEL HEATER . . . 52

REMOVAL

REMOVAL/INSTALLATION...............52

FUEL HEATER RELAY

DESCRIPTION.........................52

OPERATION...........................52

REMOVAL.............................52

INSTALLATION.........................53

FUEL INJECTION PUMP

DESCRIPTION.........................53

OPERATION...........................53

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING........................53

REMOVAL.............................54

INSTALLATION.........................55

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION.........................57

OPERATION...........................57

REMOVAL

REMOVAL/INSTALLATION...............57FUEL LINES

DESCRIPTION.........................57

OPERATION...........................57

DIAGNOSIS AND TESTING - HIGH-

PRESSURE FUEL LINE LEAKS...........58

REMOVAL.............................58

INSTALLATION.........................60

FUEL PRESSURE SENSOR

DESCRIPTION.........................60

OPERATION...........................60

REMOVAL.............................60

INSTALLATION.........................61

FUEL PRESSURE LIMITING VALVE

DESCRIPTION.........................61

OPERATION...........................61

REMOVAL.............................61

INSTALLATION.........................61

FUEL TANK

DESCRIPTION - DIESEL..................62

REMOVAL - DIESEL.....................62

INSTALLATION - DIESEL.................62

FUEL TANK MODULE

DESCRIPTION.........................63

OPERATION...........................63

REMOVAL.............................63

INSTALLATION.........................64

FUEL TRANSFER PUMP

DESCRIPTION.........................64

OPERATION...........................64

REMOVAL.............................64

INSTALLATION.........................65

CASCADE OVERFLOW VALVE

DESCRIPTION.........................66

OPERATION...........................66

REMOVAL

REMOVAL/INSTALLATION...............66

WATER IN FUEL SENSOR

DESCRIPTION.........................66

OPERATION...........................66

REMOVAL.............................66

FUEL DRAIN CIRCUIT

OPERATION...........................67

14 - 44 FUEL DELIVERY - DIESELDR

Page 1619 of 2627

FUEL FILTER / WATER

SEPARATOR

DESCRIPTION

The fuel filter/water separator assembly is located

on left side of engine above the starter motor. The

assembly also includes the fuel heater, Water-In-Fuel

(WIF) sensor, and fuel transfer pump.

OPERATION

The fuel filter/water separator protects the fuel

injection pump by removing water and contaminants

from the fuel. The construction of the filter/separator

allows fuel to pass through it, but helps prevent

moisture (water) from doing so. Moisture collects at

the bottom of the canister.

Refer to the maintenance schedules in the owners

manual for the recommended fuel filter replacement

intervals.

For draining of water from canister, refer to Fuel

Filter/Water Separator Removal/Installation section.

A Water-In-Fuel (WIF) sensor is attached to the

side of fuel filter housing. Refer to Water-In-Fuel

Sensor Description/Operation.

The fuel heater is installed into the top of the fil-

ter/separator housing. Refer to Fuel Heater Descrip-

tion/Operation.

REMOVAL

Refer to maintenance schedules in this manual, or

the owners manual for recommended fuel filter

replacement intervals.

Draining water from fuel filter/water separa-

tor housing:

The housing drain valve (Fig. 3) serves two pur-

poses. One is topartiallythe drain filter housing of

excess water. The other is tocompletelythe drain

housing for fuel filter, drain valve, heater element, ,

water-in-fuel sensor replacement or transfer pump

replacement.

The filter housing should be partially drained

whenever the water-in-fuel warning lamp remains

illuminated. (Note that lamp will be illuminated for

approximately two seconds when ignition key is ini-

tially placed in ON position for a bulb check).(1) A drain hose (Fig. 3) is located at the bottom of

drain valve. Place drain pan under drain hose.

(2)With engine not running,rotate drain valve

handle counter-clockwise (rearward) to OPEN

(DRAIN) position. Hold drain valve open until all

water and contaminants have been removed and

clean fuel exits.

(3) If drain valve, fuel heater element or Water-In-

Fuel (WIF) sensor is being replaced, drain housing

completely. Dispose of mixture in drain pan according

to applicable regulations.

(4) After draining operation, rotate valve handle

clockwise (forward) to the CLOSE position.

(5)Fuel Filter Replacement:The fuel filter is

located inside of the fuel filter housing.

(a) Clean all debris from around canister.

(b) Remove filter lid (Fig. 4) using a socket.

Attach socket to large hex on top of lid (Fig. 4).

Rotate counter-clockwise for removal. Remove

o-ring. Discard o-ring.

(c) Remove filter element by twisting element

sideways from filter lid.

(6)Water-In-Fuel (WIF) Sensor Replacement:

The WIF sensor is located on the side of the fuel fil-

ter housing (Fig. 3).

(a) Disconnect electrical connector at sensor.

(b) Clean area around sensor.

(c) Remove sensor by rotating counter-clockwise.

(d) Check condition of sensor o-ring. Replace if

damaged.

(7)Fuel Heater Element Replacement:The

heater element is located in the fuel filter housing

(Fig. 3).

(a) Remove fuel filter. See previous steps.

(b) Disconnect electrical connector.

(c) Remove two T-15 Torx head mounting screws

from fuel heater element.

(d) Remove fuel heater.

(8)Drain Valve Replacement:The drain valve

assembly is located on the side of the fuel filter hous-

ing (Fig. 3).

(a) Disconnect drain hose from the fuel drain

valve.

(b) Remove 4 drain valve mounting screws (T-15

Torx head).

(c) Remove drain valve from filter housing.

INSTALLATION

Refer to maintenance schedules for recommended

fuel filter replacement intervals.

(1) Thoroughly clean inside of filter housing, filter

cap and all related components.

(2)Fuel Filter:

(a)The engine has a self-priming low-pres-

sure fuel system. Refer to Standard Proce-

dures-Fuel System Priming.

ENGINE ROTATING (BARRING) TOOL - #7471B

(ALSO PART OF KIT #6860)

14 - 50 FUEL DELIVERY - DIESELDR

FUEL DELIVERY - DIESEL (Continued)

Page 1621 of 2627

The fuel heater element and fuel heater relay

are not computer controlled.

The heater element operates on 12 volts, 300 watts

at 0 degrees F.

DIAGNOSIS AND TESTING - FUEL HEATER

The fuel heater is used to prevent diesel fuel from

waxing during cold weather operation.

NOTE: The fuel heater element, fuel heater relay

and fuel heater temperature sensor are not con-

trolled by the Engine Control Module (ECM).

A malfunctioning fuel heater can cause a wax

build-up in the fuel filter/water separator. Wax

build-up in the filter/separator can cause engine

starting problems and prevent the engine from rev-

ving up. It can also cause blue or white fog-like

exhaust. If the heater is not operating in cold tem-

peratures, the engine may not operate due to fuel

waxing.

The fuel heater assembly is located on the side of

fuel filter housing.

The heater assembly is equipped with a built-in

fuel temperature sensor (thermostat) that senses fuel

temperature. When fuel temperature drops below 45

degrees 8 degrees F, the sensor allows current to

flow to built-in heater element to warm fuel. When

fuel temperature rises above 75 degrees 8 degrees

F, the sensor stops current flow to heater element

(circuit is open).

Voltage to operate fuel heater element is supplied

from ignition switch, through fuel heater relay (also

refer to Fuel Heater Relay), to fuel temperature sen-

sor and on to fuel heater element.

The heater element operates on 12 volts, 300 watts

at 0 degrees F. As temperature increases, power

requirements decrease.

A minimum of 7 volts is required to operate the

fuel heater. The resistance value of the heater ele-

ment is less than 1 ohm (cold) and up to 1000 ohms

warm.

TESTING

(1) Disconnect electrical connector from thermostat

(Fig. 3).

Ambient temperature must be below the circuit

close temperature. If necessary, induce this ambient

temperature by placing ice packs on thermostat to

produce an effective ambient temperature below cir-

cuit close temperature.

Measure resistance across two pins. Operating

range is 0.3 Ð 0.45 Ohms.

(2) If resistance is out of range, remove thermostat

and check resistance across terminal connections of

heater. The heater can be checked at room tempera-

ture. Operating range is 0.3 - 0.45 Ohms.(3) Replace heater if resistance is not within oper-

ating range.

(4) If heater is within operating range, replace

heater thermostat.

REMOVAL

REMOVAL/INSTALLATION

The fuel heater/element/sensor assembly is located

inside of the fuel filter housing. Refer to Fuel Filter/

Water Separator Removal/Installation for procedures.

FUEL HEATER RELAY

DESCRIPTION

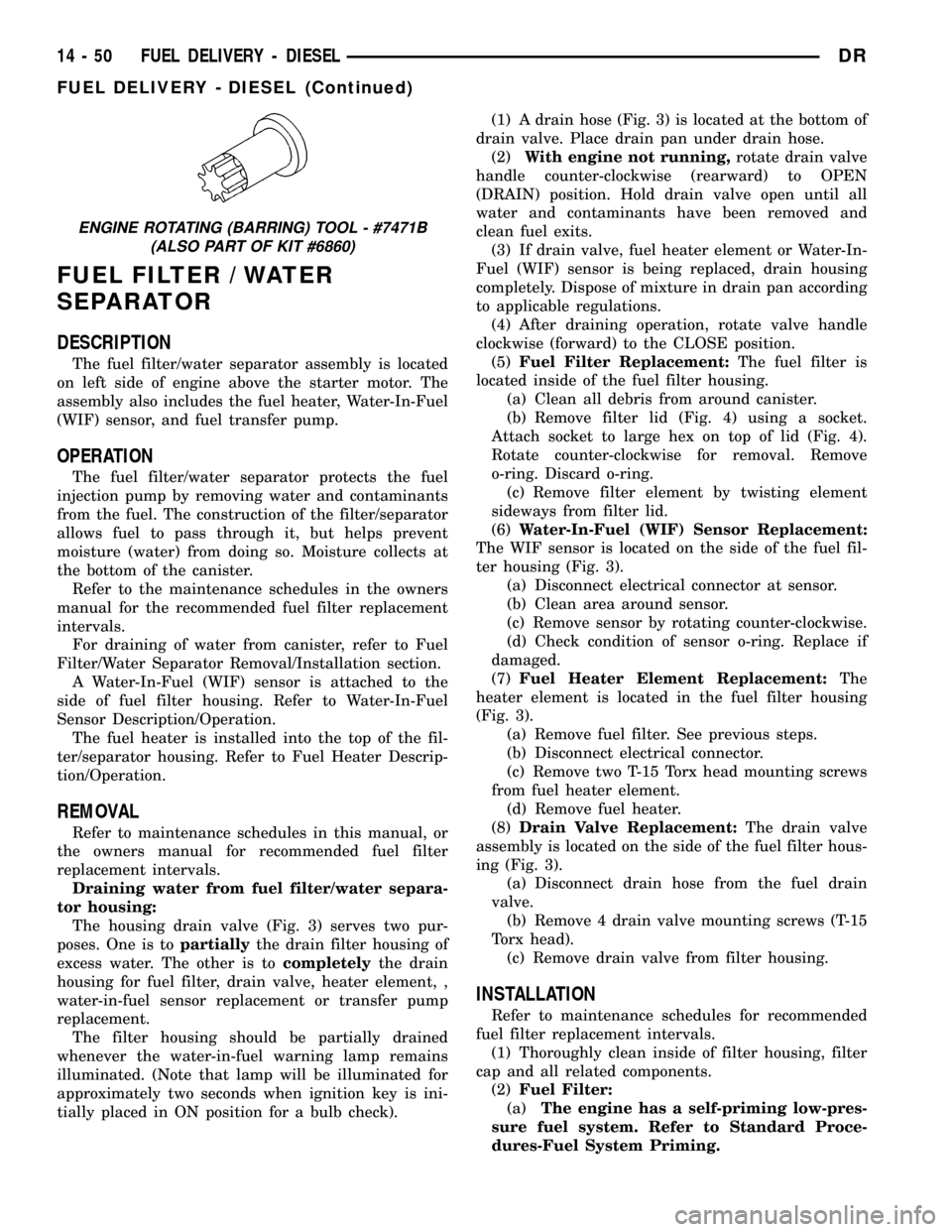

The fuel heater relay is located in Power Distribu-

tion Center (PDC) (Fig. 5). Refer to label on inside of

PDC cover for relay location.

OPERATION

Battery voltage to operate the fuel heater element

is supplied from the ignition switch through the fuel

heater relay.The fuel heater element and fuel

heater relay are not computer controlled.

REMOVAL

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 6). Refer to label under

PDC cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

Fig. 5 POWER DISTRIBUTION CENTER LOCATION

1 - CLIP

2 - BATTERY

3 - TRAY

4 - NEGATIVE CABLE

5 - POSITIVE CABLE

6 - CLIP

7 - FENDER INNER SHIELD

8 - POWER DISTRIBUTION CENTER

14 - 52 FUEL DELIVERY - DIESELDR

FUEL HEATER (Continued)

Page 1622 of 2627

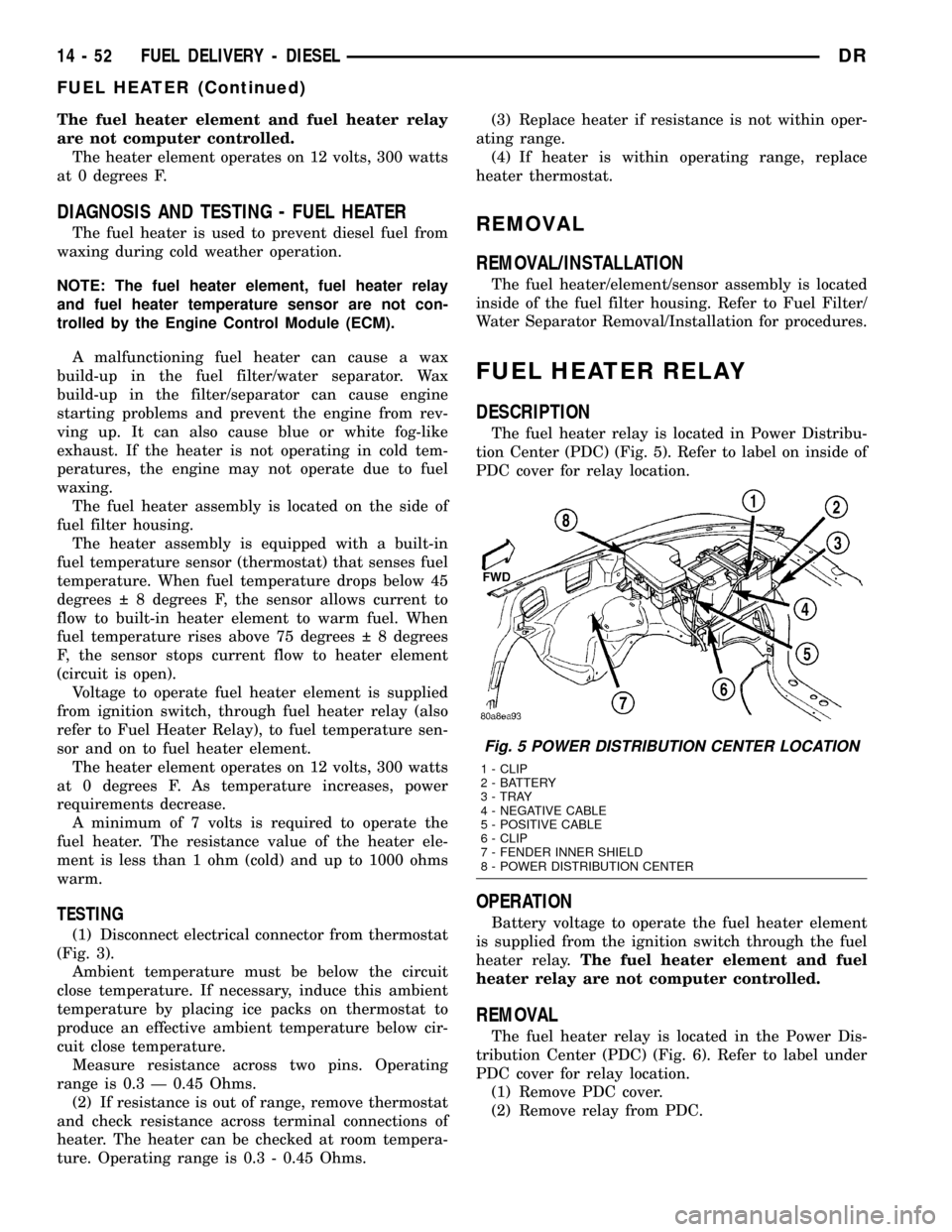

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 6). Refer to label under

PDC cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

FUEL INJECTION PUMP

DESCRIPTION

A Robert Bosch high-pressure fuel injection pump

is used. The pump is attached to the back of the tim-

ing gear cover at the left / rear side of the engine.

OPERATION

The fuel injection pump supplies high pressure to

the fuel rail independent of engine speed. This high

pressure is then accumulated in the fuel rail. High

pressure fuel is constantly supplied to the injectors

by the fuel rail. The Engine Control Module (ECM)

controls the fueling and timing of the engine by actu-

ating the injectors.

Fuel enters the system from the electric fuel trans-

fer (lift) pump, which is attached to the fuel filter

assembly. Fuel is forced through the fuel filter ele-

ment and then enters the Fuel Pump/Gear Pump,

which is attached to the rear of the fuel injection

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FCA based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail provides the actual fuel pressure. When the

actuator is opened, the maximum amount of fuel is

being supplied to the fuel injection pump. Any fuel

that does not enter the injection pump is directed to

the cascade overflow valve. The cascade overflow

valve regulates how much excess fuel is used for

lubrication of the pump and how much is returned to

the tank through the drain manifold.

Fuel entering the injection pump is pressurized to

between 300-1600 bar (4351-23206 psi) by three

radial pumping chambers. The pressurized fuel is

then supplied to the fuel rail.

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING

With the Bosch injection pump, there are no

mechanical adjustments needed or necessary to

accomplish fuel injection timing. All timing and fuel

adjustments are electrically made by the engine

mounted Engine Control Module (ECM).

Fig. 6 POWER DISTRIBUTION CENTER LOCATION

1 - CLIP

2 - BATTERY

3 - TRAY

4 - NEGATIVE CABLE

5 - POSITIVE CABLE

6 - CLIP

7 - FENDER INNER SHIELD

8 - POWER DISTRIBUTION CENTER

DRFUEL DELIVERY - DIESEL 14 - 53

FUEL HEATER RELAY (Continued)

Page 1624 of 2627

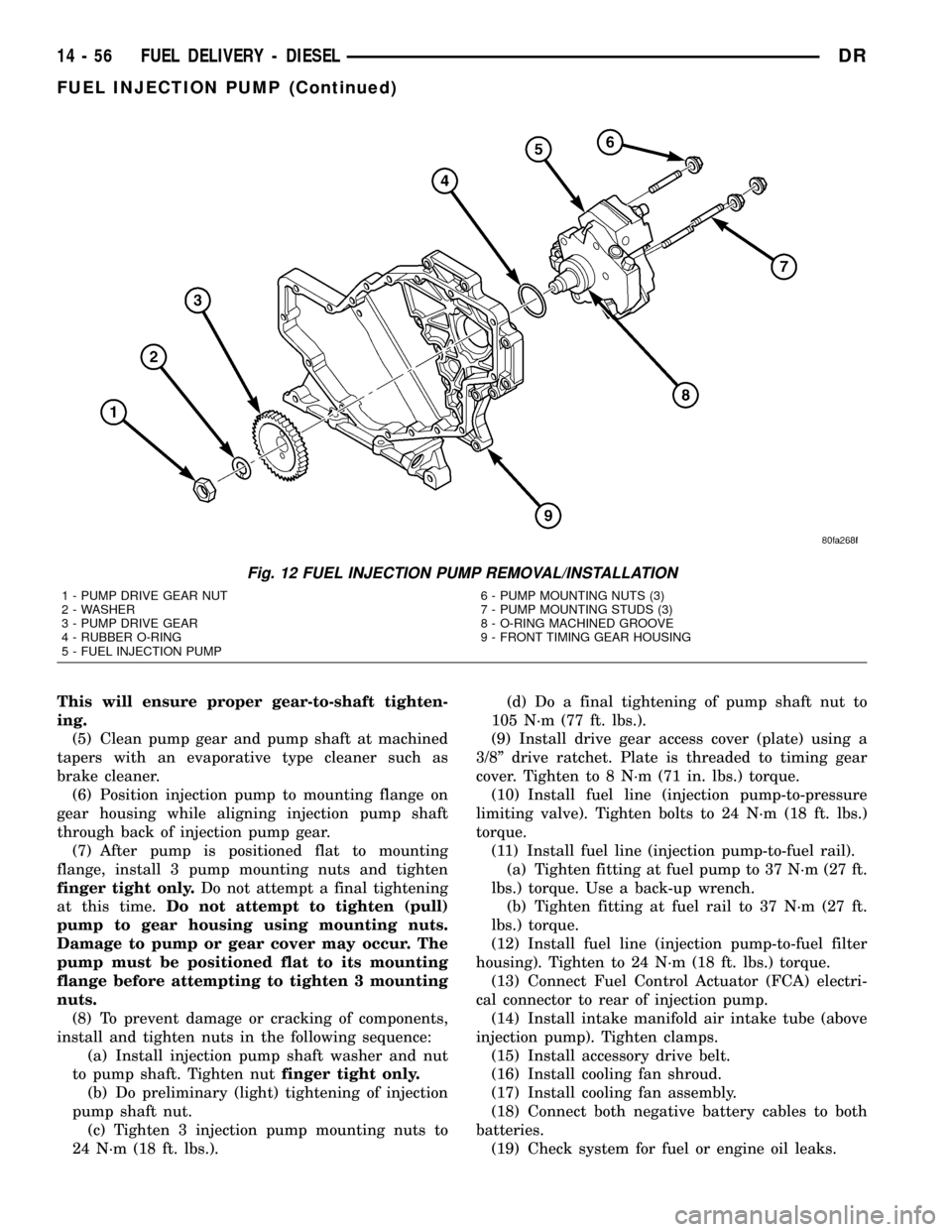

INSTALLATION

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Inspect pump mounting surfaces at pump and

mounting flange for nicks, cuts or damage. Inspect

o-ring surfaces for nicks, cuts or damage.

(2) Clean injection pump mounting flange at gear

housing. Also clean front of injection pump.

(3) Install new rubber o-ring into machined groove

(Fig. 12) at pump mounting area.

(4) Apply clean engine oilto injection pump

o-ring only.

The machined tapers on both injection pump

shaft and injection pump gear must be abso-

lutely dry, clean and free of any dirt or oil film.

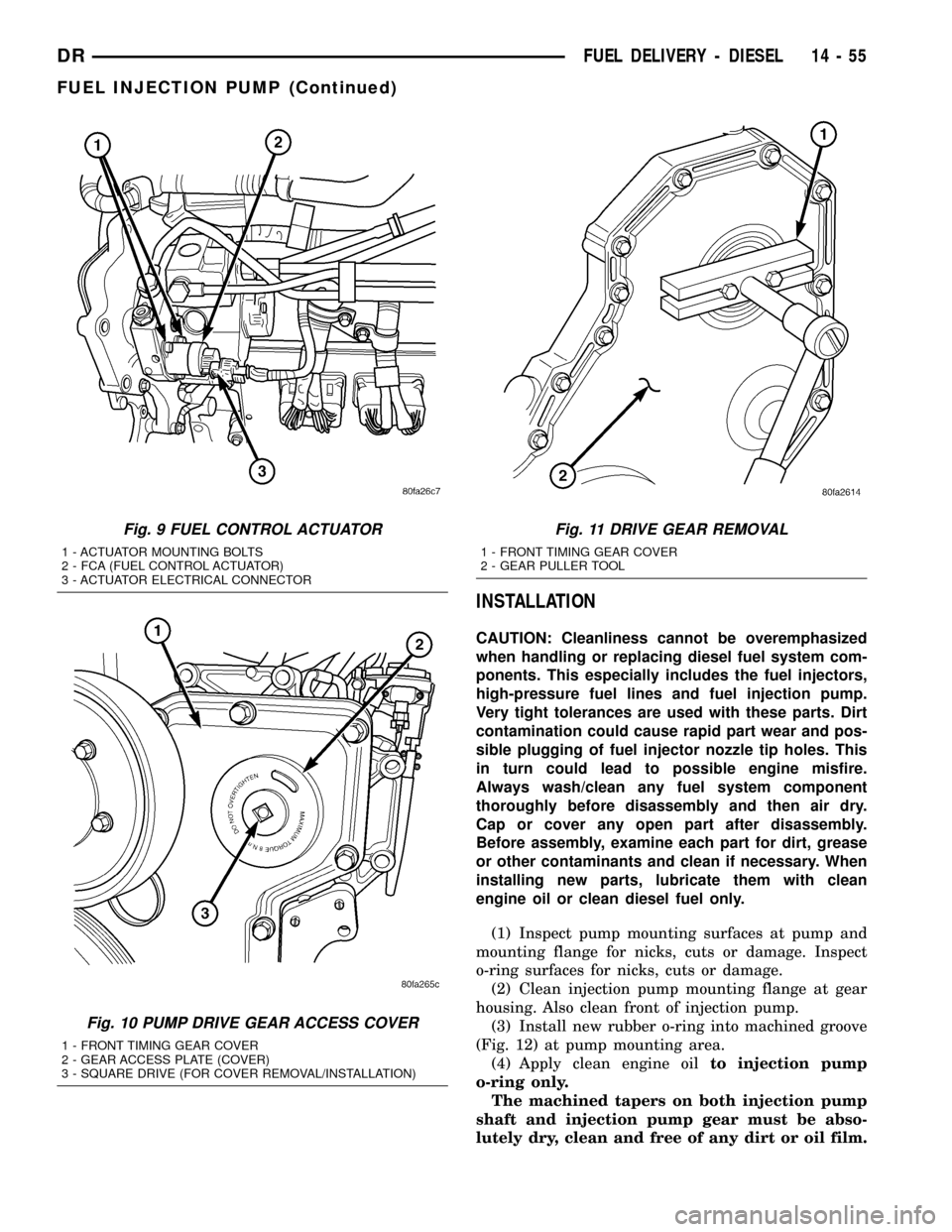

Fig. 9 FUEL CONTROL ACTUATOR

1 - ACTUATOR MOUNTING BOLTS

2 - FCA (FUEL CONTROL ACTUATOR)

3 - ACTUATOR ELECTRICAL CONNECTOR

Fig. 10 PUMP DRIVE GEAR ACCESS COVER

1 - FRONT TIMING GEAR COVER

2 - GEAR ACCESS PLATE (COVER)

3 - SQUARE DRIVE (FOR COVER REMOVAL/INSTALLATION)

Fig. 11 DRIVE GEAR REMOVAL

1 - FRONT TIMING GEAR COVER

2 - GEAR PULLER TOOL

DRFUEL DELIVERY - DIESEL 14 - 55

FUEL INJECTION PUMP (Continued)

Page 1625 of 2627

This will ensure proper gear-to-shaft tighten-

ing.

(5) Clean pump gear and pump shaft at machined

tapers with an evaporative type cleaner such as

brake cleaner.

(6) Position injection pump to mounting flange on

gear housing while aligning injection pump shaft

through back of injection pump gear.

(7) After pump is positioned flat to mounting

flange, install 3 pump mounting nuts and tighten

finger tight only.Do not attempt a final tightening

at this time.Do not attempt to tighten (pull)

pump to gear housing using mounting nuts.

Damage to pump or gear cover may occur. The

pump must be positioned flat to its mounting

flange before attempting to tighten 3 mounting

nuts.

(8) To prevent damage or cracking of components,

install and tighten nuts in the following sequence:

(a) Install injection pump shaft washer and nut

to pump shaft. Tighten nutfinger tight only.

(b) Do preliminary (light) tightening of injection

pump shaft nut.

(c) Tighten 3 injection pump mounting nuts to

24 N´m (18 ft. lbs.).(d) Do a final tightening of pump shaft nut to

105 N´m (77 ft. lbs.).

(9) Install drive gear access cover (plate) using a

3/8º drive ratchet. Plate is threaded to timing gear

cover. Tighten to 8 N´m (71 in. lbs.) torque.

(10) Install fuel line (injection pump-to-pressure

limiting valve). Tighten bolts to 24 N´m (18 ft. lbs.)

torque.

(11) Install fuel line (injection pump-to-fuel rail).

(a) Tighten fitting at fuel pump to 37 N´m (27 ft.

lbs.) torque. Use a back-up wrench.

(b) Tighten fitting at fuel rail to 37 N´m (27 ft.

lbs.) torque.

(12) Install fuel line (injection pump-to-fuel filter

housing). Tighten to 24 N´m (18 ft. lbs.) torque.

(13) Connect Fuel Control Actuator (FCA) electri-

cal connector to rear of injection pump.

(14) Install intake manifold air intake tube (above

injection pump). Tighten clamps.

(15) Install accessory drive belt.

(16) Install cooling fan shroud.

(17) Install cooling fan assembly.

(18) Connect both negative battery cables to both

batteries.

(19) Check system for fuel or engine oil leaks.

Fig. 12 FUEL INJECTION PUMP REMOVAL/INSTALLATION

1 - PUMP DRIVE GEAR NUT

2 - WASHER

3 - PUMP DRIVE GEAR

4 - RUBBER O-RING

5 - FUEL INJECTION PUMP6 - PUMP MOUNTING NUTS (3)

7 - PUMP MOUNTING STUDS (3)

8 - O-RING MACHINED GROOVE

9 - FRONT TIMING GEAR HOUSING

14 - 56 FUEL DELIVERY - DIESELDR

FUEL INJECTION PUMP (Continued)