spark plugs DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 20 of 2627

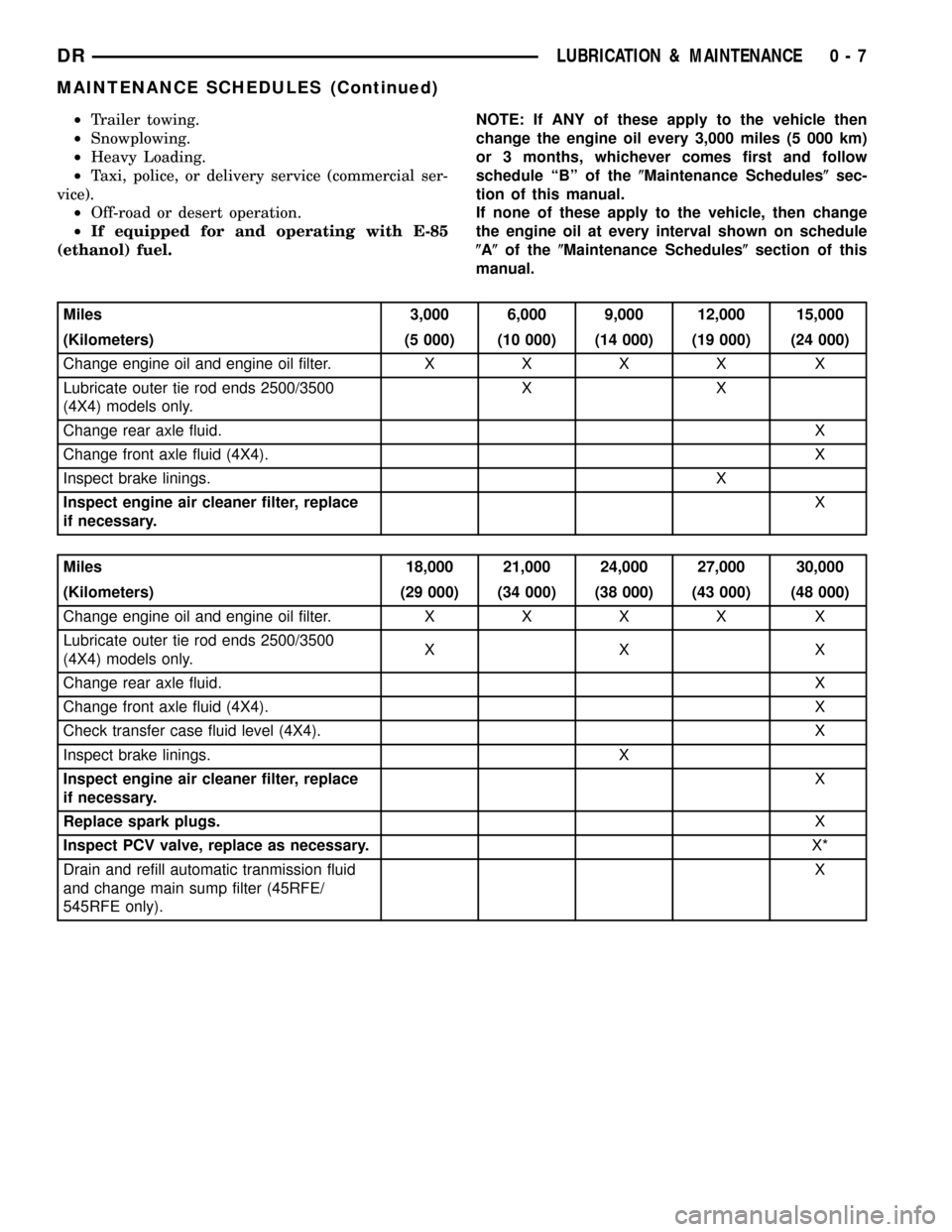

²Trailer towing.

²Snowplowing.

²Heavy Loading.

²Taxi, police, or delivery service (commercial ser-

vice).

²Off-road or desert operation.

²If equipped for and operating with E-85

(ethanol) fuel.NOTE: If ANY of these apply to the vehicle then

change the engine oil every 3,000 miles (5 000 km)

or 3 months, whichever comes first and follow

schedule ªBº of the(Maintenance Schedules(sec-

tion of this manual.

If none of these apply to the vehicle, then change

the engine oil at every interval shown on schedule

(A(of the(Maintenance Schedules(section of this

manual.

Miles 3,000 6,000 9,000 12,000 15,000

(Kilometers) (5 000) (10 000) (14 000) (19 000) (24 000)

Change engine oil and engine oil filter.XXXX X

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XX

Change rear axle fluid.X

Change front axle fluid (4X4).X

Inspect brake linings.X

Inspect engine air cleaner filter, replace

if necessary.X

Miles 18,000 21,000 24,000 27,000 30,000

(Kilometers) (29 000) (34 000) (38 000) (43 000) (48 000)

Change engine oil and engine oil filter.XXXX X

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XX X

Change rear axle fluid.X

Change front axle fluid (4X4).X

Check transfer case fluid level (4X4). X

Inspect brake linings. X

Inspect engine air cleaner filter, replace

if necessary.X

Replace spark plugs.X

Inspect PCV valve, replace as necessary.X*

Drain and refill automatic tranmission fluid

and change main sump filter (45RFE/

545RFE only).X

DRLUBRICATION & MAINTENANCE 0 - 7

MAINTENANCE SCHEDULES (Continued)

Page 21 of 2627

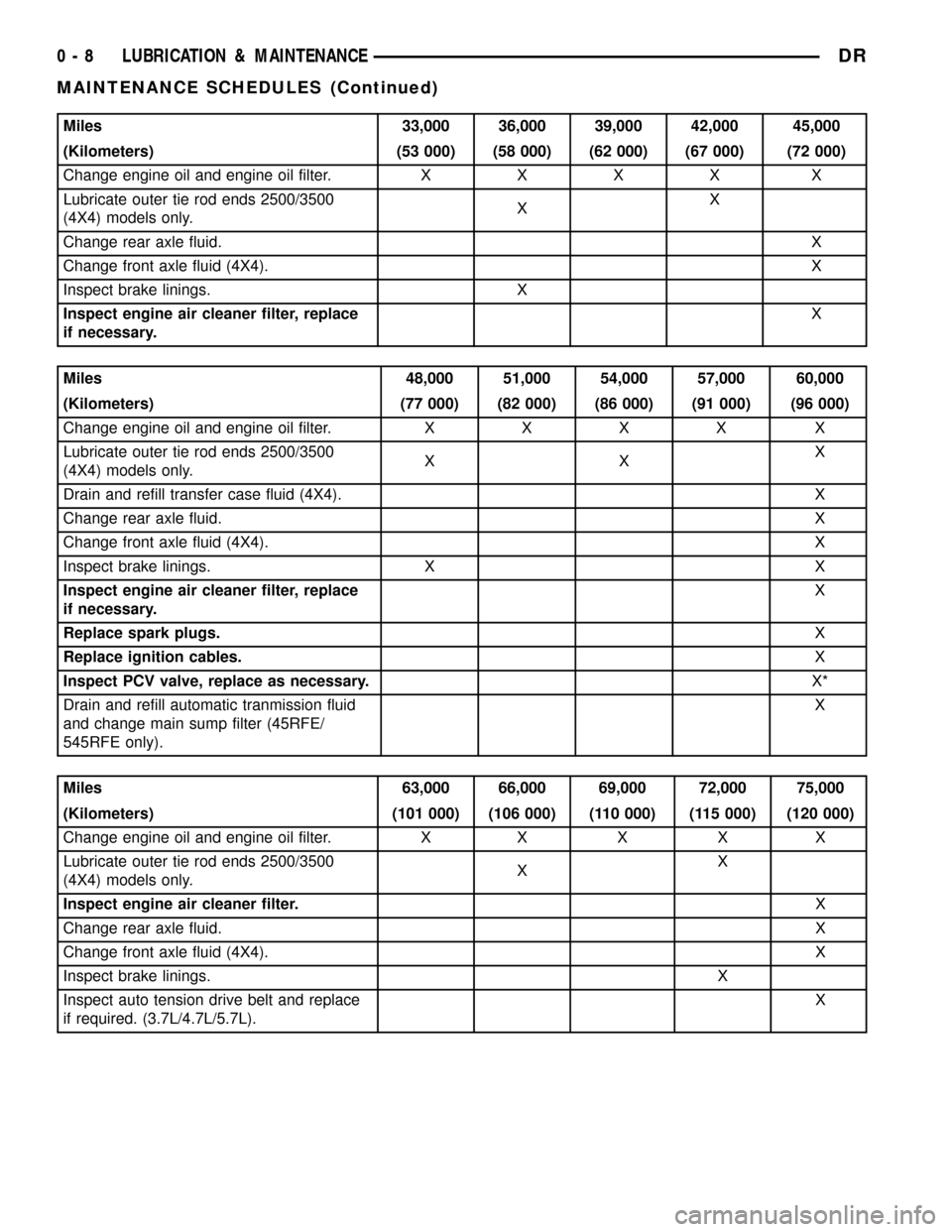

Miles 33,000 36,000 39,000 42,000 45,000

(Kilometers) (53 000) (58 000) (62 000) (67 000) (72 000)

Change engine oil and engine oil filter.XXXX X

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XX

Change rear axle fluid.X

Change front axle fluid (4X4).X

Inspect brake linings. X

Inspect engine air cleaner filter, replace

if necessary.X

Miles 48,000 51,000 54,000 57,000 60,000

(Kilometers) (77 000) (82 000) (86 000) (91 000) (96 000)

Change engine oil and engine oil filter.XXXX X

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XXX

Drain and refill transfer case fluid (4X4). X

Change rear axle fluid.X

Change front axle fluid (4X4).X

Inspect brake linings. X X

Inspect engine air cleaner filter, replace

if necessary.X

Replace spark plugs.X

Replace ignition cables.X

Inspect PCV valve, replace as necessary.X*

Drain and refill automatic tranmission fluid

and change main sump filter (45RFE/

545RFE only).X

Miles 63,000 66,000 69,000 72,000 75,000

(Kilometers) (101 000) (106 000) (110 000) (115 000) (120 000)

Change engine oil and engine oil filter. X X X X X

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XX

Inspect engine air cleaner filter.X

Change rear axle fluid.X

Change front axle fluid (4X4).X

Inspect brake linings.X

Inspect auto tension drive belt and replace

if required. (3.7L/4.7L/5.7L).X

0 - 8 LUBRICATION & MAINTENANCEDR

MAINTENANCE SCHEDULES (Continued)

Page 22 of 2627

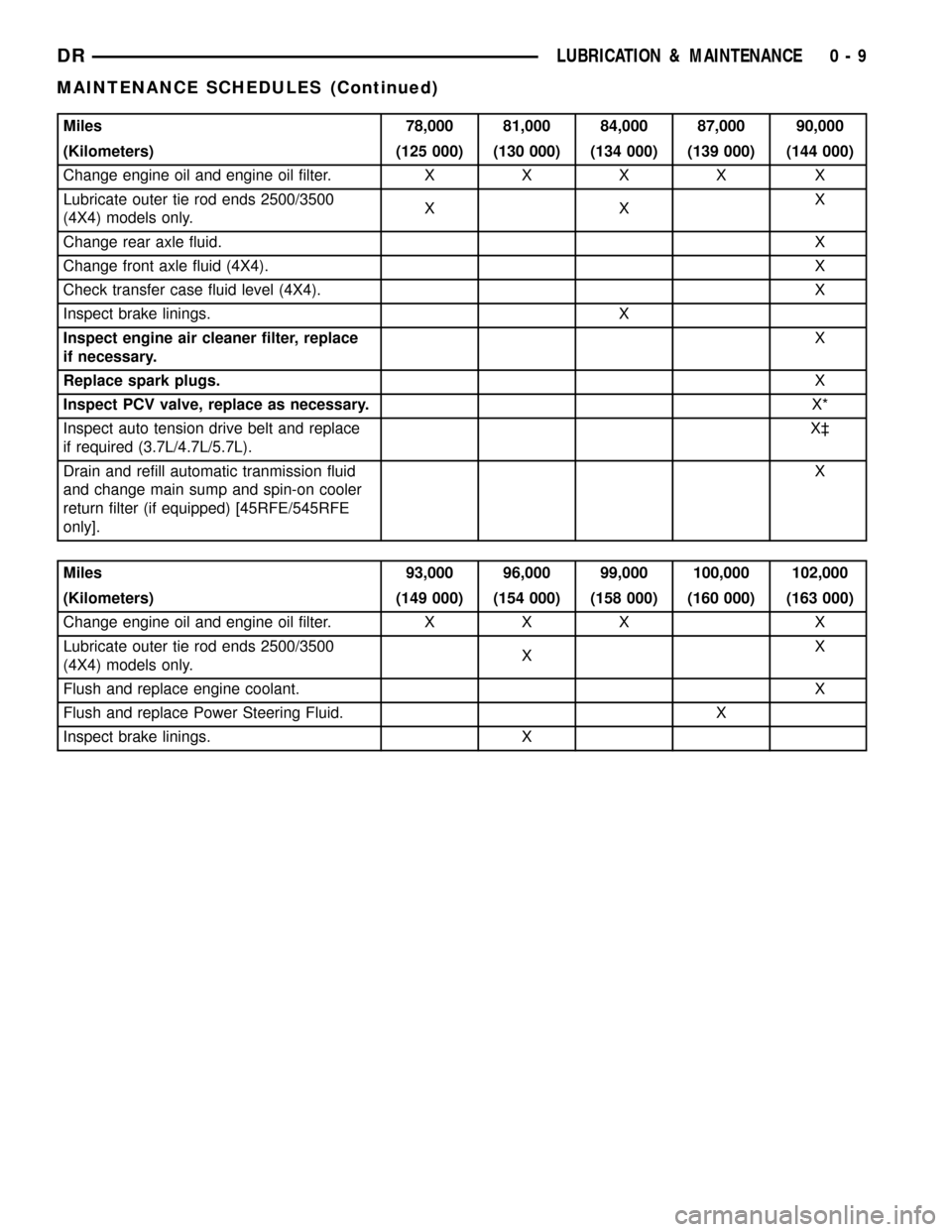

Miles 78,000 81,000 84,000 87,000 90,000

(Kilometers) (125 000) (130 000) (134 000) (139 000) (144 000)

Change engine oil and engine oil filter.XXXX X

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XXX

Change rear axle fluid.X

Change front axle fluid (4X4).X

Check transfer case fluid level (4X4). X

Inspect brake linings. X

Inspect engine air cleaner filter, replace

if necessary.X

Replace spark plugs.X

Inspect PCV valve, replace as necessary.X*

Inspect auto tension drive belt and replace

if required (3.7L/4.7L/5.7L).X³

Drain and refill automatic tranmission fluid

and change main sump and spin-on cooler

return filter (if equipped) [45RFE/545RFE

only].X

Miles 93,000 96,000 99,000 100,000 102,000

(Kilometers) (149 000) (154 000) (158 000) (160 000) (163 000)

Change engine oil and engine oil filter. X X X X

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XX

Flush and replace engine coolant.X

Flush and replace Power Steering Fluid. X

Inspect brake linings. X

DRLUBRICATION & MAINTENANCE 0 - 9

MAINTENANCE SCHEDULES (Continued)

Page 23 of 2627

Miles 105,000 108,000 111,000 114,000 117,000 120,000

(Kilometers) (168 000) (173 000) (178 000) (182 000) (187 000) (192 000)

Change engine oil and engine

oil filter.XXXXX X

Lubricate outer tie rod ends

2500/3500 (4X4) models only.XXX

Drain and refill transfer case

fluid (4X4).X

Change rear axle fluid. X X

Change front axle fluid (4X4). X X

Inspect brake linings. X X

Inspect engine air cleaner

filter, replace if necessary.XX

Replace spark plugs.X

Replace ignition cables.X

Inspect PCV valve, replace

as necessary.X*

Inspect auto tension drive belt

and replace if required

(3.7L/4.7L/5.7L).X³ X³

Drain and refill automatic

tranmission fluid and change

main sump filter (45RFE/

545RFE only).X

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

Schedule ªAº

Miles 6,000 12,000 18,000 24,000 30,000

(Kilometers) (10 000) (19 000) (29 000) (38 000) (48 000)

[Months] [6] [12] [18] [24] [30]

Change engine oil and engine oil filter.XXXX X

Check transfer case fluid level (4X4). X

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XXXX X

Inspect brake linings. X

Replace engine air cleaner filter.X

Replace spark plugs.X

0 - 10 LUBRICATION & MAINTENANCEDR

MAINTENANCE SCHEDULES (Continued)

Page 24 of 2627

![DODGE RAM 1500 1998 2.G Workshop Manual Miles 36,000 42,000 48,000 54,000 60,000 66,000

(Kilometers) (58 000) (67 000) (77 000) (84 000) (96 000) (106 000)

[Months] [36] [42] [48] [54] [60] [66]

Change engine oil and engine

oil filter.XXXXX DODGE RAM 1500 1998 2.G Workshop Manual Miles 36,000 42,000 48,000 54,000 60,000 66,000

(Kilometers) (58 000) (67 000) (77 000) (84 000) (96 000) (106 000)

[Months] [36] [42] [48] [54] [60] [66]

Change engine oil and engine

oil filter.XXXXX](/img/12/5702/w960_5702-23.png)

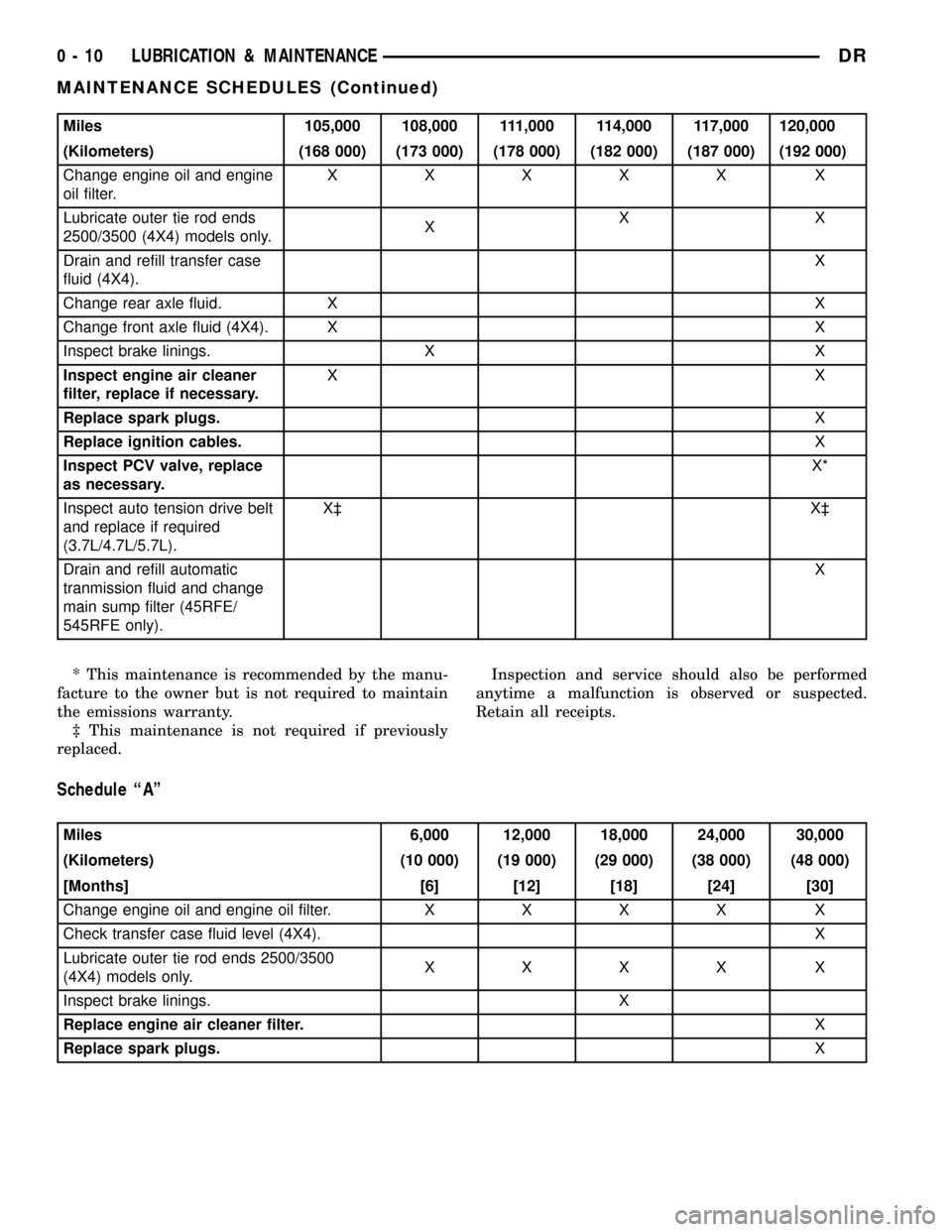

Miles 36,000 42,000 48,000 54,000 60,000 66,000

(Kilometers) (58 000) (67 000) (77 000) (84 000) (96 000) (106 000)

[Months] [36] [42] [48] [54] [60] [66]

Change engine oil and engine

oil filter.XXXXX

X

Check transfer case fluid level

(4X4).X

Lubricate outer tie rod ends

2500/3500 (4X4) models only.XXXXX X

Flush and replace engine

coolant at 60 months,

regardless of mileage.X

Inspect brake linings. X X

Replace engine air cleaner

filter.X

Replace spark plugs.X

Inspect PCV valve, replace

as necessary.X*

Replace ignition cables.X

Miles 72,000 78,000 84,000 90,000 96,000 100,000

(Kilometers) (115000) (125 000) (134 000) (144 000) (154 000) 160 000

[Months] [72] [78] [84] [90] [96]

Change engine oil and engine

oil filter.XXXXX

Lubricate outer tie rod ends

2500/3500 (4X4) models only.XXXXX

Check transfer case fluid level

(4X4).X

Flush and replace Power

Steering Fluid.X

Inspect brake linings. X X

Replace engine air cleaner

filter.X

Replace spark plugs.X

Inspect PCV valve, replace

as necessary.X*

Inspect auto tension drive belt

and replace if required

(3.7L/4.7L/5.7L).X

Drain and refill automatic

tranmission fluid and change

main sump filter and spin-on

cooler return filter (if

equipped) [45RFE/545RFE

only].X

DRLUBRICATION & MAINTENANCE 0 - 11

MAINTENANCE SCHEDULES (Continued)

Page 25 of 2627

![DODGE RAM 1500 1998 2.G Workshop Manual Miles 102,000 108,000 114,000 120,000

(Kilometers) (163 000) (173 000) (182 000) (192 000)

[Months] [102] [108] [114] [120]

Change engine oil and engine oil filter. X X X X

Drain and refill transfer c DODGE RAM 1500 1998 2.G Workshop Manual Miles 102,000 108,000 114,000 120,000

(Kilometers) (163 000) (173 000) (182 000) (192 000)

[Months] [102] [108] [114] [120]

Change engine oil and engine oil filter. X X X X

Drain and refill transfer c](/img/12/5702/w960_5702-24.png)

Miles 102,000 108,000 114,000 120,000

(Kilometers) (163 000) (173 000) (182 000) (192 000)

[Months] [102] [108] [114] [120]

Change engine oil and engine oil filter. X X X X

Drain and refill transfer case fluid (4X4). X

Flush and replace engine coolant, if not done at 60 mos. X

Lubricate outer tie rod ends 2500/3500 (4X4) models

only.XXX X

Inspect brake linings. X

Inspect auto tension drive belt and replace if required

(3.7L/4.7L/5.7L).X³X³

Replace ignition cables.X

Replace engine air cleaner filter.X

Replace spark plugs.X

Inspect PCV Valve, replace as necessary X*

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

MAINTENANCE SCHEDULES Ð 24±VALVE

CUMMINS TURBO DIESEL

There are two maintenance schedules that show

therequiredservice for your vehicle.

First is ScheduleªBº. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

²Day or night temperatures are below 0É C (32É

F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16 km (10 miles).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

²Off-road or desert operation.

NOTE: Most vehicles are operated under the condi-

tions listed for Schedule(B(.

Second is ScheduleªAº. It is for vehicles that are

not operated under any of the conditions listed under

Schedule9B9.

Use the schedule that best describes your driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.

CAUTION: Failure to perform the required mainte-

nance items may result in damage to the vehicle.At Each Stop for Fuel

²Check the engine oil level about 15 minutes

after a fully warmed engine is shut off. Checking the

oil level while the vehicle is on level ground will

improve the accuracy of the oil level reading. Add oil

only when the level is at or below the ADD or MIN

mark.

²Check the windshield washer solvent and add if

required.

²Drain water from the fuel filter.

0 - 12 LUBRICATION & MAINTENANCEDR

MAINTENANCE SCHEDULES (Continued)

Page 394 of 2627

RADIO NOISE SUPPRESSION

GROUND STRAP

DESCRIPTION

Radio noise suppression devices are factory-in-

stalled standard equipment on this vehicle. Radio

Frequency Interference (RFI) and ElectroMagnetic

Interference (EMI) can be produced by any on-board

or external source of electromagnetic energy. These

electromagnetic energy sources can radiate electro-

magnetic signals through the air, or conduct them

through the vehicle electrical system.

When the audio system converts RFI or EMI to an

audible acoustic wave form, it is referred to as radio

noise. This undesirable radio noise is generally man-

ifested in the form of ªbuzzing,º ªhissing,º ªpopping,º

ªclicking,º ªcrackling,º and/or ªwhirringº sounds. In

most cases, RFI and EMI radio noise can be sup-

pressed using a combination of vehicle and compo-

nent grounding, filtering and shielding techniques.

This vehicle is equipped with factory-installed radio

noise suppression devices that were designed to min-

imize exposure to typical sources of RFI and EMI;

thereby, minimizing radio noise complaints.

Factory-installed radio noise suppression is accom-

plished primarily through circuitry or devices that

are integral to the factory-installed radios, audio

power amplifiers and other on-board electrical com-

ponents such as generators, wiper motors, blower

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI. External radio noise

suppression devices that are used on this vehicle to

control RFI or EMI, and can be serviced, include the

following:

²Engine-to-body ground strap- This length of

braided ground strap has an eyelet terminal connec-

tor crimped to each end. One end is secured to the

engine cylinder head(s). The other is secured to the

plenum at the exhaust heat shield forward/outer

attaching stud.

²Resistor-type spark plugs- This type of spark

plug has an internal resistor connected in series

between the spark plug terminal and the center elec-

trode to help reduce the production of electromag-

netic radiation that can result in radio noise.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMIelectromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

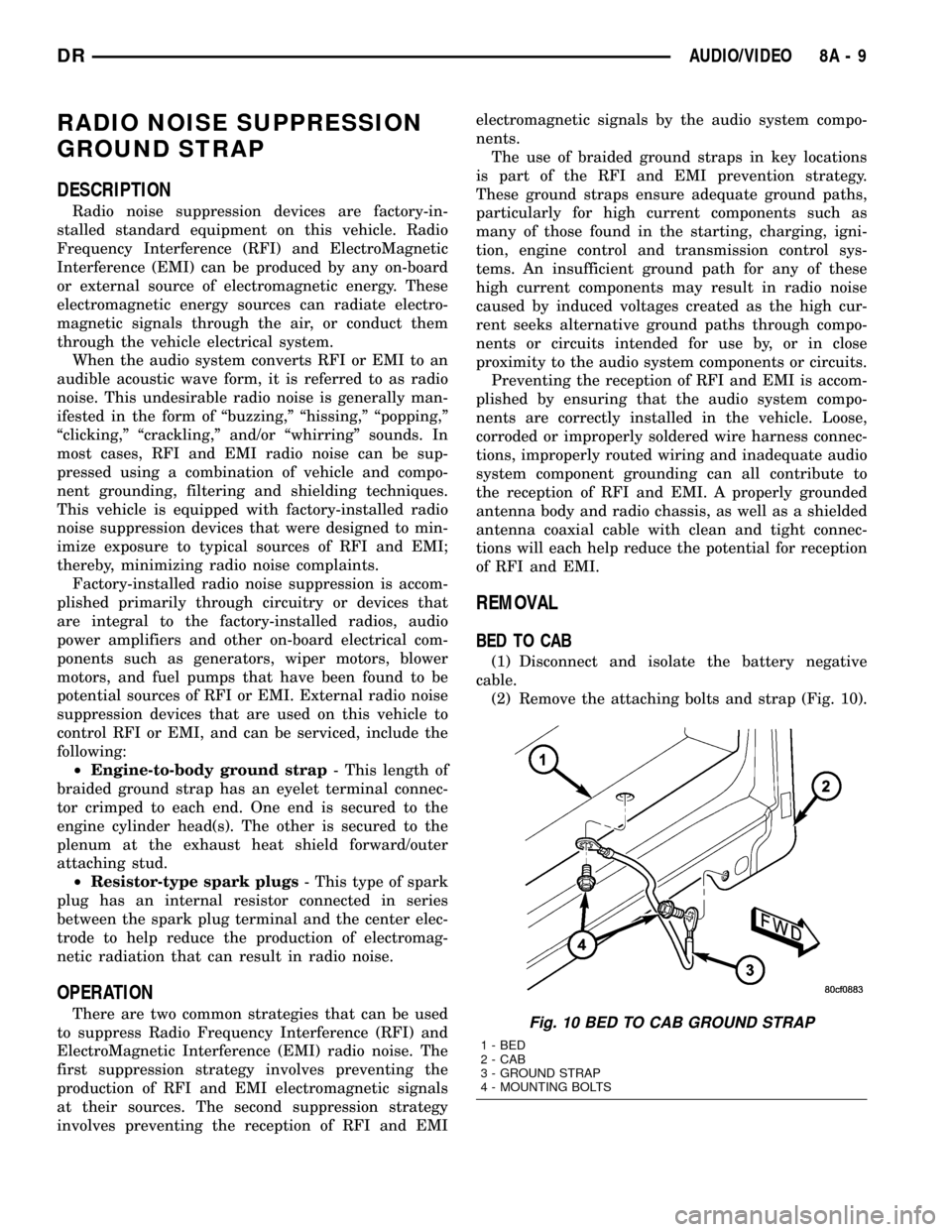

REMOVAL

BED TO CAB

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the attaching bolts and strap (Fig. 10).

Fig. 10 BED TO CAB GROUND STRAP

1 - BED

2 - CAB

3 - GROUND STRAP

4 - MOUNTING BOLTS

DRAUDIO/VIDEO 8A - 9

Page 488 of 2627

IGNITION CONTROL

TABLE OF CONTENTS

page page

IGNITION CONTROL

DESCRIPTION..........................1

SPECIFICATIONS

SPECIFICATIONS - TORQUE - IGNITION....3

ENGINE FIRING ORDER - 3.7L V-6.........4

ENGINE FIRING ORDER ± 4.7L V-8........4

FIRING ORDER / CABLE ROUTING ± 5.7L

V-8 ENGINE...........................4

SPARK PLUG CABLE RESISTANCE........4

SPARK PLUGS........................4

IGNITION COIL RESISTANCE - 3.7L V-6.....5

IGNITION COIL RESISTANCE - 4.7L V-8.....5

IGNITION COIL RESISTANCE - 5.7L V-8.....5

IGNITION TIMING......................5

AUTOMATIC SHUT DOWN RELAY

DESCRIPTION - PCM OUTPUT.............5

OPERATION

OPERATION - PCM OUTPUT.............5

OPERATION - ASD SENSE - PCM INPUT....5

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS........................5

REMOVAL.............................6

INSTALLATION..........................6

CAMSHAFT POSITION SENSOR

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................9

INSTALLATION.........................10IGNITION COIL

DESCRIPTION.........................11

OPERATION...........................12

REMOVAL.............................13

INSTALLATION.........................14

KNOCK SENSOR

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................15

INSTALLATION.........................15

SPARK PLUG

DESCRIPTION.........................17

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS.........................17

REMOVAL.............................19

CLEANING

CLEANING AND ADJUSTMENT...........20

INSTALLATION.........................20

IGNITION COIL CAPACITOR

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................21

SPARK PLUG CABLE

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................22

INSTALLATION.........................22

IGNITION CONTROL

DESCRIPTION

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

3.7L V-6 ENGINE

The 3.7L V-6 engine uses a separate ignition coil

for each cylinder. The one-piece coil bolts directly to

the cylinder head. Rubber boots seal the secondary

terminal ends of the coils to the top of all 6 spark

plugs. A separate electrical connector is used for each

coil.

Because of coil design, spark plug cables (second-

ary cables) are not used. A distributor is not used

with the 3.7L engine.

Two knock sensors (one for each cylinder bank) are

used to help control spark knock.The Auto Shutdown (ASD) relay provides battery

voltage to each ignition coil.

The ignition system consists of:

²6 Spark Plugs

²6 Separate Ignition Coils

²2 Knock Sensors

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position, 2 knock and

MAP Sensors

4.7L V-8 ENGINE

The 4.7L V-8 engine uses a separate ignition coil

for each cylinder. The one-piece coil bolts directly to

the cylinder head. Rubber boots seal the secondary

terminal ends of the coils to the top of all 8 spark

plugs. A separate electrical connector is used for each

coil.

DRIGNITION CONTROL 8I - 1

Page 489 of 2627

Because of coil design, spark plug cables (second-

ary cables) are not used. A distributor is not used

with the 4.7L engine.

Two knock sensors (one for each cylinder bank) are

used to help control spark knock.

The Auto Shutdown (ASD) relay provides battery

voltage to each ignition coil.

The ignition system consists of:

²8 Spark Plugs

²8 Separate Ignition Coils

²2 Knock Sensors

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position, 2 knock and

MAP Sensors

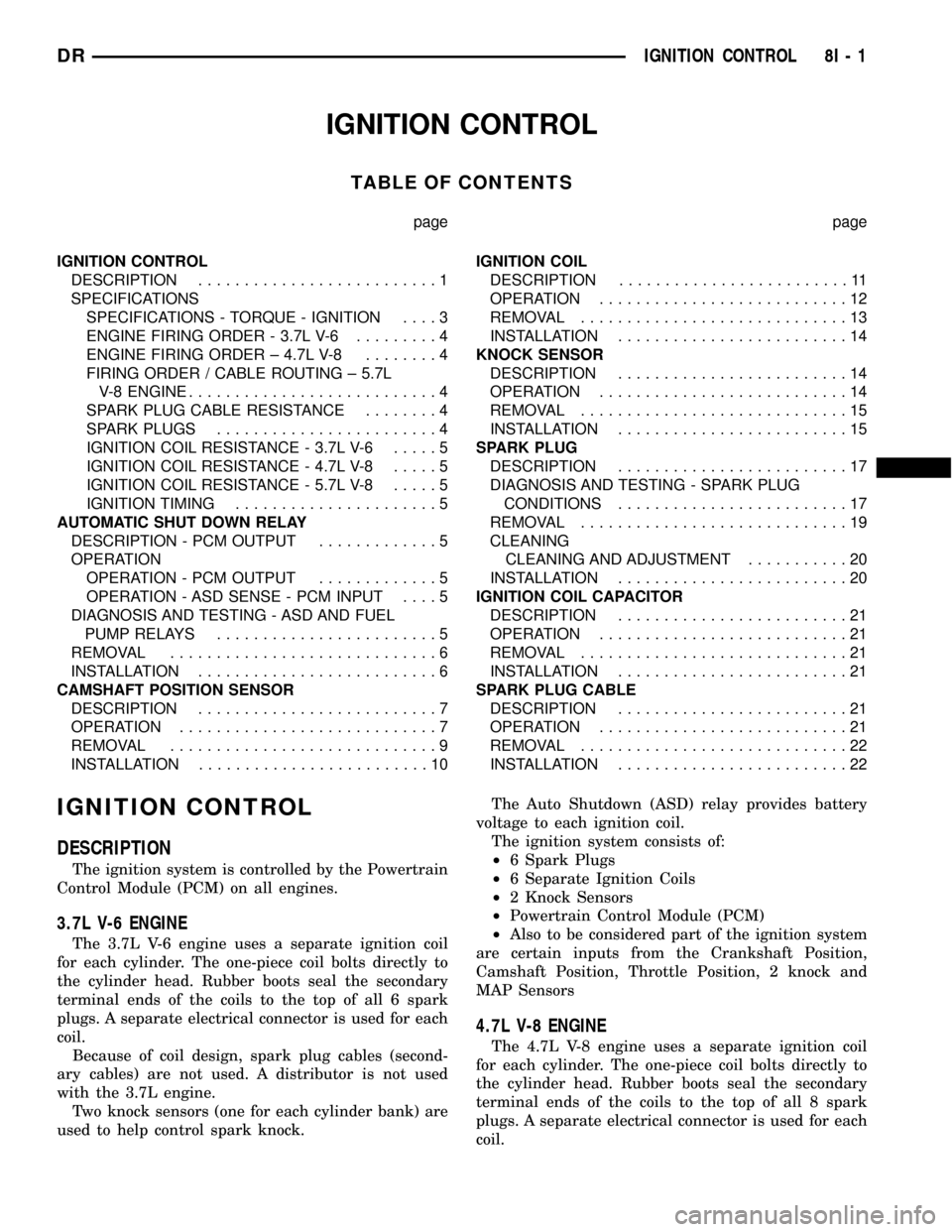

5.7L V-8 ENGINE

For additional information, also refer to Igni-

tion Coil Description and Operation.

The 5.7L V-8 engine is equipped with 16 spark

plugs. Two plugs are used for each cylinder. The 5.7L

is also equipped with 8 separate and independent

ignition coils. The one-piece coil bolts directly to the

cylinder head cover and attaches the coils secondary

output terminal directly to a spark plug using a rub-

ber boot seal. Each coil is also equipped with a sec-

ond output terminal. This second terminal connects a

conventional spark plug cable directly to a spark

plug on the opposite cylinder bank. A separate pri-

mary electrical connector is used for each coil.

Eight conventional spark plug cables are used with

the 5.7L. These cables connect a coil on one cylinder

bank, directly to a spark plug on the opposite cylin-

der bank. The cables are placed and routed in a spe-

cial plastic loom to keep them separated. This loom is

clipped to the intake manifold. To prevent a miss-

match of cables, a corresponding spark plug / coil

number is displayed on each plug cable: 1/6, 2/3, 4/7

and 5/8. These numbers can also be found on the top

of the intake manifold to the right of the throttle

body (Fig. 1).Two knock sensors (one for each cylinder bank) are

used to help control spark knock.

The 5.7L engine will not use a conventional distrib-

utor.

The ignition system consists of:

²16 Spark Plugs (2 per cylinder)

²8 Separate, Dual-Secondary Output, Ignition

Coils

²2 Knock Sensors

²8 Secondary Ignition Cables

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position, 2 knock and

MAP Sensors

Fig. 1 FIRING ORDER / CABLE ROUTING - 5.7L V-8

ENGINE

1 - TOP OF INTAKE MANIFOLD

2 - CYLINDER FIRING ORDER (IGNITION COIL NUMBER)

3 - CORRESPONDING SPARK PLUG NUMBER

8I - 2 IGNITION CONTROLDR

IGNITION CONTROL (Continued)

Page 490 of 2627

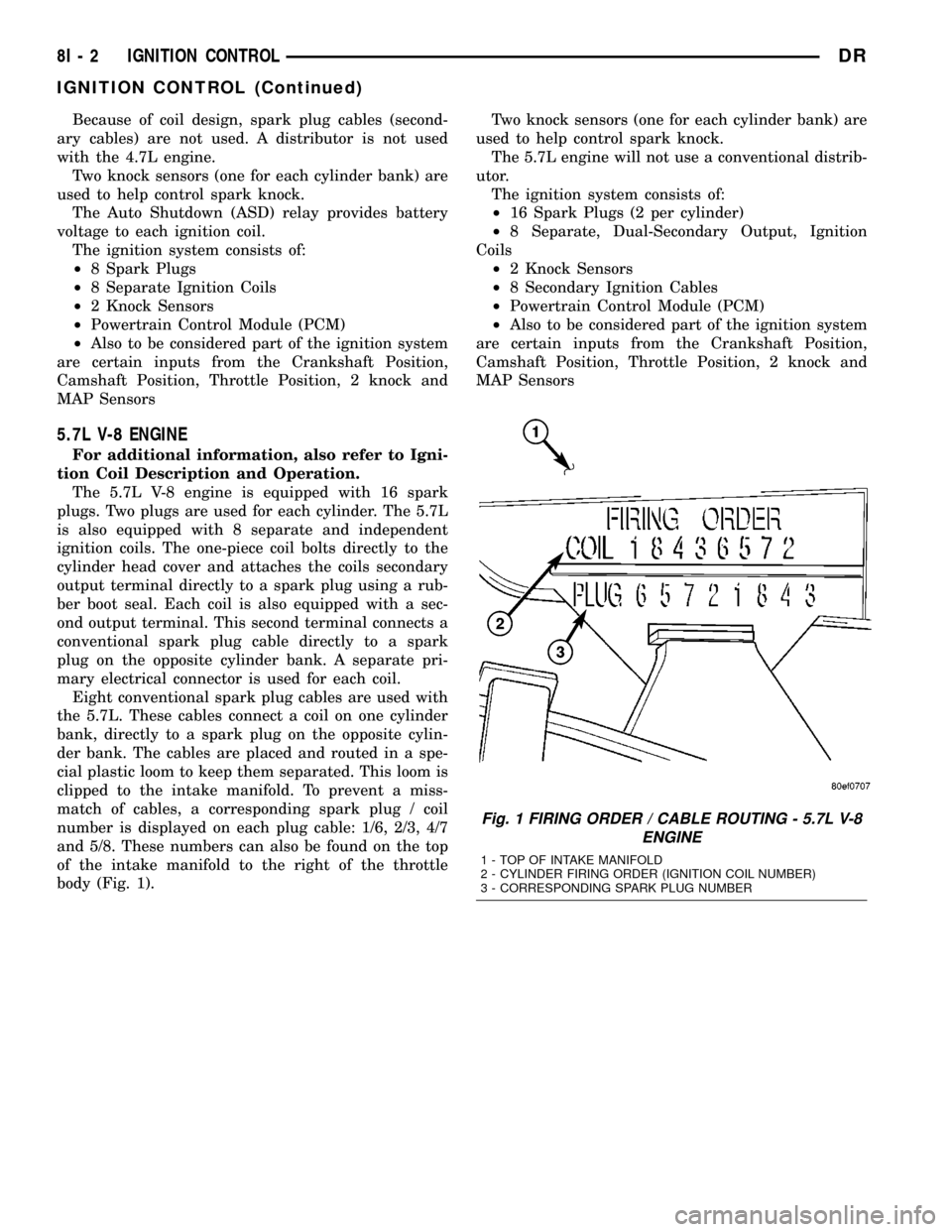

SPECIFICATIONS

SPECIFICATIONS - TORQUE - IGNITION

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Camshaft Position Sensor

- 3.7L V-6 Engine12 - 106

Camshaft Position Sensor

- 4.7L V-8 Engine12 - 106

Camshaft Position Sensor

- 5.7L V-8 Engine12 9 105

Crankshaft Position

Sensor - 3.7L V-6 Engine28 21 205

Crankshaft Position

Sensor - 4.7L V-8 Engine28 21 205

Crankshaft Position

Sensor - 5.7L V-8 Engine12 9 105

Ignition Coil Mounting -

3.7L V-6 Engine8-70

Ignition Coil Mounting -

4.7L V-8 Engine8-70

Ignition Coil Mounting -

5.7L V-8 Engine12 9 105 ( 20)

* Knock Sensor - 3.7L V-6

Engine20 15 176

* Knock Sensor - 4.7L V-8

Engine20 15 176

* Knock Sensor - 5.7L V-8

Engine20 15 176

Spark Plugs - 3.7L V-6

Engine27 20 -

Spark Plugs - 4.7L V-8

Engine27 20 -

** Spark Plugs - 5.7L V-8

Engine18 ( 3) 13 ( 2) -

* Do not apply any sealant, thread-locker or adhesive to bolts. Poor sensor performance may result.

** Torque critical tapered design. Do not exceed 15 ft. lbs.

DRIGNITION CONTROL 8I - 3

IGNITION CONTROL (Continued)