sensor DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1649 of 2627

INTAKE AIR HEATER

DESCRIPTION

The intake manifold air heater element assembly

is located in the top of the intake manifold.

OPERATION

The air heater elements are used to heat incoming

air to the intake manifold. This is done to help

engine starting and improve driveability with cool or

cold outside temperatures.

Electrical supply for the 2 air heater elements is

controlled by the Engine Control Module (ECM)

through the 2 air heater relays. Refer to Intake Man-

ifold Air Heater Relays for more information.

Two heavy-duty cables connect the 2 air heater ele-

ments to the 2 air heater relays. Each of these cables

will supply approximately 95 amps at 12 volts to an

individual heating element within the heater block

assembly.

Refer to the Powertrain Diagnostic Procedures

manual for electrical operation and complete descrip-

tion of the intake heaters, including pre-heat and

post-heat cycles.

REMOVAL

If servicing either of the heater elements, the

entire block/element assembly must be replaced.

(1) Disconnect both negative battery cables at both

batteries. Cover and isolate ends of both cables.

(2) Remove both the intake manifold air intake

tube (above injection pump), and its rubber connector

hose (Fig. 26).

(3) Lift 2 rubber covers (Fig. 27) to gain access to 2

positive (+) cable nuts. Remove these 2 nuts (Fig. 28)

and remove 2 cables from studs.

(4) Disconnect ground strap (Fig. 27) at heater ele-

ment stud.

(5) Remove wiring harness clips.

(6) Remove engine oil dipstick tube bracket from

air inlet connection and fuel filter housing.

(7) Remove 4 housing mounting bolts (Fig. 27) and

remove heater element assembly.

INSTALLATION

If servicing either of the heater elements, the

entire block/element assembly must be replaced.

(1) Using 2 new gaskets, position element assem-

bly and air housing to intake manifold.

(2) Install ground cable to air housing.

(3) Install 4 housing bolts and tighten to 24 N´m

(18 ft. lbs.) torque.

(4) Connect 2 positive (+) heater cables at cable

mounting studs.Do not allow either of the cable

eyelets to contact any other metal source other

than the cable nuts/studs.

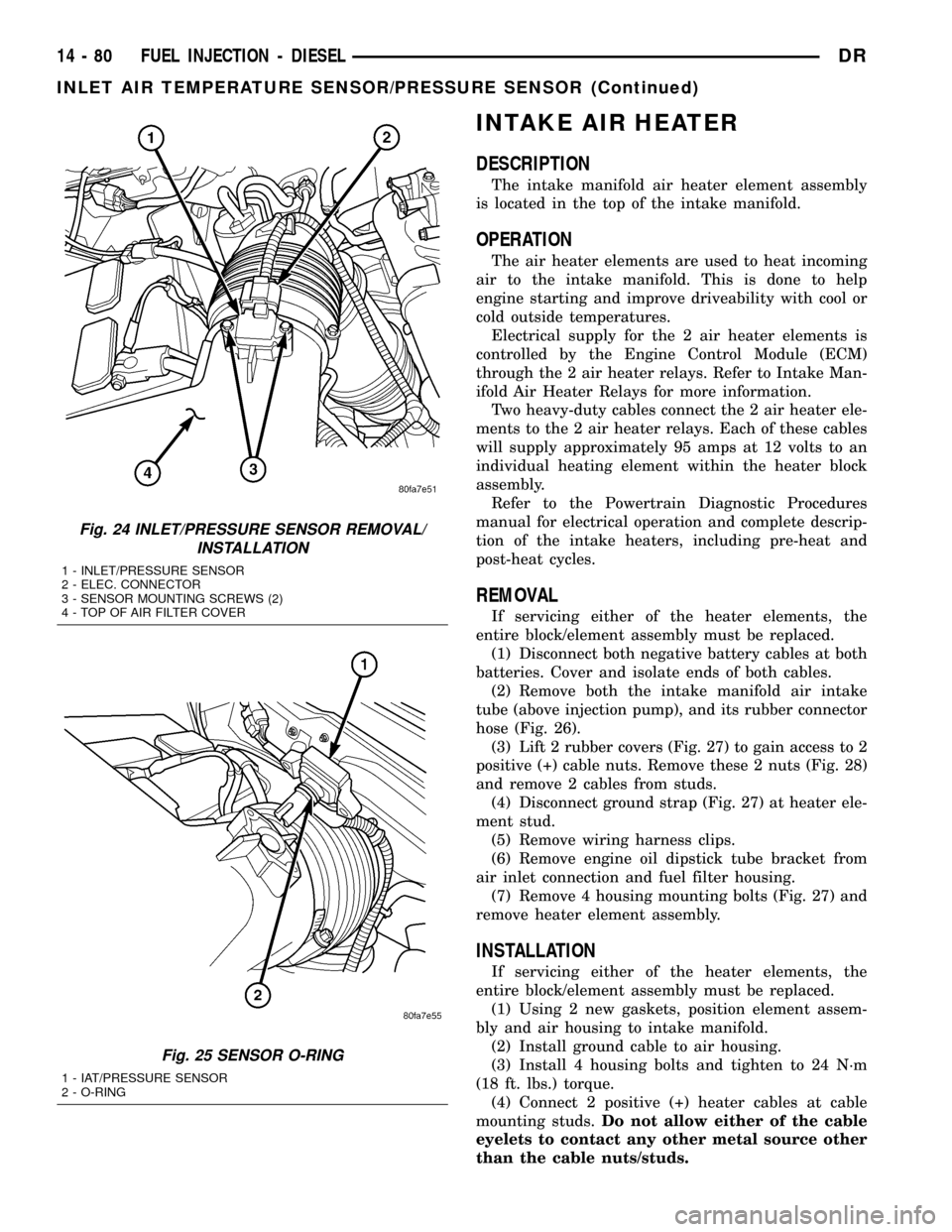

Fig. 24 INLET/PRESSURE SENSOR REMOVAL/

INSTALLATION

1 - INLET/PRESSURE SENSOR

2 - ELEC. CONNECTOR

3 - SENSOR MOUNTING SCREWS (2)

4 - TOP OF AIR FILTER COVER

Fig. 25 SENSOR O-RING

1 - IAT/PRESSURE SENSOR

2 - O-RING

14 - 80 FUEL INJECTION - DIESELDR

INLET AIR TEMPERATURE SENSOR/PRESSURE SENSOR (Continued)

Page 1651 of 2627

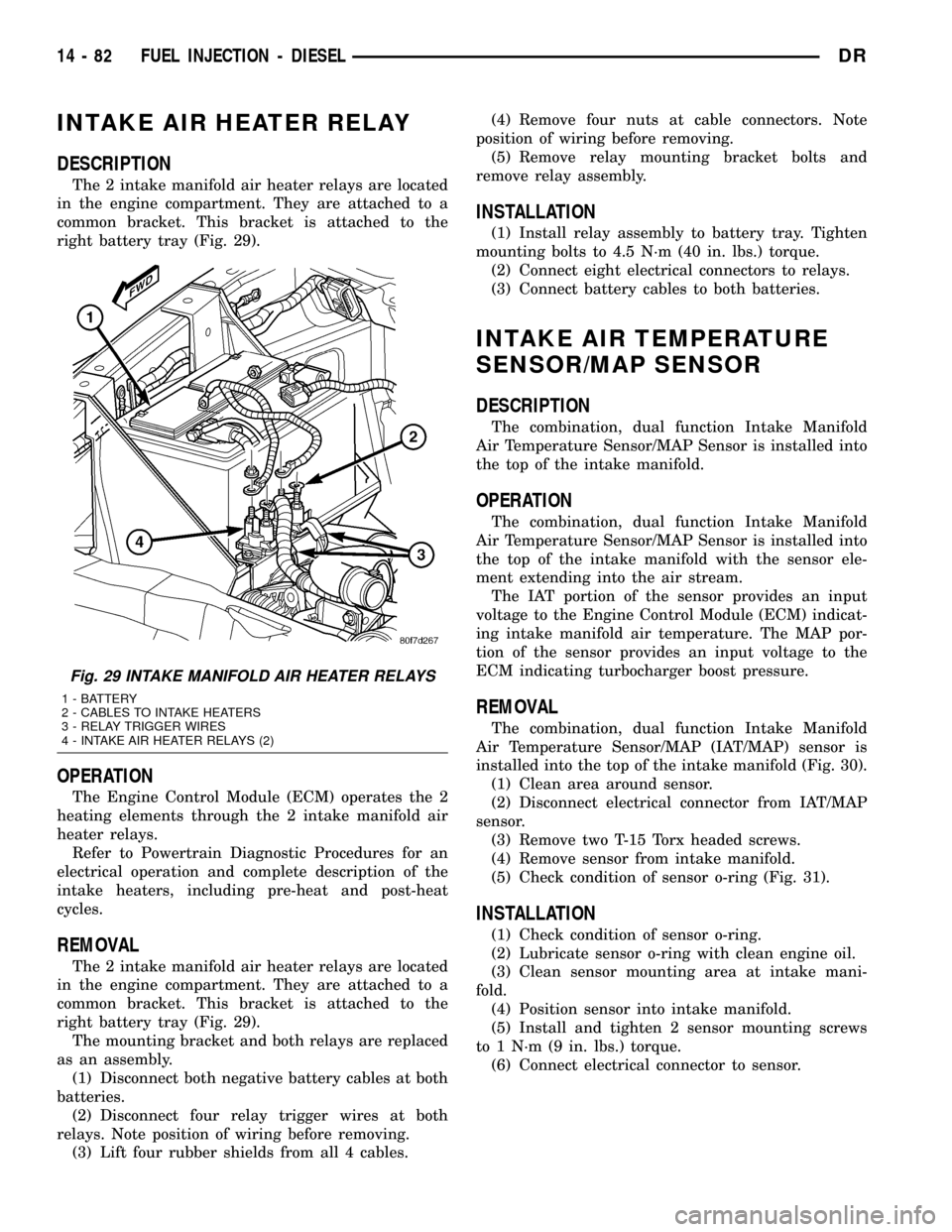

INTAKE AIR HEATER RELAY

DESCRIPTION

The 2 intake manifold air heater relays are located

in the engine compartment. They are attached to a

common bracket. This bracket is attached to the

right battery tray (Fig. 29).

OPERATION

The Engine Control Module (ECM) operates the 2

heating elements through the 2 intake manifold air

heater relays.

Refer to Powertrain Diagnostic Procedures for an

electrical operation and complete description of the

intake heaters, including pre-heat and post-heat

cycles.

REMOVAL

The 2 intake manifold air heater relays are located

in the engine compartment. They are attached to a

common bracket. This bracket is attached to the

right battery tray (Fig. 29).

The mounting bracket and both relays are replaced

as an assembly.

(1) Disconnect both negative battery cables at both

batteries.

(2) Disconnect four relay trigger wires at both

relays. Note position of wiring before removing.

(3) Lift four rubber shields from all 4 cables.(4) Remove four nuts at cable connectors. Note

position of wiring before removing.

(5) Remove relay mounting bracket bolts and

remove relay assembly.

INSTALLATION

(1) Install relay assembly to battery tray. Tighten

mounting bolts to 4.5 N´m (40 in. lbs.) torque.

(2) Connect eight electrical connectors to relays.

(3) Connect battery cables to both batteries.

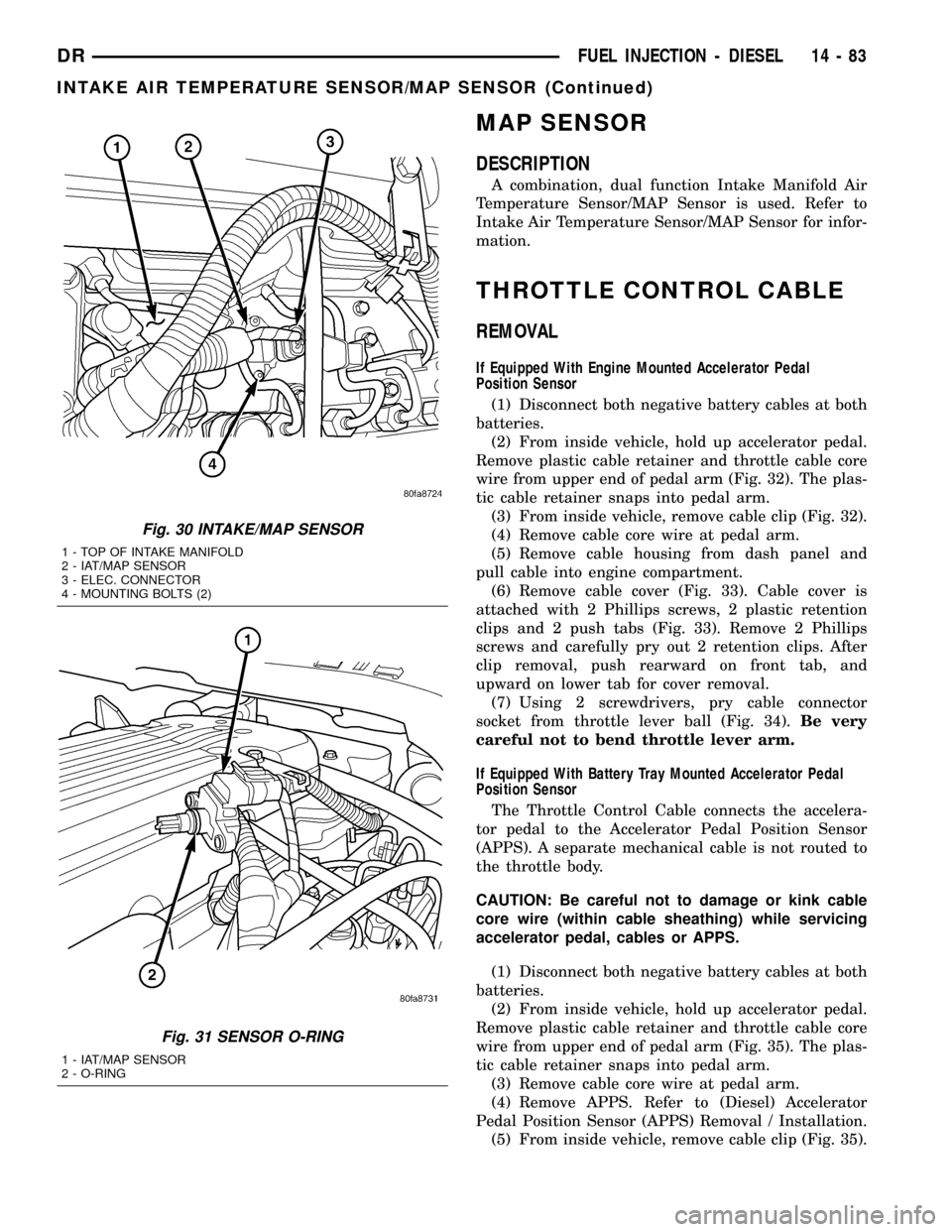

INTAKE AIR TEMPERATURE

SENSOR/MAP SENSOR

DESCRIPTION

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP Sensor is installed into

the top of the intake manifold.

OPERATION

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP Sensor is installed into

the top of the intake manifold with the sensor ele-

ment extending into the air stream.

The IAT portion of the sensor provides an input

voltage to the Engine Control Module (ECM) indicat-

ing intake manifold air temperature. The MAP por-

tion of the sensor provides an input voltage to the

ECM indicating turbocharger boost pressure.

REMOVAL

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP (IAT/MAP) sensor is

installed into the top of the intake manifold (Fig. 30).

(1) Clean area around sensor.

(2) Disconnect electrical connector from IAT/MAP

sensor.

(3) Remove two T-15 Torx headed screws.

(4) Remove sensor from intake manifold.

(5) Check condition of sensor o-ring (Fig. 31).

INSTALLATION

(1) Check condition of sensor o-ring.

(2) Lubricate sensor o-ring with clean engine oil.

(3) Clean sensor mounting area at intake mani-

fold.

(4) Position sensor into intake manifold.

(5) Install and tighten 2 sensor mounting screws

to 1 N´m (9 in. lbs.) torque.

(6) Connect electrical connector to sensor.

Fig. 29 INTAKE MANIFOLD AIR HEATER RELAYS

1 - BATTERY

2 - CABLES TO INTAKE HEATERS

3 - RELAY TRIGGER WIRES

4 - INTAKE AIR HEATER RELAYS (2)

14 - 82 FUEL INJECTION - DIESELDR

Page 1652 of 2627

MAP SENSOR

DESCRIPTION

A combination, dual function Intake Manifold Air

Temperature Sensor/MAP Sensor is used. Refer to

Intake Air Temperature Sensor/MAP Sensor for infor-

mation.

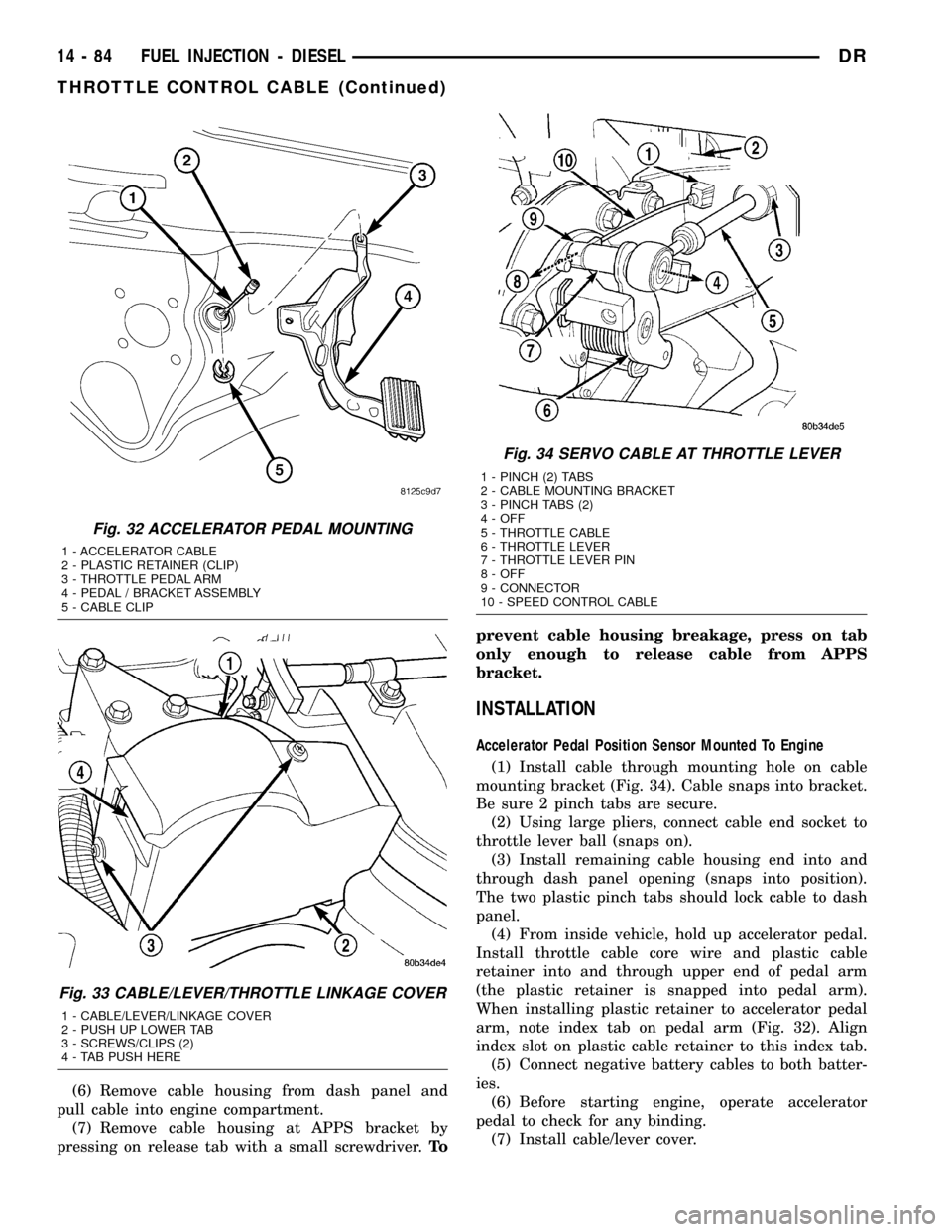

THROTTLE CONTROL CABLE

REMOVAL

If Equipped With Engine Mounted Accelerator Pedal

Position Sensor

(1) Disconnect both negative battery cables at both

batteries.

(2) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer and throttle cable core

wire from upper end of pedal arm (Fig. 32). The plas-

tic cable retainer snaps into pedal arm.

(3) From inside vehicle, remove cable clip (Fig. 32).

(4) Remove cable core wire at pedal arm.

(5) Remove cable housing from dash panel and

pull cable into engine compartment.

(6) Remove cable cover (Fig. 33). Cable cover is

attached with 2 Phillips screws, 2 plastic retention

clips and 2 push tabs (Fig. 33). Remove 2 Phillips

screws and carefully pry out 2 retention clips. After

clip removal, push rearward on front tab, and

upward on lower tab for cover removal.

(7) Using 2 screwdrivers, pry cable connector

socket from throttle lever ball (Fig. 34).Be very

careful not to bend throttle lever arm.

If Equipped With Battery Tray Mounted Accelerator Pedal

Position Sensor

The Throttle Control Cable connects the accelera-

tor pedal to the Accelerator Pedal Position Sensor

(APPS). A separate mechanical cable is not routed to

the throttle body.

CAUTION: Be careful not to damage or kink cable

core wire (within cable sheathing) while servicing

accelerator pedal, cables or APPS.

(1) Disconnect both negative battery cables at both

batteries.

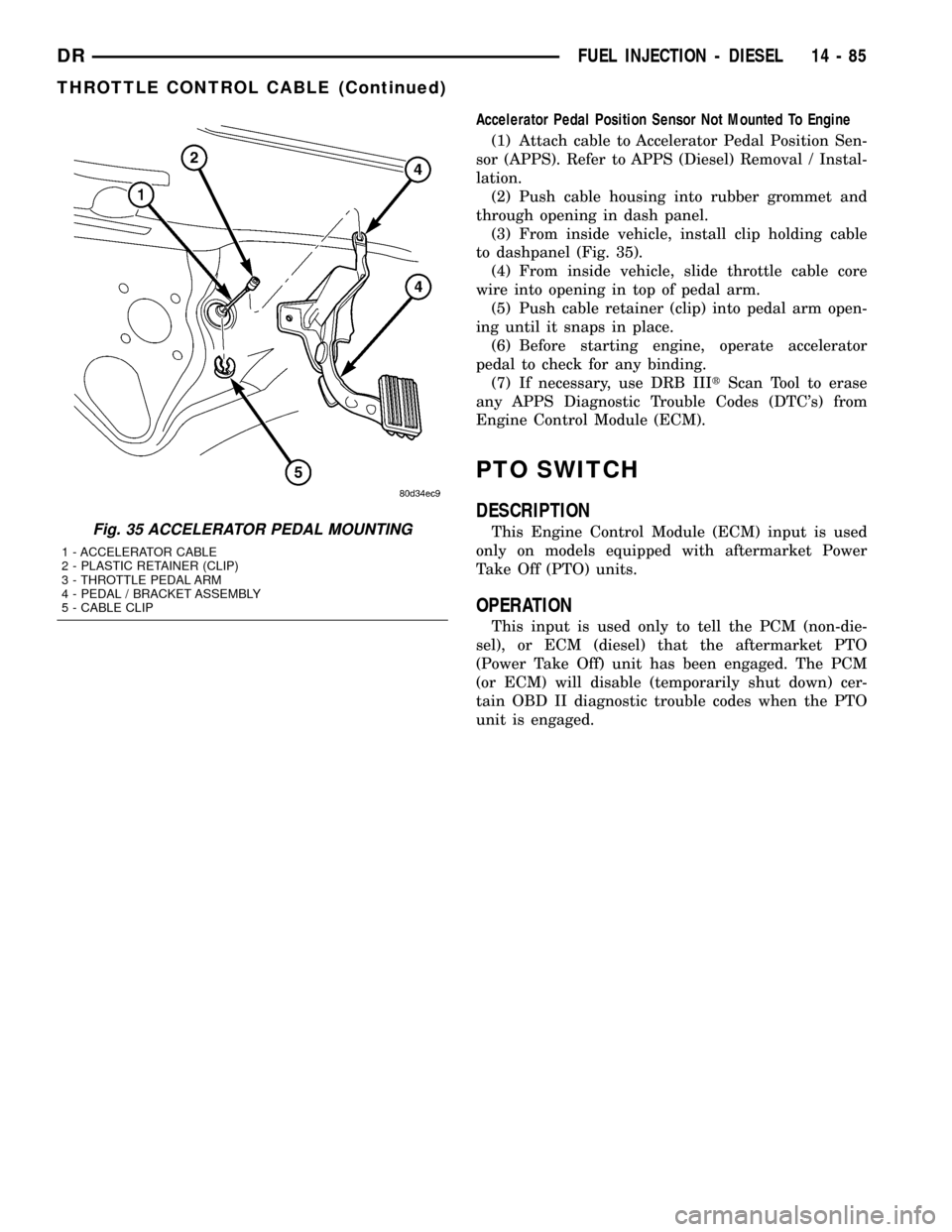

(2) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer and throttle cable core

wire from upper end of pedal arm (Fig. 35). The plas-

tic cable retainer snaps into pedal arm.

(3) Remove cable core wire at pedal arm.

(4) Remove APPS. Refer to (Diesel) Accelerator

Pedal Position Sensor (APPS) Removal / Installation.

(5) From inside vehicle, remove cable clip (Fig. 35).

Fig. 30 INTAKE/MAP SENSOR

1 - TOP OF INTAKE MANIFOLD

2 - IAT/MAP SENSOR

3 - ELEC. CONNECTOR

4 - MOUNTING BOLTS (2)

Fig. 31 SENSOR O-RING

1 - IAT/MAP SENSOR

2 - O-RING

DRFUEL INJECTION - DIESEL 14 - 83

INTAKE AIR TEMPERATURE SENSOR/MAP SENSOR (Continued)

Page 1653 of 2627

(6) Remove cable housing from dash panel and

pull cable into engine compartment.

(7) Remove cable housing at APPS bracket by

pressing on release tab with a small screwdriver.Toprevent cable housing breakage, press on tab

only enough to release cable from APPS

bracket.

INSTALLATION

Accelerator Pedal Position Sensor Mounted To Engine

(1) Install cable through mounting hole on cable

mounting bracket (Fig. 34). Cable snaps into bracket.

Be sure 2 pinch tabs are secure.

(2) Using large pliers, connect cable end socket to

throttle lever ball (snaps on).

(3) Install remaining cable housing end into and

through dash panel opening (snaps into position).

The two plastic pinch tabs should lock cable to dash

panel.

(4) From inside vehicle, hold up accelerator pedal.

Install throttle cable core wire and plastic cable

retainer into and through upper end of pedal arm

(the plastic retainer is snapped into pedal arm).

When installing plastic retainer to accelerator pedal

arm, note index tab on pedal arm (Fig. 32). Align

index slot on plastic cable retainer to this index tab.

(5) Connect negative battery cables to both batter-

ies.

(6) Before starting engine, operate accelerator

pedal to check for any binding.

(7) Install cable/lever cover.

Fig. 32 ACCELERATOR PEDAL MOUNTING

1 - ACCELERATOR CABLE

2 - PLASTIC RETAINER (CLIP)

3 - THROTTLE PEDAL ARM

4 - PEDAL / BRACKET ASSEMBLY

5 - CABLE CLIP

Fig. 33 CABLE/LEVER/THROTTLE LINKAGE COVER

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

Fig. 34 SERVO CABLE AT THROTTLE LEVER

1 - PINCH (2) TABS

2 - CABLE MOUNTING BRACKET

3 - PINCH TABS (2)

4 - OFF

5 - THROTTLE CABLE

6 - THROTTLE LEVER

7 - THROTTLE LEVER PIN

8 - OFF

9 - CONNECTOR

10 - SPEED CONTROL CABLE

14 - 84 FUEL INJECTION - DIESELDR

THROTTLE CONTROL CABLE (Continued)

Page 1654 of 2627

Accelerator Pedal Position Sensor Not Mounted To Engine

(1) Attach cable to Accelerator Pedal Position Sen-

sor (APPS). Refer to APPS (Diesel) Removal / Instal-

lation.

(2) Push cable housing into rubber grommet and

through opening in dash panel.

(3) From inside vehicle, install clip holding cable

to dashpanel (Fig. 35).

(4) From inside vehicle, slide throttle cable core

wire into opening in top of pedal arm.

(5) Push cable retainer (clip) into pedal arm open-

ing until it snaps in place.

(6) Before starting engine, operate accelerator

pedal to check for any binding.

(7) If necessary, use DRB IIItScan Tool to erase

any APPS Diagnostic Trouble Codes (DTC's) from

Engine Control Module (ECM).

PTO SWITCH

DESCRIPTION

This Engine Control Module (ECM) input is used

only on models equipped with aftermarket Power

Take Off (PTO) units.

OPERATION

This input is used only to tell the PCM (non-die-

sel), or ECM (diesel) that the aftermarket PTO

(Power Take Off) unit has been engaged. The PCM

(or ECM) will disable (temporarily shut down) cer-

tain OBD II diagnostic trouble codes when the PTO

unit is engaged.

Fig. 35 ACCELERATOR PEDAL MOUNTING

1 - ACCELERATOR CABLE

2 - PLASTIC RETAINER (CLIP)

3 - THROTTLE PEDAL ARM

4 - PEDAL / BRACKET ASSEMBLY

5 - CABLE CLIP

DRFUEL INJECTION - DIESEL 14 - 85

THROTTLE CONTROL CABLE (Continued)

Page 1748 of 2627

(5) Remove shift tower and isolator plate from

transmission shift cover.

(6) Raise and support vehicle.

(7) Remove skid plate, if equipped.

(8) Mark propeller shaft and axle yokes for instal-

lation reference and remove shaft/shafts.

(9) Remove exhaust system Y-pipe.

(10) Disconnect speed sensor and backup light

switch connectors.

(11) Support engine with safety stand and a wood

block.

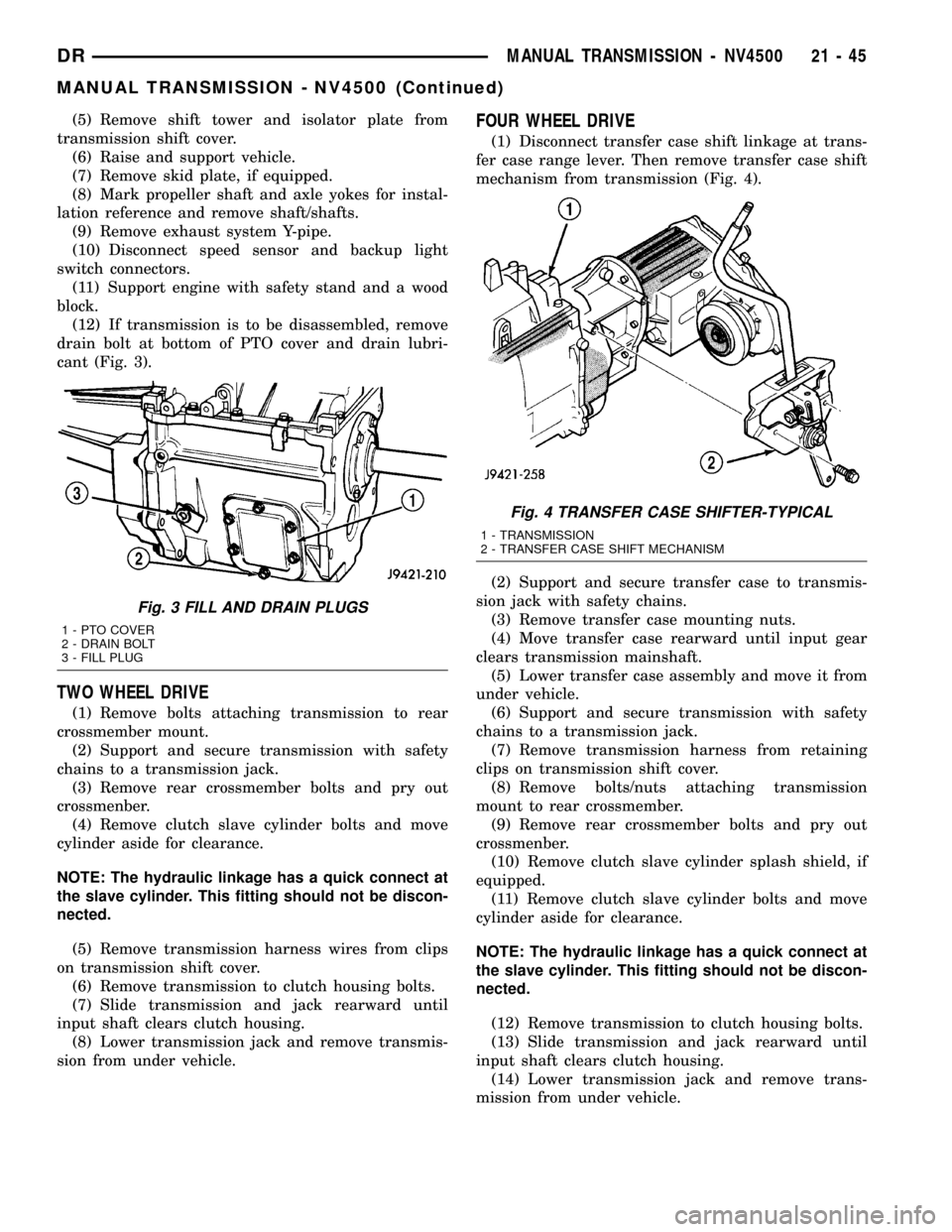

(12) If transmission is to be disassembled, remove

drain bolt at bottom of PTO cover and drain lubri-

cant (Fig. 3).

TWO WHEEL DRIVE

(1) Remove bolts attaching transmission to rear

crossmember mount.

(2) Support and secure transmission with safety

chains to a transmission jack.

(3) Remove rear crossmember bolts and pry out

crossmenber.

(4) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

NOTE: The hydraulic linkage has a quick connect at

the slave cylinder. This fitting should not be discon-

nected.

(5) Remove transmission harness wires from clips

on transmission shift cover.

(6) Remove transmission to clutch housing bolts.

(7) Slide transmission and jack rearward until

input shaft clears clutch housing.

(8) Lower transmission jack and remove transmis-

sion from under vehicle.

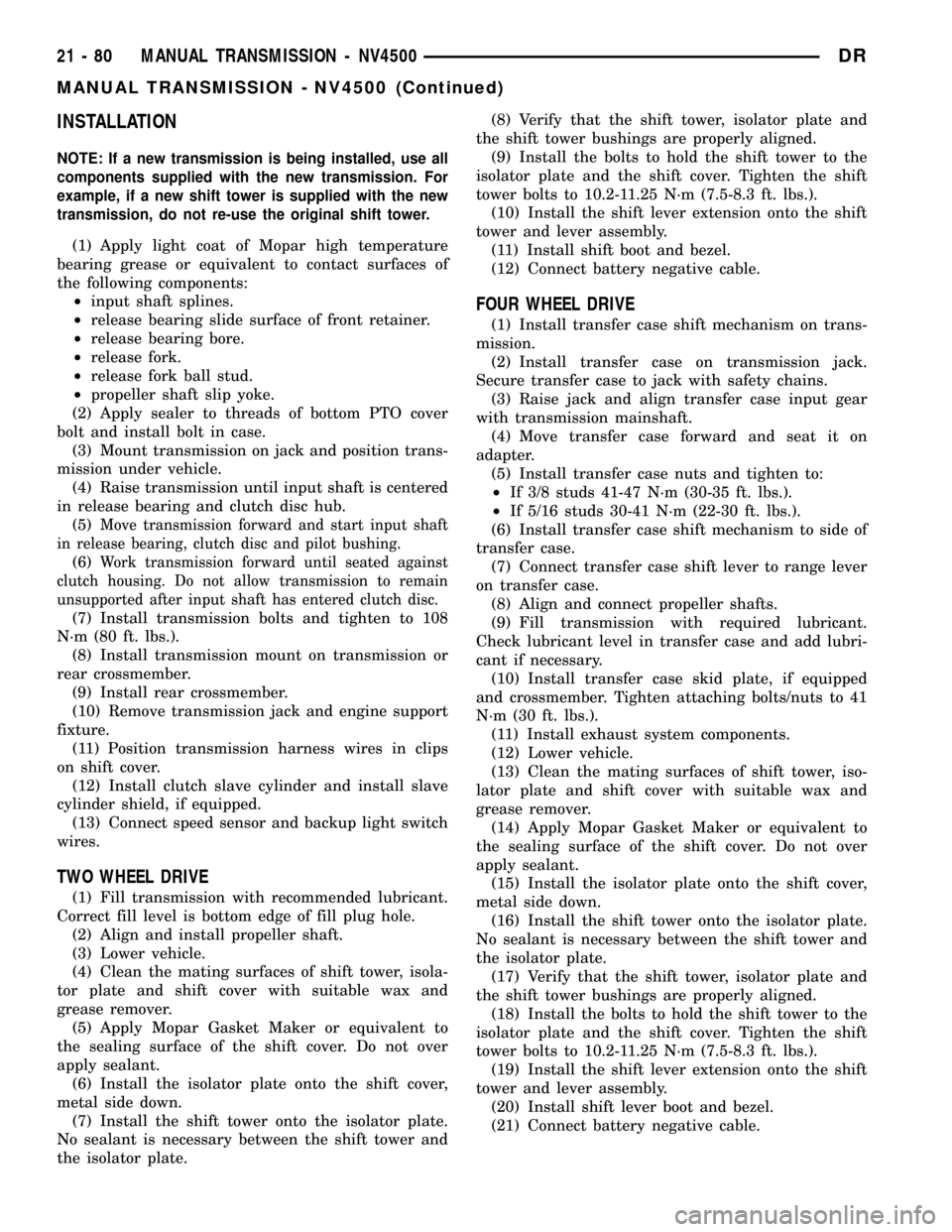

FOUR WHEEL DRIVE

(1) Disconnect transfer case shift linkage at trans-

fer case range lever. Then remove transfer case shift

mechanism from transmission (Fig. 4).

(2) Support and secure transfer case to transmis-

sion jack with safety chains.

(3) Remove transfer case mounting nuts.

(4) Move transfer case rearward until input gear

clears transmission mainshaft.

(5) Lower transfer case assembly and move it from

under vehicle.

(6) Support and secure transmission with safety

chains to a transmission jack.

(7) Remove transmission harness from retaining

clips on transmission shift cover.

(8) Remove bolts/nuts attaching transmission

mount to rear crossmember.

(9) Remove rear crossmember bolts and pry out

crossmenber.

(10) Remove clutch slave cylinder splash shield, if

equipped.

(11) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

NOTE: The hydraulic linkage has a quick connect at

the slave cylinder. This fitting should not be discon-

nected.

(12) Remove transmission to clutch housing bolts.

(13) Slide transmission and jack rearward until

input shaft clears clutch housing.

(14) Lower transmission jack and remove trans-

mission from under vehicle.

Fig. 3 FILL AND DRAIN PLUGS

1 - PTO COVER

2 - DRAIN BOLT

3 - FILL PLUG

Fig. 4 TRANSFER CASE SHIFTER-TYPICAL

1 - TRANSMISSION

2 - TRANSFER CASE SHIFT MECHANISM

DRMANUAL TRANSMISSION - NV4500 21 - 45

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1783 of 2627

INSTALLATION

NOTE: If a new transmission is being installed, use all

components supplied with the new transmission. For

example, if a new shift tower is supplied with the new

transmission, do not re-use the original shift tower.

(1) Apply light coat of Mopar high temperature

bearing grease or equivalent to contact surfaces of

the following components:

²input shaft splines.

²release bearing slide surface of front retainer.

²release bearing bore.

²release fork.

²release fork ball stud.

²propeller shaft slip yoke.

(2) Apply sealer to threads of bottom PTO cover

bolt and install bolt in case.

(3) Mount transmission on jack and position trans-

mission under vehicle.

(4) Raise transmission until input shaft is centered

in release bearing and clutch disc hub.

(5)

Move transmission forward and start input shaft

in release bearing, clutch disc and pilot bushing.

(6)Work transmission forward until seated against

clutch housing. Do not allow transmission to remain

unsupported after input shaft has entered clutch disc.

(7) Install transmission bolts and tighten to 108

N´m (80 ft. lbs.).

(8) Install transmission mount on transmission or

rear crossmember.

(9) Install rear crossmember.

(10) Remove transmission jack and engine support

fixture.

(11) Position transmission harness wires in clips

on shift cover.

(12) Install clutch slave cylinder and install slave

cylinder shield, if equipped.

(13) Connect speed sensor and backup light switch

wires.

TWO WHEEL DRIVE

(1) Fill transmission with recommended lubricant.

Correct fill level is bottom edge of fill plug hole.

(2) Align and install propeller shaft.

(3) Lower vehicle.

(4) Clean the mating surfaces of shift tower, isola-

tor plate and shift cover with suitable wax and

grease remover.

(5) Apply Mopar Gasket Maker or equivalent to

the sealing surface of the shift cover. Do not over

apply sealant.

(6) Install the isolator plate onto the shift cover,

metal side down.

(7) Install the shift tower onto the isolator plate.

No sealant is necessary between the shift tower and

the isolator plate.(8) Verify that the shift tower, isolator plate and

the shift tower bushings are properly aligned.

(9) Install the bolts to hold the shift tower to the

isolator plate and the shift cover. Tighten the shift

tower bolts to 10.2-11.25 N´m (7.5-8.3 ft. lbs.).

(10) Install the shift lever extension onto the shift

tower and lever assembly.

(11) Install shift boot and bezel.

(12) Connect battery negative cable.

FOUR WHEEL DRIVE

(1) Install transfer case shift mechanism on trans-

mission.

(2) Install transfer case on transmission jack.

Secure transfer case to jack with safety chains.

(3) Raise jack and align transfer case input gear

with transmission mainshaft.

(4) Move transfer case forward and seat it on

adapter.

(5) Install transfer case nuts and tighten to:

²If 3/8 studs 41-47 N´m (30-35 ft. lbs.).

²If 5/16 studs 30-41 N´m (22-30 ft. lbs.).

(6) Install transfer case shift mechanism to side of

transfer case.

(7) Connect transfer case shift lever to range lever

on transfer case.

(8) Align and connect propeller shafts.

(9) Fill transmission with required lubricant.

Check lubricant level in transfer case and add lubri-

cant if necessary.

(10) Install transfer case skid plate, if equipped

and crossmember. Tighten attaching bolts/nuts to 41

N´m (30 ft. lbs.).

(11) Install exhaust system components.

(12) Lower vehicle.

(13) Clean the mating surfaces of shift tower, iso-

lator plate and shift cover with suitable wax and

grease remover.

(14) Apply Mopar Gasket Maker or equivalent to

the sealing surface of the shift cover. Do not over

apply sealant.

(15) Install the isolator plate onto the shift cover,

metal side down.

(16) Install the shift tower onto the isolator plate.

No sealant is necessary between the shift tower and

the isolator plate.

(17) Verify that the shift tower, isolator plate and

the shift tower bushings are properly aligned.

(18) Install the bolts to hold the shift tower to the

isolator plate and the shift cover. Tighten the shift

tower bolts to 10.2-11.25 N´m (7.5-8.3 ft. lbs.).

(19) Install the shift lever extension onto the shift

tower and lever assembly.

(20) Install shift lever boot and bezel.

(21) Connect battery negative cable.

21 - 80 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1834 of 2627

OUTPUT SHAFT FRONT BEARING

REMOVAL............................216

INSTALLATION........................216

OUTPUT SHAFT REAR BEARING

REMOVAL............................216

INSTALLATION........................217

OVERDRIVE CLUTCH

DESCRIPTION........................217

OPERATION..........................217

OVERDRIVE UNIT

REMOVAL............................218

DISASSEMBLY........................218

CLEANING...........................225

INSPECTION.........................225

ASSEMBLY...........................226

INSTALLATION........................235

OVERRUNNING CLUTCH CAM/OVERDRIVE

PISTON RETAINER

DESCRIPTION........................236

OPERATION..........................236

DISASSEMBLY........................236

CLEANING...........................236

INSPECTION.........................237

ASSEMBLY...........................237

PISTONS

DESCRIPTION........................239

OPERATION..........................239

PLANETARY GEARTRAIN/OUTPUT SHAFT

DESCRIPTION........................241

OPERATION..........................241

DISASSEMBLY........................242

INSPECTION.........................243

ASSEMBLY...........................244

REAR CLUTCH

DESCRIPTION........................247

OPERATION..........................248

DISASSEMBLY........................248

CLEANING...........................248

INSPECTION.........................248

ASSEMBLY...........................249

REAR SERVO

DESCRIPTION........................251

OPERATION..........................251

DISASSEMBLY........................251

CLEANING...........................251

ASSEMBLY...........................251

SHIFT MECHANISM

DESCRIPTION........................252OPERATION..........................252

SOLENOID

DESCRIPTION........................252

OPERATION..........................252

SPEED SENSOR

DESCRIPTION........................253

OPERATION..........................253

THROTTLE VALVE CABLE

DESCRIPTION........................253

ADJUSTMENTS - THROTTLE VALVE CABLE . 254

TORQUE CONVERTER

DESCRIPTION........................255

OPERATION..........................259

REMOVAL............................260

INSTALLATION........................260

TORQUE CONVERTER DRAINBACK VALVE

DESCRIPTION........................261

OPERATION..........................261

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE........261

TOW/HAUL OVERDRIVE SWITCH

DESCRIPTION........................261

OPERATION..........................262

DIAGNOSIS AND TESTING - OVERDRIVE

ELECTRICAL CONTROLS..............262

REMOVAL............................262

INSTALLATION........................262

TRANSMISSION RANGE SENSOR

DESCRIPTION........................263

OPERATION..........................263

DIAGNOSIS AND TESTING - TRANSMISSION

RANGE SENSOR (TRS)................264

REMOVAL............................265

INSTALLATION........................266

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................267

OPERATION..........................267

VALVE BODY

DESCRIPTION........................267

OPERATION..........................272

REMOVAL............................286

DISASSEMBLY........................287

CLEANING...........................298

INSPECTION.........................298

ASSEMBLY...........................299

INSTALLATION........................309

ADJUSTMENTS - VALVE BODY...........310

DRAUTOMATIC TRANSMISSION - 48RE 21 - 131

Page 1842 of 2627

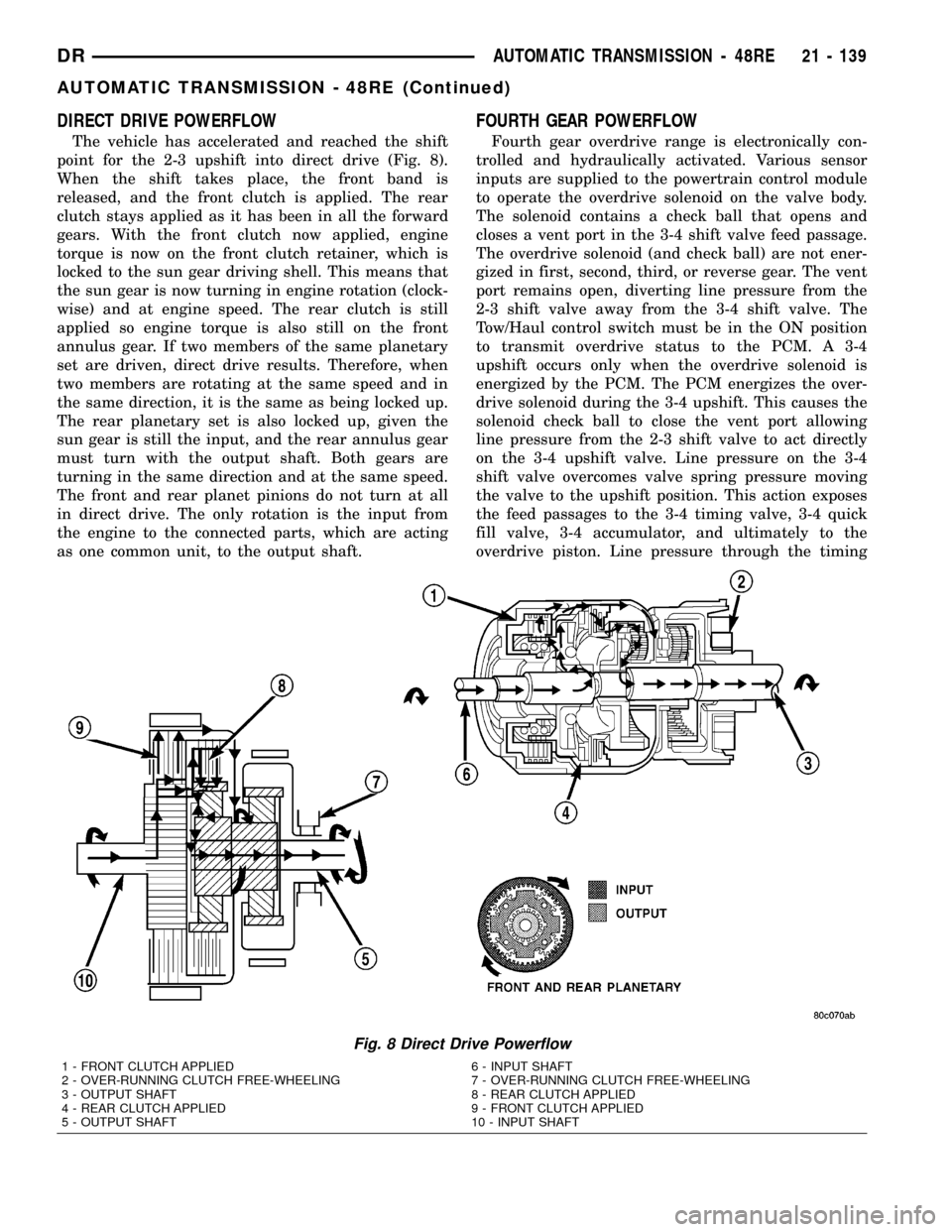

DIRECT DRIVE POWERFLOW

The vehicle has accelerated and reached the shift

point for the 2-3 upshift into direct drive (Fig. 8).

When the shift takes place, the front band is

released, and the front clutch is applied. The rear

clutch stays applied as it has been in all the forward

gears. With the front clutch now applied, engine

torque is now on the front clutch retainer, which is

locked to the sun gear driving shell. This means that

the sun gear is now turning in engine rotation (clock-

wise) and at engine speed. The rear clutch is still

applied so engine torque is also still on the front

annulus gear. If two members of the same planetary

set are driven, direct drive results. Therefore, when

two members are rotating at the same speed and in

the same direction, it is the same as being locked up.

The rear planetary set is also locked up, given the

sun gear is still the input, and the rear annulus gear

must turn with the output shaft. Both gears are

turning in the same direction and at the same speed.

The front and rear planet pinions do not turn at all

in direct drive. The only rotation is the input from

the engine to the connected parts, which are acting

as one common unit, to the output shaft.

FOURTH GEAR POWERFLOW

Fourth gear overdrive range is electronically con-

trolled and hydraulically activated. Various sensor

inputs are supplied to the powertrain control module

to operate the overdrive solenoid on the valve body.

The solenoid contains a check ball that opens and

closes a vent port in the 3-4 shift valve feed passage.

The overdrive solenoid (and check ball) are not ener-

gized in first, second, third, or reverse gear. The vent

port remains open, diverting line pressure from the

2-3 shift valve away from the 3-4 shift valve. The

Tow/Haul control switch must be in the ON position

to transmit overdrive status to the PCM. A 3-4

upshift occurs only when the overdrive solenoid is

energized by the PCM. The PCM energizes the over-

drive solenoid during the 3-4 upshift. This causes the

solenoid check ball to close the vent port allowing

line pressure from the 2-3 shift valve to act directly

on the 3-4 upshift valve. Line pressure on the 3-4

shift valve overcomes valve spring pressure moving

the valve to the upshift position. This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston. Line pressure through the timing

Fig. 8 Direct Drive Powerflow

1 - FRONT CLUTCH APPLIED 6 - INPUT SHAFT

2 - OVER-RUNNING CLUTCH FREE-WHEELING 7 - OVER-RUNNING CLUTCH FREE-WHEELING

3 - OUTPUT SHAFT 8 - REAR CLUTCH APPLIED

4 - REAR CLUTCH APPLIED 9 - FRONT CLUTCH APPLIED

5 - OUTPUT SHAFT 10 - INPUT SHAFT

DRAUTOMATIC TRANSMISSION - 48RE 21 - 139

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1846 of 2627

(3) Have helper start and run engine at 1600 rpm

for test.

(4)

Move transmission shift lever four detents rear-

ward from full forward position. This is Reverse range.

(5) Move transmission throttle lever fully forward

then fully rearward and note reading at Gauge

C-3293-SP.

(6) Pressure should be 145 - 175 psi (1000-1207

kPa) with throttle lever forward and increase to 230 -

280 psi (1586-1931 kPa) as lever is gradually moved

rearward.

Test Five - Governor Pressure

This test checks governor operation by measuring

governor pressure response to changes in vehicle

speed. It is usually not necessary to check governor

operation unless shift speeds are incorrect or if the

transmission will not downshift. The test should be

performed on the road or on a hoist that will allow

the rear wheels to rotate freely.

(1) Move 100 psi Test Gauge C-3292 to governor

pressure port.

(2) Move transmission shift lever two detents rear-

ward from full forward position. This is D range.

(3) Have helper start and run engine at curb idle

speed. Then firmly apply service brakes so wheels

will not rotate.

(4) Note governor pressure:

²

Governor pressure should be no more than 20.6

kPa (3 psi) at curb idle speed and wheels not rotating.

²If pressure exceeds 20.6 kPa (3 psi), a fault

exists in governor pressure control system.

(5) Release brakes, slowly increase engine speed,

and observe speedometer and pressure test gauge (do

not exceed 30 mph on speedometer). Governor pres-

sure should increase in proportion to vehicle speed.

Or approximately 6.89 kPa (1 psi) for every 1 mph.

(6) Governor pressure rise should be smooth and

drop back to no more than 20.6 kPa (3 psi), after

engine returns to curb idle and brakes are applied to

prevent wheels from rotating.

(7)

Compare results of pressure test with analysis

chart.

Test Six - Transmission In Overdrive Fourth Gear

This test checks line pressure at the overdrive

clutch in fourth gear range. Use 300 psi Test Gauge

C-3293-SP for this test. The test should be performed

on the road or on a chassis dyno.

(1)

Remove tachometer; it is not needed for this test.

(2) Move 300 psi Gauge to overdrive clutch pres-

sure test port. Then remove other gauge and reinstall

test port plug.

(3) Lower vehicle.

(4) Turn OD switch on.(5) Secure test gauge so it can be viewed from

drivers seat.

(6) Start engine and shift into D range.

(7) Increase vehicle speed gradually until 3-4 shift

occurs and note gauge pressure.

(8) Pressure should be 524-565 kPa (76-82 psi)

with closed throttle and increase to 690-896 kPa

(100-130 psi) at 1/2 to 3/4 throttle. Note that pres-

sure can increase to around 965 kPa (140 psi) at full

throttle.

(9) Return to shop or move vehicle off chassis

dyno.

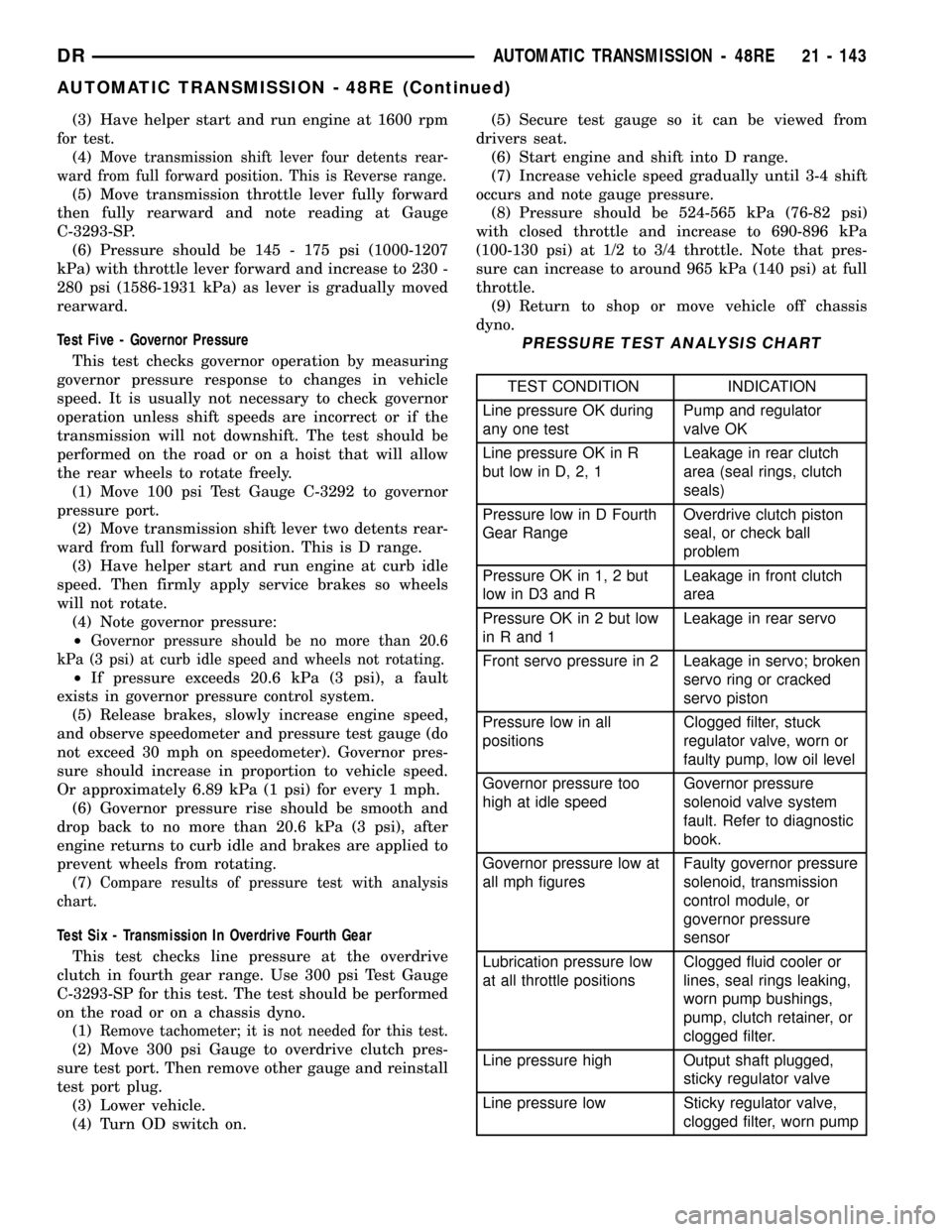

PRESSURE TEST ANALYSIS CHART

TEST CONDITION INDICATION

Line pressure OK during

any one testPump and regulator

valve OK

Line pressure OK in R

but low in D, 2, 1Leakage in rear clutch

area (seal rings, clutch

seals)

Pressure low in D Fourth

Gear RangeOverdrive clutch piston

seal, or check ball

problem

Pressure OK in 1, 2 but

low in D3 and RLeakage in front clutch

area

Pressure OK in 2 but low

in R and 1Leakage in rear servo

Front servo pressure in 2 Leakage in servo; broken

servo ring or cracked

servo piston

Pressure low in all

positionsClogged filter, stuck

regulator valve, worn or

faulty pump, low oil level

Governor pressure too

high at idle speedGovernor pressure

solenoid valve system

fault. Refer to diagnostic

book.

Governor pressure low at

all mph figuresFaulty governor pressure

solenoid, transmission

control module, or

governor pressure

sensor

Lubrication pressure low

at all throttle positionsClogged fluid cooler or

lines, seal rings leaking,

worn pump bushings,

pump, clutch retainer, or

clogged filter.

Line pressure high Output shaft plugged,

sticky regulator valve

Line pressure low Sticky regulator valve,

clogged filter, worn pump

DRAUTOMATIC TRANSMISSION - 48RE 21 - 143

AUTOMATIC TRANSMISSION - 48RE (Continued)