Body DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2304 of 2627

(7) Drill 3 mm (0.125 in.) holes in the support

squares 13 mm (0.5 in.) from the edge in the center

of one side.

(8) Scuff the backside of the body panel around the

cutout hole with a scuff pad or sandpaper.

(9) Mix enough adhesive to cover one side of all

support squares.

(10) Apply adhesive to cover one side of all support

squares.

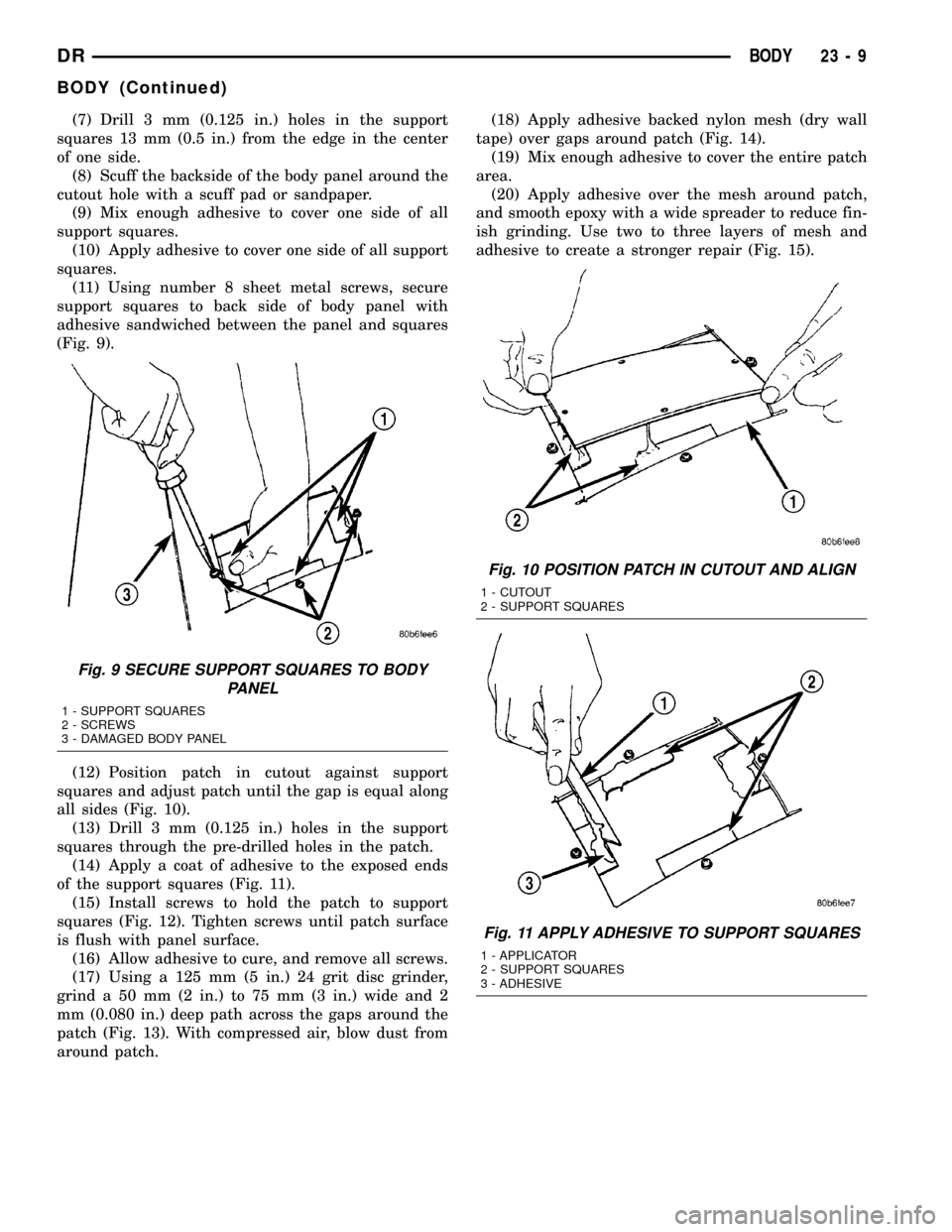

(11) Using number 8 sheet metal screws, secure

support squares to back side of body panel with

adhesive sandwiched between the panel and squares

(Fig. 9).

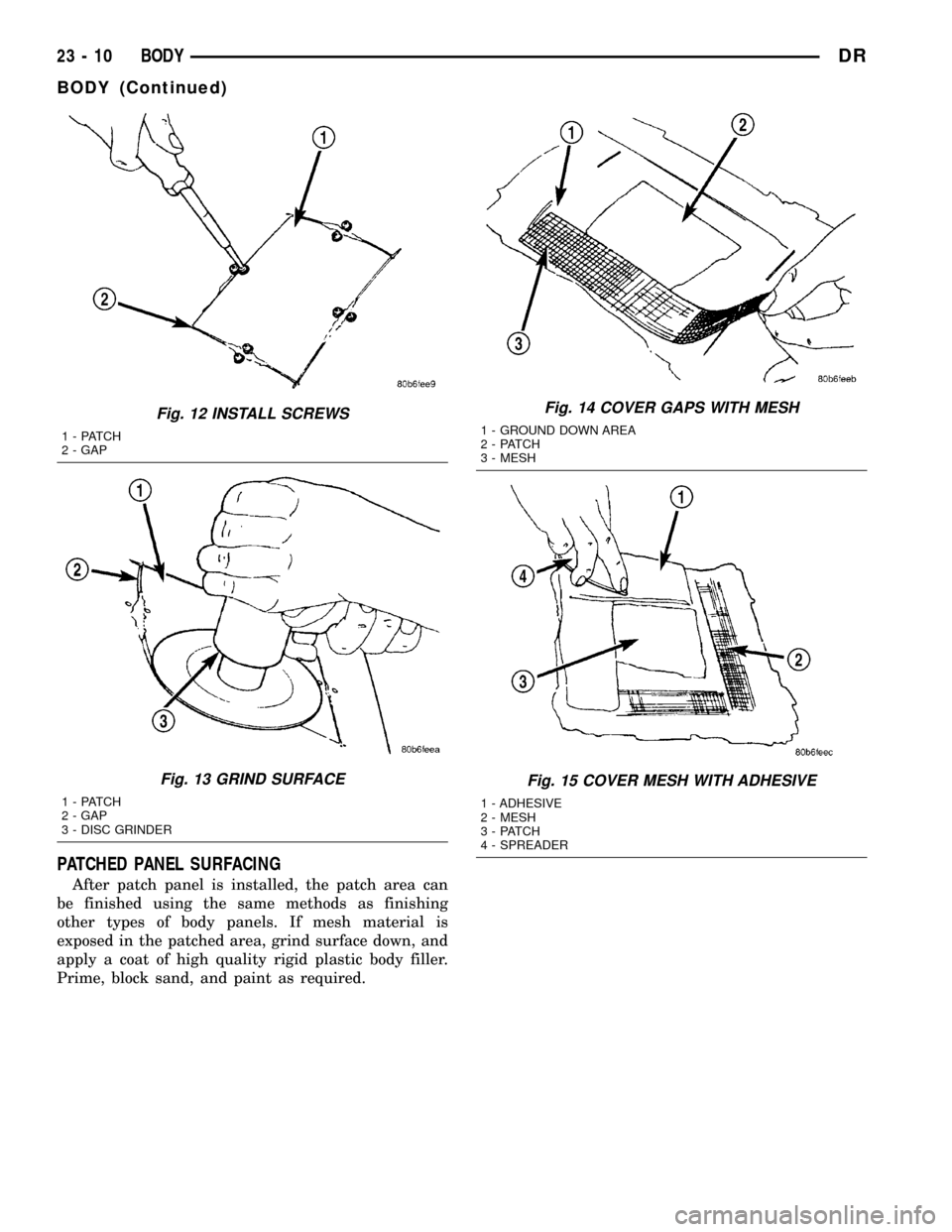

(12) Position patch in cutout against support

squares and adjust patch until the gap is equal along

all sides (Fig. 10).

(13) Drill 3 mm (0.125 in.) holes in the support

squares through the pre-drilled holes in the patch.

(14) Apply a coat of adhesive to the exposed ends

of the support squares (Fig. 11).

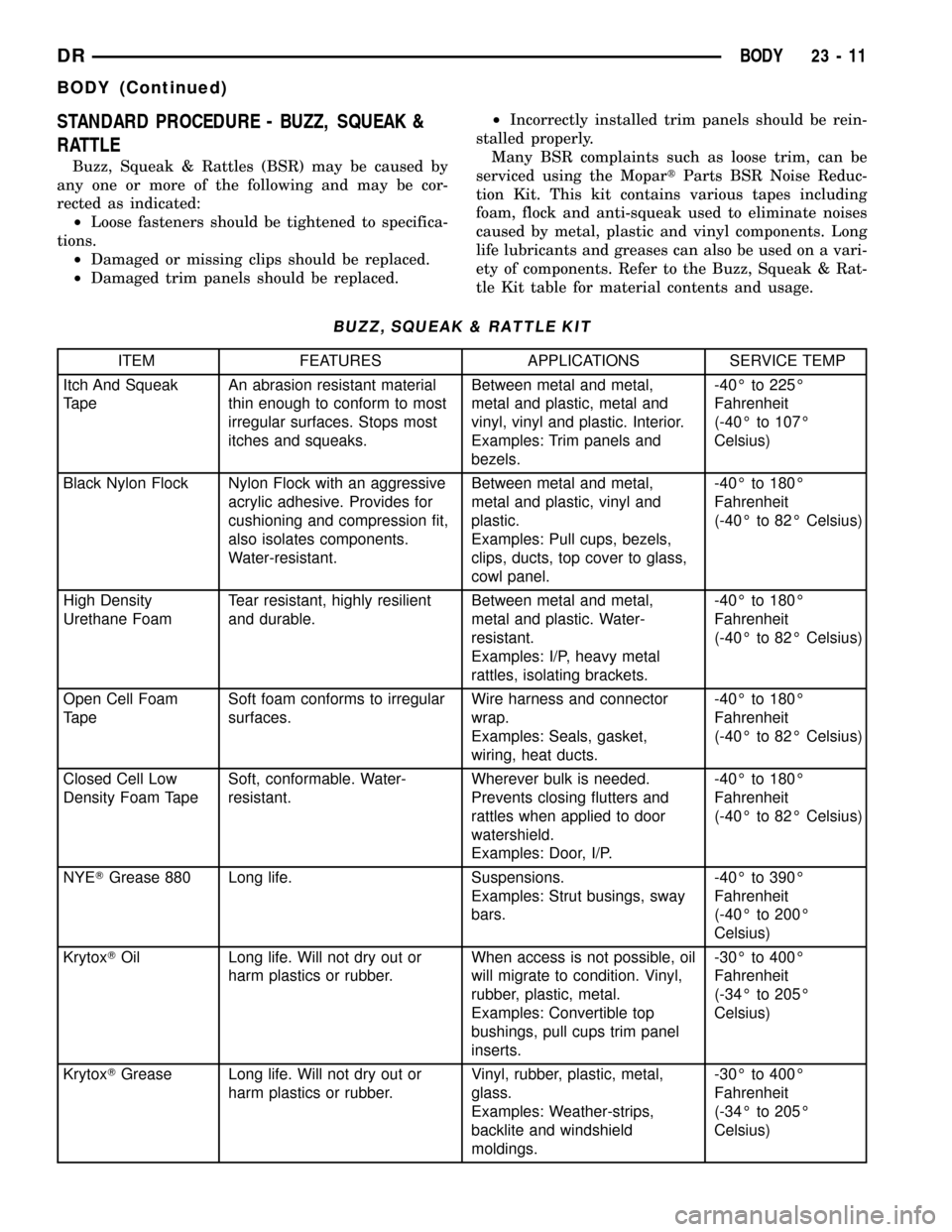

(15) Install screws to hold the patch to support

squares (Fig. 12). Tighten screws until patch surface

is flush with panel surface.

(16) Allow adhesive to cure, and remove all screws.

(17) Using a 125 mm (5 in.) 24 grit disc grinder,

grind a 50 mm (2 in.) to 75 mm (3 in.) wide and 2

mm (0.080 in.) deep path across the gaps around the

patch (Fig. 13). With compressed air, blow dust from

around patch.(18) Apply adhesive backed nylon mesh (dry wall

tape) over gaps around patch (Fig. 14).

(19) Mix enough adhesive to cover the entire patch

area.

(20) Apply adhesive over the mesh around patch,

and smooth epoxy with a wide spreader to reduce fin-

ish grinding. Use two to three layers of mesh and

adhesive to create a stronger repair (Fig. 15).

Fig. 9 SECURE SUPPORT SQUARES TO BODY

PANEL

1 - SUPPORT SQUARES

2 - SCREWS

3 - DAMAGED BODY PANEL

Fig. 10 POSITION PATCH IN CUTOUT AND ALIGN

1 - CUTOUT

2 - SUPPORT SQUARES

Fig. 11 APPLY ADHESIVE TO SUPPORT SQUARES

1 - APPLICATOR

2 - SUPPORT SQUARES

3 - ADHESIVE

DRBODY 23 - 9

BODY (Continued)

Page 2305 of 2627

PATCHED PANEL SURFACING

After patch panel is installed, the patch area can

be finished using the same methods as finishing

other types of body panels. If mesh material is

exposed in the patched area, grind surface down, and

apply a coat of high quality rigid plastic body filler.

Prime, block sand, and paint as required.

Fig. 12 INSTALL SCREWS

1 - PATCH

2 - GAP

Fig. 13 GRIND SURFACE

1 - PATCH

2 - GAP

3 - DISC GRINDER

Fig. 14 COVER GAPS WITH MESH

1 - GROUND DOWN AREA

2 - PATCH

3 - MESH

Fig. 15 COVER MESH WITH ADHESIVE

1 - ADHESIVE

2 - MESH

3 - PATCH

4 - SPREADER

23 - 10 BODYDR

BODY (Continued)

Page 2306 of 2627

STANDARD PROCEDURE - BUZZ, SQUEAK &

RATTLE

Buzz, Squeak & Rattles (BSR) may be caused by

any one or more of the following and may be cor-

rected as indicated:

²Loose fasteners should be tightened to specifica-

tions.

²Damaged or missing clips should be replaced.

²Damaged trim panels should be replaced.²Incorrectly installed trim panels should be rein-

stalled properly.

Many BSR complaints such as loose trim, can be

serviced using the MopartParts BSR Noise Reduc-

tion Kit. This kit contains various tapes including

foam, flock and anti-squeak used to eliminate noises

caused by metal, plastic and vinyl components. Long

life lubricants and greases can also be used on a vari-

ety of components. Refer to the Buzz, Squeak & Rat-

tle Kit table for material contents and usage.

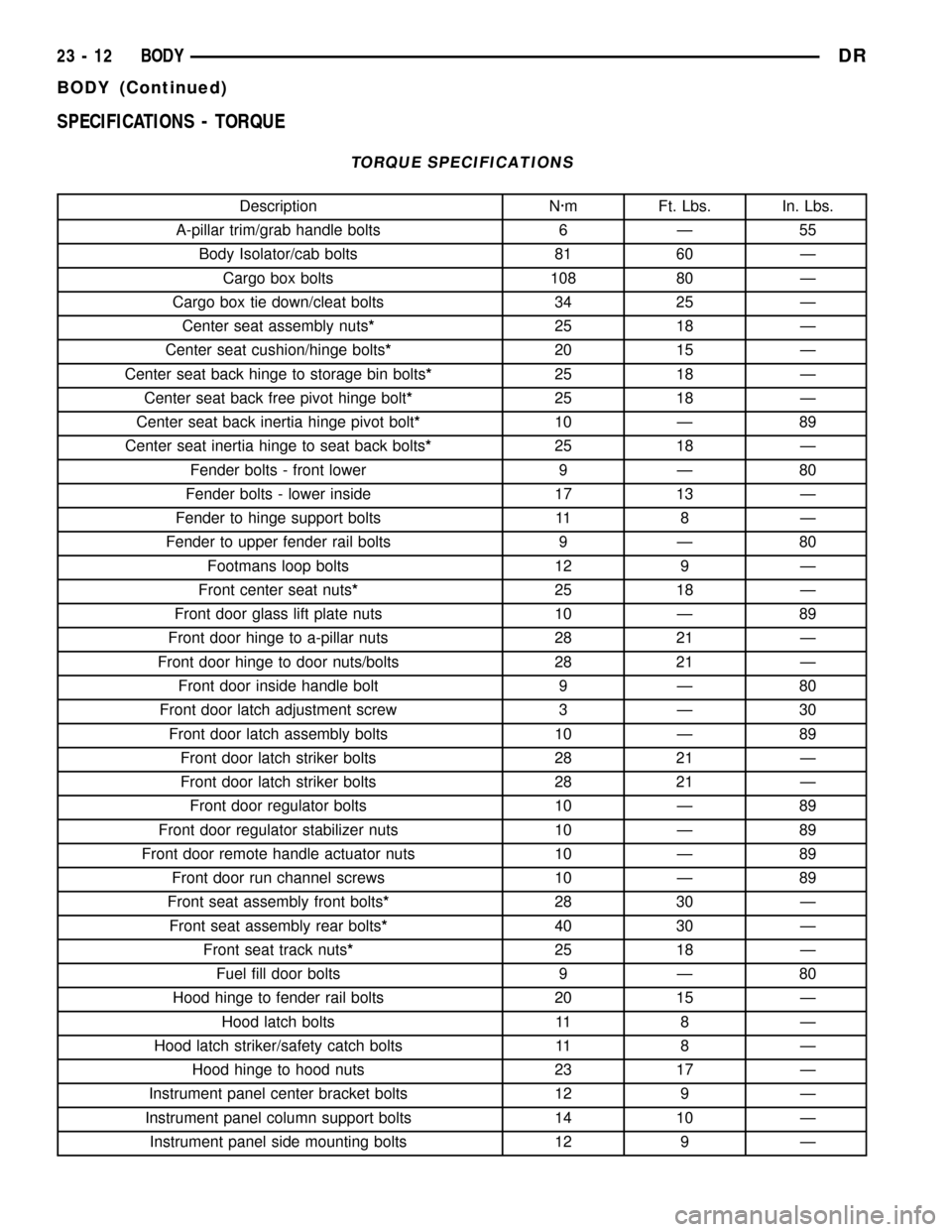

BUZZ, SQUEAK & RATTLE KIT

ITEM FEATURES APPLICATIONS SERVICE TEMP

Itch And Squeak

TapeAn abrasion resistant material

thin enough to conform to most

irregular surfaces. Stops most

itches and squeaks.Between metal and metal,

metal and plastic, metal and

vinyl, vinyl and plastic. Interior.

Examples: Trim panels and

bezels.-40É to 225É

Fahrenheit

(-40É to 107É

Celsius)

Black Nylon Flock Nylon Flock with an aggressive

acrylic adhesive. Provides for

cushioning and compression fit,

also isolates components.

Water-resistant.Between metal and metal,

metal and plastic, vinyl and

plastic.

Examples: Pull cups, bezels,

clips, ducts, top cover to glass,

cowl panel.-40É to 180É

Fahrenheit

(-40É to 82É Celsius)

High Density

Urethane FoamTear resistant, highly resilient

and durable.Between metal and metal,

metal and plastic. Water-

resistant.

Examples: I/P, heavy metal

rattles, isolating brackets.-40É to 180É

Fahrenheit

(-40É to 82É Celsius)

Open Cell Foam

TapeSoft foam conforms to irregular

surfaces.Wire harness and connector

wrap.

Examples: Seals, gasket,

wiring, heat ducts.-40É to 180É

Fahrenheit

(-40É to 82É Celsius)

Closed Cell Low

Density Foam TapeSoft, conformable. Water-

resistant.Wherever bulk is needed.

Prevents closing flutters and

rattles when applied to door

watershield.

Examples: Door, I/P.-40É to 180É

Fahrenheit

(-40É to 82É Celsius)

NYETGrease 880 Long life. Suspensions.

Examples: Strut busings, sway

bars.-40É to 390É

Fahrenheit

(-40É to 200É

Celsius)

KrytoxTOil Long life. Will not dry out or

harm plastics or rubber.When access is not possible, oil

will migrate to condition. Vinyl,

rubber, plastic, metal.

Examples: Convertible top

bushings, pull cups trim panel

inserts.-30É to 400É

Fahrenheit

(-34É to 205É

Celsius)

KrytoxTGrease Long life. Will not dry out or

harm plastics or rubber.Vinyl, rubber, plastic, metal,

glass.

Examples: Weather-strips,

backlite and windshield

moldings.-30É to 400É

Fahrenheit

(-34É to 205É

Celsius)

DRBODY 23 - 11

BODY (Continued)

Page 2307 of 2627

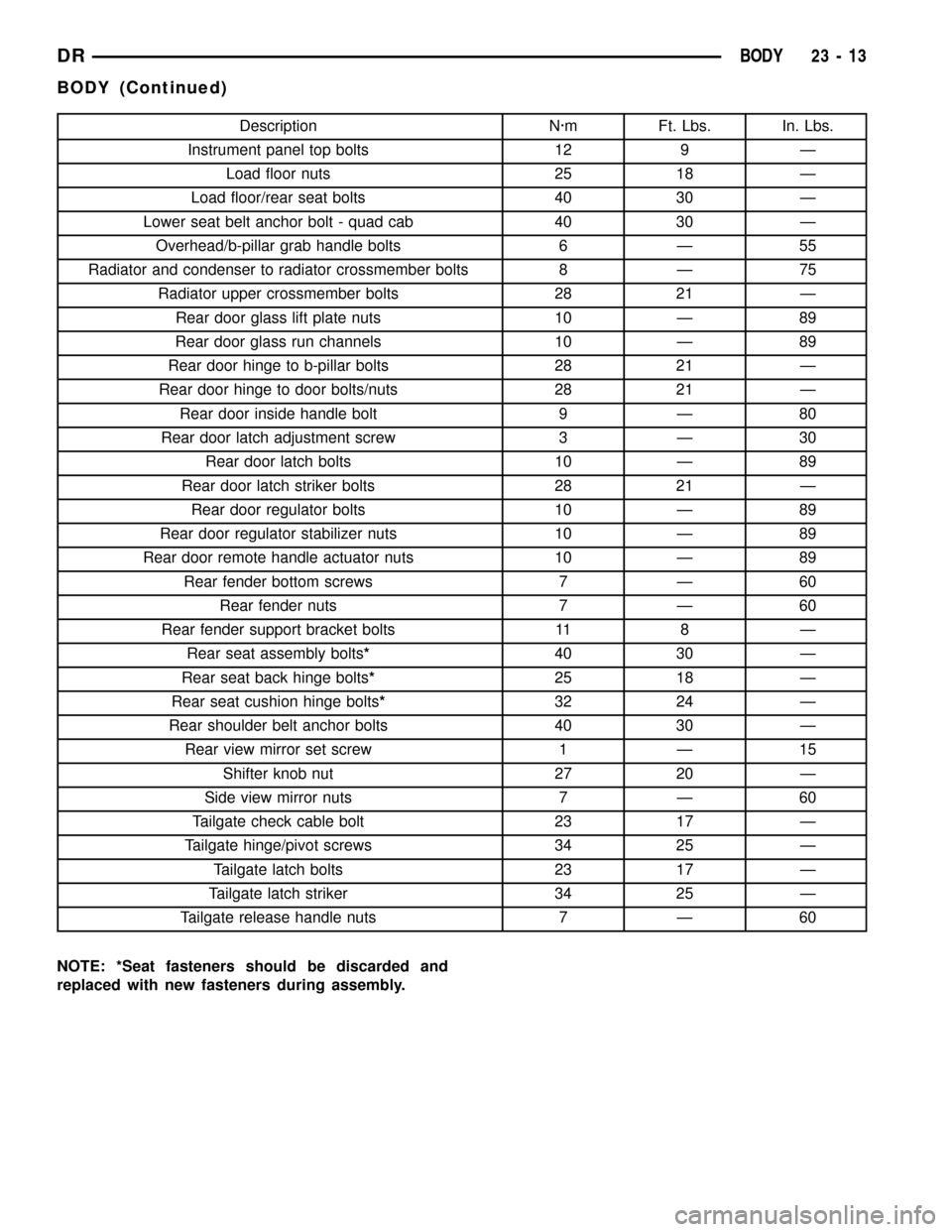

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

Description N´m Ft. Lbs. In. Lbs.

A-pillar trim/grab handle bolts 6 Ð 55

Body Isolator/cab bolts 81 60 Ð

Cargo box bolts 108 80 Ð

Cargo box tie down/cleat bolts 34 25 Ð

Center seat assembly nuts*25 18 Ð

Center seat cushion/hinge bolts*20 15 Ð

Center seat back hinge to storage bin bolts*25 18 Ð

Center seat back free pivot hinge bolt*25 18 Ð

Center seat back inertia hinge pivot bolt*10 Ð 89

Center seat inertia hinge to seat back bolts*25 18 Ð

Fender bolts - front lower 9 Ð 80

Fender bolts - lower inside 17 13 Ð

Fender to hinge support bolts 11 8 Ð

Fender to upper fender rail bolts 9 Ð 80

Footmans loop bolts 12 9 Ð

Front center seat nuts*25 18 Ð

Front door glass lift plate nuts 10 Ð 89

Front door hinge to a-pillar nuts 28 21 Ð

Front door hinge to door nuts/bolts 28 21 Ð

Front door inside handle bolt 9 Ð 80

Front door latch adjustment screw 3 Ð 30

Front door latch assembly bolts 10 Ð 89

Front door latch striker bolts 28 21 Ð

Front door latch striker bolts 28 21 Ð

Front door regulator bolts 10 Ð 89

Front door regulator stabilizer nuts 10 Ð 89

Front door remote handle actuator nuts 10 Ð 89

Front door run channel screws 10 Ð 89

Front seat assembly front bolts*28 30 Ð

Front seat assembly rear bolts*40 30 Ð

Front seat track nuts*25 18 Ð

Fuel fill door bolts 9 Ð 80

Hood hinge to fender rail bolts 20 15 Ð

Hood latch bolts 11 8 Ð

Hood latch striker/safety catch bolts 11 8 Ð

Hood hinge to hood nuts 23 17 Ð

Instrument panel center bracket bolts 12 9 Ð

Instrument panel column support bolts 14 10 Ð

Instrument panel side mounting bolts 12 9 Ð

23 - 12 BODYDR

BODY (Continued)

Page 2308 of 2627

Description N´m Ft. Lbs. In. Lbs.

Instrument panel top bolts 12 9 Ð

Load floor nuts 25 18 Ð

Load floor/rear seat bolts 40 30 Ð

Lower seat belt anchor bolt - quad cab 40 30 Ð

Overhead/b-pillar grab handle bolts 6 Ð 55

Radiator and condenser to radiator crossmember bolts 8 Ð 75

Radiator upper crossmember bolts 28 21 Ð

Rear door glass lift plate nuts 10 Ð 89

Rear door glass run channels 10 Ð 89

Rear door hinge to b-pillar bolts 28 21 Ð

Rear door hinge to door bolts/nuts 28 21 Ð

Rear door inside handle bolt 9 Ð 80

Rear door latch adjustment screw 3 Ð 30

Rear door latch bolts 10 Ð 89

Rear door latch striker bolts 28 21 Ð

Rear door regulator bolts 10 Ð 89

Rear door regulator stabilizer nuts 10 Ð 89

Rear door remote handle actuator nuts 10 Ð 89

Rear fender bottom screws 7 Ð 60

Rear fender nuts 7 Ð 60

Rear fender support bracket bolts 11 8 Ð

Rear seat assembly bolts*40 30 Ð

Rear seat back hinge bolts*25 18 Ð

Rear seat cushion hinge bolts*32 24 Ð

Rear shoulder belt anchor bolts 40 30 Ð

Rear view mirror set screw 1 Ð 15

Shifter knob nut 27 20 Ð

Side view mirror nuts 7 Ð 60

Tailgate check cable bolt 23 17 Ð

Tailgate hinge/pivot screws 34 25 Ð

Tailgate latch bolts 23 17 Ð

Tailgate latch striker 34 25 Ð

Tailgate release handle nuts 7 Ð 60

NOTE: *Seat fasteners should be discarded and

replaced with new fasteners during assembly.

DRBODY 23 - 13

BODY (Continued)

Page 2309 of 2627

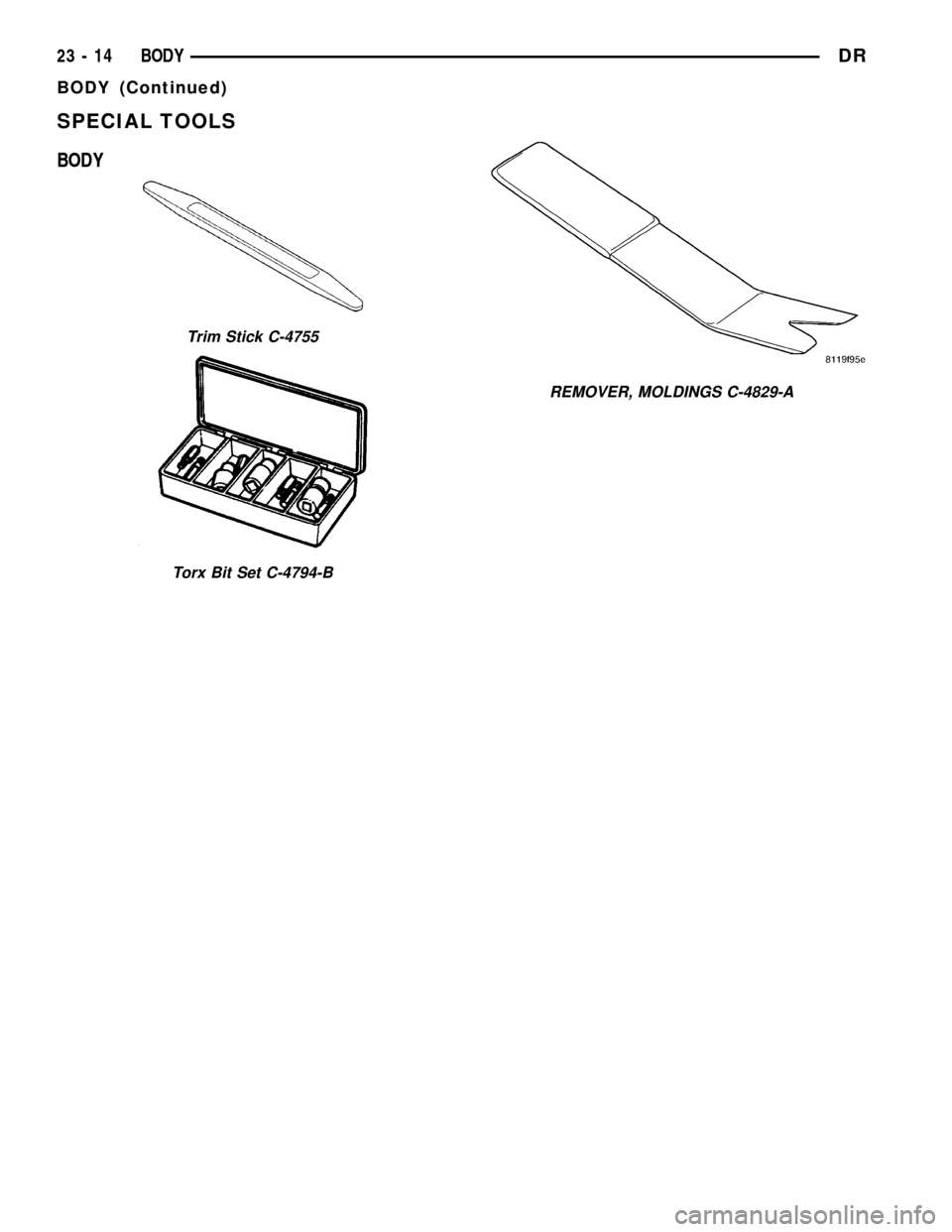

SPECIAL TOOLS

BODY

Trim Stick C-4755

Torx Bit Set C-4794-B

REMOVER, MOLDINGS C-4829-A

23 - 14 BODYDR

BODY (Continued)

Page 2311 of 2627

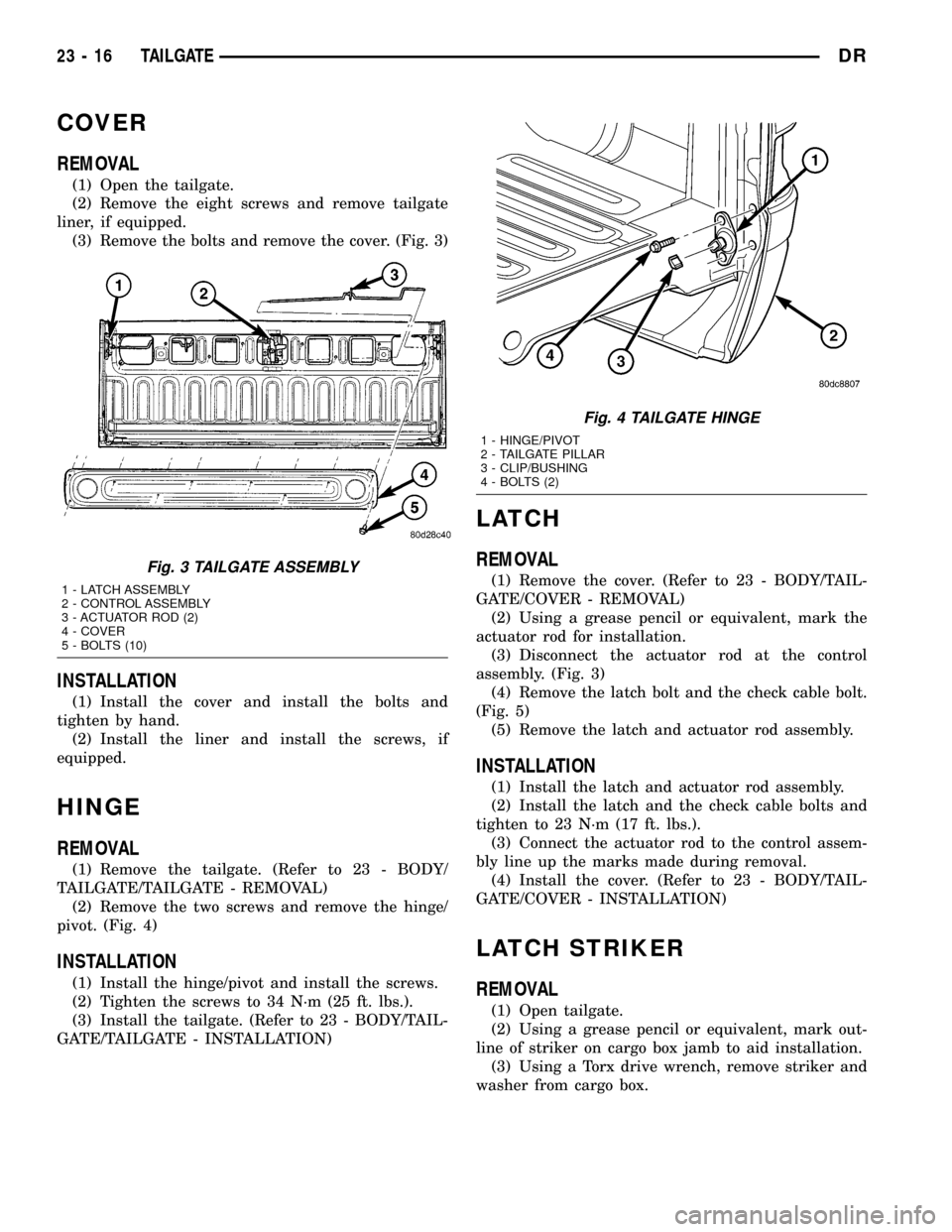

COVER

REMOVAL

(1) Open the tailgate.

(2) Remove the eight screws and remove tailgate

liner, if equipped.

(3) Remove the bolts and remove the cover. (Fig. 3)

INSTALLATION

(1) Install the cover and install the bolts and

tighten by hand.

(2) Install the liner and install the screws, if

equipped.

HINGE

REMOVAL

(1) Remove the tailgate. (Refer to 23 - BODY/

TAILGATE/TAILGATE - REMOVAL)

(2) Remove the two screws and remove the hinge/

pivot. (Fig. 4)

INSTALLATION

(1) Install the hinge/pivot and install the screws.

(2) Tighten the screws to 34 N´m (25 ft. lbs.).

(3) Install the tailgate. (Refer to 23 - BODY/TAIL-

GATE/TAILGATE - INSTALLATION)

LATCH

REMOVAL

(1) Remove the cover. (Refer to 23 - BODY/TAIL-

GATE/COVER - REMOVAL)

(2) Using a grease pencil or equivalent, mark the

actuator rod for installation.

(3) Disconnect the actuator rod at the control

assembly. (Fig. 3)

(4) Remove the latch bolt and the check cable bolt.

(Fig. 5)

(5) Remove the latch and actuator rod assembly.

INSTALLATION

(1) Install the latch and actuator rod assembly.

(2) Install the latch and the check cable bolts and

tighten to 23 N´m (17 ft. lbs.).

(3) Connect the actuator rod to the control assem-

bly line up the marks made during removal.

(4) Install the cover. (Refer to 23 - BODY/TAIL-

GATE/COVER - INSTALLATION)

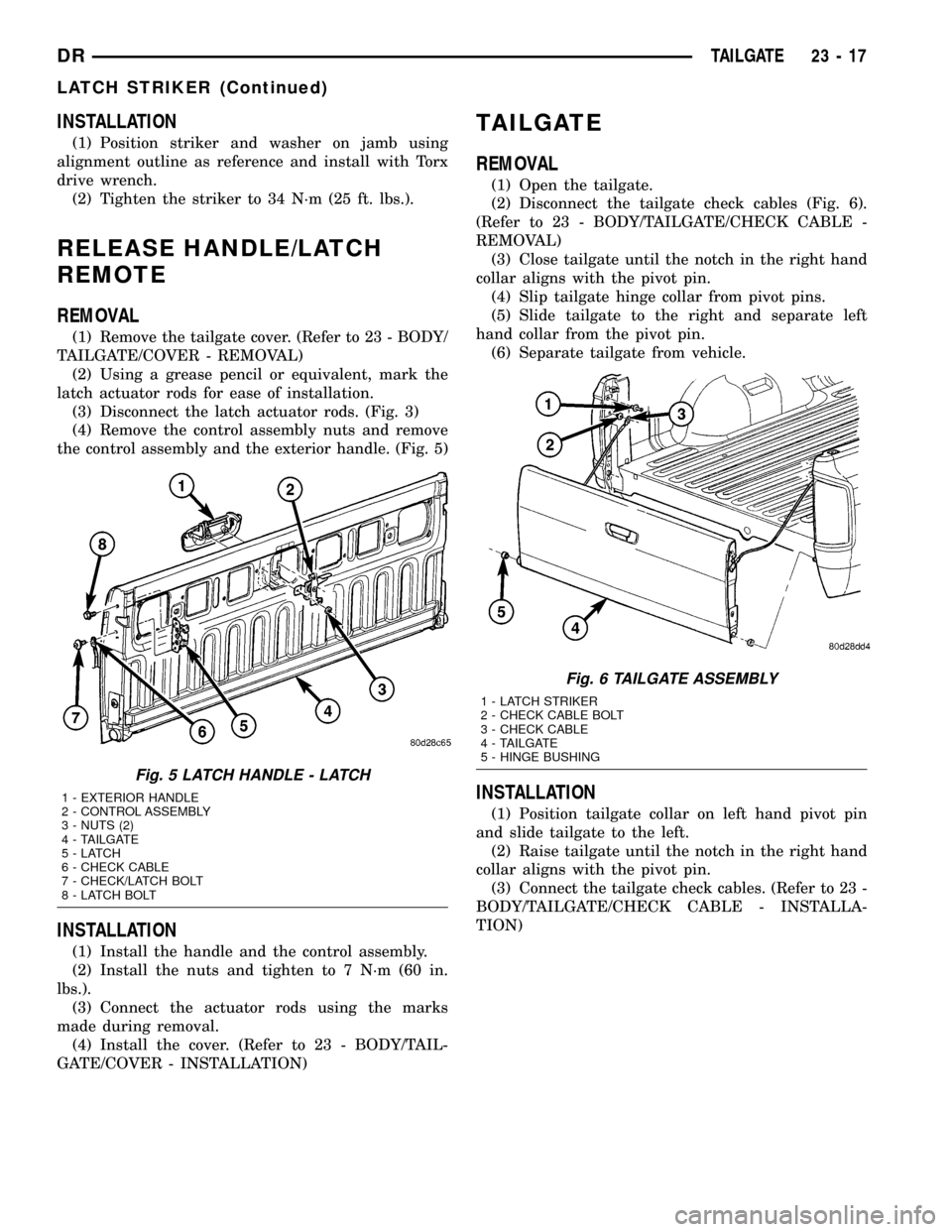

LATCH STRIKER

REMOVAL

(1) Open tailgate.

(2) Using a grease pencil or equivalent, mark out-

line of striker on cargo box jamb to aid installation.

(3) Using a Torx drive wrench, remove striker and

washer from cargo box.

Fig. 3 TAILGATE ASSEMBLY

1 - LATCH ASSEMBLY

2 - CONTROL ASSEMBLY

3 - ACTUATOR ROD (2)

4 - COVER

5 - BOLTS (10)

Fig. 4 TAILGATE HINGE

1 - HINGE/PIVOT

2 - TAILGATE PILLAR

3 - CLIP/BUSHING

4 - BOLTS (2)

23 - 16 TAILGATEDR

Page 2312 of 2627

INSTALLATION

(1) Position striker and washer on jamb using

alignment outline as reference and install with Torx

drive wrench.

(2) Tighten the striker to 34 N´m (25 ft. lbs.).

RELEASE HANDLE/LATCH

REMOTE

REMOVAL

(1) Remove the tailgate cover. (Refer to 23 - BODY/

TAILGATE/COVER - REMOVAL)

(2) Using a grease pencil or equivalent, mark the

latch actuator rods for ease of installation.

(3) Disconnect the latch actuator rods. (Fig. 3)

(4) Remove the control assembly nuts and remove

the control assembly and the exterior handle. (Fig. 5)

INSTALLATION

(1) Install the handle and the control assembly.

(2) Install the nuts and tighten to 7 N´m (60 in.

lbs.).

(3) Connect the actuator rods using the marks

made during removal.

(4) Install the cover. (Refer to 23 - BODY/TAIL-

GATE/COVER - INSTALLATION)

TAILGATE

REMOVAL

(1) Open the tailgate.

(2) Disconnect the tailgate check cables (Fig. 6).

(Refer to 23 - BODY/TAILGATE/CHECK CABLE -

REMOVAL)

(3) Close tailgate until the notch in the right hand

collar aligns with the pivot pin.

(4) Slip tailgate hinge collar from pivot pins.

(5) Slide tailgate to the right and separate left

hand collar from the pivot pin.

(6) Separate tailgate from vehicle.

INSTALLATION

(1) Position tailgate collar on left hand pivot pin

and slide tailgate to the left.

(2) Raise tailgate until the notch in the right hand

collar aligns with the pivot pin.

(3) Connect the tailgate check cables. (Refer to 23 -

BODY/TAILGATE/CHECK CABLE - INSTALLA-

TION)

Fig. 5 LATCH HANDLE - LATCH

1 - EXTERIOR HANDLE

2 - CONTROL ASSEMBLY

3 - NUTS (2)

4 - TAILGATE

5-LATCH

6 - CHECK CABLE

7 - CHECK/LATCH BOLT

8 - LATCH BOLT

Fig. 6 TAILGATE ASSEMBLY

1 - LATCH STRIKER

2 - CHECK CABLE BOLT

3 - CHECK CABLE

4 - TAILGATE

5 - HINGE BUSHING

DRTAILGATE 23 - 17

LATCH STRIKER (Continued)

Page 2313 of 2627

DOOR - FRONT

TABLE OF CONTENTS

page page

DOOR

REMOVAL.............................18

INSTALLATION.........................18

ADJUSTMENTS

ADJUSTMENT........................19

DOOR GLASS

REMOVAL.............................20

INSTALLATION.........................20

EXTERIOR HANDLE

REMOVAL.............................20

INSTALLATION.........................21

GLASS RUN CHANNEL

REMOVAL.............................21

INSTALLATION.........................22

HINGE

REMOVAL.............................22

INSTALLATION.........................22

INSIDE HANDLE ACTUATOR

REMOVAL.............................22

INSTALLATION.........................22

LATCH

REMOVAL.............................23

INSTALLATION.........................23

ADJUSTMENTS

ADJUSTMENT........................23LATCH STRIKER

REMOVAL.............................23

INSTALLATION.........................23

ADJUSTMENTS

ADJUSTMENT........................24

LOCK CYLINDER

REMOVAL.............................24

INSTALLATION.........................24

TRIM PANEL

REMOVAL.............................24

INSTALLATION.........................24

WATERDAM

REMOVAL.............................25

INSTALLATION.........................25

WINDOW REGULATOR - POWER

REMOVAL.............................25

INSTALLATION.........................26

WINDOW REGULATOR - MANUAL

REMOVAL.............................26

INSTALLATION.........................27

SIDE VIEW MIRROR FLAG

REMOVAL.............................27

INSTALLATION.........................27

DOOR

REMOVAL

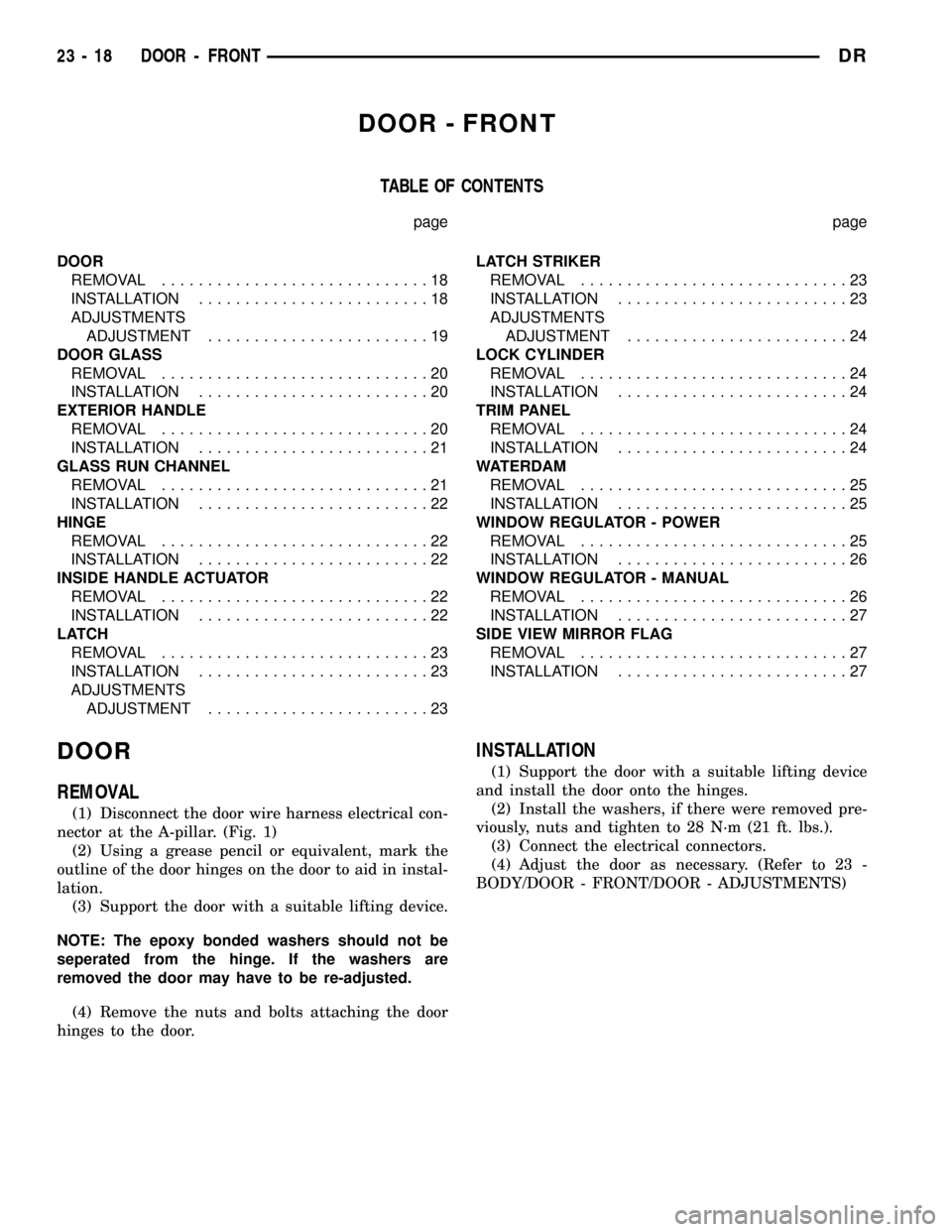

(1) Disconnect the door wire harness electrical con-

nector at the A-pillar. (Fig. 1)

(2) Using a grease pencil or equivalent, mark the

outline of the door hinges on the door to aid in instal-

lation.

(3) Support the door with a suitable lifting device.

NOTE: The epoxy bonded washers should not be

seperated from the hinge. If the washers are

removed the door may have to be re-adjusted.

(4) Remove the nuts and bolts attaching the door

hinges to the door.

INSTALLATION

(1) Support the door with a suitable lifting device

and install the door onto the hinges.

(2) Install the washers, if there were removed pre-

viously, nuts and tighten to 28 N´m (21 ft. lbs.).

(3) Connect the electrical connectors.

(4) Adjust the door as necessary. (Refer to 23 -

BODY/DOOR - FRONT/DOOR - ADJUSTMENTS)

23 - 18 DOOR - FRONTDR

Page 2314 of 2627

ADJUSTMENTS

ADJUSTMENT

NOTE: For vehicles with four doors, it is recom-

mended that you adjust the rear door before adjust-

ing the front door. (Refer to 23 - BODY/DOORS -

REAR/DOOR - ADJUSTMENTS)

²Door adjustment measurements should be

taken from stationary or welded body panels like

the roof, rocker or quarter panels.

²During adjustment procedures, it is recom-

mended that all the hinge fasteners be loosened

except for the upper most fasteners. Adjustments

can be made using the upper bolts to hold the door

with final torque of the fasteners occurring after

correct door positioning is achieved.

²A suitable body sealant should be used when

removing or moving the hinges.

FORE/AFT

NOTE: Fore/aft (lateral) door adjustment is done by

loosening the hinge to the hinge pillar fasteners

one hinge at a time and moving the door to the cor-

rect position.

(1) Support the door with a suitable lifting device.

(2)

Loosen the hinge to hinge pillar fasteners. (Refer

to 23 - BODY/DOOR - FRONT/HINGE - REMOVAL)

(3) Adjust the door to the correct position. (Refer

to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)(4) Tighten the hinge pillar fasteners to 28 N´m

(21 ft. lbs.).

UP/DOWN

NOTE: Up/down door adjustment is done by loosen-

ing either the hinge to the hinge pillar fasteners or

the hinge to door fasteners and moving the door to

the correct position.

NOTE: When adjustment of the door requires the

loosening of the door to hinge fasteners, it will be

necessary to separate the epoxy bonded washers

with a chisel or other suitable tool.

NOTE: When the up/down adjustments are done

correctly, the top of the door is positioned over

flush to the roof. (Refer to 23 - BODY/BODY STRUC-

TURE/GAP AND FLUSH - SPECIFICATIONS)

(1) Support the door with a suitable lifting device.

(2) Loosen the latch striker bolts. (Refer to 23 -

BODY/DOOR - FRONT/LATCH STRIKER -

REMOVAL)

(3) Loosen the hinge to door fasteners (Refer to 23

- BODY/DOOR - FRONT/DOOR - REMOVAL) or

loosen the hinge to hinge pillar fasteners (Refer to 23

- BODY/DOOR - FRONT/HINGE - REMOVAL).

(4) Adjust the door to the correct position. (Refer

to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

(5) Tighten the hinge pillar fasteners or the door

to hinges fasteners to 28 N´m (21 ft. lbs.).

(6) Tighten the latch striker bolts. (Refer to 23 -

BODY/DOOR - FRONT/LATCH STRIKER - INSTAL-

LATION)

IN/OUT

NOTE: In/out door adjustment is done by loosening

the hinge to door fasteners one hinge at a time and

moving the door to the correct position.

NOTE: When adjustment of the door requires the

loosening of the door to hinge fasteners, it will be

necessary to separate the epoxy bonded washers

with a chisel or other suitable tool.

(1) Support the door with a suitable lifting device.

(2) Loosen the latch striker bolts. (Refer to 23 -

BODY/DOOR - FRONT/LATCH STRIKER -

REMOVAL)

(3) Loosen the hinge to door fasteners. (Refer to 23

- BODY/DOOR - FRONT/DOOR - REMOVAL)

Fig. 1 FRONT DOOR

1 - NUTS (2)

2 - UPPER HINGE

3 - STUDS

4 - FRONT DOOR

5 - WIRE HARNESS

6 - LOWER HINGE

7 - ELECTRICAL CONNECTORS (2)

8 - BOLTS (2)

DRDOOR - FRONT 23 - 19

DOOR (Continued)