Front lamp DODGE RAM 1500 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 358 of 2627

CAUTION: A number or letter is stamped into the

tongue of the constant tension clamps (Fig. 19). If

replacement is necessary, use only an original

equipment clamp with a matching number, letter

and width.

(7) Remove the radiator upper hose clamp and

upper hose at the thermostat housing.

(8) Position the wiring harness (behind thermostat

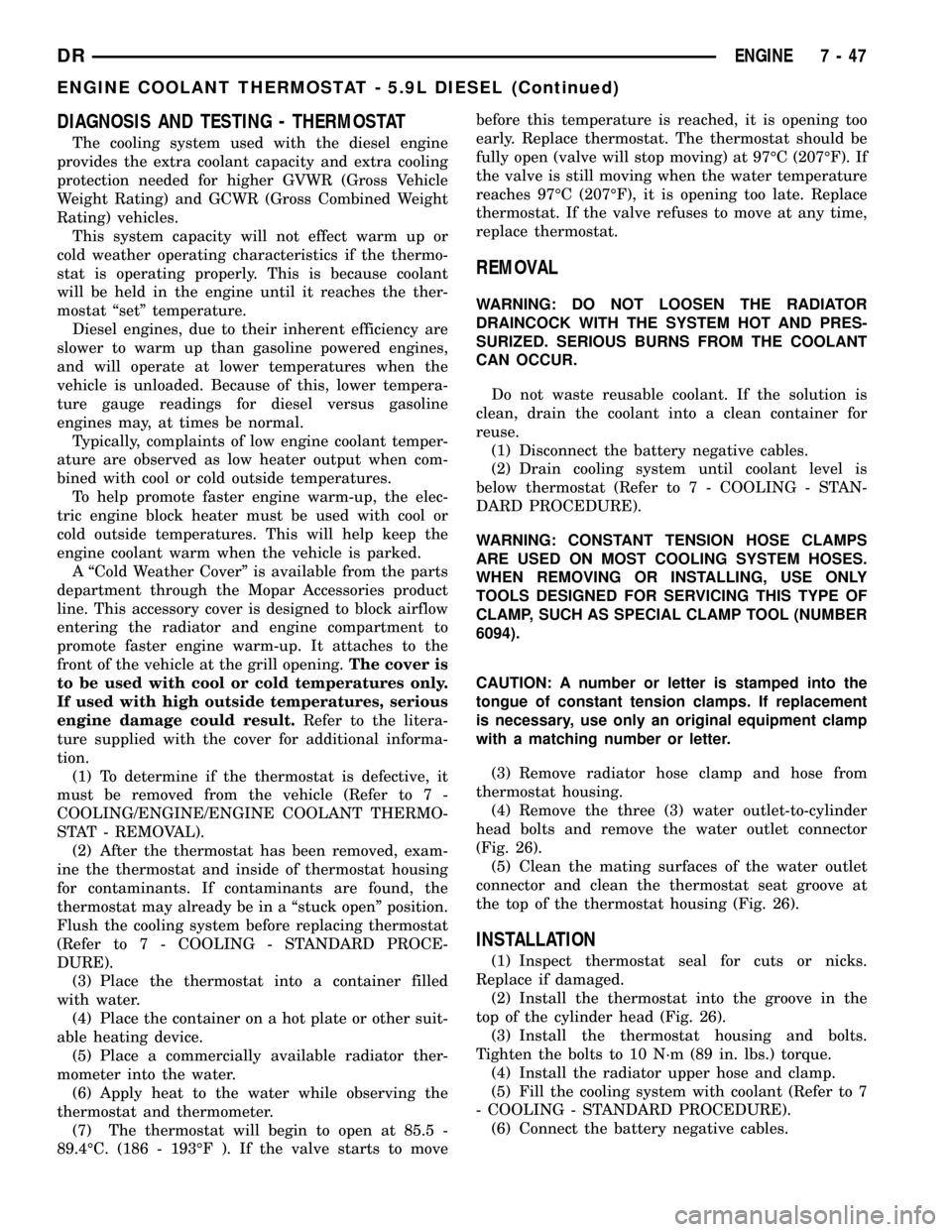

housing) to gain access to the thermostat housing.(9) Remove the thermostat housing mounting

bolts, thermostat housing, gasket and thermostat

(Fig. 20). Discard old gasket.

INSTALLATION

(1) Clean the mating areas of the intake manifold

and thermostat housing.

(2) Install the thermostat (spring side down) into

the recessed machined groove on the intake manifold

(Fig. 20).

(3) Install the gasket on the intake manifold and

over the thermostat (Fig. 20).

(4) Position the thermostat housing to the intake

manifold.Note:The word FRONT stamped on hous-

ing (Fig. 21). For adequate clearance, thismustbe

placed towards the front of the vehicle. The housing

is slightly angled forward after the installation to the

intake manifold.

(5) Install the housing-to-intake manifold bolts.

Tighten the bolts to 23 N´m (200 in. lbs.).

(6) Install the radiator upper hose to the thermo-

stat housing.

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump

rotating in wrong direction. Refer to (Fig. 22) for the

correct 5.9L engine belt routing. The correct belt

with correct length must be used.

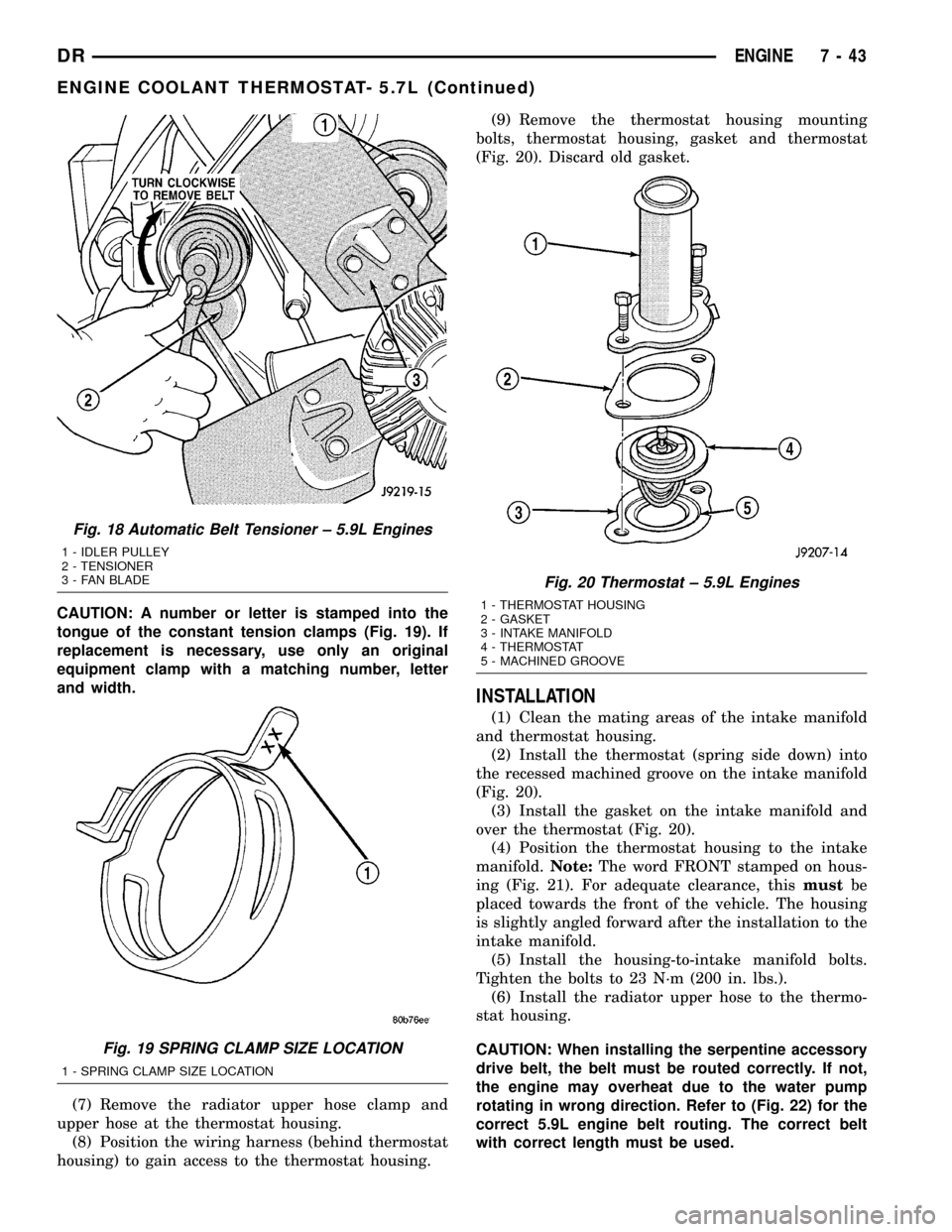

Fig. 18 Automatic Belt Tensioner ± 5.9L Engines

1 - IDLER PULLEY

2 - TENSIONER

3 - FAN BLADE

Fig. 19 SPRING CLAMP SIZE LOCATION

1 - SPRING CLAMP SIZE LOCATION

Fig. 20 Thermostat ± 5.9L Engines

1 - THERMOSTAT HOUSING

2 - GASKET

3 - INTAKE MANIFOLD

4 - THERMOSTAT

5 - MACHINED GROOVE

DRENGINE 7 - 43

ENGINE COOLANT THERMOSTAT- 5.7L (Continued)

Page 362 of 2627

DIAGNOSIS AND TESTING - THERMOSTAT

The cooling system used with the diesel engine

provides the extra coolant capacity and extra cooling

protection needed for higher GVWR (Gross Vehicle

Weight Rating) and GCWR (Gross Combined Weight

Rating) vehicles.

This system capacity will not effect warm up or

cold weather operating characteristics if the thermo-

stat is operating properly. This is because coolant

will be held in the engine until it reaches the ther-

mostat ªsetº temperature.

Diesel engines, due to their inherent efficiency are

slower to warm up than gasoline powered engines,

and will operate at lower temperatures when the

vehicle is unloaded. Because of this, lower tempera-

ture gauge readings for diesel versus gasoline

engines may, at times be normal.

Typically, complaints of low engine coolant temper-

ature are observed as low heater output when com-

bined with cool or cold outside temperatures.

To help promote faster engine warm-up, the elec-

tric engine block heater must be used with cool or

cold outside temperatures. This will help keep the

engine coolant warm when the vehicle is parked.

A ªCold Weather Coverº is available from the parts

department through the Mopar Accessories product

line. This accessory cover is designed to block airflow

entering the radiator and engine compartment to

promote faster engine warm-up. It attaches to the

front of the vehicle at the grill opening.The cover is

to be used with cool or cold temperatures only.

If used with high outside temperatures, serious

engine damage could result.Refer to the litera-

ture supplied with the cover for additional informa-

tion.

(1) To determine if the thermostat is defective, it

must be removed from the vehicle (Refer to 7 -

COOLING/ENGINE/ENGINE COOLANT THERMO-

STAT - REMOVAL).

(2) After the thermostat has been removed, exam-

ine the thermostat and inside of thermostat housing

for contaminants. If contaminants are found, the

thermostat may already be in a ªstuck openº position.

Flush the cooling system before replacing thermostat

(Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(3) Place the thermostat into a container filled

with water.

(4) Place the container on a hot plate or other suit-

able heating device.

(5) Place a commercially available radiator ther-

mometer into the water.

(6) Apply heat to the water while observing the

thermostat and thermometer.

(7) The thermostat will begin to open at 85.5 -

89.4ÉC. (186 - 193ÉF ). If the valve starts to movebefore this temperature is reached, it is opening too

early. Replace thermostat. The thermostat should be

fully open (valve will stop moving) at 97ÉC (207ÉF). If

the valve is still moving when the water temperature

reaches 97ÉC (207ÉF), it is opening too late. Replace

thermostat. If the valve refuses to move at any time,

replace thermostat.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

(1) Disconnect the battery negative cables.

(2) Drain cooling system until coolant level is

below thermostat (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094).

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(3) Remove radiator hose clamp and hose from

thermostat housing.

(4) Remove the three (3) water outlet-to-cylinder

head bolts and remove the water outlet connector

(Fig. 26).

(5) Clean the mating surfaces of the water outlet

connector and clean the thermostat seat groove at

the top of the thermostat housing (Fig. 26).

INSTALLATION

(1) Inspect thermostat seal for cuts or nicks.

Replace if damaged.

(2) Install the thermostat into the groove in the

top of the cylinder head (Fig. 26).

(3) Install the thermostat housing and bolts.

Tighten the bolts to 10 N´m (89 in. lbs.) torque.

(4) Install the radiator upper hose and clamp.

(5) Fill the cooling system with coolant (Refer to 7

- COOLING - STANDARD PROCEDURE).

(6) Connect the battery negative cables.

DRENGINE 7 - 47

ENGINE COOLANT THERMOSTAT - 5.9L DIESEL (Continued)

Page 370 of 2627

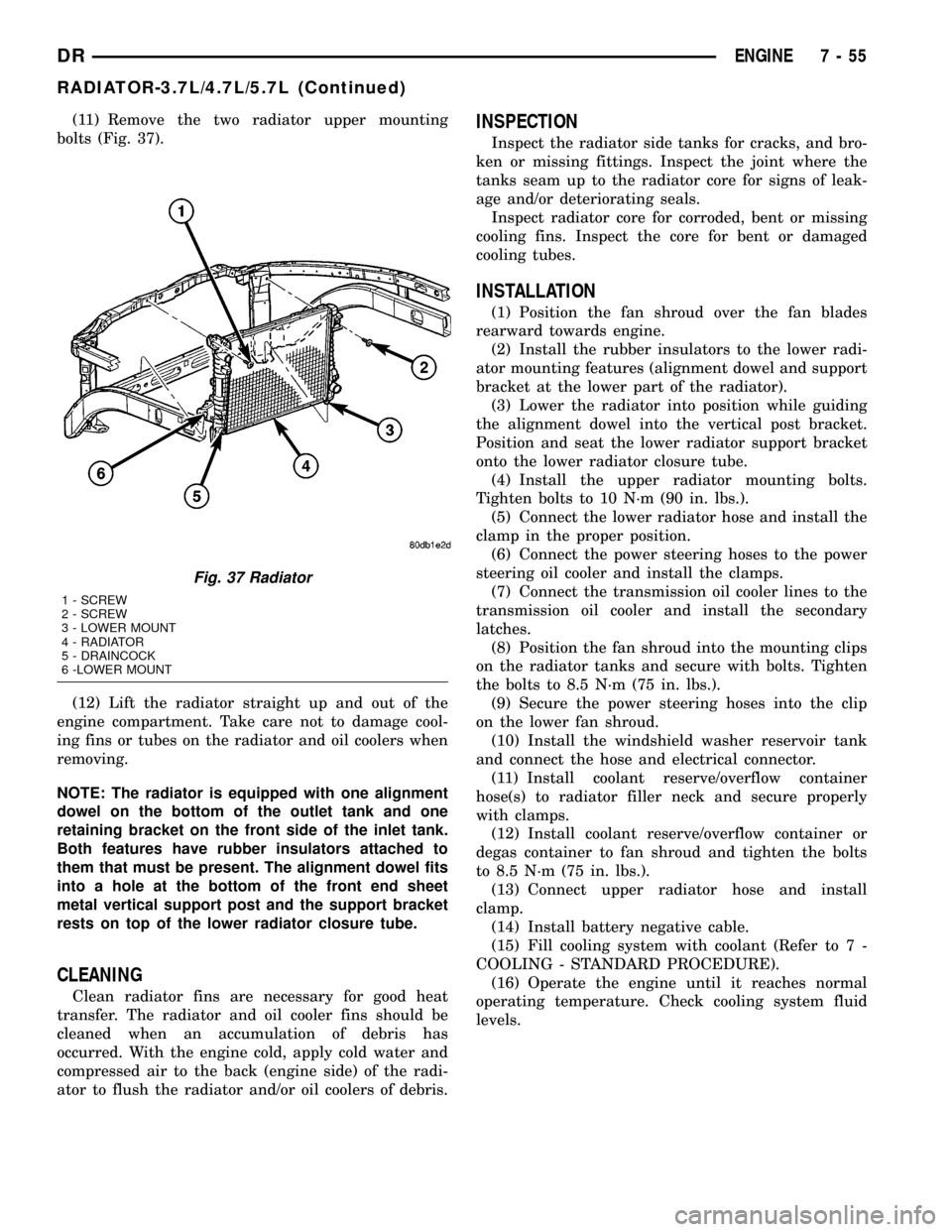

(11) Remove the two radiator upper mounting

bolts (Fig. 37).

(12) Lift the radiator straight up and out of the

engine compartment. Take care not to damage cool-

ing fins or tubes on the radiator and oil coolers when

removing.

NOTE: The radiator is equipped with one alignment

dowel on the bottom of the outlet tank and one

retaining bracket on the front side of the inlet tank.

Both features have rubber insulators attached to

them that must be present. The alignment dowel fits

into a hole at the bottom of the front end sheet

metal vertical support post and the support bracket

rests on top of the lower radiator closure tube.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and oil cooler fins should be

cleaned when an accumulation of debris has

occurred. With the engine cold, apply cold water and

compressed air to the back (engine side) of the radi-

ator to flush the radiator and/or oil coolers of debris.

INSPECTION

Inspect the radiator side tanks for cracks, and bro-

ken or missing fittings. Inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

INSTALLATION

(1) Position the fan shroud over the fan blades

rearward towards engine.

(2) Install the rubber insulators to the lower radi-

ator mounting features (alignment dowel and support

bracket at the lower part of the radiator).

(3) Lower the radiator into position while guiding

the alignment dowel into the vertical post bracket.

Position and seat the lower radiator support bracket

onto the lower radiator closure tube.

(4) Install the upper radiator mounting bolts.

Tighten bolts to 10 N´m (90 in. lbs.).

(5) Connect the lower radiator hose and install the

clamp in the proper position.

(6) Connect the power steering hoses to the power

steering oil cooler and install the clamps.

(7) Connect the transmission oil cooler lines to the

transmission oil cooler and install the secondary

latches.

(8) Position the fan shroud into the mounting clips

on the radiator tanks and secure with bolts. Tighten

the bolts to 8.5 N´m (75 in. lbs.).

(9) Secure the power steering hoses into the clip

on the lower fan shroud.

(10) Install the windshield washer reservoir tank

and connect the hose and electrical connector.

(11) Install coolant reserve/overflow container

hose(s) to radiator filler neck and secure properly

with clamps.

(12) Install coolant reserve/overflow container or

degas container to fan shroud and tighten the bolts

to 8.5 N´m (75 in. lbs.).

(13) Connect upper radiator hose and install

clamp.

(14) Install battery negative cable.

(15) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Operate the engine until it reaches normal

operating temperature. Check cooling system fluid

levels.

Fig. 37 Radiator

1 - SCREW

2 - SCREW

3 - LOWER MOUNT

4 - RADIATOR

5 - DRAINCOCK

6 -LOWER MOUNT

DRENGINE 7 - 55

RADIATOR-3.7L/4.7L/5.7L (Continued)

Page 379 of 2627

REMOVAL

NOTE:

The water pump on all models can be removed

without discharging the air conditioning system (if

equipped).

The water pump on all gas powered engines is

bolted directly to the engine timing chain case/

cover.

On the 8.0L V-10 engine, a rubber o-ring (instead of

a gasket) is used as a seal between the water pump

and timing chain case/cover.

If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for

fatigue cracks, loose blades or loose rivets that could

have resulted from excessive vibration. Replace fan if

any of these conditions are found. Also check condi-

tion of the thermal viscous fan drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - DIAGNOSIS AND TESTING).

(1) Disconnect negative battery cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

(3) Remove windshield washer reservoir tank from

radiator fan shroud.

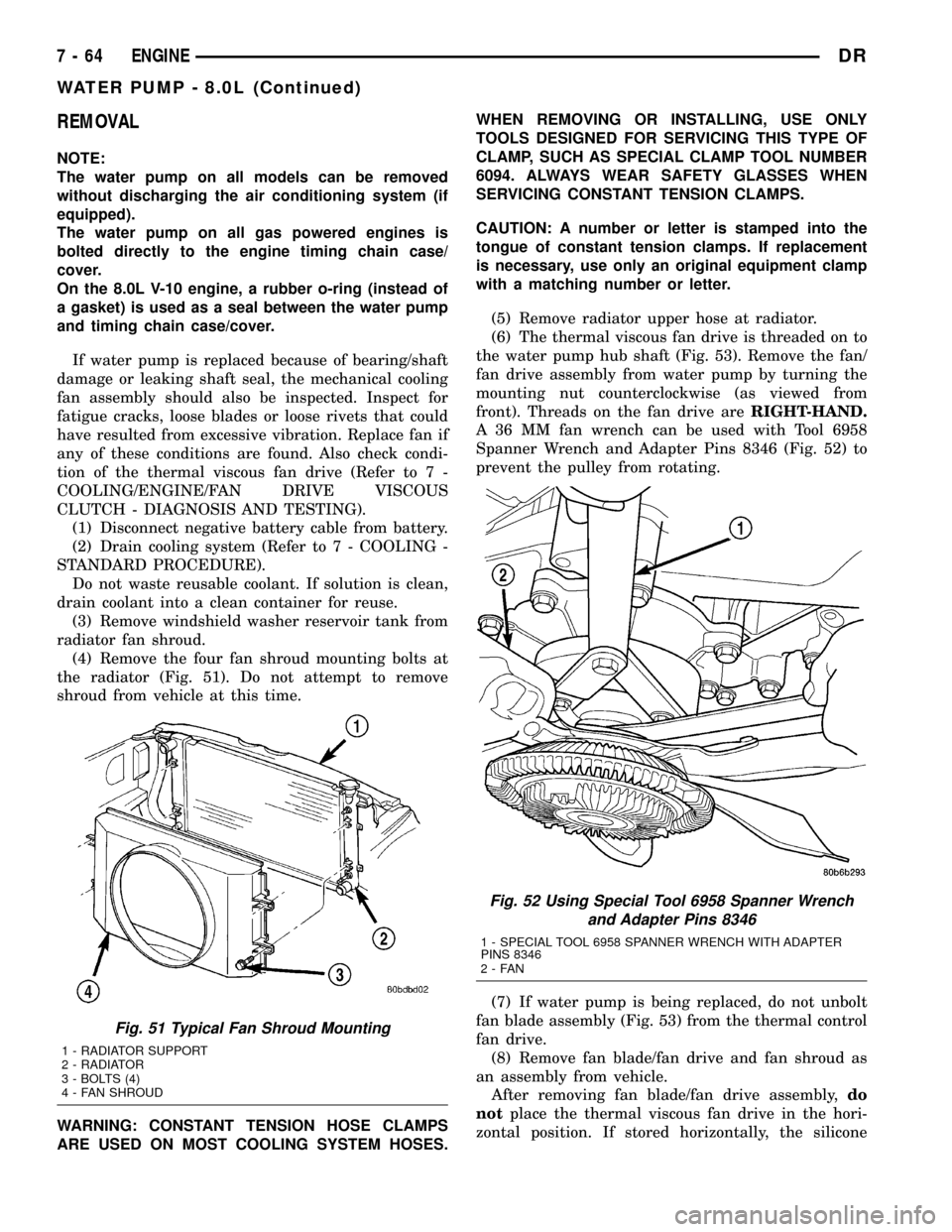

(4) Remove the four fan shroud mounting bolts at

the radiator (Fig. 51). Do not attempt to remove

shroud from vehicle at this time.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL NUMBER

6094. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(5) Remove radiator upper hose at radiator.

(6) The thermal viscous fan drive is threaded on to

the water pump hub shaft (Fig. 53). Remove the fan/

fan drive assembly from water pump by turning the

mounting nut counterclockwise (as viewed from

front). Threads on the fan drive areRIGHT-HAND.

A 36 MM fan wrench can be used with Tool 6958

Spanner Wrench and Adapter Pins 8346 (Fig. 52) to

prevent the pulley from rotating.

(7) If water pump is being replaced, do not unbolt

fan blade assembly (Fig. 53) from the thermal control

fan drive.

(8) Remove fan blade/fan drive and fan shroud as

an assembly from vehicle.

After removing fan blade/fan drive assembly,do

notplace the thermal viscous fan drive in the hori-

zontal position. If stored horizontally, the silicone

Fig. 51 Typical Fan Shroud Mounting

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

Fig. 52 Using Special Tool 6958 Spanner Wrench

and Adapter Pins 8346

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

7 - 64 ENGINEDR

WATER PUMP - 8.0L (Continued)

Page 381 of 2627

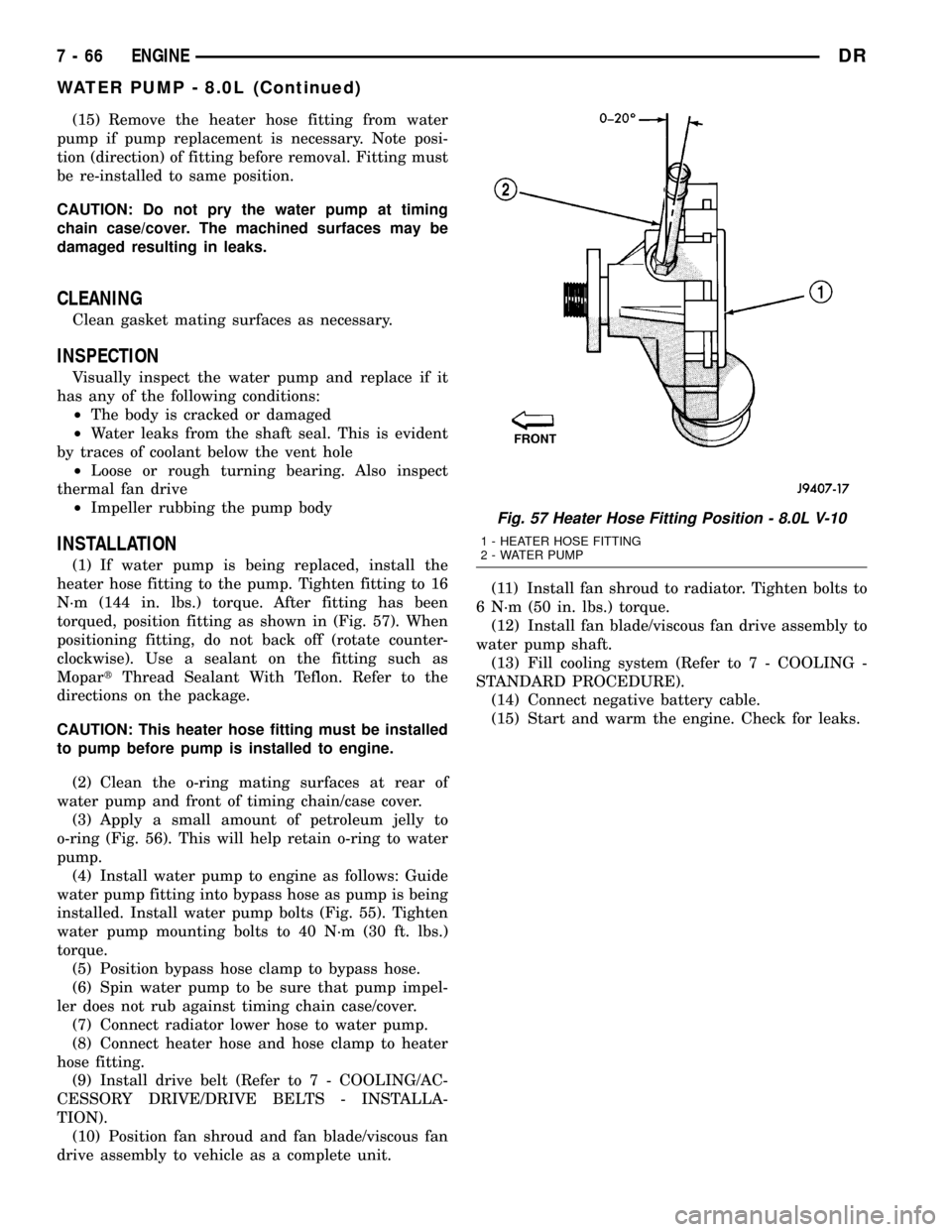

(15) Remove the heater hose fitting from water

pump if pump replacement is necessary. Note posi-

tion (direction) of fitting before removal. Fitting must

be re-installed to same position.

CAUTION: Do not pry the water pump at timing

chain case/cover. The machined surfaces may be

damaged resulting in leaks.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing. Also inspect

thermal fan drive

²Impeller rubbing the pump body

INSTALLATION

(1) If water pump is being replaced, install the

heater hose fitting to the pump. Tighten fitting to 16

N´m (144 in. lbs.) torque. After fitting has been

torqued, position fitting as shown in (Fig. 57). When

positioning fitting, do not back off (rotate counter-

clockwise). Use a sealant on the fitting such as

MopartThread Sealant With Teflon. Refer to the

directions on the package.

CAUTION: This heater hose fitting must be installed

to pump before pump is installed to engine.

(2) Clean the o-ring mating surfaces at rear of

water pump and front of timing chain/case cover.

(3) Apply a small amount of petroleum jelly to

o-ring (Fig. 56). This will help retain o-ring to water

pump.

(4) Install water pump to engine as follows: Guide

water pump fitting into bypass hose as pump is being

installed. Install water pump bolts (Fig. 55). Tighten

water pump mounting bolts to 40 N´m (30 ft. lbs.)

torque.

(5) Position bypass hose clamp to bypass hose.

(6) Spin water pump to be sure that pump impel-

ler does not rub against timing chain case/cover.

(7) Connect radiator lower hose to water pump.

(8) Connect heater hose and hose clamp to heater

hose fitting.

(9) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(10) Position fan shroud and fan blade/viscous fan

drive assembly to vehicle as a complete unit.(11) Install fan shroud to radiator. Tighten bolts to

6 N´m (50 in. lbs.) torque.

(12) Install fan blade/viscous fan drive assembly to

water pump shaft.

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect negative battery cable.

(15) Start and warm the engine. Check for leaks.

Fig. 57 Heater Hose Fitting Position - 8.0L V-10

1 - HEATER HOSE FITTING

2 - WATER PUMP

7 - 66 ENGINEDR

WATER PUMP - 8.0L (Continued)

Page 402 of 2627

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME WARNING SYSTEM

DESCRIPTION..........................1

OPERATION............................1DIAGNOSIS AND TESTING - CHIME

WARNING SYSTEM.....................3

CHIME WARNING SYSTEM

DESCRIPTION

A chime warning system is standard factory-in-

stalled equipment on this model. The chime warning

system uses a single chime tone generator that is

integral to the instrument cluster to provide an audi-

ble indication of various vehicle conditions that may

require the attention of the vehicle operator. The

chime warning system includes the following major

components, which are described in further detail

elsewhere in this service information:

²Door Ajar Switch- A door ajar switch is inte-

gral to each door latch. This switch provides an input

to the chime warning system indicating whether the

front doors are open or closed.

²Ignition Switch- A key-in ignition switch is

integral to the ignition switch. The key-in ignition

switch provides an input to the chime warning sys-

tem indicating whether a key is present in the igni-

tion lock cylinder.

²Instrument Cluster- The instrument cluster

contains an integral chime tone generator, integrated

circuitry, a central processing unit and the program-

ming to provide all of the proper chime warning sys-

tem features based upon the monitored inputs. The

instrument cluster circuitry monitors hard-wired

switch inputs, as well as message inputs received

from other vehicle electronic modules on the Pro-

grammable Communications Interface (PCI) data bus

network.

²Headlamp Switch- The headlamp switch pro-

vides an input to the chime warning system indicat-

ing when the exterior lamps are turned On or Off.

²Seat Belt Switch- A seat belt switch is inte-

gral to the driver seat belt buckle-half unit. The seat

belt switch provides an input to the chime warning

system indicating whether the driver seat belt is fas-

tened.

Hard wired circuitry connects many of the chime

warning system components to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained bymany different methods. Refer to the appropriate

wiring information.

The instrument cluster chime warning system cir-

cuitry and the integral chime tone generator cannot

be adjusted or repaired. If the instrument cluster or

the chime tone generator are damaged or faulty, the

instrument cluster must be replaced.

OPERATION

The chime warning system is designed to provide

an audible output as an indication of various condi-

tions that may require the attention or awareness of

the vehicle operator. The chime warning system com-

ponents operate on battery voltage received through

the Ignition-Off Draw (IOD) fuse in the Power Distri-

bution Center (PDC) so that the system may operate

regardless of the ignition switch position.

The chime warning system provides an audible

warning to the vehicle operator under the following

conditions:

²Air Bag Warning- The instrument cluster

chime tone generator will generate a single chime

tone when the airbag indicator is illuminated for an

airbag system fault condition. The instrument cluster

uses airbag indicator lamp-on and lamp-off message

inputs received from the Airbag Control Module

(ACM) over the Programmable Communications

Interface (PCI) data bus indicating that the airbag

indicator should be illuminated for an airbag system

fault condition.

²Door Ajar Warning- The instrument cluster

chime tone generator will generate a single chimes to

announce that the hard wired inputs from the door

ajar switches and the ignition switch as well as an

engine speed message input received from the PCM

over the PCI data bus indicate that a driver or pas-

senger door is opened with the ignition switch in the

On position and vehicle speed present.

²Engine Coolant Temperature High Warning

(Diesel Engine Only)- The instrument cluster

chime tone generator will generate a single chime

tone when the check gauges indicator is illuminated

for a high or critical engine coolant temperature con-

dition. The instrument cluster uses engine coolant

temperature message inputs received from the diesel

DRCHIME/BUZZER 8B - 1

Page 403 of 2627

Engine Control Module (ECM) over the PCI data bus

to illuminate the check gauges indicator for a coolant

temperature high condition.

²Fasten Seat Belt Warning- The instrument

cluster chime tone generator will generate repetitive

chimes at a slow rate each time the ignition switch is

turned to the On or Start positions to announce that

the hard wired inputs from the seat belt switch and

the ignition switch indicate that the driver side front

seat belt is not fastened. The chimes will continue to

sound for a duration of about six seconds, until the

driver side front seat belt is fastened, or until the

ignition switch is turned to the Off position, which-

ever occurs first.

²Head/Park Lamps-On Warning- The instru-

ment cluster chime tone generator will generate

repetitive chimes at a slow rate to announce that the

hard wired inputs from the driver door ajar switch,

the ignition switch, and the exterior lighting circuitry

of the headlamp switch indicate that the exterior

lamps are turned On with the driver door opened

and the ignition switch in the Off position. The

chimes will continue to sound until the exterior

lamps are turned Off, the driver door is closed, or the

ignition switch is turned to the On position, or the

battery protection time-out expires, whichever occurs

first.

²Key-In-Ignition Warning- The instrument

cluster chime tone generator will generate repetitive

chimes at a slow rate to announce that the hard

wired inputs from the driver door ajar switch, the

ignition switch, and the key-in ignition circuitry of

the ignition switch indicate that the key is in the

ignition lock cylinder with the driver door opened

and the ignition switch in the Off position. The

chimes will continue to sound until the key is

removed from the ignition lock cylinder, the driver

door is closed, or the ignition switch is turned to the

On position, whichever occurs first.

²Low Fuel Warning- The instrument cluster

chime tone generator will generate one chime tone

when the low fuel indicator is illuminated by the

instrument cluster. The instrument cluster uses a

percent tank full message input received from the

PCM over the PCI data bus indicating that there is

less than about one-eighth tank of fuel remaining to

illuminate the low fuel indicator. This chime feature

will only occur once in an ignition cycle.

²Low Oil Pressure Warning (Diesel Engine

Only)- The instrument cluster chime tone generator

will generate repetitive chimes at a fast rate when

the check gauges indicator is illuminated for a low oil

pressure condition. The instrument cluster uses

engine speed and oil pressure message inputs

received from the diesel Engine Control Module

(ECM) over the PCI data bus indicating that theengine is running and that the oil pressure is low to

illuminate the check gauges indicator. The chimes

will continue to sound for five seconds, until the

engine oil pressure message indicates that the oil

pressure is not low, or until the engine speed mes-

sage indicates that the engine is not running, which-

ever occurs first. This chime tone will only occur once

in an ignition cycle.

²Low Wash Warning- The instrument cluster

chime tone generator will generate one chime tone

when the low washer fluid indicator is illuminated by

the instrument cluster. The instrument cluster uses a

message input received from the Front Control Mod-

ule (FCM) over the PCI data bus indicating that

washer fluid level is low within the washer reservoir.

This chime feature will only occur once in an ignition

cycle.

²Overspeed Warning- The instrument cluster

chime tone generator will generate one chime tone to

announce that a vehicle speed message input

received from the PCM over the PCI data bus indi-

cates that the vehicle speed is above a pre-programed

limit.

²Park Brake Reminder- The instrument clus-

ter chime tone generator will generate ten repetitive

chimes at a slow rate to announce that the hard

wired input from the park brake switch and a vehicle

speed message input received from the PCM over the

PCI data bus indicates that the park brake is applied

and the vehicle is moving. This chime feature will

repeat each time the input conditions are met.

²Sentry Key Immobilizer System ªCustomer

Learnº Mode Announcement- This chime feature

is only active on vehicles equipped with the optional

Sentry Key Immobilizer System (SKIS) and sold in

markets where the optional ªCustomer Learnº pro-

gramming feature is available. The instrument clus-

ter chime tone generator will generate one chime to

announce that a status message input received from

the Sentry Key Immobilizer Module (SKIM) over the

PCI data bus indicates that the SKIS is in the ªCus-

tomer Learnº mode, which is used for programming

additional sentry key transponders.

²Transmission Temperature High Warning

(Automatic Transmission only)- The instrument

cluster chime tone generator will generate repetitive

chimes at a slow rate when the transmission temper-

ature indicator is illuminated for a high or critical

transmission fluid temperature condition. The instru-

ment cluster uses transmission temperature message

inputs received from the Transmission Control Mod-

ule (TCM) over the PCI data bus to illuminate the

indicator for a transmission temperature high condi-

tion.

²Turn Signal On Warning- The instrument

cluster chime tone generator will generate repetitive

8B - 2 CHIME/BUZZERDR

CHIME WARNING SYSTEM (Continued)

Page 412 of 2627

FRONT CONTROL MODULE

DESCRIPTION

The Front Control Module (FCM) is a micro con-

troller based module located in the left front corner

of the engine compartment. On this model the inte-

grated power module must be positioned aside in

order to access the front control module. The front

control module mates to the power distribution cen-

ter to form the Integrated Power Module (IPM). The

integrated power module connects directly to the bat-

tery and provides the primary means of circuit pro-

tection and power distribution for all vehicle

electrical systems. The front control module controls

power to some of these vehicle systems electrical and

electromechanical loads based on inputs received

from hard wired switch inputs and data received on

the PCI bus circuit (J1850).

For information on theIntegrated Power Mod-

ule Refer to the Power Distribution Sectionof

the service manual.

OPERATION

As messages are sent over the PCI bus circuit, the

front control module reads these messages and con-

trols power to some of the vehicles electrical systems

by completing the circuit to ground (low side driver)

or completing the circuit to 12 volt power (high side

driver). The following functions areControlledby

the Front Control Module:

²Headlamp Power with Voltage Regulation

²Windshield Wiper ªON/OFFº Relay Actuation

²Windshield Wiper ªHI/LOº Relay Actuation

²Windshield Washer Pump Motor

²Fog Lamp Relay Actuation

²Park Lamp Relay Actuation

²Horn Relay Actuation

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection

²Power Ground

²Ambient Temperature Sensing

²Ignition Switch Run

²Washer Fluid Level Switch

²Windshield Wiper Park Switch

²PCI Bus Circuit

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRI-

CAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3) Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straightfrom the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the inte-

grated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - INSTALLATION).

(4) Connect the positive and negative battery

cables.

DRELECTRONIC CONTROL MODULES 8E - 5

Page 413 of 2627

HEATED SEAT MODULE

DESCRIPTION

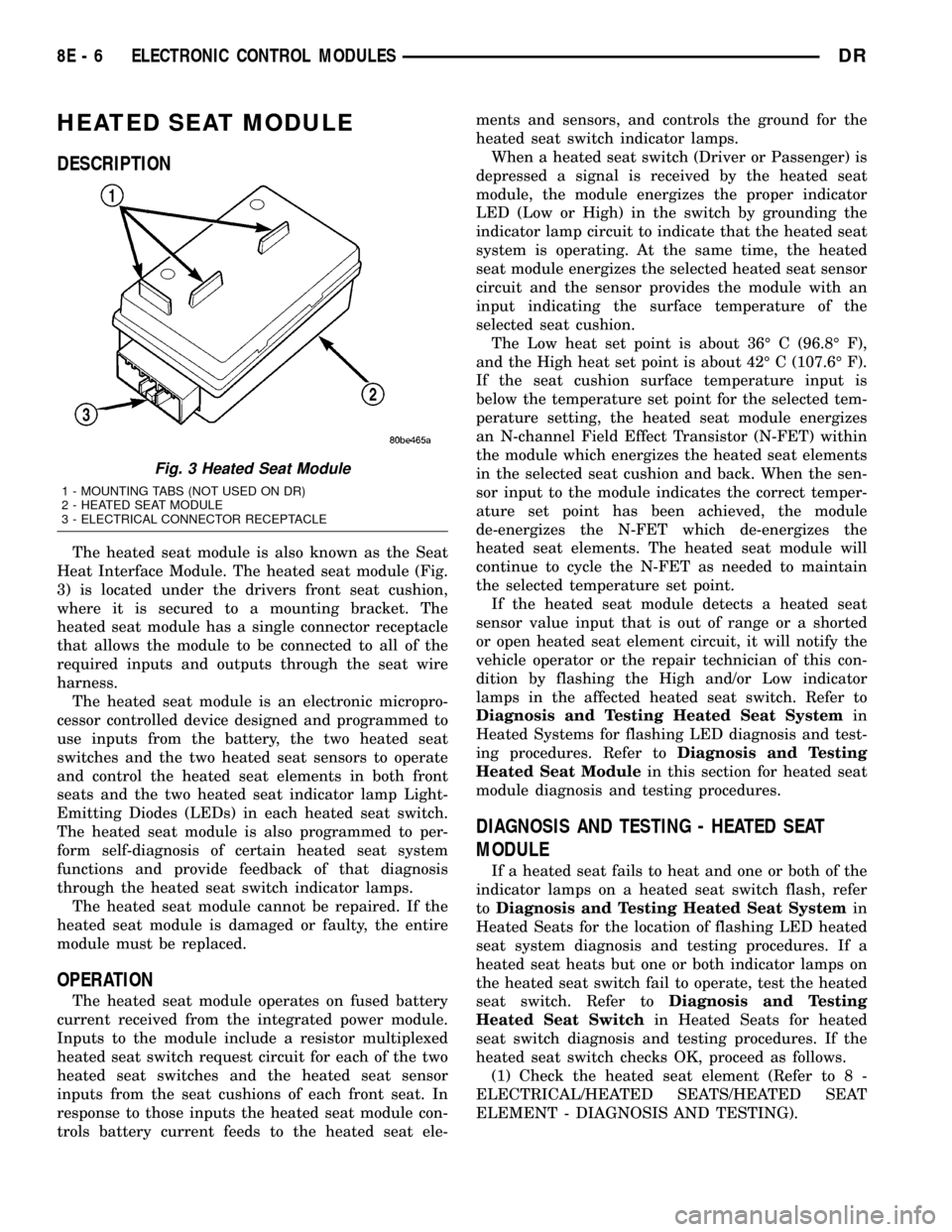

The heated seat module is also known as the Seat

Heat Interface Module. The heated seat module (Fig.

3) is located under the drivers front seat cushion,

where it is secured to a mounting bracket. The

heated seat module has a single connector receptacle

that allows the module to be connected to all of the

required inputs and outputs through the seat wire

harness.

The heated seat module is an electronic micropro-

cessor controlled device designed and programmed to

use inputs from the battery, the two heated seat

switches and the two heated seat sensors to operate

and control the heated seat elements in both front

seats and the two heated seat indicator lamp Light-

Emitting Diodes (LEDs) in each heated seat switch.

The heated seat module is also programmed to per-

form self-diagnosis of certain heated seat system

functions and provide feedback of that diagnosis

through the heated seat switch indicator lamps.

The heated seat module cannot be repaired. If the

heated seat module is damaged or faulty, the entire

module must be replaced.

OPERATION

The heated seat module operates on fused battery

current received from the integrated power module.

Inputs to the module include a resistor multiplexed

heated seat switch request circuit for each of the two

heated seat switches and the heated seat sensor

inputs from the seat cushions of each front seat. In

response to those inputs the heated seat module con-

trols battery current feeds to the heated seat ele-ments and sensors, and controls the ground for the

heated seat switch indicator lamps.

When a heated seat switch (Driver or Passenger) is

depressed a signal is received by the heated seat

module, the module energizes the proper indicator

LED (Low or High) in the switch by grounding the

indicator lamp circuit to indicate that the heated seat

system is operating. At the same time, the heated

seat module energizes the selected heated seat sensor

circuit and the sensor provides the module with an

input indicating the surface temperature of the

selected seat cushion.

The Low heat set point is about 36É C (96.8É F),

and the High heat set point is about 42É C (107.6É F).

If the seat cushion surface temperature input is

below the temperature set point for the selected tem-

perature setting, the heated seat module energizes

an N-channel Field Effect Transistor (N-FET) within

the module which energizes the heated seat elements

in the selected seat cushion and back. When the sen-

sor input to the module indicates the correct temper-

ature set point has been achieved, the module

de-energizes the N-FET which de-energizes the

heated seat elements. The heated seat module will

continue to cycle the N-FET as needed to maintain

the selected temperature set point.

If the heated seat module detects a heated seat

sensor value input that is out of range or a shorted

or open heated seat element circuit, it will notify the

vehicle operator or the repair technician of this con-

dition by flashing the High and/or Low indicator

lamps in the affected heated seat switch. Refer to

Diagnosis and Testing Heated Seat Systemin

Heated Systems for flashing LED diagnosis and test-

ing procedures. Refer toDiagnosis and Testing

Heated Seat Modulein this section for heated seat

module diagnosis and testing procedures.

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE

If a heated seat fails to heat and one or both of the

indicator lamps on a heated seat switch flash, refer

toDiagnosis and Testing Heated Seat Systemin

Heated Seats for the location of flashing LED heated

seat system diagnosis and testing procedures. If a

heated seat heats but one or both indicator lamps on

the heated seat switch fail to operate, test the heated

seat switch. Refer toDiagnosis and Testing

Heated Seat Switchin Heated Seats for heated

seat switch diagnosis and testing procedures. If the

heated seat switch checks OK, proceed as follows.

(1) Check the heated seat element (Refer to 8 -

ELECTRICAL/HEATED SEATS/HEATED SEAT

ELEMENT - DIAGNOSIS AND TESTING).

Fig. 3 Heated Seat Module

1 - MOUNTING TABS (NOT USED ON DR)

2 - HEATED SEAT MODULE

3 - ELECTRICAL CONNECTOR RECEPTACLE

8E - 6 ELECTRONIC CONTROL MODULESDR

Page 476 of 2627

HEATED SEAT SYSTEM

TABLE OF CONTENTS

page page

HEATED SEAT SYSTEM

DESCRIPTION..........................7

OPERATION............................8

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM.............................8

HEATED SEAT ELEMENT

DESCRIPTION..........................9

OPERATION...........................10

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT...........................10

REMOVAL.............................10

INSTALLATION.........................10

HEATED SEAT SENSOR

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR............................11REMOVAL.............................11

HEATED SEAT SWITCH

DESCRIPTION.........................11

OPERATION...........................12

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH............................12

REMOVAL.............................13

INSTALLATION.........................13

HEATED SEAT MODULE

DESCRIPTION.........................13

OPERATION...........................14

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE............................14

REMOVAL.............................15

INSTALLATION.........................15

HEATED SEAT SYSTEM

DESCRIPTION

Individually controlled, electrically heated front

seats are available as a factory-installed option on

some DR models. Vehicles with this option can be

visually identified by the leather trim seats and two

separate heated seat switches mounted in the lower

center of the instrument panel. The heated seat sys-

tem allows the front seat driver and passenger to

select from two different levels of electrical seat heat-

ing, or no seat heating to suit their individual com-

fort requirements. The heated seat system for this

vehicle includes the following major components,

which are described in further detail later in this sec-

tion:

²Heated Seat Switches- Two heated seat

switches are used per vehicle. One switch is used for

each front seat. The switches are mounted in the

instrument panel, below the radio (Fig. 1). Each

switch also includes two Light-Emitting Diode (LED)

indicator lamps and an incandescent back lighting

bulb.

²Heated Seat Module- also referred to as the

Seat Heat Interface Module (SHIM), this module con-

tains the solid state electronic control and diagnostic

logic circuitry for the heated seat system. One heated

seat module is used per vehicle and is mounted

under the drivers front seat cushion (Fig. 1). Refer to

the Electronic Control Modules section of the servicemanual for additional heated seat module informa-

tion.

²Heated Seat Elements- Four heated seat ele-

ments are used per vehicle. One element is used for

each front seat back and one element and sensor

assembly is used for each front seat cushion (Fig. 1).

The heating elements are integral to the individual

front seat and seat back cushions and cannot be

removed once installed at the factory. Replacement

seat heating elements are available, without having

to replace the entire seat cushion or trim cover. Refer

to the detailed procedure later in this section.

²Heated Seat Sensors- Two heated seat sen-

sors are used per vehicle. One heated seat tempera-

ture sensor is used for each front seat cushion. The

sensors are integral to the individual front seat cush-

ion heating elements (Fig. 1) and cannot be removed

once installed at the factory. Replacement seat heat-

ing elements with the sensors are available, without

having to replace the entire seat cushion or trim

cover. Refer to the detailed procedure later in this

section.

Following are general descriptions and operations

of the major components in the heated seat system.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the heated seat system. Refer toWiringfor the

location of complete heated seat system wiring dia-

grams.

DRHEATED SEAT SYSTEM 8G - 7