Transmission and transfer case DODGE RAM 1500 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1050 of 2627

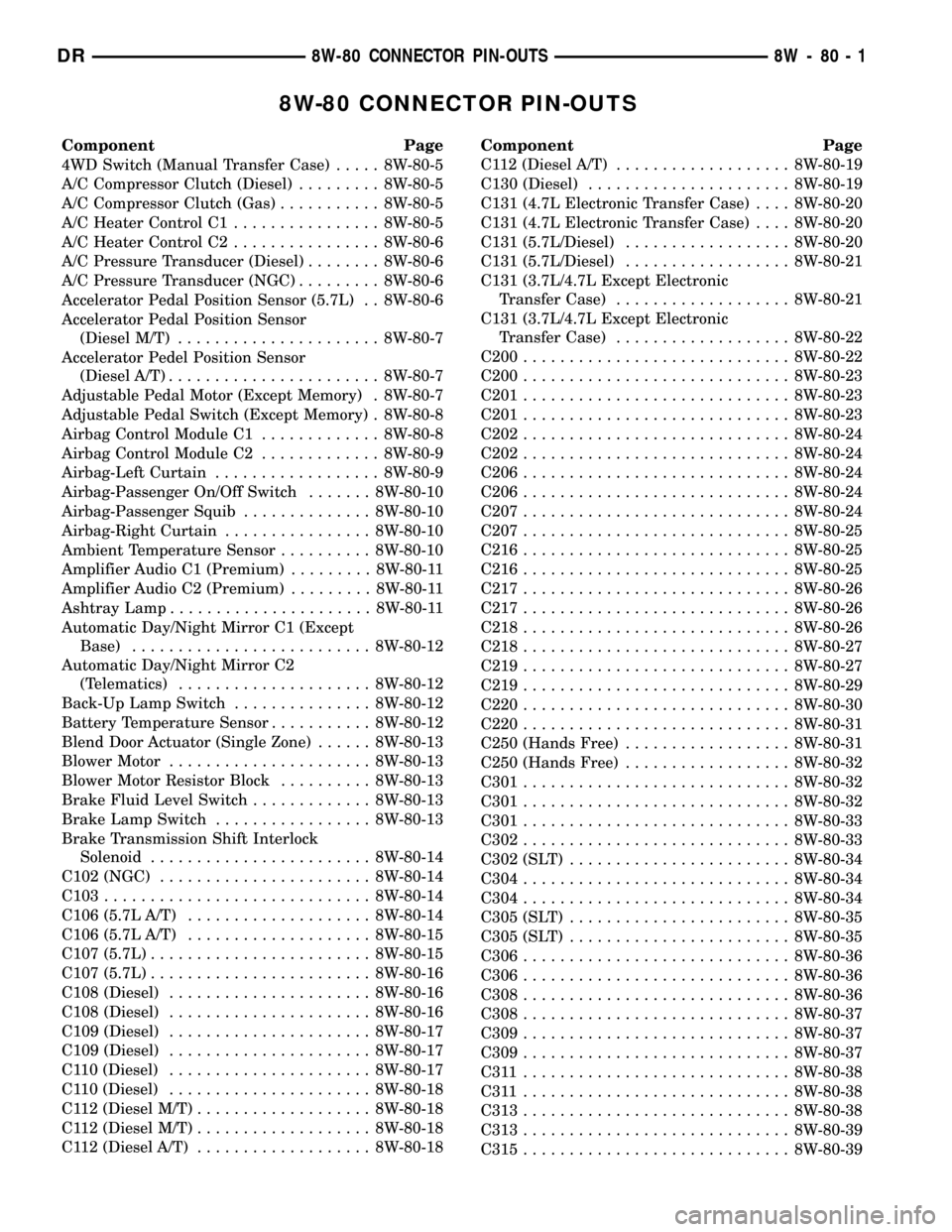

8W-80 CONNECTOR PIN-OUTS

Component Page

4WD Switch (Manual Transfer Case)..... 8W-80-5

A/C Compressor Clutch (Diesel)......... 8W-80-5

A/C Compressor Clutch (Gas)........... 8W-80-5

A/C Heater Control C1................ 8W-80-5

A/C Heater Control C2................ 8W-80-6

A/C Pressure Transducer (Diesel)........ 8W-80-6

A/C Pressure Transducer (NGC)......... 8W-80-6

Accelerator Pedal Position Sensor (5.7L) . . 8W-80-6

Accelerator Pedal Position Sensor

(Diesel M/T)...................... 8W-80-7

Accelerator Pedel Position Sensor

(Diesel A/T)....................... 8W-80-7

Adjustable Pedal Motor (Except Memory) . 8W-80-7

Adjustable Pedal Switch (Except Memory) . 8W-80-8

Airbag Control Module C1............. 8W-80-8

Airbag Control Module C2............. 8W-80-9

Airbag-Left Curtain.................. 8W-80-9

Airbag-Passenger On/Off Switch....... 8W-80-10

Airbag-Passenger Squib.............. 8W-80-10

Airbag-Right Curtain................ 8W-80-10

Ambient Temperature Sensor.......... 8W-80-10

Amplifier Audio C1 (Premium)......... 8W-80-11

Amplifier Audio C2 (Premium)......... 8W-80-11

Ashtray Lamp...................... 8W-80-11

Automatic Day/Night Mirror C1 (Except

Base).......................... 8W-80-12

Automatic Day/Night Mirror C2

(Telematics)..................... 8W-80-12

Back-Up Lamp Switch............... 8W-80-12

Battery Temperature Sensor........... 8W-80-12

Blend Door Actuator (Single Zone)...... 8W-80-13

Blower Motor...................... 8W-80-13

Blower Motor Resistor Block.......... 8W-80-13

Brake Fluid Level Switch............. 8W-80-13

Brake Lamp Switch................. 8W-80-13

Brake Transmission Shift Interlock

Solenoid........................ 8W-80-14

C102 (NGC)....................... 8W-80-14

C103............................. 8W-80-14

C106 (5.7L A/T).................... 8W-80-14

C106 (5.7L A/T).................... 8W-80-15

C107 (5.7L)........................ 8W-80-15

C107 (5.7L)........................ 8W-80-16

C108 (Diesel)...................... 8W-80-16

C108 (Diesel)...................... 8W-80-16

C109 (Diesel)...................... 8W-80-17

C109 (Diesel)...................... 8W-80-17

C110 (Diesel)...................... 8W-80-17

C110 (Diesel)...................... 8W-80-18

C112 (Diesel M/T)................... 8W-80-18

C112 (Diesel M/T)................... 8W-80-18

C112 (Diesel A/T)................... 8W-80-18Component Page

C112 (Diesel A/T)................... 8W-80-19

C130 (Diesel)...................... 8W-80-19

C131 (4.7L Electronic Transfer Case).... 8W-80-20

C131 (4.7L Electronic Transfer Case).... 8W-80-20

C131 (5.7L/Diesel).................. 8W-80-20

C131 (5.7L/Diesel).................. 8W-80-21

C131 (3.7L/4.7L Except Electronic

Transfer Case)................... 8W-80-21

C131 (3.7L/4.7L Except Electronic

Transfer Case)................... 8W-80-22

C200............................. 8W-80-22

C200............................. 8W-80-23

C201............................. 8W-80-23

C201............................. 8W-80-23

C202............................. 8W-80-24

C202............................. 8W-80-24

C206............................. 8W-80-24

C206............................. 8W-80-24

C207............................. 8W-80-24

C207............................. 8W-80-25

C216............................. 8W-80-25

C216............................. 8W-80-25

C217............................. 8W-80-26

C217............................. 8W-80-26

C218............................. 8W-80-26

C218............................. 8W-80-27

C219............................. 8W-80-27

C219............................. 8W-80-29

C220............................. 8W-80-30

C220............................. 8W-80-31

C250 (Hands Free).................. 8W-80-31

C250 (Hands Free).................. 8W-80-32

C301............................. 8W-80-32

C301............................. 8W-80-32

C301............................. 8W-80-33

C302............................. 8W-80-33

C302 (SLT)........................ 8W-80-34

C304............................. 8W-80-34

C304............................. 8W-80-34

C305 (SLT)........................ 8W-80-35

C305 (SLT)........................ 8W-80-35

C306............................. 8W-80-36

C306............................. 8W-80-36

C308............................. 8W-80-36

C308............................. 8W-80-37

C309............................. 8W-80-37

C309............................. 8W-80-37

C311 ............................. 8W-80-38

C311 ............................. 8W-80-38

C313............................. 8W-80-38

C313............................. 8W-80-39

C315............................. 8W-80-39

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 1

Page 1154 of 2627

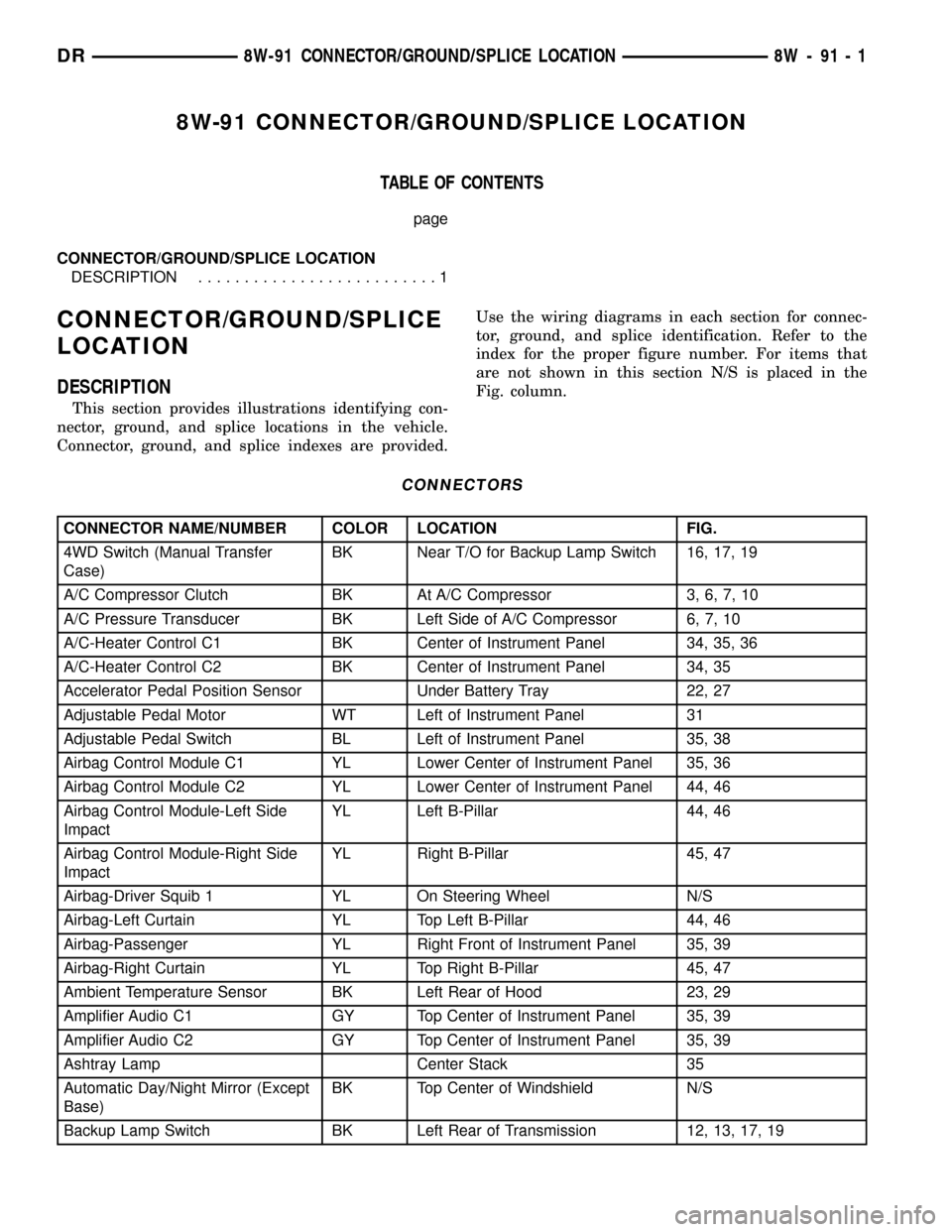

8W-91 CONNECTOR/GROUND/SPLICE LOCATION

TABLE OF CONTENTS

page

CONNECTOR/GROUND/SPLICE LOCATION

DESCRIPTION..........................1

CONNECTOR/GROUND/SPLICE

LOCATION

DESCRIPTION

This section provides illustrations identifying con-

nector, ground, and splice locations in the vehicle.

Connector, ground, and splice indexes are provided.Use the wiring diagrams in each section for connec-

tor, ground, and splice identification. Refer to the

index for the proper figure number. For items that

are not shown in this section N/S is placed in the

Fig. column.

CONNECTORS

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

4WD Switch (Manual Transfer

Case)BK Near T/O for Backup Lamp Switch 16, 17, 19

A/C Compressor Clutch BK At A/C Compressor 3, 6, 7, 10

A/C Pressure Transducer BK Left Side of A/C Compressor 6, 7, 10

A/C-Heater Control C1 BK Center of Instrument Panel 34, 35, 36

A/C-Heater Control C2 BK Center of Instrument Panel 34, 35

Accelerator Pedal Position Sensor Under Battery Tray 22, 27

Adjustable Pedal Motor WT Left of Instrument Panel 31

Adjustable Pedal Switch BL Left of Instrument Panel 35, 38

Airbag Control Module C1 YL Lower Center of Instrument Panel 35, 36

Airbag Control Module C2 YL Lower Center of Instrument Panel 44, 46

Airbag Control Module-Left Side

ImpactYL Left B-Pillar 44, 46

Airbag Control Module-Right Side

ImpactYL Right B-Pillar 45, 47

Airbag-Driver Squib 1 YL On Steering Wheel N/S

Airbag-Left Curtain YL Top Left B-Pillar 44, 46

Airbag-Passenger YL Right Front of Instrument Panel 35, 39

Airbag-Right Curtain YL Top Right B-Pillar 45, 47

Ambient Temperature Sensor BK Left Rear of Hood 23, 29

Amplifier Audio C1 GY Top Center of Instrument Panel 35, 39

Amplifier Audio C2 GY Top Center of Instrument Panel 35, 39

Ashtray Lamp Center Stack 35

Automatic Day/Night Mirror (Except

Base)BK Top Center of Windshield N/S

Backup Lamp Switch BK Left Rear of Transmission 12, 13, 17, 19

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 1

Page 1419 of 2627

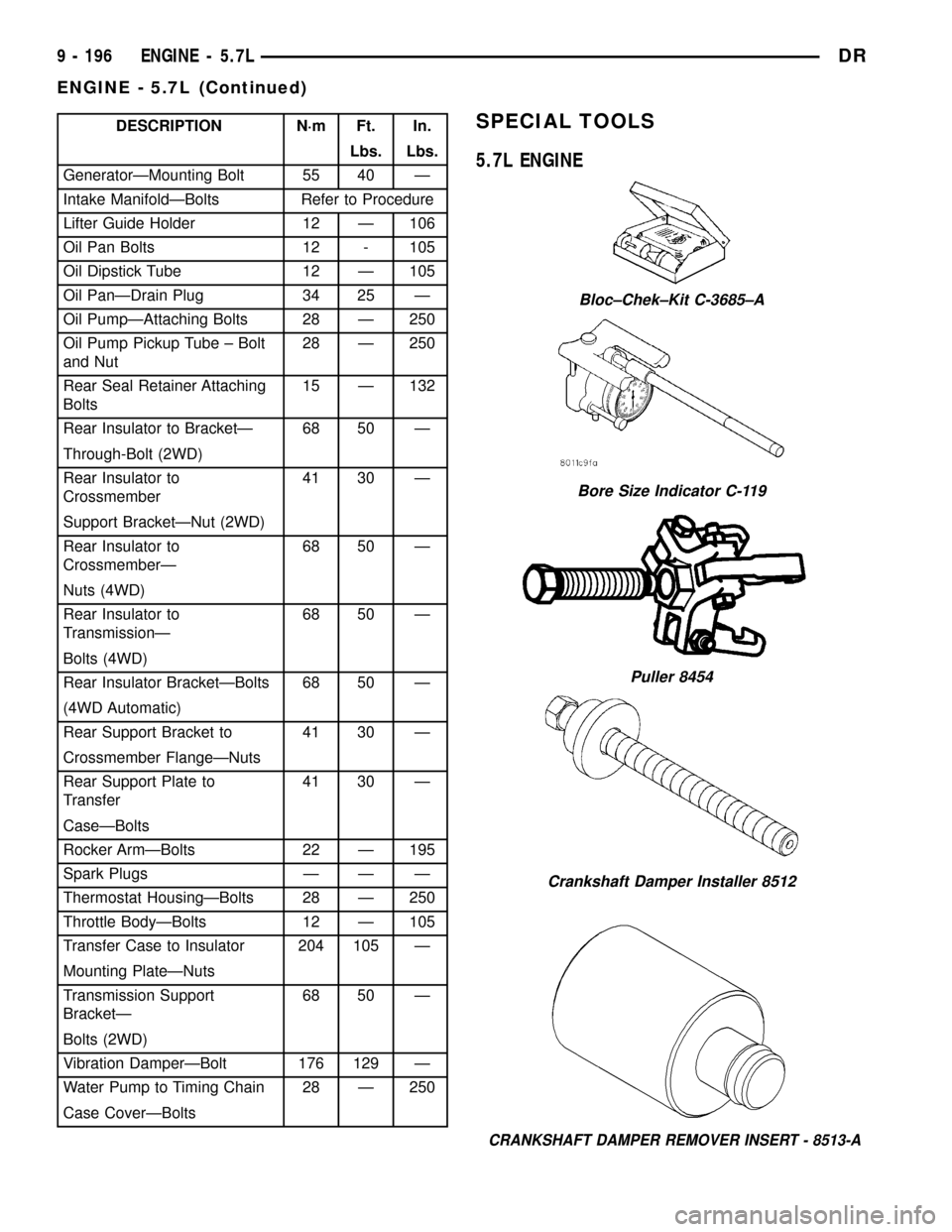

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

GeneratorÐMounting Bolt 55 40 Ð

Intake ManifoldÐBolts Refer to Procedure

Lifter Guide Holder 12 Ð 106

Oil Pan Bolts 12 - 105

Oil Dipstick Tube 12 Ð 105

Oil PanÐDrain Plug 34 25 Ð

Oil PumpÐAttaching Bolts 28 Ð 250

Oil Pump Pickup Tube ± Bolt

and Nut28 Ð 250

Rear Seal Retainer Attaching

Bolts15 Ð 132

Rear Insulator to BracketÐ 68 50 Ð

Through-Bolt (2WD)

Rear Insulator to

Crossmember41 30 Ð

Support BracketÐNut (2WD)

Rear Insulator to

CrossmemberÐ68 50 Ð

Nuts (4WD)

Rear Insulator to

TransmissionÐ68 50 Ð

Bolts (4WD)

Rear Insulator BracketÐBolts 68 50 Ð

(4WD Automatic)

Rear Support Bracket to 41 30 Ð

Crossmember FlangeÐNuts

Rear Support Plate to

Transfer41 30 Ð

CaseÐBolts

Rocker ArmÐBolts 22 Ð 195

Spark Plugs Ð Ð Ð

Thermostat HousingÐBolts 28 Ð 250

Throttle BodyÐBolts 12 Ð 105

Transfer Case to Insulator 204 105 Ð

Mounting PlateÐNuts

Transmission Support

BracketÐ68 50 Ð

Bolts (2WD)

Vibration DamperÐBolt 176 129 Ð

Water Pump to Timing Chain 28 Ð 250

Case CoverÐBoltsSPECIAL TOOLS

5.7L ENGINE

CRANKSHAFT DAMPER REMOVER INSERT - 8513-A

Bloc±Chek±Kit C-3685±A

Bore Size Indicator C-119

Puller 8454

Crankshaft Damper Installer 8512

9 - 196 ENGINE - 5.7LDR

ENGINE - 5.7L (Continued)

Page 1464 of 2627

(10) Drain engine oil. Remove and discard the oil

filter (Refer to 9 - ENGINE/LUBRICATION/OIL FIL-

TER - REMOVAL).

(11) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(12) Install a new oil filter (Refer to 9 - ENGINE/

LUBRICATION/OIL FILTER - INSTALLATION).

(13) Fill engine crankcase with the specified

amount and grade of oil (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES - SPECIFICA-

TIONS).

(14) Connect the negative cable(s) to the battery.

(15) Start the engine and check for any leaks.

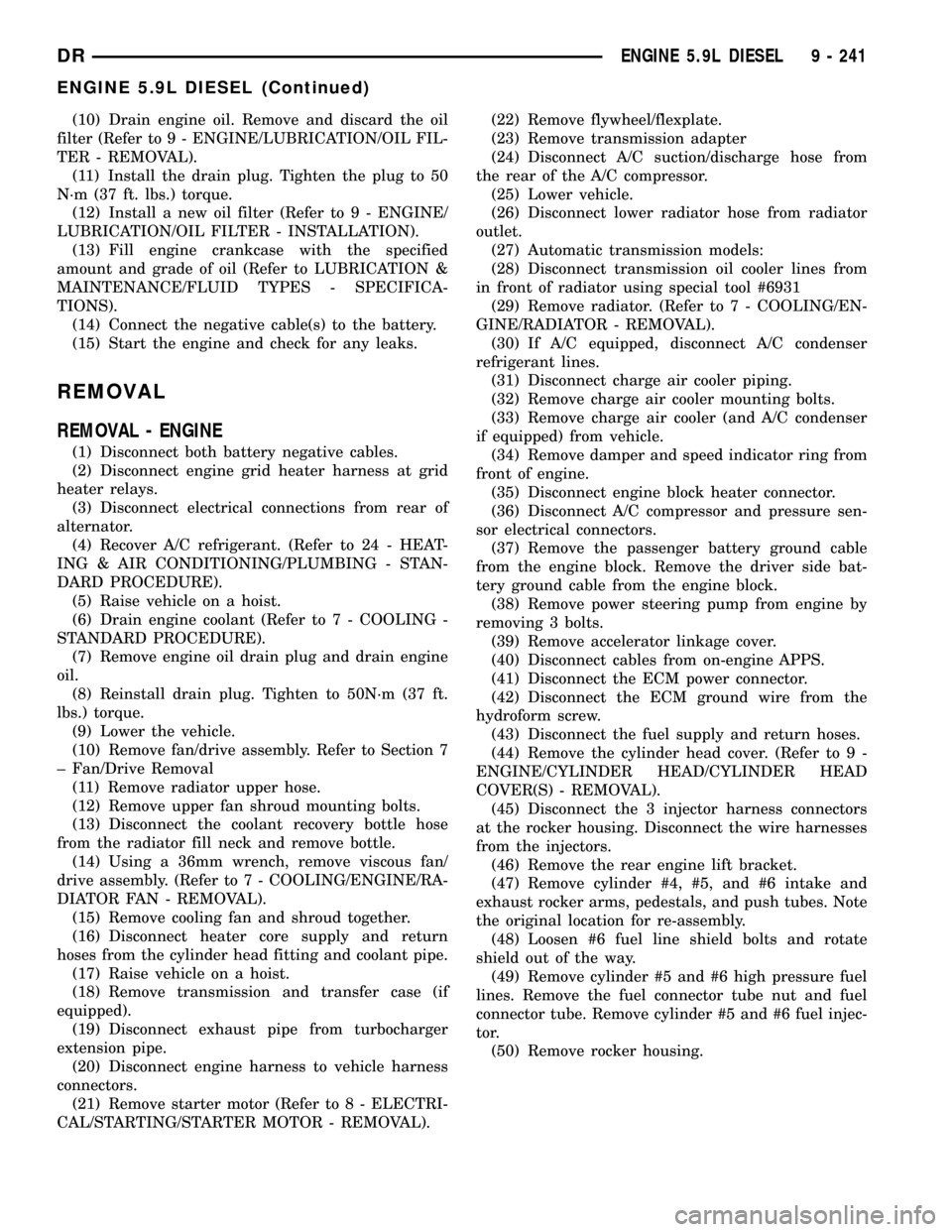

REMOVAL

REMOVAL - ENGINE

(1) Disconnect both battery negative cables.

(2) Disconnect engine grid heater harness at grid

heater relays.

(3) Disconnect electrical connections from rear of

alternator.

(4) Recover A/C refrigerant. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

(5) Raise vehicle on a hoist.

(6) Drain engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Remove engine oil drain plug and drain engine

oil.

(8) Reinstall drain plug. Tighten to 50N´m (37 ft.

lbs.) torque.

(9) Lower the vehicle.

(10) Remove fan/drive assembly. Refer to Section 7

± Fan/Drive Removal

(11) Remove radiator upper hose.

(12) Remove upper fan shroud mounting bolts.

(13) Disconnect the coolant recovery bottle hose

from the radiator fill neck and remove bottle.

(14) Using a 36mm wrench, remove viscous fan/

drive assembly. (Refer to 7 - COOLING/ENGINE/RA-

DIATOR FAN - REMOVAL).

(15) Remove cooling fan and shroud together.

(16) Disconnect heater core supply and return

hoses from the cylinder head fitting and coolant pipe.

(17) Raise vehicle on a hoist.

(18) Remove transmission and transfer case (if

equipped).

(19) Disconnect exhaust pipe from turbocharger

extension pipe.

(20) Disconnect engine harness to vehicle harness

connectors.

(21) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).(22) Remove flywheel/flexplate.

(23) Remove transmission adapter

(24) Disconnect A/C suction/discharge hose from

the rear of the A/C compressor.

(25) Lower vehicle.

(26) Disconnect lower radiator hose from radiator

outlet.

(27) Automatic transmission models:

(28) Disconnect transmission oil cooler lines from

in front of radiator using special tool #6931

(29) Remove radiator. (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(30) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(31) Disconnect charge air cooler piping.

(32) Remove charge air cooler mounting bolts.

(33) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(34) Remove damper and speed indicator ring from

front of engine.

(35) Disconnect engine block heater connector.

(36) Disconnect A/C compressor and pressure sen-

sor electrical connectors.

(37) Remove the passenger battery ground cable

from the engine block. Remove the driver side bat-

tery ground cable from the engine block.

(38) Remove power steering pump from engine by

removing 3 bolts.

(39) Remove accelerator linkage cover.

(40) Disconnect cables from on-engine APPS.

(41) Disconnect the ECM power connector.

(42) Disconnect the ECM ground wire from the

hydroform screw.

(43) Disconnect the fuel supply and return hoses.

(44) Remove the cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(45) Disconnect the 3 injector harness connectors

at the rocker housing. Disconnect the wire harnesses

from the injectors.

(46) Remove the rear engine lift bracket.

(47) Remove cylinder #4, #5, and #6 intake and

exhaust rocker arms, pedestals, and push tubes. Note

the original location for re-assembly.

(48) Loosen #6 fuel line shield bolts and rotate

shield out of the way.

(49) Remove cylinder #5 and #6 high pressure fuel

lines. Remove the fuel connector tube nut and fuel

connector tube. Remove cylinder #5 and #6 fuel injec-

tor.

(50) Remove rocker housing.

DRENGINE 5.9L DIESEL 9 - 241

ENGINE 5.9L DIESEL (Continued)

Page 1466 of 2627

(8) Replace injector o-ring and sealing washer on

injectors #5 and #6. Install injectors and torque using

the following steps:

²Step 1ÐInstall injector hold-down capscrews

and torque to 5 N´m (44 in. lbs.) torque.

²Step 2ÐLoosen injector hold-down capscrews.

²Step 3ÐInstall HPC connector tube and nut.

Torque nut to 15 N´m (11 ft. lbs.) torque.

²Step 4ÐTorque injector hold-down capscrews to

10 N´m (89 in. lbs.) torque.

²Step 5ÐTorque HPC connector tube nut to 50

N´m (37 ft. lbs.) torque.

(9) Install #5 and #6 high pressure fuel lines. Fol-

low correct torque sequence per section 14. Torque

fuel line fittings to 30 N-m (22 ft-lb). Torque brace

capscrew to 24 N-m (18 ft-lb).

(10) Install rear engine lift bracket. Torque to 77

N-m (57 ft-lb).

(11) Install push tubes, rocker arms, and pedestals

for cylinders #4, #5, and #6. Torque the mounting

bolts to 36 N-m (27 ft-lbs).

(12) Reset valve lash on cylinders #4, #5, and #6.

Torque adjusting nuts to 24 N-m (18 ft-lbs).

(13) Install cylinder head cover. Torque to 24 N-m

(18 ft-lbs).(Refer to 9 - ENGINE/CYLINDER HEAD -

INSTALLATION).

(14) Connect breather tube and lube oil drain tube

to breather housing cover. Install breather housing.

Torque capscrews to 24 N-m (18 ft-lbs)

(15) Connect fuel supply and return hoses.

(16) Connect ECM ground to hydroform screw.

Connect ECM power connector.

(17) Install the APPS cable(s) to the APPS. Install

the throttle linkage cover.

(18) Install the power steering pump.

(19) Install the damper and speed indicator ring.

Torque to 40 N-m (30 ft-lb) plus 60 degrees.

(20) Connect the engine block heater connection.

(21) Connect the A/C compressor and pressure sen-

sor connectors

(22) Install the charge air cooler and a/c condenser

(if equipped). Install and tighten the charge air

cooler mounting bolts to 2 N-m (17 in-lbs).

(23) Connect the charge air cooler piping. Torque

all clamps to 8 N-m (72 in-lbs).

(24) Connect the a/c refrigerant lines to the a/c

condenser (if equipped).

(25) Install the radiator upper support panel.

(26) Install radiator.

(27) Connect the transmission quick-connect oil

cooler lines.(28) Raise vehicle.

(29) Connect a/c compressor suction/discharge hose

(if equipped).

(30) Install the radiator lower hose and clamps.

(31) Install the battery negative cables to the

engine block on the driver and passenger side.

(32) Install the transmission adapter with a new

camshaft rectangular ring seal. Torque to 77 N-m (57

ft-lb).

(33) Install the flywheel/flexplate. Torque to 137

N-m (101 ft-lb).

(34) Install the starter motor. Torque to 43 N-m

(32 ft-lb). (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(35) Connect engine to vehicle harness connectors.

(36) Install transmission and transfer case (if

equipped).

(37) Connect the exhaust pipe to the turbocharger

elbow.

(38) Connect the transmission auxiliary oil cooler

lines (if equipped).

(39) Lower the vehicle.

(40) Connect the heater core supply and return

hoses.

(41) Install the cooling fan and upper fan shroud

at the same time. (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - INSTALLATION).

(42) Install the coolant recovery bottle.

(43) Install the windshield washer bottle.

(44) Install the upper radiator hose and clamps.

(45) Raise vehicle.

(46) Connect electronically controlled fan drive

wire harness. Install lower radiator fan shroud.

(47) Change oil filter and install new engine oil.

(48) Fill the cooling system with coolant. (Refer to

7 - COOLING - STANDARD PROCEDURE).

(49) Connect grid heater harness at grid heater

relays.

(50) Connect electrical connections to rear of alter-

nator.

(51) Start the engine and inspect for engine oil,

coolant, and fuel leaks.

INSTALLATIONÐCRANKCASE BREATHER

(1) Install a new o-ring onto the breather element.

(2) Lubricate o-ring and install into cylinder head

cover. Torque capscrews to 10 N´m (89 in. lbs.).

(3) Connect breather tube and lube oil drain tube.

(4) Install breather cover (Fig. 4). Torque to 24

N´m (18 ft. lbs.)

(5) Install oil fill cap.

DRENGINE 5.9L DIESEL 9 - 243

ENGINE 5.9L DIESEL (Continued)

Page 1499 of 2627

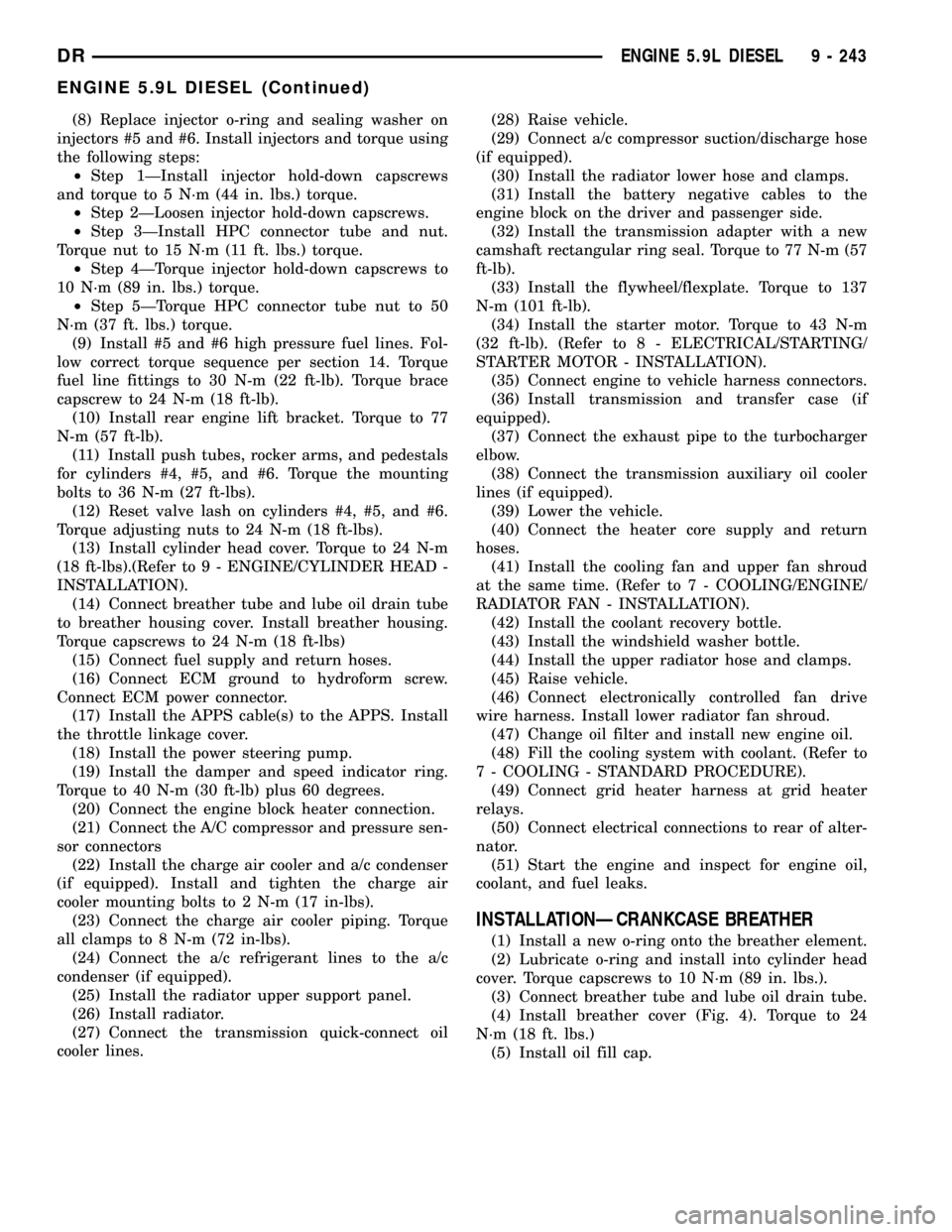

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the cover to the gear housing, aligning

the seal pilot with the nose of the crankshaft (Fig.

70).

(8) Install the cover bolts and tighten to 24 N´m

(18 ft. lbs.) torque. Remove pilot tool.

(9) Install dust shield over nose of crankshaft.

(10) Install the crankshaft damper and speed indi-

cator ring. Torque the bolts to 40 N´m (30 ft. lbs.).

Then rotate an additional 60É. Use the engine bar-

ring tool to keep the engine from rotating during

tightening operation.

(11) Install the fan support/hub assembly and

torque bolts to 32 N´m (24 ft. lbs.).

(12) Install power steering pump.

(13) Install accessory drive belt tensioner. Torque

bolt to 43 Nm (32 ft.lbs.).

(14) Install cooling fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(15) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(16) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(17) Connect battery negative cables.

(18) Start engine and check for oil leaks.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the transmission and transfer case (if

equipped).(3) Remove the clutch cover and disc (if manual

transmission equipped) (Refer to 6 - CLUTCH/

CLUTCH DISC - REMOVAL).

(4) Remove the flywheel or converter drive plate.

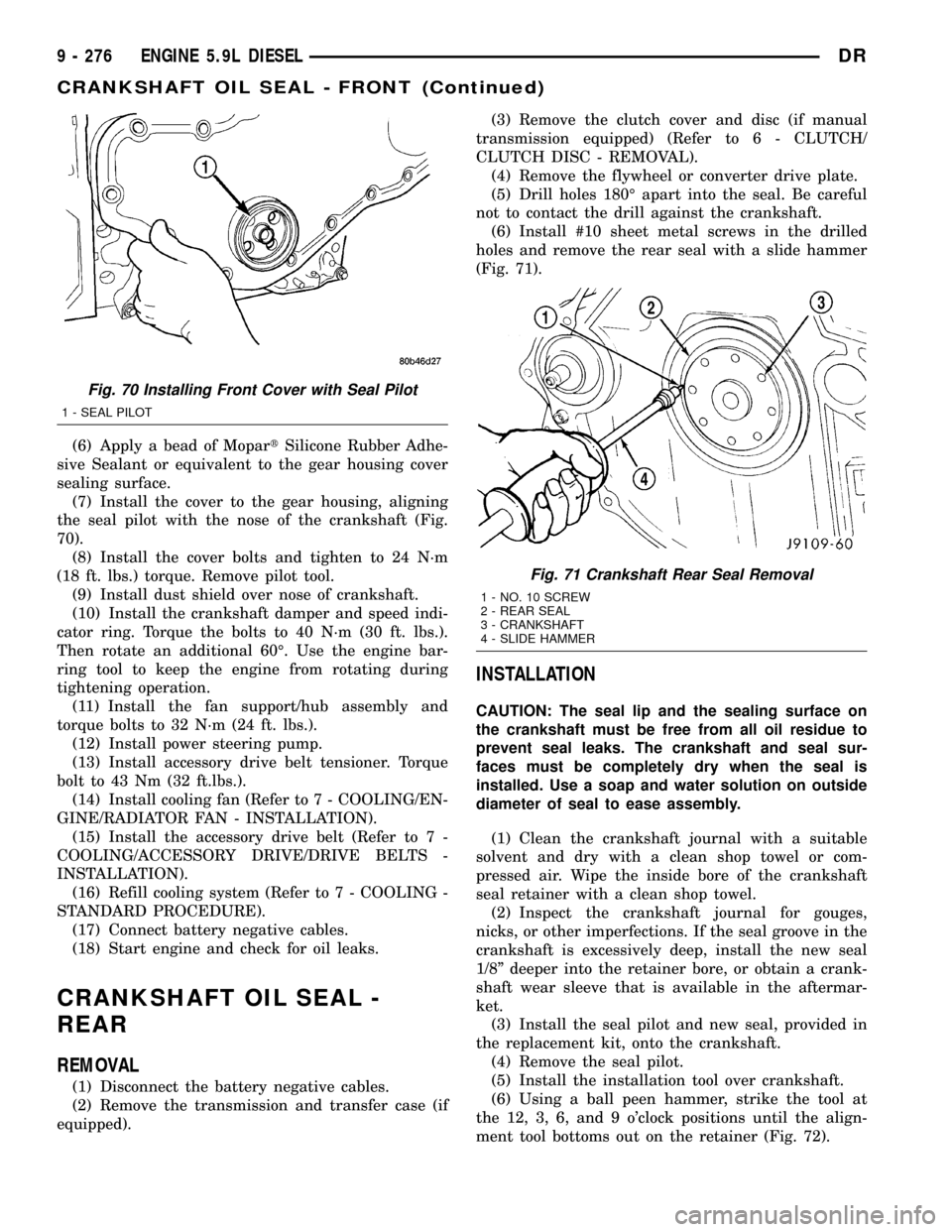

(5) Drill holes 180É apart into the seal. Be careful

not to contact the drill against the crankshaft.

(6) Install #10 sheet metal screws in the drilled

holes and remove the rear seal with a slide hammer

(Fig. 71).

INSTALLATION

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(1) Clean the crankshaft journal with a suitable

solvent and dry with a clean shop towel or com-

pressed air. Wipe the inside bore of the crankshaft

seal retainer with a clean shop towel.

(2) Inspect the crankshaft journal for gouges,

nicks, or other imperfections. If the seal groove in the

crankshaft is excessively deep, install the new seal

1/8º deeper into the retainer bore, or obtain a crank-

shaft wear sleeve that is available in the aftermar-

ket.

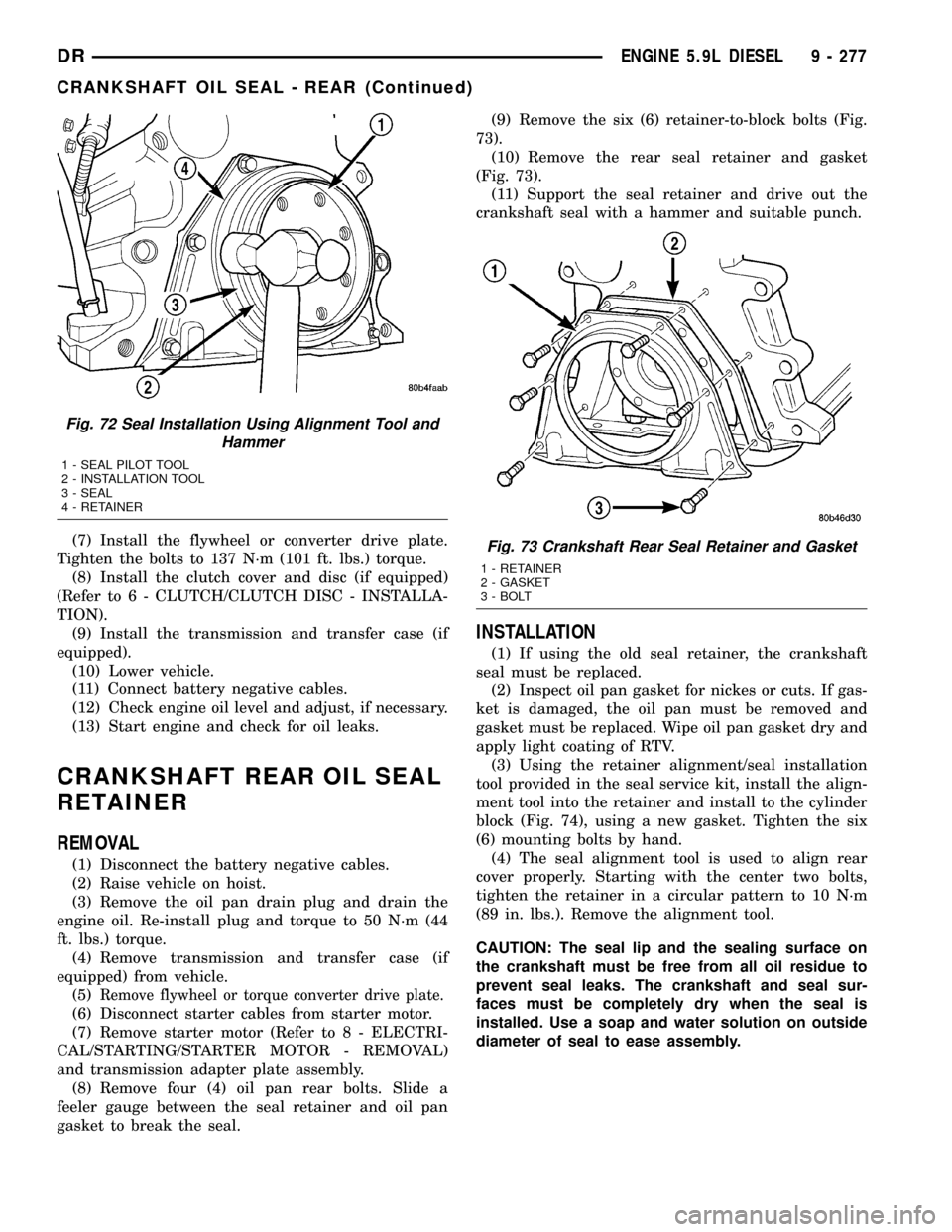

(3) Install the seal pilot and new seal, provided in

the replacement kit, onto the crankshaft.

(4) Remove the seal pilot.

(5) Install the installation tool over crankshaft.

(6) Using a ball peen hammer, strike the tool at

the 12, 3, 6, and 9 o'clock positions until the align-

ment tool bottoms out on the retainer (Fig. 72).

Fig. 70 Installing Front Cover with Seal Pilot

1 - SEAL PILOT

Fig. 71 Crankshaft Rear Seal Removal

1 - NO. 10 SCREW

2 - REAR SEAL

3 - CRANKSHAFT

4 - SLIDE HAMMER

9 - 276 ENGINE 5.9L DIESELDR

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1500 of 2627

(7) Install the flywheel or converter drive plate.

Tighten the bolts to 137 N´m (101 ft. lbs.) torque.

(8) Install the clutch cover and disc (if equipped)

(Refer to 6 - CLUTCH/CLUTCH DISC - INSTALLA-

TION).

(9) Install the transmission and transfer case (if

equipped).

(10) Lower vehicle.

(11) Connect battery negative cables.

(12) Check engine oil level and adjust, if necessary.

(13) Start engine and check for oil leaks.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Remove the oil pan drain plug and drain the

engine oil. Re-install plug and torque to 50 N´m (44

ft. lbs.) torque.

(4) Remove transmission and transfer case (if

equipped) from vehicle.

(5)

Remove flywheel or torque converter drive plate.

(6) Disconnect starter cables from starter motor.

(7) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(8) Remove four (4) oil pan rear bolts. Slide a

feeler gauge between the seal retainer and oil pan

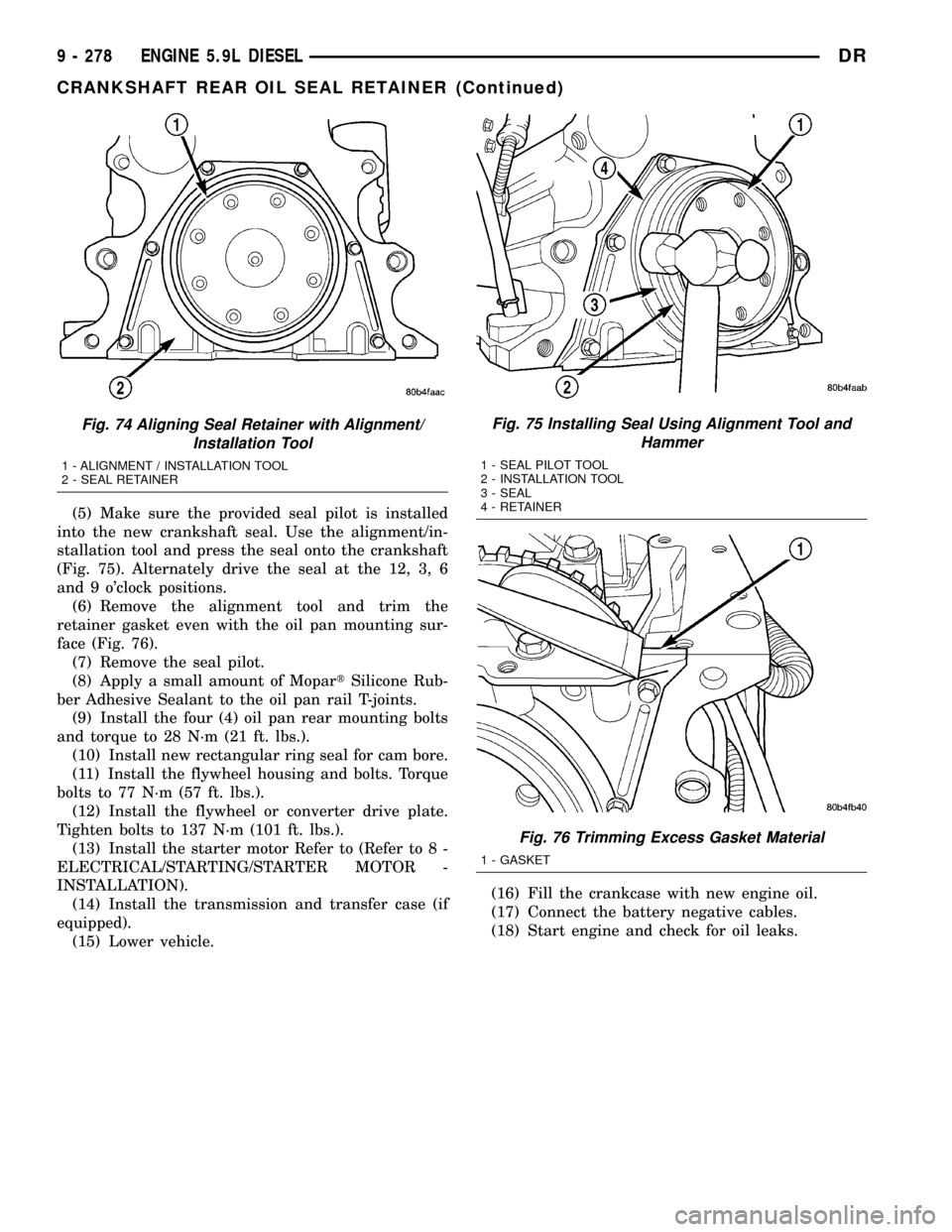

gasket to break the seal.(9) Remove the six (6) retainer-to-block bolts (Fig.

73).

(10) Remove the rear seal retainer and gasket

(Fig. 73).

(11) Support the seal retainer and drive out the

crankshaft seal with a hammer and suitable punch.

INSTALLATION

(1) If using the old seal retainer, the crankshaft

seal must be replaced.

(2) Inspect oil pan gasket for nickes or cuts. If gas-

ket is damaged, the oil pan must be removed and

gasket must be replaced. Wipe oil pan gasket dry and

apply light coating of RTV.

(3) Using the retainer alignment/seal installation

tool provided in the seal service kit, install the align-

ment tool into the retainer and install to the cylinder

block (Fig. 74), using a new gasket. Tighten the six

(6) mounting bolts by hand.

(4) The seal alignment tool is used to align rear

cover properly. Starting with the center two bolts,

tighten the retainer in a circular pattern to 10 N´m

(89 in. lbs.). Remove the alignment tool.

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

Fig. 72 Seal Installation Using Alignment Tool and

Hammer

1 - SEAL PILOT TOOL

2 - INSTALLATION TOOL

3 - SEAL

4 - RETAINER

Fig. 73 Crankshaft Rear Seal Retainer and Gasket

1 - RETAINER

2 - GASKET

3 - BOLT

DRENGINE 5.9L DIESEL 9 - 277

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1501 of 2627

(5) Make sure the provided seal pilot is installed

into the new crankshaft seal. Use the alignment/in-

stallation tool and press the seal onto the crankshaft

(Fig. 75). Alternately drive the seal at the 12, 3, 6

and 9 o'clock positions.

(6) Remove the alignment tool and trim the

retainer gasket even with the oil pan mounting sur-

face (Fig. 76).

(7) Remove the seal pilot.

(8) Apply a small amount of MopartSilicone Rub-

ber Adhesive Sealant to the oil pan rail T-joints.

(9) Install the four (4) oil pan rear mounting bolts

and torque to 28 N´m (21 ft. lbs.).

(10) Install new rectangular ring seal for cam bore.

(11) Install the flywheel housing and bolts. Torque

bolts to 77 N´m (57 ft. lbs.).

(12) Install the flywheel or converter drive plate.

Tighten bolts to 137 N´m (101 ft. lbs.).

(13) Install the starter motor Refer to (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(14) Install the transmission and transfer case (if

equipped).

(15) Lower vehicle.(16) Fill the crankcase with new engine oil.

(17) Connect the battery negative cables.

(18) Start engine and check for oil leaks.

Fig. 74 Aligning Seal Retainer with Alignment/

Installation Tool

1 - ALIGNMENT / INSTALLATION TOOL

2 - SEAL RETAINER

Fig. 75 Installing Seal Using Alignment Tool and

Hammer

1 - SEAL PILOT TOOL

2 - INSTALLATION TOOL

3 - SEAL

4 - RETAINER

Fig. 76 Trimming Excess Gasket Material

1 - GASKET

9 - 278 ENGINE 5.9L DIESELDR

CRANKSHAFT REAR OIL SEAL RETAINER (Continued)

Page 1516 of 2627

OIL COOLER & LINES

CLEANING

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter from below using a cap-style filter

wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional

1¤2turn.

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Install engine support fixture # 8534.

(3) Raise vehicle on hoist.

(4) Disconnect starter cables from starter motor.

(5) Remove transmission and transfer case (if

equipped).

(6) Remove flywheel or flexplate.

(7) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(8) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).(9) Install the oil pan drain plug if sealing surface

is not damaged and tighten to 50 N´m (37 ft. lbs.)

torque.

(10) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(11) Remove oil pan and suction tube.

CLEANING

Remove all gasket material from the oil pan and

cylinder block sealing surfaces. Extra effort may be

required around T-joint areas. Clean oil pan and

flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces

for cracks and damage. Replace any defective compo-

nent. Inspect the oil drain plug and drain hole

threads. Inspect the oil pan sealing surface for

straightness. Repair any minor imperfections with a

ball-peen hammer. Do not attempt to repair an oil

pan by welding.

INSTALLATION

(1) Fill the T-joint between the pan rail/gear hous-

ing and pan rail/rear seal retainer with sealant. Use

MopartSilicone Rubber Adhesive Sealant or equiva-

lent.

(2) Place suction tube in oil pan and guide them

into place. Using a new tube to block gasket, install

and tighten the suction tube bolts by hand. Starting

with the oil pump inlet bolts, tighten the bolts to 24

N´m (18 ft. lbs.) torque. Tighten the remaining tube

brace bolts to 43 N´m (32 ft. lbs.) torque.

(3) Starting in the center and working outward,

tighten the oil pan bolts to 28 N´m (21 ft. lbs.)

torque.

(4) Install the flywheel housing assembly with the

starter motor attached and tighten bolts to 77 N´m

(57 ft. lbs.) torque.

(5) Connect starter motor cables.

(6) Install the flywheel or flexplate. Torque to 137

N´m (101 ft. lbs.).

(7) Install transmission and transfer case (if

equipped).

(8) Lower vehicle.

(9) Remove the engine support fixture # 8534.

(10) Install battery negative cables.

(11) Fill the crankcase with new engine oil.

(12) Start engine and check for leaks. Stop engine,

check oil level, and adjust, if necessary.

DRENGINE 5.9L DIESEL 9 - 293

Page 1544 of 2627

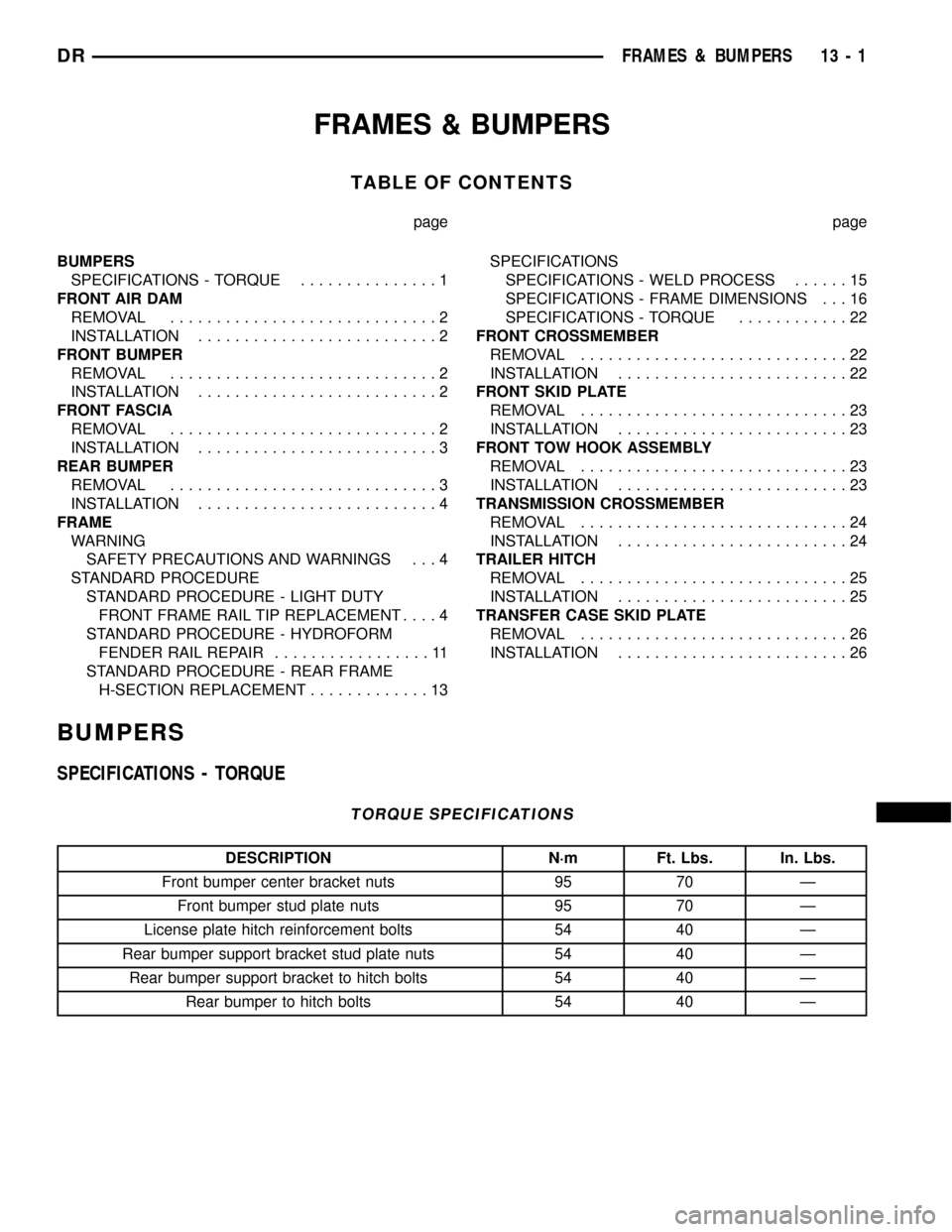

FRAMES & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT AIR DAM

REMOVAL.............................2

INSTALLATION..........................2

FRONT BUMPER

REMOVAL.............................2

INSTALLATION..........................2

FRONT FASCIA

REMOVAL.............................2

INSTALLATION..........................3

REAR BUMPER

REMOVAL.............................3

INSTALLATION..........................4

FRAME

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 4

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY

FRONT FRAME RAIL TIP REPLACEMENT....4

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR.................11

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT.............13SPECIFICATIONS

SPECIFICATIONS - WELD PROCESS......15

SPECIFICATIONS - FRAME DIMENSIONS . . . 16

SPECIFICATIONS - TORQUE............22

FRONT CROSSMEMBER

REMOVAL.............................22

INSTALLATION.........................22

FRONT SKID PLATE

REMOVAL.............................23

INSTALLATION.........................23

FRONT TOW HOOK ASSEMBLY

REMOVAL.............................23

INSTALLATION.........................23

TRANSMISSION CROSSMEMBER

REMOVAL.............................24

INSTALLATION.........................24

TRAILER HITCH

REMOVAL.............................25

INSTALLATION.........................25

TRANSFER CASE SKID PLATE

REMOVAL.............................26

INSTALLATION.........................26

BUMPERS

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front bumper center bracket nuts 95 70 Ð

Front bumper stud plate nuts 95 70 Ð

License plate hitch reinforcement bolts 54 40 Ð

Rear bumper support bracket stud plate nuts 54 40 Ð

Rear bumper support bracket to hitch bolts 54 40 Ð

Rear bumper to hitch bolts 54 40 Ð

DRFRAMES & BUMPERS 13 - 1