change time DODGE RAM 1500 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 638 of 2627

receptacles that face the instrument panel, while the

inner end of the tape terminates at the pigtail wires

and connector receptacles on the hub of the clock-

spring rotor that face the steering wheel.

Service replacement clocksprings are shipped pre-

centered and with a molded plastic locking pin that

snaps into a receptacle on the rotor and is engaged

between two tabs on the upper surface of the rotor

case. The locking pin secures the centered clock-

spring rotor to the clockspring case during shipment

and handling, but must be removed from the clock-

spring after it is installed on the steering column.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - STANDARD PROCEDURE - CLOCK-

SPRING CENTERING).

The clockspring cannot be repaired. If the clock-

spring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electri-

cal continuity between the fixed instrument panel

wire harness and the electrical components mounted

on or in the rotating steering wheel. On this model

the rotating electrical components include the driver

airbag, the horn switch, the speed control switches,

and the remote radio switches, if the vehicle is so

equipped. The clockspring case is positioned and

secured to the multi-function switch mounting hous-

ing near the top of the steering column. The connec-

tor receptacles on the tail of the fixed clockspring

case connect the clockspring to the vehicle electrical

system through two take outs with connectors from

the instrument panel wire harness.The clockspring rotor is movable and is keyed by

an engagement dowel that is molded onto the rotor

hub between two fins that are cast into the lower

surface of the steering wheel armature. A yellow rub-

ber boot is installed over the engagement dowel to

eliminate contact noise between the dowel and the

steering wheel. The two lobes on the turn signal can-

cel cam on the lower surface of the clockspring rotor

hub contact a turn signal cancel actuator of the

multi-function switch to provide automatic turn sig-

nal cancellation.

Two short, yellow-sleeved pigtail wires on the

upper surface of the clockspring rotor connect the

clockspring to the driver airbag, while a steering

wheel wire harness connects the two connector recep-

tacles on the upper surface of the clockspring rotor to

the horn switch feed pigtail wire connector and, if

the vehicle is so equipped, to the optional speed con-

trol and remote radio switches on the steering wheel.

Like the clockspring in a timepiece, the clockspring

tape has travel limits and can be damaged by being

wound too tightly during full stop-to-stop steering

wheel rotation. To prevent this from occurring, the

clockspring is centered when it is installed on the

steering column. Centering the clockspring indexes

the clockspring tape to the movable steering compo-

nents so that the tape can operate within its

designed travel limits. However, if the clockspring is

removed from the steering column or if the steering

shaft is disconnected from the steering gear, the

clockspring spool can change position relative to the

movable steering components. The clockspring must

be re-centered following completion of this service or

the tape may be damaged.

Service replacement clocksprings are shipped pre-

centered and with a plastic locking pin installed.

This locking pin should not be removed until the

clockspring has been installed on the steering col-

umn. If the locking pin is removed before the clock-

spring is installed on a steering column, the

clockspring centering procedure must be performed.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - STANDARD PROCEDURE - CLOCK-

SPRING CENTERING).

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering compo-

nents so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

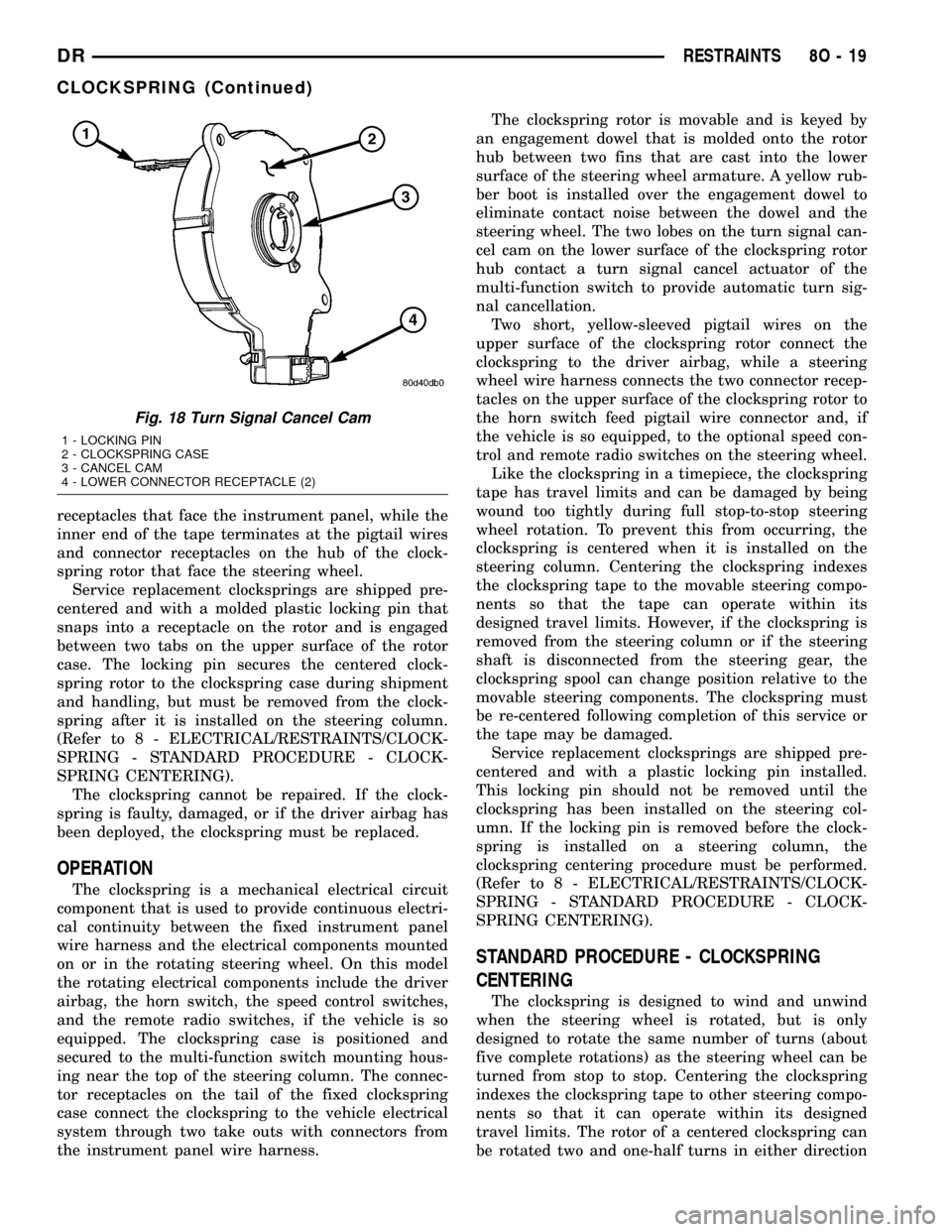

Fig. 18 Turn Signal Cancel Cam

1 - LOCKING PIN

2 - CLOCKSPRING CASE

3 - CANCEL CAM

4 - LOWER CONNECTOR RECEPTACLE (2)

DRRESTRAINTS 8O - 19

CLOCKSPRING (Continued)

Page 645 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, THE DRIVER AIRBAG TRIM COVER MUST

NEVER BE PAINTED. REPLACEMENT TRIM COV-

ERS ARE SERVICED IN THE ORIGINAL COLORS.

PAINT MAY CHANGE THE WAY IN WHICH THE

MATERIAL OF THE TRIM COVER RESPONDS TO AN

AIRBAG DEPLOYMENT. FAILURE TO OBSERVE

THIS WARNING COULD RESULT IN OCCUPANT

INJURIES UPON AIRBAG DEPLOYMENT.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Remove the driver airbag from the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) Place the driver airbag on a suitable clean and

dry work surface with the trim cover facing down. If

the trim cover will be reused, be certain to take the

proper precautions to prevent the trim cover from

receiving cosmetic damage during the following pro-

cedures.

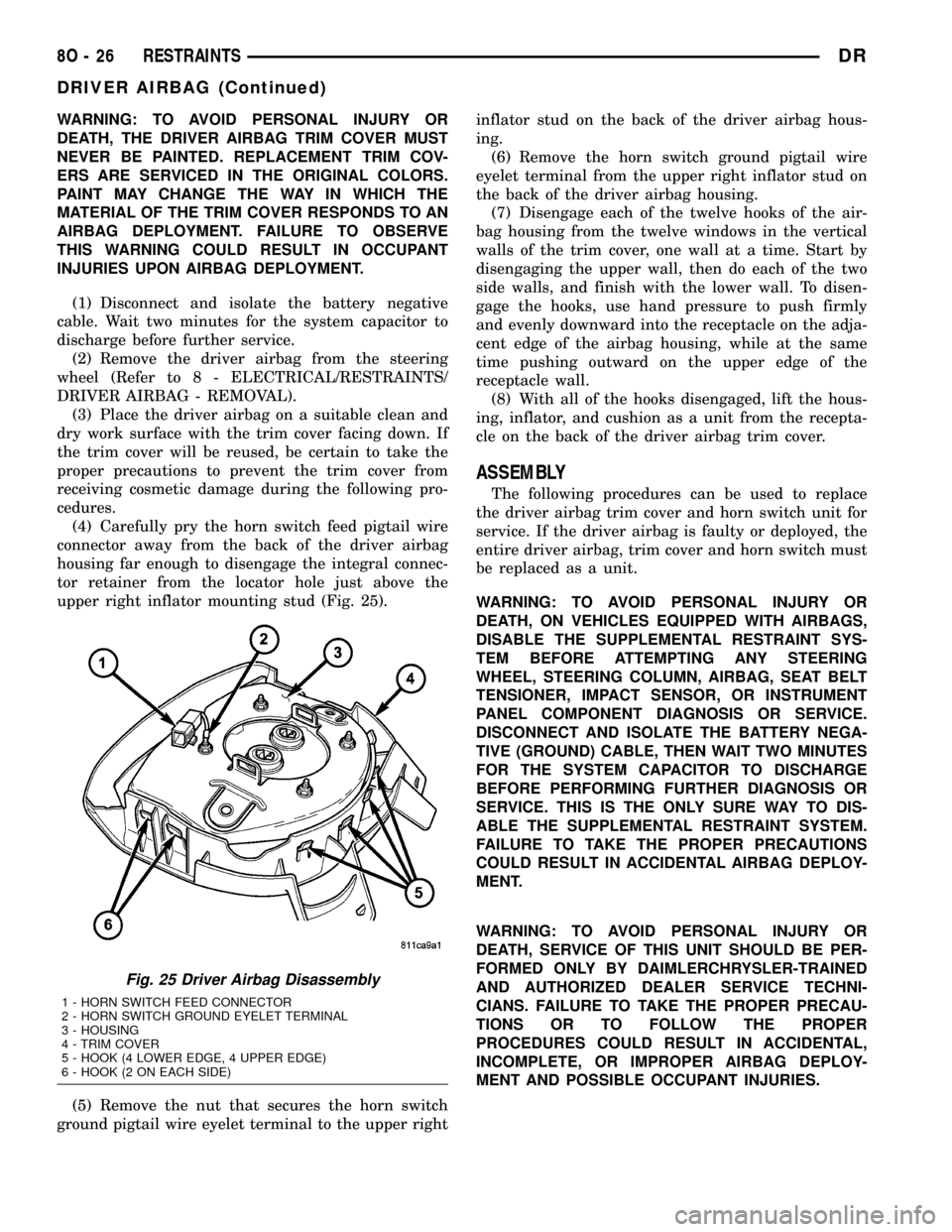

(4) Carefully pry the horn switch feed pigtail wire

connector away from the back of the driver airbag

housing far enough to disengage the integral connec-

tor retainer from the locator hole just above the

upper right inflator mounting stud (Fig. 25).

(5) Remove the nut that secures the horn switch

ground pigtail wire eyelet terminal to the upper rightinflator stud on the back of the driver airbag hous-

ing.

(6) Remove the horn switch ground pigtail wire

eyelet terminal from the upper right inflator stud on

the back of the driver airbag housing.

(7) Disengage each of the twelve hooks of the air-

bag housing from the twelve windows in the vertical

walls of the trim cover, one wall at a time. Start by

disengaging the upper wall, then do each of the two

side walls, and finish with the lower wall. To disen-

gage the hooks, use hand pressure to push firmly

and evenly downward into the receptacle on the adja-

cent edge of the airbag housing, while at the same

time pushing outward on the upper edge of the

receptacle wall.

(8) With all of the hooks disengaged, lift the hous-

ing, inflator, and cushion as a unit from the recepta-

cle on the back of the driver airbag trim cover.

ASSEMBLY

The following procedures can be used to replace

the driver airbag trim cover and horn switch unit for

service. If the driver airbag is faulty or deployed, the

entire driver airbag, trim cover and horn switch must

be replaced as a unit.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, SERVICE OF THIS UNIT SHOULD BE PER-

FORMED ONLY BY DAIMLERCHRYSLER-TRAINED

AND AUTHORIZED DEALER SERVICE TECHNI-

CIANS. FAILURE TO TAKE THE PROPER PRECAU-

TIONS OR TO FOLLOW THE PROPER

PROCEDURES COULD RESULT IN ACCIDENTAL,

INCOMPLETE, OR IMPROPER AIRBAG DEPLOY-

MENT AND POSSIBLE OCCUPANT INJURIES.

Fig. 25 Driver Airbag Disassembly

1 - HORN SWITCH FEED CONNECTOR

2 - HORN SWITCH GROUND EYELET TERMINAL

3 - HOUSING

4 - TRIM COVER

5 - HOOK (4 LOWER EDGE, 4 UPPER EDGE)

6 - HOOK (2 ON EACH SIDE)

8O - 26 RESTRAINTSDR

DRIVER AIRBAG (Continued)

Page 647 of 2627

driver airbag housing. Tighten the nut to 7 N´m (65

in. lbs.).

(11) Using hand pressure, push the integral

retainer of the horn switch feed pigtail wire connec-

tor into the locator hole just above the upper right

inflator mounting stud on the back of the driver air-

bag.

(12) Reinstall the driver airbag onto the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

INSTALLATION

The following procedure is for replacement of a

faulty or damaged driver airbag. If the airbag is

faulty or damaged, but not deployed, review the rec-

ommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the driver airbag has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE DRIVER

AIRBAG, OR BECOMING ENTRAPPED BETWEEN

THE DRIVER AIRBAG CUSHION AND THE DRIVER

AIRBAG TRIM COVER. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN OCCUPANT INJURIES

UPON AIRBAG DEPLOYMENT.WARNING: TO AVOID PERSONAL INJURY OR

DEATH, THE DRIVER AIRBAG TRIM COVER MUST

NEVER BE PAINTED. REPLACEMENT AIRBAGS

ARE SERVICED WITH TRIM COVERS IN THE ORIG-

INAL COLORS. PAINT MAY CHANGE THE WAY IN

WHICH THE MATERIAL OF THE TRIM COVER

RESPONDS TO AN AIRBAG DEPLOYMENT. FAIL-

URE TO OBSERVE THIS WARNING COULD RESULT

IN OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Position the driver airbag close enough to the

steering wheel to reconnect the three electrical con-

nections on the back of the airbag housing (Fig. 24).

(2) When installing the driver airbag, reconnect

the two clockspring driver airbag pigtail wire connec-

tors to the airbag inflator connector receptacles by

pressing straight in on the connector. Be certain to

engage each keyed and color-coded connector to the

matching connector receptacle. You can be certain

that each connector is fully engaged in its receptacle

by listening carefully for a distinct, audible click as

the connector latches snap into place.

(3) Reconnect the steering wheel wire harness con-

nector for the horn switch to the horn switch feed

pigtail wire connector, which is located on the back of

the driver airbag housing.

(4) Carefully position the driver airbag in the

steering wheel (Fig. 23). Be certain that the clock-

spring pigtail wires and the steering wheel wire har-

ness in the steering wheel hub area are not pinched

between the driver airbag and the steering wheel

armature.

(5) From the underside of the steering wheel,

install and tighten the two screws that secure the

driver airbag to the steering wheel armature.

Tighten the screws to 10 N´m (90 in. lbs.).

(6) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

8O - 28 RESTRAINTSDR

DRIVER AIRBAG (Continued)

Page 661 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, THE PASSENGER AIRBAG DOOR MUST

NEVER BE PAINTED. REPLACEMENT PASSENGER

AIRBAG UNITS ARE SERVICED WITH DOORS IN

THE ORIGINAL COLORS. PAINT MAY CHANGE THE

WAY IN WHICH THE MATERIAL OF THE AIRBAG

DOOR RESPONDS TO AN AIRBAG DEPLOYMENT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN OCCUPANT INJURIES UPON AIRBAG

DEPLOYMENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE PAS-

SENGER AIRBAG, OR BECOMING ENTRAPPED

BETWEEN THE PASSENGER AIRBAG CUSHION

AND THE PASSENGER AIRBAG DOOR. FAILURE TO

OBSERVE THIS WARNING COULD RESULT IN

OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Carefully position the passenger airbag and

airbag door to the instrument panel as a unit.

(2) Reconnect the passenger airbag pigtail wire

connector to the instrument panel wire harness con-

nector for the airbag. This connector is secured to the

inboard side of the airbag housing.Be certain that

the latch on the connector and the red Connec-

tor Position Assurance (CPA) lock are each

fully engaged.

(3) Position the passenger airbag housing and door

unit into the instrument panel.

(4) Using hand pressure, press firmly and evenly

over each of the seven snap features on the upper

and outboard edges of the passenger airbag door

until they snap into their receptacles in the instru-

ment panel base trim.

(5) Reach through and above the glove box opening

to install and tighten the two screws that secure the

passenger airbag front brackets to the instrument

panel structural support (Fig. 37). Tighten the screws

to 6 N´m (55 in. lbs.).

(6) Reach through and above the glove box opening

to install and tighten the two screws that secure the

passenger airbag rear brackets to the upper glove

box opening reinforcement. Tighten the screws to 6

N´m (55 in. lbs.).

(7) Install and tighten the six screws that secure

the inboard and lower flanges of the passenger air-

bag door to the instrument panel (Fig. 36). Tighten

the screws to 2 N´m (20 in. lbs.).

(8) Install and tighten the screw that secures the

mounting tab of the panel outlet housing to the

upper glove box opening reinforcement. Tighten the

screw to 2 N´m (20 in. lbs.).(9) Reinstall the lower surround onto the instru-

ment panel. (Refer to 23 - BODY/INSTRUMENT

PANEL/LOWER SURROUND - INSTALLATION).

(10) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

PASSENGER AIRBAG ON/OFF

SWITCH

DESCRIPTION

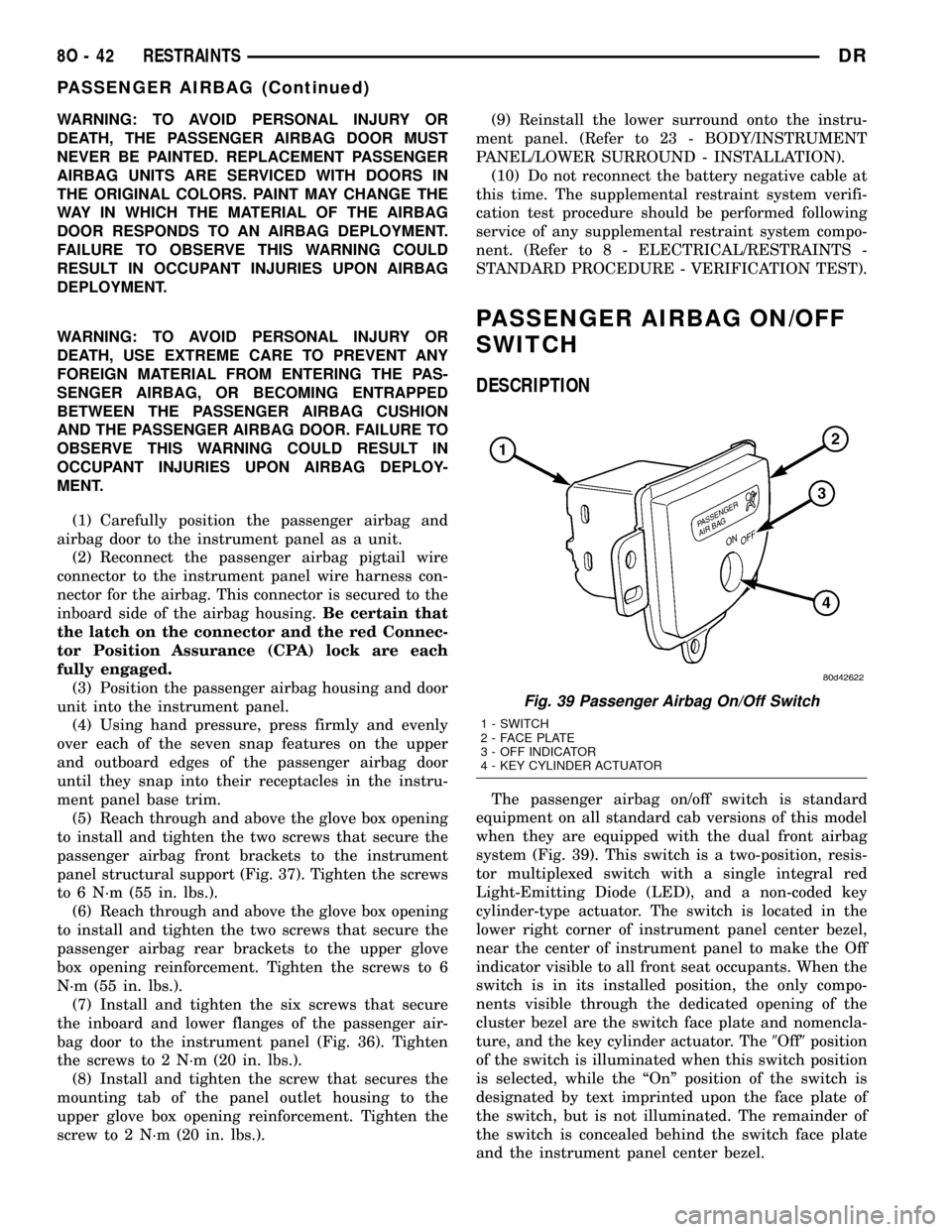

The passenger airbag on/off switch is standard

equipment on all standard cab versions of this model

when they are equipped with the dual front airbag

system (Fig. 39). This switch is a two-position, resis-

tor multiplexed switch with a single integral red

Light-Emitting Diode (LED), and a non-coded key

cylinder-type actuator. The switch is located in the

lower right corner of instrument panel center bezel,

near the center of instrument panel to make the Off

indicator visible to all front seat occupants. When the

switch is in its installed position, the only compo-

nents visible through the dedicated opening of the

cluster bezel are the switch face plate and nomencla-

ture, and the key cylinder actuator. The9Off9position

of the switch is illuminated when this switch position

is selected, while the ªOnº position of the switch is

designated by text imprinted upon the face plate of

the switch, but is not illuminated. The remainder of

the switch is concealed behind the switch face plate

and the instrument panel center bezel.

Fig. 39 Passenger Airbag On/Off Switch

1 - SWITCH

2 - FACE PLATE

3 - OFF INDICATOR

4 - KEY CYLINDER ACTUATOR

8O - 42 RESTRAINTSDR

PASSENGER AIRBAG (Continued)

Page 702 of 2627

the wiper motor was operating at high speed, the

FCM immediately de-energizes the wiper high/low

relay causing the wiper motor to return to low speed

operation. Then one of two events will occur. The

event that occurs depends upon the position of the

wiper blades on the windshield at the moment that

the control knob Off position is selected.

If the wiper blades are in the down position on the

windshield when the Off position is selected, the

park switch that is integral to the wiper motor is

closed to ground and provides a hard wired park

switch sense input to the FCM. The FCM then de-en-

ergizes the wiper on/off relay and the wiper motor

ceases to operate. If the wiper blades are not in the

down position on the windshield at the moment the

Off position is selected, the park switch is an open

circuit and the FCM keeps the wiper on/off relay

energized, which causes the wiper motor to continue

running at low speed until the wiper blades are in

the down position on the windshield and the park

switch input to the FCM is again closed to ground.

INTERMITTENT WIPE MODE

When the control knob on the control stalk of the

multi-function switch is moved to one of the Delay

interval positions the instrument cluster sends an

electronic wiper switch delay message to the FCM,

then the FCM electronic intermittent wipe logic cir-

cuit responds by calculating the correct length of

time between wiper sweeps based upon the selected

delay interval input. The FCM monitors the changing

state of the wiper motor park switch through a hard

wired park switch sense input. This input allows the

FCM to determine the proper intervals at which to

energize and de-energize the wiper on/off relay to

operate the wiper motor intermittently for one low

speed cycle at a time.

The FCM logic is also programmed to provide vehi-

cle speed sensitivity to the selected intermittent wipe

delay intervals. In order to provide this feature the

FCM monitors electronic vehicle speed messages

from the Powertrain Control Module (PCM) and dou-

bles the selected delay interval whenever the vehicle

speed is about sixteen kilometers-per-hour (ten miles-

per-hour) or less.

PULSE WIPE MODE

When the control knob on the control stalk of the

multi-function switch is depressed to the momentary

Wash position for less than about one-half second,

the instrument cluster sends an electronic washer

switch message to the FCM, then the FCM the ener-

gizes the wiper on/off relay for one complete wipe

cycle. The FCM de-energizes the relay when the state

of the park switch sense changes to ground, parking

the wiper blades near the base of the windshield.WASH MODE

When the control knob on the control stalk of the

multi-function switch is depressed to the momentary

Wash position for more than about one-half second,

the instrument cluster sends an electronic washer

switch message to the FCM, then the FCM directs

battery current to the washer pump/motor unit. This

will cause the washer pump/motor unit to be ener-

gized for as long as the Wash switch is held closed up

to about thirty seconds, and to de-energize when the

front Wash switch is released.

When the control knob is depressed to the momen-

tary Wash position while the wiper system is operat-

ing in one of the Delay interval positions, the washer

pump/motor operation is the same. However, the

FCM also energizes the wiper on/off relay to override

the selected delay interval and operate the wiper

motor in a continuous low speed mode for as long as

the control knob is held depressed, then de-energizes

the relay and reverts to the selected delay mode

interval several wipe cycles after the control knob is

released. If the control knob is held depressed for

more than about thirty seconds, the FCM will sus-

pend washer pump/motor operation until the knob is

released for about two seconds, then cycled back to

the Wash position.

WIPE-AFTER-WASH MODE

When the control knob on the control stalk of the

multi-function switch is depressed to the momentary

Wash position for more than about one-half second

while the wiper system is not operating, the instru-

ment cluster sends an electronic washer switch mes-

sage to the FCM, then the FCM the directs battery

current to the washer pump/motor unit and energizes

the wiper on/off relay. This will cause the washer

pump/motor unit to be energized and operate the

wiper motor in a continuous low speed mode for as

long as the Wash switch is held closed up to about

thirty seconds. When the control knob is released,

the FCM de-energizes the washer pump/motor unit,

but allows the wiper motor to operate for several

additional wipe cycles before it de-energizes the

wiper on/off relay and parks the wiper blades near

the base of the windshield.

If the control knob is held depressed for more than

about thirty seconds, the FCM will suspend washer

pump/motor operation until the knob is released for

about two seconds, then cycled back to the Wash

position; however, the wipers will continue to operate

for as long as the Wash switch is held closed. The

FCM monitors the changing state of the wiper motor

park switch through a hard wired wiper park switch

sense circuit input. This input allows the FCM to

count the number of wipe cycles that occur after the

Wash switch is released, and to determine the proper

DRWIPERS/WASHERS 8R - 5

WIPERS/WASHERS (Continued)

Page 716 of 2627

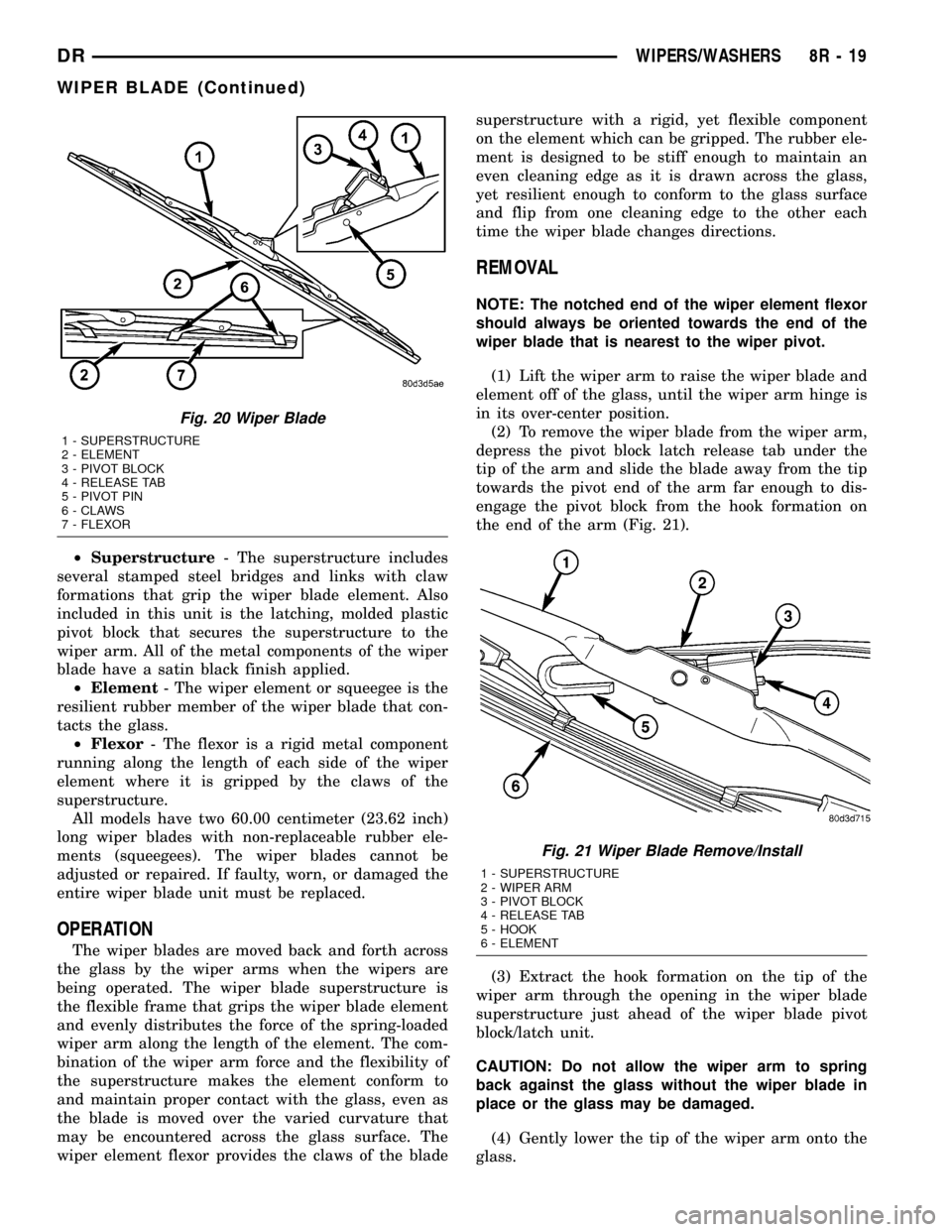

²Superstructure- The superstructure includes

several stamped steel bridges and links with claw

formations that grip the wiper blade element. Also

included in this unit is the latching, molded plastic

pivot block that secures the superstructure to the

wiper arm. All of the metal components of the wiper

blade have a satin black finish applied.

²Element- The wiper element or squeegee is the

resilient rubber member of the wiper blade that con-

tacts the glass.

²Flexor- The flexor is a rigid metal component

running along the length of each side of the wiper

element where it is gripped by the claws of the

superstructure.

All models have two 60.00 centimeter (23.62 inch)

long wiper blades with non-replaceable rubber ele-

ments (squeegees). The wiper blades cannot be

adjusted or repaired. If faulty, worn, or damaged the

entire wiper blade unit must be replaced.

OPERATION

The wiper blades are moved back and forth across

the glass by the wiper arms when the wipers are

being operated. The wiper blade superstructure is

the flexible frame that grips the wiper blade element

and evenly distributes the force of the spring-loaded

wiper arm along the length of the element. The com-

bination of the wiper arm force and the flexibility of

the superstructure makes the element conform to

and maintain proper contact with the glass, even as

the blade is moved over the varied curvature that

may be encountered across the glass surface. The

wiper element flexor provides the claws of the bladesuperstructure with a rigid, yet flexible component

on the element which can be gripped. The rubber ele-

ment is designed to be stiff enough to maintain an

even cleaning edge as it is drawn across the glass,

yet resilient enough to conform to the glass surface

and flip from one cleaning edge to the other each

time the wiper blade changes directions.

REMOVAL

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper pivot.

(1) Lift the wiper arm to raise the wiper blade and

element off of the glass, until the wiper arm hinge is

in its over-center position.

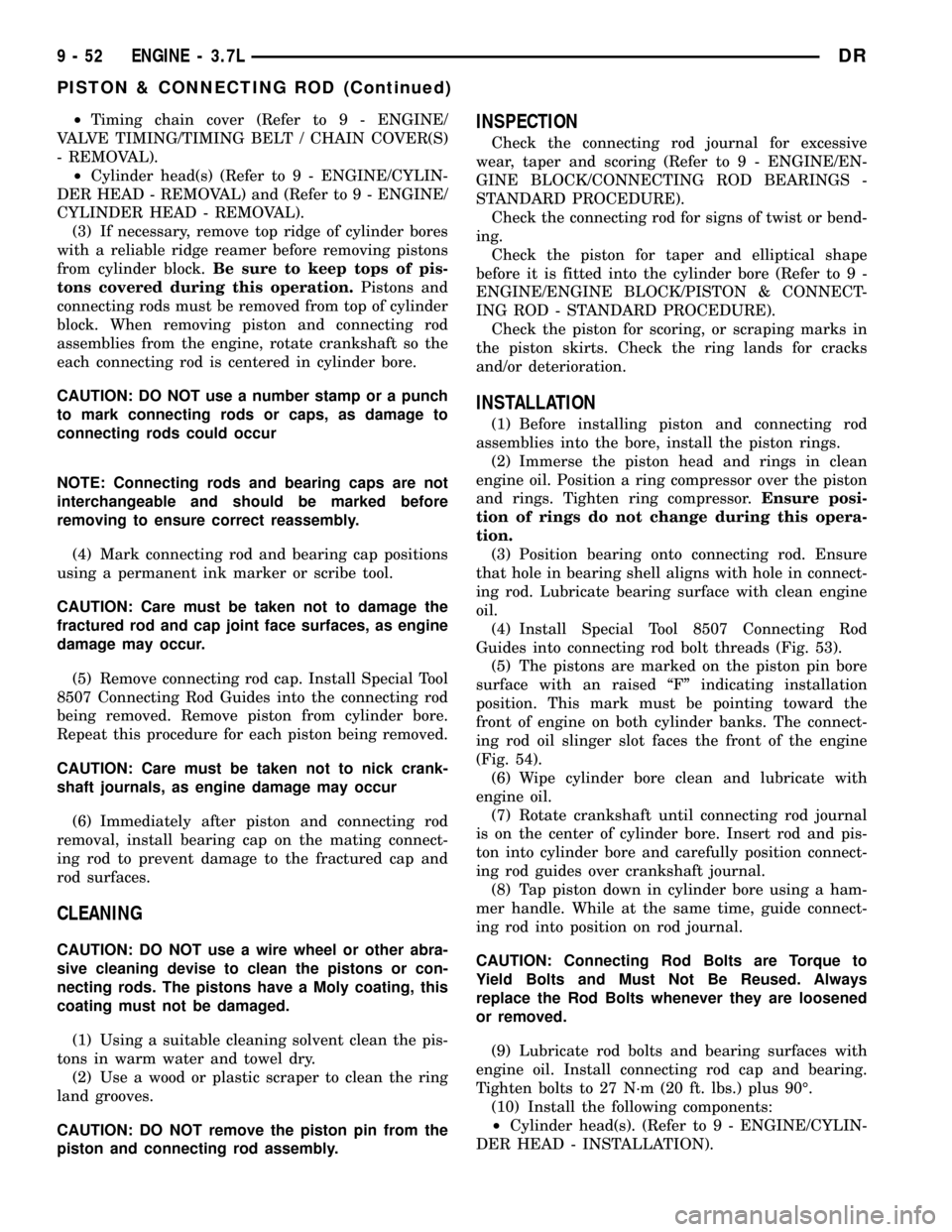

(2) To remove the wiper blade from the wiper arm,

depress the pivot block latch release tab under the

tip of the arm and slide the blade away from the tip

towards the pivot end of the arm far enough to dis-

engage the pivot block from the hook formation on

the end of the arm (Fig. 21).

(3) Extract the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure just ahead of the wiper blade pivot

block/latch unit.

CAUTION: Do not allow the wiper arm to spring

back against the glass without the wiper blade in

place or the glass may be damaged.

(4) Gently lower the tip of the wiper arm onto the

glass.

Fig. 20 Wiper Blade

1 - SUPERSTRUCTURE

2 - ELEMENT

3 - PIVOT BLOCK

4 - RELEASE TAB

5 - PIVOT PIN

6 - CLAWS

7 - FLEXOR

Fig. 21 Wiper Blade Remove/Install

1 - SUPERSTRUCTURE

2 - WIPER ARM

3 - PIVOT BLOCK

4 - RELEASE TAB

5 - HOOK

6 - ELEMENT

DRWIPERS/WASHERS 8R - 19

WIPER BLADE (Continued)

Page 1275 of 2627

²Timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL).

²Cylinder head(s) (Refer to 9 - ENGINE/CYLIN-

DER HEAD - REMOVAL) and (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(3) If necessary, remove top ridge of cylinder bores

with a reliable ridge reamer before removing pistons

from cylinder block.Be sure to keep tops of pis-

tons covered during this operation.Pistons and

connecting rods must be removed from top of cylinder

block. When removing piston and connecting rod

assemblies from the engine, rotate crankshaft so the

each connecting rod is centered in cylinder bore.

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods or caps, as damage to

connecting rods could occur

NOTE: Connecting rods and bearing caps are not

interchangeable and should be marked before

removing to ensure correct reassembly.

(4) Mark connecting rod and bearing cap positions

using a permanent ink marker or scribe tool.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint face surfaces, as engine

damage may occur.

(5) Remove connecting rod cap. Install Special Tool

8507 Connecting Rod Guides into the connecting rod

being removed. Remove piston from cylinder bore.

Repeat this procedure for each piston being removed.

CAUTION: Care must be taken not to nick crank-

shaft journals, as engine damage may occur

(6) Immediately after piston and connecting rod

removal, install bearing cap on the mating connect-

ing rod to prevent damage to the fractured cap and

rod surfaces.

CLEANING

CAUTION: DO NOT use a wire wheel or other abra-

sive cleaning devise to clean the pistons or con-

necting rods. The pistons have a Moly coating, this

coating must not be damaged.

(1) Using a suitable cleaning solvent clean the pis-

tons in warm water and towel dry.

(2) Use a wood or plastic scraper to clean the ring

land grooves.

CAUTION: DO NOT remove the piston pin from the

piston and connecting rod assembly.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Before installing piston and connecting rod

assemblies into the bore, install the piston rings.

(2) Immerse the piston head and rings in clean

engine oil. Position a ring compressor over the piston

and rings. Tighten ring compressor.Ensure posi-

tion of rings do not change during this opera-

tion.

(3) Position bearing onto connecting rod. Ensure

that hole in bearing shell aligns with hole in connect-

ing rod. Lubricate bearing surface with clean engine

oil.

(4) Install Special Tool 8507 Connecting Rod

Guides into connecting rod bolt threads (Fig. 53).

(5) The pistons are marked on the piston pin bore

surface with an raised ªFº indicating installation

position. This mark must be pointing toward the

front of engine on both cylinder banks. The connect-

ing rod oil slinger slot faces the front of the engine

(Fig. 54).

(6) Wipe cylinder bore clean and lubricate with

engine oil.

(7) Rotate crankshaft until connecting rod journal

is on the center of cylinder bore. Insert rod and pis-

ton into cylinder bore and carefully position connect-

ing rod guides over crankshaft journal.

(8) Tap piston down in cylinder bore using a ham-

mer handle. While at the same time, guide connect-

ing rod into position on rod journal.

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

(9) Lubricate rod bolts and bearing surfaces with

engine oil. Install connecting rod cap and bearing.

Tighten bolts to 27 N´m (20 ft. lbs.) plus 90É.

(10) Install the following components:

²Cylinder head(s). (Refer to 9 - ENGINE/CYLIN-

DER HEAD - INSTALLATION).

9 - 52 ENGINE - 3.7LDR

PISTON & CONNECTING ROD (Continued)

Page 1295 of 2627

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about five

minutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING at beginning of this

section.

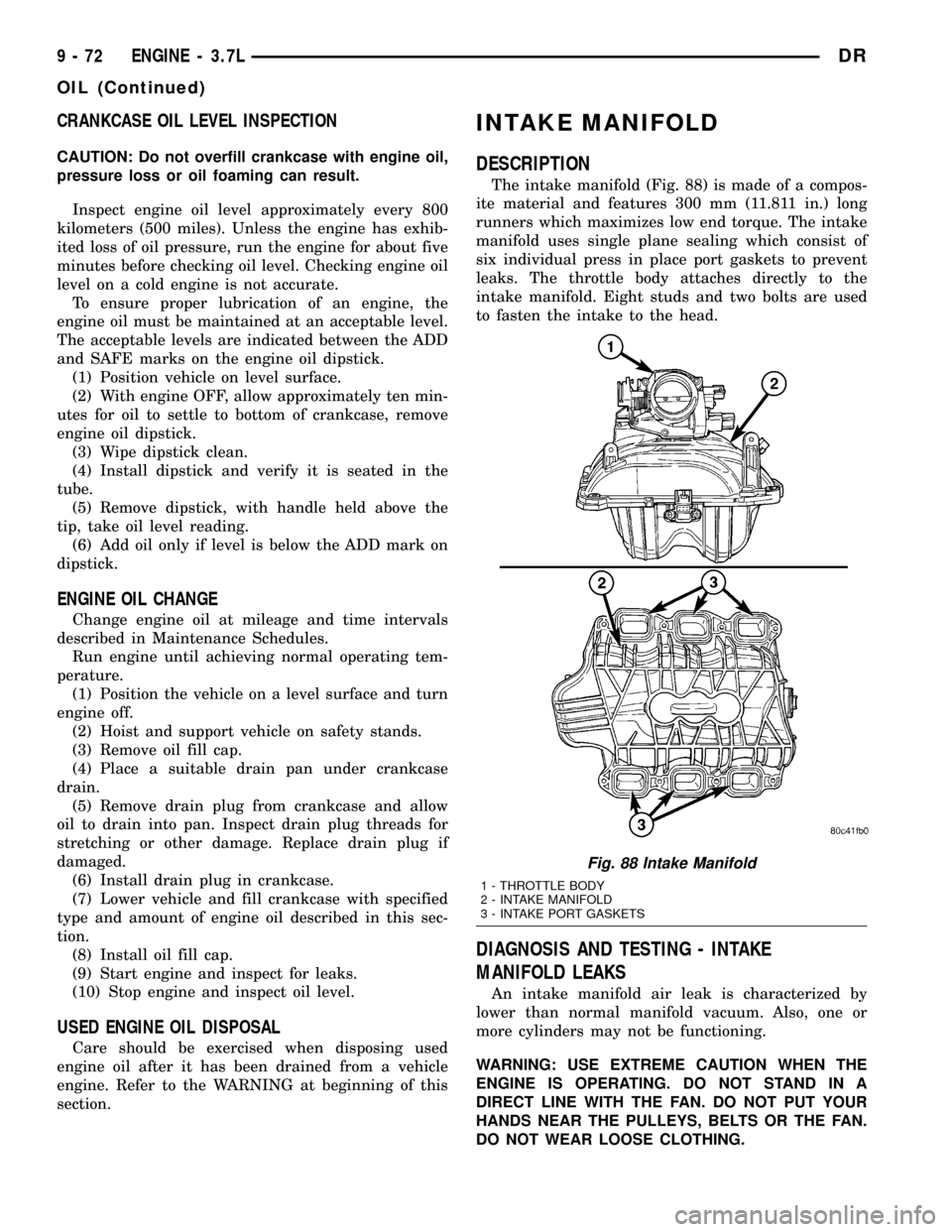

INTAKE MANIFOLD

DESCRIPTION

The intake manifold (Fig. 88) is made of a compos-

ite material and features 300 mm (11.811 in.) long

runners which maximizes low end torque. The intake

manifold uses single plane sealing which consist of

six individual press in place port gaskets to prevent

leaks. The throttle body attaches directly to the

intake manifold. Eight studs and two bolts are used

to fasten the intake to the head.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

Fig. 88 Intake Manifold

1 - THROTTLE BODY

2 - INTAKE MANIFOLD

3 - INTAKE PORT GASKETS

9 - 72 ENGINE - 3.7LDR

OIL (Continued)

Page 1377 of 2627

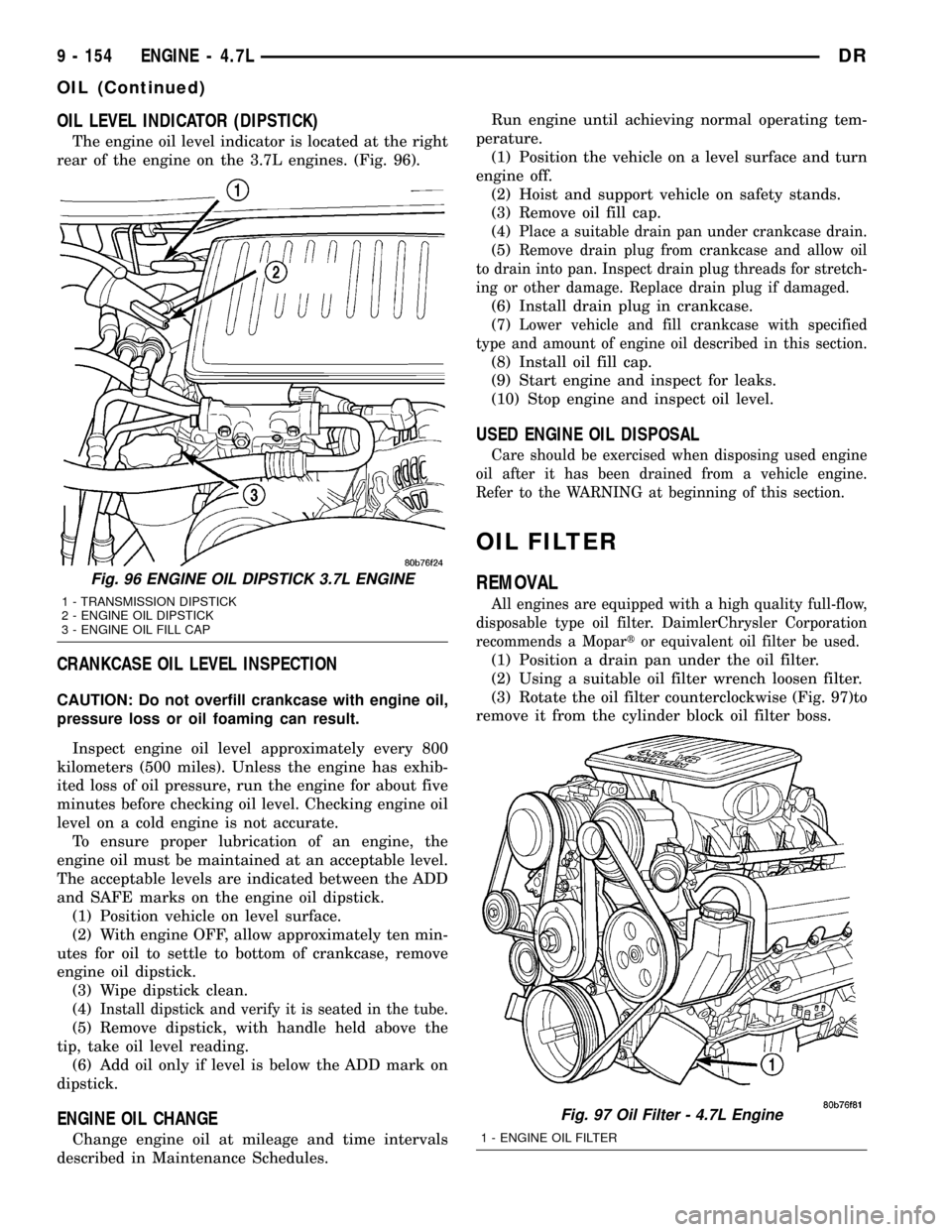

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

rear of the engine on the 3.7L engines. (Fig. 96).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about five

minutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4)

Install dipstick and verify it is seated in the tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

(3) Remove oil fill cap.

(4)

Place a suitable drain pan under crankcase drain.

(5)Remove drain plug from crankcase and allow oil

to drain into pan. Inspect drain plug threads for stretch-

ing or other damage. Replace drain plug if damaged.

(6) Install drain plug in crankcase.

(7)

Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this section.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used engine

oil after it has been drained from a vehicle engine.

Refer to the WARNING at beginning of this section.

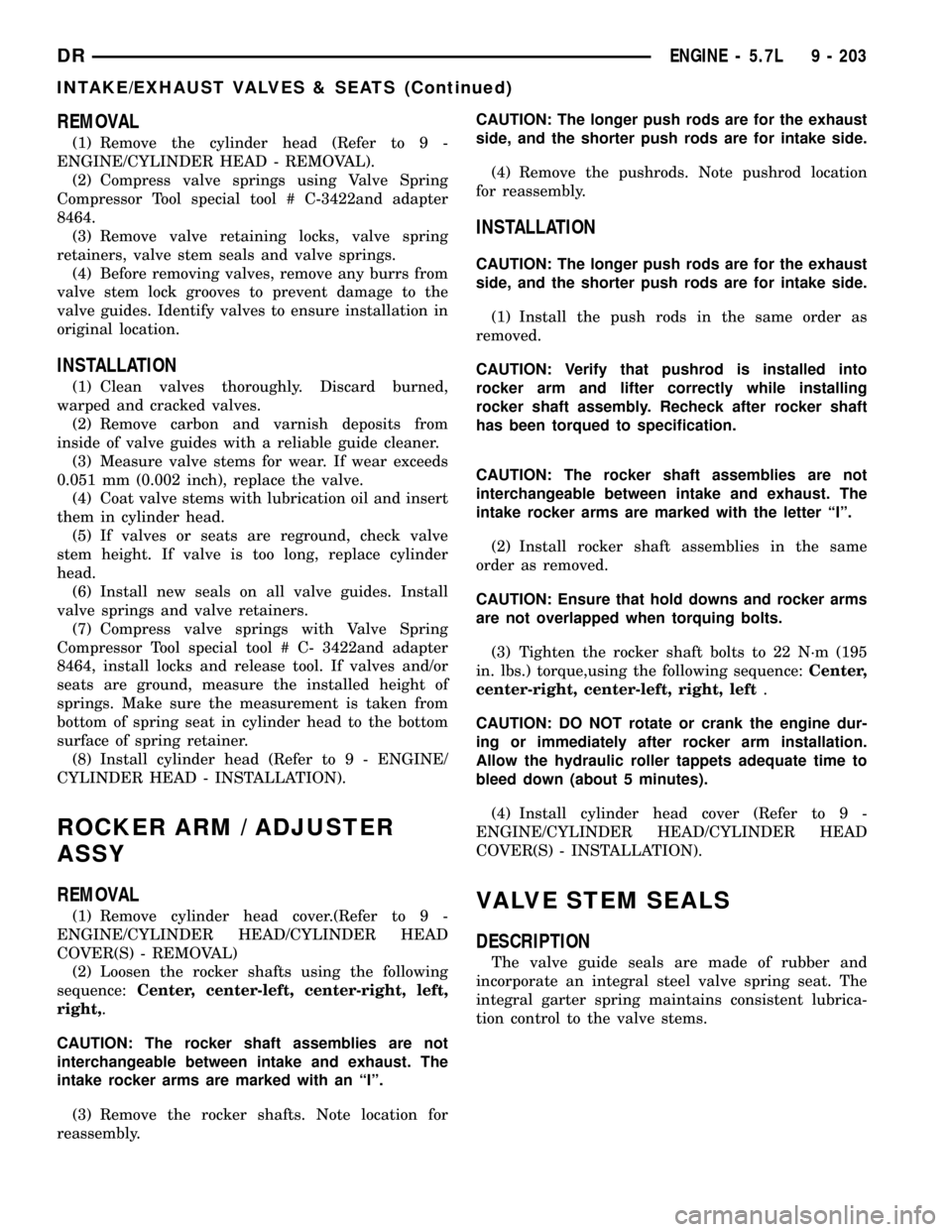

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-flow,

disposable type oil filter. DaimlerChrysler Corporation

recommends a Mopartor equivalent oil filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise (Fig. 97)to

remove it from the cylinder block oil filter boss.

Fig. 96 ENGINE OIL DIPSTICK 3.7L ENGINE

1 - TRANSMISSION DIPSTICK

2 - ENGINE OIL DIPSTICK

3 - ENGINE OIL FILL CAP

Fig. 97 Oil Filter - 4.7L Engine

1 - ENGINE OIL FILTER

9 - 154 ENGINE - 4.7LDR

OIL (Continued)

Page 1426 of 2627

REMOVAL

(1) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(2) Compress valve springs using Valve Spring

Compressor Tool special tool # C-3422and adapter

8464.

(3) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(4) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

valve guides. Identify valves to ensure installation in

original location.

INSTALLATION

(1) Clean valves thoroughly. Discard burned,

warped and cracked valves.

(2) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(3) Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 inch), replace the valve.

(4) Coat valve stems with lubrication oil and insert

them in cylinder head.

(5) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(6) Install new seals on all valve guides. Install

valve springs and valve retainers.

(7) Compress valve springs with Valve Spring

Compressor Tool special tool # C- 3422and adapter

8464, install locks and release tool. If valves and/or

seats are ground, measure the installed height of

springs. Make sure the measurement is taken from

bottom of spring seat in cylinder head to the bottom

surface of spring retainer.

(8) Install cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

ROCKER ARM / ADJUSTER

ASSY

REMOVAL

(1) Remove cylinder head cover.(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(2) Loosen the rocker shafts using the following

sequence:Center, center-left, center-right, left,

right,.

CAUTION: The rocker shaft assemblies are not

interchangeable between intake and exhaust. The

intake rocker arms are marked with an ªIº.

(3) Remove the rocker shafts. Note location for

reassembly.CAUTION: The longer push rods are for the exhaust

side, and the shorter push rods are for intake side.

(4) Remove the pushrods. Note pushrod location

for reassembly.

INSTALLATION

CAUTION: The longer push rods are for the exhaust

side, and the shorter push rods are for intake side.

(1) Install the push rods in the same order as

removed.

CAUTION: Verify that pushrod is installed into

rocker arm and lifter correctly while installing

rocker shaft assembly. Recheck after rocker shaft

has been torqued to specification.

CAUTION: The rocker shaft assemblies are not

interchangeable between intake and exhaust. The

intake rocker arms are marked with the letter ªIº.

(2) Install rocker shaft assemblies in the same

order as removed.

CAUTION: Ensure that hold downs and rocker arms

are not overlapped when torquing bolts.

(3) Tighten the rocker shaft bolts to 22 N´m (195

in. lbs.) torque,using the following sequence:Center,

center-right, center-left, right, left.

CAUTION: DO NOT rotate or crank the engine dur-

ing or immediately after rocker arm installation.

Allow the hydraulic roller tappets adequate time to

bleed down (about 5 minutes).

(4) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

VALVE STEM SEALS

DESCRIPTION

The valve guide seals are made of rubber and

incorporate an integral steel valve spring seat. The

integral garter spring maintains consistent lubrica-

tion control to the valve stems.

DRENGINE - 5.7L 9 - 203

INTAKE/EXHAUST VALVES & SEATS (Continued)