change time DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1642 of 2627

When the leading edge of the tonewheel notch

passes the tip of the CKP, the following occurs: The

interruption of magnetic field causes the voltage to

switch high resulting in a signal of approximately 5

volts.

When the trailing edge of the tonewheel notch

passes the tip of the CKP, the following occurs: The

change of the magnetic field causes the signal voltage

to switch low to 0 volts.

The Camshaft Position Sensor (CMP) also provides

a signal to the Engine Control Module (ECM) at all

times when the engine is running. The ECM uses

this CMP information primarily on engine start-up.

Once the engine is running, the ECM uses the CMP

as a backup sensor for engine speed.

REMOVAL

(1) Raise and support vehicle

(2) Disconnect electrical connector at CKP sensor

(Fig. 12).

(3) Remove 1 sensor mounting bolt.

(4) Remove CKP sensor.

INSTALLATION

(1) Position and install CKP sensor to engine.

(2) Install 1 sensor mounting bolt and tighten to 9

N´m (80 in. lbs.) torque.(3) Install electrical connector to CKP sensor (Fig.

12).

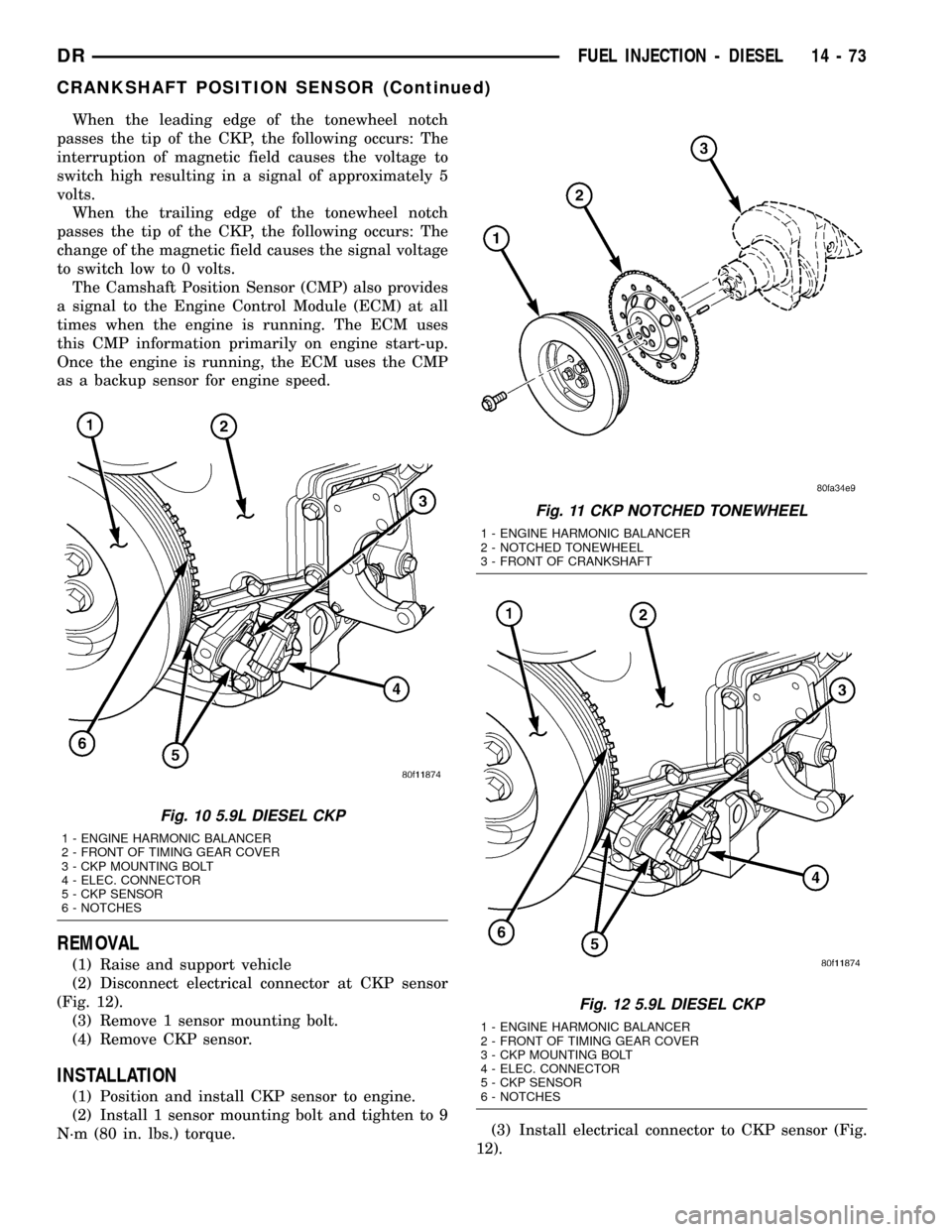

Fig. 10 5.9L DIESEL CKP

1 - ENGINE HARMONIC BALANCER

2 - FRONT OF TIMING GEAR COVER

3 - CKP MOUNTING BOLT

4 - ELEC. CONNECTOR

5 - CKP SENSOR

6 - NOTCHES

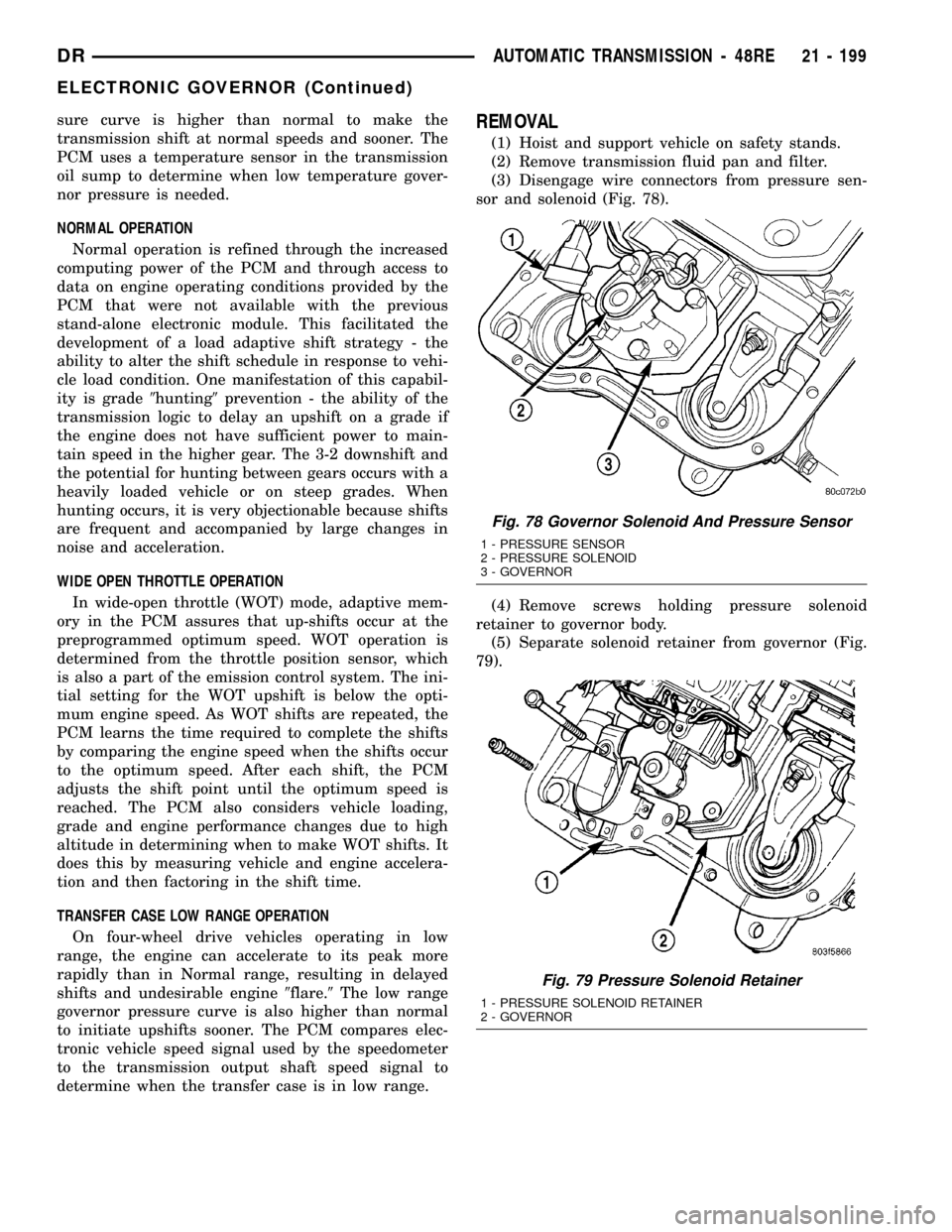

Fig. 11 CKP NOTCHED TONEWHEEL

1 - ENGINE HARMONIC BALANCER

2 - NOTCHED TONEWHEEL

3 - FRONT OF CRANKSHAFT

Fig. 12 5.9L DIESEL CKP

1 - ENGINE HARMONIC BALANCER

2 - FRONT OF TIMING GEAR COVER

3 - CKP MOUNTING BOLT

4 - ELEC. CONNECTOR

5 - CKP SENSOR

6 - NOTCHES

DRFUEL INJECTION - DIESEL 14 - 73

CRANKSHAFT POSITION SENSOR (Continued)

Page 1902 of 2627

sure curve is higher than normal to make the

transmission shift at normal speeds and sooner. The

PCM uses a temperature sensor in the transmission

oil sump to determine when low temperature gover-

nor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased

computing power of the PCM and through access to

data on engine operating conditions provided by the

PCM that were not available with the previous

stand-alone electronic module. This facilitated the

development of a load adaptive shift strategy - the

ability to alter the shift schedule in response to vehi-

cle load condition. One manifestation of this capabil-

ity is grade9hunting9prevention - the ability of the

transmission logic to delay an upshift on a grade if

the engine does not have sufficient power to main-

tain speed in the higher gear. The 3-2 downshift and

the potential for hunting between gears occurs with a

heavily loaded vehicle or on steep grades. When

hunting occurs, it is very objectionable because shifts

are frequent and accompanied by large changes in

noise and acceleration.

WIDE OPEN THROTTLE OPERATION

In wide-open throttle (WOT) mode, adaptive mem-

ory in the PCM assures that up-shifts occur at the

preprogrammed optimum speed. WOT operation is

determined from the throttle position sensor, which

is also a part of the emission control system. The ini-

tial setting for the WOT upshift is below the opti-

mum engine speed. As WOT shifts are repeated, the

PCM learns the time required to complete the shifts

by comparing the engine speed when the shifts occur

to the optimum speed. After each shift, the PCM

adjusts the shift point until the optimum speed is

reached. The PCM also considers vehicle loading,

grade and engine performance changes due to high

altitude in determining when to make WOT shifts. It

does this by measuring vehicle and engine accelera-

tion and then factoring in the shift time.

TRANSFER CASE LOW RANGE OPERATION

On four-wheel drive vehicles operating in low

range, the engine can accelerate to its peak more

rapidly than in Normal range, resulting in delayed

shifts and undesirable engine9flare.9The low range

governor pressure curve is also higher than normal

to initiate upshifts sooner. The PCM compares elec-

tronic vehicle speed signal used by the speedometer

to the transmission output shaft speed signal to

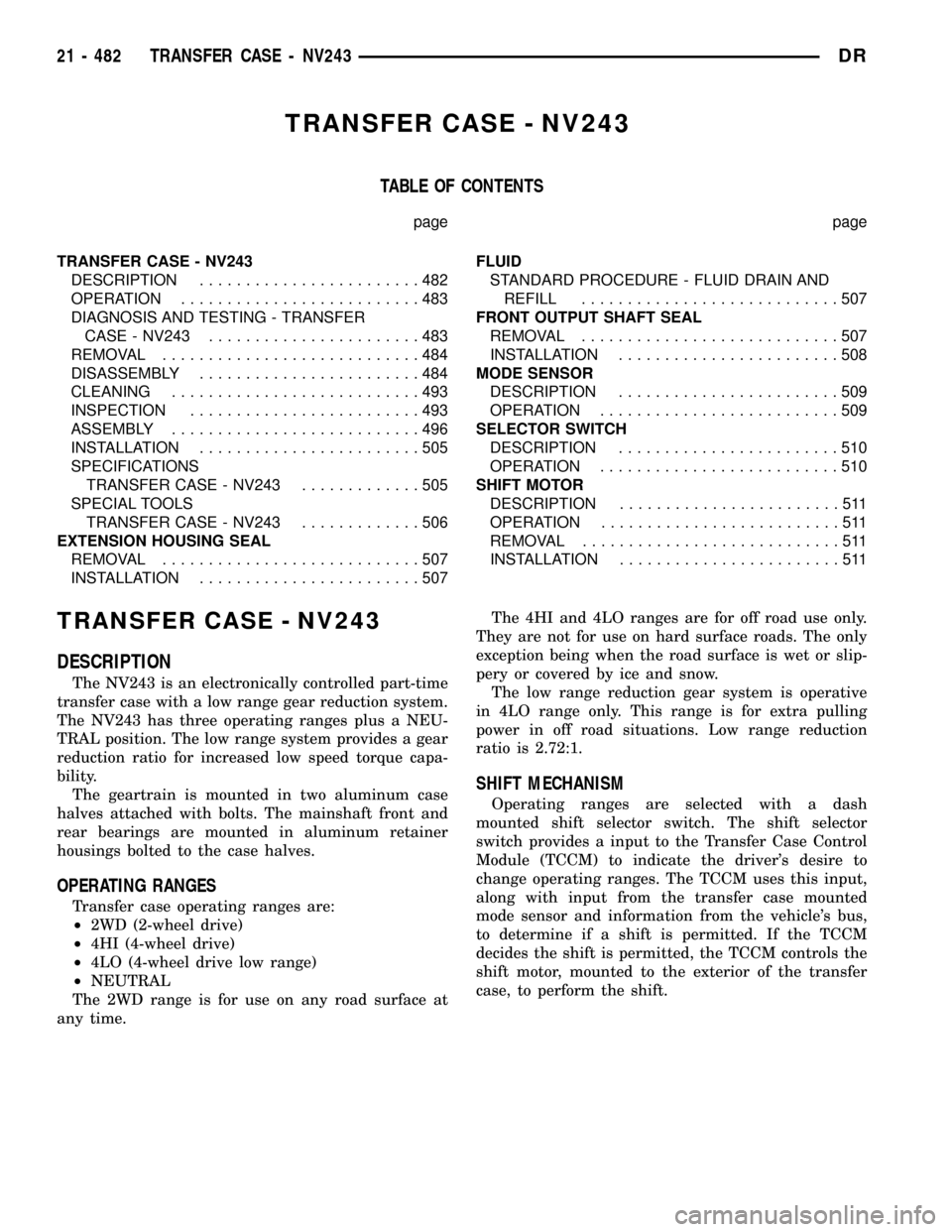

determine when the transfer case is in low range.REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove transmission fluid pan and filter.

(3) Disengage wire connectors from pressure sen-

sor and solenoid (Fig. 78).

(4) Remove screws holding pressure solenoid

retainer to governor body.

(5) Separate solenoid retainer from governor (Fig.

79).

Fig. 78 Governor Solenoid And Pressure Sensor

1 - PRESSURE SENSOR

2 - PRESSURE SOLENOID

3 - GOVERNOR

Fig. 79 Pressure Solenoid Retainer

1 - PRESSURE SOLENOID RETAINER

2 - GOVERNOR

DRAUTOMATIC TRANSMISSION - 48RE 21 - 199

ELECTRONIC GOVERNOR (Continued)

Page 2185 of 2627

TRANSFER CASE - NV243

TABLE OF CONTENTS

page page

TRANSFER CASE - NV243

DESCRIPTION........................482

OPERATION..........................483

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV243.......................483

REMOVAL............................484

DISASSEMBLY........................484

CLEANING...........................493

INSPECTION.........................493

ASSEMBLY...........................496

INSTALLATION........................505

SPECIFICATIONS

TRANSFER CASE - NV243.............505

SPECIAL TOOLS

TRANSFER CASE - NV243.............506

EXTENSION HOUSING SEAL

REMOVAL............................507

INSTALLATION........................507FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................507

FRONT OUTPUT SHAFT SEAL

REMOVAL............................507

INSTALLATION........................508

MODE SENSOR

DESCRIPTION........................509

OPERATION..........................509

SELECTOR SWITCH

DESCRIPTION........................510

OPERATION..........................510

SHIFT MOTOR

DESCRIPTION........................511

OPERATION..........................511

REMOVAL............................511

INSTALLATION........................511

TRANSFER CASE - NV243

DESCRIPTION

The NV243 is an electronically controlled part-time

transfer case with a low range gear reduction system.

The NV243 has three operating ranges plus a NEU-

TRAL position. The low range system provides a gear

reduction ratio for increased low speed torque capa-

bility.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum retainer

housings bolted to the case halves.

OPERATING RANGES

Transfer case operating ranges are:

²2WD (2-wheel drive)

²4HI (4-wheel drive)

²4LO (4-wheel drive low range)

²NEUTRAL

The 2WD range is for use on any road surface at

any time.The 4HI and 4LO ranges are for off road use only.

They are not for use on hard surface roads. The only

exception being when the road surface is wet or slip-

pery or covered by ice and snow.

The low range reduction gear system is operative

in 4LO range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1.

SHIFT MECHANISM

Operating ranges are selected with a dash

mounted shift selector switch. The shift selector

switch provides a input to the Transfer Case Control

Module (TCCM) to indicate the driver's desire to

change operating ranges. The TCCM uses this input,

along with input from the transfer case mounted

mode sensor and information from the vehicle's bus,

to determine if a shift is permitted. If the TCCM

decides the shift is permitted, the TCCM controls the

shift motor, mounted to the exterior of the transfer

case, to perform the shift.

21 - 482 TRANSFER CASE - NV243DR

Page 2215 of 2627

TRANSFER CASE - NV244 GENII

TABLE OF CONTENTS

page page

TRANSFER CASE - NV244 GENII

DESCRIPTION........................512

OPERATION..........................513

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV244.......................513

REMOVAL............................514

DISASSEMBLY........................514

CLEANING...........................523

INSPECTION.........................523

ASSEMBLY...........................525

INSTALLATION........................534

SPECIFICATIONS

TRANSFER CASE - NV244 GENII........535

SPECIAL TOOLS

TRANSFER CASE - NV244 GENII........535

EXTENSION HOUSING SEAL

REMOVAL............................536

INSTALLATION........................536FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................537

FRONT OUTPUT SHAFT SEAL

REMOVAL............................537

INSTALLATION........................538

MODE SENSOR

DESCRIPTION........................538

OPERATION..........................539

SELECTOR SWITCH

DESCRIPTION........................539

OPERATION..........................540

SHIFT MOTOR

DESCRIPTION........................541

OPERATION..........................541

REMOVAL............................541

INSTALLATION........................541

TRANSFER CASE - NV244

GENII

DESCRIPTION

The NV244 GENII is an electronically controlled

full and part-time transfer case with no two wheel

drive operation.

A differential in the transfer case is used to control

torque transfer to the front and rear axles. A low

range gear reduction system provides increased low

speed torque capability for off road operation. The

low range provides a 2.72:1 reduction ratio.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum retainer

housings bolted to the case halves.

OPERATING RANGES

NV244 GENII operating ranges are:

²AWD(All-Wheel Drive)

²4HI (Part-time)

²4LO

²NEUTRAL

The AWD mode can be used at any time and on

any road surface.The 4HI (Part-time) and 4LO ranges are for off

road use only. The only time these ranges can be

used is when the road surface is covered with snow,

ice, or other loose slippery material.

SHIFT MECHANISM

Operating ranges are selected with a dash

mounted shift selector switch. The shift selector

switch provides a input to the Transfer Case Control

Module (TCCM) to indicate the driver's desire to

change operating ranges. The TCCM uses this input,

along with the input from the transfer case mounted

mode sensor and information from the vehicle's bus,

to determine if a shift is permitted. If the TCCM

decides the shift is permitted, the TCCM controls the

shift motor, mounted to the exterior of the transfer

case, to perform the shift.

21 - 512 TRANSFER CASE - NV244 GENIIDR

Page 2245 of 2627

TRANSFER CASE - NV273

TABLE OF CONTENTS

page page

TRANSFER CASE - NV273

DESCRIPTION........................542

OPERATION..........................543

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV273.......................543

REMOVAL............................544

DISASSEMBLY........................544

CLEANING...........................554

INSPECTION.........................554

ASSEMBLY...........................556

INSTALLATION........................568

SPECIFICATIONS

TRANSFER CASE - NV273.............568

SPECIAL TOOLS

TRANSFER CASE NV271/NV273.........569

EXTENSION HOUSING SEAL AND DUST BOOT

REMOVAL............................571

INSTALLATION........................571FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................571

FRONT OUTPUT SHAFT SEAL

REMOVAL............................572

INSTALLATION........................572

MODE SENSOR

DESCRIPTION........................573

OPERATION..........................573

SELECTOR SWITCH

DESCRIPTION........................574

OPERATION..........................574

SHIFT MOTOR

DESCRIPTION........................575

OPERATION..........................575

REMOVAL............................575

INSTALLATION........................575

TRANSFER CASE - NV273

DESCRIPTION

The NV273 is an electronically controlled part-time

transfer case with a low range gear reduction system.

The NV273 has three operating ranges plus a NEU-

TRAL position. The low range system provides a gear

reduction ratio for increased low speed torque capa-

bility.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum case halves.

OPERATING RANGES

Transfer case operating ranges are:

²2WD (2-wheel drive)

²4HI (4-wheel drive)

²4LO (4-wheel drive low range)

²NEUTRAL

The 2WD range is for use on any road surface at

any time.The 4HI and 4LO ranges are for off road use only.

They are not for use on hard surface roads. The only

exception being when the road surface is wet or slip-

pery or covered by ice and snow.

The low range reduction gear system is operative

in 4LO range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1.

SHIFT MECHANISM

Operating ranges are selected with a dash

mounted shift selector switch. The shift selector

switch provides a input to the Transfer Case Control

Module (TCCM) to indicate the driver's desire to

change operating ranges. The TCCM uses this input,

along with input from the transfer case mounted

mode sensor and information from the vehicle's bus,

to determine if a shift is permitted. If the TCCM

decides the shift is permitted, the TCCM controls the

shift motor, mounted to the exterior of the transfer

case, to perform the shift.

21 - 542 TRANSFER CASE - NV273DR

Page 2328 of 2627

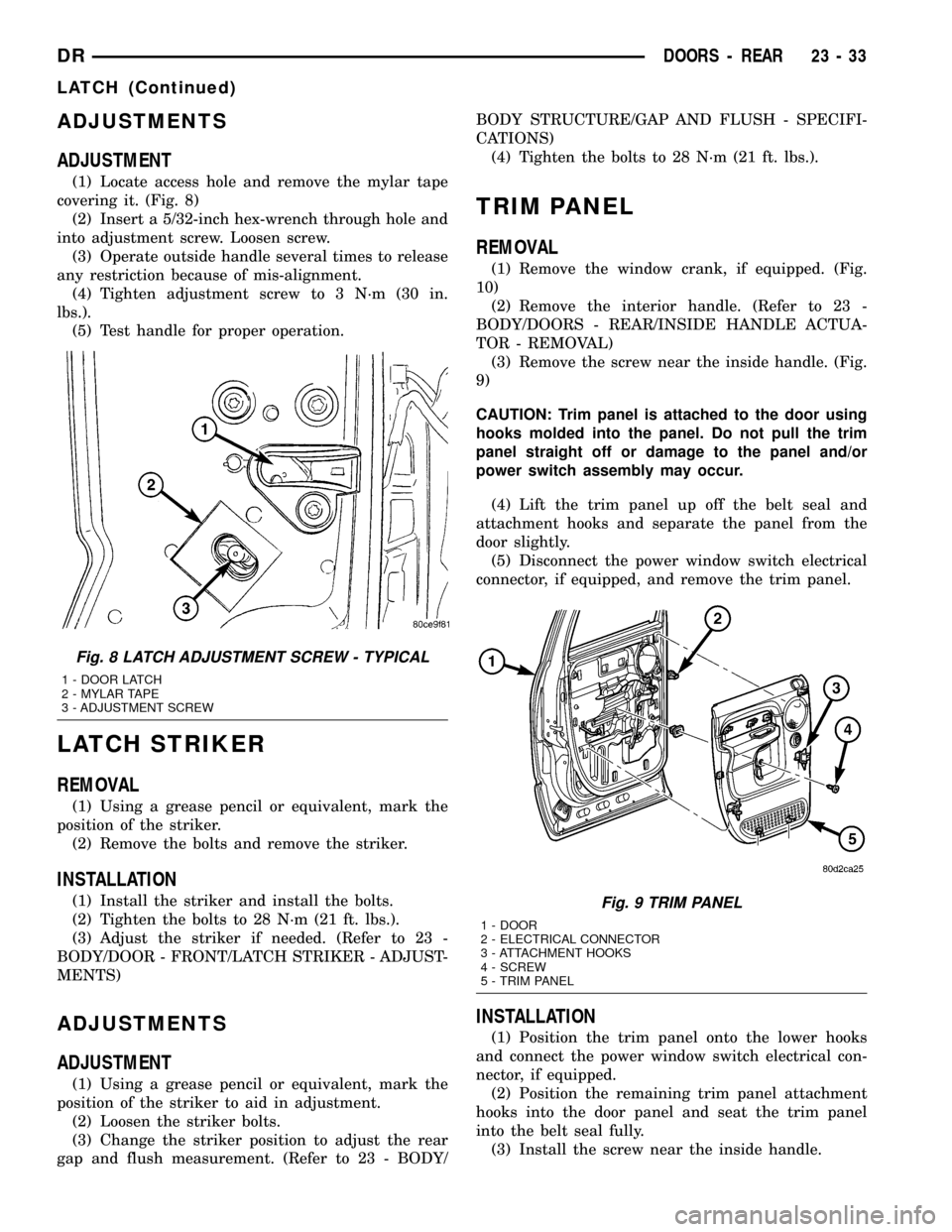

ADJUSTMENTS

ADJUSTMENT

(1) Locate access hole and remove the mylar tape

covering it. (Fig. 8)

(2) Insert a 5/32-inch hex-wrench through hole and

into adjustment screw. Loosen screw.

(3) Operate outside handle several times to release

any restriction because of mis-alignment.

(4) Tighten adjustment screw to 3 N´m (30 in.

lbs.).

(5) Test handle for proper operation.

LATCH STRIKER

REMOVAL

(1) Using a grease pencil or equivalent, mark the

position of the striker.

(2) Remove the bolts and remove the striker.

INSTALLATION

(1) Install the striker and install the bolts.

(2) Tighten the bolts to 28 N´m (21 ft. lbs.).

(3) Adjust the striker if needed. (Refer to 23 -

BODY/DOOR - FRONT/LATCH STRIKER - ADJUST-

MENTS)

ADJUSTMENTS

ADJUSTMENT

(1) Using a grease pencil or equivalent, mark the

position of the striker to aid in adjustment.

(2) Loosen the striker bolts.

(3) Change the striker position to adjust the rear

gap and flush measurement. (Refer to 23 - BODY/BODY STRUCTURE/GAP AND FLUSH - SPECIFI-

CATIONS)

(4) Tighten the bolts to 28 N´m (21 ft. lbs.).

TRIM PANEL

REMOVAL

(1) Remove the window crank, if equipped. (Fig.

10)

(2) Remove the interior handle. (Refer to 23 -

BODY/DOORS - REAR/INSIDE HANDLE ACTUA-

TOR - REMOVAL)

(3) Remove the screw near the inside handle. (Fig.

9)

CAUTION: Trim panel is attached to the door using

hooks molded into the panel. Do not pull the trim

panel straight off or damage to the panel and/or

power switch assembly may occur.

(4) Lift the trim panel up off the belt seal and

attachment hooks and separate the panel from the

door slightly.

(5) Disconnect the power window switch electrical

connector, if equipped, and remove the trim panel.

INSTALLATION

(1) Position the trim panel onto the lower hooks

and connect the power window switch electrical con-

nector, if equipped.

(2) Position the remaining trim panel attachment

hooks into the door panel and seat the trim panel

into the belt seal fully.

(3) Install the screw near the inside handle.

Fig. 8 LATCH ADJUSTMENT SCREW - TYPICAL

1 - DOOR LATCH

2 - MYLAR TAPE

3 - ADJUSTMENT SCREW

Fig. 9 TRIM PANEL

1 - DOOR

2 - ELECTRICAL CONNECTOR

3 - ATTACHMENT HOOKS

4 - SCREW

5 - TRIM PANEL

DRDOORS - REAR 23 - 33

LATCH (Continued)

Page 2550 of 2627

(12) Reconnect the battery negative cable.

(13) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(14) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

HEATER CORE

DESCRIPTION

The heater core is located in the HVAC housing,

behind the instrument panel. It is a heat exchanger

made of rows of tubes and fins.

OPERATION

Engine coolant is circulated through the heater

hoses to the heater core at all times. As the coolant

flows through the heater core, heat is removed from

the engine and is transferred to the heater core fins

and tubes. Air directed through the heater core picks

up the heat from the heater core fins. The blend door

allows control of the heater output air temperature

by regulating the amount of air flowing through the

heater core within the HVAC housing. The blower

motor speed controls the volume of air flowing

through the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced.

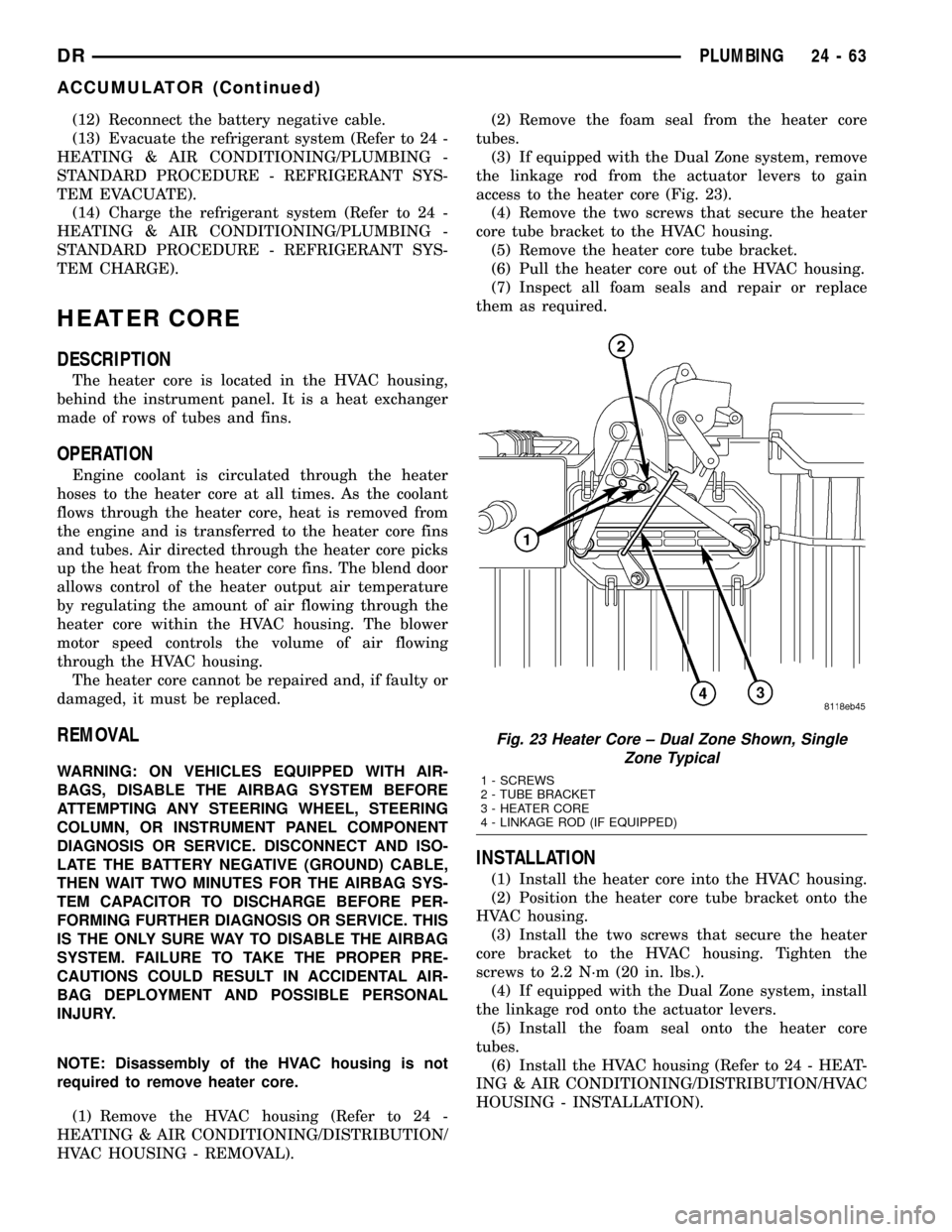

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: Disassembly of the HVAC housing is not

required to remove heater core.

(1) Remove the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL).(2) Remove the foam seal from the heater core

tubes.

(3) If equipped with the Dual Zone system, remove

the linkage rod from the actuator levers to gain

access to the heater core (Fig. 23).

(4) Remove the two screws that secure the heater

core tube bracket to the HVAC housing.

(5) Remove the heater core tube bracket.

(6) Pull the heater core out of the HVAC housing.

(7) Inspect all foam seals and repair or replace

them as required.

INSTALLATION

(1) Install the heater core into the HVAC housing.

(2) Position the heater core tube bracket onto the

HVAC housing.

(3) Install the two screws that secure the heater

core bracket to the HVAC housing. Tighten the

screws to 2.2 N´m (20 in. lbs.).

(4) If equipped with the Dual Zone system, install

the linkage rod onto the actuator levers.

(5) Install the foam seal onto the heater core

tubes.

(6) Install the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION).

Fig. 23 Heater Core ± Dual Zone Shown, Single

Zone Typical

1 - SCREWS

2 - TUBE BRACKET

3 - HEATER CORE

4 - LINKAGE ROD (IF EQUIPPED)

DRPLUMBING 24 - 63

ACCUMULATOR (Continued)

Page 2562 of 2627

EMISSIONS CONTROL

TABLE OF CONTENTS

page page

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - STATE DISPLAY TEST

MODE...............................1

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE...............................1

DESCRIPTION - DIAGNOSTIC TROUBLE

CODES..............................1

DESCRIPTION - TASK MANAGER..........1DESCRIPTION - MONITORED SYSTEMS....2

DESCRIPTION - TRIP DEFINITION.........4

DESCRIPTION - COMPONENT MONITORS . . 4

OPERATION

OPERATION..........................5

OPERATION - TASK MANAGER...........5

OPERATION - NON-MONITORED CIRCUITS . . 8

EVAPORATIVE EMISSIONS................10

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. Connect

the DRB scan tool to the data link connector and

access the state display screen. Then access either

State Display Inputs and Outputs or State Display

Sensors.

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly. Connect the DRB scan tool to the data link

connector and access the Actuators screen.

DESCRIPTION - DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Obtain the applicable Powertrain Diagnostic

Manual.

(2) Obtain the DRB Scan Tool.

(3) Connect the DRB Scan Tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(4) Turn the ignition switch on and access the

ªRead Faultº screen.

(5) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(6) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

DESCRIPTION - TASK MANAGER

The PCM is responsible for efficiently coordinating

the operation of all the emissions-related compo-

nents. The PCM is also responsible for determining if

the diagnostic systems are operating properly. The

software designed to carry out these responsibilities

is call the 'Task Manager'.

DREMISSIONS CONTROL 25 - 1

Page 2563 of 2627

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator Lamp

(MIL) will be illuminated. These monitors generate

Diagnostic Trouble Codes that can be displayed with

the MIL or a scan tool.

The following is a list of the system monitors:

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Leak Detection Pump Monitor (if equipped)

All these system monitors require two consecutive

trips with the malfunction present to set a fault.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

The following is an operation and description of

each system monitor :

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The O2S is also the main sensing element for the

Catalyst and Fuel Monitors.

The O2S can fail in any or all of the following

manners:

²slow response rate

²reduced output voltage

²dynamic shift

²shorted or open circuits

Response rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richerthan optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt. A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) shorted to volt-

age DTC, as well as a O2S heater DTC, the O2S

fault MUST be repaired first. Before checking the

O2S fault, verify that the heater circuit is operating

correctly.

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572 É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The voltage readings taken from the O2S sensor

are very temperature sensitive. The readings are not

accurate below 300ÉC. Heating of the O2S sensor is

done to allow the engine controller to shift to closed

loop control as soon as possible. The heating element

used to heat the O2S sensor must be tested to ensure

that it is heating the sensor properly.

The O2S sensor circuit is monitored for a drop in

voltage. The sensor output is used to test the heater

by isolating the effect of the heater element on the

O2S sensor output voltage from the other effects.

LEAK DETECTION PUMP MONITOR (IF EQUIPPED)

The leak detection assembly incorporates two pri-

mary functions: it must detect a leak in the evapora-

tive system and seal the evaporative system so the

leak detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

25 - 2 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2567 of 2627

For example, when the MIL is illuminated for an

Oxygen Sensor fault, the Task Manager does not run

the Catalyst Monitor until the Oxygen Sensor fault is

remedied. Since the Catalyst Monitor is based on sig-

nals from the Oxygen Sensor, running the test would

produce inaccurate results.

²Conflict

There are situations when the Task Manager does

not run a test if another monitor is in progress. In

these situations, the effects of another monitor run-

ning could result in an erroneous failure. If thiscon-

flictis present, the monitor is not run until the

conflicting condition passes. Most likely the monitor

will run later after the conflicting monitor has

passed.

For example, if the Fuel System Monitor is in

progress, the Task Manager does not run the EGR

Monitor. Since both tests monitor changes in air/fuel

ratio and adaptive fuel compensation, the monitors

will conflict with each other.

²Suspend

Occasionally the Task Manager may not allow a two

trip fault to mature. The Task Manager willsus-

pendthe maturing of a fault if a condition exists

that may induce an erroneous failure. This prevents

illuminating the MIL for the wrong fault and allows

more precis diagnosis.

For example, if the PCM is storing a one trip fault

for the Oxygen Sensor and the EGR monitor, the

Task Manager may still run the EGR Monitor but

will suspend the results until the Oxygen Sensor

Monitor either passes or fails. At that point the Task

Manager can determine if the EGR system is actu-

ally failing or if an Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

25 - 6 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)