oil DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1747 of 2627

The driver selects a particular gear by moving the

shift lever to the desired gear position. This move-

ment moves the internal transmission shift compo-

nents to begin the shift sequence. As the shift lever

moves the selected shift rail, the shift fork attached

to that rail begins to move. The fork is positioned in

a groove in the outer circumference of the synchro-

nizer sleeve. As the shift fork moves the synchronizer

sleeve, the synchronizer begins to speed-up or slow

down the selected gear (depending on whether the

driver is up-shifting or down-shifting). The synchro-

nizer does this by having the synchronizer hub

splined to the mainshaft, or the countershaft in some

cases, and moving the blocker ring into contact with

the gear's friction cone. As the blocker ring and fric-

tion cone come together, the gear speed is brought up

or down to the speed of the synchronizer. As the two

speeds match, the splines on the inside of the syn-

chronizer sleeve become aligned with the teeth on

the blocker ring and the friction cone and eventually

will slide over the teeth, locking the gear to the

mainshaft, or countershaft, through the synchronizer.

DIAGNOSIS AND TESTING

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill or an incor-

rect lubricant level check. A correct lubricant level

check can only be made when the vehicle is level.

Also allow the lubricant to settle for a minute or so

before checking. These recommendations will ensure

an accurate check and avoid an underfill or overfill

condition. Always check the lubricant level after any

addition of fluid to avoid an incorrect lubricant level

condition.

Leaks can occur at the mating surfaces of the gear

case, adaptor or extension housing, or from the front/

rear seals. A suspected leak could also be the result

of an overfill condition. Leaks at the rear of the

extension or adapter housing will be from the hous-

ing oil seals. Leaks at component mating surfaces

will probably be the result of inadequate sealer, gaps

in the sealer, incorrect bolt tightening or use of a

non-recommended sealer. A leak at the front of the

transmission will be from either the front bearing

retainer or retainer seal. Lubricant may be seen drip-

ping from the clutch housing after extended opera-

tion. If the leak is severe, it may also contaminate

the clutch disc causing the disc to slip, grab and or

chatter.

HARD SHIFTING

Hard shifting is usually caused by a low lubricant

level, improper or contaminated lubricants. The con-

sequence of using non-recommended lubricants isnoise, excessive wear, internal bind and hard shift-

ing. Substantial lubricant leaks can result in gear,

shift rail, synchro, and bearing damage. If a leak

goes undetected for an extended period, the first indi-

cations of component damage are usually hard shift-

ing and noise.

Component damage, incorrect clutch adjustment or

damaged clutch pressure plate or disc are additional

probable causes of increased shift effort. Incorrect

adjustment or a worn/damaged pressure plate or disc

can cause incorrect release. If clutch problem is

advanced, gear clash during shifts can result. Worn

or damaged synchro rings can cause gear clash when

shifting into any forward gear. In some new or

rebuilt transmissions, new synchro rings may tend to

stick slightly causing hard or noisy shifts. In most

cases this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur-

ing normal operation. Rotating gears generate a mild

whine that is audible, but generally only at extreme

speeds. Severe highly audible transmission noise is

generally the initial indicator of a lubricant problem.

Insufficient, improper or contaminated lubricant

will promote rapid wear of gears, synchros, shift

rails, forks and bearings. The overheating caused by

a lubricant problem, can also lead to gear breakage.

REMOVAL

(1) Shift transmission into Neutral.

(2) Remove shift boot screws from floorpan and

slide boot upward on the shift lever.

(3) Remove shift lever extension from shift tower

and lever assembly.

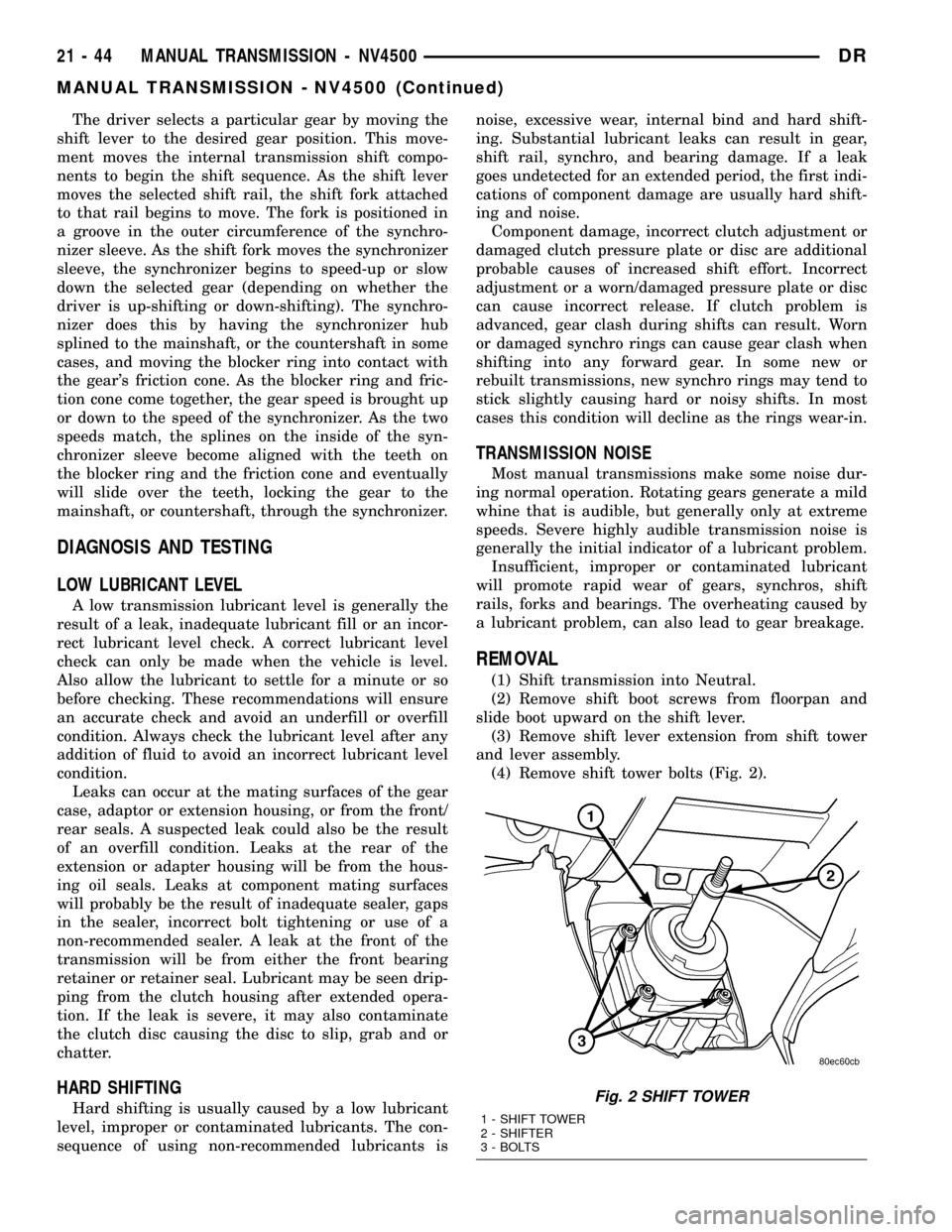

(4) Remove shift tower bolts (Fig. 2).

Fig. 2 SHIFT TOWER

1 - SHIFT TOWER

2 - SHIFTER

3 - BOLTS

21 - 44 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1778 of 2627

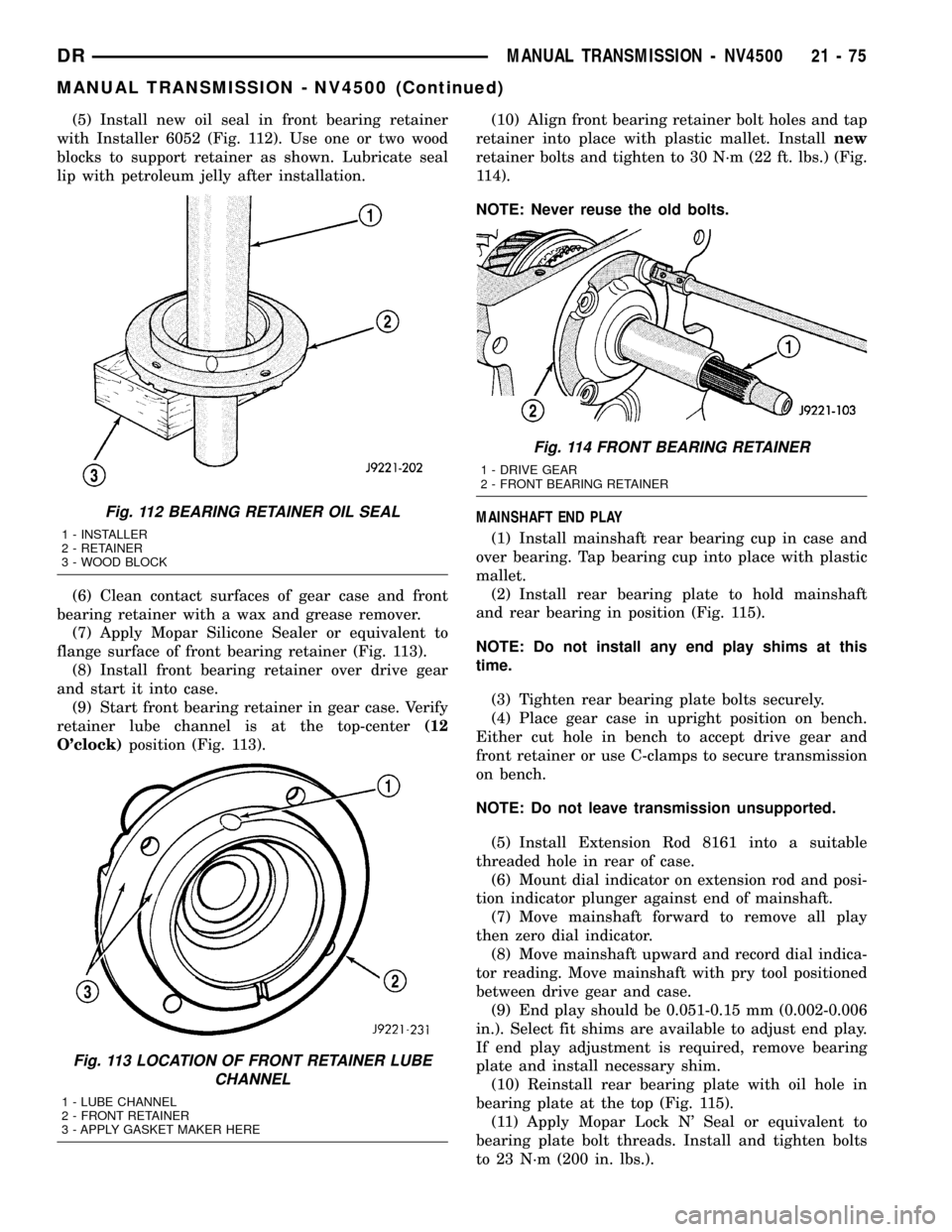

(5) Install new oil seal in front bearing retainer

with Installer 6052 (Fig. 112). Use one or two wood

blocks to support retainer as shown. Lubricate seal

lip with petroleum jelly after installation.

(6) Clean contact surfaces of gear case and front

bearing retainer with a wax and grease remover.

(7) Apply Mopar Silicone Sealer or equivalent to

flange surface of front bearing retainer (Fig. 113).

(8) Install front bearing retainer over drive gear

and start it into case.

(9) Start front bearing retainer in gear case. Verify

retainer lube channel is at the top-center(12

O'clock)position (Fig. 113).(10) Align front bearing retainer bolt holes and tap

retainer into place with plastic mallet. Installnew

retainer bolts and tighten to 30 N´m (22 ft. lbs.) (Fig.

114).

NOTE: Never reuse the old bolts.

MAINSHAFT END PLAY

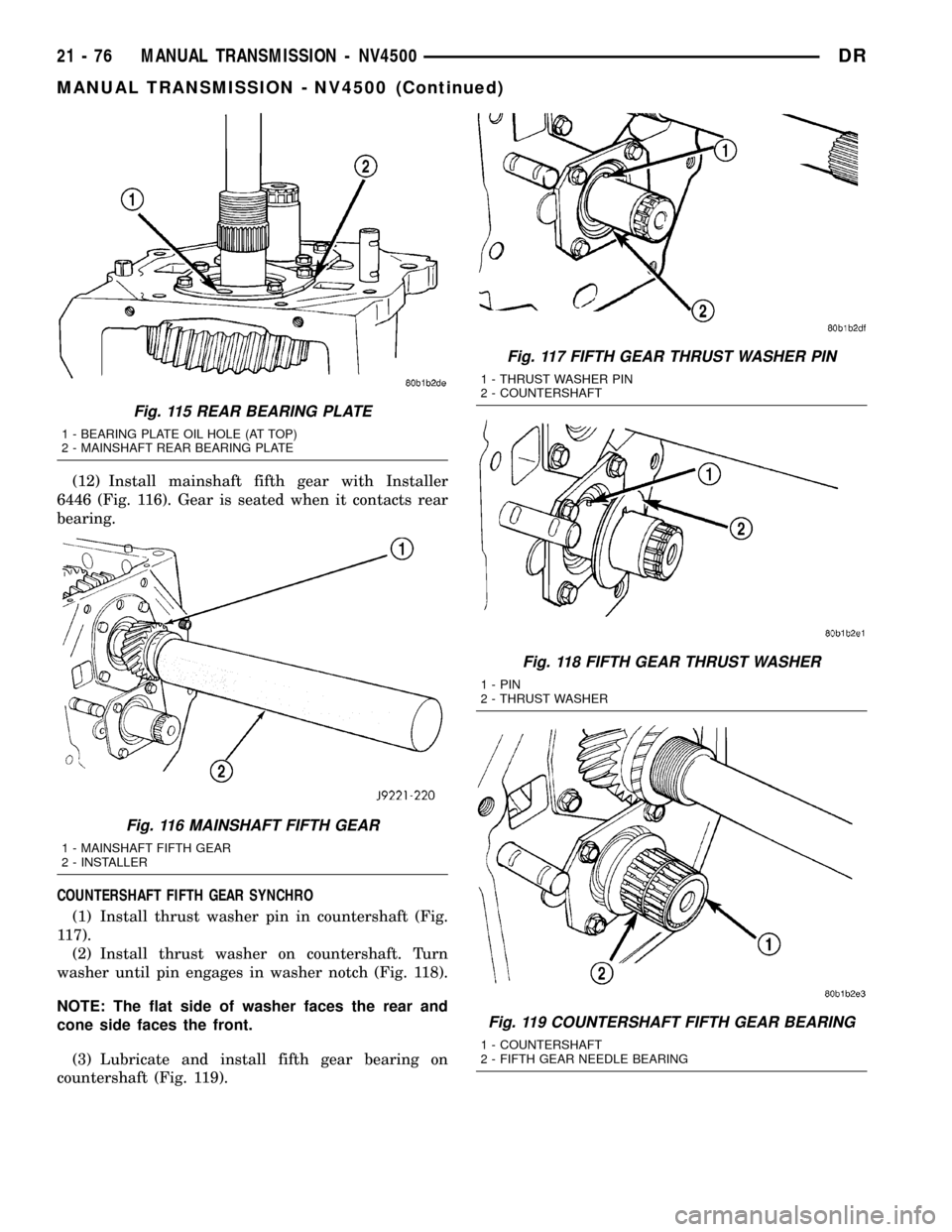

(1) Install mainshaft rear bearing cup in case and

over bearing. Tap bearing cup into place with plastic

mallet.

(2) Install rear bearing plate to hold mainshaft

and rear bearing in position (Fig. 115).

NOTE: Do not install any end play shims at this

time.

(3) Tighten rear bearing plate bolts securely.

(4) Place gear case in upright position on bench.

Either cut hole in bench to accept drive gear and

front retainer or use C-clamps to secure transmission

on bench.

NOTE: Do not leave transmission unsupported.

(5) Install Extension Rod 8161 into a suitable

threaded hole in rear of case.

(6) Mount dial indicator on extension rod and posi-

tion indicator plunger against end of mainshaft.

(7) Move mainshaft forward to remove all play

then zero dial indicator.

(8) Move mainshaft upward and record dial indica-

tor reading. Move mainshaft with pry tool positioned

between drive gear and case.

(9) End play should be 0.051-0.15 mm (0.002-0.006

in.). Select fit shims are available to adjust end play.

If end play adjustment is required, remove bearing

plate and install necessary shim.

(10) Reinstall rear bearing plate with oil hole in

bearing plate at the top (Fig. 115).

(11) Apply Mopar Lock N' Seal or equivalent to

bearing plate bolt threads. Install and tighten bolts

to 23 N´m (200 in. lbs.).

Fig. 112 BEARING RETAINER OIL SEAL

1 - INSTALLER

2 - RETAINER

3 - WOOD BLOCK

Fig. 113 LOCATION OF FRONT RETAINER LUBE

CHANNEL

1 - LUBE CHANNEL

2 - FRONT RETAINER

3 - APPLY GASKET MAKER HERE

Fig. 114 FRONT BEARING RETAINER

1 - DRIVE GEAR

2 - FRONT BEARING RETAINER

DRMANUAL TRANSMISSION - NV4500 21 - 75

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1779 of 2627

(12) Install mainshaft fifth gear with Installer

6446 (Fig. 116). Gear is seated when it contacts rear

bearing.

COUNTERSHAFT FIFTH GEAR SYNCHRO

(1) Install thrust washer pin in countershaft (Fig.

117).

(2) Install thrust washer on countershaft. Turn

washer until pin engages in washer notch (Fig. 118).

NOTE: The flat side of washer faces the rear and

cone side faces the front.

(3) Lubricate and install fifth gear bearing on

countershaft (Fig. 119).

Fig. 115 REAR BEARING PLATE

1 - BEARING PLATE OIL HOLE (AT TOP)

2 - MAINSHAFT REAR BEARING PLATE

Fig. 116 MAINSHAFT FIFTH GEAR

1 - MAINSHAFT FIFTH GEAR

2 - INSTALLER

Fig. 117 FIFTH GEAR THRUST WASHER PIN

1 - THRUST WASHER PIN

2 - COUNTERSHAFT

Fig. 118 FIFTH GEAR THRUST WASHER

1 - PIN

2 - THRUST WASHER

Fig. 119 COUNTERSHAFT FIFTH GEAR BEARING

1 - COUNTERSHAFT

2 - FIFTH GEAR NEEDLE BEARING

21 - 76 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1793 of 2627

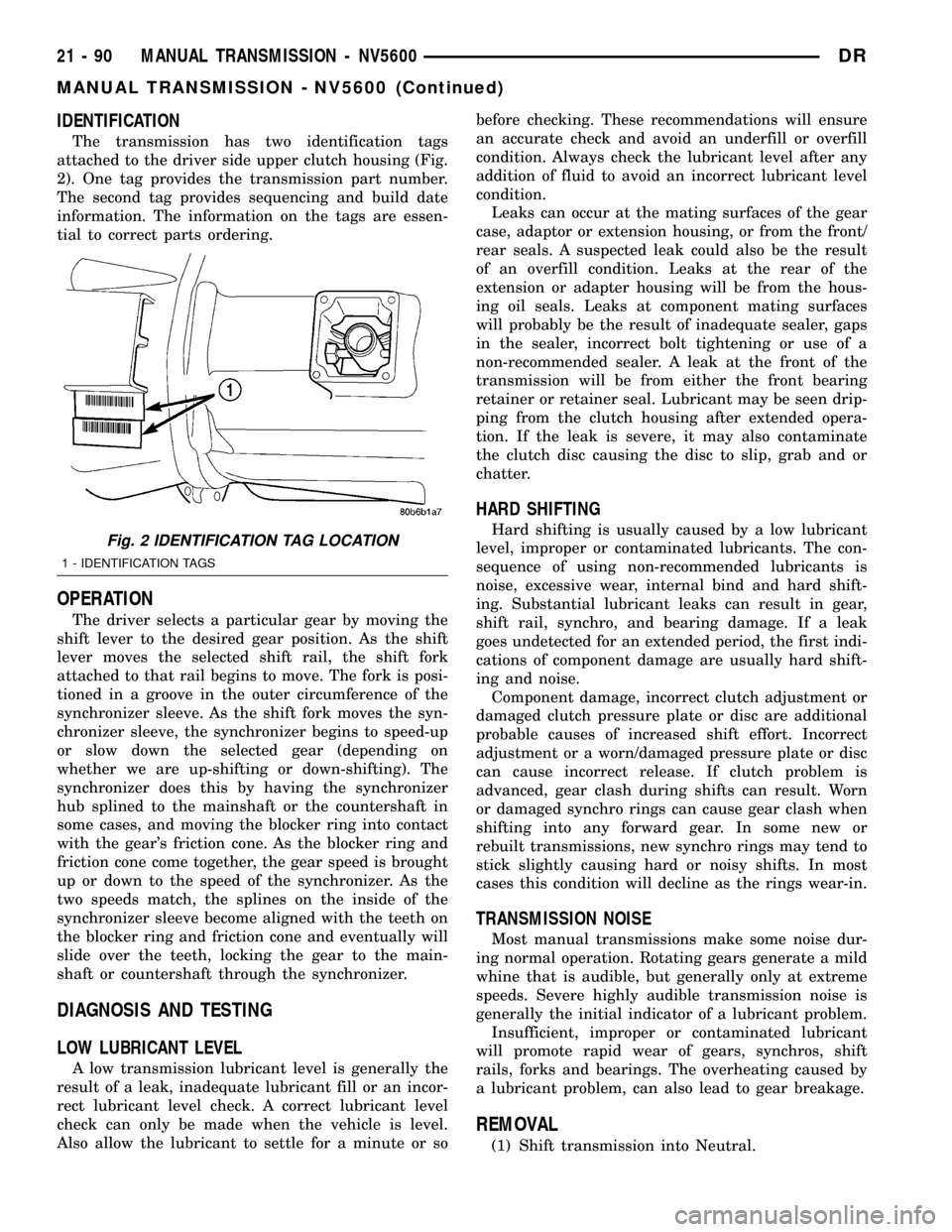

IDENTIFICATION

The transmission has two identification tags

attached to the driver side upper clutch housing (Fig.

2). One tag provides the transmission part number.

The second tag provides sequencing and build date

information. The information on the tags are essen-

tial to correct parts ordering.

OPERATION

The driver selects a particular gear by moving the

shift lever to the desired gear position. As the shift

lever moves the selected shift rail, the shift fork

attached to that rail begins to move. The fork is posi-

tioned in a groove in the outer circumference of the

synchronizer sleeve. As the shift fork moves the syn-

chronizer sleeve, the synchronizer begins to speed-up

or slow down the selected gear (depending on

whether we are up-shifting or down-shifting). The

synchronizer does this by having the synchronizer

hub splined to the mainshaft or the countershaft in

some cases, and moving the blocker ring into contact

with the gear's friction cone. As the blocker ring and

friction cone come together, the gear speed is brought

up or down to the speed of the synchronizer. As the

two speeds match, the splines on the inside of the

synchronizer sleeve become aligned with the teeth on

the blocker ring and friction cone and eventually will

slide over the teeth, locking the gear to the main-

shaft or countershaft through the synchronizer.

DIAGNOSIS AND TESTING

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill or an incor-

rect lubricant level check. A correct lubricant level

check can only be made when the vehicle is level.

Also allow the lubricant to settle for a minute or sobefore checking. These recommendations will ensure

an accurate check and avoid an underfill or overfill

condition. Always check the lubricant level after any

addition of fluid to avoid an incorrect lubricant level

condition.

Leaks can occur at the mating surfaces of the gear

case, adaptor or extension housing, or from the front/

rear seals. A suspected leak could also be the result

of an overfill condition. Leaks at the rear of the

extension or adapter housing will be from the hous-

ing oil seals. Leaks at component mating surfaces

will probably be the result of inadequate sealer, gaps

in the sealer, incorrect bolt tightening or use of a

non-recommended sealer. A leak at the front of the

transmission will be from either the front bearing

retainer or retainer seal. Lubricant may be seen drip-

ping from the clutch housing after extended opera-

tion. If the leak is severe, it may also contaminate

the clutch disc causing the disc to slip, grab and or

chatter.

HARD SHIFTING

Hard shifting is usually caused by a low lubricant

level, improper or contaminated lubricants. The con-

sequence of using non-recommended lubricants is

noise, excessive wear, internal bind and hard shift-

ing. Substantial lubricant leaks can result in gear,

shift rail, synchro, and bearing damage. If a leak

goes undetected for an extended period, the first indi-

cations of component damage are usually hard shift-

ing and noise.

Component damage, incorrect clutch adjustment or

damaged clutch pressure plate or disc are additional

probable causes of increased shift effort. Incorrect

adjustment or a worn/damaged pressure plate or disc

can cause incorrect release. If clutch problem is

advanced, gear clash during shifts can result. Worn

or damaged synchro rings can cause gear clash when

shifting into any forward gear. In some new or

rebuilt transmissions, new synchro rings may tend to

stick slightly causing hard or noisy shifts. In most

cases this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur-

ing normal operation. Rotating gears generate a mild

whine that is audible, but generally only at extreme

speeds. Severe highly audible transmission noise is

generally the initial indicator of a lubricant problem.

Insufficient, improper or contaminated lubricant

will promote rapid wear of gears, synchros, shift

rails, forks and bearings. The overheating caused by

a lubricant problem, can also lead to gear breakage.

REMOVAL

(1) Shift transmission into Neutral.

Fig. 2 IDENTIFICATION TAG LOCATION

1 - IDENTIFICATION TAGS

21 - 90 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1804 of 2627

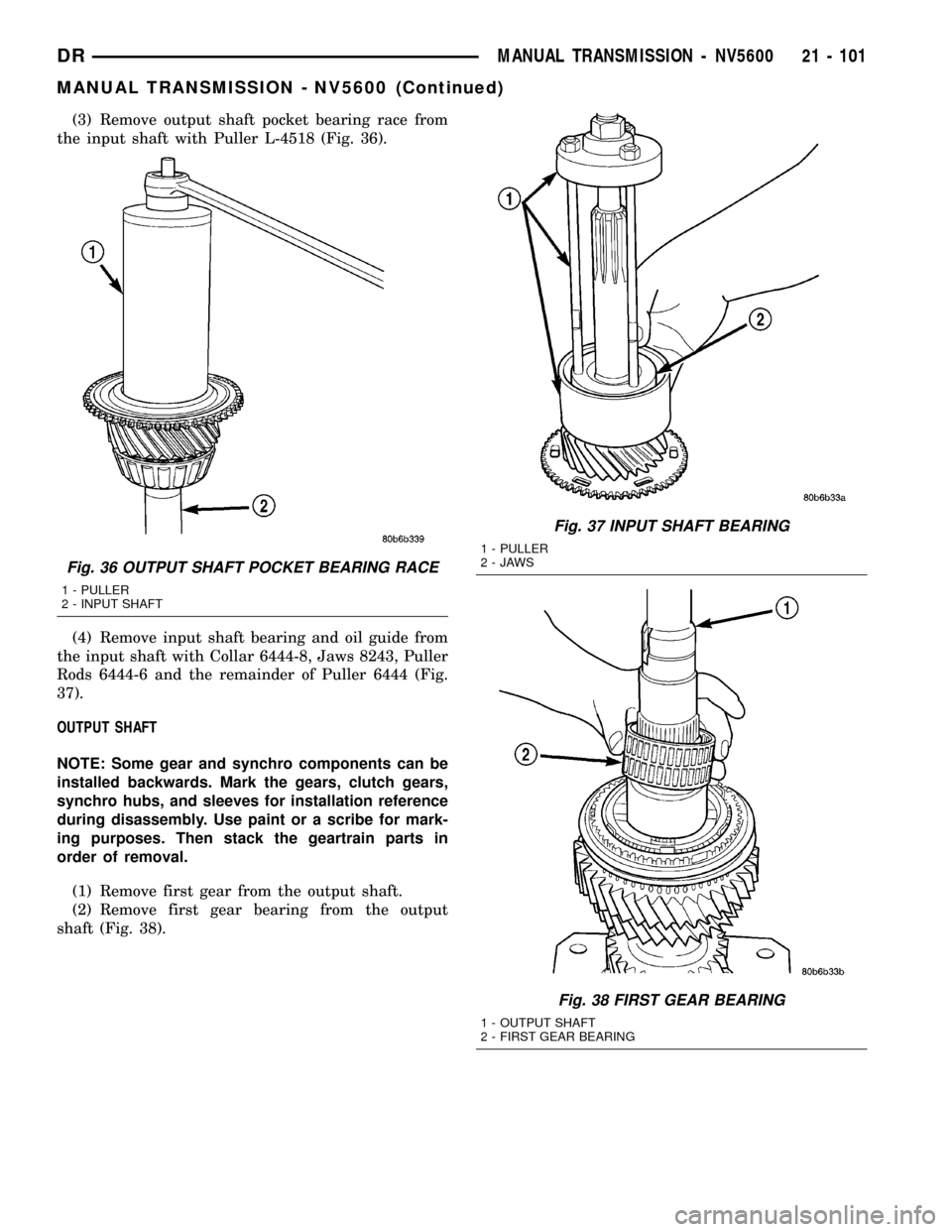

(3) Remove output shaft pocket bearing race from

the input shaft with Puller L-4518 (Fig. 36).

(4) Remove input shaft bearing and oil guide from

the input shaft with Collar 6444-8, Jaws 8243, Puller

Rods 6444-6 and the remainder of Puller 6444 (Fig.

37).

OUTPUT SHAFT

NOTE: Some gear and synchro components can be

installed backwards. Mark the gears, clutch gears,

synchro hubs, and sleeves for installation reference

during disassembly. Use paint or a scribe for mark-

ing purposes. Then stack the geartrain parts in

order of removal.

(1) Remove first gear from the output shaft.

(2) Remove first gear bearing from the output

shaft (Fig. 38).

Fig. 36 OUTPUT SHAFT POCKET BEARING RACE

1 - PULLER

2 - INPUT SHAFT

Fig. 37 INPUT SHAFT BEARING

1 - PULLER

2-JAWS

Fig. 38 FIRST GEAR BEARING

1 - OUTPUT SHAFT

2 - FIRST GEAR BEARING

DRMANUAL TRANSMISSION - NV5600 21 - 101

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1808 of 2627

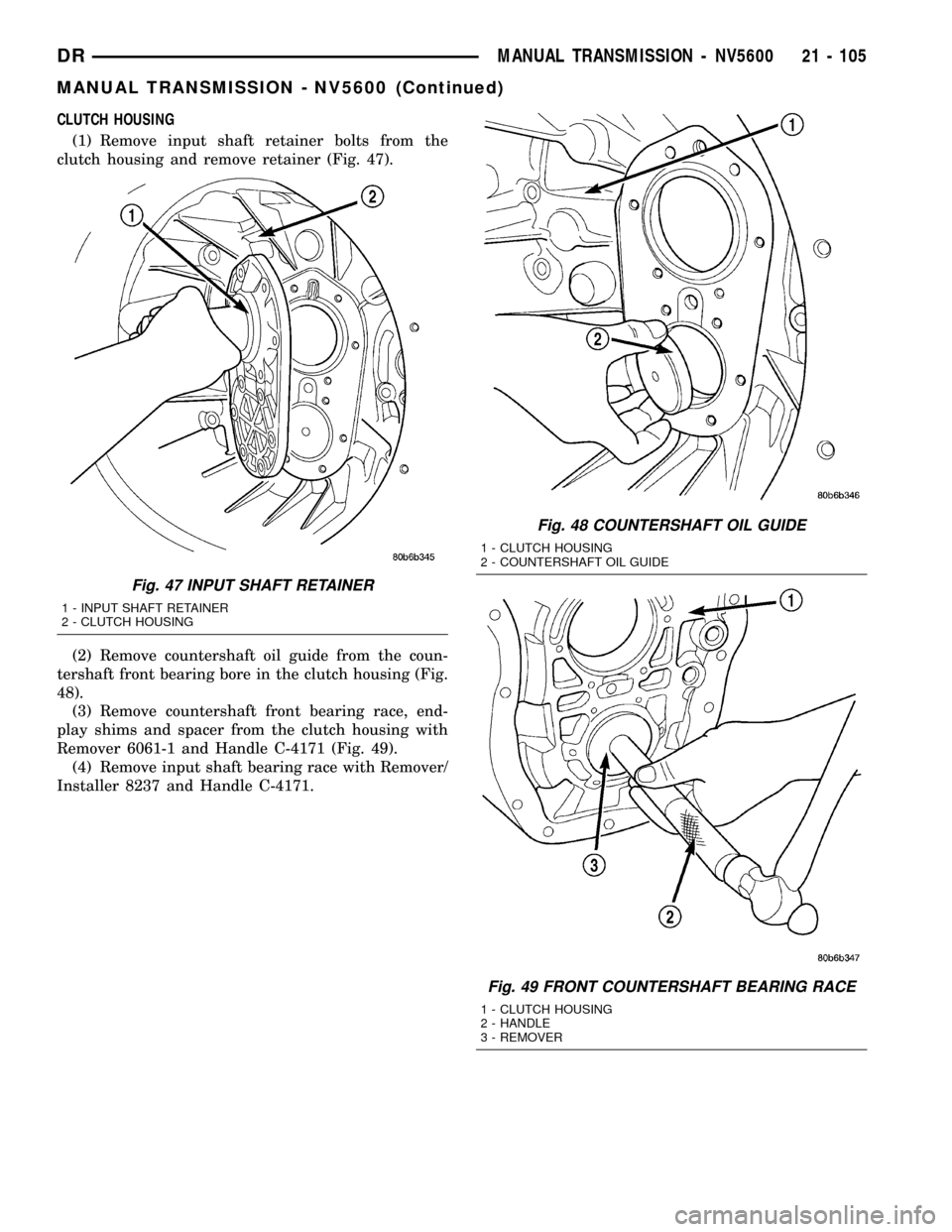

CLUTCH HOUSING

(1) Remove input shaft retainer bolts from the

clutch housing and remove retainer (Fig. 47).

(2) Remove countershaft oil guide from the coun-

tershaft front bearing bore in the clutch housing (Fig.

48).

(3) Remove countershaft front bearing race, end-

play shims and spacer from the clutch housing with

Remover 6061-1 and Handle C-4171 (Fig. 49).

(4) Remove input shaft bearing race with Remover/

Installer 8237 and Handle C-4171.

Fig. 47 INPUT SHAFT RETAINER

1 - INPUT SHAFT RETAINER

2 - CLUTCH HOUSING

Fig. 48 COUNTERSHAFT OIL GUIDE

1 - CLUTCH HOUSING

2 - COUNTERSHAFT OIL GUIDE

Fig. 49 FRONT COUNTERSHAFT BEARING RACE

1 - CLUTCH HOUSING

2 - HANDLE

3 - REMOVER

DRMANUAL TRANSMISSION - NV5600 21 - 105

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1809 of 2627

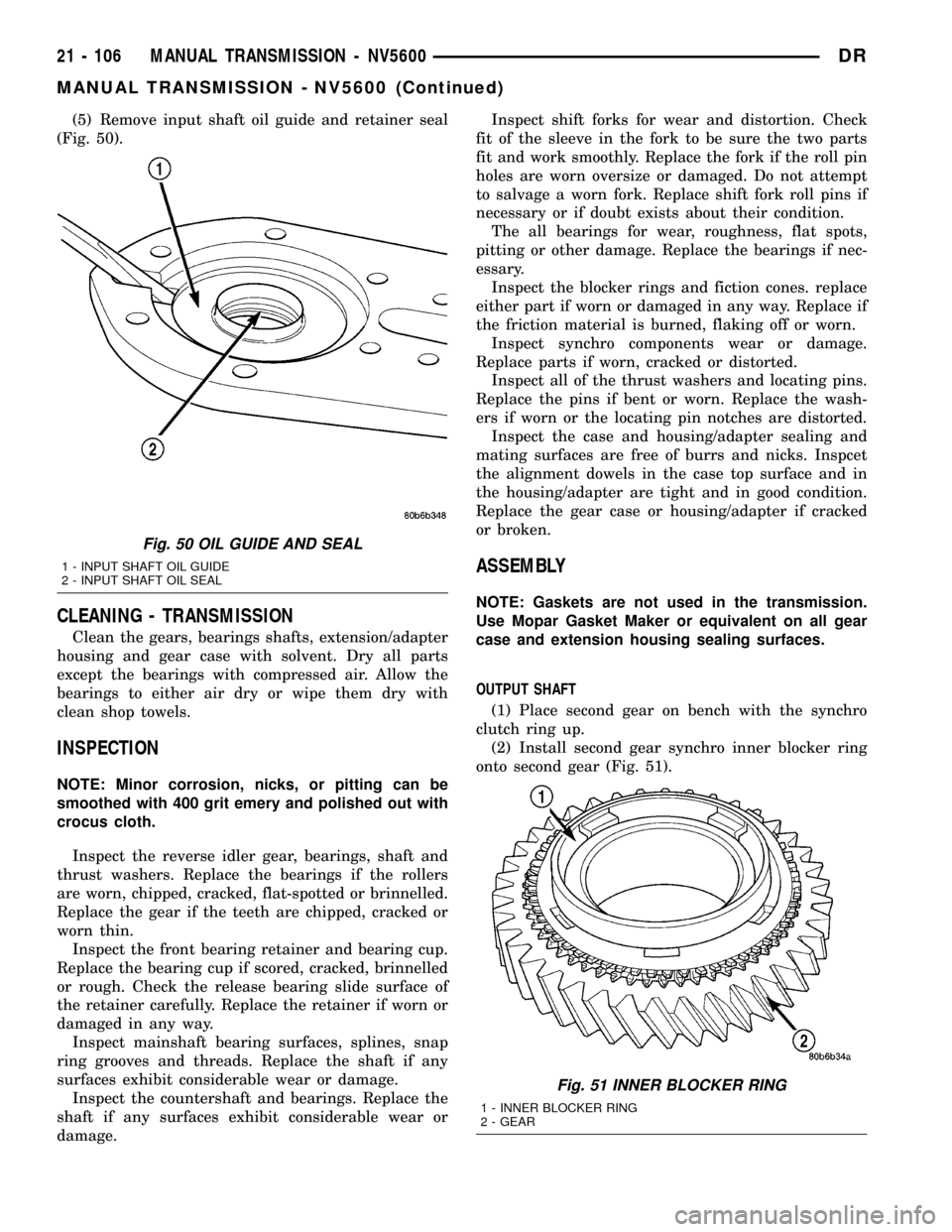

(5) Remove input shaft oil guide and retainer seal

(Fig. 50).

CLEANING - TRANSMISSION

Clean the gears, bearings shafts, extension/adapter

housing and gear case with solvent. Dry all parts

except the bearings with compressed air. Allow the

bearings to either air dry or wipe them dry with

clean shop towels.

INSPECTION

NOTE: Minor corrosion, nicks, or pitting can be

smoothed with 400 grit emery and polished out with

crocus cloth.

Inspect the reverse idler gear, bearings, shaft and

thrust washers. Replace the bearings if the rollers

are worn, chipped, cracked, flat-spotted or brinnelled.

Replace the gear if the teeth are chipped, cracked or

worn thin.

Inspect the front bearing retainer and bearing cup.

Replace the bearing cup if scored, cracked, brinnelled

or rough. Check the release bearing slide surface of

the retainer carefully. Replace the retainer if worn or

damaged in any way.

Inspect mainshaft bearing surfaces, splines, snap

ring grooves and threads. Replace the shaft if any

surfaces exhibit considerable wear or damage.

Inspect the countershaft and bearings. Replace the

shaft if any surfaces exhibit considerable wear or

damage.Inspect shift forks for wear and distortion. Check

fit of the sleeve in the fork to be sure the two parts

fit and work smoothly. Replace the fork if the roll pin

holes are worn oversize or damaged. Do not attempt

to salvage a worn fork. Replace shift fork roll pins if

necessary or if doubt exists about their condition.

The all bearings for wear, roughness, flat spots,

pitting or other damage. Replace the bearings if nec-

essary.

Inspect the blocker rings and fiction cones. replace

either part if worn or damaged in any way. Replace if

the friction material is burned, flaking off or worn.

Inspect synchro components wear or damage.

Replace parts if worn, cracked or distorted.

Inspect all of the thrust washers and locating pins.

Replace the pins if bent or worn. Replace the wash-

ers if worn or the locating pin notches are distorted.

Inspect the case and housing/adapter sealing and

mating surfaces are free of burrs and nicks. Inspcet

the alignment dowels in the case top surface and in

the housing/adapter are tight and in good condition.

Replace the gear case or housing/adapter if cracked

or broken.

ASSEMBLY

NOTE: Gaskets are not used in the transmission.

Use Mopar Gasket Maker or equivalent on all gear

case and extension housing sealing surfaces.

OUTPUT SHAFT

(1) Place second gear on bench with the synchro

clutch ring up.

(2) Install second gear synchro inner blocker ring

onto second gear (Fig. 51).

Fig. 50 OIL GUIDE AND SEAL

1 - INPUT SHAFT OIL GUIDE

2 - INPUT SHAFT OIL SEAL

Fig. 51 INNER BLOCKER RING

1 - INNER BLOCKER RING

2 - GEAR

21 - 106 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1817 of 2627

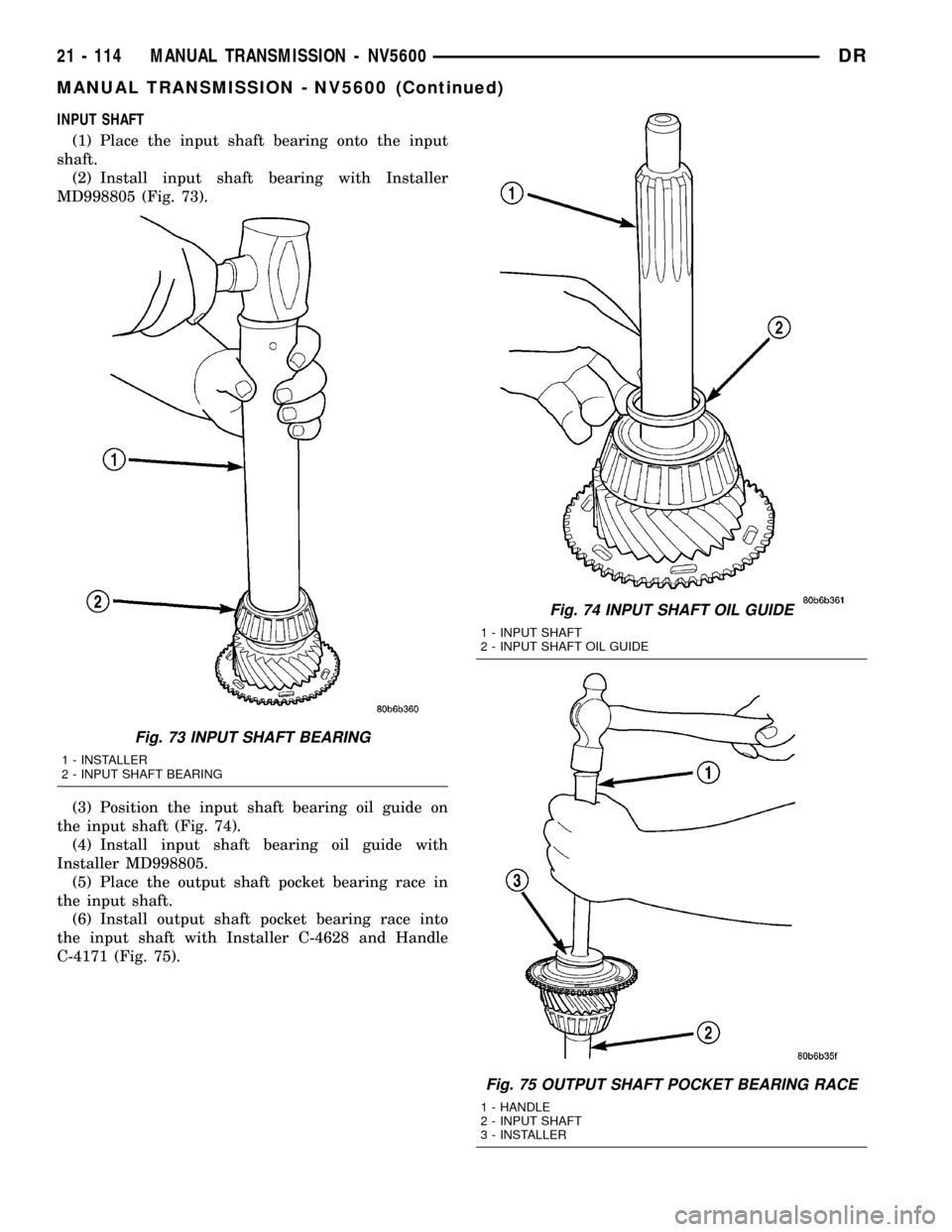

INPUT SHAFT

(1) Place the input shaft bearing onto the input

shaft.

(2) Install input shaft bearing with Installer

MD998805 (Fig. 73).

(3) Position the input shaft bearing oil guide on

the input shaft (Fig. 74).

(4) Install input shaft bearing oil guide with

Installer MD998805.

(5) Place the output shaft pocket bearing race in

the input shaft.

(6) Install output shaft pocket bearing race into

the input shaft with Installer C-4628 and Handle

C-4171 (Fig. 75).

Fig. 73 INPUT SHAFT BEARING

1 - INSTALLER

2 - INPUT SHAFT BEARING

Fig. 74 INPUT SHAFT OIL GUIDE

1 - INPUT SHAFT

2 - INPUT SHAFT OIL GUIDE

Fig. 75 OUTPUT SHAFT POCKET BEARING RACE

1 - HANDLE

2 - INPUT SHAFT

3 - INSTALLER

21 - 114 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1818 of 2627

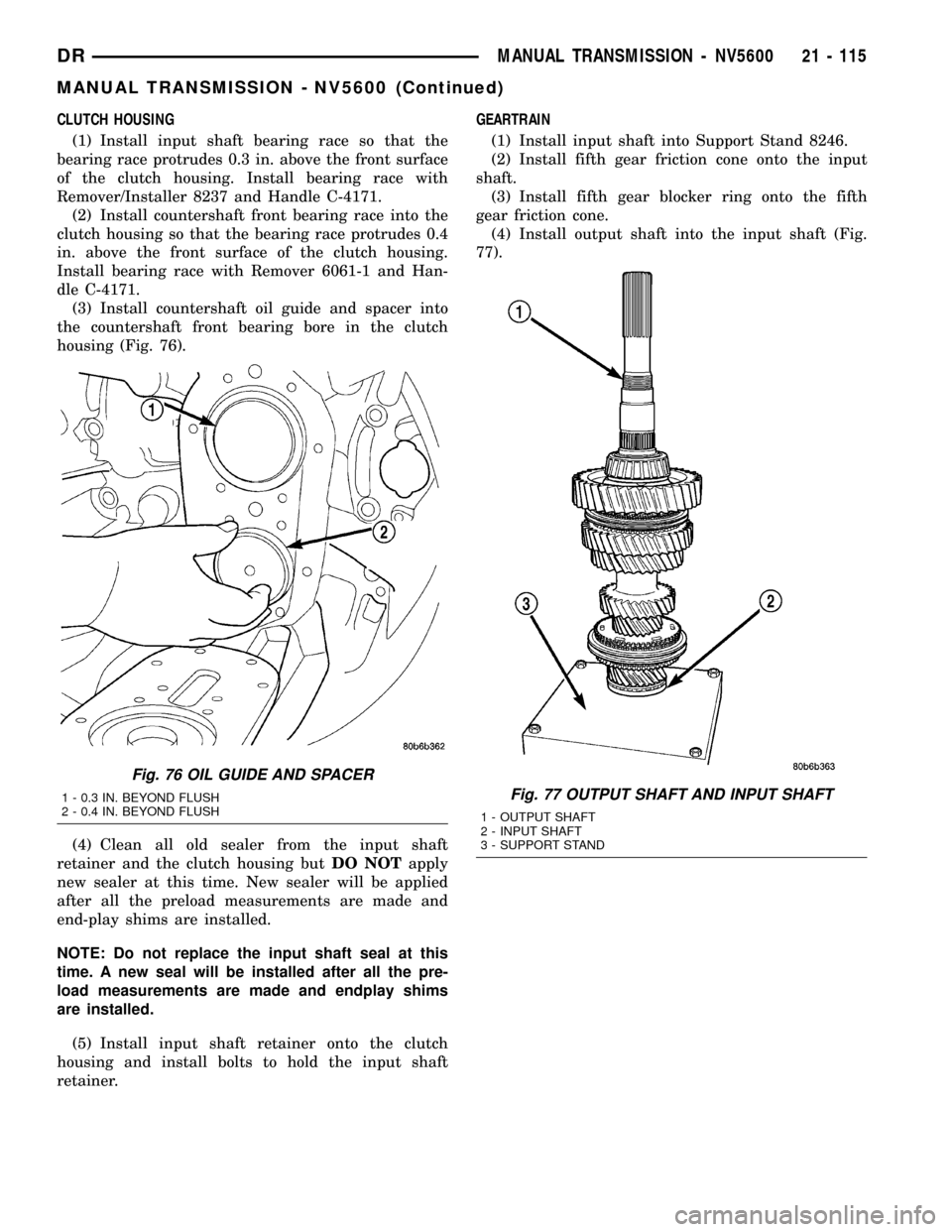

CLUTCH HOUSING

(1) Install input shaft bearing race so that the

bearing race protrudes 0.3 in. above the front surface

of the clutch housing. Install bearing race with

Remover/Installer 8237 and Handle C-4171.

(2) Install countershaft front bearing race into the

clutch housing so that the bearing race protrudes 0.4

in. above the front surface of the clutch housing.

Install bearing race with Remover 6061-1 and Han-

dle C-4171.

(3) Install countershaft oil guide and spacer into

the countershaft front bearing bore in the clutch

housing (Fig. 76).

(4) Clean all old sealer from the input shaft

retainer and the clutch housing butDO NOTapply

new sealer at this time. New sealer will be applied

after all the preload measurements are made and

end-play shims are installed.

NOTE: Do not replace the input shaft seal at this

time. A new seal will be installed after all the pre-

load measurements are made and endplay shims

are installed.

(5) Install input shaft retainer onto the clutch

housing and install bolts to hold the input shaft

retainer.GEARTRAIN

(1) Install input shaft into Support Stand 8246.

(2) Install fifth gear friction cone onto the input

shaft.

(3) Install fifth gear blocker ring onto the fifth

gear friction cone.

(4) Install output shaft into the input shaft (Fig.

77).

Fig. 76 OIL GUIDE AND SPACER

1 - 0.3 IN. BEYOND FLUSH

2 - 0.4 IN. BEYOND FLUSHFig. 77 OUTPUT SHAFT AND INPUT SHAFT

1 - OUTPUT SHAFT

2 - INPUT SHAFT

3 - SUPPORT STAND

DRMANUAL TRANSMISSION - NV5600 21 - 115

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1821 of 2627

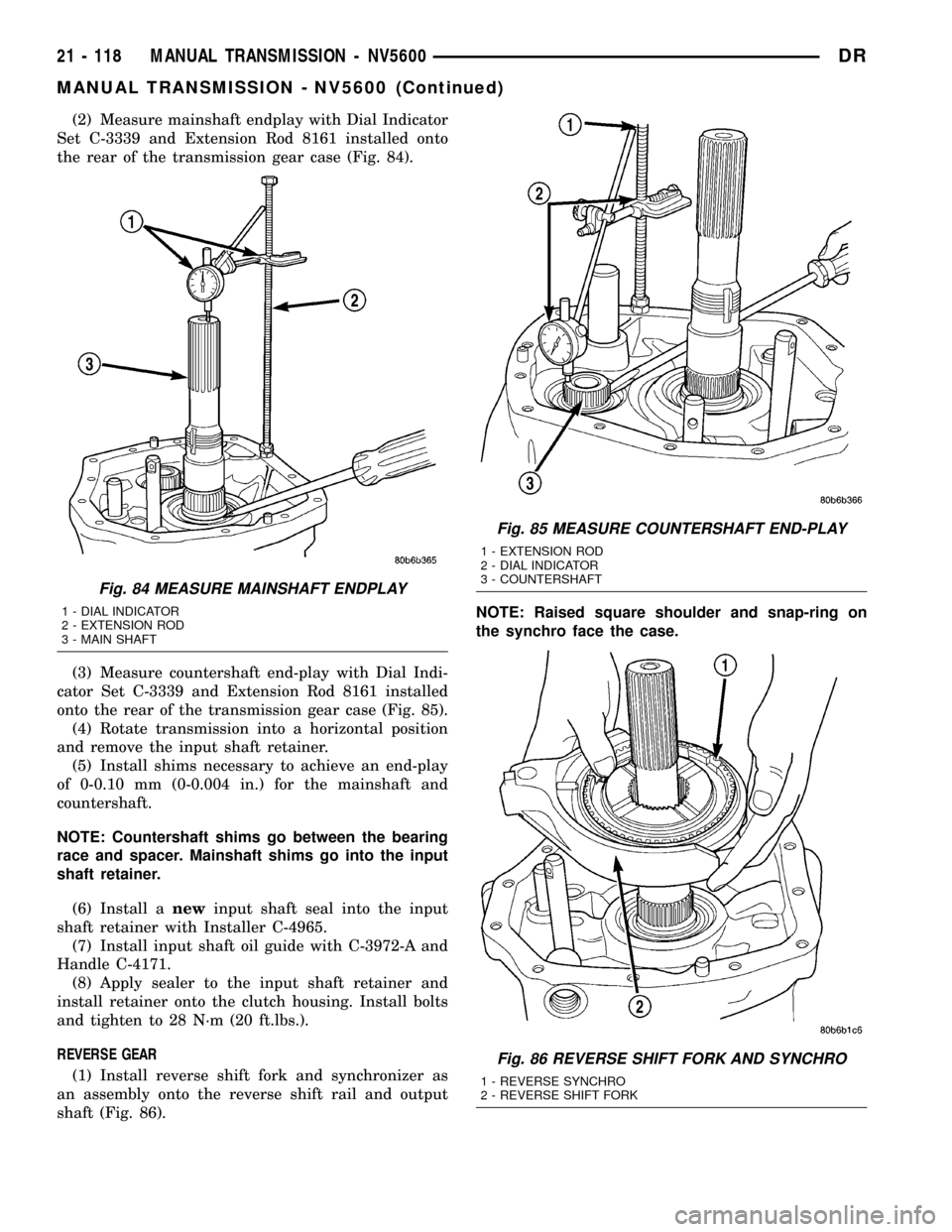

(2) Measure mainshaft endplay with Dial Indicator

Set C-3339 and Extension Rod 8161 installed onto

the rear of the transmission gear case (Fig. 84).

(3) Measure countershaft end-play with Dial Indi-

cator Set C-3339 and Extension Rod 8161 installed

onto the rear of the transmission gear case (Fig. 85).

(4) Rotate transmission into a horizontal position

and remove the input shaft retainer.

(5) Install shims necessary to achieve an end-play

of 0-0.10 mm (0-0.004 in.) for the mainshaft and

countershaft.

NOTE: Countershaft shims go between the bearing

race and spacer. Mainshaft shims go into the input

shaft retainer.

(6) Install anewinput shaft seal into the input

shaft retainer with Installer C-4965.

(7) Install input shaft oil guide with C-3972-A and

Handle C-4171.

(8) Apply sealer to the input shaft retainer and

install retainer onto the clutch housing. Install bolts

and tighten to 28 N´m (20 ft.lbs.).

REVERSE GEAR

(1) Install reverse shift fork and synchronizer as

an assembly onto the reverse shift rail and output

shaft (Fig. 86).NOTE: Raised square shoulder and snap-ring on

the synchro face the case.

Fig. 84 MEASURE MAINSHAFT ENDPLAY

1 - DIAL INDICATOR

2 - EXTENSION ROD

3 - MAIN SHAFT

Fig. 85 MEASURE COUNTERSHAFT END-PLAY

1 - EXTENSION ROD

2 - DIAL INDICATOR

3 - COUNTERSHAFT

Fig. 86 REVERSE SHIFT FORK AND SYNCHRO

1 - REVERSE SYNCHRO

2 - REVERSE SHIFT FORK

21 - 118 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)