Removal DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1586 of 2627

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

5.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in intake manifold.

(5) Guide each injector into intake manifold. Be

careful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on shoulders. Pushleftfuel

rail down until injectors have bottomed on shoulders.

(7) Install 4 fuel rail holdown clamps and 4 mount-

ing bolts. Refer to Torque Specifications.

(8) Position spark plug cable tray and cable assem-

bly to intake manifold. Snap 4 cable tray retaining

clips into intake manifold.

(9) Install all cables to spark plugs and ignition

coils.

(10) Connect electrical connector to throttle body.

(11) Install electrical connectors to all 8 ignition

coils. Refer to Ignition Coil Removal/Installation.

(12) Connect electrical connector to throttle body.

(13) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(14) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(15) Install air resonator to throttle body (2 bolts).

(16) Install flexible air duct to air box.

(17) Connect battery cable to battery.

(18) Start engine and check for leaks.

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for place-

ment of the fuel pump module, and (if equipped) cer-

tain ORVR components.

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.Two check (control) valves are mounted into the

top of the fuel tank. Refer to Fuel Tank Check Valve

for additional information.

An evaporation control system is connected to the

fuel tank to reduce emissions of fuel vapors into the

atmosphere. When fuel evaporates from the fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP) and/or an On-Board Refueling

Vapor Recovery (ORVR) system. Refer to Emission

Control System for additional information.

REMOVAL- EXCEPT DIESEL

Fuel Tank Draining

WARNING: THE FUEL SYSTEM MAY BE UNDER

CONSTANT FUEL PRESSURE EVEN WITH THE

ENGINE OFF. THIS PRESSURE MUST BE

RELEASED BEFORE SERVICING FUEL TANK.

Two different procedures may be used to drain fuel

tank: through the fuel fill fitting on tank, or using

the DRBtscan tool. Due to a one-way check valve

installed into the fuel fill opening fitting at the tank,

the tank cannot be drained conventionally at the fill

cap.

The quickest draining procedure involves removing

the rubber fuel fill hose.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRB scan tool for fuel pump

activation procedures. Before disconnecting fuel line

at fuel rail, release fuel pressure. Refer to the Fuel

System Pressure Release Procedure for procedures.

Attach end of special test hose tool number 6541,

6539, 6631 or 6923 at fuel rail disconnection (tool

number will depend on model and/or engine applica-

tion). Position opposite end of this hose tool to an

approved gasoline draining station. Activate fuel

pump and drain tank until empty.

If electric fuel pump is not operating, fuel must be

drained through fuel fill fitting at tank. Refer to fol-

lowing procedures.

(1) Release fuel system pressure.

(2) Raise vehicle.

(3) Thoroughly clean area around fuel fill fitting

and rubber fuel fill hose at tank.

(4) If vehicle is equipped with 4 doors and a 6 foot

(short) box, remove left-rear tire/wheel.

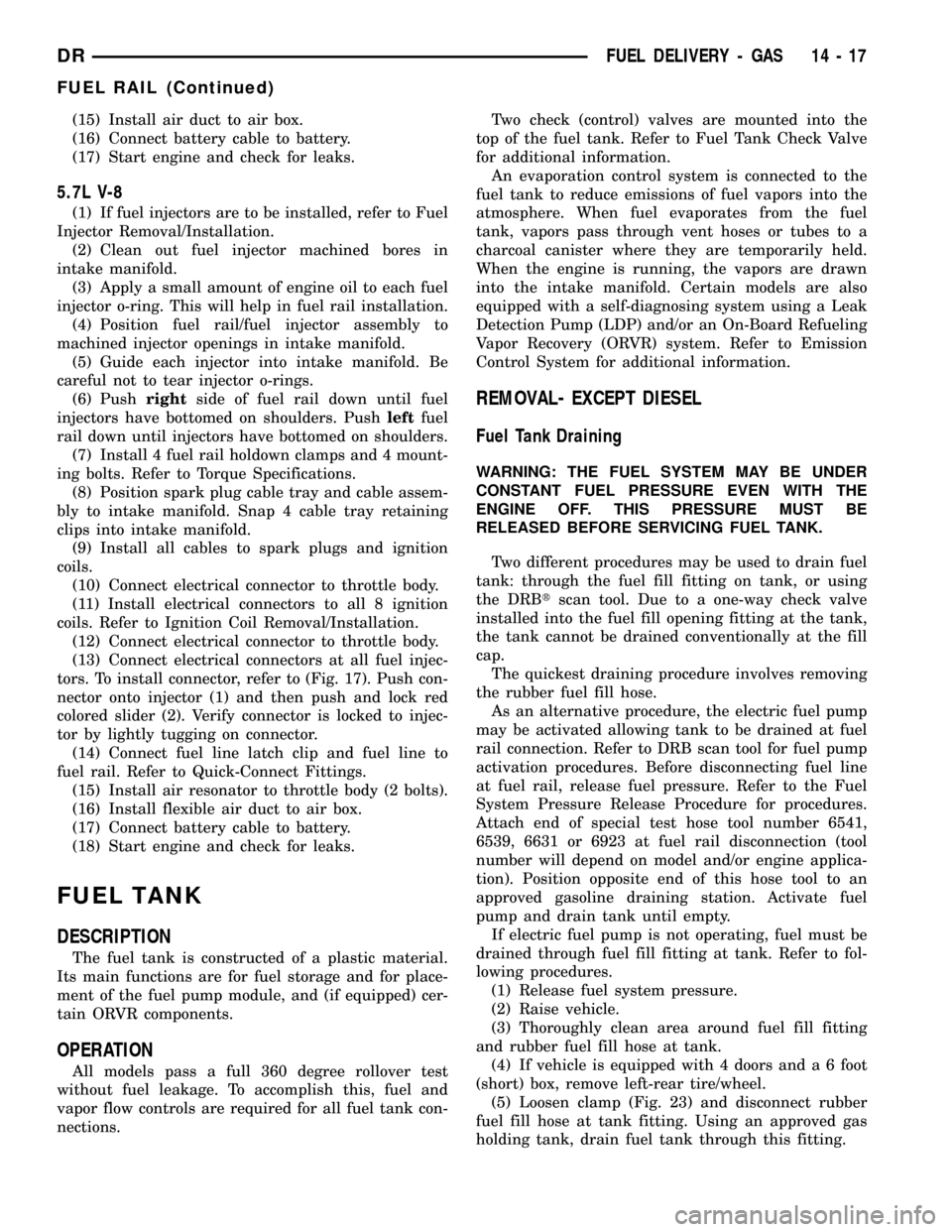

(5) Loosen clamp (Fig. 23) and disconnect rubber

fuel fill hose at tank fitting. Using an approved gas

holding tank, drain fuel tank through this fitting.

DRFUEL DELIVERY - GAS 14 - 17

FUEL RAIL (Continued)

Page 1587 of 2627

Tank Removal

(1) Loosen clamp and disconnect rubber fuel vent

hose (Fig. 23) at tank fitting.

(2) Support tank with a hydraulic jack.

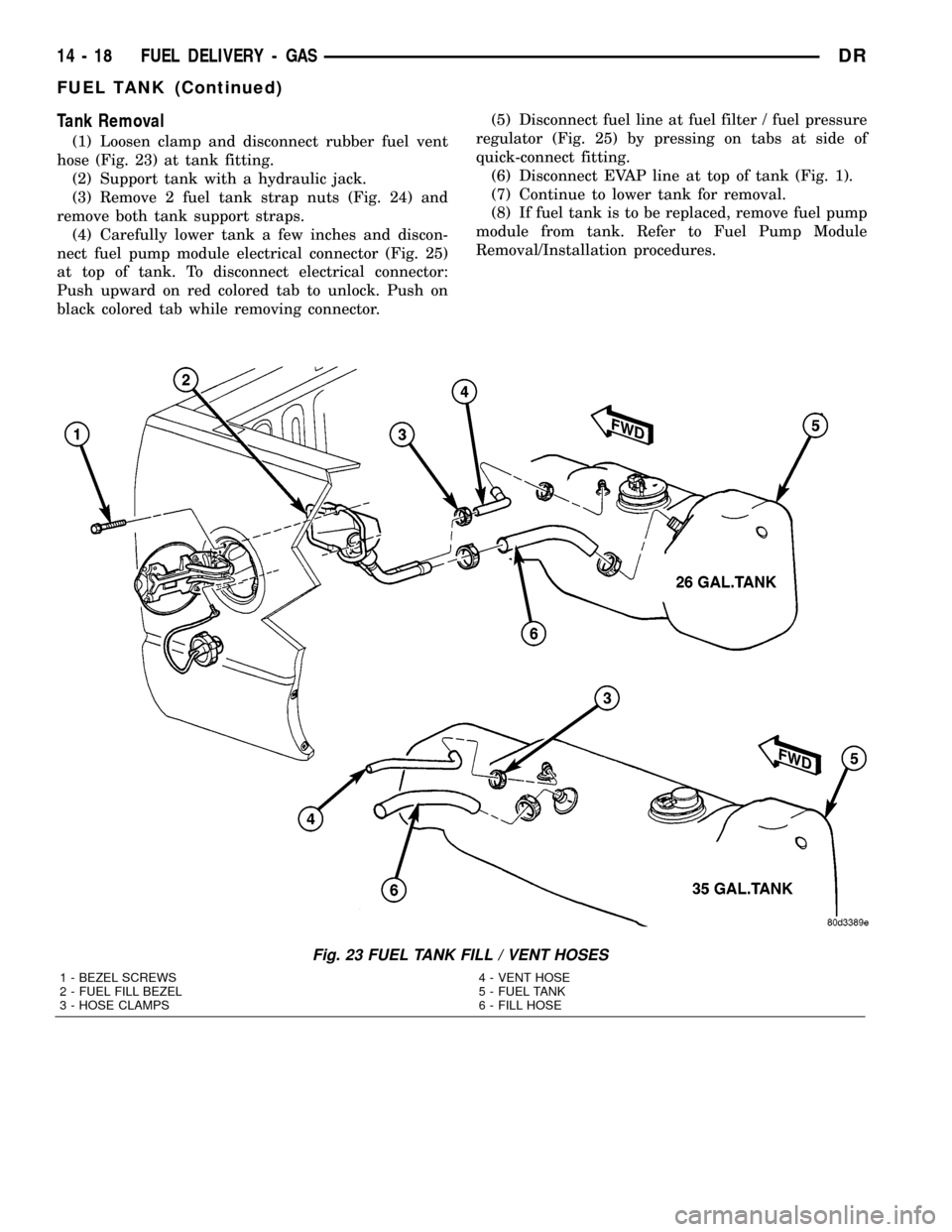

(3) Remove 2 fuel tank strap nuts (Fig. 24) and

remove both tank support straps.

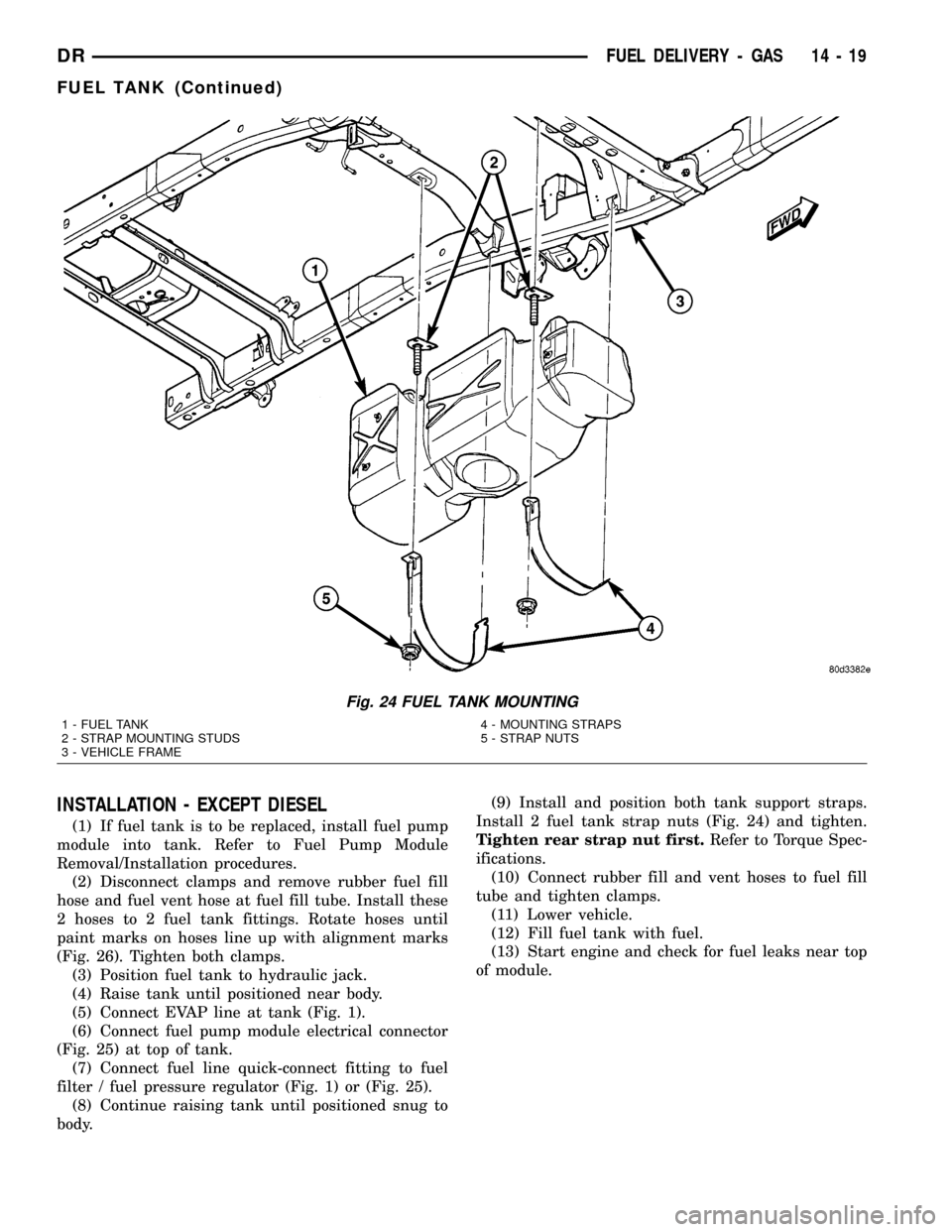

(4) Carefully lower tank a few inches and discon-

nect fuel pump module electrical connector (Fig. 25)

at top of tank. To disconnect electrical connector:

Push upward on red colored tab to unlock. Push on

black colored tab while removing connector.(5) Disconnect fuel line at fuel filter / fuel pressure

regulator (Fig. 25) by pressing on tabs at side of

quick-connect fitting.

(6) Disconnect EVAP line at top of tank (Fig. 1).

(7) Continue to lower tank for removal.

(8) If fuel tank is to be replaced, remove fuel pump

module from tank. Refer to Fuel Pump Module

Removal/Installation procedures.

Fig. 23 FUEL TANK FILL / VENT HOSES

1 - BEZEL SCREWS

2 - FUEL FILL BEZEL

3 - HOSE CLAMPS4 - VENT HOSE

5 - FUEL TANK

6 - FILL HOSE

14 - 18 FUEL DELIVERY - GASDR

FUEL TANK (Continued)

Page 1588 of 2627

INSTALLATION - EXCEPT DIESEL

(1) If fuel tank is to be replaced, install fuel pump

module into tank. Refer to Fuel Pump Module

Removal/Installation procedures.

(2) Disconnect clamps and remove rubber fuel fill

hose and fuel vent hose at fuel fill tube. Install these

2 hoses to 2 fuel tank fittings. Rotate hoses until

paint marks on hoses line up with alignment marks

(Fig. 26). Tighten both clamps.

(3) Position fuel tank to hydraulic jack.

(4) Raise tank until positioned near body.

(5) Connect EVAP line at tank (Fig. 1).

(6) Connect fuel pump module electrical connector

(Fig. 25) at top of tank.

(7) Connect fuel line quick-connect fitting to fuel

filter / fuel pressure regulator (Fig. 1) or (Fig. 25).

(8) Continue raising tank until positioned snug to

body.(9) Install and position both tank support straps.

Install 2 fuel tank strap nuts (Fig. 24) and tighten.

Tighten rear strap nut first.Refer to Torque Spec-

ifications.

(10) Connect rubber fill and vent hoses to fuel fill

tube and tighten clamps.

(11) Lower vehicle.

(12) Fill fuel tank with fuel.

(13) Start engine and check for fuel leaks near top

of module.

Fig. 24 FUEL TANK MOUNTING

1 - FUEL TANK

2 - STRAP MOUNTING STUDS

3 - VEHICLE FRAME4 - MOUNTING STRAPS

5 - STRAP NUTS

DRFUEL DELIVERY - GAS 14 - 19

FUEL TANK (Continued)

Page 1589 of 2627

INLET FILTER

REMOVAL

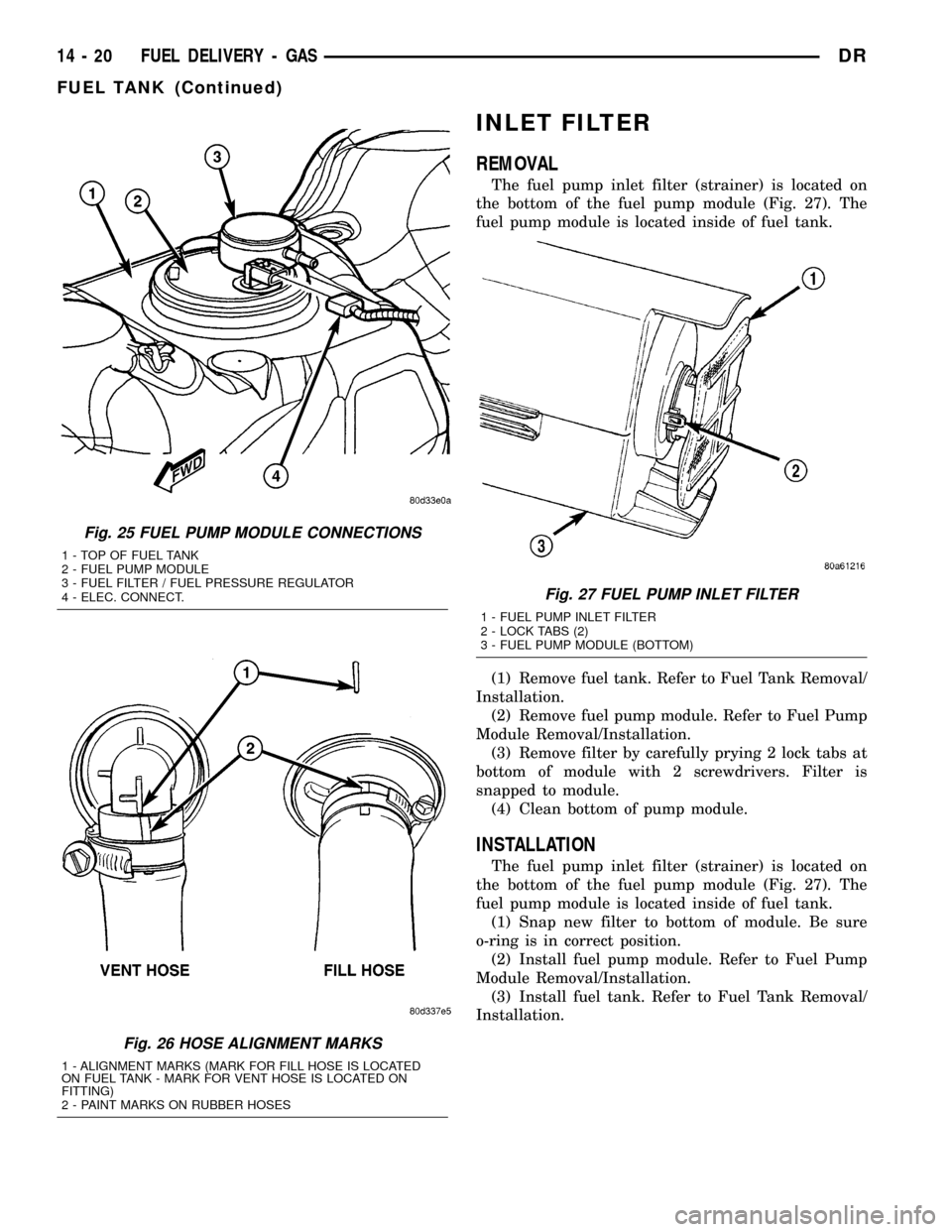

The fuel pump inlet filter (strainer) is located on

the bottom of the fuel pump module (Fig. 27). The

fuel pump module is located inside of fuel tank.

(1) Remove fuel tank. Refer to Fuel Tank Removal/

Installation.

(2) Remove fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(3) Remove filter by carefully prying 2 lock tabs at

bottom of module with 2 screwdrivers. Filter is

snapped to module.

(4) Clean bottom of pump module.

INSTALLATION

The fuel pump inlet filter (strainer) is located on

the bottom of the fuel pump module (Fig. 27). The

fuel pump module is located inside of fuel tank.

(1) Snap new filter to bottom of module. Be sure

o-ring is in correct position.

(2) Install fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(3) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

Fig. 25 FUEL PUMP MODULE CONNECTIONS

1 - TOP OF FUEL TANK

2 - FUEL PUMP MODULE

3 - FUEL FILTER / FUEL PRESSURE REGULATOR

4 - ELEC. CONNECT.

Fig. 26 HOSE ALIGNMENT MARKS

1 - ALIGNMENT MARKS (MARK FOR FILL HOSE IS LOCATED

ON FUEL TANK - MARK FOR VENT HOSE IS LOCATED ON

FITTING)

2 - PAINT MARKS ON RUBBER HOSES

Fig. 27 FUEL PUMP INLET FILTER

1 - FUEL PUMP INLET FILTER

2 - LOCK TABS (2)

3 - FUEL PUMP MODULE (BOTTOM)

14 - 20 FUEL DELIVERY - GASDR

FUEL TANK (Continued)

Page 1590 of 2627

FUEL INJECTION - GAS

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL

REMOVAL.............................21

INSTALLATION.........................21

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................22

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................24

INSTALLATION.........................25

FUEL INJECTOR

DESCRIPTION.........................26

OPERATION

OPERATION - FUEL INJECTOR..........26

OPERATION - PCM OUTPUT............27

REMOVAL.............................27

INSTALLATION.........................27

FUEL PUMP RELAY

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................28

INSTALLATION.........................28

IDLE AIR CONTROL MOTOR

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................29

INSTALLATION.........................29INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................30

INSTALLATION.........................31

MAP SENSOR

DESCRIPTION.........................32

OPERATION...........................32

REMOVAL.............................33

INSTALLATION.........................34

OXYGEN SENSOR

DESCRIPTION.........................35

REMOVAL.............................35

INSTALLATION.........................36

PTO SWITCH

DESCRIPTION.........................36

OPERATION...........................36

THROTTLE BODY

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................37

THROTTLE CONTROL CABLE

REMOVAL.............................38

INSTALLATION.........................40

THROTTLE POSITION SENSOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................41

INSTALLATION.........................43

ACCELERATOR PEDAL

REMOVAL

The following procedure applies only to vehicles

without the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

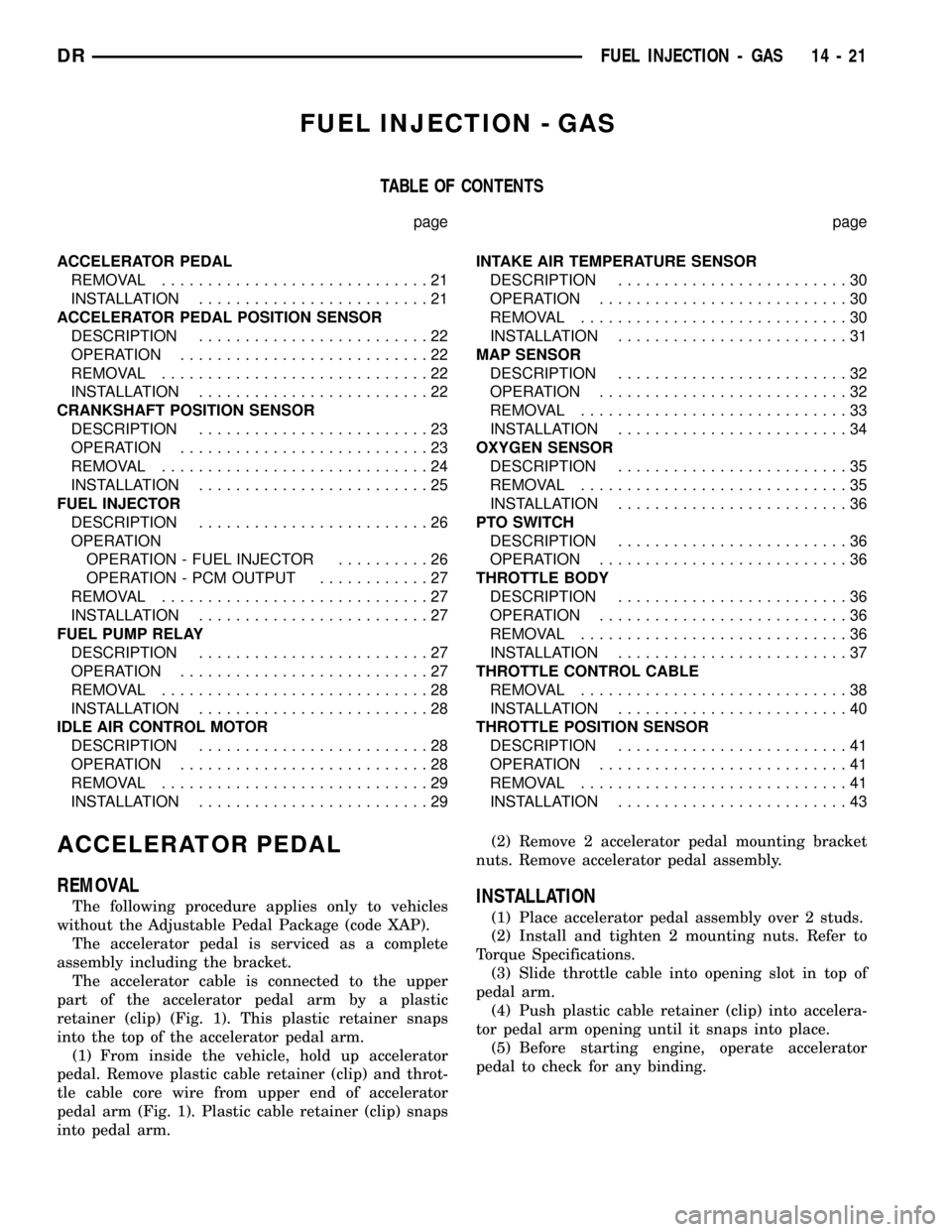

The accelerator cable is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throt-

tle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.INSTALLATION

(1) Place accelerator pedal assembly over 2 studs.

(2) Install and tighten 2 mounting nuts. Refer to

Torque Specifications.

(3) Slide throttle cable into opening slot in top of

pedal arm.

(4) Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

DRFUEL INJECTION - GAS 14 - 21

Page 1591 of 2627

ACCELERATOR PEDAL

POSITION SENSOR

DESCRIPTION

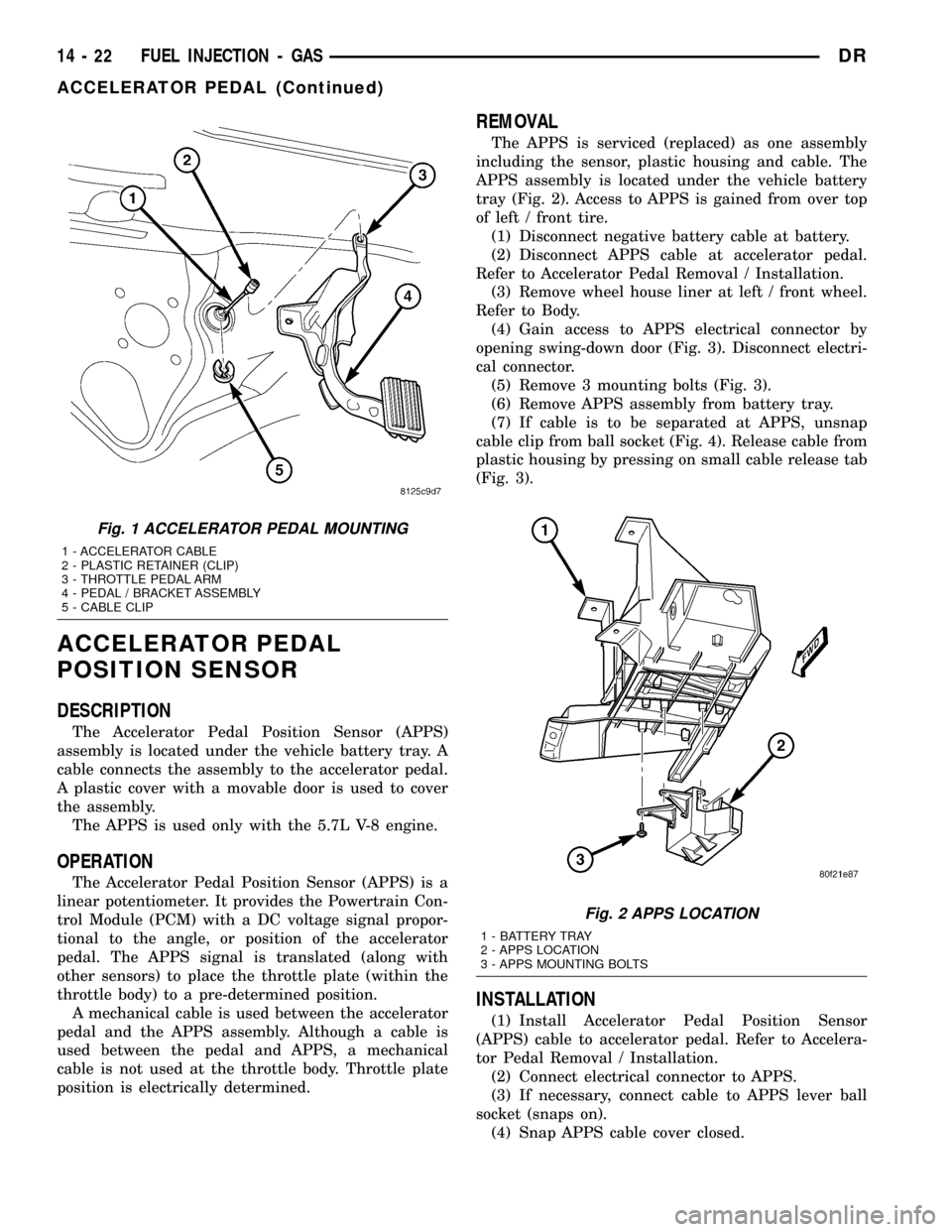

The Accelerator Pedal Position Sensor (APPS)

assembly is located under the vehicle battery tray. A

cable connects the assembly to the accelerator pedal.

A plastic cover with a movable door is used to cover

the assembly.

The APPS is used only with the 5.7L V-8 engine.

OPERATION

The Accelerator Pedal Position Sensor (APPS) is a

linear potentiometer. It provides the Powertrain Con-

trol Module (PCM) with a DC voltage signal propor-

tional to the angle, or position of the accelerator

pedal. The APPS signal is translated (along with

other sensors) to place the throttle plate (within the

throttle body) to a pre-determined position.

A mechanical cable is used between the accelerator

pedal and the APPS assembly. Although a cable is

used between the pedal and APPS, a mechanical

cable is not used at the throttle body. Throttle plate

position is electrically determined.

REMOVAL

The APPS is serviced (replaced) as one assembly

including the sensor, plastic housing and cable. The

APPS assembly is located under the vehicle battery

tray (Fig. 2). Access to APPS is gained from over top

of left / front tire.

(1) Disconnect negative battery cable at battery.

(2) Disconnect APPS cable at accelerator pedal.

Refer to Accelerator Pedal Removal / Installation.

(3) Remove wheel house liner at left / front wheel.

Refer to Body.

(4) Gain access to APPS electrical connector by

opening swing-down door (Fig. 3). Disconnect electri-

cal connector.

(5) Remove 3 mounting bolts (Fig. 3).

(6) Remove APPS assembly from battery tray.

(7) If cable is to be separated at APPS, unsnap

cable clip from ball socket (Fig. 4). Release cable from

plastic housing by pressing on small cable release tab

(Fig. 3).

INSTALLATION

(1) Install Accelerator Pedal Position Sensor

(APPS) cable to accelerator pedal. Refer to Accelera-

tor Pedal Removal / Installation.

(2) Connect electrical connector to APPS.

(3) If necessary, connect cable to APPS lever ball

socket (snaps on).

(4) Snap APPS cable cover closed.

Fig. 1 ACCELERATOR PEDAL MOUNTING

1 - ACCELERATOR CABLE

2 - PLASTIC RETAINER (CLIP)

3 - THROTTLE PEDAL ARM

4 - PEDAL / BRACKET ASSEMBLY

5 - CABLE CLIP

Fig. 2 APPS LOCATION

1 - BATTERY TRAY

2 - APPS LOCATION

3 - APPS MOUNTING BOLTS

14 - 22 FUEL INJECTION - GASDR

ACCELERATOR PEDAL (Continued)

Page 1593 of 2627

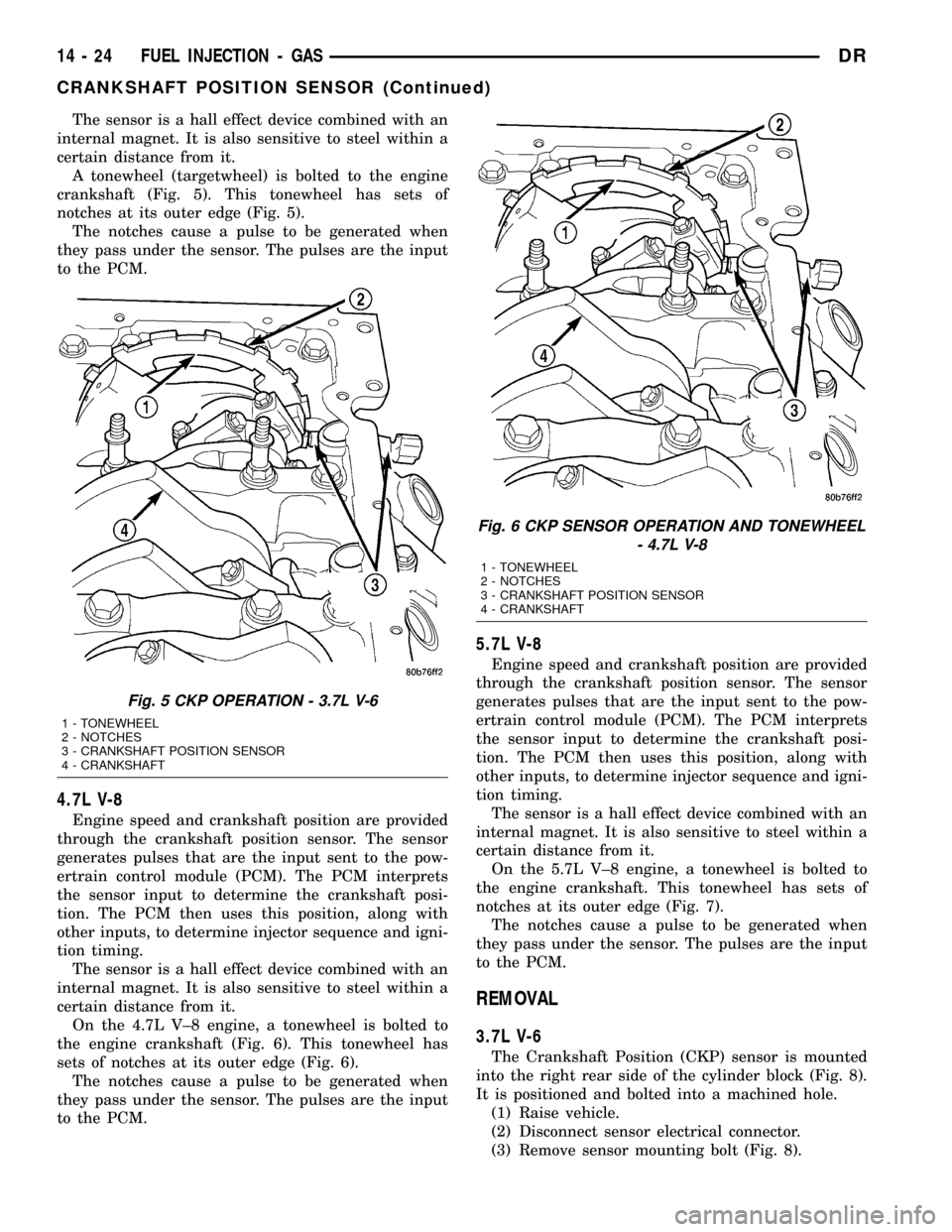

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

A tonewheel (targetwheel) is bolted to the engine

crankshaft (Fig. 5). This tonewheel has sets of

notches at its outer edge (Fig. 5).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

4.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On the 4.7L V±8 engine, a tonewheel is bolted to

the engine crankshaft (Fig. 6). This tonewheel has

sets of notches at its outer edge (Fig. 6).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

5.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On the 5.7L V±8 engine, a tonewheel is bolted to

the engine crankshaft. This tonewheel has sets of

notches at its outer edge (Fig. 7).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

REMOVAL

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block (Fig. 8).

It is positioned and bolted into a machined hole.

(1) Raise vehicle.

(2) Disconnect sensor electrical connector.

(3) Remove sensor mounting bolt (Fig. 8).

Fig. 5 CKP OPERATION - 3.7L V-6

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

Fig. 6 CKP SENSOR OPERATION AND TONEWHEEL

- 4.7L V-8

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

14 - 24 FUEL INJECTION - GASDR

CRANKSHAFT POSITION SENSOR (Continued)

Page 1594 of 2627

(4) Carefully twist sensor from cylinder block.

(5) Check condition of sensor o-ring.

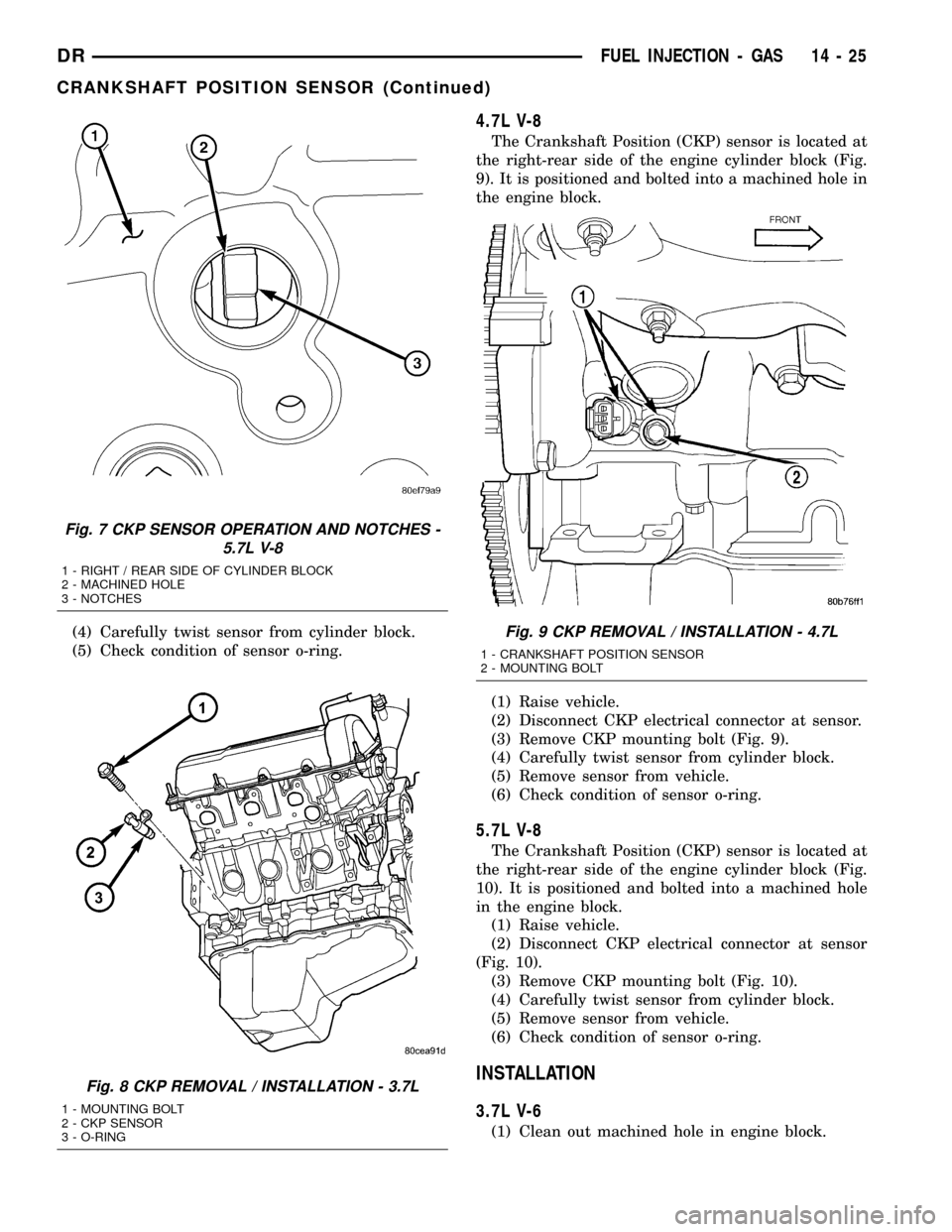

4.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block (Fig.

9). It is positioned and bolted into a machined hole in

the engine block.

(1) Raise vehicle.

(2) Disconnect CKP electrical connector at sensor.

(3) Remove CKP mounting bolt (Fig. 9).

(4) Carefully twist sensor from cylinder block.

(5) Remove sensor from vehicle.

(6) Check condition of sensor o-ring.

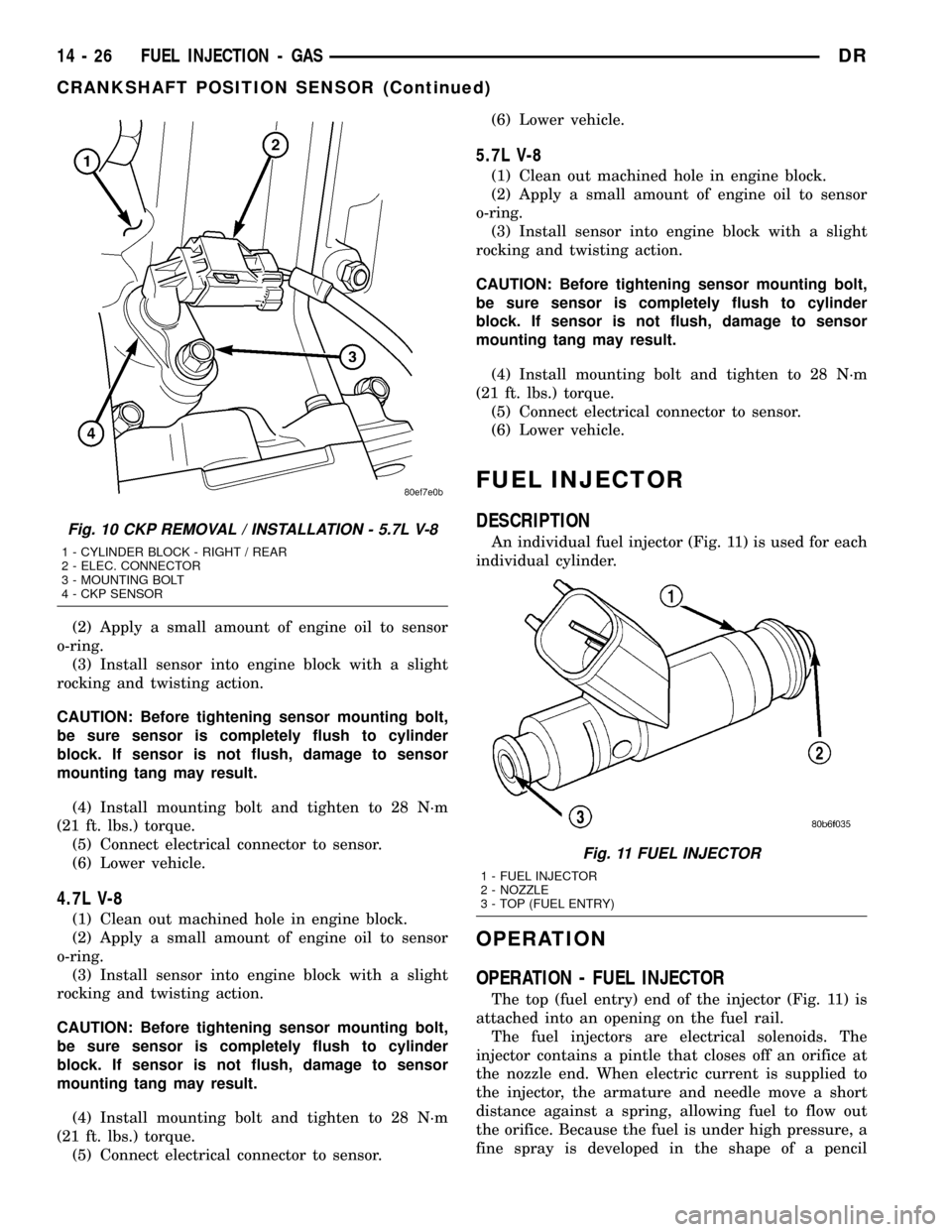

5.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block (Fig.

10). It is positioned and bolted into a machined hole

in the engine block.

(1) Raise vehicle.

(2) Disconnect CKP electrical connector at sensor

(Fig. 10).

(3) Remove CKP mounting bolt (Fig. 10).

(4) Carefully twist sensor from cylinder block.

(5) Remove sensor from vehicle.

(6) Check condition of sensor o-ring.

INSTALLATION

3.7L V-6

(1) Clean out machined hole in engine block.

Fig. 7 CKP SENSOR OPERATION AND NOTCHES -

5.7L V-8

1 - RIGHT / REAR SIDE OF CYLINDER BLOCK

2 - MACHINED HOLE

3 - NOTCHES

Fig. 8 CKP REMOVAL / INSTALLATION - 3.7L

1 - MOUNTING BOLT

2 - CKP SENSOR

3 - O-RING

Fig. 9 CKP REMOVAL / INSTALLATION - 4.7L

1 - CRANKSHAFT POSITION SENSOR

2 - MOUNTING BOLT

DRFUEL INJECTION - GAS 14 - 25

CRANKSHAFT POSITION SENSOR (Continued)

Page 1595 of 2627

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Lower vehicle.

4.7L V-8

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.(6) Lower vehicle.

5.7L V-8

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Lower vehicle.

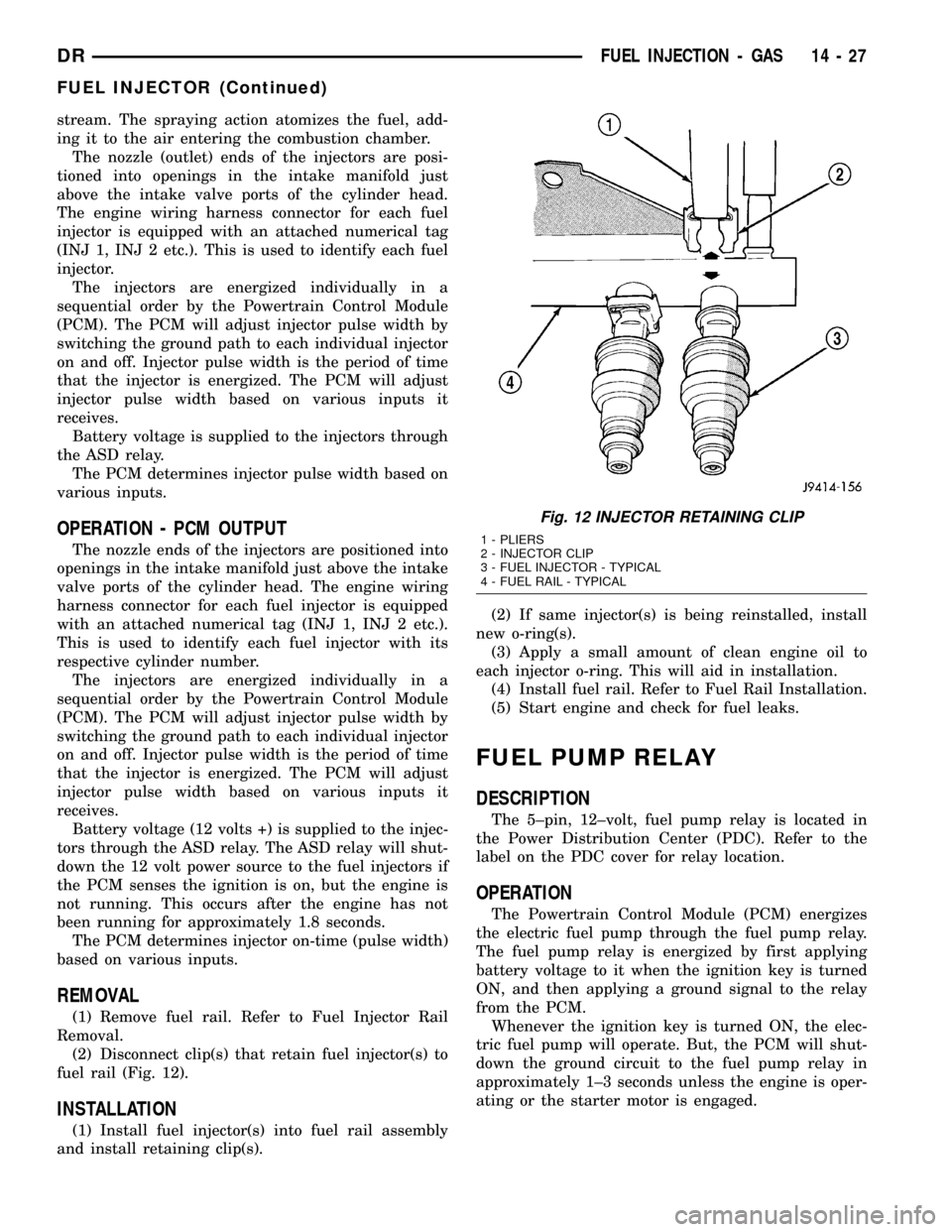

FUEL INJECTOR

DESCRIPTION

An individual fuel injector (Fig. 11) is used for each

individual cylinder.

OPERATION

OPERATION - FUEL INJECTOR

The top (fuel entry) end of the injector (Fig. 11) is

attached into an opening on the fuel rail.

The fuel injectors are electrical solenoids. The

injector contains a pintle that closes off an orifice at

the nozzle end. When electric current is supplied to

the injector, the armature and needle move a short

distance against a spring, allowing fuel to flow out

the orifice. Because the fuel is under high pressure, a

fine spray is developed in the shape of a pencil

Fig. 10 CKP REMOVAL / INSTALLATION - 5.7L V-8

1 - CYLINDER BLOCK - RIGHT / REAR

2 - ELEC. CONNECTOR

3 - MOUNTING BOLT

4 - CKP SENSOR

Fig. 11 FUEL INJECTOR

1 - FUEL INJECTOR

2 - NOZZLE

3 - TOP (FUEL ENTRY)

14 - 26 FUEL INJECTION - GASDR

CRANKSHAFT POSITION SENSOR (Continued)

Page 1596 of 2627

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just

above the intake valve ports of the cylinder head.

The engine wiring harness connector for each fuel

injector is equipped with an attached numerical tag

(INJ 1, INJ 2 etc.). This is used to identify each fuel

injector.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width)

based on various inputs.

REMOVAL

(1) Remove fuel rail. Refer to Fuel Injector Rail

Removal.

(2) Disconnect clip(s) that retain fuel injector(s) to

fuel rail (Fig. 12).

INSTALLATION

(1) Install fuel injector(s) into fuel rail assembly

and install retaining clip(s).(2) If same injector(s) is being reinstalled, install

new o-ring(s).

(3) Apply a small amount of clean engine oil to

each injector o-ring. This will aid in installation.

(4) Install fuel rail. Refer to Fuel Rail Installation.

(5) Start engine and check for fuel leaks.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

Fig. 12 INJECTOR RETAINING CLIP

1 - PLIERS

2 - INJECTOR CLIP

3 - FUEL INJECTOR - TYPICAL

4 - FUEL RAIL - TYPICAL

DRFUEL INJECTION - GAS 14 - 27

FUEL INJECTOR (Continued)