Engine DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1447 of 2627

OIL PAN

REMOVAL

(1) Disconnect the negative battery cable.

(2) Install engine support fixture special tool #

8534.Do not raise engine at this time.

(3) Loosen both left and right side engine mount

through bolts. Do not remove bolts.

(4) Remove the structural dust cover, if equipped.

(5) Drain engine oil.

(6) Remove the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).

CAUTION: Only raise the engine enough to provide

clearance for oil pan removal. Check for proper

clearance at fan shroud to fan and cowl to intake

manifold.

(7) Raise engine using special tool # 8534 to pro-

vide clearance to remove oil pan.

NOTE: Do not pry on oil pan or oil pan gasket. Gas-

ket is integral to engine windage tray and does not

come out with oil pan.

(8) Remove the oil pan mounting bolts and oil pan.

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(9) Unbolt oil pump pickup tube and remove tube.

(10) Inspect the integral windage tray and gasket

and replace as needed.

INSTALLATION

(1) Clean the oil pan gasket mating surface of the

block and oil pan.

(2) Inspect the integral windage tray and gasket

and replace as needed.

(3) Reinstall the oil pump pickup tube with new

o-ring. Tighten tube to pump fasteners to 28 N´m

(250 in. lbs.).

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(4) Position the oil pan and install the mounting

bolts and studs.. Tighten the mounting bolts to 12

N´m (105 in.lbs.).

(5) Lower the engine into mounts using special

tool # 8534.

(6) Install both the left and right side engine

mount through bolts. Tighten the nuts to 68 N´m (50

ft. lbs.).(7) Remove special tool # 8534.

(8) Install structural dust cover, if equipped.

(9) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(10) Fill engine oil.

(11) Reconnect the negative battery cable.

(12) Start engine and check for leaks.

OIL PUMP

REMOVAL

(1) Remove the oil pan and pick-up tube(Refer to 9

- ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(2) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(3) Remove the four bolts, and the oil pump.

CLEANING

(1) Wash all parts in a suitable solvent.

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump. If

these components are disassembled and or

removed from the pump the entire oil pump assem-

bly must be replaced.

(1) Remove the pump cover.

(2) Clean all parts thoroughly. Mating surface of

the oil pump housing should be smooth. If the pump

cover is scratched or grooved the oil pump assembly

should be replaced.

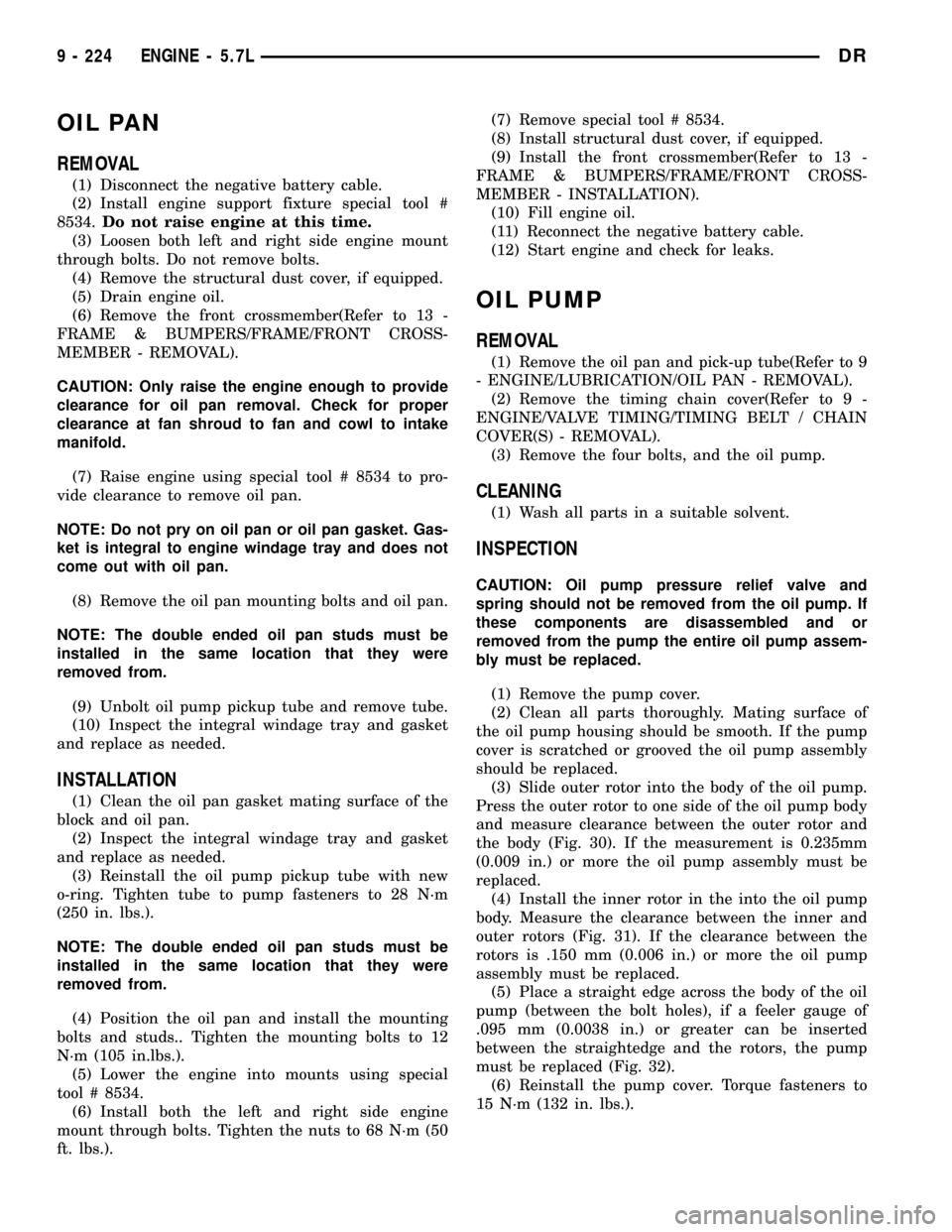

(3) Slide outer rotor into the body of the oil pump.

Press the outer rotor to one side of the oil pump body

and measure clearance between the outer rotor and

the body (Fig. 30). If the measurement is 0.235mm

(0.009 in.) or more the oil pump assembly must be

replaced.

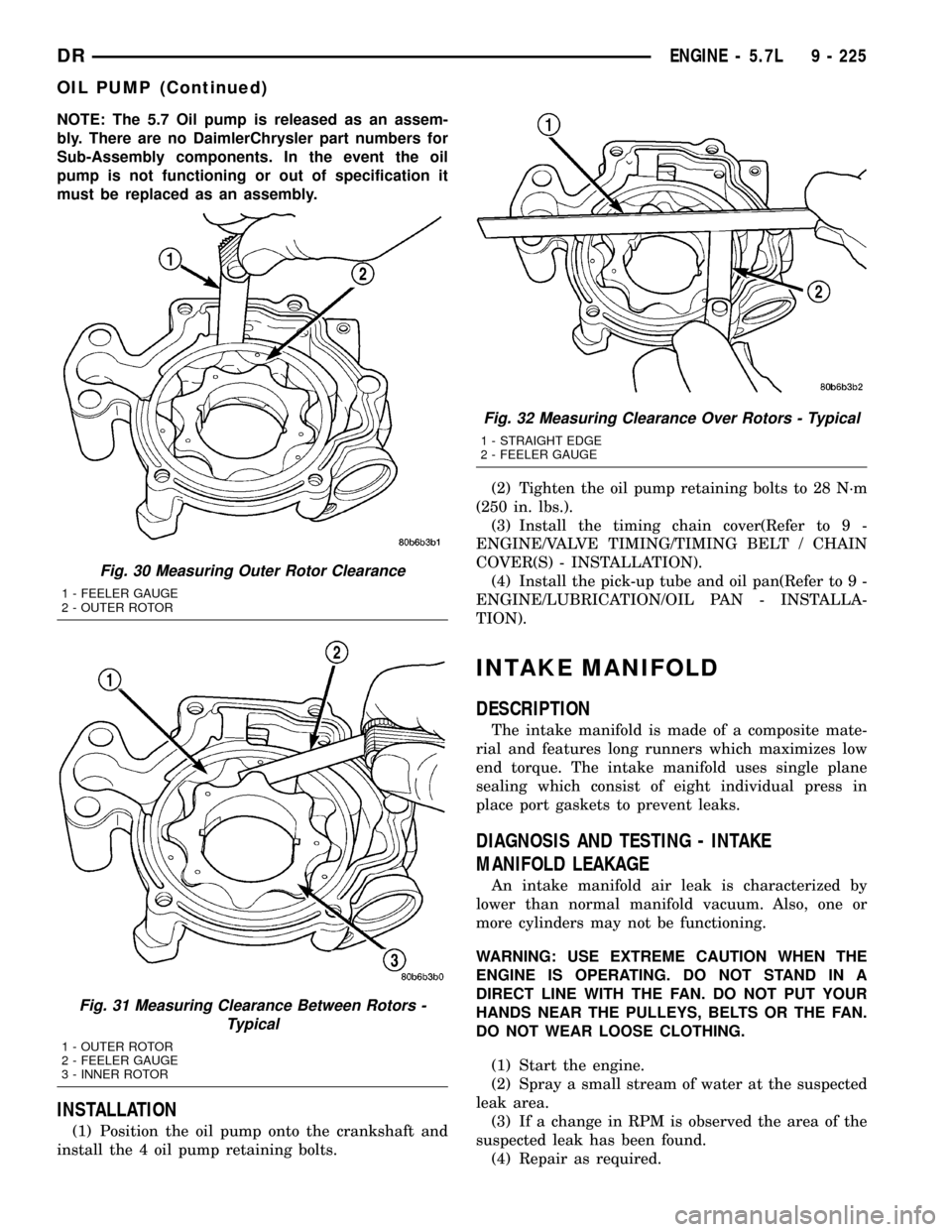

(4) Install the inner rotor in the into the oil pump

body. Measure the clearance between the inner and

outer rotors (Fig. 31). If the clearance between the

rotors is .150 mm (0.006 in.) or more the oil pump

assembly must be replaced.

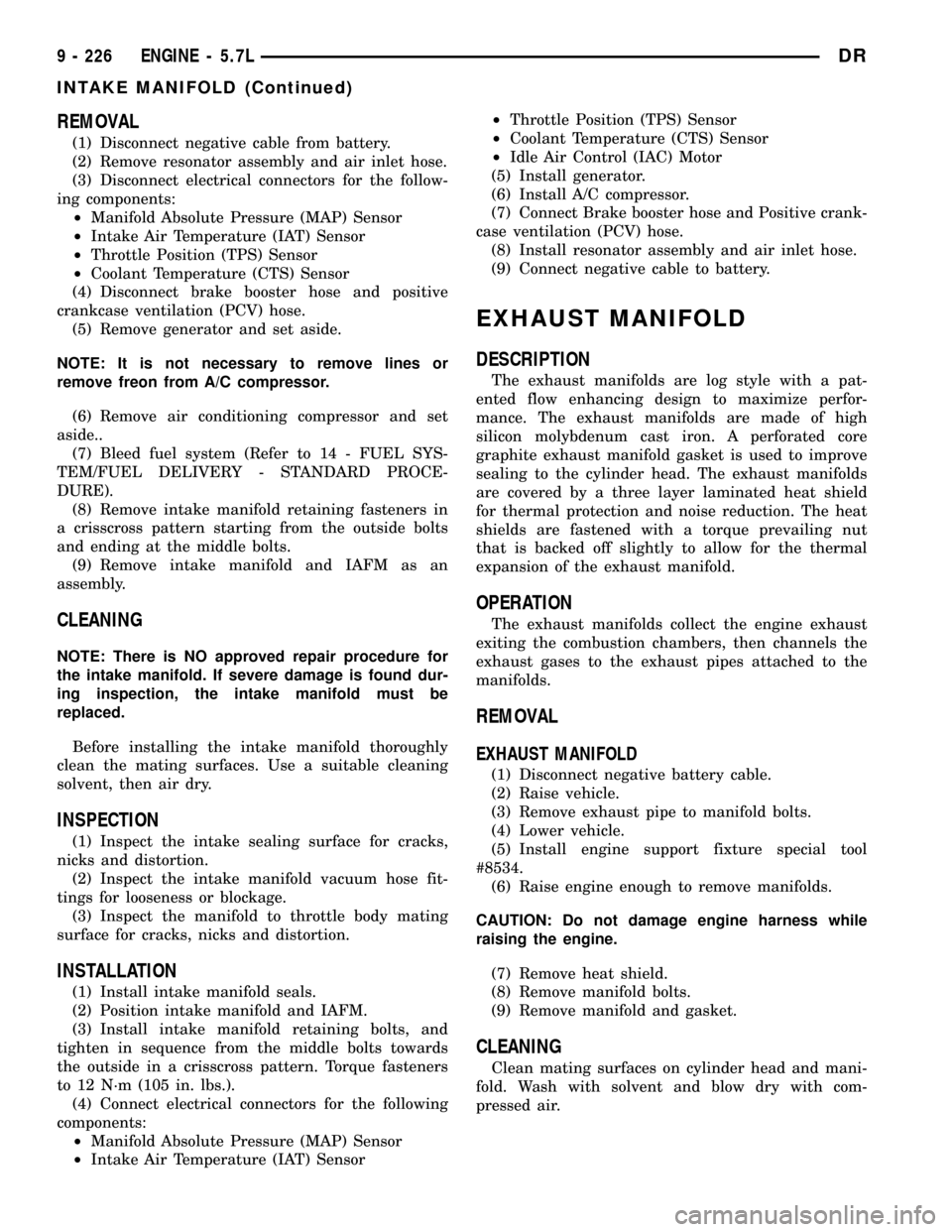

(5) Place a straight edge across the body of the oil

pump (between the bolt holes), if a feeler gauge of

.095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced (Fig. 32).

(6) Reinstall the pump cover. Torque fasteners to

15 N´m (132 in. lbs.).

9 - 224 ENGINE - 5.7LDR

Page 1448 of 2627

NOTE: The 5.7 Oil pump is released as an assem-

bly. There are no DaimlerChrysler part numbers for

Sub-Assembly components. In the event the oil

pump is not functioning or out of specification it

must be replaced as an assembly.

INSTALLATION

(1) Position the oil pump onto the crankshaft and

install the 4 oil pump retaining bolts.(2) Tighten the oil pump retaining bolts to 28 N´m

(250 in. lbs.).

(3) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(4) Install the pick-up tube and oil pan(Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is made of a composite mate-

rial and features long runners which maximizes low

end torque. The intake manifold uses single plane

sealing which consist of eight individual press in

place port gaskets to prevent leaks.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

Fig. 30 Measuring Outer Rotor Clearance

1 - FEELER GAUGE

2 - OUTER ROTOR

Fig. 31 Measuring Clearance Between Rotors -

Typical

1 - OUTER ROTOR

2 - FEELER GAUGE

3 - INNER ROTOR

Fig. 32 Measuring Clearance Over Rotors - Typical

1 - STRAIGHT EDGE

2 - FEELER GAUGE

DRENGINE - 5.7L 9 - 225

OIL PUMP (Continued)

Page 1449 of 2627

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect electrical connectors for the follow-

ing components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

(4) Disconnect brake booster hose and positive

crankcase ventilation (PCV) hose.

(5) Remove generator and set aside.

NOTE: It is not necessary to remove lines or

remove freon from A/C compressor.

(6) Remove air conditioning compressor and set

aside..

(7) Bleed fuel system (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY - STANDARD PROCE-

DURE).

(8) Remove intake manifold retaining fasteners in

a crisscross pattern starting from the outside bolts

and ending at the middle bolts.

(9) Remove intake manifold and IAFM as an

assembly.

CLEANING

NOTE: There is NO approved repair procedure for

the intake manifold. If severe damage is found dur-

ing inspection, the intake manifold must be

replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.

(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

INSTALLATION

(1) Install intake manifold seals.

(2) Position intake manifold and IAFM.

(3) Install intake manifold retaining bolts, and

tighten in sequence from the middle bolts towards

the outside in a crisscross pattern. Torque fasteners

to 12 N´m (105 in. lbs.).

(4) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Install generator.

(6) Install A/C compressor.

(7) Connect Brake booster hose and Positive crank-

case ventilation (PCV) hose.

(8) Install resonator assembly and air inlet hose.

(9) Connect negative cable to battery.

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nut

that is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

exhaust gases to the exhaust pipes attached to the

manifolds.

REMOVAL

EXHAUST MANIFOLD

(1) Disconnect negative battery cable.

(2) Raise vehicle.

(3) Remove exhaust pipe to manifold bolts.

(4) Lower vehicle.

(5) Install engine support fixture special tool

#8534.

(6) Raise engine enough to remove manifolds.

CAUTION: Do not damage engine harness while

raising the engine.

(7) Remove heat shield.

(8) Remove manifold bolts.

(9) Remove manifold and gasket.

CLEANING

Clean mating surfaces on cylinder head and mani-

fold. Wash with solvent and blow dry with com-

pressed air.

9 - 226 ENGINE - 5.7LDR

INTAKE MANIFOLD (Continued)

Page 1450 of 2627

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

EXHAUST MANIFOLD

(1) Install manifold gasket and manifold.

(2) Install manifold bolts and tighten to 25 N´m

(18 ft. lbs.).

(3) Install heat shield and tighten nuts to 15 N´m

(11 ft. lbs.).

(4) Lower engine.

CAUTION: Do not damage engine harness while

lowering the engine.

(5) Remove engine support fixture from engine.

(6) Raise vehicle.

(7) Tighten right and left side engine mount

through bolts.

(8) Install exhaust flange to pipe bolts.

(9) Lower vehicle.

(10) Connect negative battery cable.

TIMING/CHAIN COVER

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove air cleaner assembly.

(3) Drain cooling system.

(4) Remove accessory drive belt.

(5) Remove fan and fan drive assembly (Refer to 7

- COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

(6) Remove coolant bottle and washer bottle.

(7) Remove fan shroud.

NOTE: It is not necessary to disconnect A/C lines or

discharge freon.

(8) Remove A/C compressor and set aside.

(9) Remove the generator.

(10) Remove upper radiator hose.

(11) Disconnect both heater hoses at timing cover.

(12) Disconnect lower radiator hose at engine.

(13) Remove accessory drive belt tensioner and

both idler pulleys.

(14) Remove crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).NOTE: Do not remove the hoses from the power

steering pump.

(15) Remove power steering pump and set aside.

(16) Remove the dipstick support bolt.

(17) Drain the engine oil.

(18) Remove the oil pan and pick up tube(Refer to

9 - ENGINE/LUBRICATION/OIL PAN - REMOVAL).

NOTE: It is not necessary to remove water pump for

timing cover removal.

(19) Remove timing cover bolts and remove cover.

INSTALLATION

(1) Clean timing chain cover and block surface.

NOTE: Always install a new gasket on timing cover.

(2) Install cover and new gasket. Tighten fasteners

to 28 N´m (250 in. lbs.).

NOTE: The large lifting stud is torqued to 55 N´m

(40 ft. lbs.).

(3) Install the oil pan and pick up tube(Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(4) Install the A/C compressor.

(5) Install the generator.

(6) Install power steering pump.

(7) Install the dipstick support bolt.

(8) Install the thermostat housing.

(9) Install crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(10) Install accessory drive belt tensioner assembly

and both idler pulleys.

(11) Install radiator lower hose.

(12) Install both heater hoses.

(13) Install radiator fan shroud.

(14) Install the fan and fan drive assembly

(15) Install the accessory drive belt.

(16) Install the coolant bottle and washer bottle.

(17) Install the upper radiator hose.

(18) Install the air cleaner assembly.

(19) Fill cooling system.

(20) Refill engine oil.

(21) Connect the battery negative cable.

DRENGINE - 5.7L 9 - 227

EXHAUST MANIFOLD (Continued)

Page 1451 of 2627

TIMING/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect battery negative cable.

(2) Drain cooling system.

(3) Remove Timing Chain Cover.

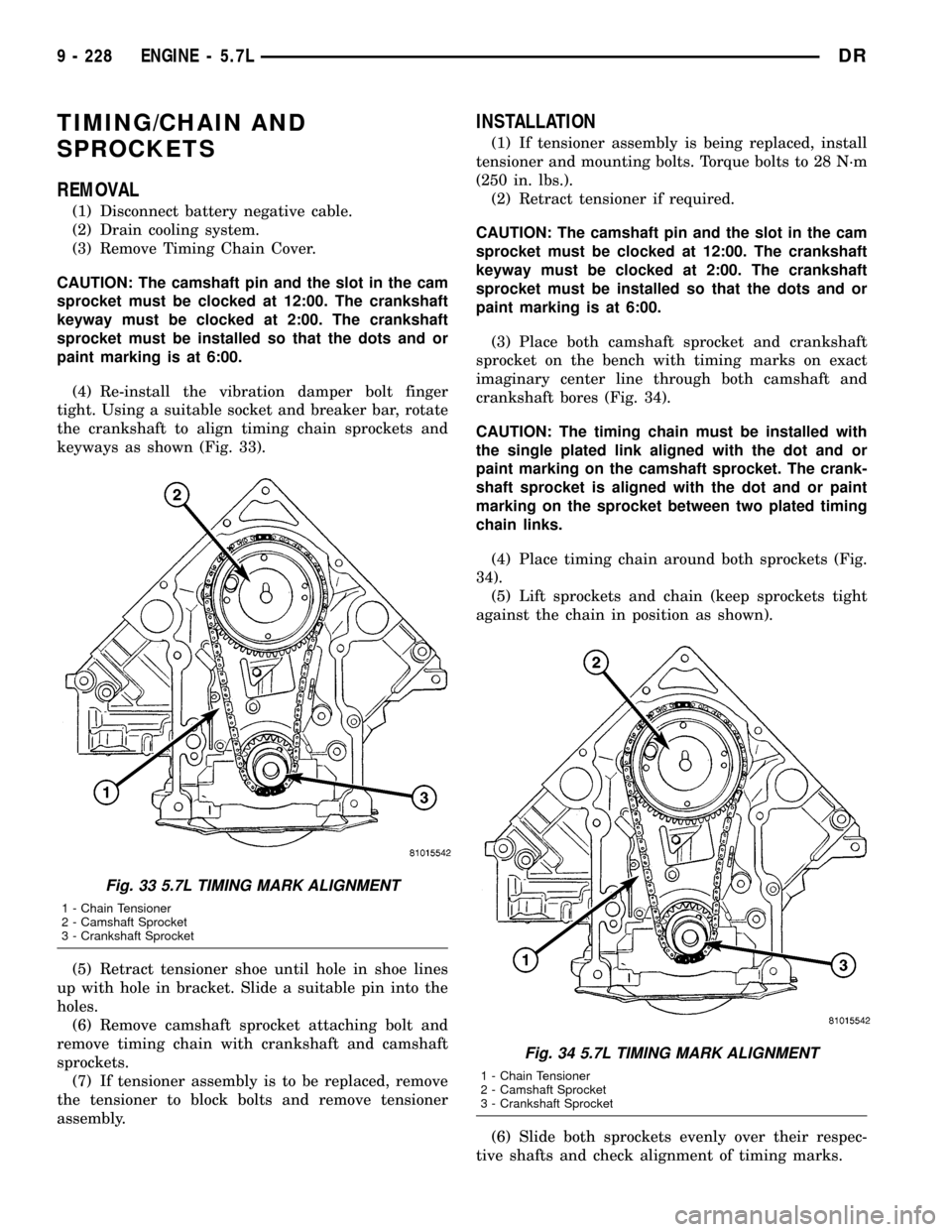

CAUTION: The camshaft pin and the slot in the cam

sprocket must be clocked at 12:00. The crankshaft

keyway must be clocked at 2:00. The crankshaft

sprocket must be installed so that the dots and or

paint marking is at 6:00.

(4) Re-install the vibration damper bolt finger

tight. Using a suitable socket and breaker bar, rotate

the crankshaft to align timing chain sprockets and

keyways as shown (Fig. 33).

(5) Retract tensioner shoe until hole in shoe lines

up with hole in bracket. Slide a suitable pin into the

holes.

(6) Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets.

(7) If tensioner assembly is to be replaced, remove

the tensioner to block bolts and remove tensioner

assembly.

INSTALLATION

(1) If tensioner assembly is being replaced, install

tensioner and mounting bolts. Torque bolts to 28 N´m

(250 in. lbs.).

(2) Retract tensioner if required.

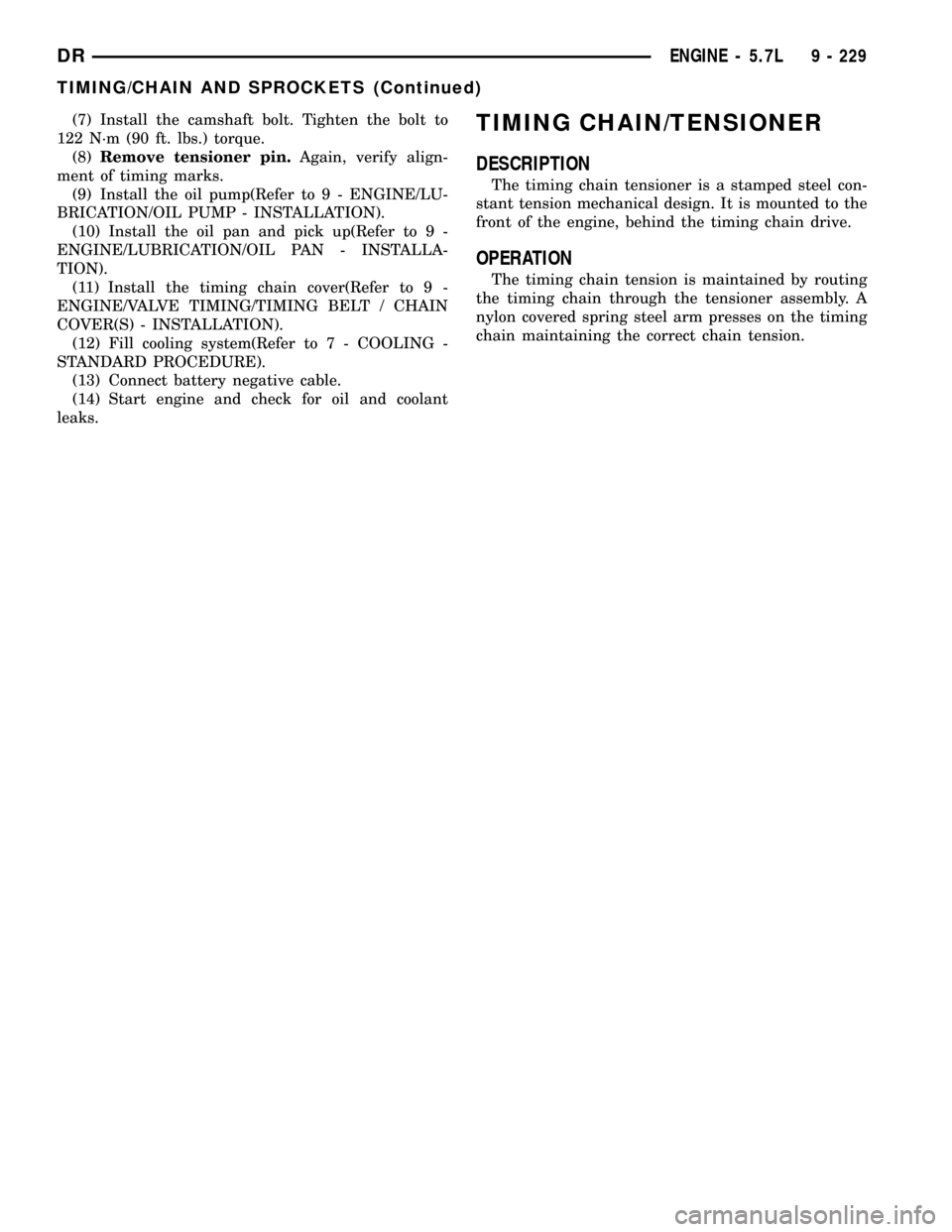

CAUTION: The camshaft pin and the slot in the cam

sprocket must be clocked at 12:00. The crankshaft

keyway must be clocked at 2:00. The crankshaft

sprocket must be installed so that the dots and or

paint marking is at 6:00.

(3) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores (Fig. 34).

CAUTION: The timing chain must be installed with

the single plated link aligned with the dot and or

paint marking on the camshaft sprocket. The crank-

shaft sprocket is aligned with the dot and or paint

marking on the sprocket between two plated timing

chain links.

(4) Place timing chain around both sprockets (Fig.

34).

(5) Lift sprockets and chain (keep sprockets tight

against the chain in position as shown).

(6) Slide both sprockets evenly over their respec-

tive shafts and check alignment of timing marks.

Fig. 33 5.7L TIMING MARK ALIGNMENT

1 - Chain Tensioner

2 - Camshaft Sprocket

3 - Crankshaft Sprocket

Fig. 34 5.7L TIMING MARK ALIGNMENT

1 - Chain Tensioner

2 - Camshaft Sprocket

3 - Crankshaft Sprocket

9 - 228 ENGINE - 5.7LDR

Page 1452 of 2627

(7) Install the camshaft bolt. Tighten the bolt to

122 N´m (90 ft. lbs.) torque.

(8)Remove tensioner pin.Again, verify align-

ment of timing marks.

(9) Install the oil pump(Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(10) Install the oil pan and pick up(Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(11) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(12) Fill cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect battery negative cable.

(14) Start engine and check for oil and coolant

leaks.TIMING CHAIN/TENSIONER

DESCRIPTION

The timing chain tensioner is a stamped steel con-

stant tension mechanical design. It is mounted to the

front of the engine, behind the timing chain drive.

OPERATION

The timing chain tension is maintained by routing

the timing chain through the tensioner assembly. A

nylon covered spring steel arm presses on the timing

chain maintaining the correct chain tension.

DRENGINE - 5.7L 9 - 229

TIMING/CHAIN AND SPROCKETS (Continued)

Page 1453 of 2627

ENGINE 5.9L DIESEL

TABLE OF CONTENTS

page page

ENGINE 5.9L DIESEL

DESCRIPTION........................232

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE

DIAGNOSIS - MECHANICAL............233

DIAGNOSIS AND TESTINGÐSMOKE

DIAGNOSIS CHARTS.................236

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION/LEAKAGE TESTS.......239

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS........239

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS........240

STANDARD PROCEDUREÐHYDROSTATIC

LOCK..............................240

REMOVAL

REMOVAL - ENGINE..................241

REMOVALÐCRANKCASE BREATHER....242

INSTALLATION

INSTALLATION - ENGINE..............242

INSTALLATIONÐCRANKCASE BREATHER . 243

SPECIFICATIONS

SPECIFICATIONS - 5.9L DIESEL.........244

TORQUE...........................245

SPECIAL TOOLS

5.9L DIESEL ENGINE.................246

ENGINE DATA PLATE

DESCRIPTION........................248

AIR CLEANER ELEMENT

REMOVAL............................248

INSTALLATION........................249

CYLINDER HEAD

DESCRIPTION........................249

REMOVAL............................249

CLEANING

CLEANINGÐCYLINDER HEAD..........251

CLEANINGÐCROSSHEADS............251

CLEANINGÐPUSHRODS..............252

INSPECTION

INSPECTION - CYLINDER HEAD.........252

INSPECTIONÐCROSSHEADS..........252

INSPECTIONÐPUSHRODS.............253

INSTALLATION........................253

CYLINDER HEAD COVER(S)

REMOVAL

REMOVALÐCYLINDER HEAD COVER....255

REMOVALÐROCKER HOUSING.........255

CLEANING...........................255INSPECTION.........................255

INSTALLATION

INSTALLATIONÐCYLINDER HEAD COVER . 255

INSTALLATION - ROCKER HOUSING.....255

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION........................256

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVES,

GUIDES AND SPRINGS................256

STANDARD PROCEDURE - VALVE LASH

ADJUSTMENT AND VERIFICATION.......259

REMOVAL - VALVE SPRINGS AND SEALS . . . 260

INSTALLATION........................261

ROCKER ARM / ADJUSTER ASSY

DESCRIPTION........................261

REMOVAL............................261

CLEANING...........................262

INSPECTION.........................262

INSTALLATION........................263

ENGINE BLOCK

STANDARD PROCEDURE

STANDARD PROCEDURE - CYLINDER

BLOCK REFACING...................264

STANDARD PROCEDURE - CYLINDER

BORE - DE-GLAZE...................264

STANDARD PROCEDUREÐCYLINDER

BORE REPAIR.......................265

STANDARD PROCEDUREÐCAM BORE

REPAIR ............................267

INSPECTION.........................267

CAMSHAFT & BEARINGS (IN BLOCK)

REMOVAL

REMOVALÐCAMSHAFT BEARINGS......268

REMOVAL - CAMSHAFT...............268

INSPECTION.........................270

INSTALLATION

INSTALLATION - CAMSHAFT BEARINGS . . 271

INSTALLATION - CAMSHAFT............271

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE................272

CRANKSHAFT AND GEAR

DESCRIPTION........................273

REMOVAL - GEAR.....................273

INSTALLATION - GEAR..................273

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE - MAIN BEARING

CLEARANCE........................274

9 - 230 ENGINE 5.9L DIESELDR

Page 1454 of 2627

CRANKSHAFT OIL SEAL - FRONT

REMOVAL............................275

INSTALLATION........................275

CRANKSHAFT OIL SEAL - REAR

REMOVAL............................276

INSTALLATION........................276

CRANKSHAFT REAR OIL SEAL RETAINER

REMOVAL............................277

INSTALLATION........................277

SOLID LIFTERS/TAPPETS

REMOVAL............................279

CLEANING...........................279

INSPECTION.........................279

INSTALLATION........................280

PISTON & CONNECTING ROD

DESCRIPTION........................281

STANDARD PROCEDURE - HEAD GASKET

SELECTION.........................281

REMOVAL............................281

CLEANINGÐPISTON AND CONNECTING

ROD ..............................282

INSPECTION

INSPECTION - PISTONS...............282

INSPECTIONÐCONNECTING ROD.......283

INSTALLATION........................283

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING............................284

VIBRATION DAMPER

REMOVAL............................285

INSPECTION.........................285

INSTALLATION........................286

FRONT MOUNT

REMOVAL............................286

INSTALLATION........................287

REAR MOUNT

REMOVAL............................288

INSTALLATION........................288

LUBRICATION

DESCRIPTION........................289

OPERATION..........................289

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE.........................289

OIL

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE OIL

LEVEL.............................292STANDARD PROCEDURE - ENGINE OIL

SERVICE...........................292

OIL COOLER & LINES

CLEANING

CLEANING AND INSPECTION...........293

OIL FILTER

REMOVAL............................293

INSTALLATION........................293

OIL PAN

REMOVAL............................293

CLEANING...........................293

INSPECTION.........................293

INSTALLATION........................293

OIL PRESSURE RELIEF VALVE

REMOVAL............................294

CLEANING...........................294

INSPECTION.........................294

INSTALLATION........................294

OIL PRESSURE SWITCH

REMOVAL............................294

INSTALLATION........................294

OIL PUMP

REMOVAL............................294

CLEANING...........................295

INSPECTION.........................295

INSTALLATION........................296

INTAKE MANIFOLD

REMOVAL............................297

CLEANING...........................297

INSPECTION.........................297

INSTALLATION........................298

EXHAUST MANIFOLD

REMOVAL............................298

CLEANING...........................298

INSPECTION.........................298

INSTALLATION........................298

VALVE TIMING

STANDARD PROCEDURE - TIMING

VERIFICATION.......................299

GEAR HOUSING

REMOVAL............................299

INSTALLATION........................300

GEAR HOUSING COVER

REMOVAL............................301

INSTALLATION........................301

DRENGINE 5.9L DIESEL 9 - 231

Page 1455 of 2627

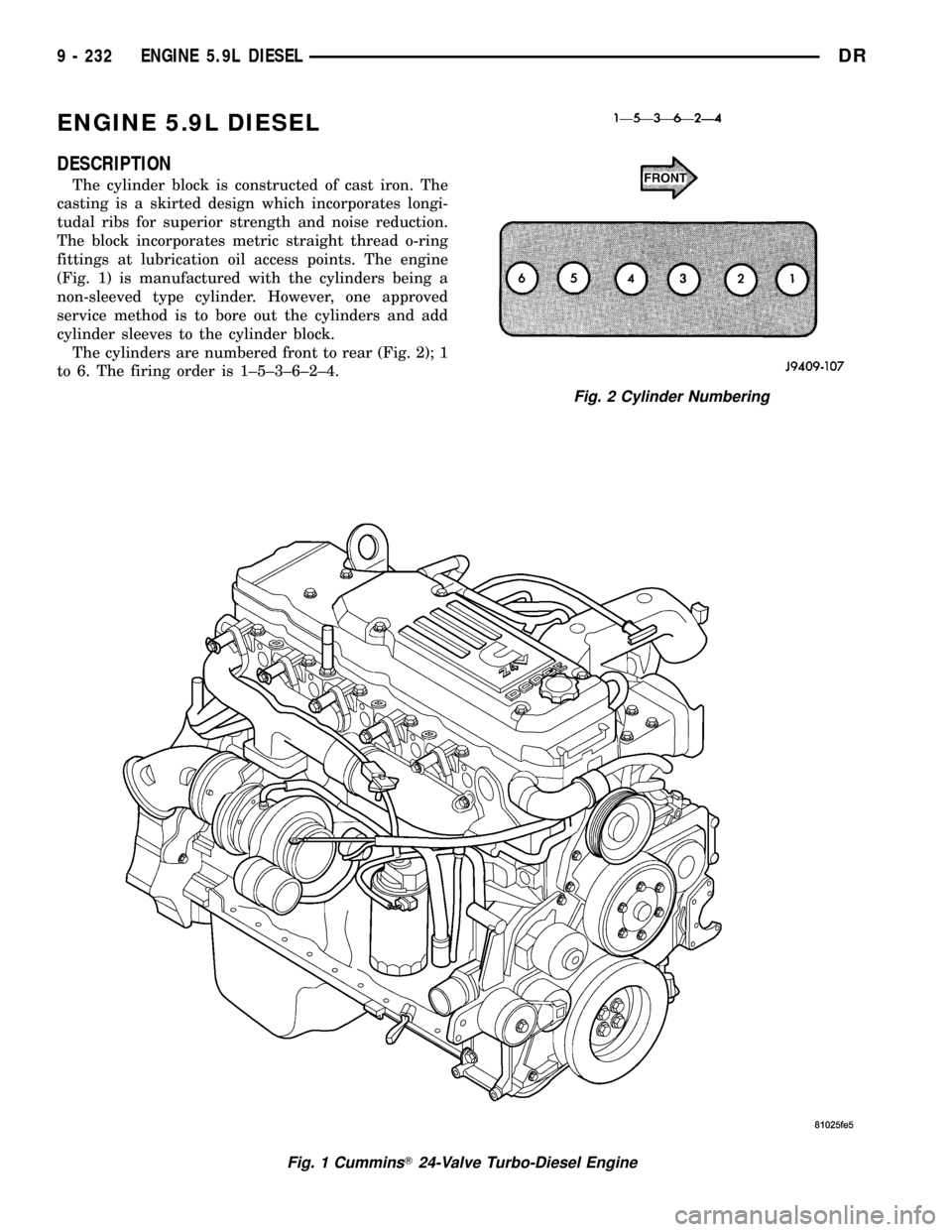

ENGINE 5.9L DIESEL

DESCRIPTION

The cylinder block is constructed of cast iron. The

casting is a skirted design which incorporates longi-

tudal ribs for superior strength and noise reduction.

The block incorporates metric straight thread o-ring

fittings at lubrication oil access points. The engine

(Fig. 1) is manufactured with the cylinders being a

non-sleeved type cylinder. However, one approved

service method is to bore out the cylinders and add

cylinder sleeves to the cylinder block.

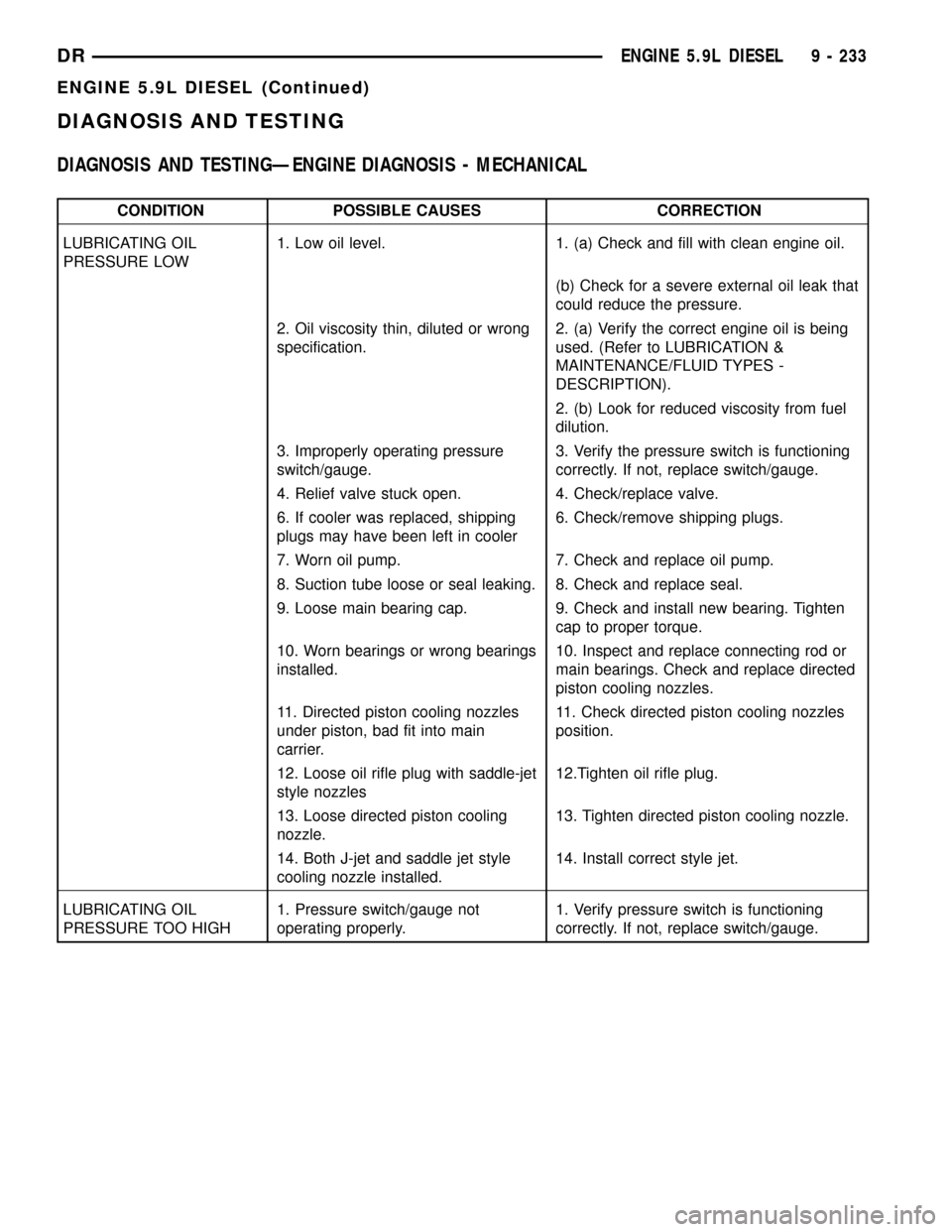

The cylinders are numbered front to rear (Fig. 2); 1

to 6. The firing order is 1±5±3±6±2±4.

Fig. 1 CumminsT24-Valve Turbo-Diesel Engine

Fig. 2 Cylinder Numbering

9 - 232 ENGINE 5.9L DIESELDR

Page 1456 of 2627

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

LUBRICATING OIL

PRESSURE LOW1. Low oil level. 1. (a) Check and fill with clean engine oil.

(b) Check for a severe external oil leak that

could reduce the pressure.

2. Oil viscosity thin, diluted or wrong

specification.2. (a) Verify the correct engine oil is being

used. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

DESCRIPTION).

2. (b) Look for reduced viscosity from fuel

dilution.

3. Improperly operating pressure

switch/gauge.3. Verify the pressure switch is functioning

correctly. If not, replace switch/gauge.

4. Relief valve stuck open. 4. Check/replace valve.

6. If cooler was replaced, shipping

plugs may have been left in cooler6. Check/remove shipping plugs.

7. Worn oil pump. 7. Check and replace oil pump.

8. Suction tube loose or seal leaking. 8. Check and replace seal.

9. Loose main bearing cap. 9. Check and install new bearing. Tighten

cap to proper torque.

10. Worn bearings or wrong bearings

installed.10. Inspect and replace connecting rod or

main bearings. Check and replace directed

piston cooling nozzles.

11. Directed piston cooling nozzles

under piston, bad fit into main

carrier.11. Check directed piston cooling nozzles

position.

12. Loose oil rifle plug with saddle-jet

style nozzles12.Tighten oil rifle plug.

13. Loose directed piston cooling

nozzle.13. Tighten directed piston cooling nozzle.

14. Both J-jet and saddle jet style

cooling nozzle installed.14. Install correct style jet.

LUBRICATING OIL

PRESSURE TOO HIGH1. Pressure switch/gauge not

operating properly.1. Verify pressure switch is functioning

correctly. If not, replace switch/gauge.

DRENGINE 5.9L DIESEL 9 - 233

ENGINE 5.9L DIESEL (Continued)